Patents

Literature

32results about How to "Adjustable dwell time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

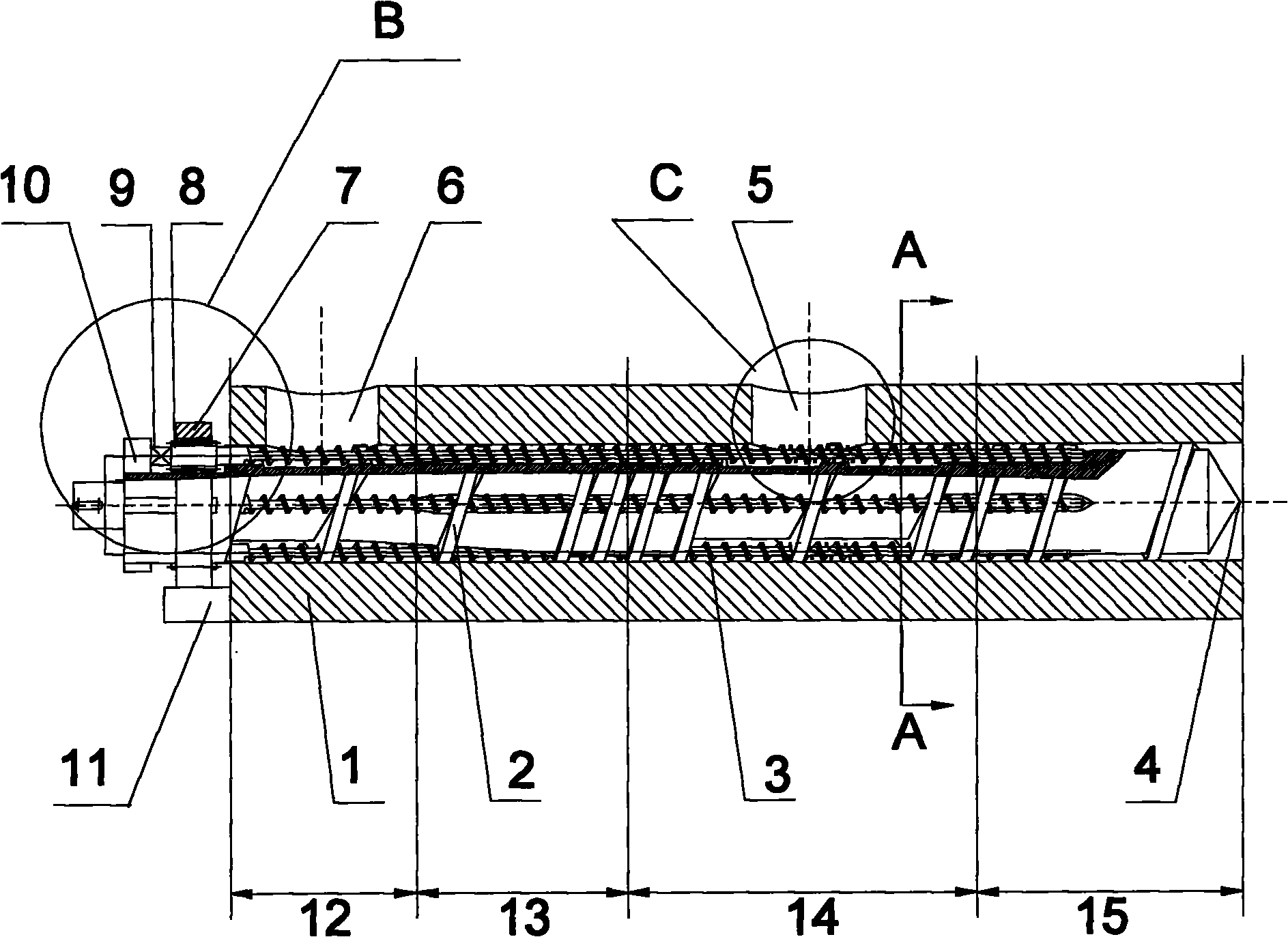

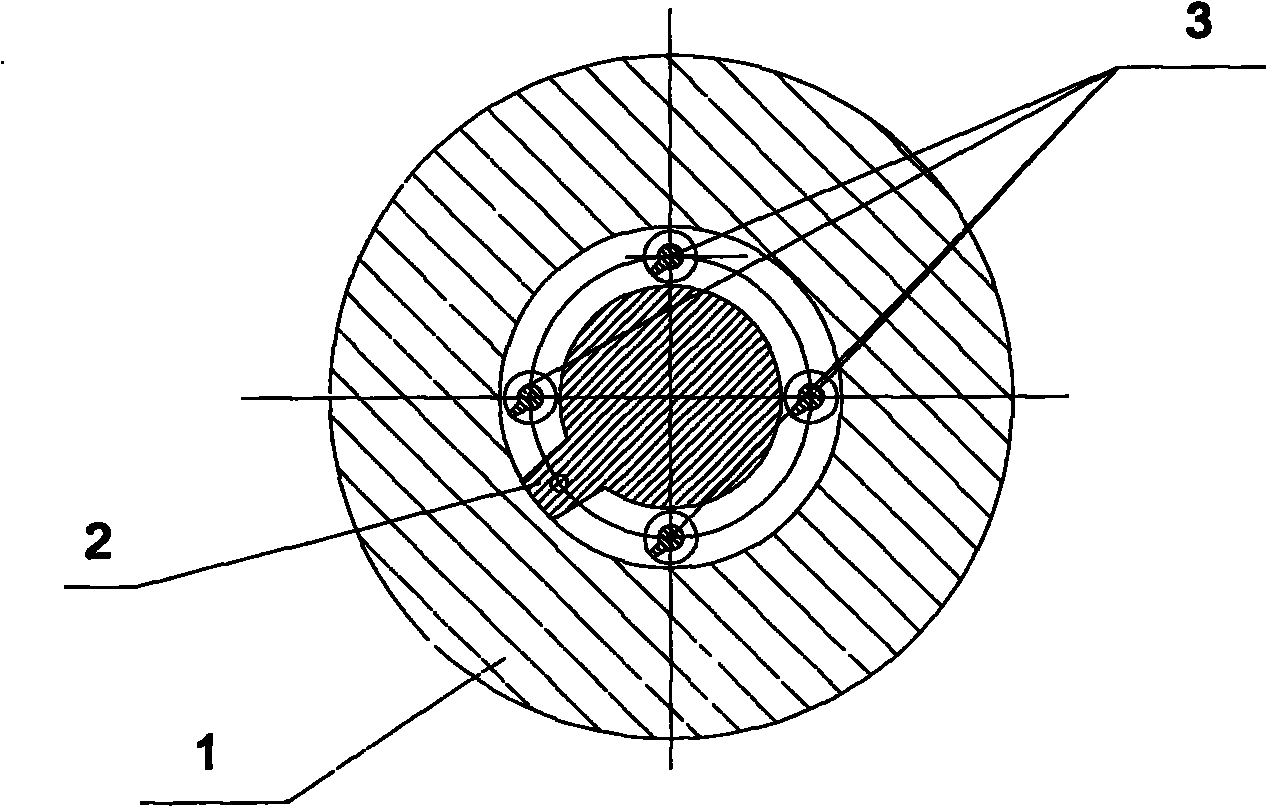

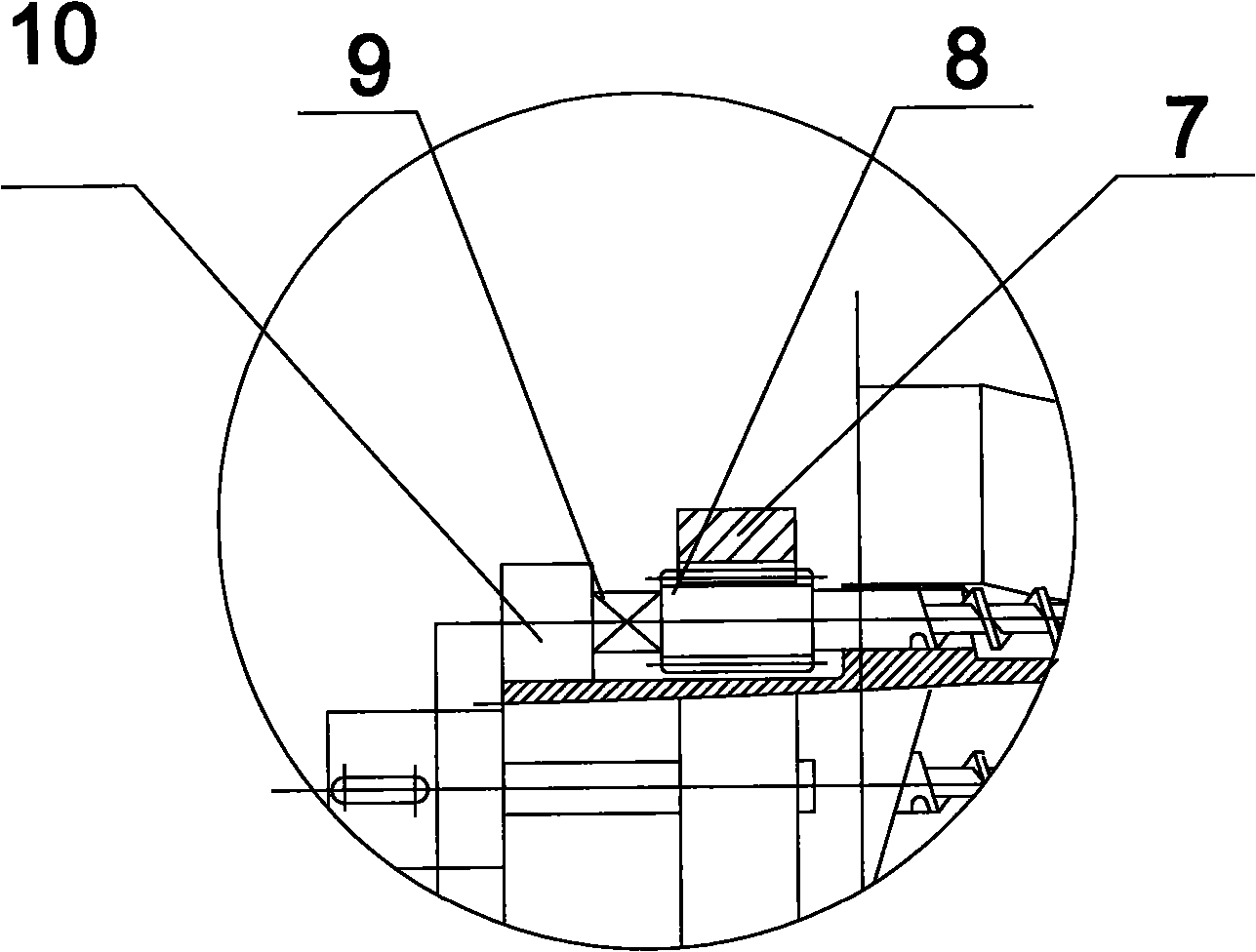

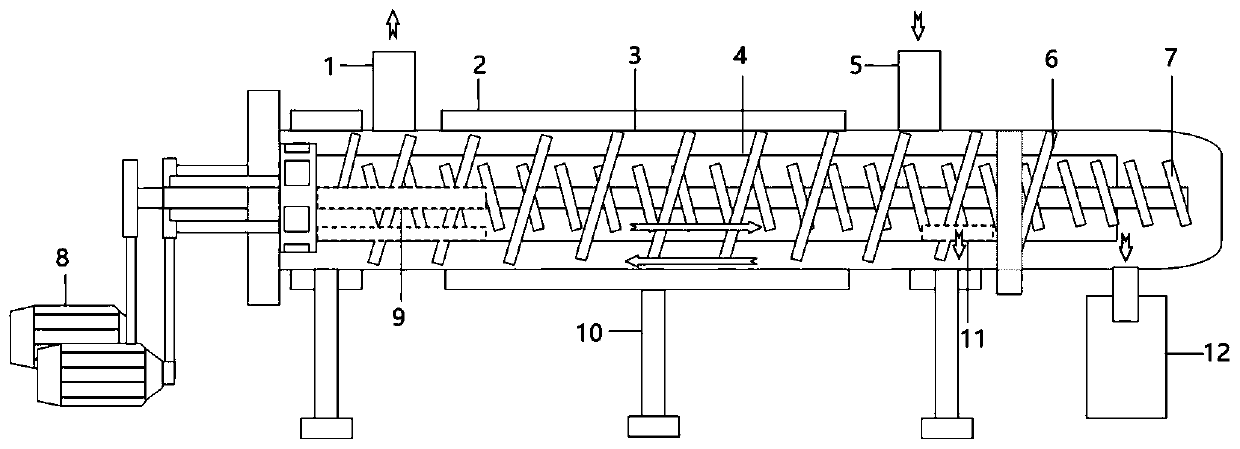

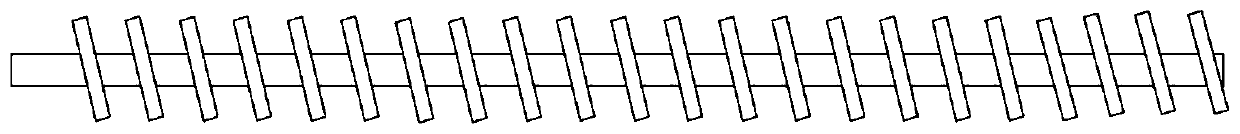

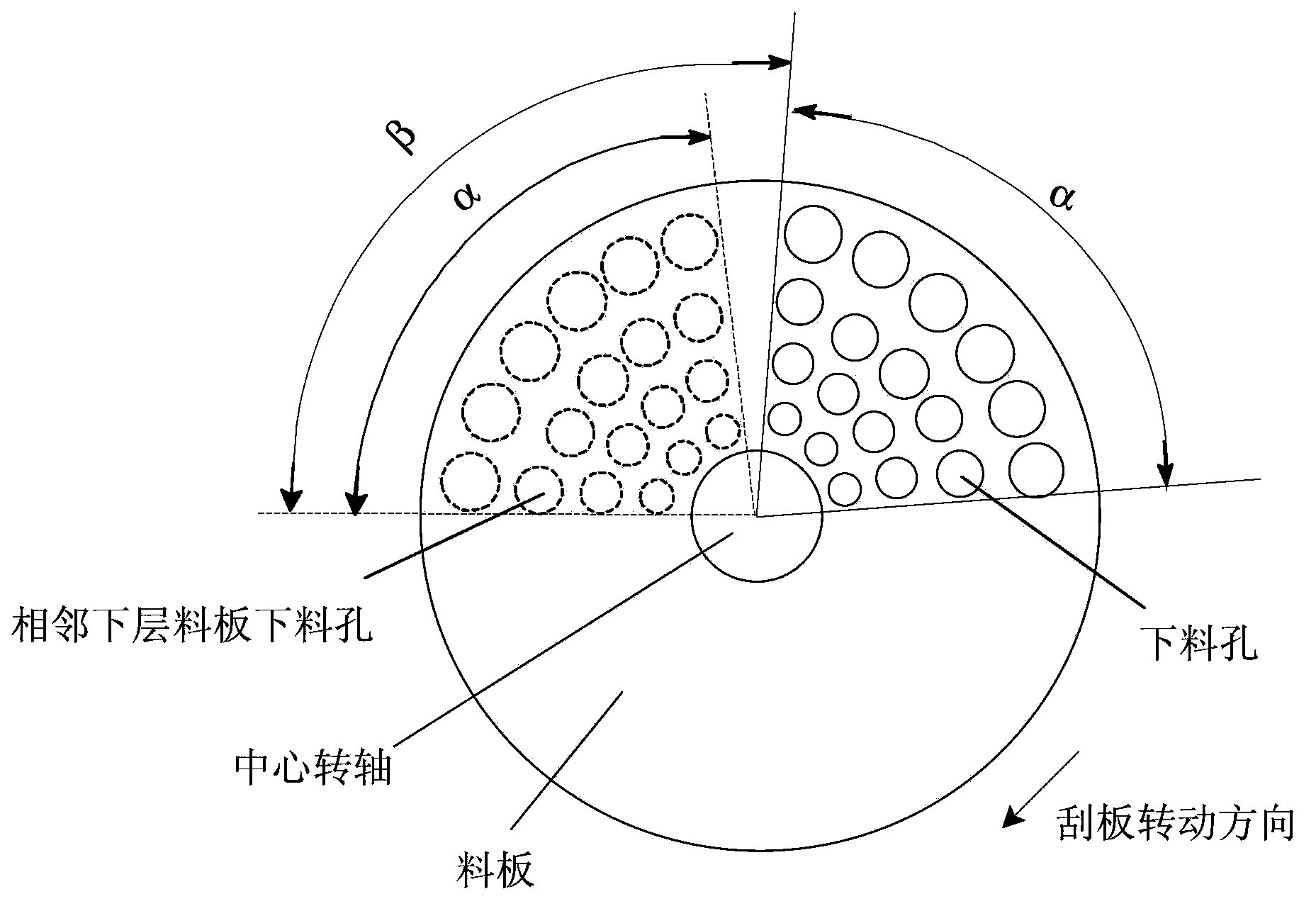

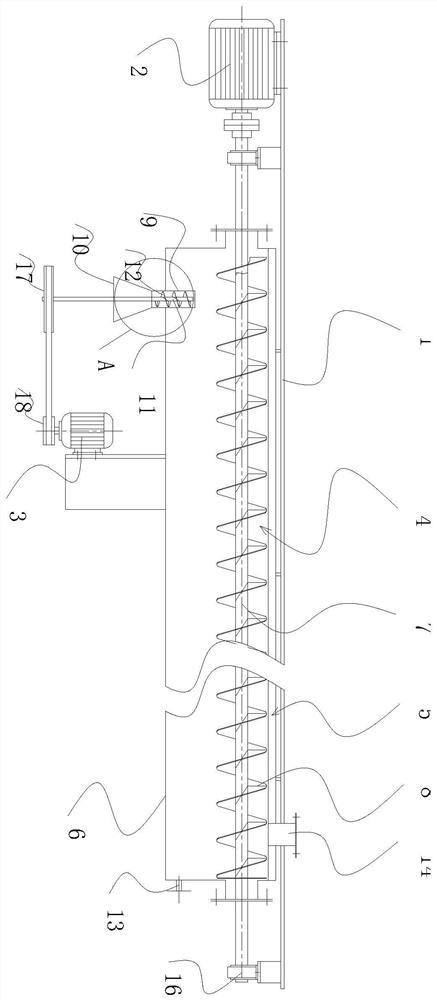

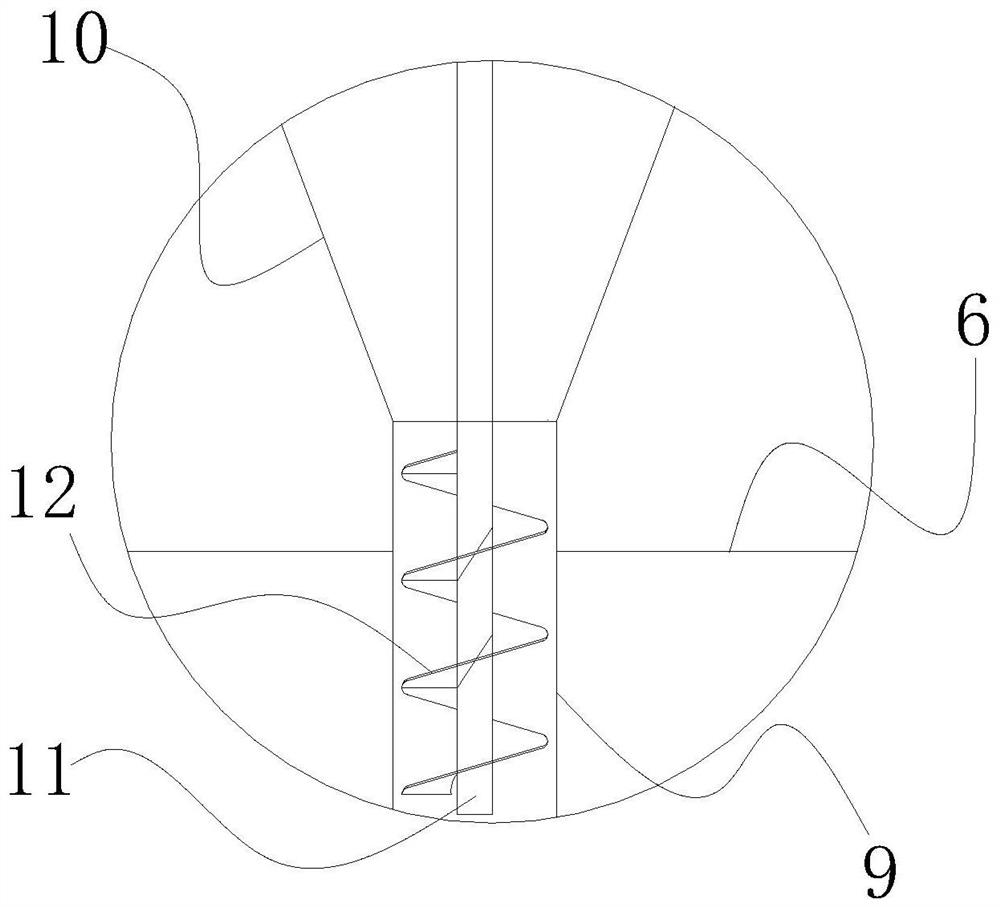

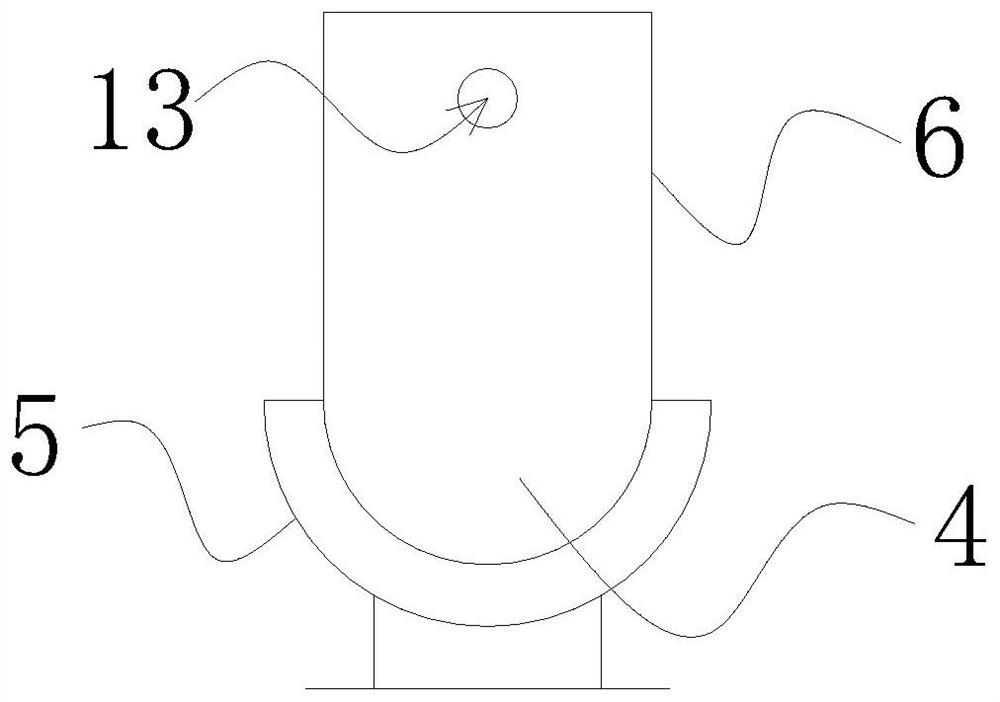

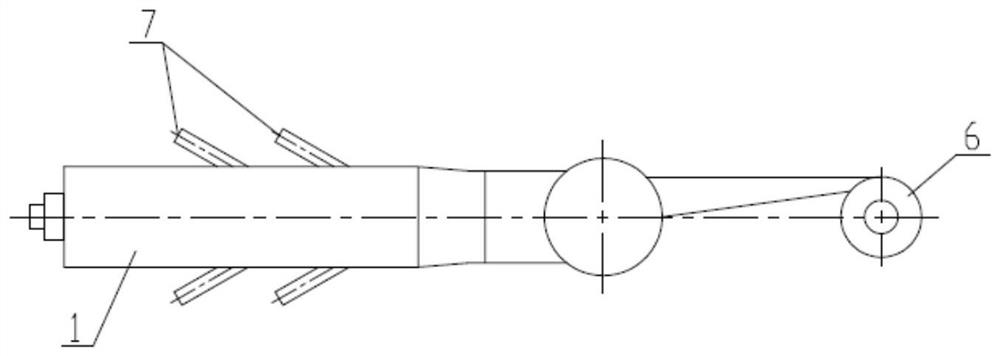

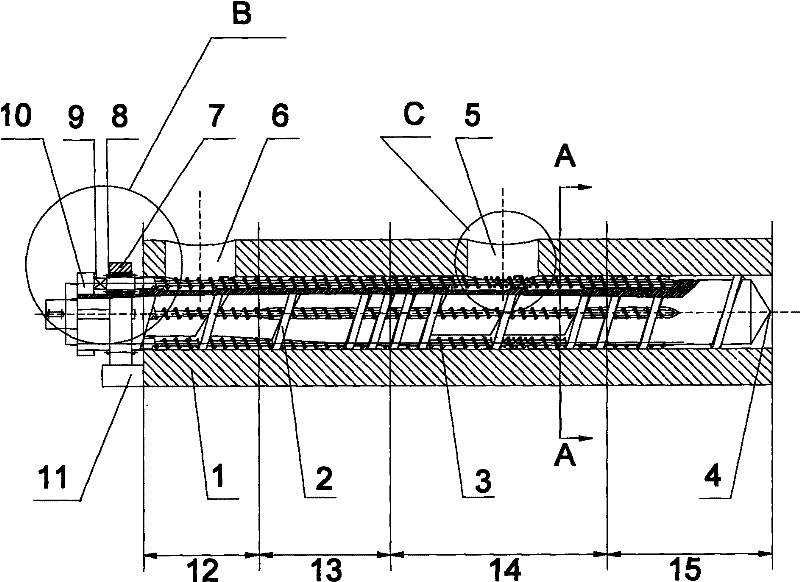

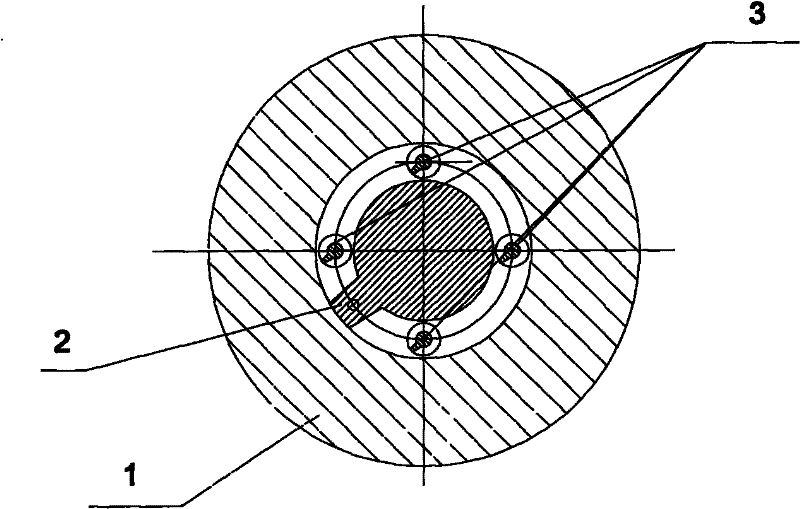

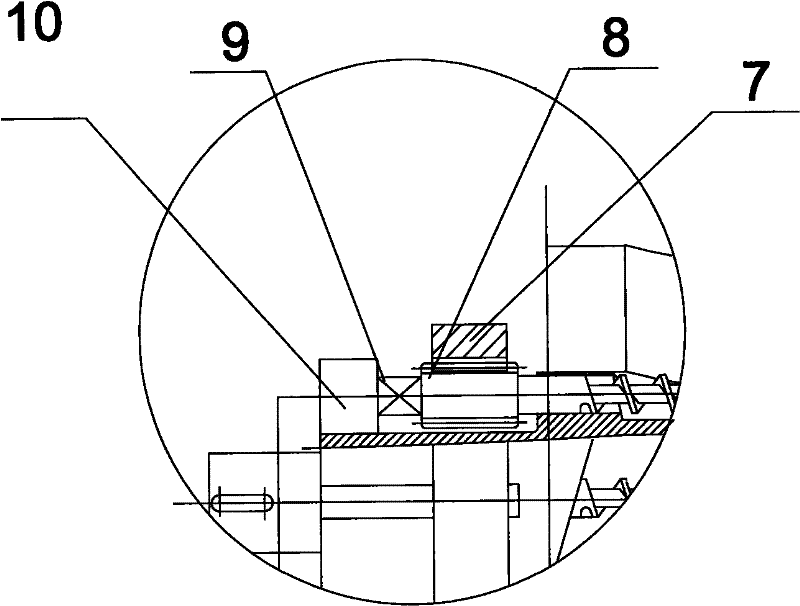

Embedded planetary-screw pulsation plasticizing exhaust extruder and method

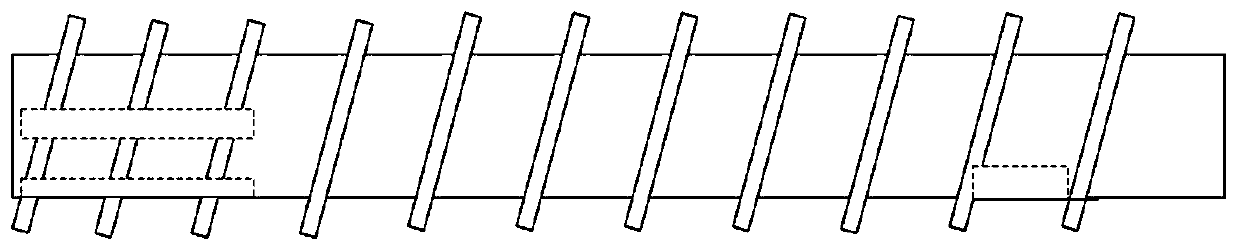

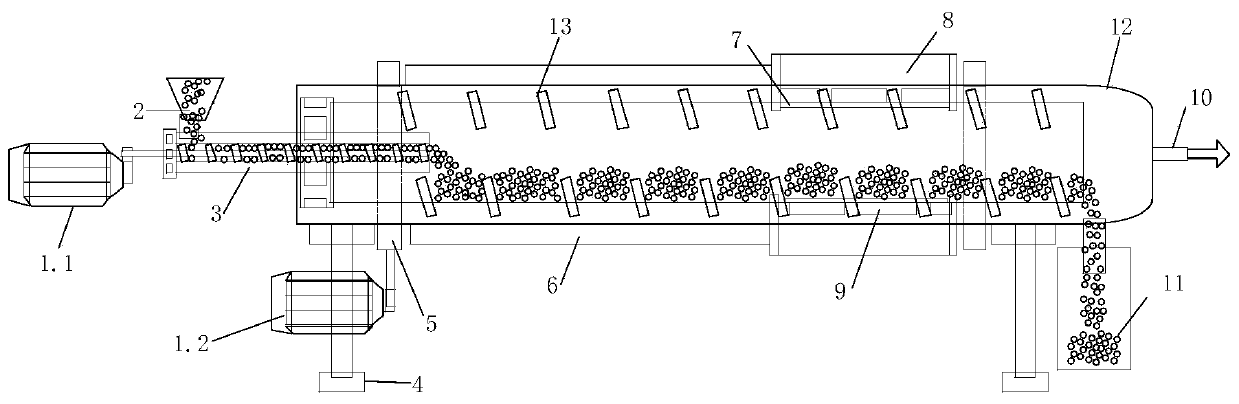

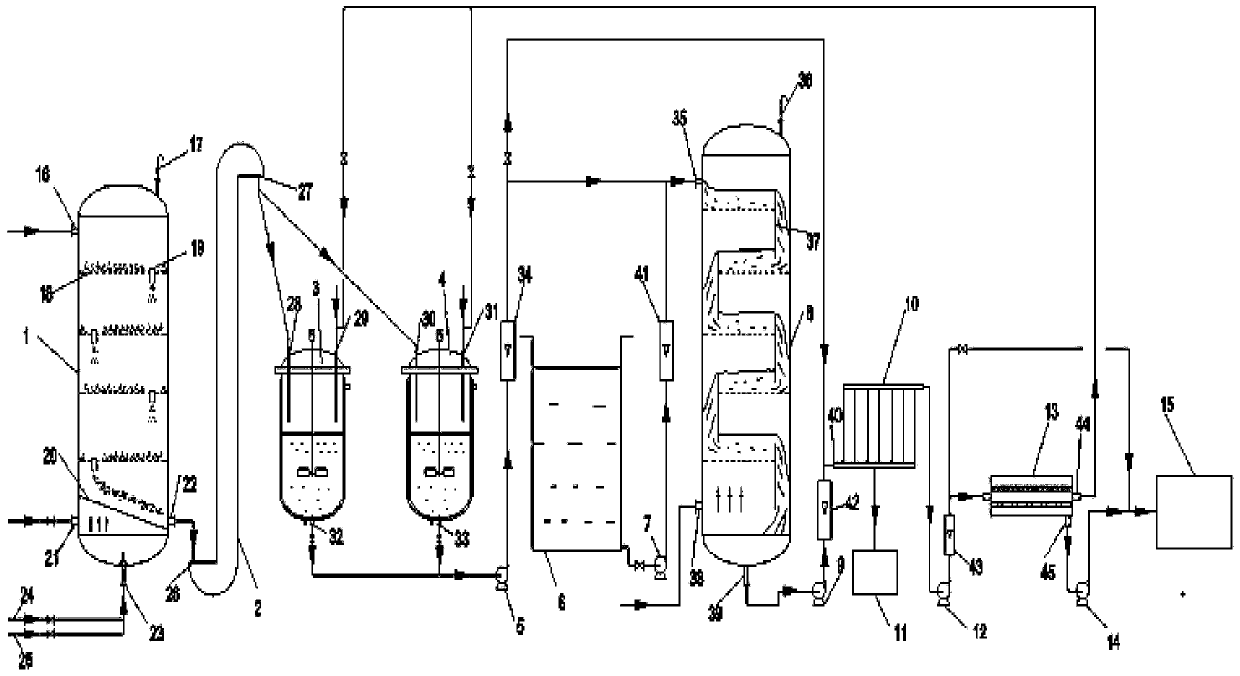

The invention provides an embedded planetary-screw pulsation plasticizing exhaust extruder, which comprises a screw mechanism, a cylinder, a feed inlet, an air outlet, a discharge outlet and an actuating unit, wherein the screw mechanism comprises a main screw and a plurality of planetary screws, and the axis of the main screw is coincident with the axis of the cylinder; the screw arris of the main screw is provided with a plurality of holes which are matched with the planetary screws; the planetary screws are respectively inserted in the holes of the screw arris of the main screw, embedded into a screw slot and distributed around the main screw; the axes of the planetary screws are parallel to the axis of the main screw; the actuating unit comprises pulsation gears, planetary gears and a pulsation-gear transmission mechanism; the planetary gears are fixed at the ends of the planetary screws and are engaged with the pulsation gears; and the pulsation gears are connected with the pulsation-gear transmission mechanism. The invention also provides an embedded planetary-screw pulsation plasticizing exhaust method implemented by the device. The embedded planetary screw pulsation plasticizing exhaust extruder and the embedded planetary-screw pulsation plasticizing exhaust method have the advantages of adjustable retention time, low energy consumption, thorough exhaust, good uniformity of phase structure control, and the like.

Owner:GUANGDONG IND TECHN COLLEGE

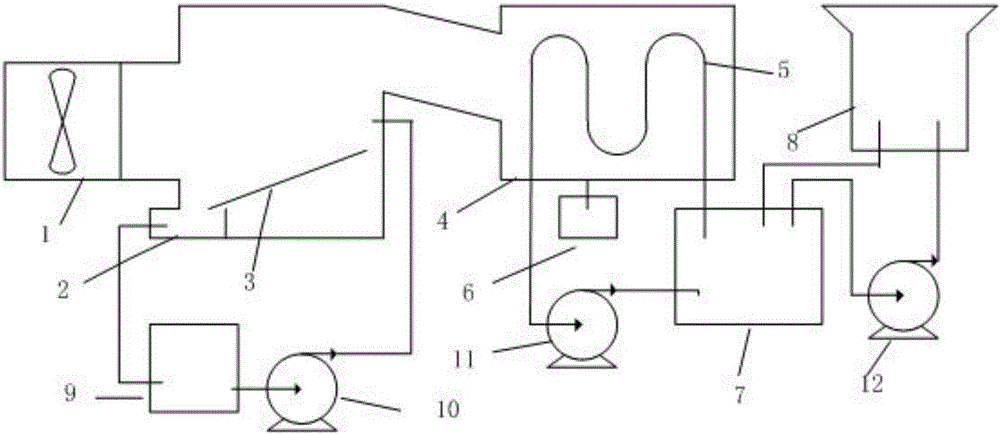

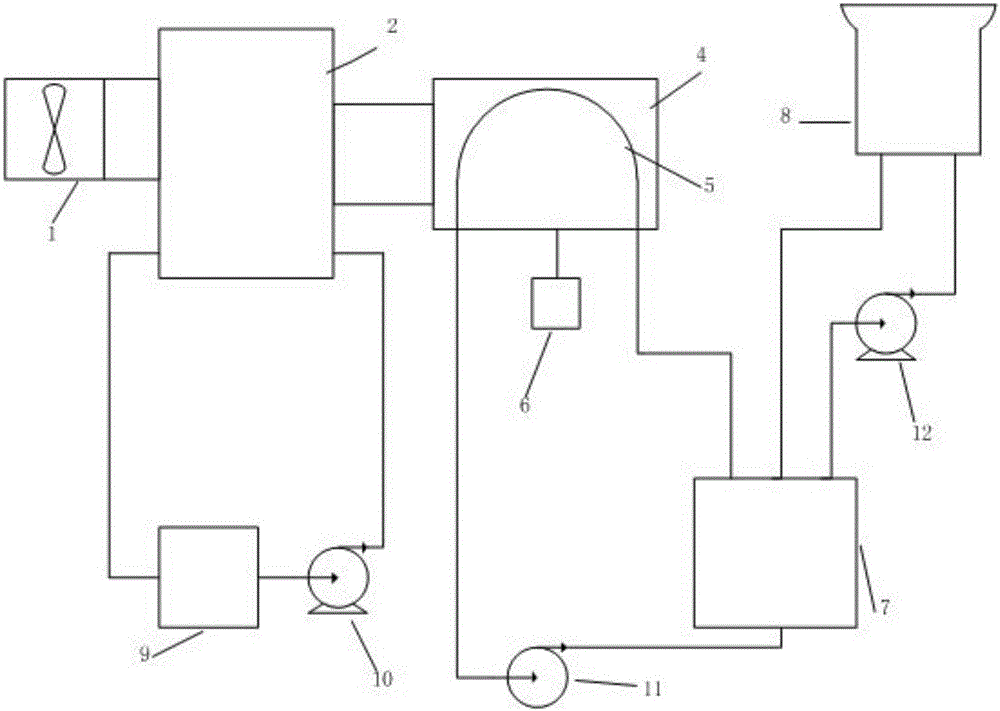

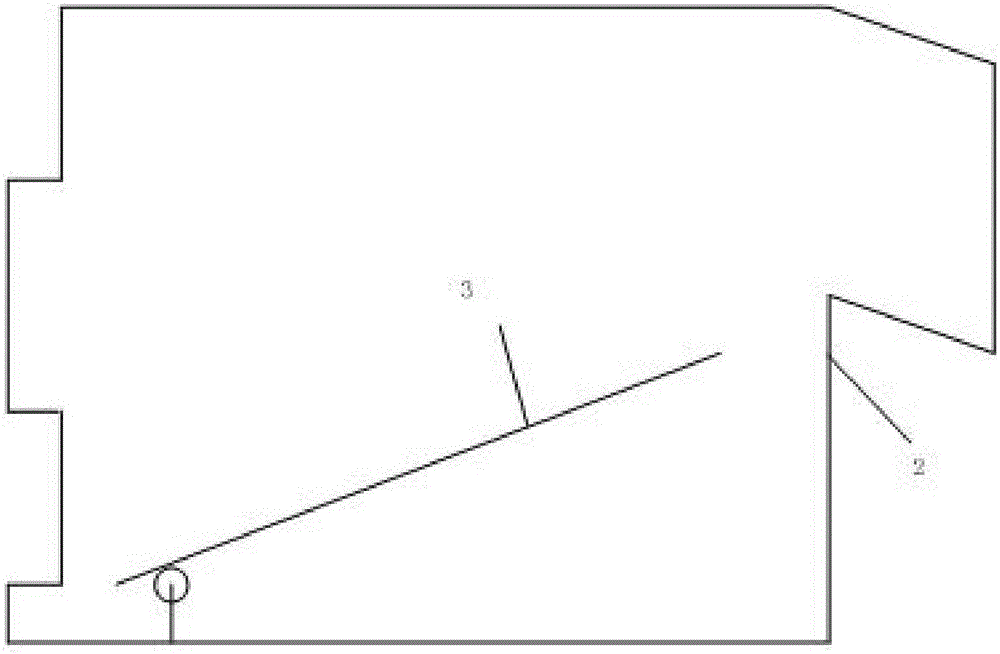

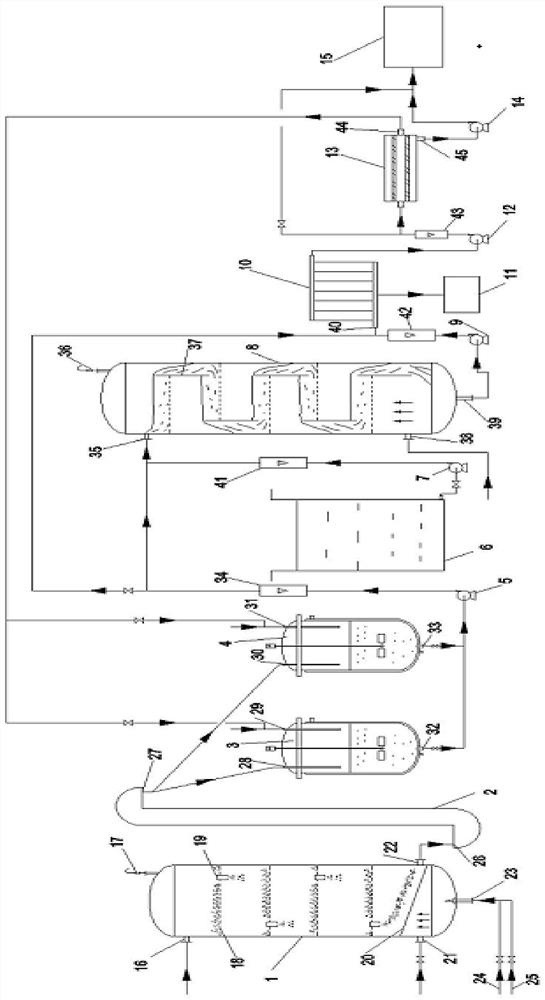

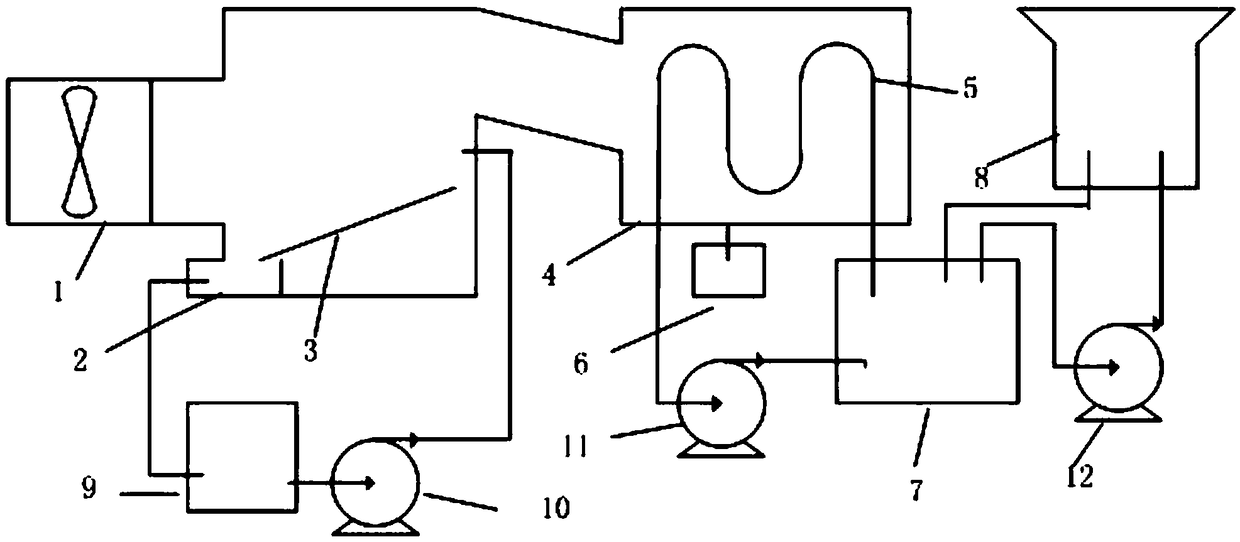

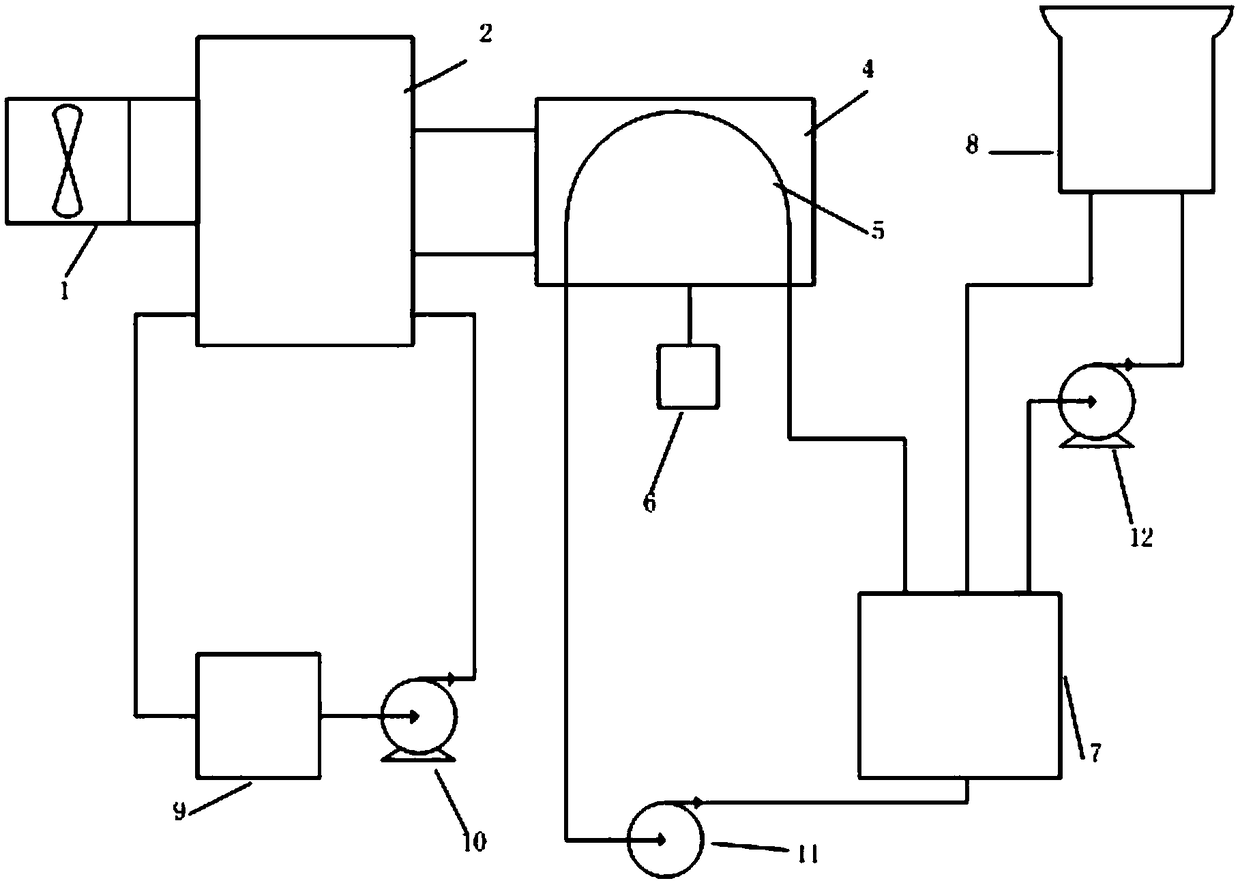

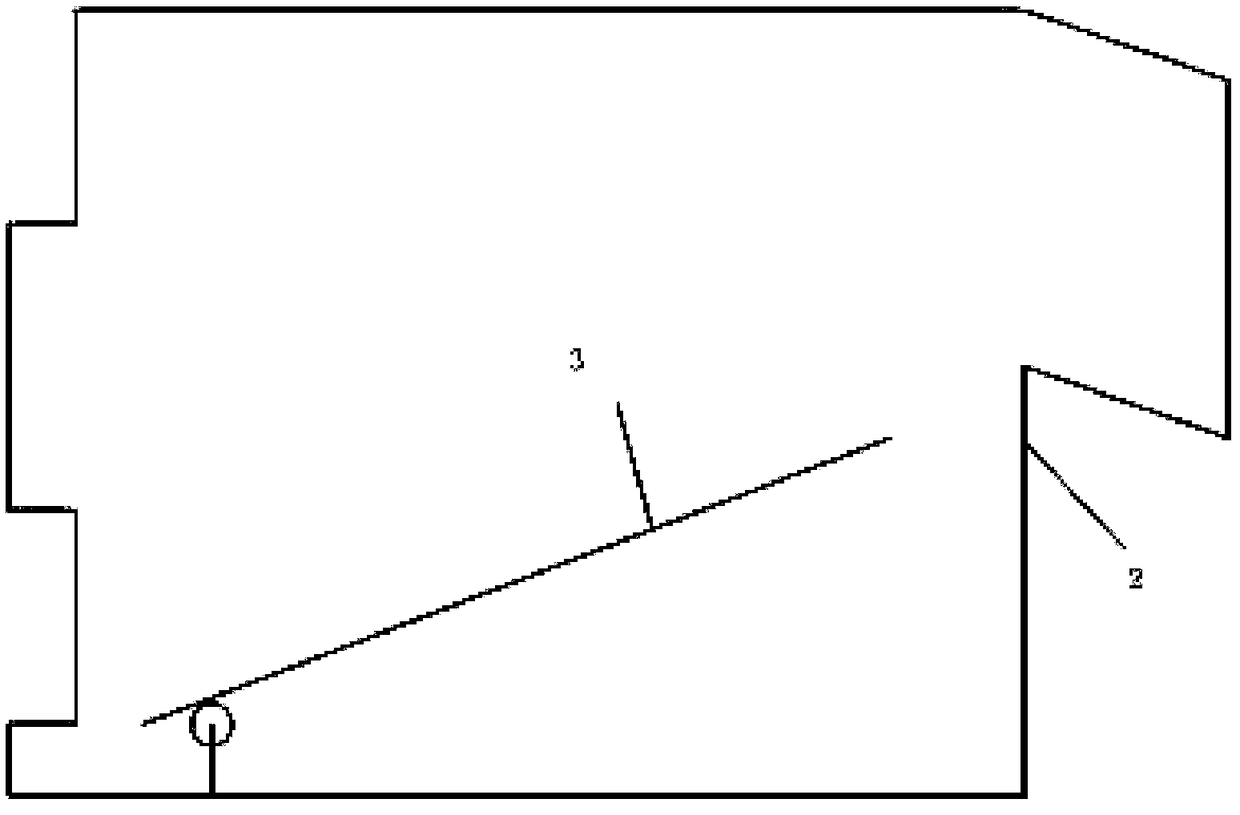

Seawater desalination device

InactiveCN105936521AFast evaporationIncrease the output speedGeneral water supply conservationSeawater treatmentEngineeringFresh water

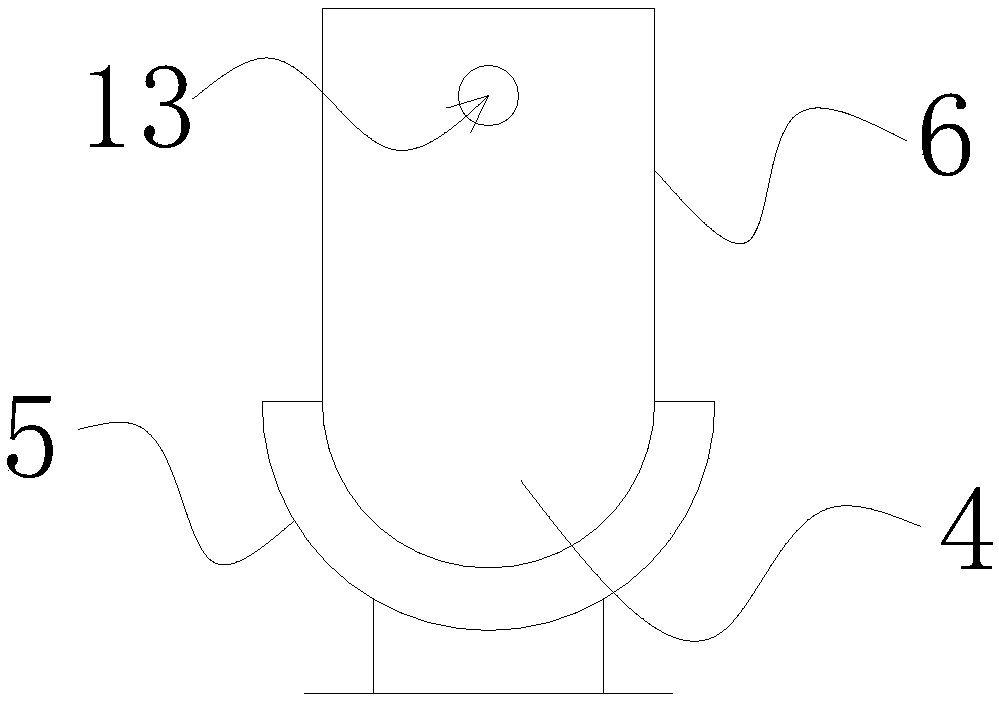

The invention discloses a seawater desalination device, which includes an evaporator (2). The top side wall of the evaporator (2) is provided with a wind inlet, an evaporator (2) side wall that is level with and opposite to the wind inlet is provided with a damp and hot steam outlet, the top of the evaporator (2) is provided with a cold seawater inlet, the bottom of the evaporator (2) is equipped with a hot seawater outlet, the evaporator (2) is internally provided with an inclined heating plate (3), the high end of the heating plate (3) is located right below the cold seawater inlet, the damp and hot steam outlet is connected to a condenser (4), the condenser (4) is internally provided with a snakelike cooling pipe (5), the inlet and outlet of the snakelike cooling pipe (5) are respectively connected to a cooling box (7), and a fresh water collecting box (6 ) is connected below the condenser (4). The seawater desalination device provided by the invention is used for concentrated seawater desalination to produce fresh water, and can guarantee residents' drinking water supply in coastal water-deficient areas.

Owner:HOHAI UNIV CHANGZHOU

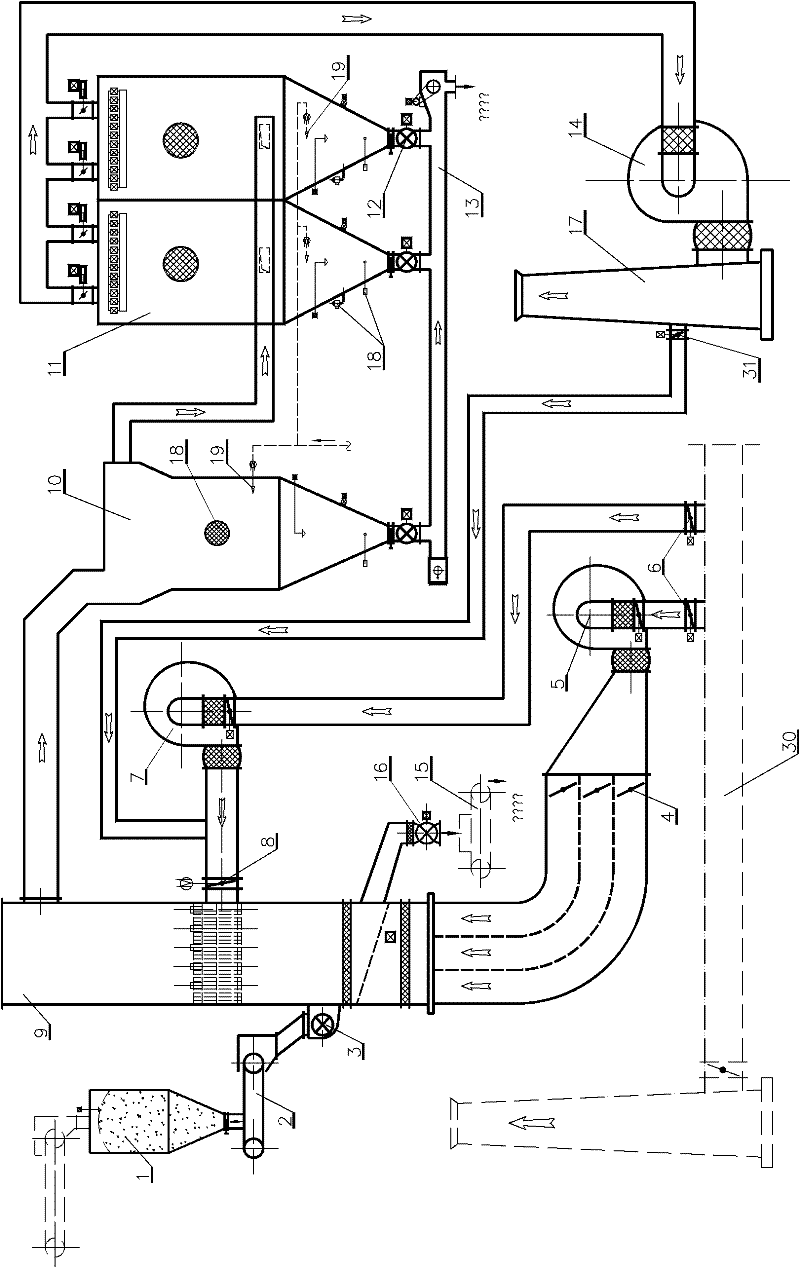

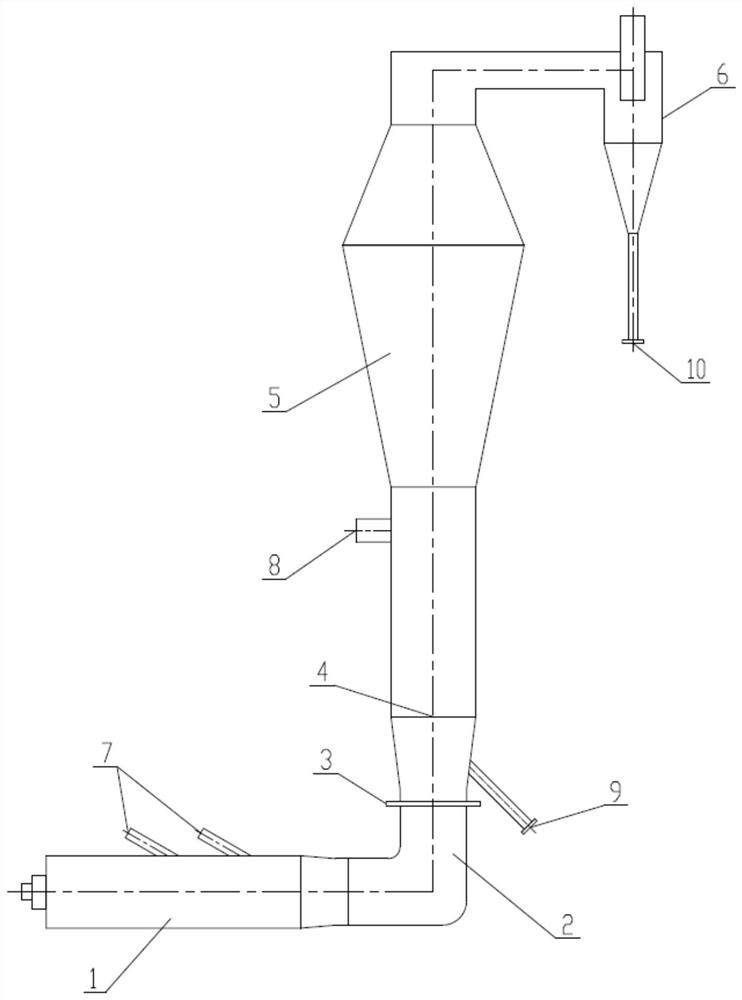

Process for calcining ammonium metavanadate for preparing powdered vanadium pentoxide

InactiveCN102021315AAdjustable dwell timeSolve the problem of easy cakingExhaust gasElectric heating

The invention relates to a process for calcining ammonium metavanadate for preparing powdered vanadium pentoxide. The process comprises the following steps of: (1) feeding ammonium metavanadate containing water of less than or equal to 1 percent by weight into an electric heating rotary furnace provided with an anti-agglomeration facility by using a feeder; (2) heating to rise the temperature to 510-560 DEG C, holding the temperature for 60-180 minutes, then cooling to 300-350 DEG C and discharging; (3) sending the material which has a temperature of 300-350 DEG C and is obtained in the step (2) into a cooling drum, and continuing to cool to 40-50 DEG C to obtain finished powder vanadium pentoxide; and (4) collecting a small quantity of vanadium pentoxide contained in tail gas of the rotary furnace by using a cyclone dust collector, carrying out primary water washing and secondary water washing on the tail gas to ensure that the ammonia content in the tail gas is reduced to reach an exhaust standard and then exhausting. The invention has the advantages of simple and reliable process, safe deamination, energy saving and environmental protection and is convenient to operate.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

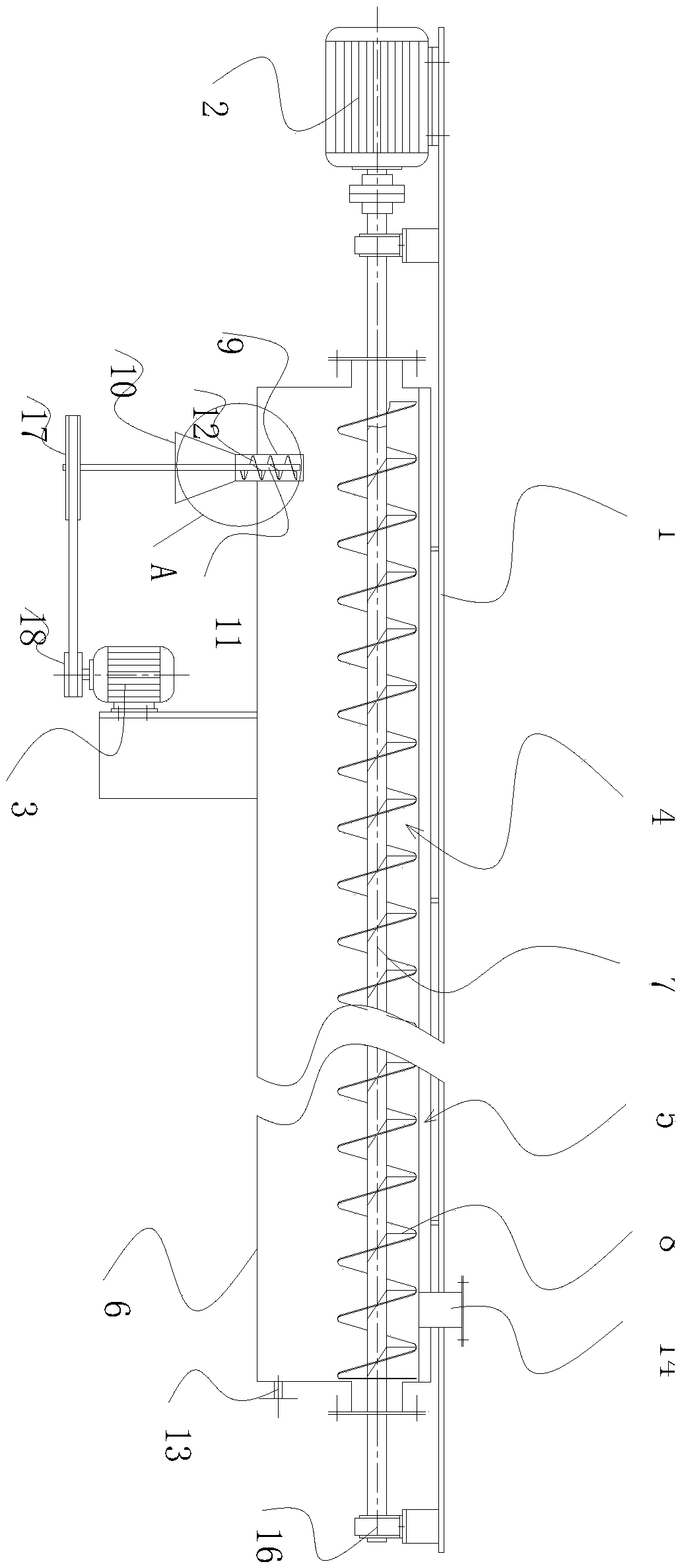

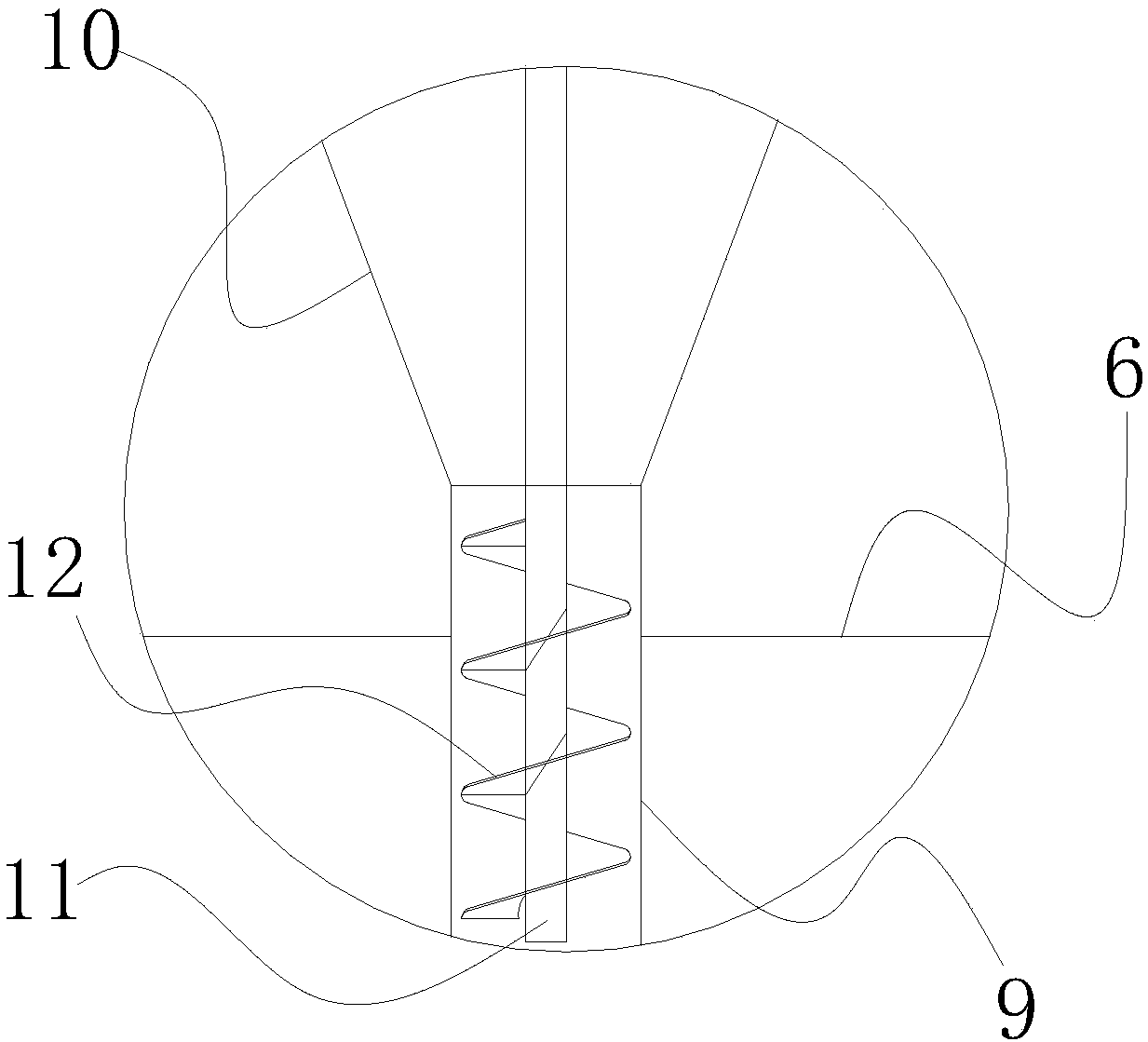

Double-helix pyrolysis reactor based on pyrolytic carbon internal circulation enhanced heat transfer

InactiveCN111286349AAchieve pyrolysis conversionImprove heat transfer performanceBiofuelsIndirect and direct heating destructive distillationEnhanced heat transferEngineering

The invention discloses a double-helix pyrolysis reactor based on pyrolytic carbon internal circulation enhanced heat transfer, and belongs to the technical field of renewable energy utilization, wherein the double-helix pyrolysis reactor adopts a horizontal cylindrical outer helix drum as a main body, a pyrolysis gas outlet is formed in the upper end of the left part of the outer helix drum, a feeding hole is formed in the upper end of the right part of the outer helix drum, a pyrolytic carbon collecting box is arranged at the lower end of the right part of the outer helix drum, and an electric heating device is arranged on the outer side of the outer helix drum, and three support frames arranged at the lower part of the outer helix drum are used for supporting the outer helix drum; two coaxial rotating screw rods with opposite blade spiral directions, namely an outer screw rod and an inner screw rod, are arranged in the outer helix drum, a pyrolytic carbon exchange port is formed inthe left side of an inner helix drum, a carbon circulating port is formed in the lower end of the right side of the inner helix drum, and the pyrolytic carbon collecting box is arranged at the lower end of the right side of the outer helix drum; materials are conveyed through the spiral structure, the heat transfer performance of the device is improved, the biomass treatment capacity per unit volume is increased, and a solution is provided for the heat source problem of a movable pyrolysis device.

Owner:SOUTHEAST UNIV

Waste tire cracking device and method based on combination of dividing wall heat exchange and microwave heating

InactiveCN111471476AReduce the temperatureSolve the problem of large thermal resistanceProductsReagentsElectric machineSpiral blade

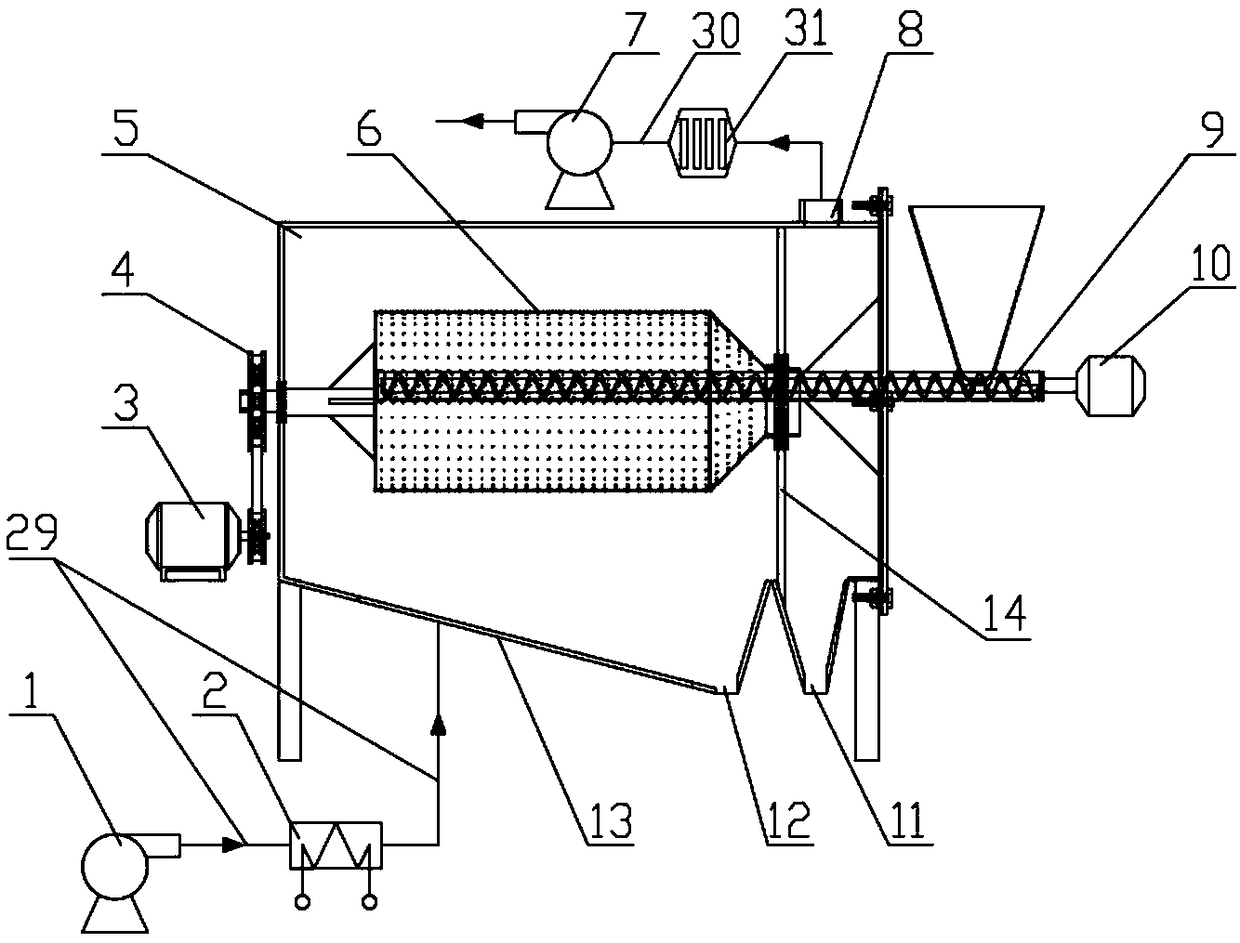

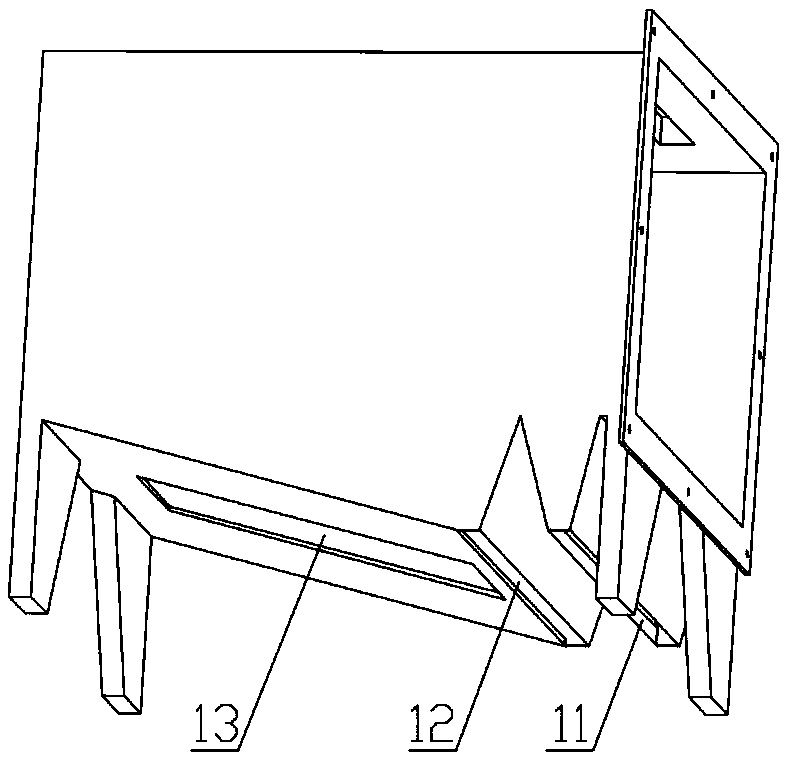

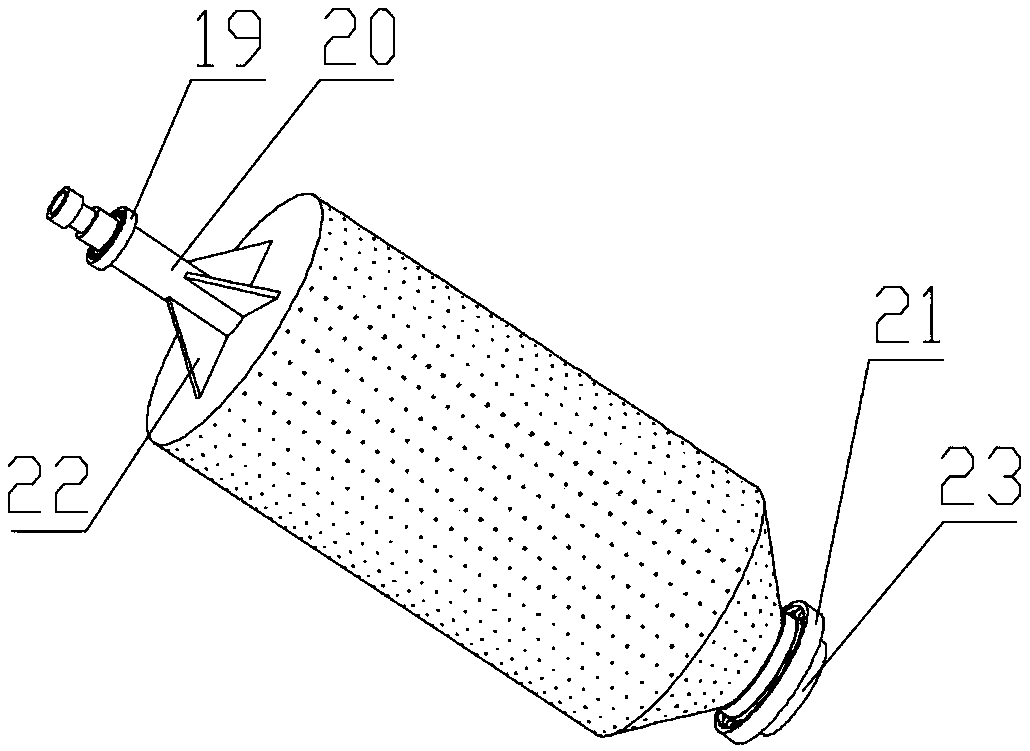

The invention discloses a waste tire cracking device and method based on combination of dividing wall heat exchange and microwave heating. The main body of the cracking device is a horizontal cylindrical shell (12); a spiral conveying device (3) is arranged on the left side of the shell; the right half section of the spiral conveying device is positioned in the shell; a feeding opening (2) is arranged in the upper part of the left side of the spiral conveying device; the spiral conveying device is driven by a first speed regulating motor (1.1); a pyrolytic carbon black collecting box (11) is arranged at the lower end of the right side of the shell, an electric heating device (6) is installed on the front section outside the shell, a microwave heating device (9) of a microwave heating section is installed on the rear section outside the shell, four supporting frames (4) are arranged on the lower portion of the shell to support the whole device, and spiral blades (13) are arranged in theshell and penetrate through the shell from left to right. The spiral structure is used for conveying materials, so that the material adaptability of the reactor is improved; and the waste tire particles are slightly carbonized in the continuous temperature rising process of front-section electric heating, so that the wave absorbing property of the waste tire particles is greatly improved.

Owner:SOUTHEAST UNIV

Carbonization and activation device for active coke production

The invention belongs to the field of chemical engineering devices and relates to a carbonization and activation device for active coke production. The device comprises a material channel and flues at two sides of the material channel. The device also comprises a preheating section, a carbonization section, an activation section and a cooling section and the sections are orderly arranged from top to bottom along a vertical direction. The flues in the carbonization and activation sections are respectively provided with gas burners. The flue in the activation section is provided with an activator inlet. The device realizes combination of carbonization and activation, has less processes, uniform and continuous reaction processes, a fast activation rate, a high raw material utilization rate and high production power, greatly reduces power and energy consumption and has a low cost and a high product yield.

Owner:赵英杰

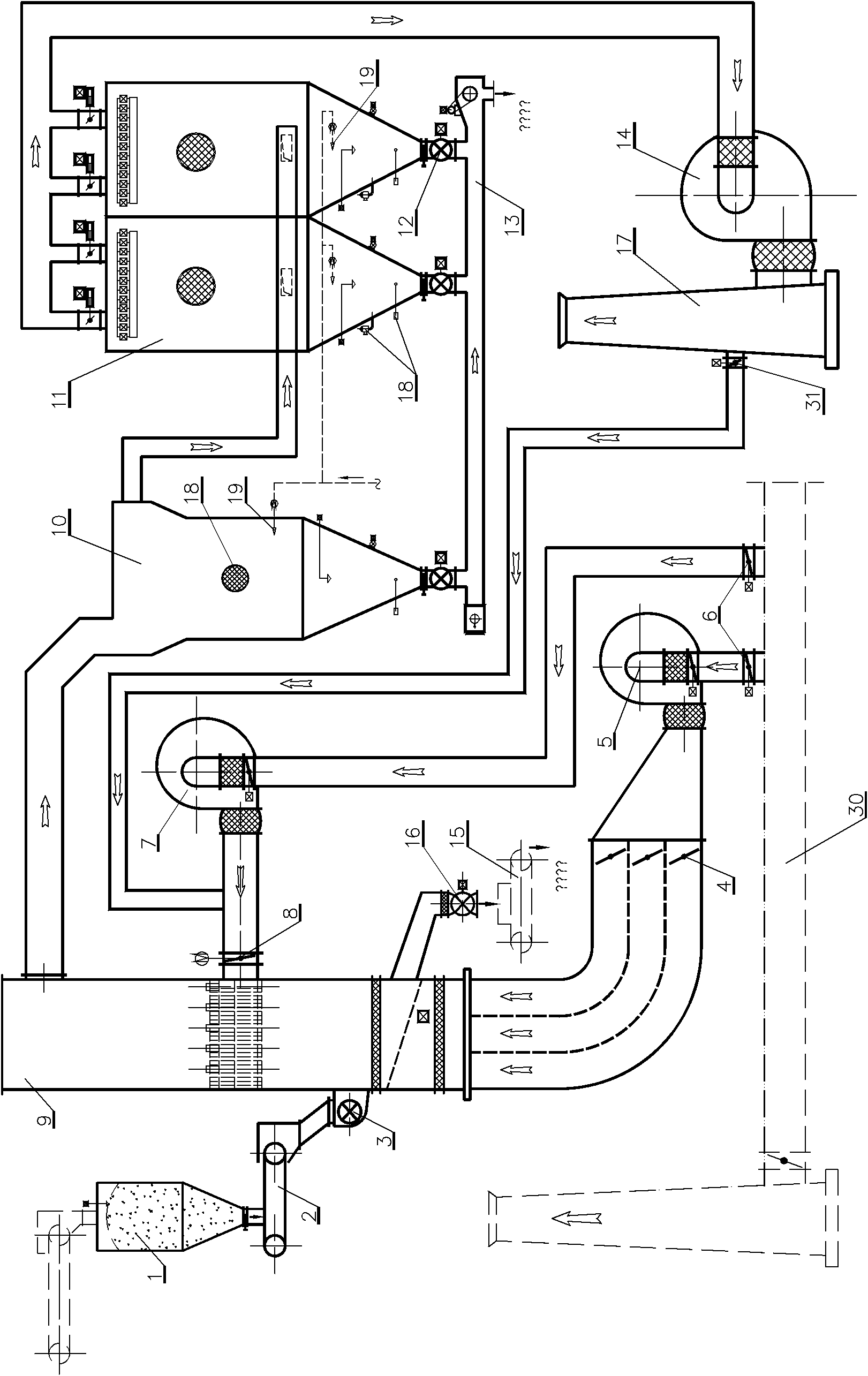

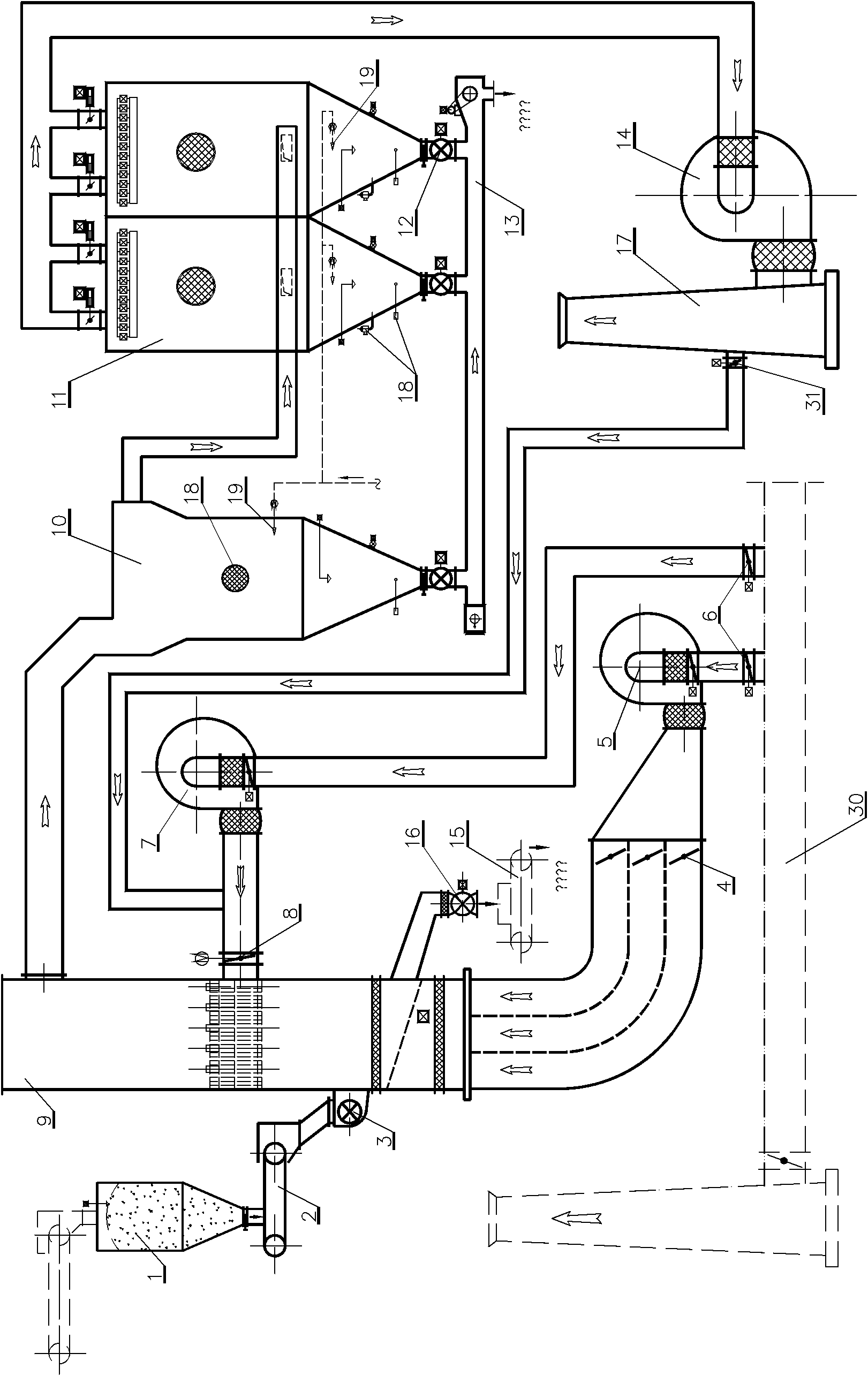

Full-boiling vibration propelled coal moisture control and grading integrated equipment

ActiveCN102304377AImprove energy savingAchieve particle size classificationDrying solid materials with heatCoke ovensFixed bedMoisture

The invention relates to full-boiling vibration propelled coal moisture control and grading integrated equipment, which comprises a primary air inlet section, a secondary air inlet section, and a vibration distribution plate, wherein the primary air inlet section is positioned below the vibration distribution plate, and a sedimentation separation area is positioned in an area above the vibration distribution plate; the vibration distribution plate has an obliquely arranged fluidized bed structure; the top airflow outlet of a grader is connected with a fine particle separation device; the outlet of the fine particle separation device is connected with the inlet of a fine particle recycling device; the upper part of the fine particle recycling device is communicated with a smoke exhaust fanthrough a connecting pipeline; and the smoke exhaust fan is connected with a chimney. Coke oven flue gas is taken as a heat medium; and according to a characteristic that raw material coal has high heat and mass transfer efficiency in a full-boiling fluidized state and low heat and mass transfer efficiency in a fixed bed and half-boiling fluidized state, a coal material can be subjected to moisture control uniformly and efficiently, and can be efficiently graded.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

Fluidized bed drying equipment

InactiveCN109028766AUniform temperature distributionImprove heat transfer performanceDrying solid materials with heatDrying gas arrangementsFluidized bed dryingAutomatic control

The invention discloses fluidized bed drying equipment. The equipment integrally designs a material drying system, a separation system and a collection system based on the fluidizing drying technologyand the centrifugal principle, and materials have the advantages that heating is uniform, the time in a drying roller can be adjusted, the drying speed is high, products obtained after material drying are separated thoroughly, multiple dried articles can be collected at the same time, and the automation degree is high. A box body is composed of an inner heat conduction layer, a middle heating layer and an outer heat preservation layer, the heat energy utilization rate is high, a temperature controller and a timer are arranged, and therefore automatic control is achieved; temperature distribution in a fluidized bed is uniform, and the heat transfer effect is good; and the temperature and the air speed can be automatically controlled at the same time, the phenomenon of non-uniform partial heating of the materials is avoided, and the fluidized bed drying equipment is especially suitable for drying thermosensitive materials. The reliability of a screw feeding mechanism is high; a dust removal device can reduce the amount of dust in waste gas and is beneficial to environment protection; and the equipment structure is simple, and the fluidized bed drying equipment is suitable for beingused and popularized in drying and separating of crop and chemical products.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Device used for removing organic impurities in by-product sodium chloride in chlorine chemical process

ActiveCN109956484ASolve the blockageSolve wear and tearAlkali metal halide purificationSlagFluidized bed

The invention belongs to the technical field of chemistry industry, and relates to a device used for removing organic impurities in by-product sodium chloride in chlorine chemical process. The devicecomprises a high temperature oxidation reactor, a dissolving kettle A, a dissolving kettle B, a liquid phase deep oxidation tower, a liquid solid filter, a solid slag tank, and a fine filter which areconnected successively. In application process, firstly, the multilayer fluidized bed type high temperature oxidation reactor is adopted for high temperature oxidation of most organic impurities in by-product sodium chloride, then in the liquid phase deep oxidation tower, residual trace amount organic impurities are subjected to deep oxidation, and a nanofiltration membrane separator is adopted to remove high molecular organic matter impurities further, so that requirements of ionic membrane caustic soda industrial devices on organic impurities in sodium chloride are satisfied. The device islarge in operation flexibility, and high in organic impurity processing efficiency.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

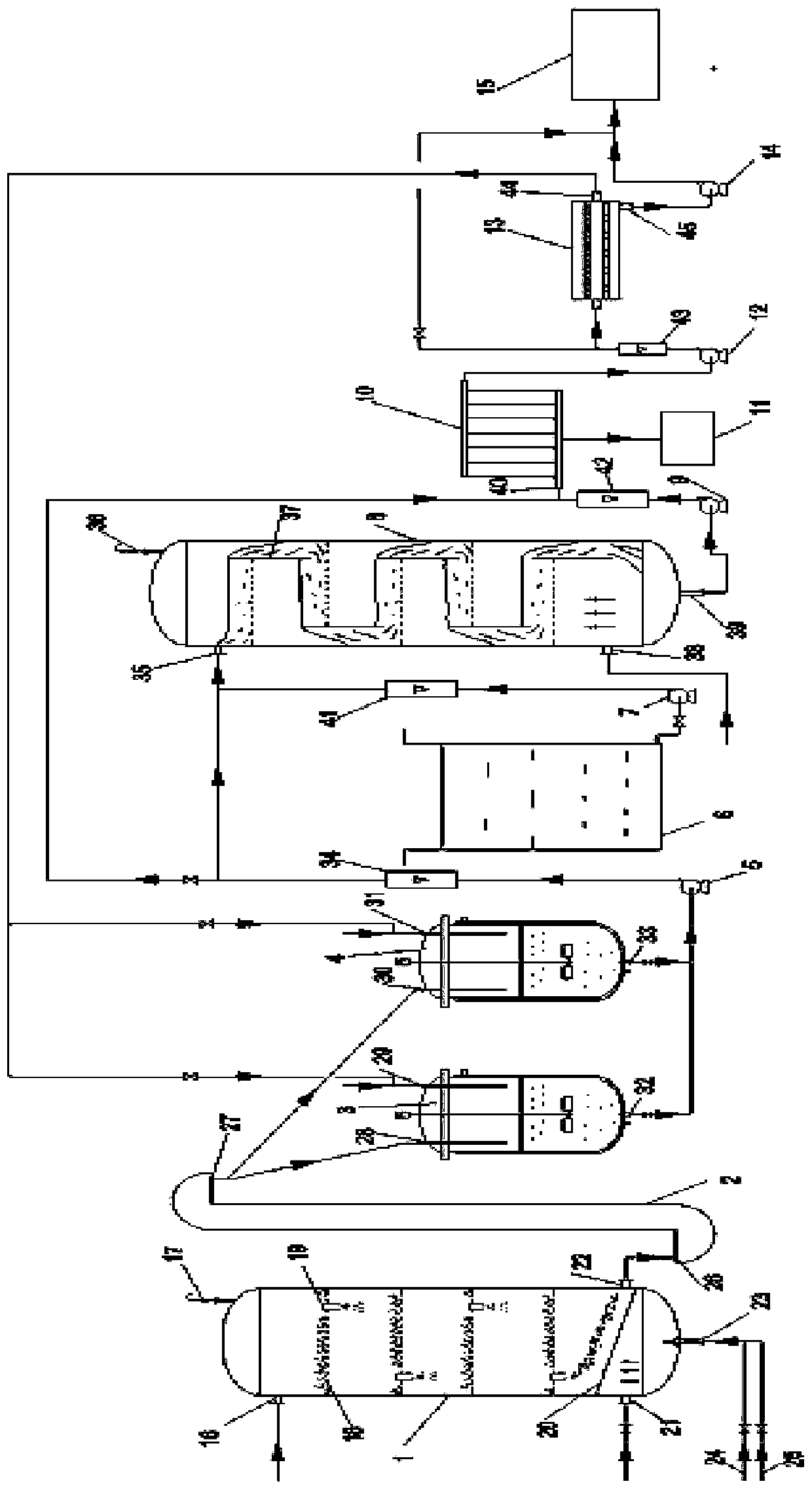

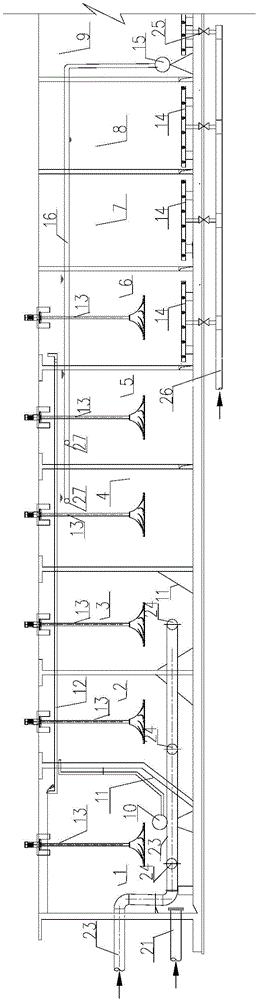

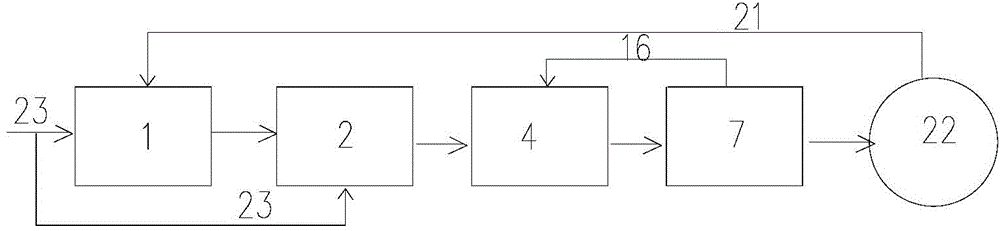

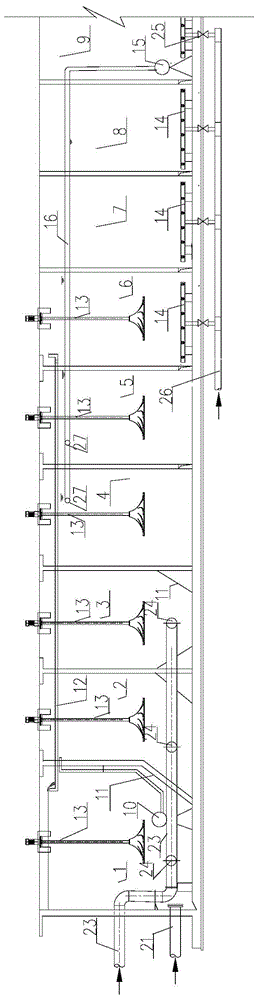

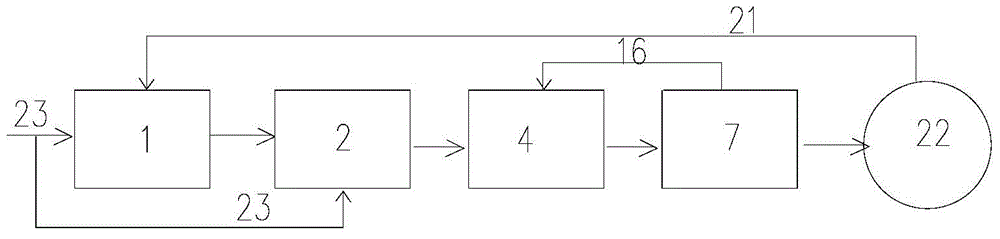

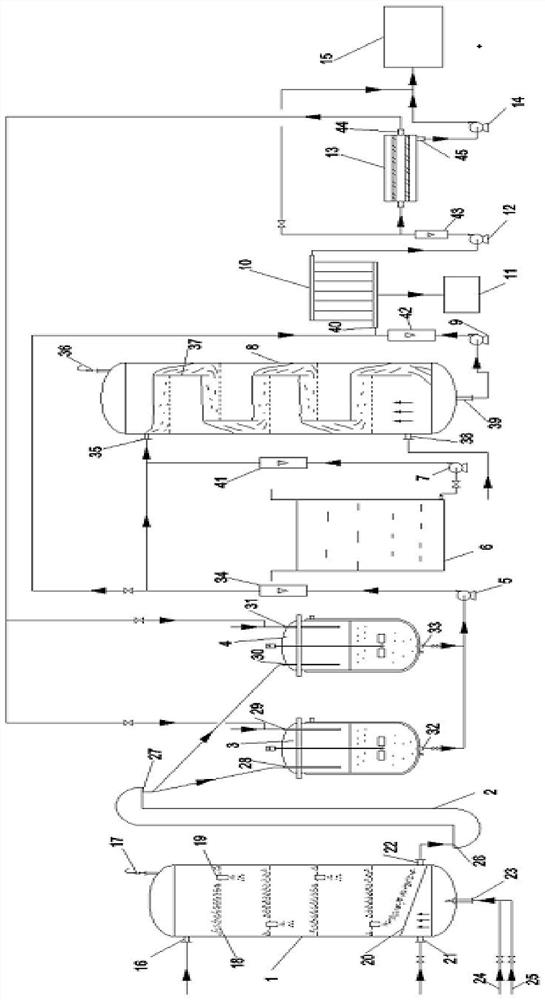

Multi-cell A<2>O system of sludge anoxic and strengthened fermentation hydrolysis and application thereof

ActiveCN104671602AImprove the effectIncrease hydraulic retention timeMultistage water/sewage treatmentHigh concentrationReflux

The invention provides a multi-cell A<2>O system of sludge anoxic and strengthened fermentation hydrolysis. The system comprises a sludge anoxic cell, a strengthened fermentation hydrolysis cell, an anoxic cell, an aerobic cell and a secondary sedimentation tank, wherein a water inlet pipe is connected with the sludge anoxic cell; the aerobic cell is connected with the anoxic cell through an internal reflux pipeline; and 2 or 3 strengthened fermentation hydrolysis cells, 2 or 3 anoxic cells and 2-4 aerobic cells are provided. By adopting the system provided by the invention, the sludge of the sludge anoxic cell is denitrified through endogenous respiration, and the internal carbon source in sludge is fully used so that more carbon sources are applied to a nitrogen and phosphorus removal biological reaction of the mainstream AAO technology; the nitrate content of the sludge anoxic cell can be reduced to 0, the redox potential in the strengthened fermentation hydrolysis cell is very low, and the effect of anaerobic phosphorus release is improved; and meanwhile, hydrolysis fermentation is performed through a high-concentration sludge layer in the strengthened fermentation hydrolysis cell, macromolecular or refractory organic substances in the inflow water are converted into low-molecular-weight fatty acid, and a high-quality carbon source is provided for the anaerobic phosphorus release and anoxic denitrification reactions.

Owner:THUNIP CORP LTD

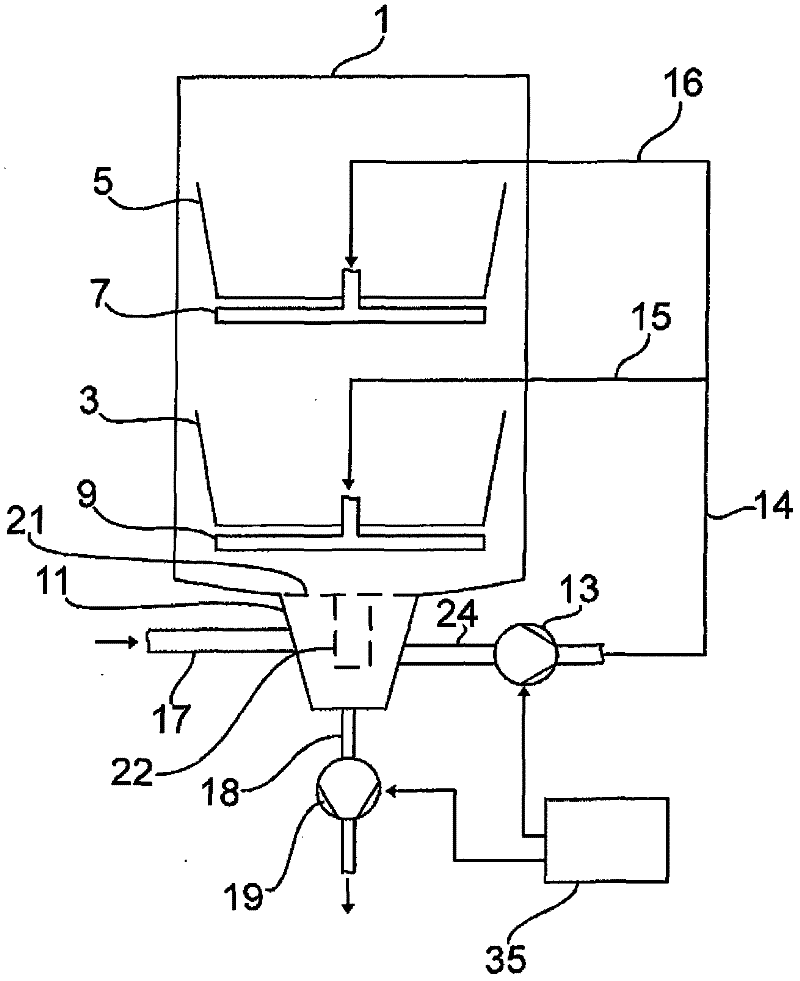

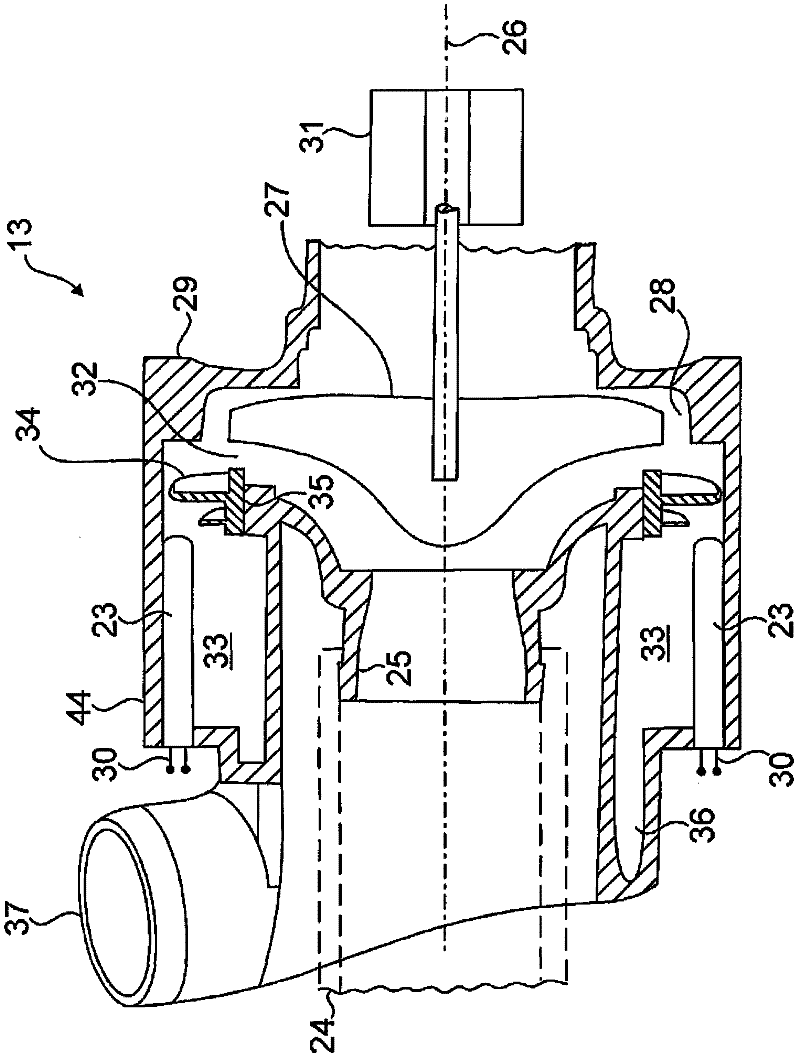

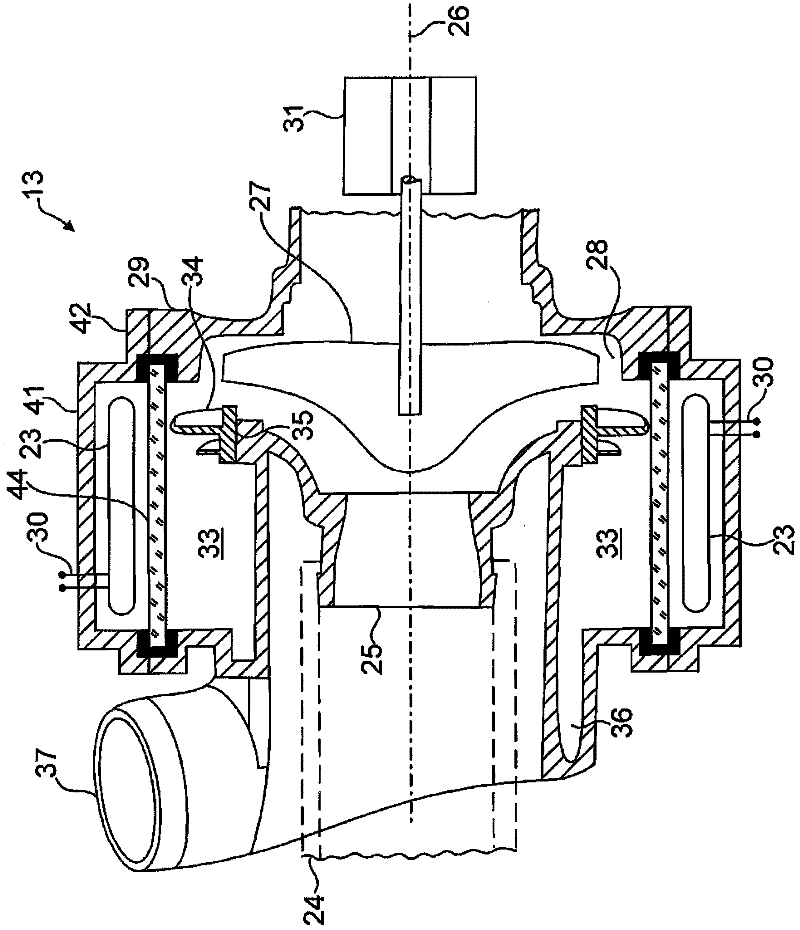

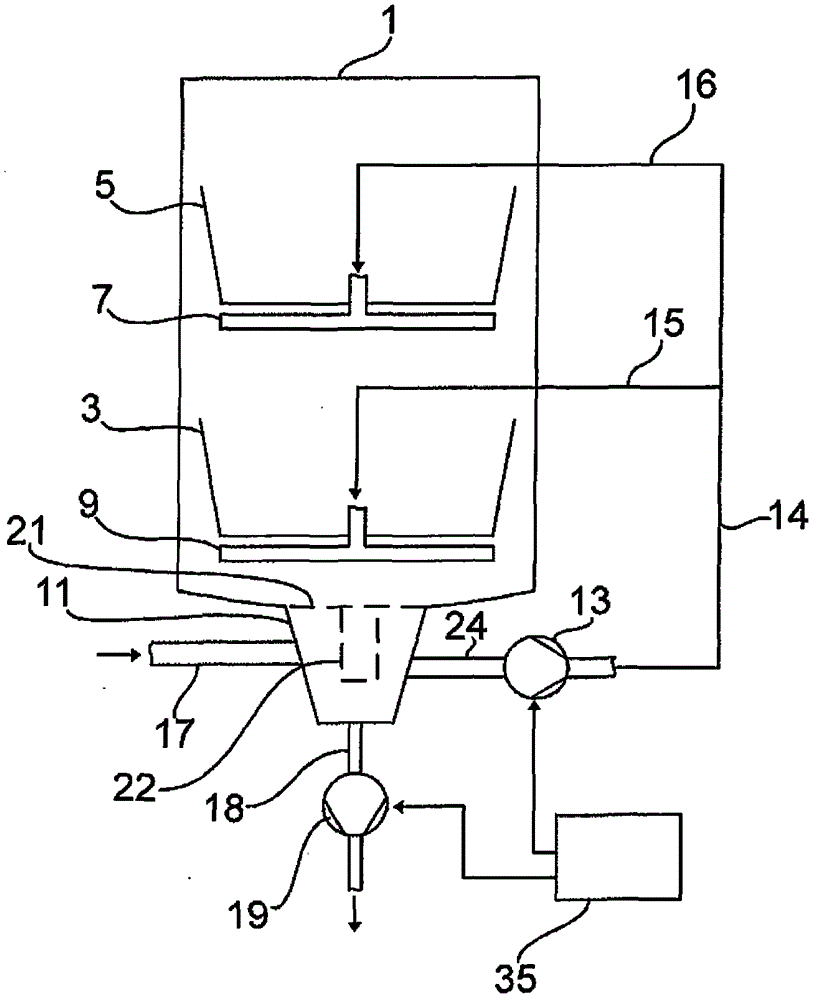

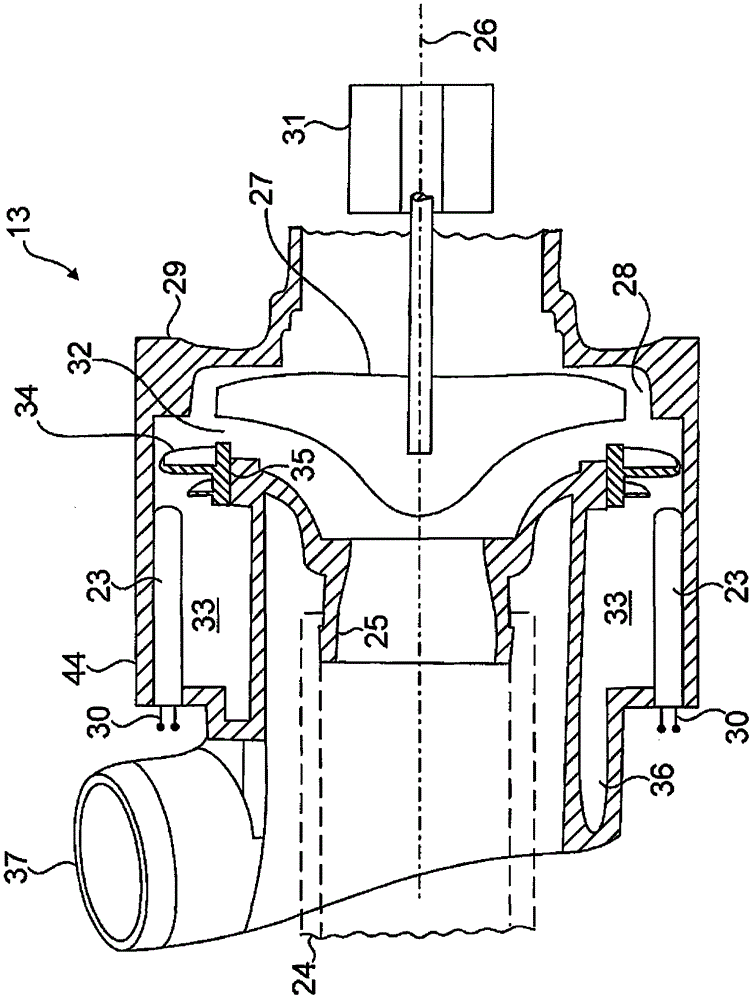

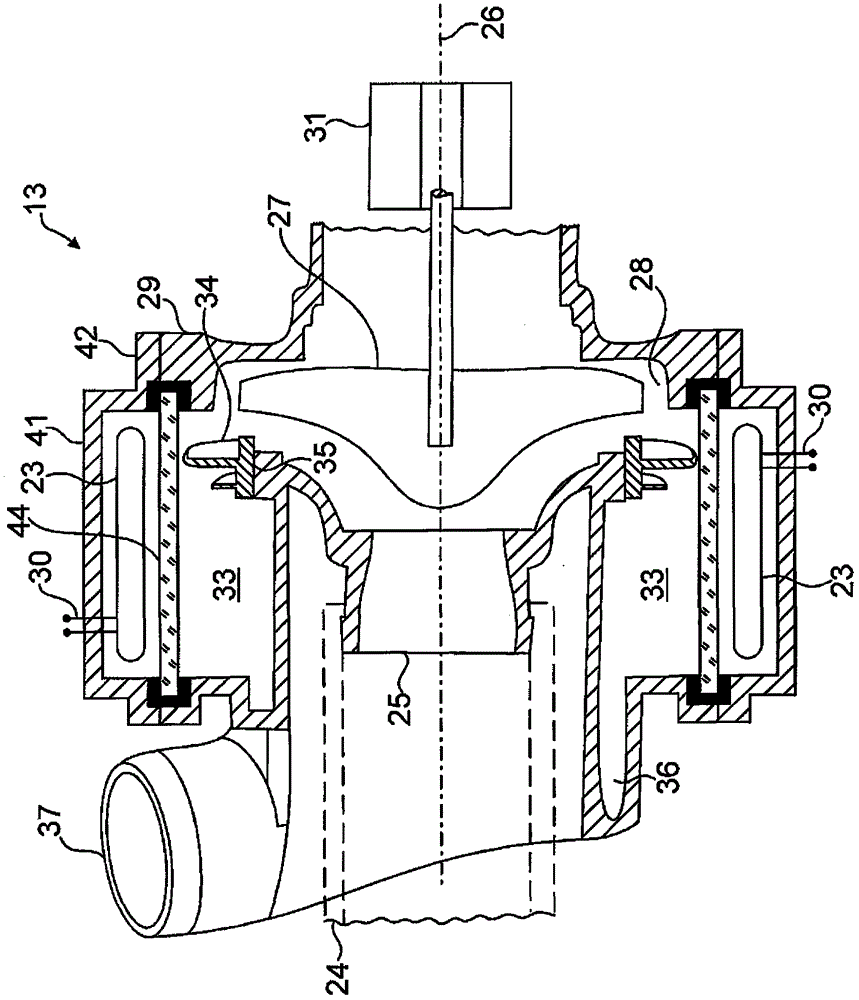

Water-conducting domestic appliance, particularly dishwashing machine

ActiveCN102342820AEffective disinfectionExtended stayTableware washing/rinsing machine detailsOther washing machinesHydraulic circuitEngineering

The invention relates to a water-conducting domestic appliance, particularly a dishwashing machine, which comprises a hydraulic circuit in which the circulation of a rinsing liquid is realized through a liquid pump (13). According to the invention, at least one UV-radiating element (23) is arranged inside the liquid pump (13) for the UV irradiation of the rinsing liquid inside the liquid pump (13).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Sludge anoxic and intensified fermentative hydrolysis of multi-format a 2 oSystem and its application

ActiveCN104671602BCarbon savingImprove the effect of phosphorus releaseMultistage water/sewage treatmentEndogenous respirationSludge

The invention provides a multi-cell A<2>O system of sludge anoxic and strengthened fermentation hydrolysis. The system comprises a sludge anoxic cell, a strengthened fermentation hydrolysis cell, an anoxic cell, an aerobic cell and a secondary sedimentation tank, wherein a water inlet pipe is connected with the sludge anoxic cell; the aerobic cell is connected with the anoxic cell through an internal reflux pipeline; and 2 or 3 strengthened fermentation hydrolysis cells, 2 or 3 anoxic cells and 2-4 aerobic cells are provided. By adopting the system provided by the invention, the sludge of the sludge anoxic cell is denitrified through endogenous respiration, and the internal carbon source in sludge is fully used so that more carbon sources are applied to a nitrogen and phosphorus removal biological reaction of the mainstream AAO technology; the nitrate content of the sludge anoxic cell can be reduced to 0, the redox potential in the strengthened fermentation hydrolysis cell is very low, and the effect of anaerobic phosphorus release is improved; and meanwhile, hydrolysis fermentation is performed through a high-concentration sludge layer in the strengthened fermentation hydrolysis cell, macromolecular or refractory organic substances in the inflow water are converted into low-molecular-weight fatty acid, and a high-quality carbon source is provided for the anaerobic phosphorus release and anoxic denitrification reactions.

Owner:THUNIP CORP LTD

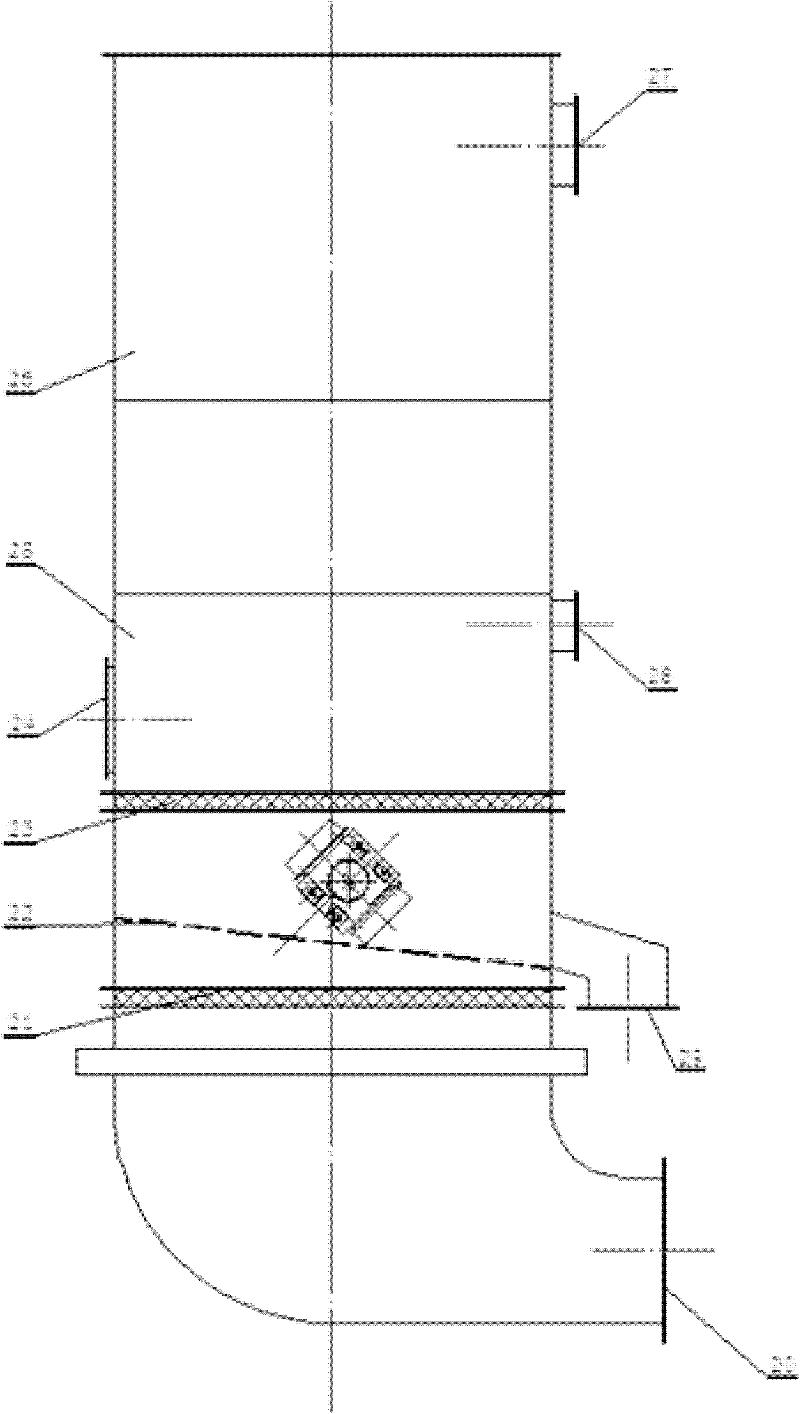

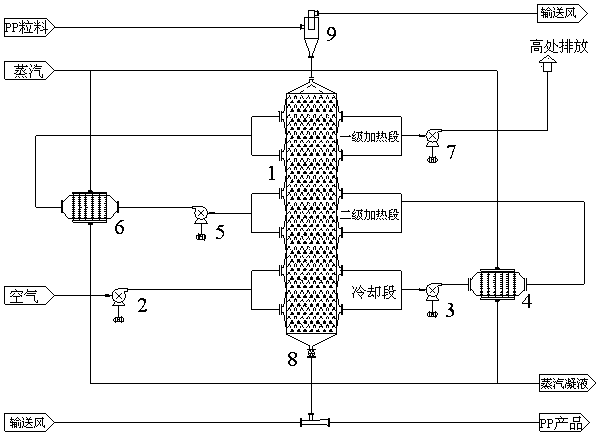

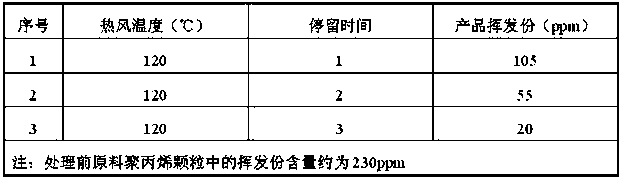

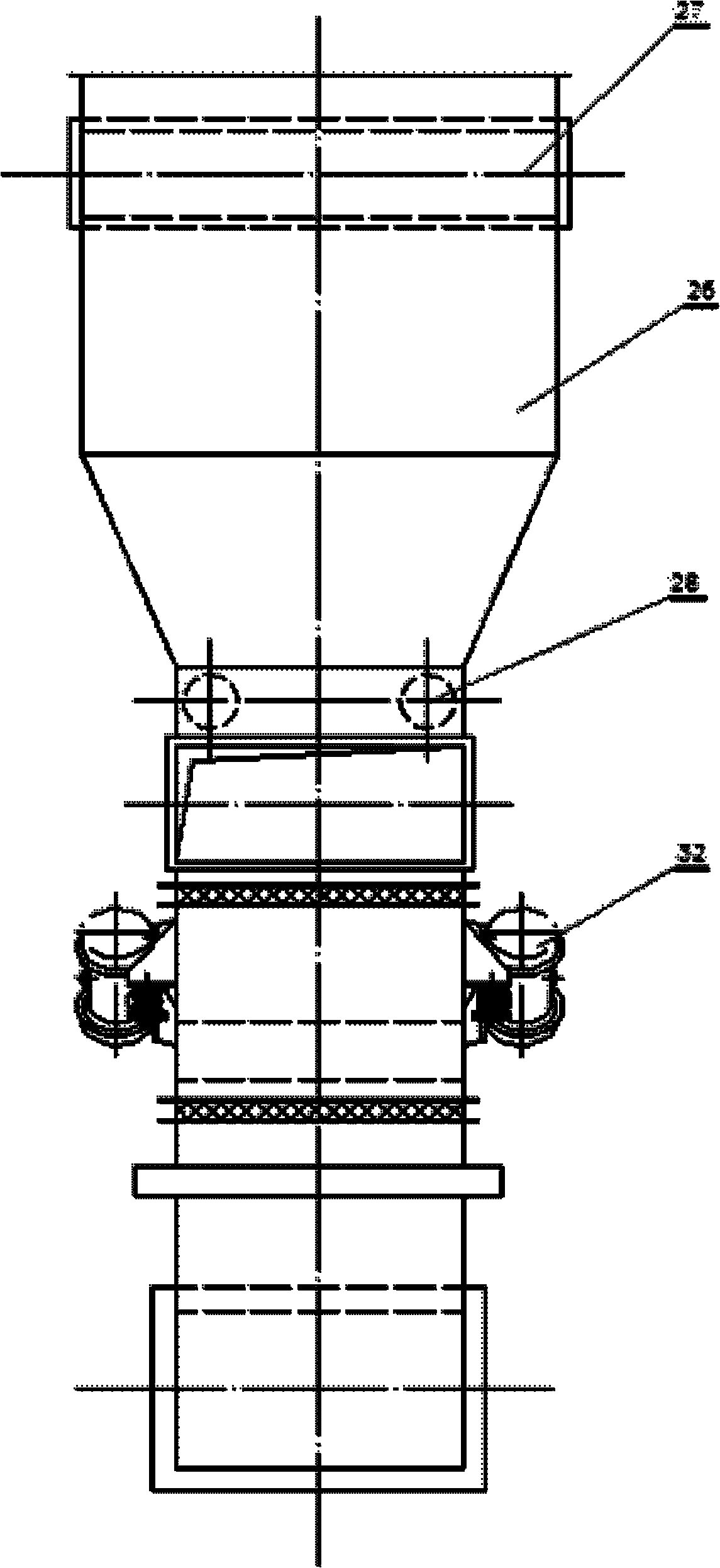

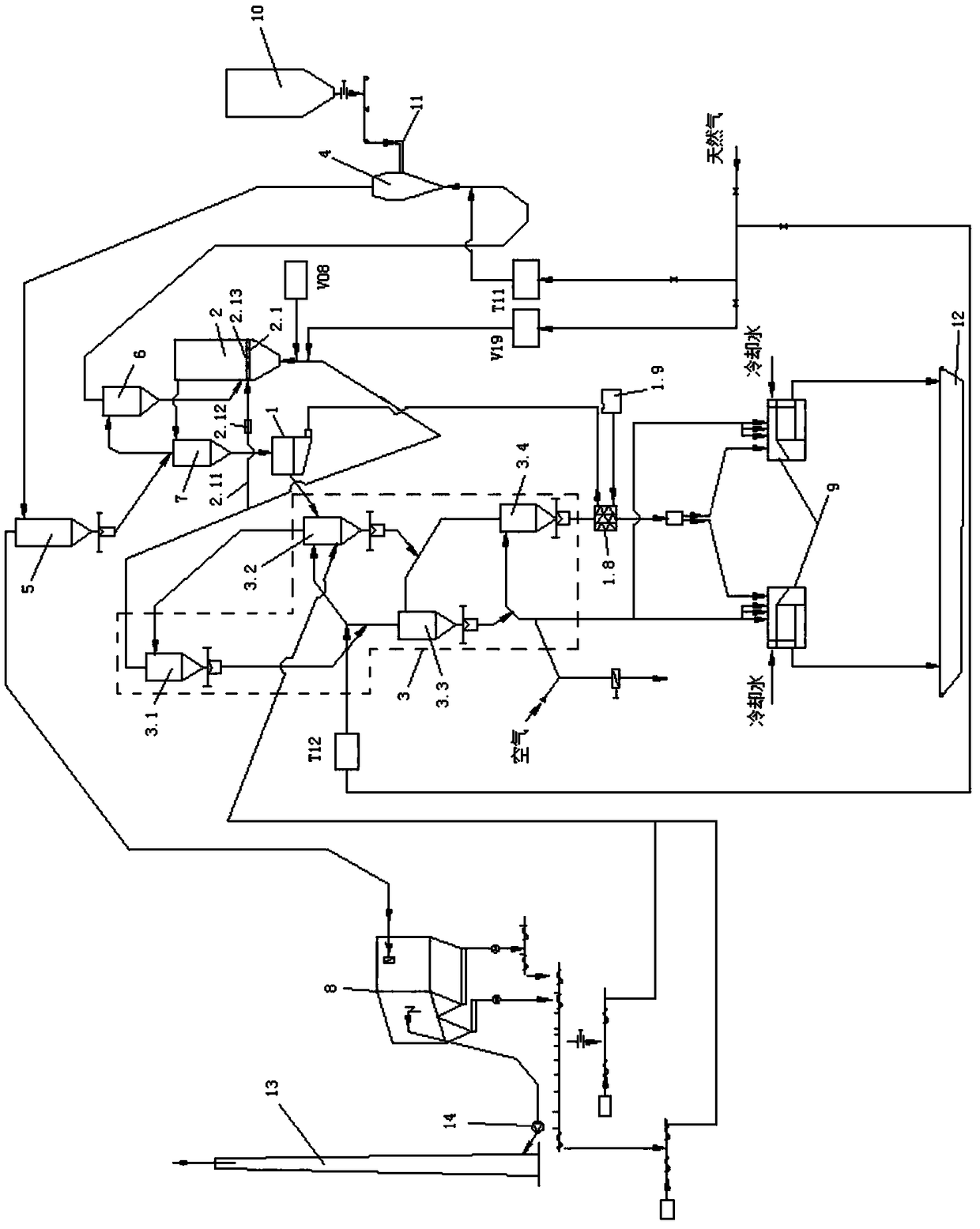

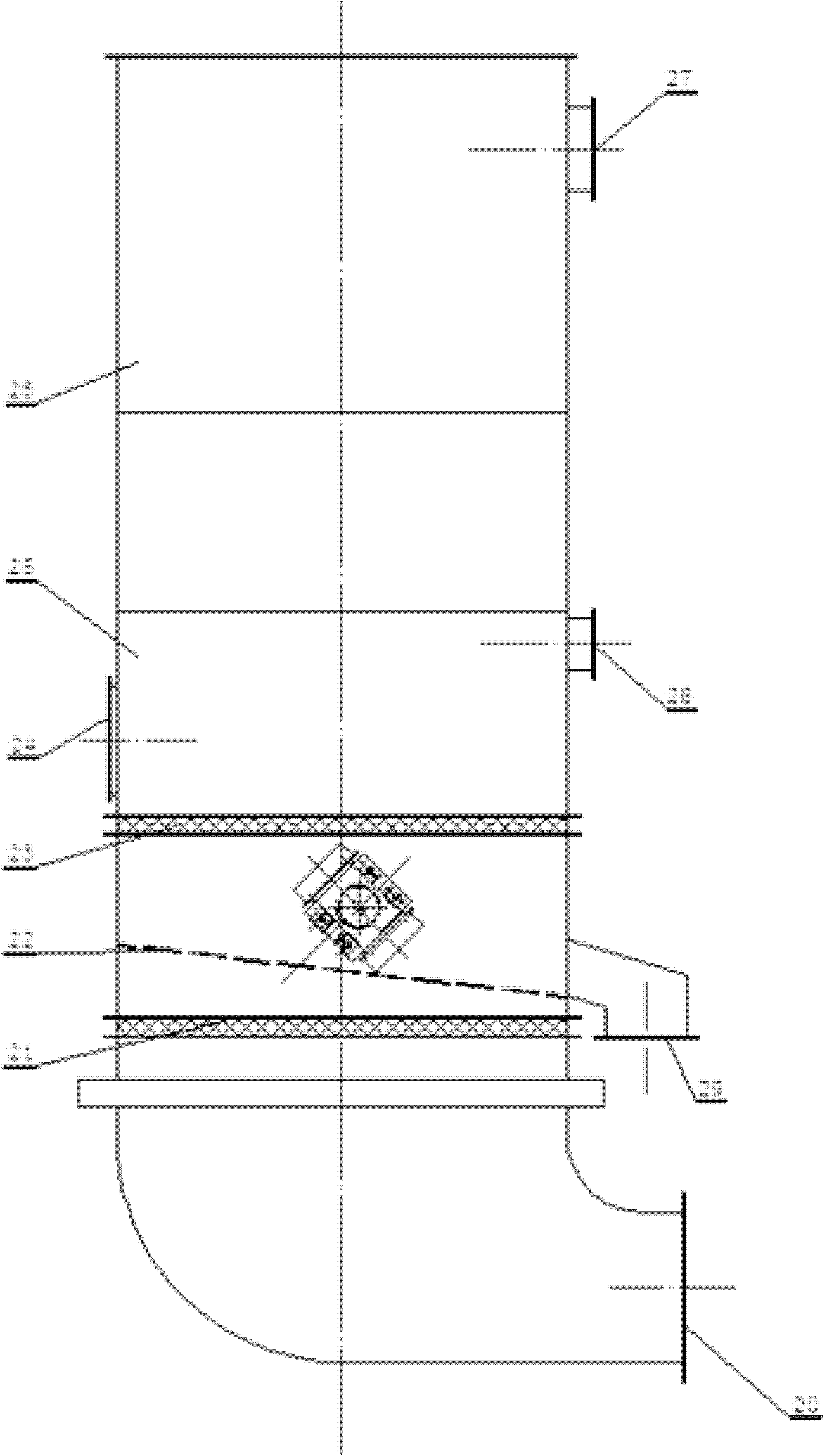

A system for removing VOC from polypropylene pellets and its application method

The invention relates to a VOC removal system for a polypropylene granular material, wherein the system comprises a roof type devolatilization tower with a weighing control system, a cyclone dust collector, a first-class heater and a second-class heater. A material inlet is arranged at the top of the roof type devolatilization tower, and a rotary discharging valve with a variable speed device is arranged at the bottom of the roof type devolatilization tower; the material inlet is connected with the cyclone dust collector; one side of the roof type devolatilization tower is successively provided with a first-class air inlet, a second-class air outlet and a cooling air inlet successively from top to bottom, and the other side is successively provided with a first-class air outlet, a second-class air inlet and a cooling air outlet successively from top to bottom; the first-class air inlets are connected with the second-class air outlets; the secondary air inlets are connected with the cooling air outlets; the material inlet in the roof type devolatilization tower is provided with a feeding uniform distributor; roof type drying pipes are distributed uniformly below the feeding uniformdistributor; the weighing control system is connected with the feeding uniform distributor and the variable speed device. The invention also discloses an application method of the system. The VOC removal system has the advantages of simple structure, less investment, high stability and good devolatilization effect.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Full-boiling vibration propelled coal humidifying and grading process

ActiveCN102311746AImprove energy savingAchieve particle size classificationDrying solid materials with heatCoke ovensFlue gasFixed bed

The invention relates to a full-boiling vibration propelled coal humidifying and grading process. In the process, flue gas of a coke oven is taken as a heat source, a coal humidifying and grading machine is taken as coal fluidizing and humidifying equipment, and integration of coal humidifying and coal grading is realized according to principle of a vibrated fluidized bed under the action of secondary air, wherein the coal humidifying and grading machine comprises a primary air inlet section, a secondary air inlet section and a vibration distribution plate; the primary air inlet section is arranged at the lower part of the vibration distribution plate, and region at the upper part of the vibration distribution plate is a deposition separation region; and the vibration distribution plate is a vibrated fluidized bed structure which is arranged in an inclined manner, the secondary air inlet section is arranged at the upper part of the vibration distribution plate, and an airflow outlet is arranged at the top part of a grading machine. In the process, waste flue gas of the coke oven is taken as a heat medium, and the characteristics that raw material coal has high heat and mass transfer efficiency under the condition of a full-boiling fluidized bed and has low heat and mass transfer efficiency under the condition of a fixed bed and a semi-boiling fluidized bed are utilized, thus uniform and high-efficiency humidifying of coal can be realized and high-efficiency grading of the coal can also be realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

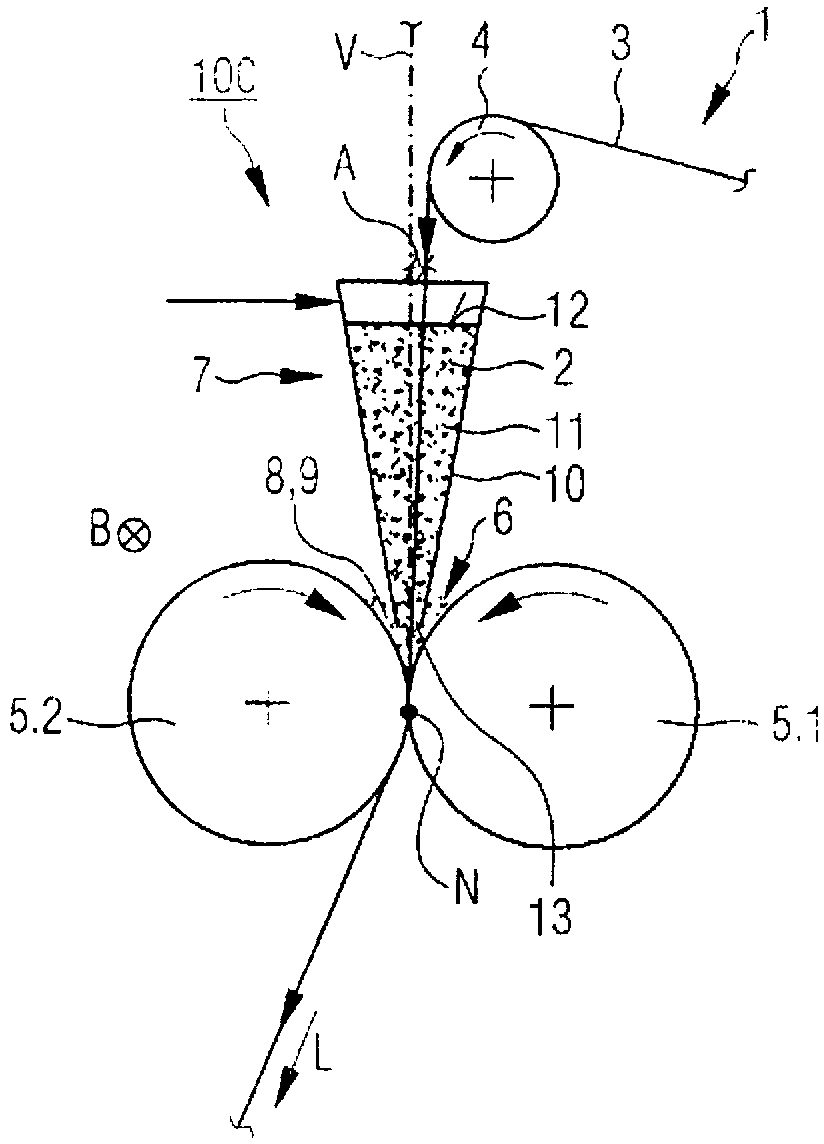

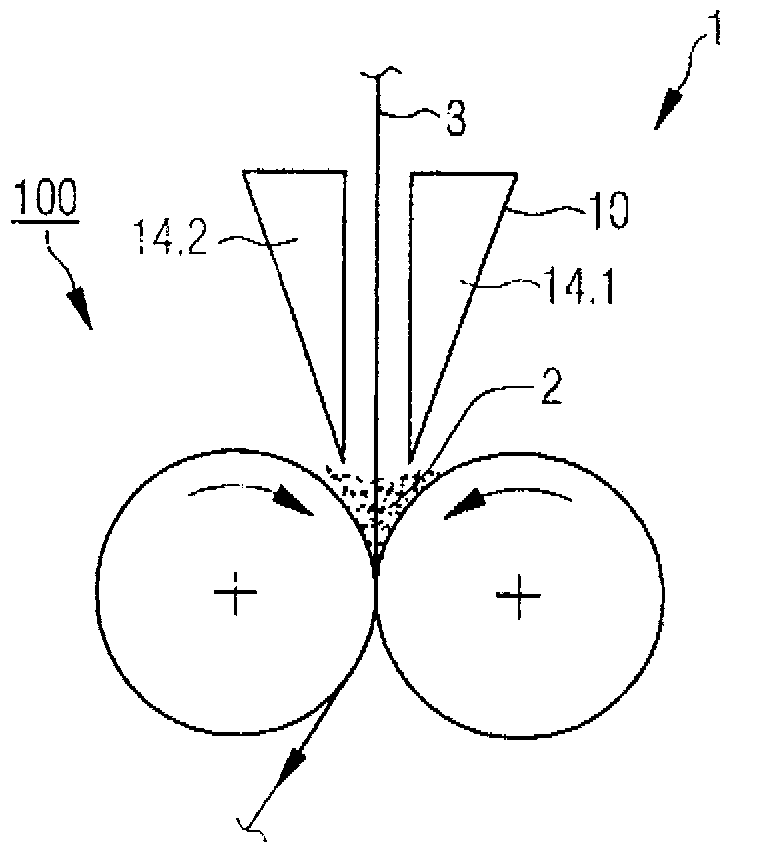

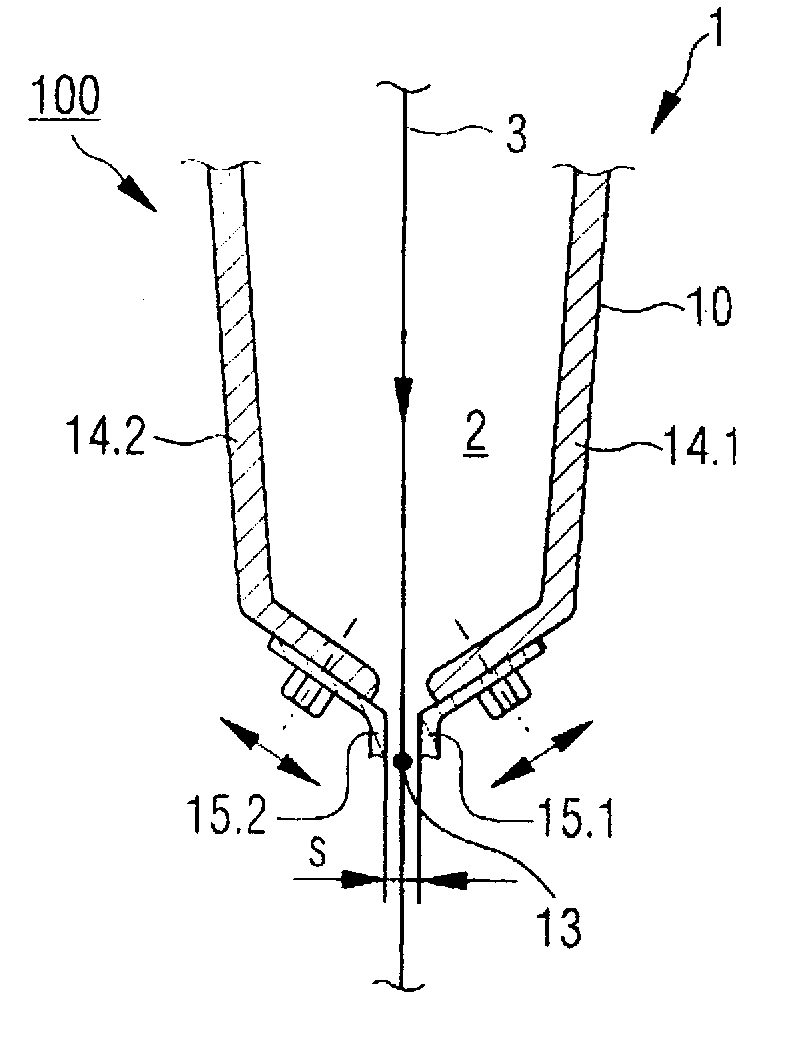

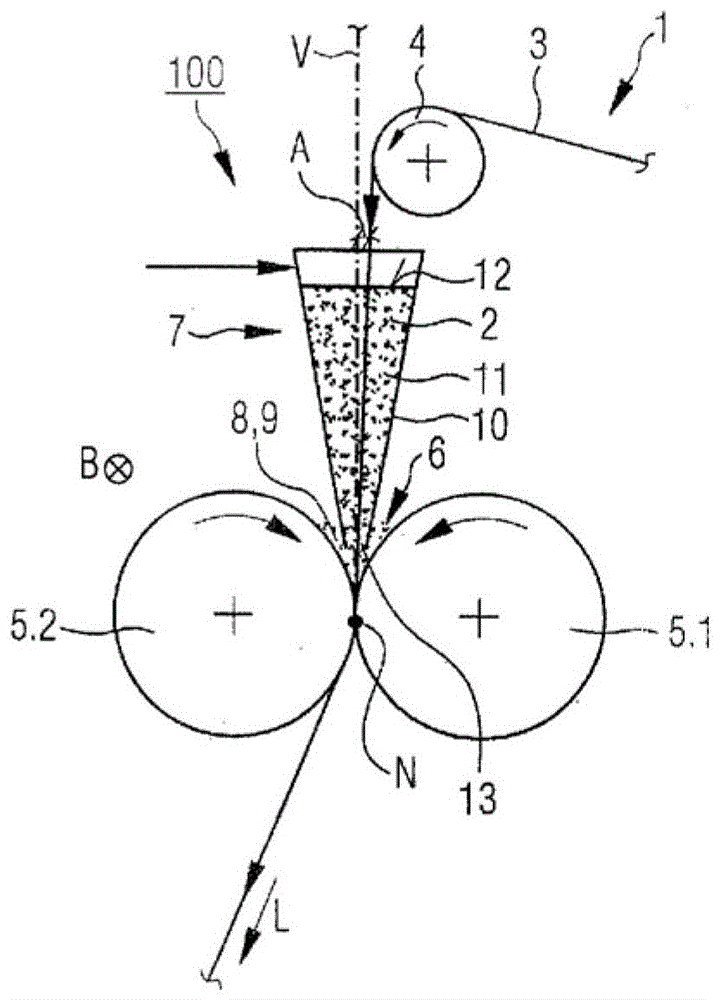

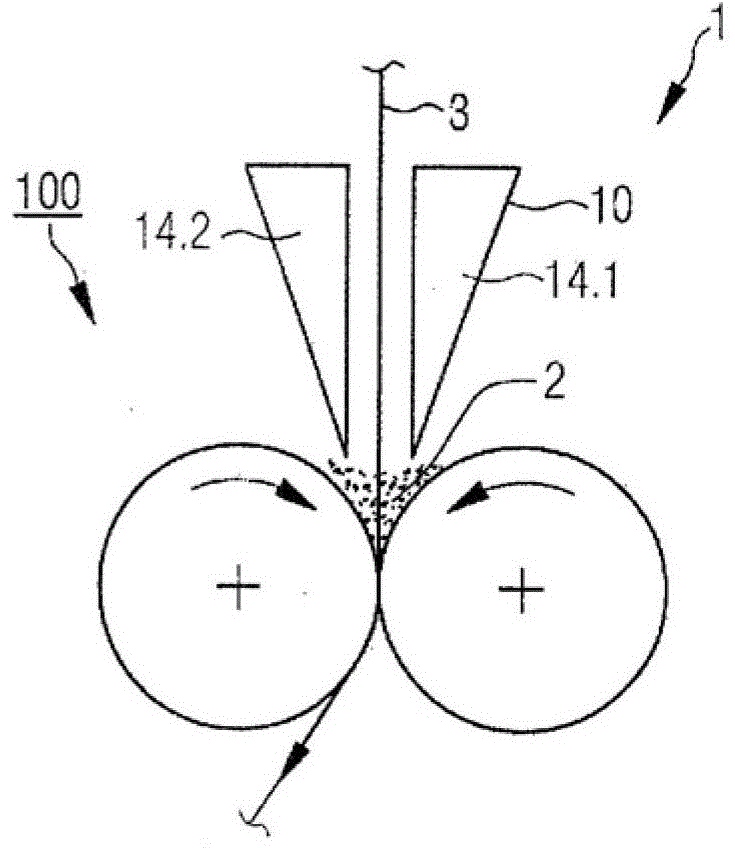

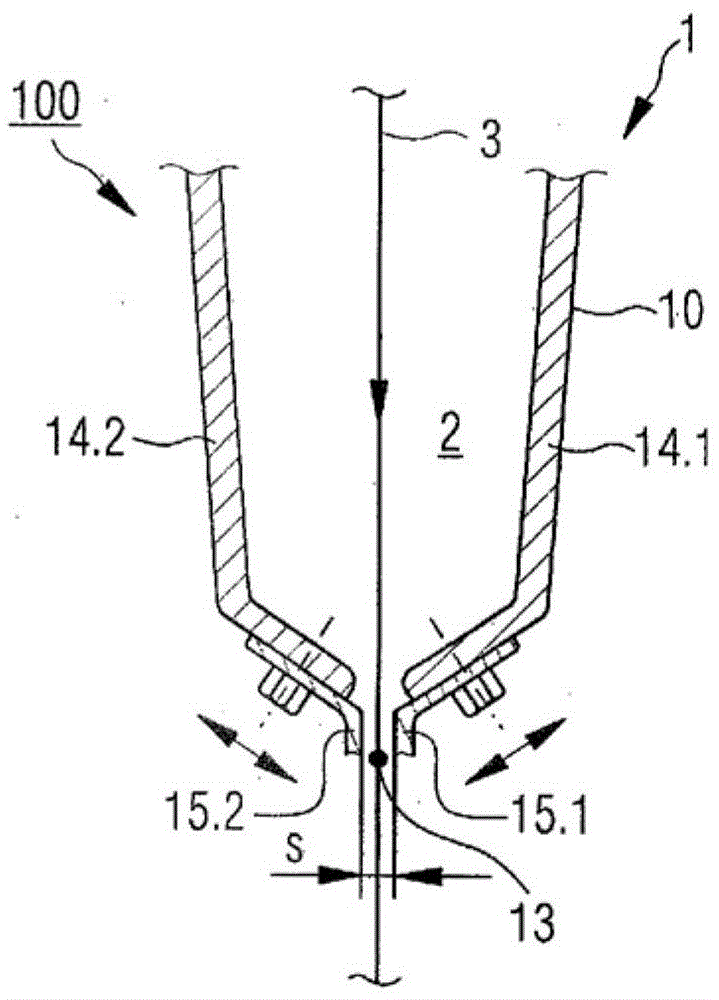

Device and method for applying a medium to a moving fibrous web on both sides

ActiveCN102905797AGuaranteed geometryReduce wearLiquid surface applicatorsPaper/cardboardCardboardFiber

The invention relates to device (1) for applying a liquid or pasty medium (2) to a moving fibrous web (3), in particular a paper, bank note paper, cardboard, or packaging paper web, on both sides, comprising a first application roller (5.1) and a second application roller (5.2), which extend at least over the width of the moving fibrous web (3) and which form a roller gap (N) having a roller inlet area (6), through which roller gap the moving fibrous web (3) can be fed, and comprising a feed device (7) for feeding the liquid or pasty medium (2) into the roller inlet area (6) of the two application rollers (5.1, 5.2), wherein during the operation of the device (1), a liquid sump (8) is formed in the roller inlet area (6) of the two application rollers (5.1, 5.2), through which liquid sump the moving fibrous web runs, and by means of which feed device the level (9) of the liquid sump (8); can be adjusted. The device (1) according to the invention is characterized in that at least one immersion bath device (10) that also accommodates the liquid or pasty medium (2) is arranged upstream from the liquid sump (8) and the roller gap (N) as viewed in the web movement direction (L) of the moving fibrous web (3).

Owner:VOITH PATENT GMBH

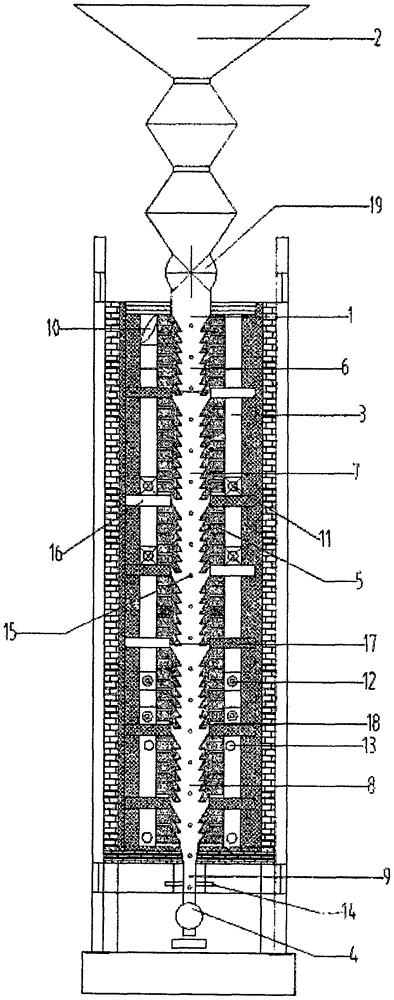

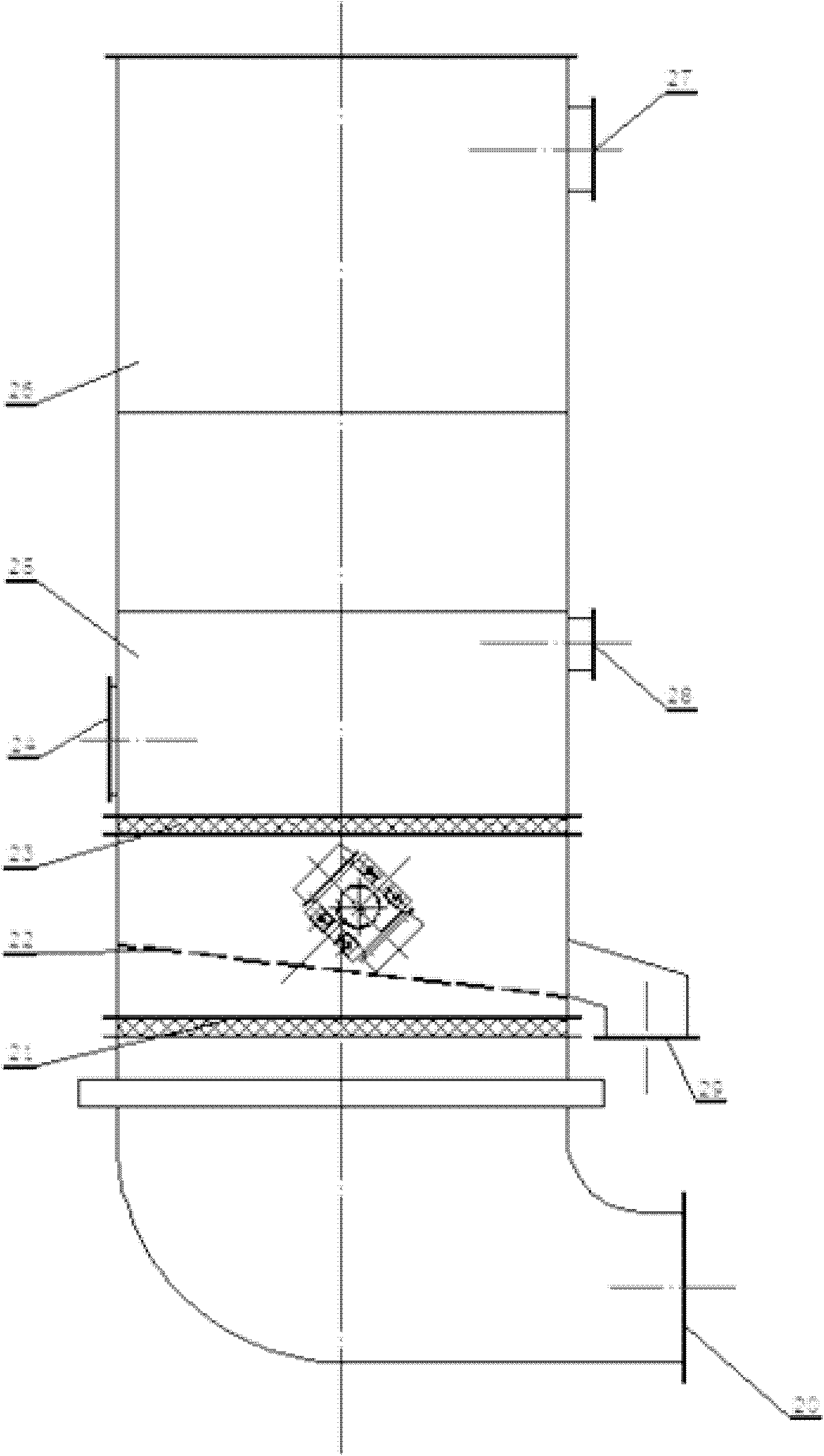

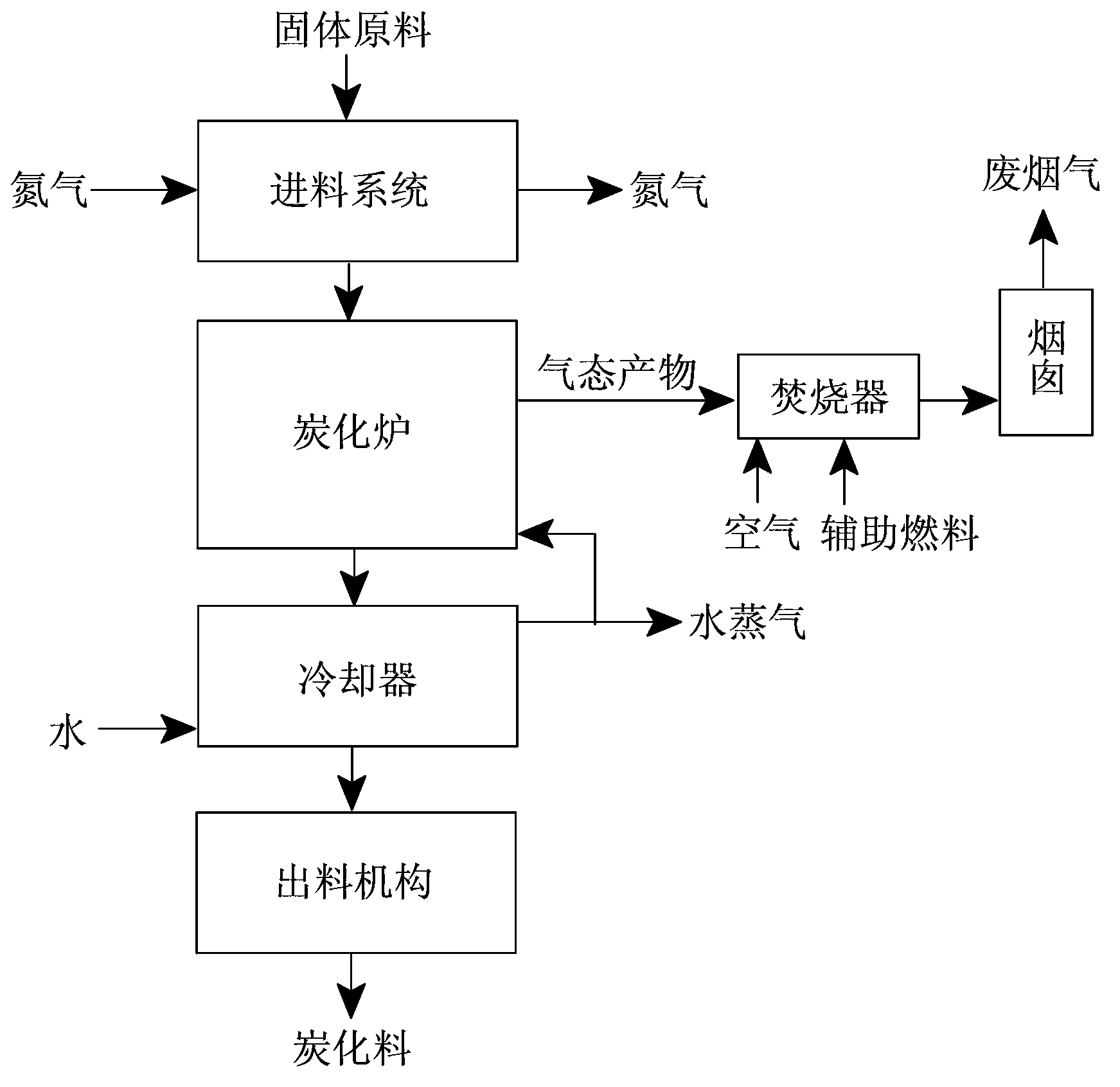

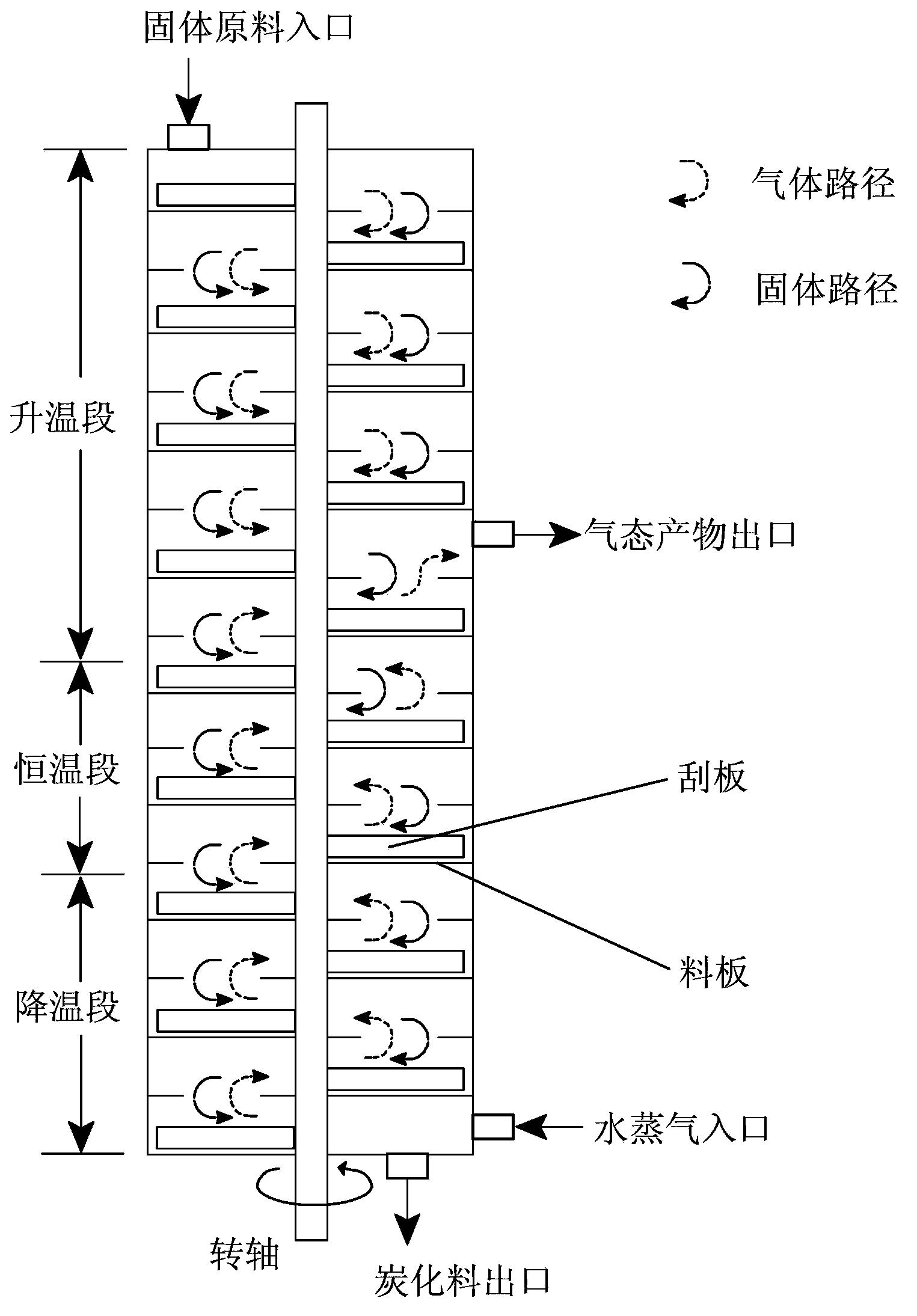

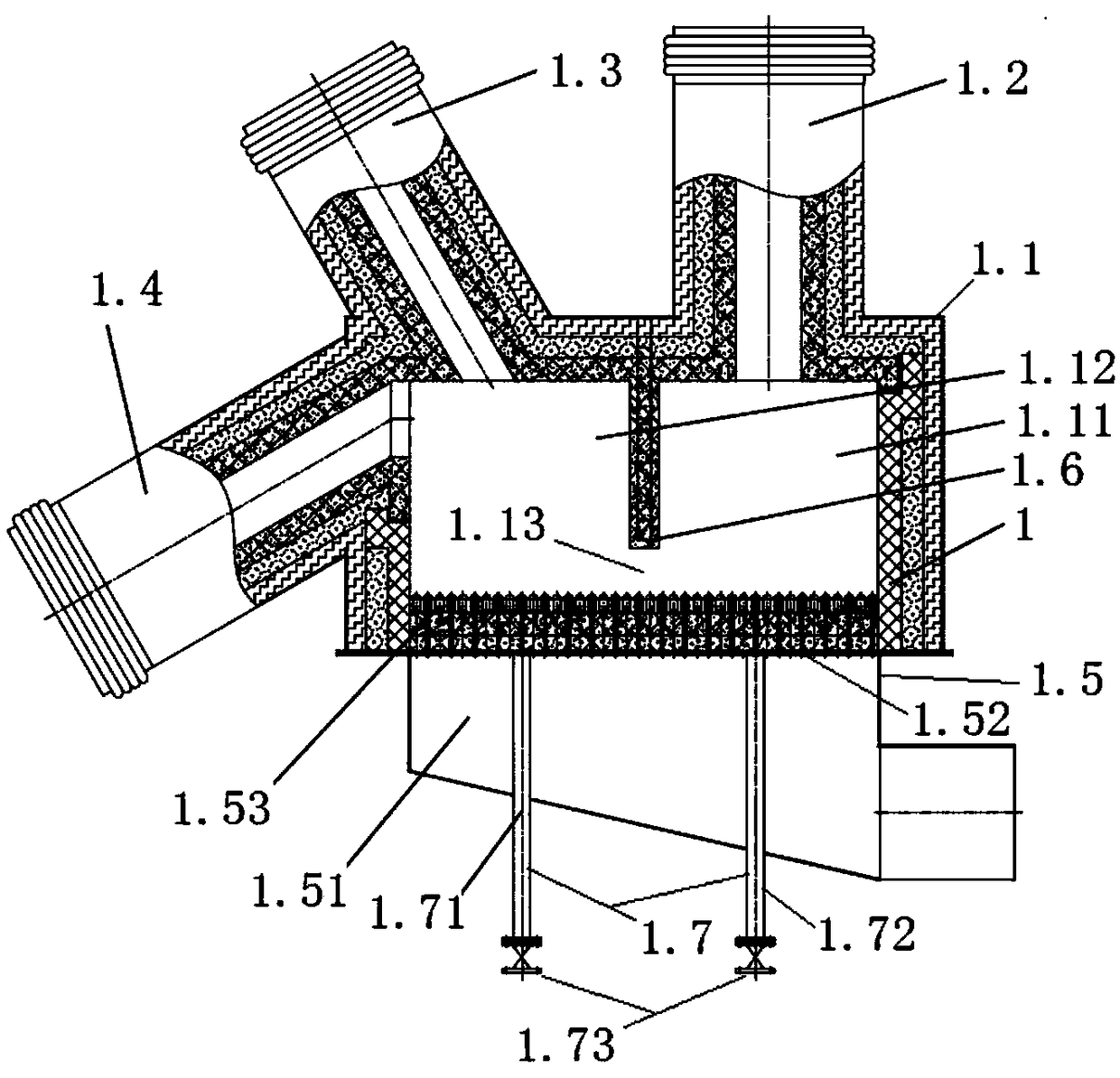

Continuously carbonizing device and method for preparing intermediate product carbonized material of carbon molecular sieve

ActiveCN103072967BAdjustable dwell timeStable temperatureCarbon preparation/purificationFurnace temperatureMolecular sieve

The invention discloses a continuously carbonizing device and method for preparing intermediate product carbonized material of a carbon molecular sieve. Particle objects are carbonized continuously inside a vertical carbonizing furnace provided with multi-section heating furnace temperature control; the furnace temperature distribution of the carbonizing furnace is constant, the processed solid material is carbonized inside the carbonizing furnace after being sequentially subjected to heating, temperature-keeping and cooling; water vapor inside the carbonizing furnace serves as cooling medium, activating agent and protective atmosphere; compositions of the gaseous product generated by the carbonized solid material are stable, the gaseous product has excellent flammability, and is discharged outside after complete combustion; the activated reaction of the processed material is controllable in space and time, and the obtained carbonized material production has stable performance; and the unit equipment has big processing capacity, and the equipment investment and running cost are low. The continuously carbonizing method provided by the invention has the characteristics of high efficiency, low consumption and environmental protection.

Owner:DALIAN UNIV OF TECH

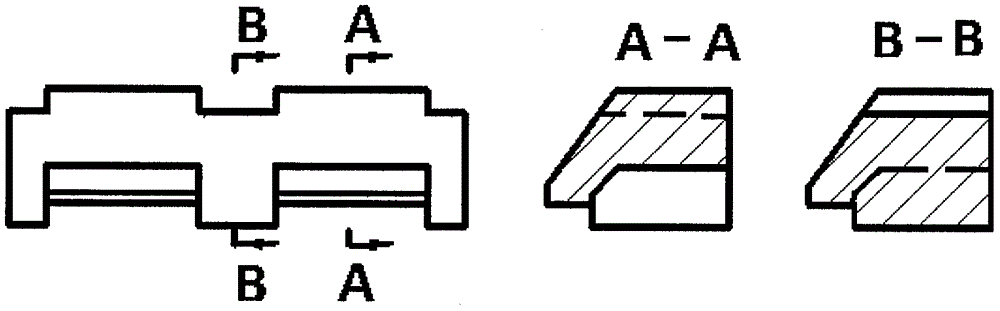

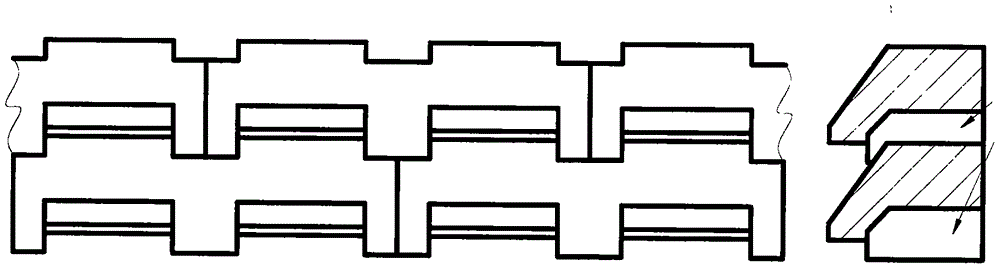

Three-dimensional dynamic column plate

PendingCN113289569AEasy to separateAdjustable dwell timeChemical/physical/physico-chemical processesFractional distillationMass transferStructural engineering

The invention discloses a three-dimensional dynamic column plate which comprises a column plate and a three-dimensional dynamic mass transfer unit mounted on the column plate, wherein each three-dimensional dynamic mass transfer unit comprises a fixed end plate, a movable end plate, an injection plate and a separation plate; the bottom of the fixed end plate is mounted on the column plate, an injection channel is defined by the edge of the fixed end plate, the edge of the movable end plate, the side edge of the injection plate and the upper end of the separation plate, the injection plate is arranged on the side edge of the fixed end plate, and a movable groove is formed in the fixed end plate; a fixed part matched with the movable groove is formed at the lower part of the movable end plate and is used for moving up and down in the movable groove, the top of the movable end plate is connected with the separation plate, a gap is reserved between the separation plate and the upper part of the injection plate, and a lower gap is reserved between the lower part of the injection plate and the column plate. Compared with a traditional column plate, the operation flexibility of the column plate is improved to 30-200%; wherein the movable end plate moves up and down relative to the fixed end plate, so that the distance between the separation plate and the spraying plate is adjusted, the gas-liquid separation effect is improved, and the suitable operation range is wider.

Owner:TIANJIN PULAITE SCI & TECH DEV +1

Process for calcining ammonium metavanadate for preparing powdered vanadium pentoxide

InactiveCN102021315BAdjustable dwell timeSolve the problem of easy cakingAmmonium metavanadateAmmonia

The invention relates to a process for calcining ammonium metavanadate for preparing powdered vanadium pentoxide. The process comprises the following steps of: (1) feeding ammonium metavanadate containing water of less than or equal to 1 percent by weight into an electric heating rotary furnace provided with an anti-agglomeration facility by using a feeder; (2) heating to rise the temperature to 510-560 DEG C, holding the temperature for 60-180 minutes, then cooling to 300-350 DEG C and discharging; (3) sending the material which has a temperature of 300-350 DEG C and is obtained in the step (2) into a cooling drum, and continuing to cool to 40-50 DEG C to obtain finished powder vanadium pentoxide; and (4) collecting a small quantity of vanadium pentoxide contained in tail gas of the rotary furnace by using a cyclone dust collector, carrying out primary water washing and secondary water washing on the tail gas to ensure that the ammonia content in the tail gas is reduced to reach an exhaust standard and then exhausting. The invention has the advantages of simple and reliable process, safe deamination, energy saving and environmental protection and is convenient to operate.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

A device and method for removing organic impurities in by-product sodium chloride salt

ActiveCN109956485BImprove thermal efficiencyUniform and controllable operating temperatureAlkali metal halide purificationChloride saltFluid phase

The invention belongs to the technical field of chemical technology and equipment, and relates to a device and method for purifying and recovering sodium chloride salt, a by-product of the chlorination process, including a high-temperature oxidation reactor, a dissolution kettle A, a dissolution kettle B, a liquid-phase deep oxidation tower, a liquid-solid Filter, solid slag tank, nanofiltration membrane separator. Firstly, the high-temperature oxidation of most of the organic impurities in the complex by-product sodium chloride salt is carried out through a multi-layer fluidized bed high-temperature oxidation reactor, and then the remaining trace organic impurities are deeply oxidized in the liquid phase deep oxidation tower, and then passed through The nanofiltration membrane separator further removes the macromolecular organic impurities in order to meet the requirements of the ion membrane caustic soda industrial unit for the organic impurities in the raw material of sodium chloride. The device and the method provided by the invention have the characteristics of high operating flexibility, high efficiency of treating organic impurities, and the like.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

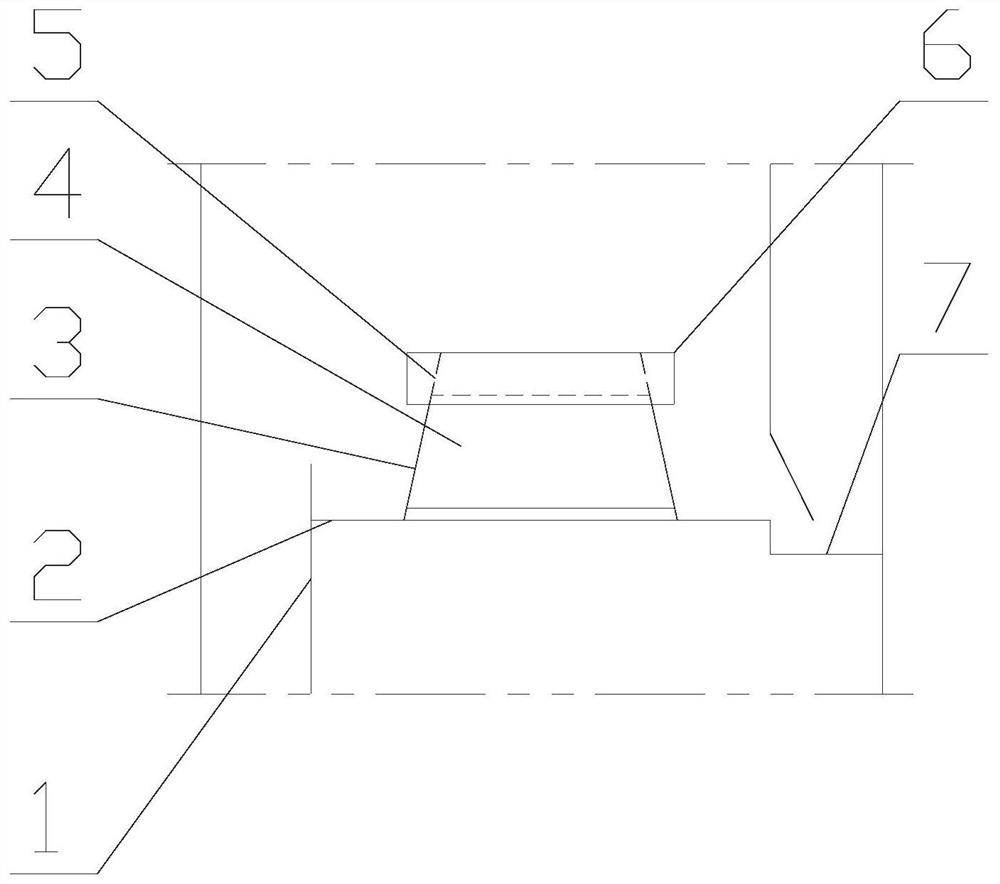

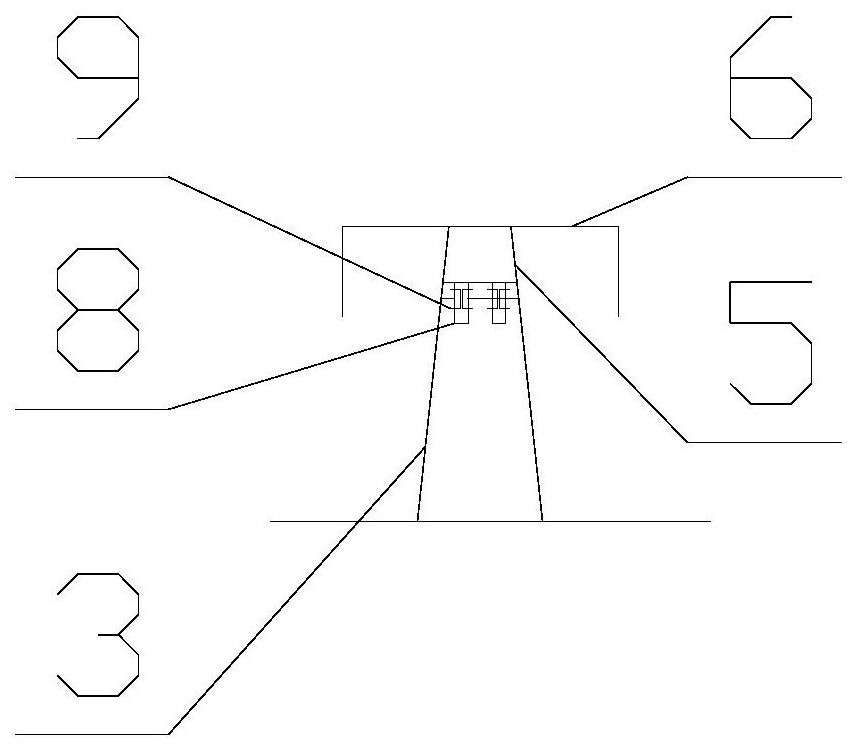

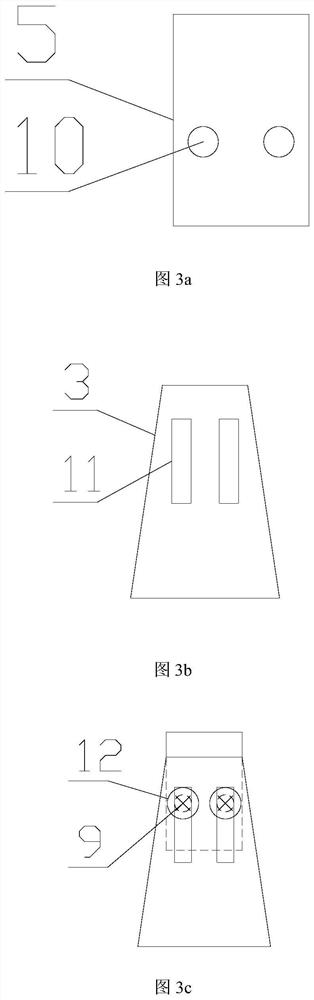

Crystal form transformation energy-saving device, alumina roasting system and production method thereof

PendingCN108726549ASimple structureEasy to makeAluminium compoundsChemical industryNitrogen oxidesRetention time

The invention provides a crystal form transformation energy-saving device, which comprises a main box body, a blanking pipe, a pressure equalizing pipe, a return pipe and a wind distribution mechanism. The crystal form transformation energy-saving device has the effects of simple structure and convenient making, is convenient to control an appropriate retention time of materials in the main box body, ensures the completion of material crystal form transformation, and enables the product to reach the quality requirements of high-quality metallurgical grade alumina. The invention also provides an alumina roasting system, which includes a main roasting furnace, a cyclone separation device and the crystal form transformation energy-saving device. Through combination of the crystal form transformation energy-saving device and an existing alumina roasting system, the alumina roasting system provided by the invention has the characteristics of lowering the temperature of the main roasting furnace, reducing the unit consumption of fuels or increasing the productivity of the roasting furnace, reducing the initial nitrogen oxide concentration of the roasting furnace and the like, and throughthe design of a secondary air supply apparatus, the initial nitrogen oxide emission of the roasting furnace is greatly reduced. The invention also discloses a production method of alumina, the methodhas the advantages of simplified technological process, high efficiency, energy saving and emission reduction, and is easy for industrial production.

Owner:HUNAN SIWEI ENERGY ENVIRONMENT ENG

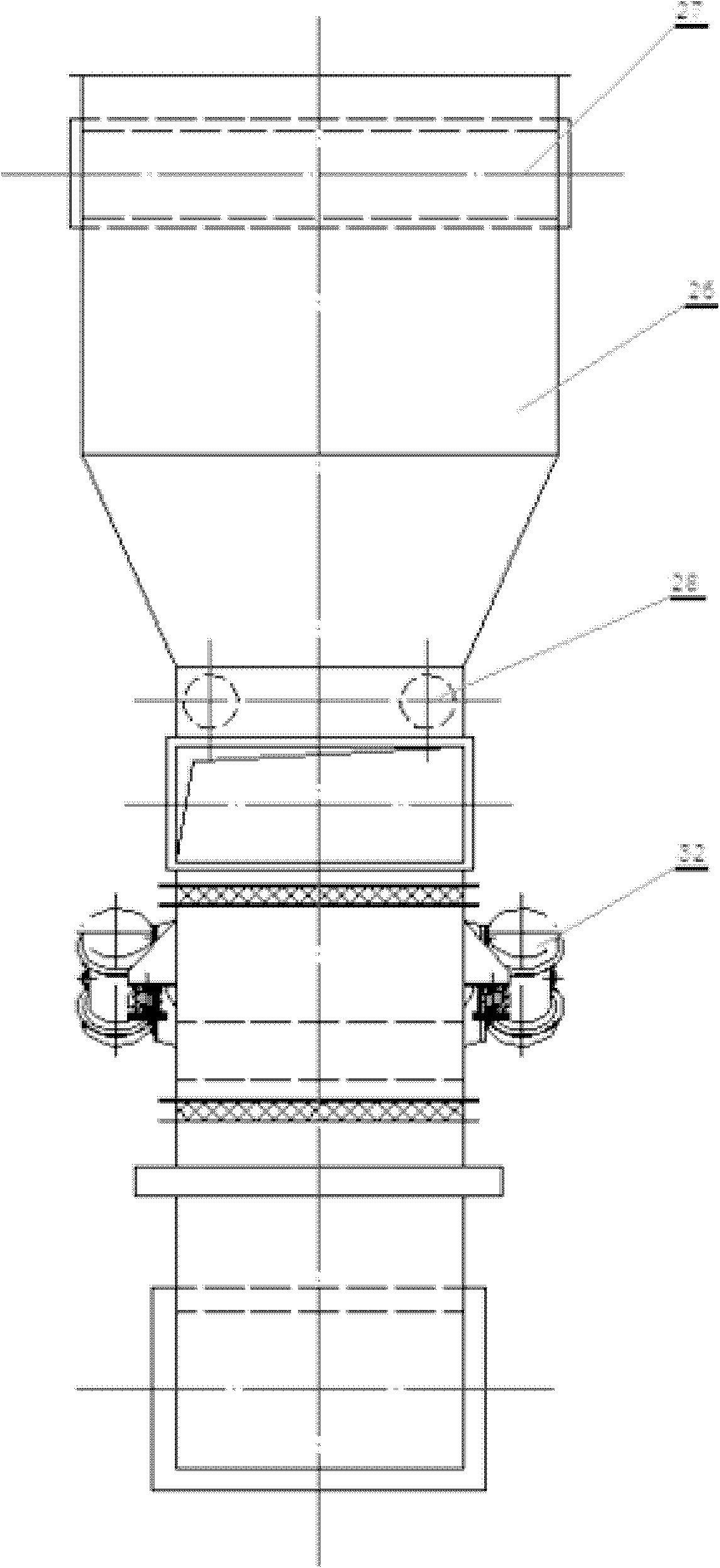

Device for Continuously Separating Hexachloroethane from Perchlorethylene Solid Waste

ActiveCN108911945BAdjustable propulsion speedAdjustable dwell timeHalogenated hydrocarbon separation/purificationTetrachloroethyleneHelical blade

A device for continuously separating hexachloroethane from tetrachlorethylene solid waste, including a base, a speed-regulating motor, a driving motor, and a strip groove. The outer wall of the strip groove is covered with a heating jacket, and the opening of the strip groove is Sealed by the sealing cover, a speed regulating shaft is rotatably arranged in the strip groove, and a first helical blade extending in the axial direction is arranged on the speed regulating shaft, and the first helical blade cooperates with the groove wall of the strip groove to seal One end of the cover body is fixed with a feed vertical pipe, and the upper opening of the feed vertical pipe is connected with a tapered feed hopper. A drive shaft is rotatably arranged in the feed vertical pipe, and a first axially extending shaft is provided on the drive shaft. Two helical blades, the second helical blade is matched with the inner wall of the feed vertical pipe, the other end of the sealing cover is provided with an exhaust port for connecting with the material steam trap, and the bottom of the strip groove is provided with a discharge pipe, The discharge pipe is located below the other end of the first helical blade.

Owner:重庆天原化工有限公司

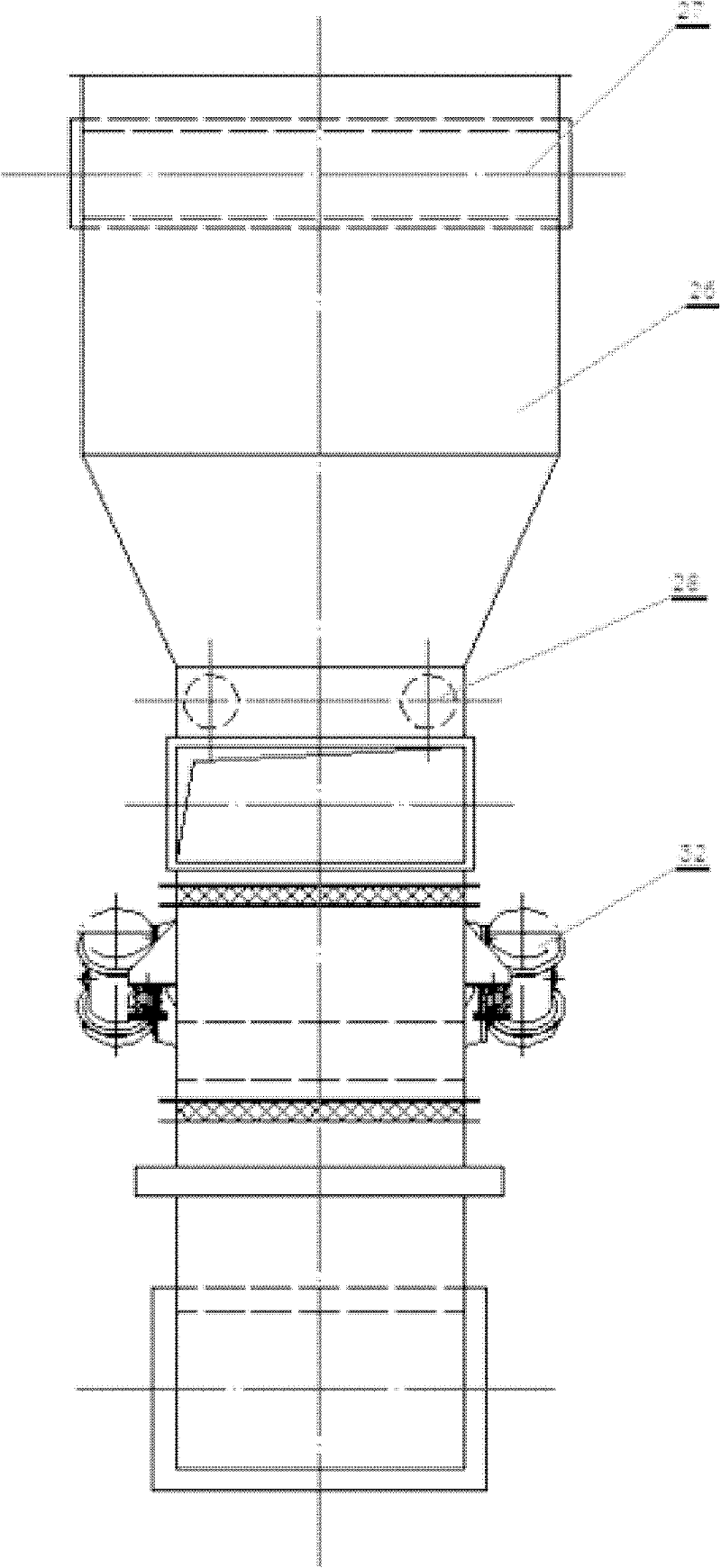

Low-temperature roasting furnace for producing amorphous aluminum oxide from crystalline aluminum chloride

PendingCN114046666ALarge heat capacityGood load regulation performanceAluminium oxide/hydroxide preparationFurnace coolingAluminium chlorideHot air oven

The utility model relates to a low-temperature roasting furnace for producing amorphous aluminum oxide from crystalline aluminum chloride. The low-temperature roasting furnace comprises a hot-blast stove (1), an air chamber (2), an air distribution plate (3), a hearth reaction area (4), a hearth flaring section (5), a cyclone separator (6), a cooling air port (7), a feed port (8), a hearth discharge port (9) and a cyclone separator blanking leg (10). According to the invention, the temperature of the hearth reaction area is controlled at the low-temperature decomposition temperature point of the crystalline aluminum chloride, and the crystalline aluminum chloride can have enough residence time in the hearth reaction area, so that the crystalline aluminum chloride can be converted into amorphous aluminum oxide to the greatest extent.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD

Coating apparatus and method for coating media on both sides of a moving fibrous web

ActiveCN102905797BIncrease the lengthExtension of timeLiquid surface applicatorsPaper/cardboardFiberCardboard

Owner:VOITH PATENT GMBH

A device for removing organic impurities in by-product sodium chloride salt in a chlorination process

ActiveCN109956484BImprove thermal efficiencyHigh thermal efficiency utilizationAlkali metal halide purificationFluid phaseFluidized bed

The invention belongs to the technical field of chemical equipment, and relates to a device for removing organic impurities in sodium chloride salt, a by-product of the chlorination process, which includes a high-temperature oxidation reactor, a dissolution kettle A, a dissolution kettle B, and a liquid-phase deep oxidation tower connected in sequence , liquid-solid filter, solid slag tank, and fine filter. First, the majority of organic impurities in the by-product sodium chloride salt are oxidized at high temperature through a multi-layer fluidized bed high-temperature oxidation reactor, and then in the liquid phase deep oxidation tower Deeply oxidize the remaining trace organic impurities, and then further remove the macromolecular organic impurities through the nanofiltration membrane separator, so as to meet the requirements of the ion membrane caustic soda industrial device for the organic impurities in the raw material of sodium chloride. The invention provides The device has the characteristics of large operating flexibility and high efficiency in the treatment of organic impurities.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Full-boiling vibration propelled coal humidifying and grading process

ActiveCN102311746BImprove energy savingAchieve particle size classificationDrying solid materials with heatCoke ovensFlue gasFixed bed

The invention relates to a full-boiling vibration propelled coal humidifying and grading process. In the process, flue gas of a coke oven is taken as a heat source, a coal humidifying and grading machine is taken as coal fluidizing and humidifying equipment, and integration of coal humidifying and coal grading is realized according to principle of a vibrated fluidized bed under the action of secondary air, wherein the coal humidifying and grading machine comprises a primary air inlet section, a secondary air inlet section and a vibration distribution plate; the primary air inlet section is arranged at the lower part of the vibration distribution plate, and region at the upper part of the vibration distribution plate is a deposition separation region; and the vibration distribution plate is a vibrated fluidized bed structure which is arranged in an inclined manner, the secondary air inlet section is arranged at the upper part of the vibration distribution plate, and an airflow outlet is arranged at the top part of a grading machine. In the process, waste flue gas of the coke oven is taken as a heat medium, and the characteristics that raw material coal has high heat and mass transfer efficiency under the condition of a full-boiling fluidized bed and has low heat and mass transfer efficiency under the condition of a fixed bed and a semi-boiling fluidized bed are utilized, thus uniform and high-efficiency humidifying of coal can be realized and high-efficiency grading of the coal can also be realized.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

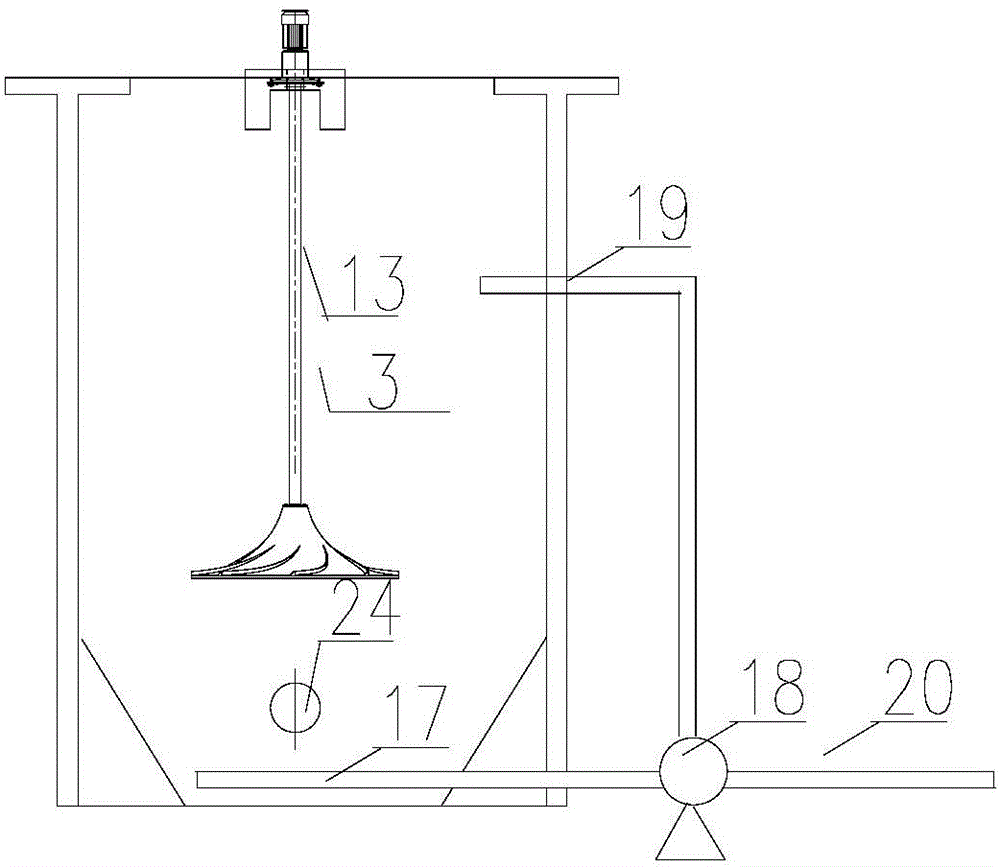

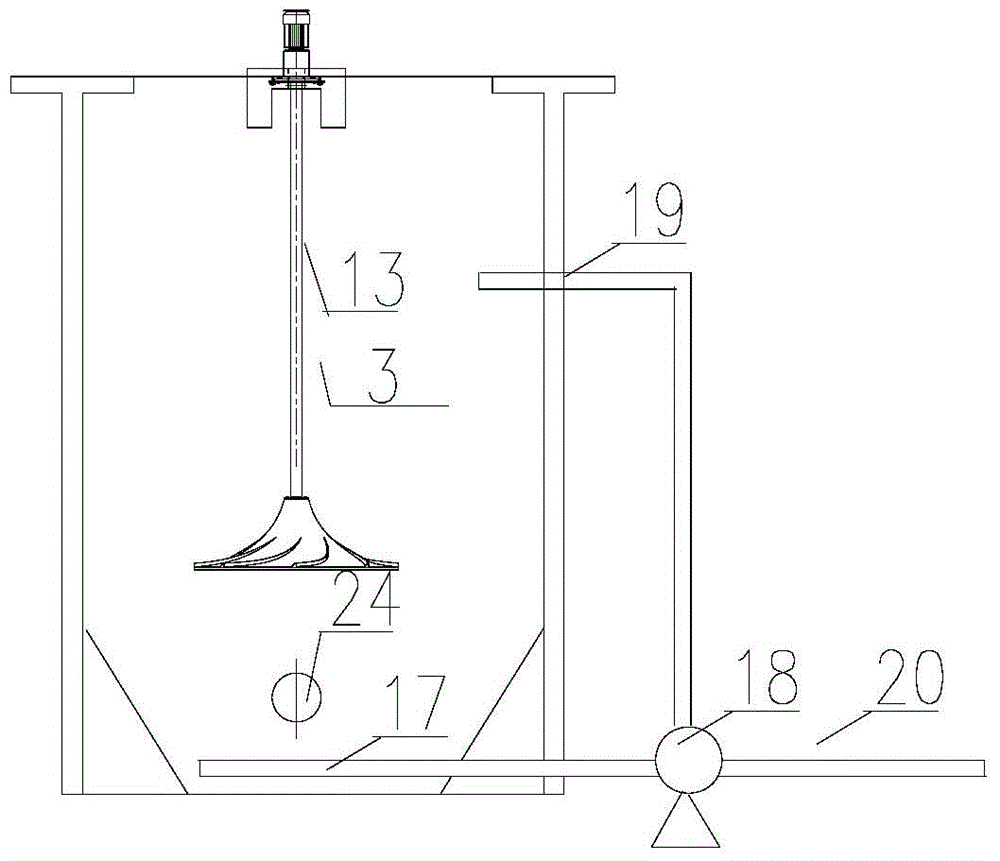

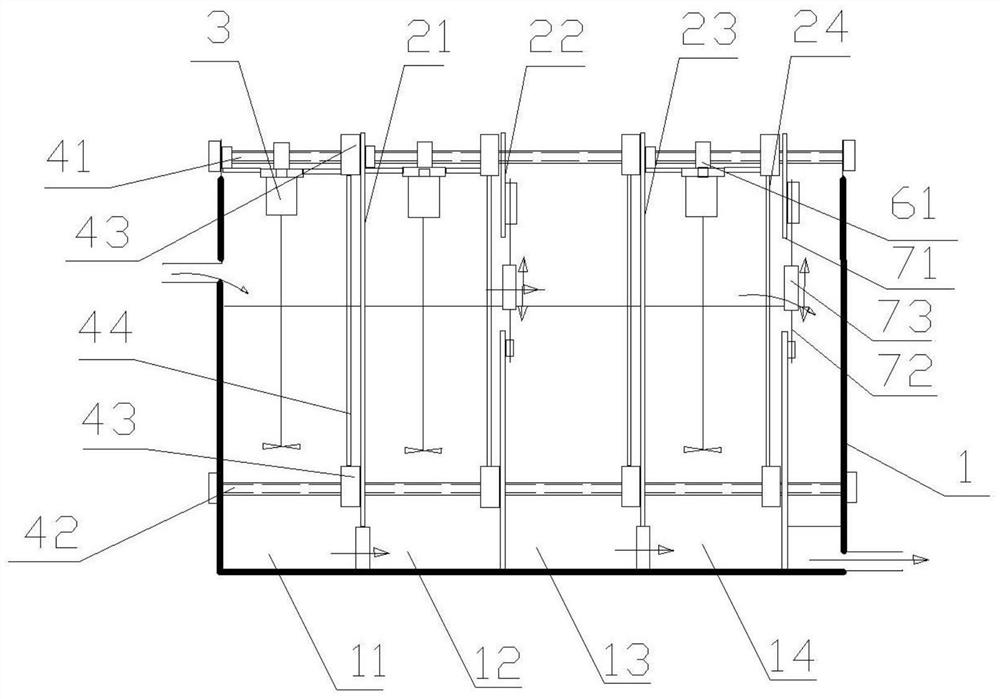

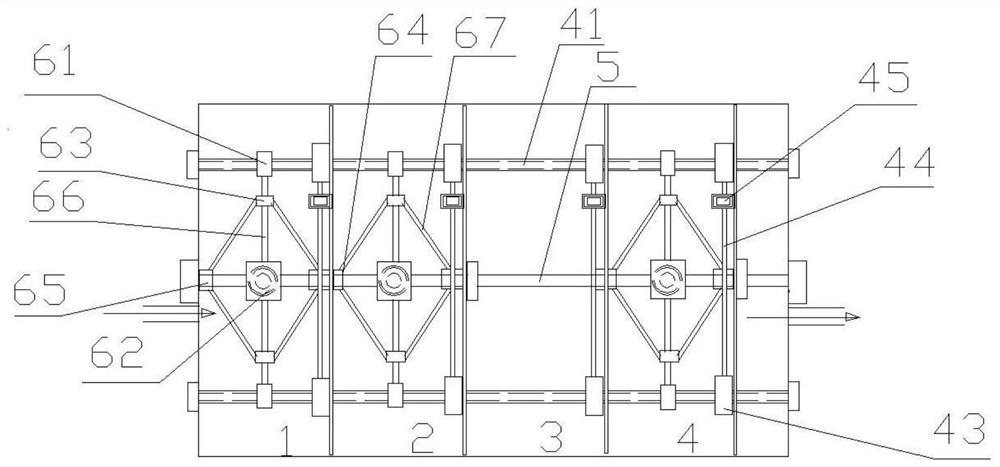

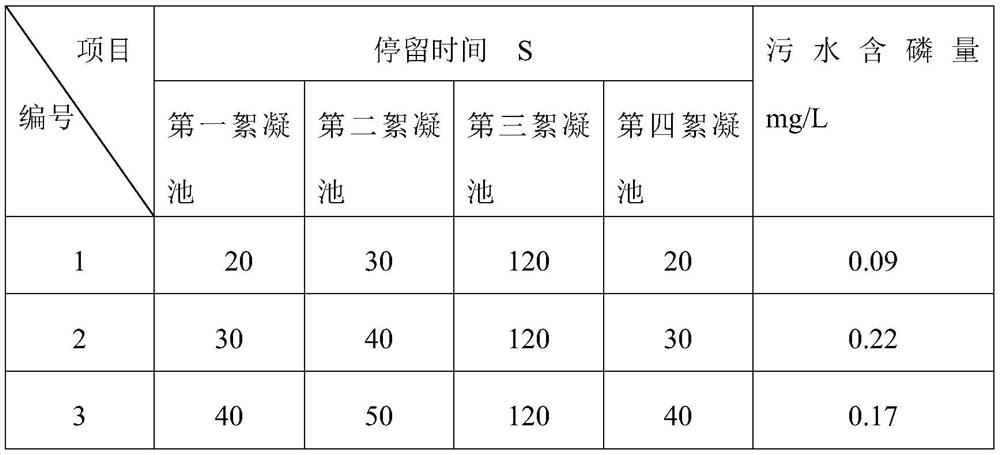

A flocculation device capable of adjusting the effect of flocculation reaction and a method of using it in combination with a phosphorus removal agent

ActiveCN110143657BProcessing speedOptimize and improve dephosphorization effectWater/sewage treatment by flocculation/precipitationPhysical chemistryEngineering

The invention discloses a flocculation device capable of adjusting the flocculation reaction effect and a method for using it in combination with a phosphorus removal agent. Four partitions are vertically arranged in the flocculation device, and the tank body is divided into a first flocculation pool, a second flocculation pool, and a third flocculation pool. The flocculation pool, the fourth flocculation pool and the fifth pool; the partitions can be moved to adjust the volume of the five pools; the first flocculation pool, the second flocculation pool and the fourth flocculation pool are equipped with adjustable speed mixers. Add polyacrylic acid or sodium polyacrylate to the first flocculation tank, add inorganic flocculant and polydimethyldiallylammonium chloride to the second flocculation tank, and add anionic polyacrylamide to the fourth flocculation tank. The present invention regulates the flocculation reaction and achieves the best effect of flocculation phosphorus removal by adjusting the two main factors of residence time and stirring speed, and the device and the medicament are used together.

Owner:安徽红太阳生物化学有限公司

A seawater desalination device

InactiveCN105936521BFast evaporationIncrease the output speedGeneral water supply conservationSeawater treatmentFresh waterEngineering

Owner:HOHAI UNIV CHANGZHOU

Device for continuously separating hexachloroethane in tetrachloroethylene solid waste

ActiveCN108911945AIncreased push distanceEasy to separateHalogenated hydrocarbon separation/purificationSpiral bladeDrive shaft

A device for continuously separating hexachloroethane in tetrachloroethylene solid waste. The device comprises a base, a speed regulating motor, a driving motor and a strip groove; the outer side wallof the strip groove is covered with a heating jacket, and the opening of the strip groove is sealed by a sealing cover body; a speed regulating shaft is rotatably disposed in the strip groove; a first spiral blade extending along the axial direction is arranged on the speed regulating shaft, and the first spiral blade is in clearance fit with the groove wall of the strip groove; a feeding vertical pipe is fixed at one end of the sealing cover body, and a tapered feeding hopper is connected to the upper end opening of the feeding vertical pipe; a driving shaft is rotatably arranged in the feeding vertical pipe; the driving shaft is provided with a second spiral blade extending along the axial direction; the second spiral blade is in clearance fit with the inner wall of the feeding verticalpipe; the other end of the sealing cover body is provided with an exhaust port for connecting with a material steam trap; the bottom of the strip groove is provided with a discharge pipe; and the discharge pipe is located below the other end of the first spiral blade.

Owner:重庆天原化工有限公司

Household appliances running on water, especially dishwashers

ActiveCN102342820BEffective disinfectionExtended stayTableware washing/rinsing machine detailsOther washing machinesHydraulic circuitIrradiation

The invention relates to a water-operated household appliance, in particular a dishwasher, having a hydraulic circuit in which washing fluid can be circulated by means of a fluid pump (13). According to the invention, at least one UV irradiation element (23) is arranged for UV irradiation of the washing fluid within the fluid pump (13).

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Embedded planetary-screw pulsation plasticizing exhaust extruder and method

ActiveCN101837633BImprove delivery efficiencyImprove extrusion outputRetention timeGear transmission

The invention provides an embedded planetary-screw pulsation plasticizing exhaust extruder, which comprises a screw mechanism, a cylinder, a feed inlet, an air outlet, a discharge outlet and an actuating unit, wherein the screw mechanism comprises a main screw and a plurality of planetary screws, and the axis of the main screw is coincident with the axis of the cylinder; the screw arris of the main screw is provided with a plurality of holes which are matched with the planetary screws; the planetary screws are respectively inserted in the holes of the screw arris of the main screw, embedded into a screw slot and distributed around the main screw; the axes of the planetary screws are parallel to the axis of the main screw; the actuating unit comprises pulsation gears, planetary gears and apulsation-gear transmission mechanism; the planetary gears are fixed at the ends of the planetary screws and are engaged with the pulsation gears; and the pulsation gears are connected with the pulsation-gear transmission mechanism. The invention also provides an embedded planetary-screw pulsation plasticizing exhaust method implemented by the device. The embedded planetary screw pulsation plasticizing exhaust extruder and the embedded planetary-screw pulsation plasticizing exhaust method have the advantages of adjustable retention time, low energy consumption, thorough exhaust, good uniformity of phase structure control, and the like.

Owner:GUANGDONG IND TECHN COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com