Embedded planetary-screw pulsation plasticizing exhaust extruder and method

A planetary screw and extrusion device technology, applied in the field of embedded planetary screw pulsation plasticizing exhaust extrusion device, can solve the problems of difficult to control uniform mixing performance, pressure pulsation effect, and limited space for improving mixing effect, etc. The effect of improving the exhaust efficiency and thoroughness, changing the melting mechanism and process, and improving the solid conveying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

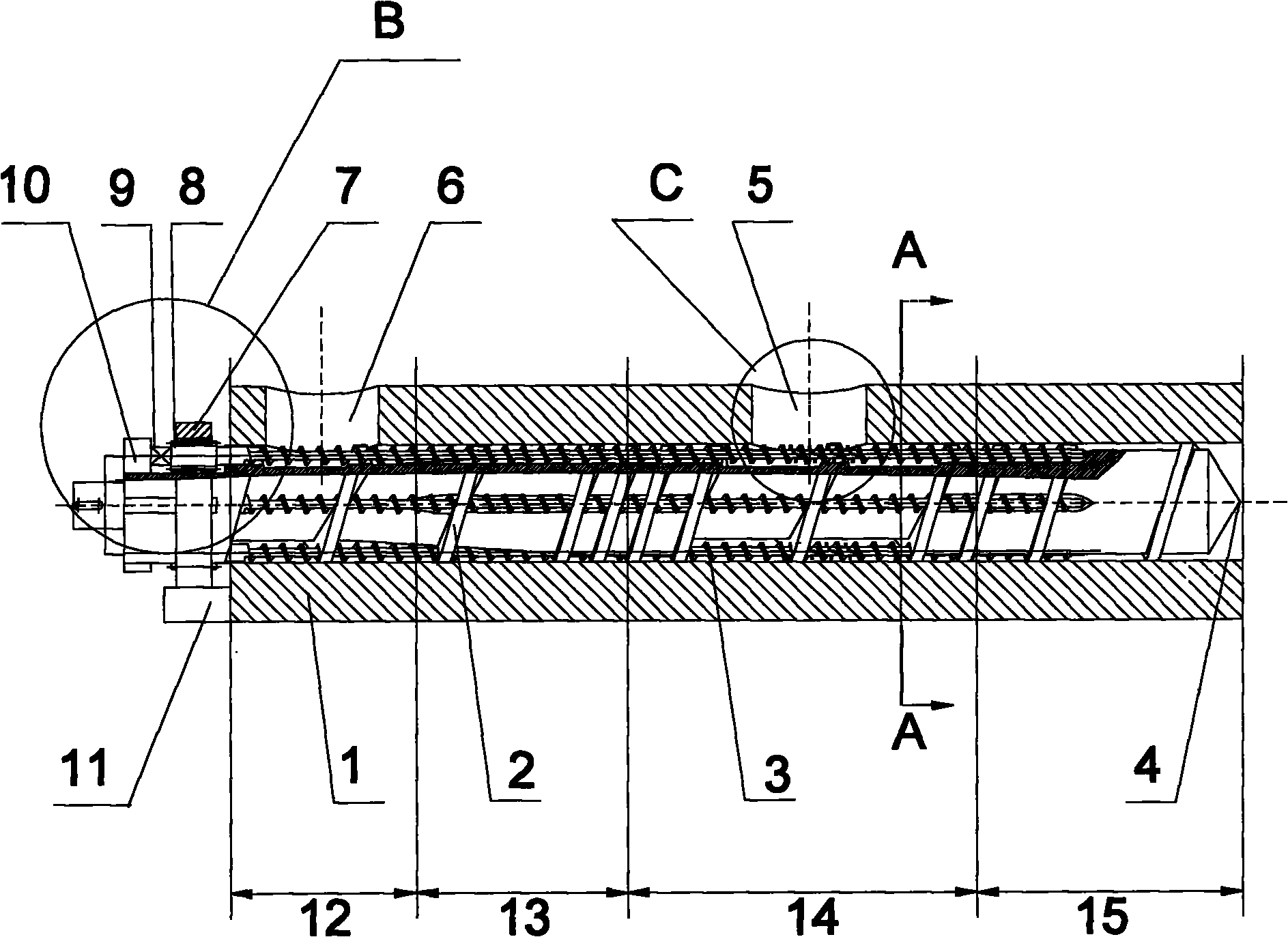

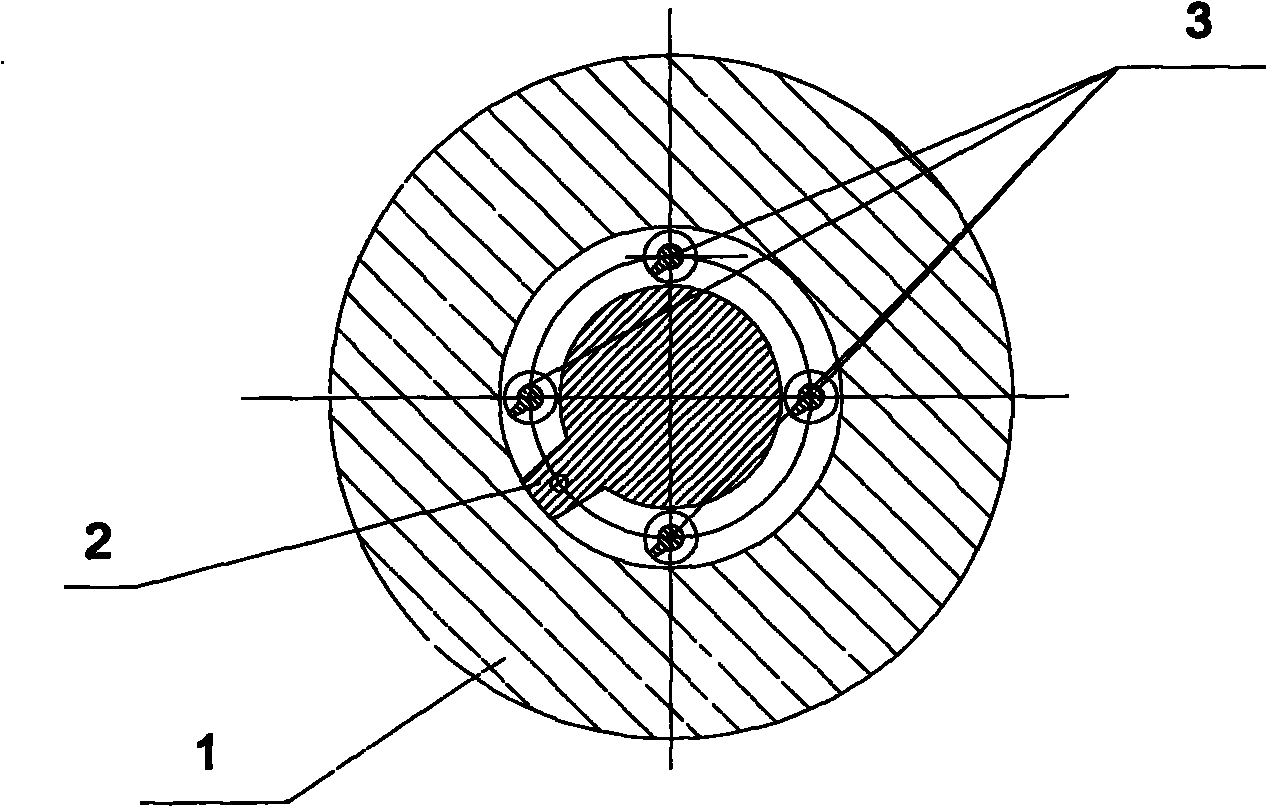

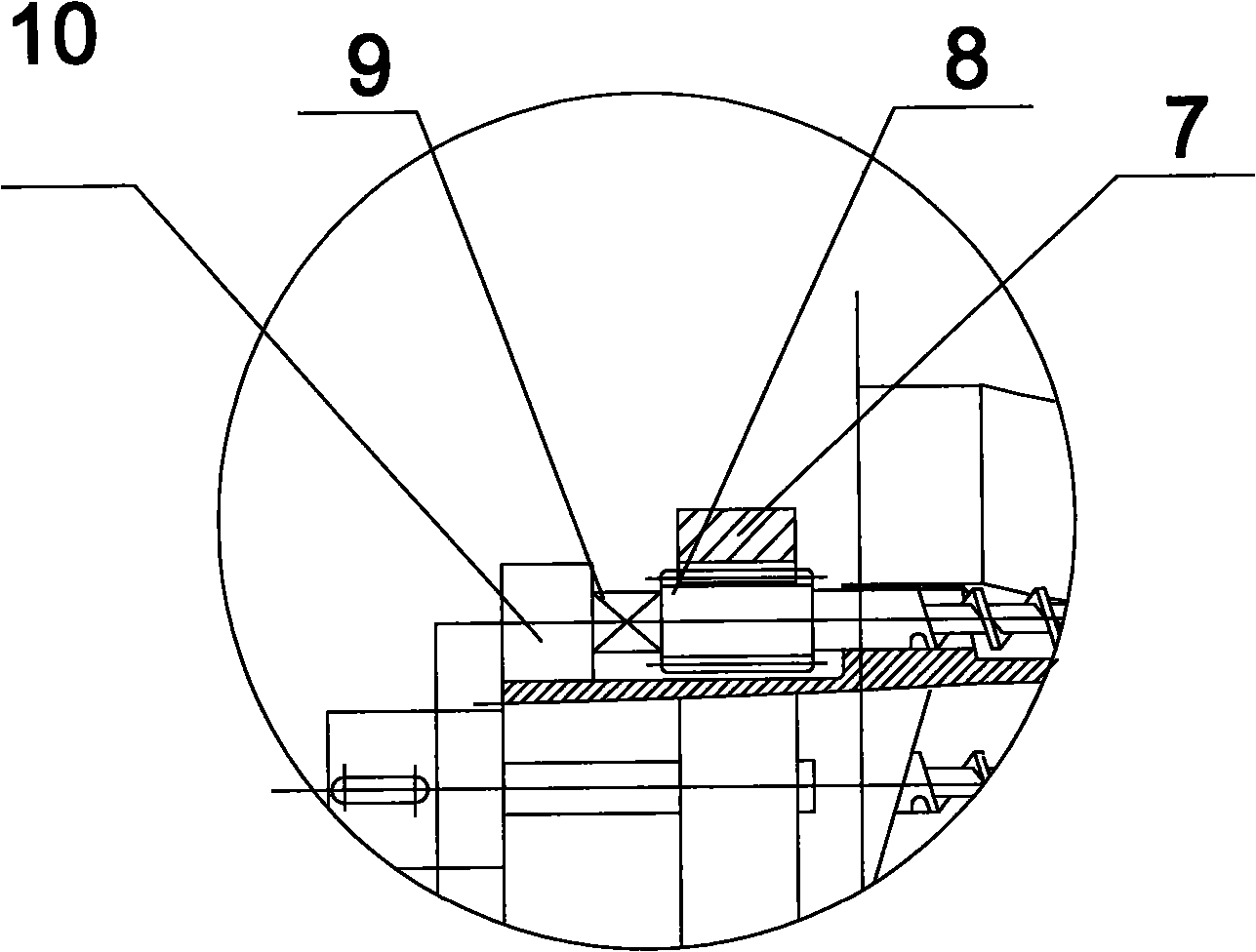

[0044] Figure 1 ~ Figure 3 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the embedded planetary screw 3 pulsating plasticizing exhaust extrusion device includes a screw mechanism, a barrel 1, a feed port 6, an exhaust port 5, a discharge port 4 and a power mechanism, and the power mechanism is located at The end of the barrel 1 is connected with the screw mechanism; the screw mechanism is arranged inside the barrel 1 and placed horizontally, and the inside of the barrel 1 is a solid conveying section 12, a melting section 13, an exhaust section 14 and a mixing Extrusion section 15; described feed inlet 6 is arranged on the cylinder 1 top of solid delivery section 12, and exhaust port 5 is located on the cylinder 1 top of exhaust section 14, and feed inlet 6 and exhaust outlet 5 are all connected with The barrel 1 is connected; the discharge port 4 is located at the end of the barrel 1; figure 2 As shown, the screw mechanism ...

Embodiment 2

[0060] This embodiment has the same structure as Embodiment 1 except for the following features: the outer surface of the planetary screw 3 in the solid conveying section is provided with a multi-head intermittent thread structure; Figure 6 As shown, the planetary screw 3 in the exhaust section is provided with a helical blade 17 whose diameter is larger than the outer diameter of the planetary screw 3 .

[0061] Such as Figure 5 As shown, the pulsating gear 7 is a spur gear; the planetary gear 8 is a spur gear; the pulsating gear transmission mechanism 11 is a sprocket mechanism.

[0062] Such as Figure 7 As shown, the number of planetary screws 3 is 8, and each planetary screw 3 is inserted into each hole of the main screw flight and embedded in the screw groove, and each planetary screw 3 is evenly distributed around the main screw, and its axis is in line with the The axes of the main screws are parallel.

Embodiment 3

[0064] Present embodiment except following feature other structures are with embodiment 1: as Figure 8 As shown, the hole provided on the flight of the main screw 2 and matched with the planetary screw is a figure-eight hole 19, and the number of the figure-eight holes 19 on the flight of each circumference is eight, and each figure-eight hole 19 Both are connected with two planetary screws 18, 20, the two planetary screws are co-rotating twin-screws, and each figure-eight hole 19 is formed by two circular arcs, and the central axis of the two circular arcs is the center of the twin-screw. distance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com