Full-boiling vibration propelled coal moisture control and grading integrated equipment

A push-type, coal-humidity control technology, which is applied in lighting and heating equipment, hearth furnaces, drying solid materials, etc., to achieve remarkable energy-saving effects, high heat and mass transfer efficiency, and reduce processing capacity and power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

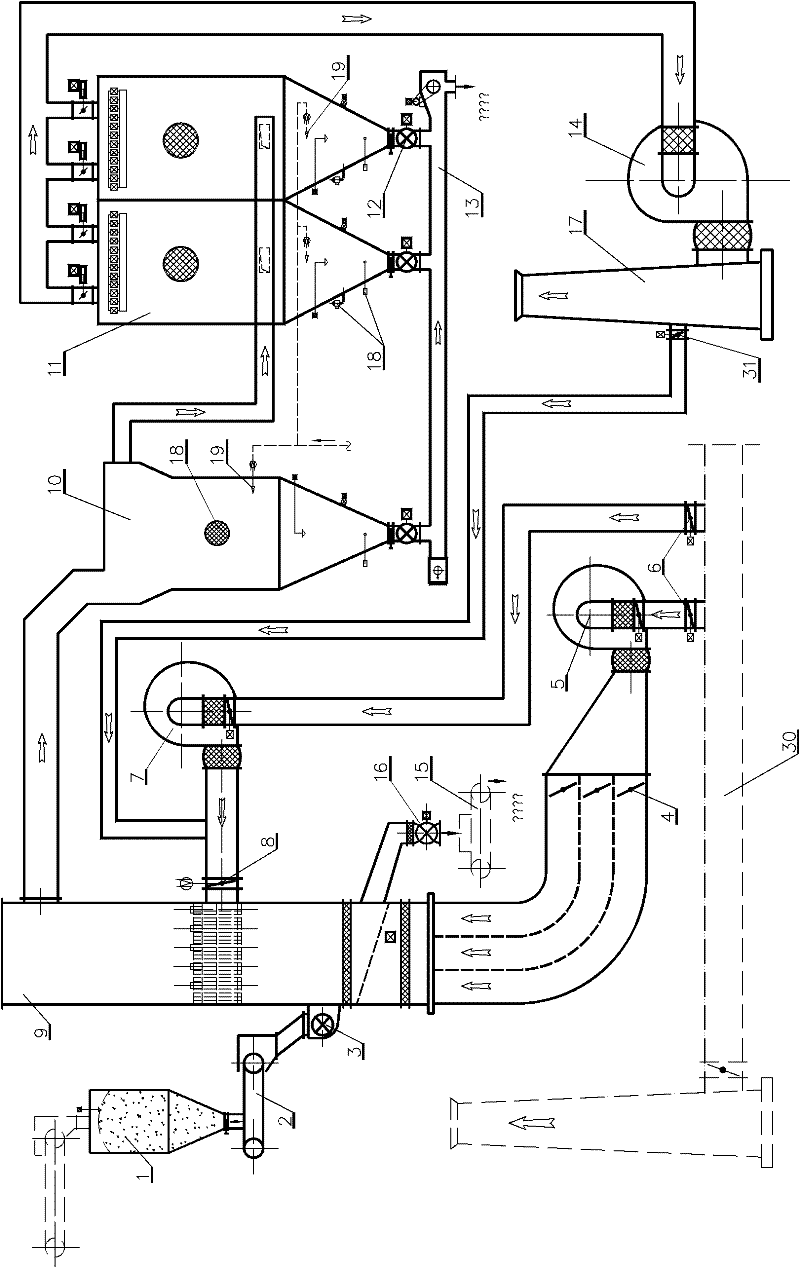

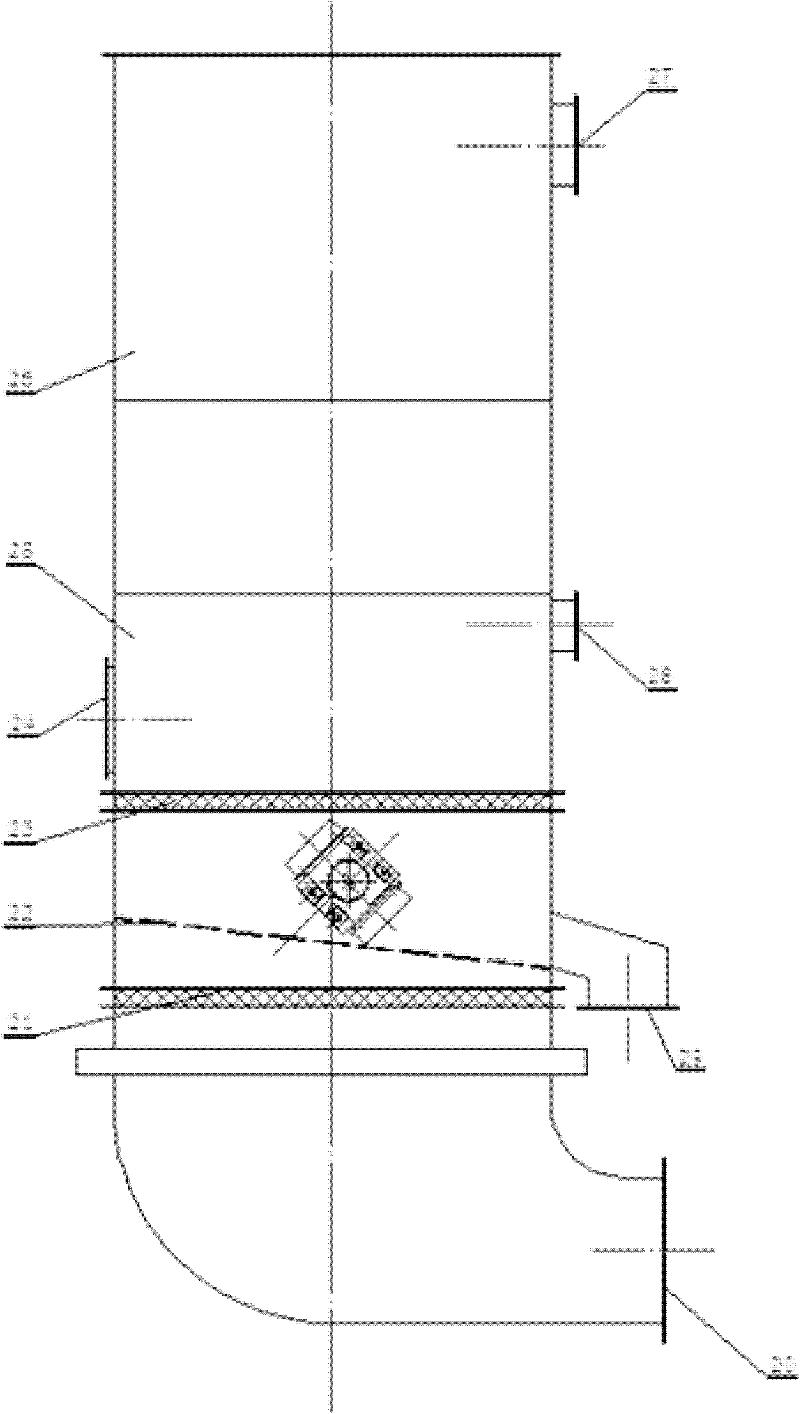

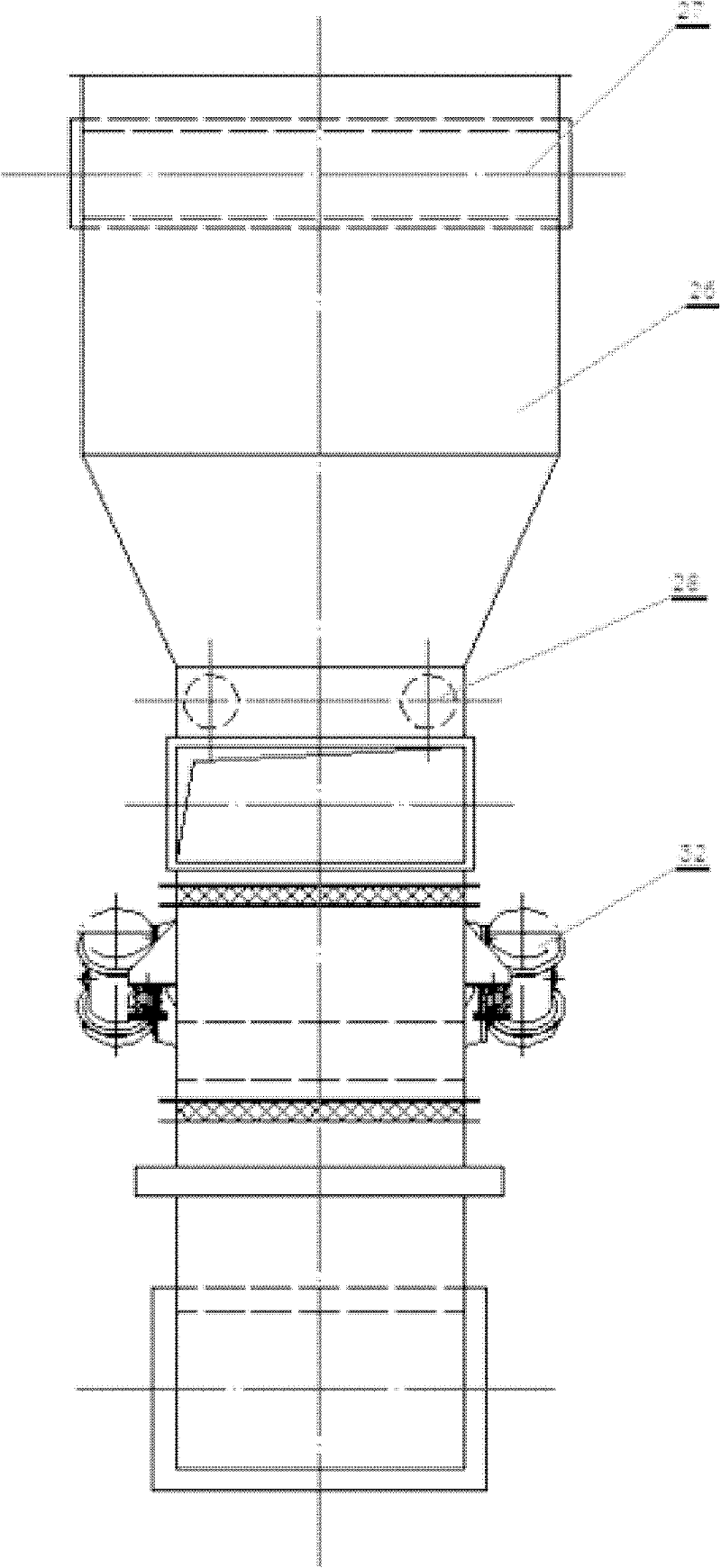

[0036] The full-boiling vibration-propelled coal humidity control and classification integrated equipment of the present invention will be further described in detail in conjunction with the accompanying drawings:

[0037] The present invention adopts the coal humidity control classifier as the coal material fluidization and humidity control equipment, utilizes the working principle of the vibrating fluidized bed and under the action of the secondary air, makes the coal materials with different particle sizes in the coal humidity control classifier In different states of movement and humidity control: Large particle coal materials are distributed under the fluidized layer to form a fixed bed or a fluidized bed with a relatively low fluidization height. The coal humidity control classifier flows in the direction of the humidity control coal outlet 29, and finally flows out from the humidity control coal outlet 29, and the fine particle coal material in the full boiling fluidizat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com