Patents

Literature

85results about How to "Avoid over crushing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

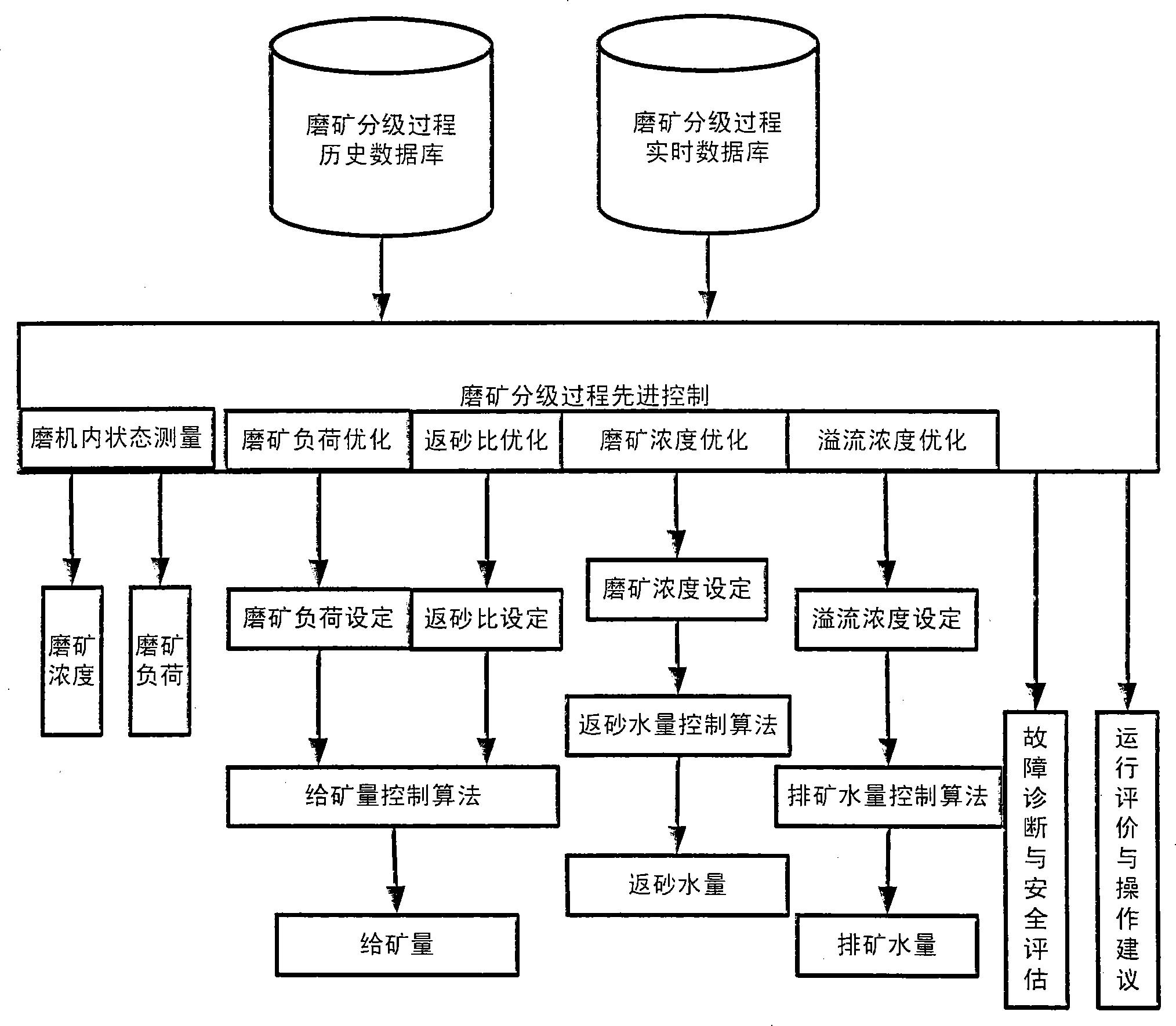

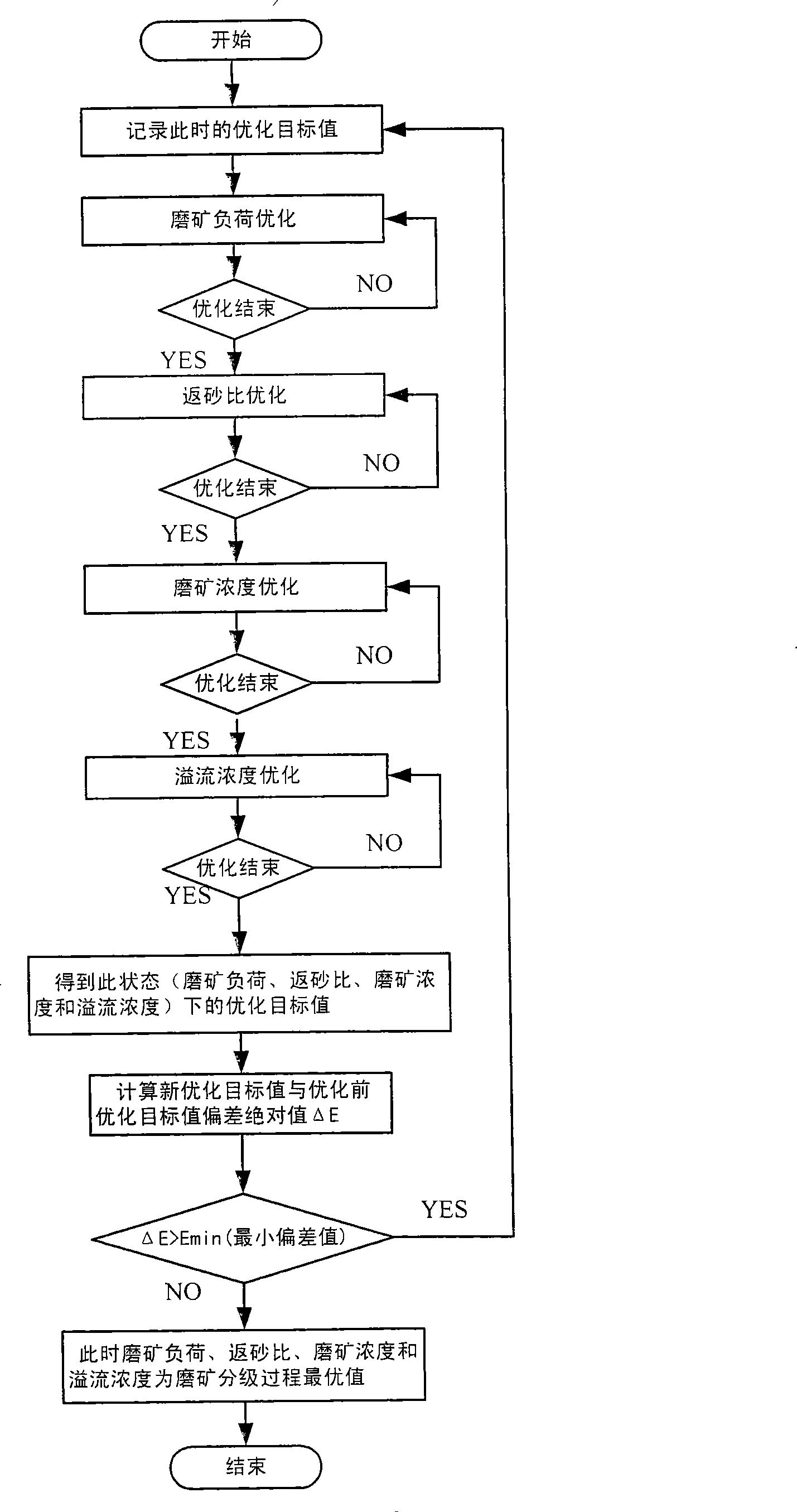

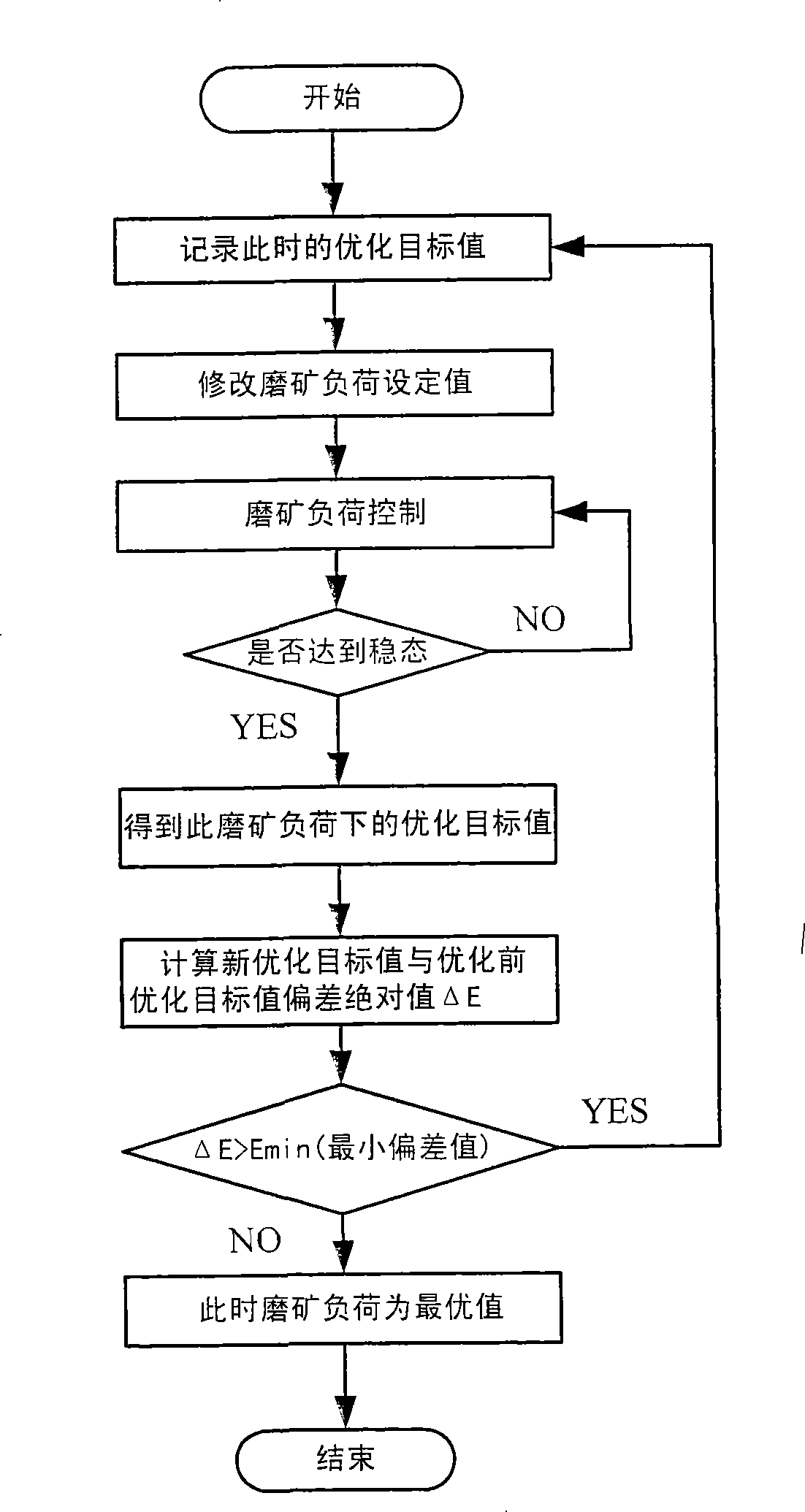

Optimization control method for grind grading process

InactiveCN101244403ARealize online measurementImprove pass rateElectric testing/monitoringGrain treatmentsComing outWater volume

The invention discloses an optimal control method for grinding and grading mineral powder, which is characterized in that: the grinding load and grinding concentration is obtained by sampling grinding-grading process signal, with the help of the advanced control and through testing the state in the grinder; the optimal grinding load, the optimal sand-returning ratio, the optimal grinding concentration and the optimal overflow concentration are obtained through the grinding load optimization, the sand-returning ratio optimization, the grinding concentration optimization and the overflow concentration optimization; the feeding quantity is obtained through the control algorithm of the feeding quantity ; the sand-returning water volume is obtained through the control algorithm of the sand-returning water volume; the discharging water volume is obtained through the control algorithm of the discharging water volume. The optimal control method has advantages that: the global optimization to the grinding-grading process is realized; and meanwhile the diagnosis is done to reveal the fault of the grinding-grading process; the appraisal and analysis is executed in the grinding-grading process; reasonable advice is come out; continuous, stable, safe and economic running is ensured; so the method is widely used in the grinding-grading process and similar wet milling process in other industry crafts.

Owner:徐宝平

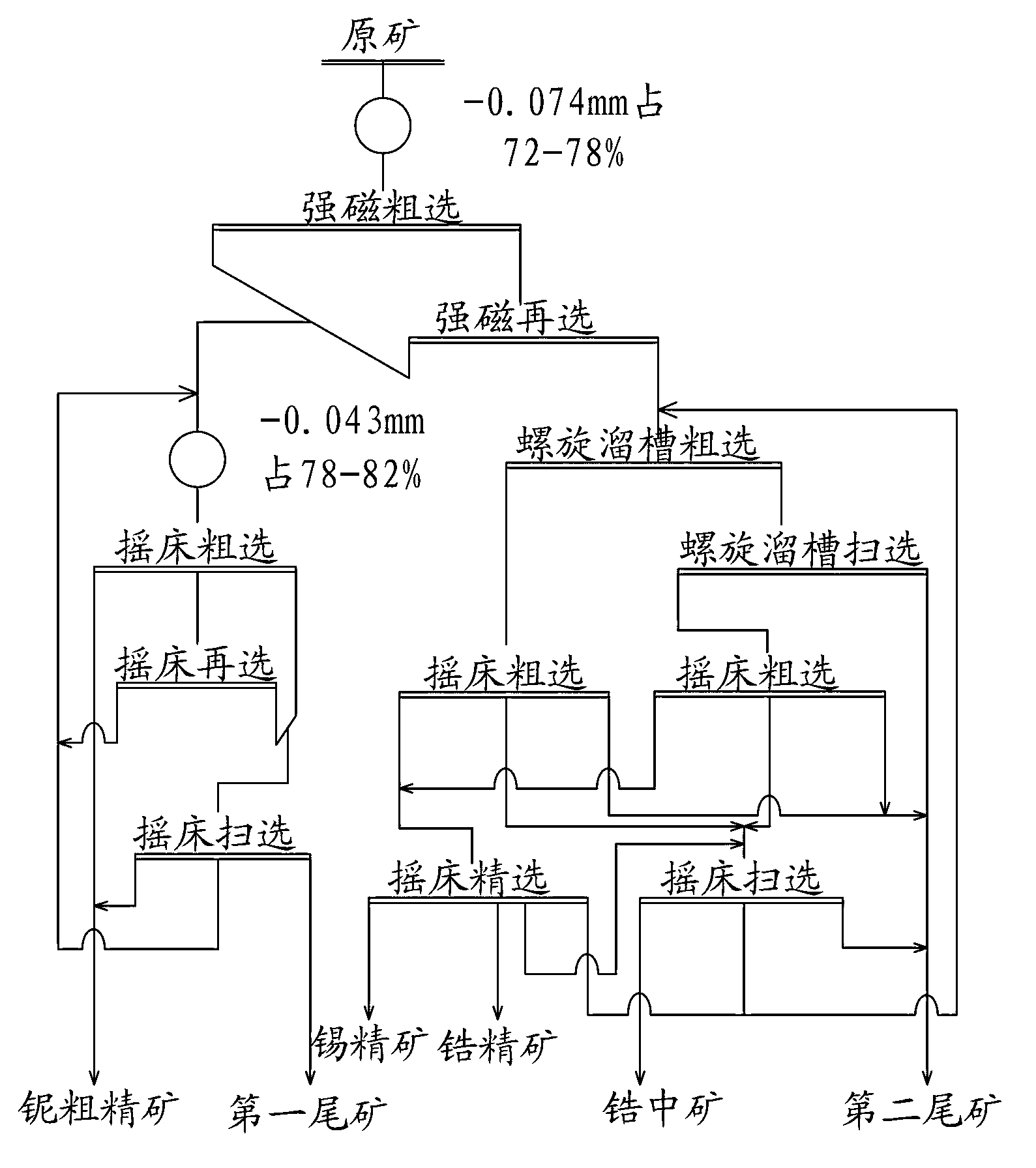

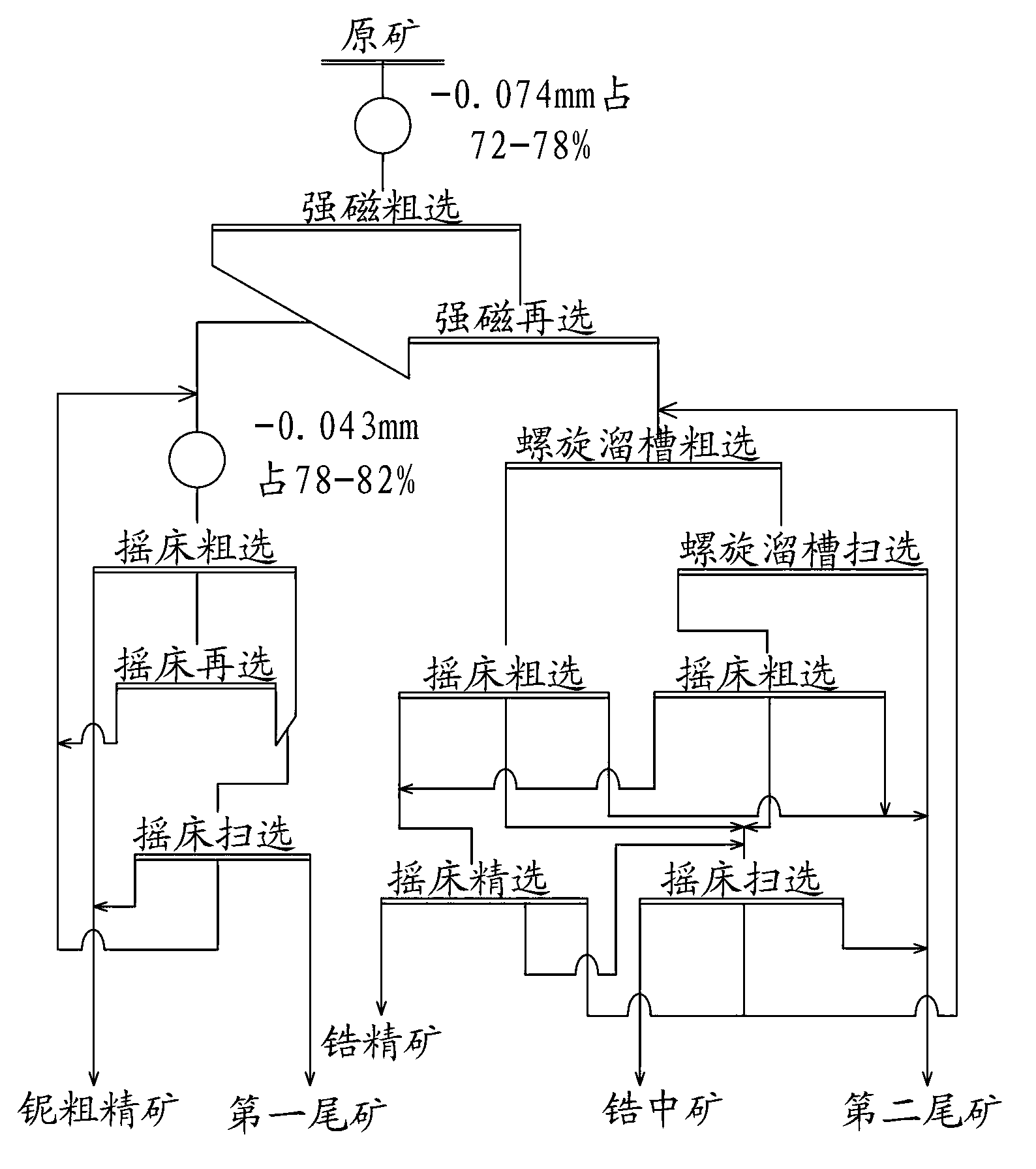

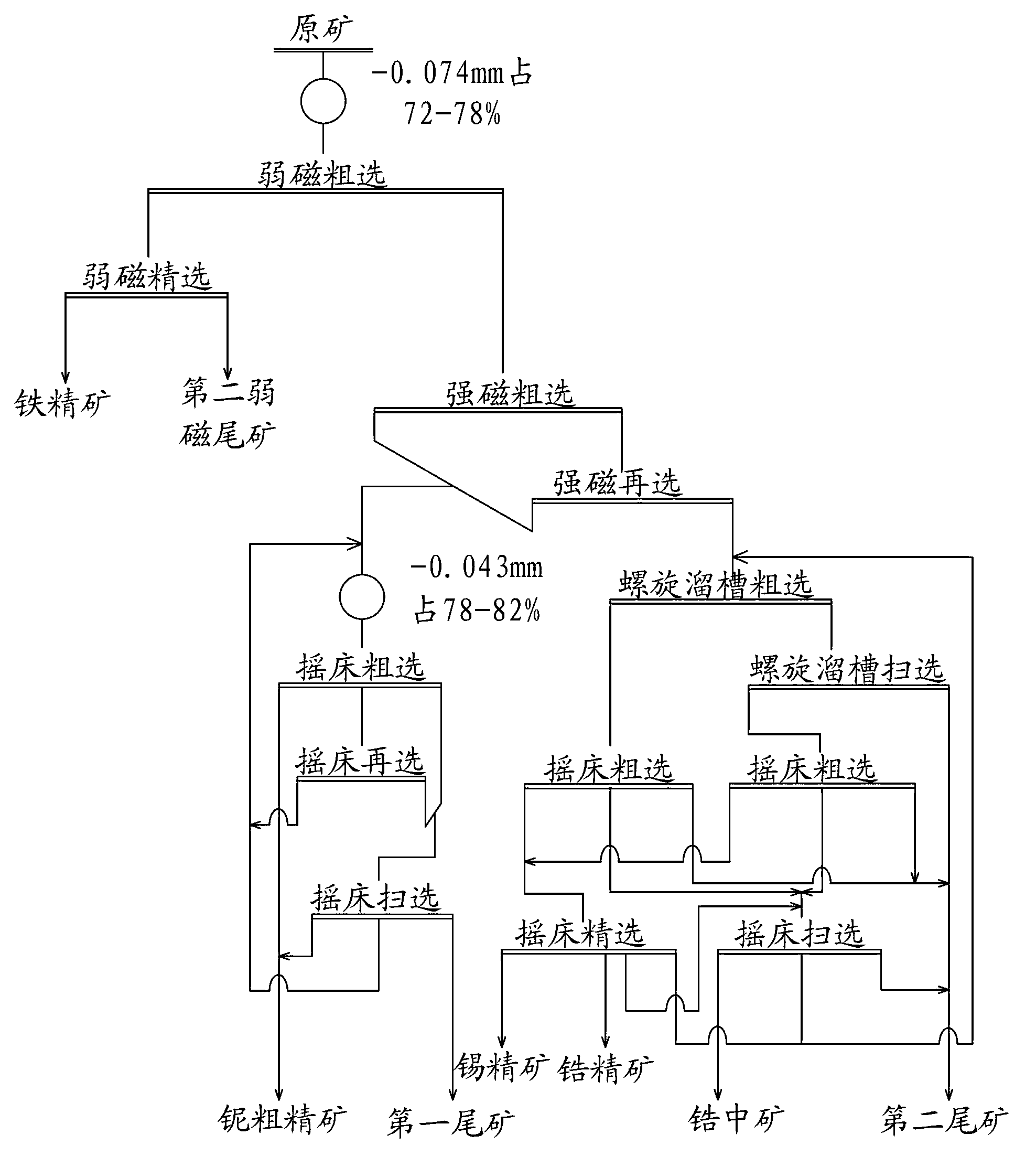

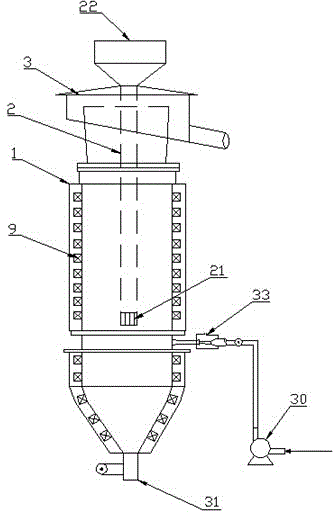

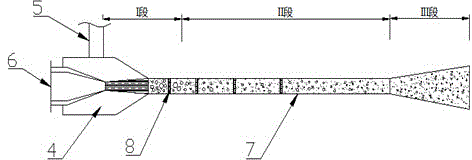

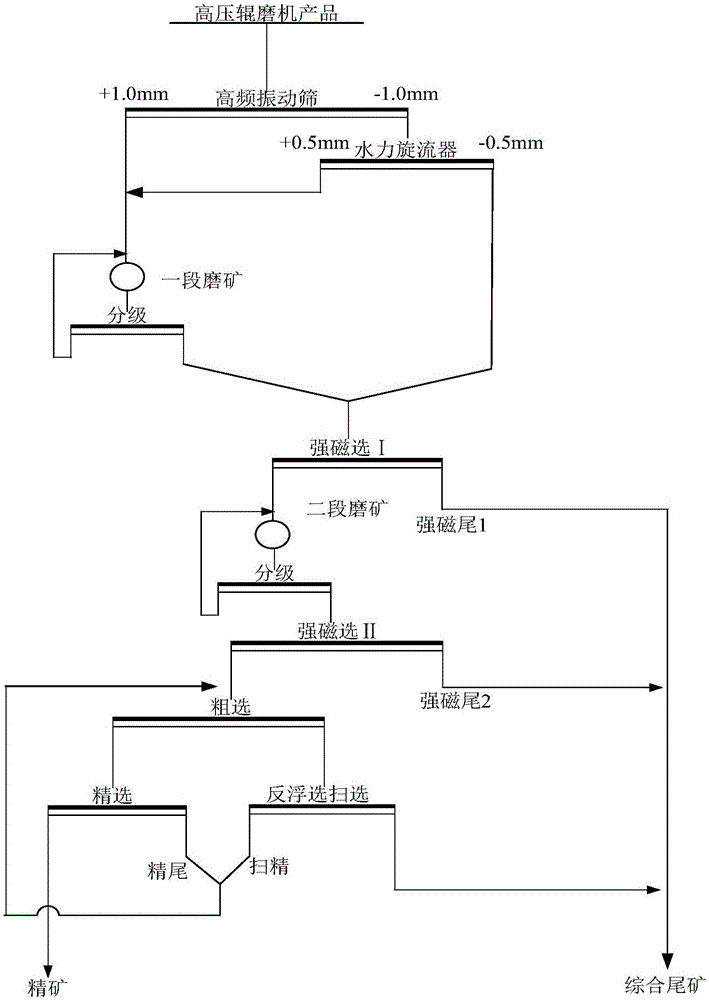

Ore dressing technology for comprehensively recovering lean and fine wiikite

The invention relates to an ore dressing technology for comprehensively recovering lean and fine wiikite, which comprises the following steps of: 1) carrying out primary-stage ore grinding after raw ore is broken, and preparing into ore pulp; 2) carrying out strong-magnet rough dressing on the ore pulp in a vertical-ring high-gradient magnetic separator to obtain first strong-magnet concentrate and first strong-magnet tailing, and carrying out strong-magnet re-dressing on the first strong-magnet tailing in the vertical-ring high-gradient magnetic separator to obtain second strong-magnet concentrate and second strong-magnet tailing; 3) combining the first strong-magnet concentrate and the second strong-magnet concentrate to obtain strong-magnet rough concentrate, and respectively carrying out the following operation modes: A) carrying out secondary-stage ore grinding on the strong-magnet rough concentrate, and carrying out tabling to obtain niobium rough concentrate and first tailing; and B) firstly carrying out spiral sluice ore dressing on the second strong-magnet tailing, then carrying out tabling to obtain zirconium concentrate and (or) tin concentrate, zirconium middling and second tailing. The ore dressing technology disclosed by the invention has the advantage that the aim of effectively and comprehensively recovering niobium ores associated with ore impurities, low grade and fine granularity can be realized.

Owner:镇康县金宏矿业有限公司 +1

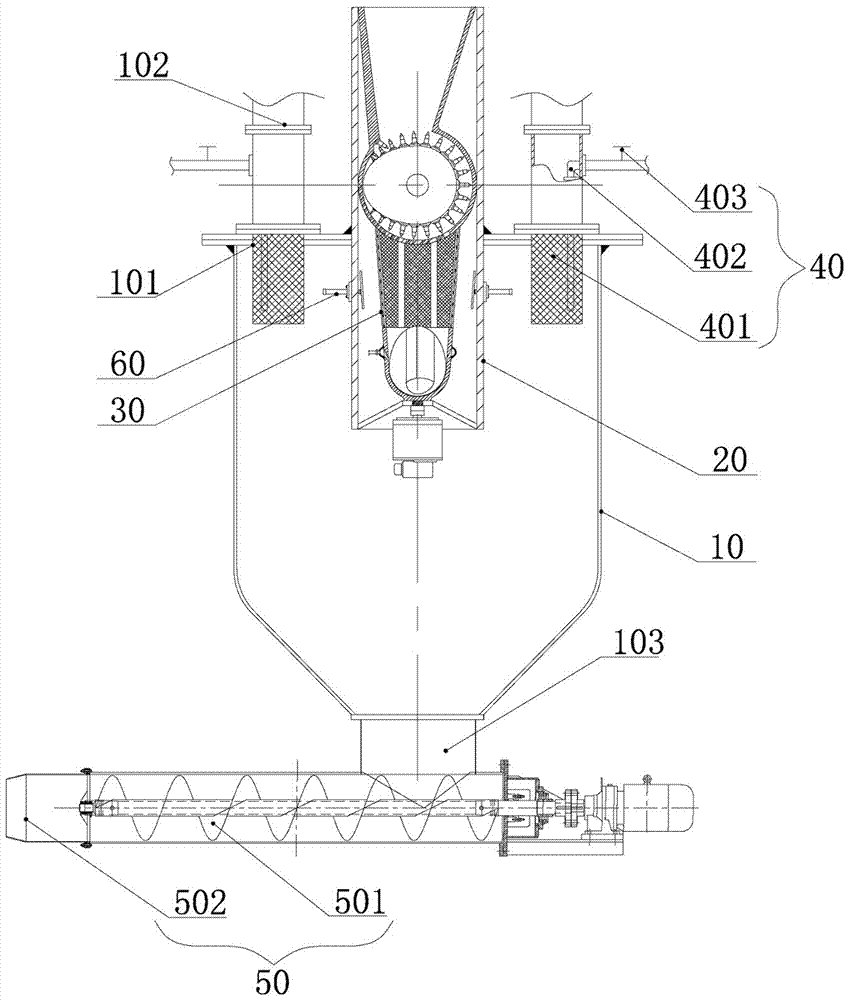

Quality improvement and impurity reduction ore dressing method of ferromagnetic minerals

InactiveCN104888959AImprove featured performanceEfficient selection effectFlotationMagnetic separationGranularityWater flow

The invention provides a quality improvement and impurity reduction ore dressing method of ferromagnetic minerals. The method is characterized in that the ferromagnetic minerals are cleaned, and the cleaning process comprises the following steps: 1, adding a flotation agent to crude concentrates, and carrying out size mixing, wherein the weight of ores with the granularity of 0.07-4mm in the crude concentrates is 80-90% of the total weight of the crude concentrates, and the flotation agent comprises a collector and an inhibitor; and 2, adding a material obtained in step 1 into a floating agglomeration electromagnetic cleaning device, and controlling the magnetic field intensity of the floating agglomeration electromagnetic cleaning device to be 11.94-63.69kA / m, the magnetic field transformation period to be 2-6s and the rising water flow speed to be 2-6cm / s. The method allows high-quality ferromagnetic mineral products to be obtained, greatly reduces the content of impurities, greatly shortens the ore dressing process of the ferromagnetic minerals, and has huge market economic benefit.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

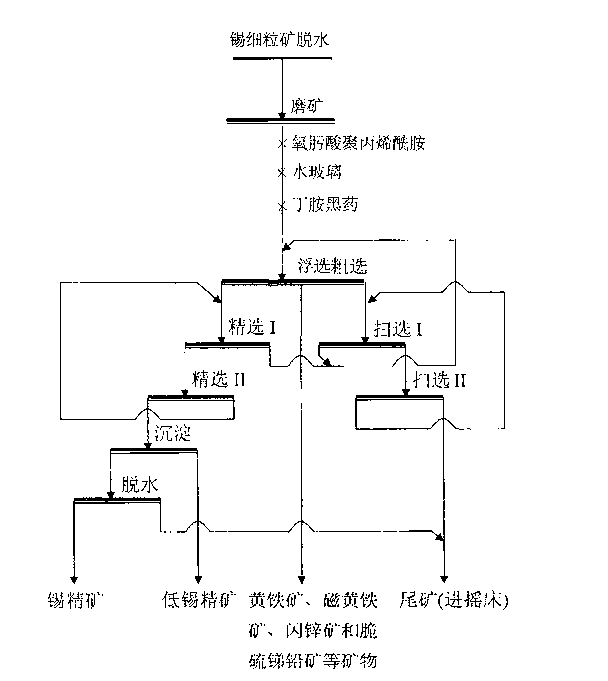

Method for selectively milling cassiterite multi-metal sulfides ores

The invention discloses a method for selectively milling cassiterite multi-metal sulfides ores. In the method, by utilizing the hydrophily / hydrophobicity difference between the surface of cassiterite and the surfaces of sulfides ores such as pyrite, pyrrhotite, blende and jamesonite, and by adding a floating agent in a milling process, floatation separation of cassiterite and the sulfides ores in ores can be realized under a condition of larger milling granularity by using a floatation method. The method disclosed by the invention can be adopted for treating the cassiterite multi-metal sulfides ore which contains 0.5 to 1 percent of Sn and 12 to 17 percent of S; and by adopting the method, the ore milling granularity required in floatation can be decreased, the content of fine-grained cassiterite (with the granularity of minus 0.039 millimeter) is reduced by 20 percent, and over-crushing phenomena of cassiterite are greatly reduced.

Owner:CENT SOUTH UNIV +1

Selective milling-flotation method for cassiterite multi-metal sulfide ore

The invention discloses a selective milling-floatation method for cassiterite multi-metal sulfide ore. In the method, cassiterite multi-metal sulfide ore is selectively milled, so that the surface hydrophilic / hydrophobic properties of cassiterite and sulfide minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like in ore are changed, the surface of cassiterite does not react with a flotation collector but reacts with hydroxamic acid polyacrylamide, and selective flocculation is performed on the surfaces of cassiterite minerals; and surfaces of minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like do not adsorb hydrophilic substances, and a fresh surface which is obtained by milling ore and dissociating reacts with a flotation collector which is added into an ore mill, so that floatability is realized for the surface hydrophilic property, the problems of low cassiterite floatation efficiency, high tin loss rate and severe environmental pollution caused by excessive smashing of cassiterite with the conventional floatation method in the ore dressing process of cassiterite multi-metal sulfide ore are solved, and the recovery of cassiterite with a subsequent gravity separation technology is facilitated.

Owner:GUANGXI GAOFENG MINE IND

Method for preventing and treating rock burst through deep-hole pressure release blasting

The invention discloses a method for preventing and treating rock burst through deep-hole pressure release blasting. The method comprises the steps that firstly, two stress concentration areas on the two sides are determined, and that is, the bust starting areas where the rock burst is possible to occur; secondly, single-row blast holes perpendicular to the axial direction of a roadway are symmetrically drilled in the two sides of the roadway, the depth of each blast hole at least reaches a bearing pressure peak area, the loaded length and a central detonating point approximate a peak stress position, and the loading mode is a non-coupling spaced loading mode; thirdly, PVC casing pipes are adopted to assist in loading and uniformly distributed to be three sections in each blast hole, a detonator is installed on each blasting cartridge, and the blast holes are sealed through clay; fourthly, detonator connecting wires in the same blast hole are connected in series, a net formed by connecting the detonator connecting wires in both the blast holes in series is in parallel connection with a leading wire to switch in a blasting machine; and finally, blasting operation is conducted through the blasting machine. According to the method for preventing and treating the rock burst through deep-hole pressure release blasting, the blasting energy can be utilized sufficiently, by carrying out pressure release blasting on the bust starting areas of the roadway sides where the rock burst is possible to occur, and the purpose that the danger level of the roadway rock burst is reduced is achieved.

Owner:ANHUI UNIV OF SCI & TECH

Preparation process of sini powder

ActiveCN102379949AIncrease crushing outputLow crushing temperaturePowder deliveryNervous disorderMedicinal herbsBran

The invention discloses a preparation process of sini powder, which comprises the following steps: respectively performing decoction on four medicines, namely 40-80 parts of Chinese thorowax root, 40-80 parts of bitter orange stir-fried with bran, 40-80 parts of white paeony root and 40-80 parts of liquoric root, for preparing decoction pieces; respectively extracting the Chinese thorowax root and the white paeony root and respectively concentrating to form concentrated solution with the relative density of 1.05-1.10 for standby; drying and smashing Chinese thorowax root medicine residue, white paeony root medicine residue, the bitter orange stir-fried with the bran and the liquoric root, then laying on a drying tray, placing into a microwave vacuum dryer for drying and sterilization, smashing into very coarse powder, pouring the very coarse powder into a trough type mixing machine, sequentially slowly adding the concentrated solution of the Chinese thorowax root and the white paeony root medicinal materials for mixing, and uniformly mixing; placing the very coarse powder of the medicinal materials mixed with the concentrated solution into the microwave vacuum drying device for drying and sterilization, taking out, and placing into a multifunctional smashing and grading machine for smashing, wherein coarse powder can completely pass through a sieve No. 2 and the powder mixed in the coarse powder, which can pass through a sieve No. 4, does not exceed 20% by weight; and then packaging.

Owner:FUZHOU JINXIANG CHINESE MEDICINE PHARMA

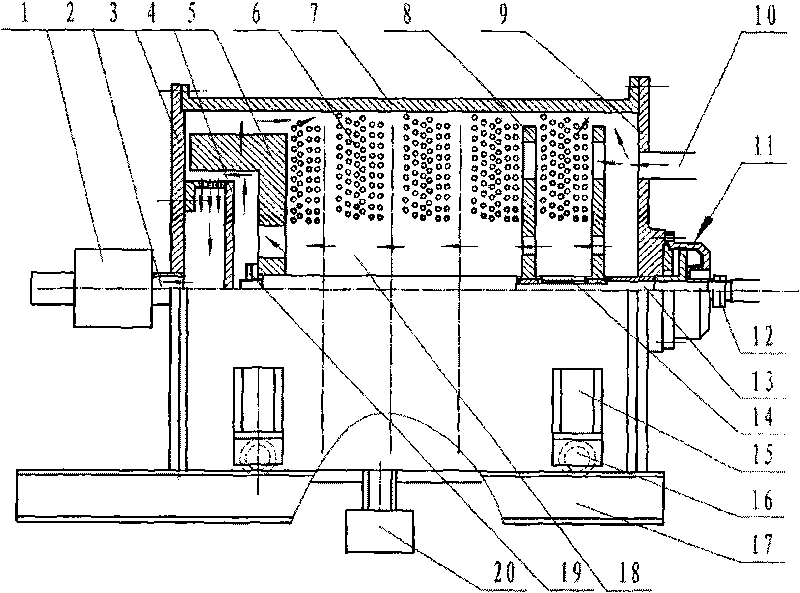

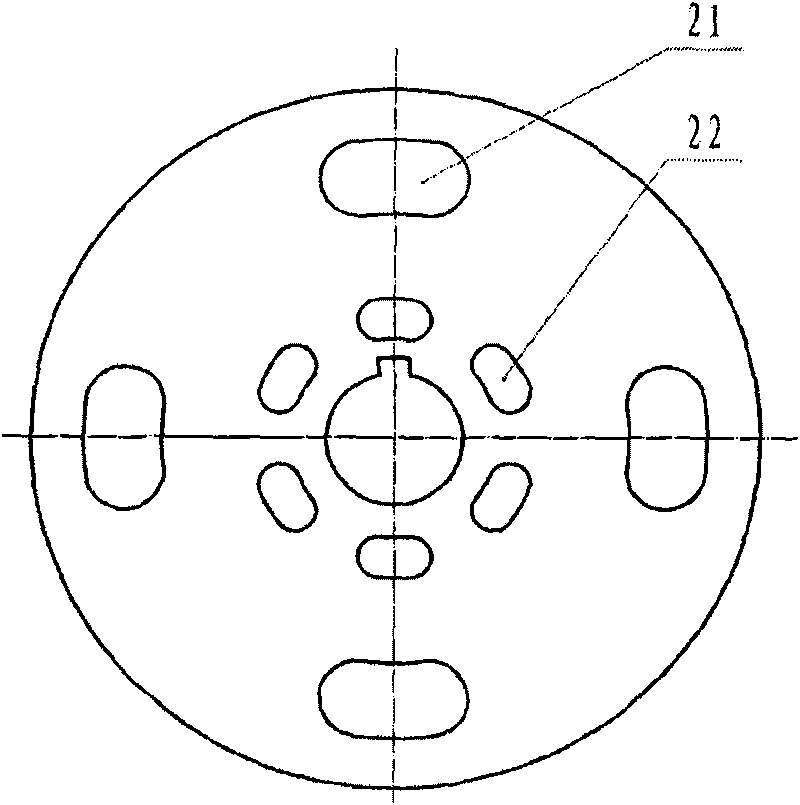

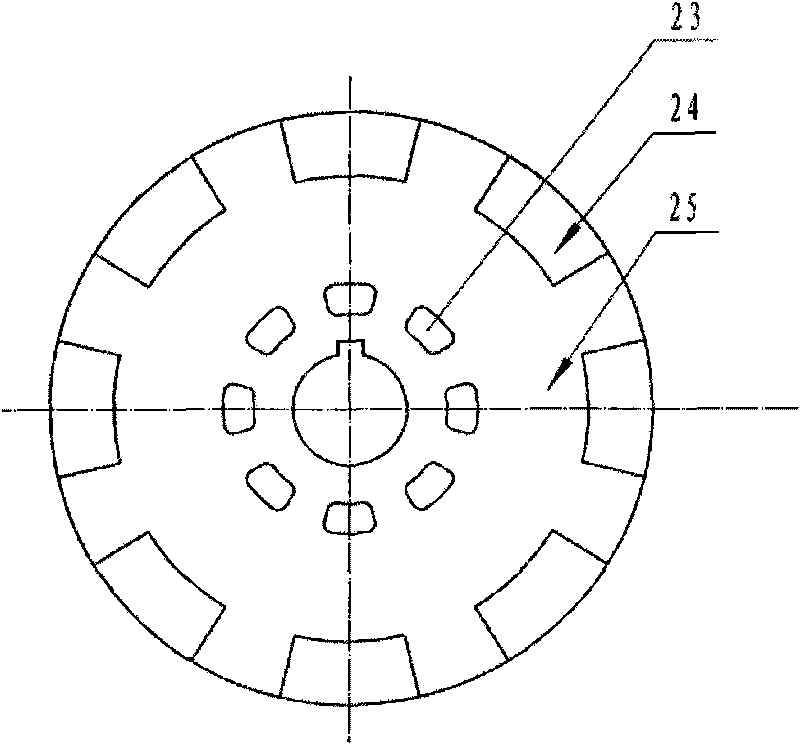

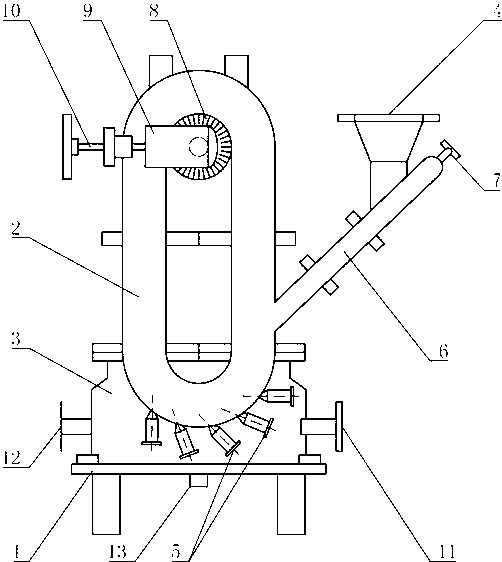

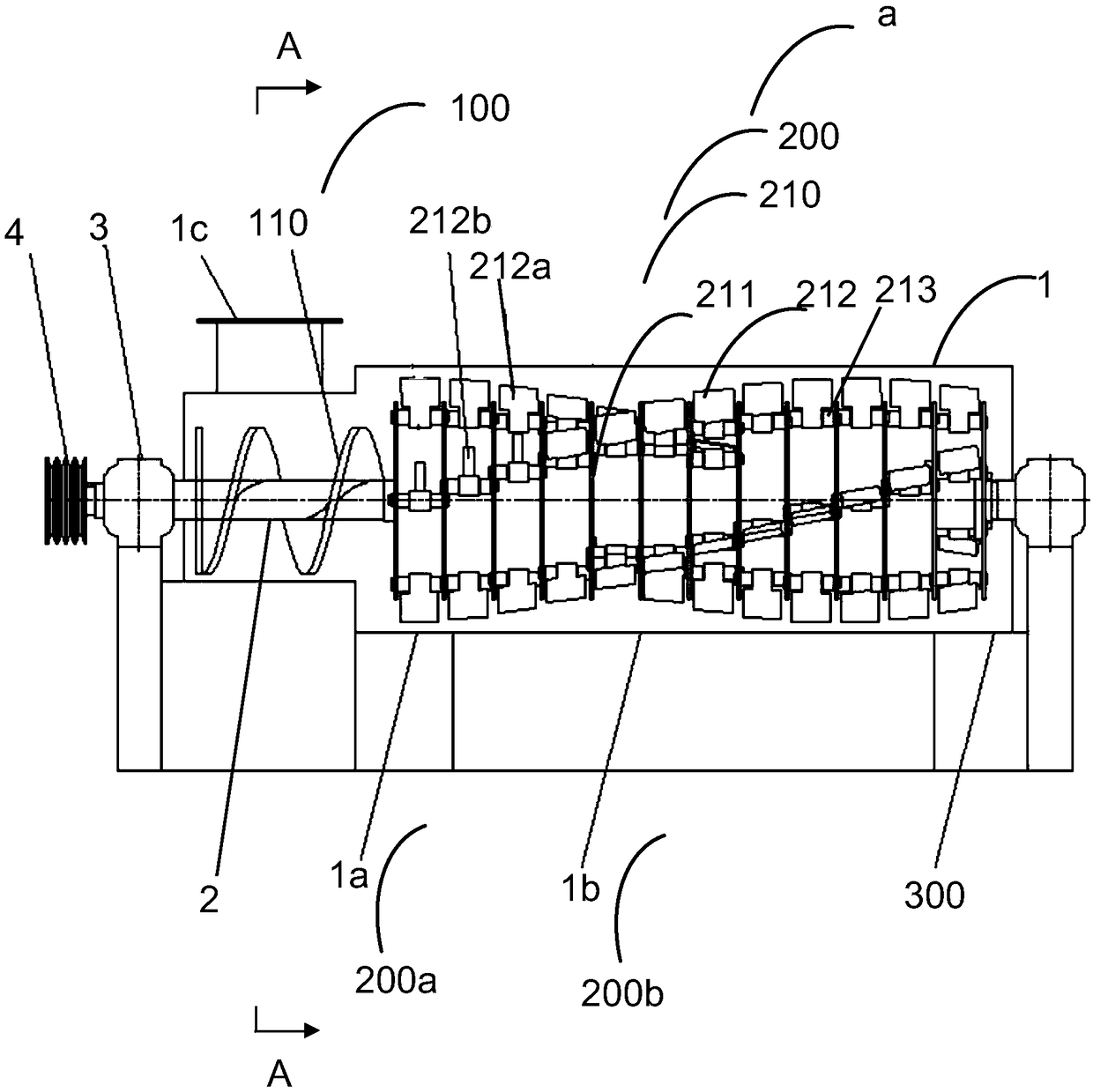

Horizontal grinding mill with built-in classifying turbine

InactiveCN101700504AOvercoming frictional resistanceReduce starting powerEngine sealsGrain treatmentsImpellerTurbine

The invention relates to a horizontal grinding mill with built-in classifying turbine, the technical solution of which is that a grinding chamber [18] is filled with grinding medium [6], a medium discharging valve [20] is installed on the middle of the bottom of a cylinder [7], a feeding pipe [10] is above a right end cover [9] of the grinding chamber [18] and a medium discharging pipe [2] is concentrically communicated with the grinding chamber [18] by a left end cover [3]. The length of the cylinder [7] is 1.5 to 2.5 times of the diameter thereof. A fairing [4] is fixedly installed on the left end cover [3] of the grinding chamber [18]. A classifying turbine [5] is vertically installed on the left end of a spindle [13]. A clearance between the classifying turbine [5] and the left end cover [3] is 5mm to 10mm. Five to eight mixing turbines [8] are vertically installed on the spindle [13]. The distance between the mixing turbines [8] decreases gradually from left to right and the right distance is 0.9 to 0.95 times of the left distance. The right end of the spindle [13] is connected with a driving mechanism by the right end cover [9] and a sealing device [11]. The invention has low starting power and can grind and classify with a function of selectively grinding.

Owner:WUHAN UNIV OF SCI & TECH +1

Electromagnetic shielding composite material and preparation method thereof

ActiveCN111454546AReduced Catalytic AgingImprove electromagnetic shielding performanceShielding materialsAnoxomerFiber

The invention relates to an electromagnetic shielding composite material and a preparation method thereof. The electromagnetic shielding composite material comprises the following components in partsby weight: 100 parts of matrix resin, 15-20 parts of metallized carbon fibers, 10-12 parts of FeSiAl alloy powder, 6-8 parts of silver-plated carbon nanotubes, 3-5 parts of a toughening agent, 0.3-0.6part of a coupling agent, 0.5-1 part of a compounded antioxidant and 0.2-0.3 part of a lubricant. The electromagnetic shielding composite material provided by the invention is high in electromagneticshielding effect, and the high strength of a composite material molded part can be maintained. According to the preparation method provided by the invention, the combination of the metallized carbonfiber and the FeSiAl alloy powder with the matrix resin can be increased, the catalytic aging of various metal components in a material system to a plastic matrix is weakened, the excessive crushing of the carbon fiber in the mixing process of an extruder can be effectively avoided; meanwhile, the good mixing of all the components is ensured.

Owner:诺思贝瑞新材料科技(苏州)有限公司

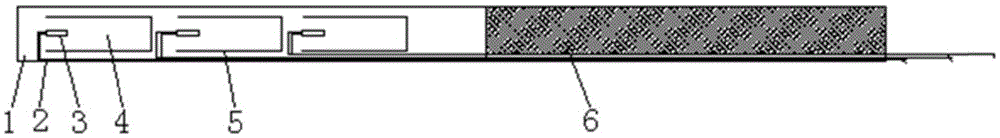

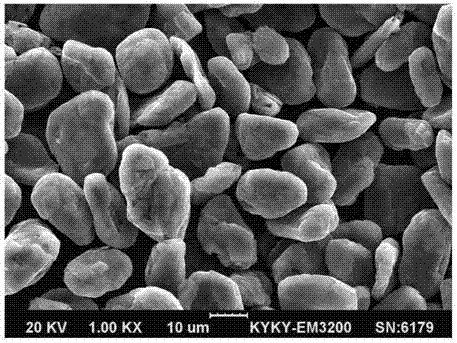

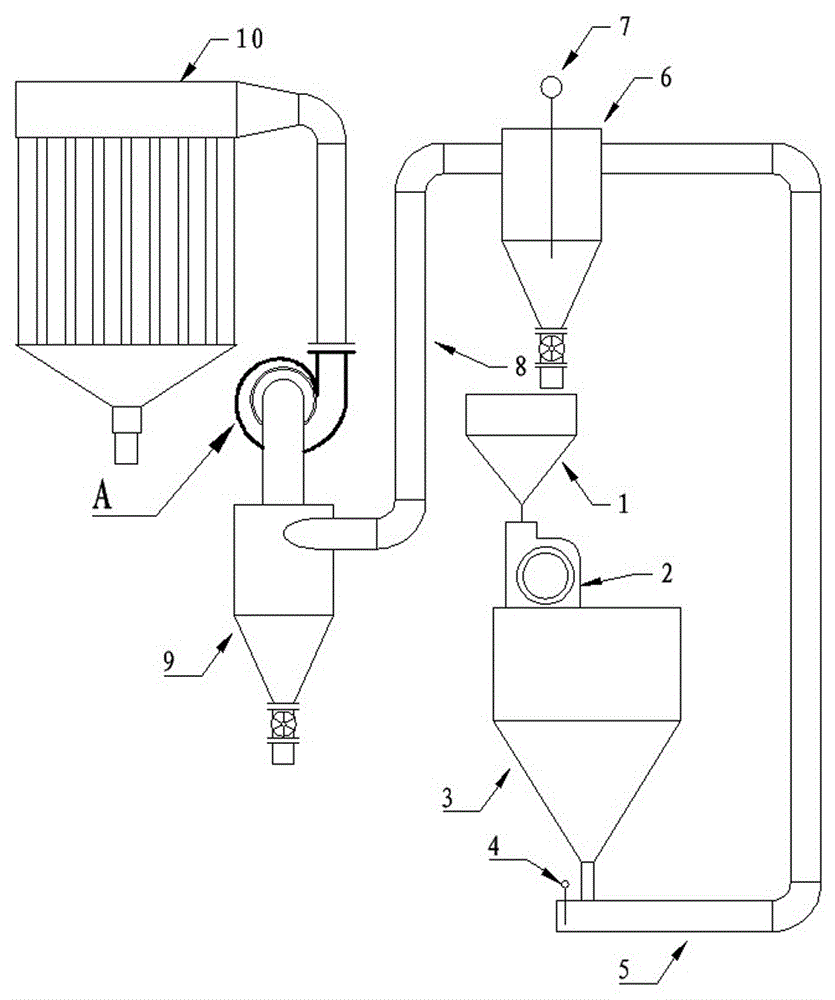

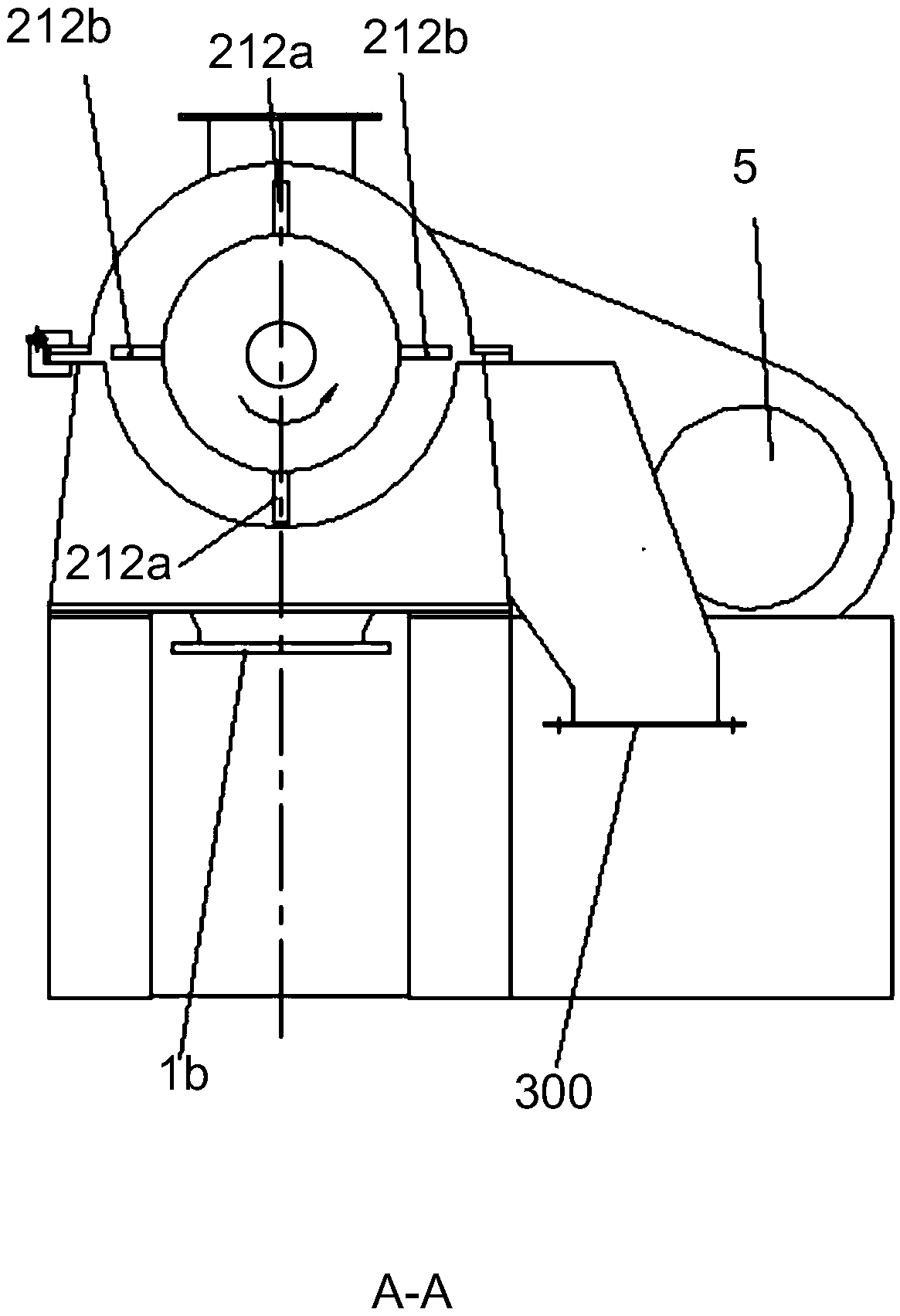

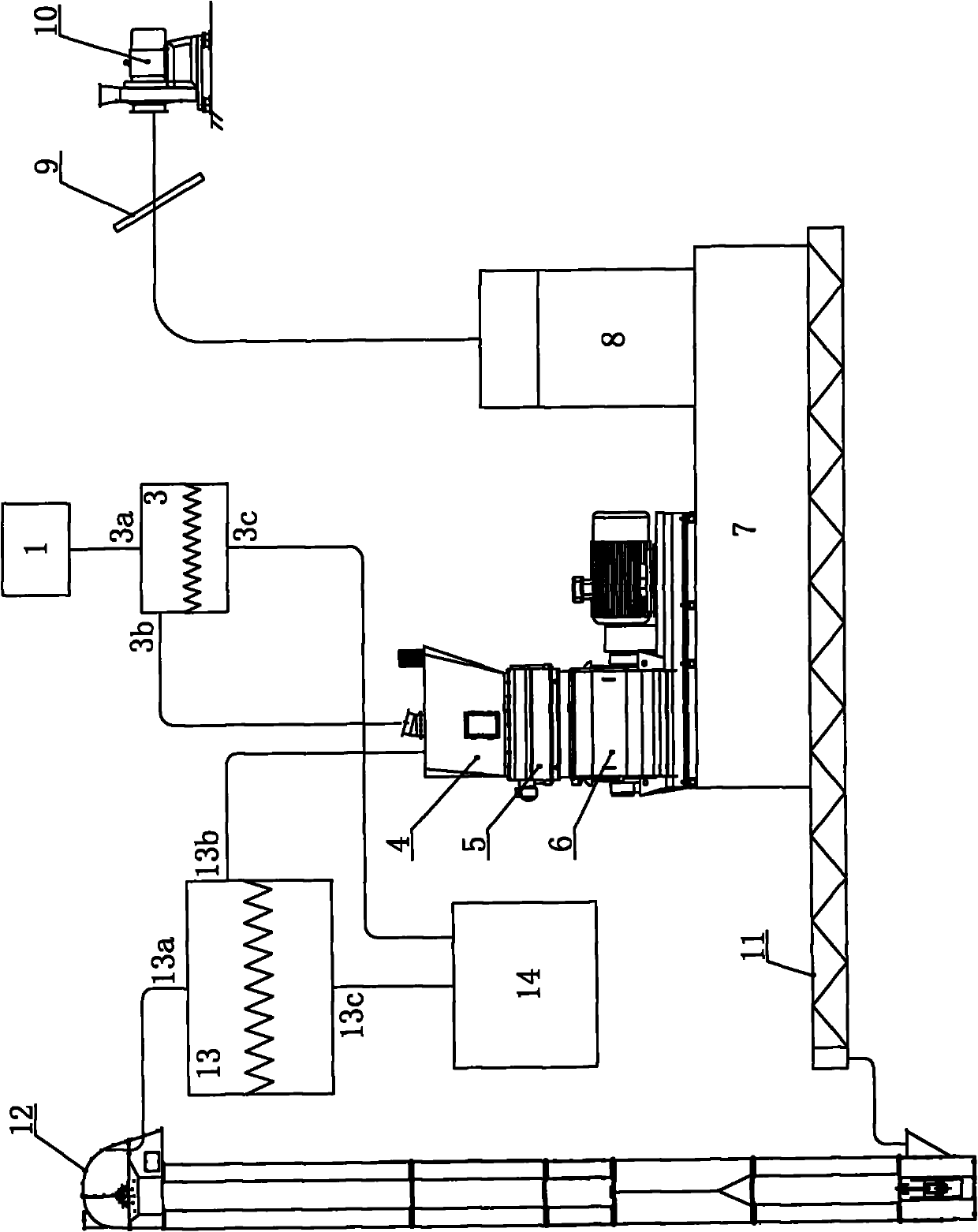

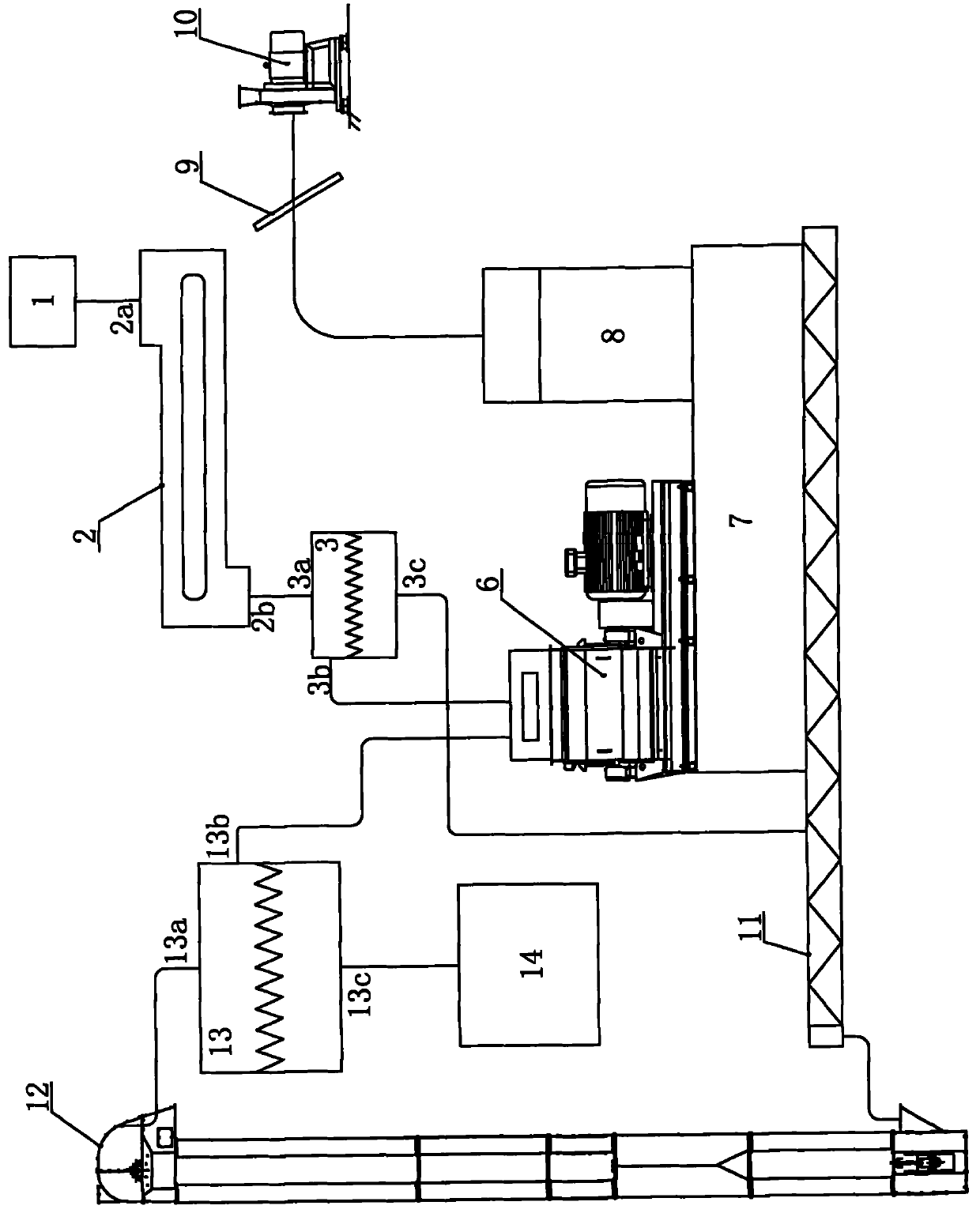

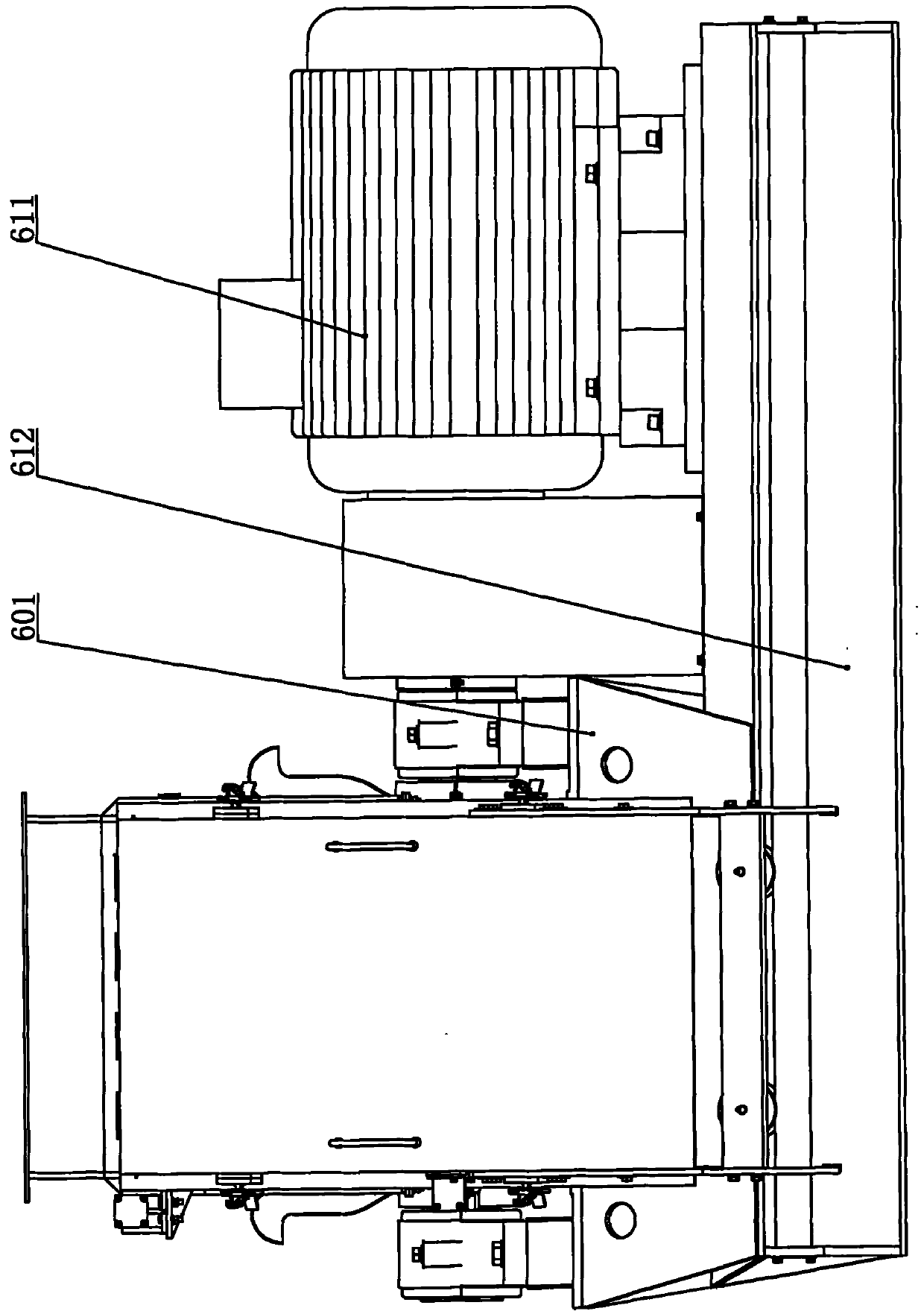

Lithium ion battery carbon negative electrode material grinding shaping technological process and production system thereof

ActiveCN103904302AHigh degree of automationIncrease productivityElectrode manufacturing processesCarbon compoundsElectrical batteryPulverizer

The invention provides a lithium ion battery carbon negative electrode material grinding shaping technological process. The process comprises the following steps: step one, feeding graphite in an inner grading ultra-fine grinding pulverizer, wherein particles with qualified sizes automatically flow out along with airflow under the rotation of an inner grading turbine, and coarse particles fall in a pulverizing area for continuous pulverizing until the particle sizes are qualified; and step two, enabling graphite powder with qualified particle diameters obtained in the step one to flow in a centrifugal classifier along with the airflow, wherein the powder with the particle size of smaller than 35 microns is discharged to a cyclone batcher from an airflow classifier material exhaust hole for collection, and coarse powder is discharged out from a return feeding hole. The ultra-fine grinding pulverizer with an inner grading device is adopted for replacing a plurality of airflow pulverizers to realize ultra-fine grinding, so that qualified fine powder is classified and extracted in time, over crushing is prevented, the product yield is improved, and the production yield is more than 90%.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

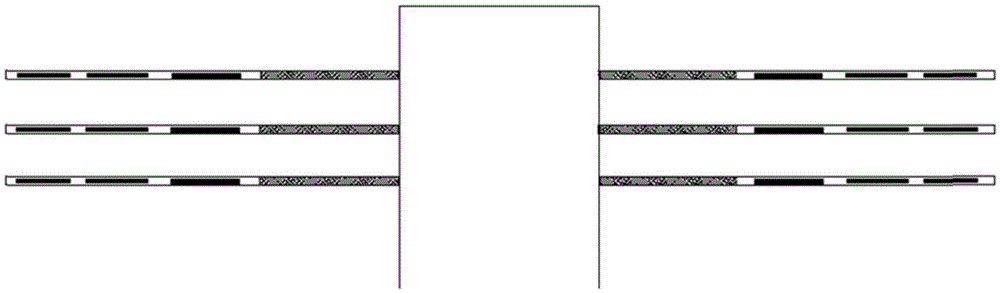

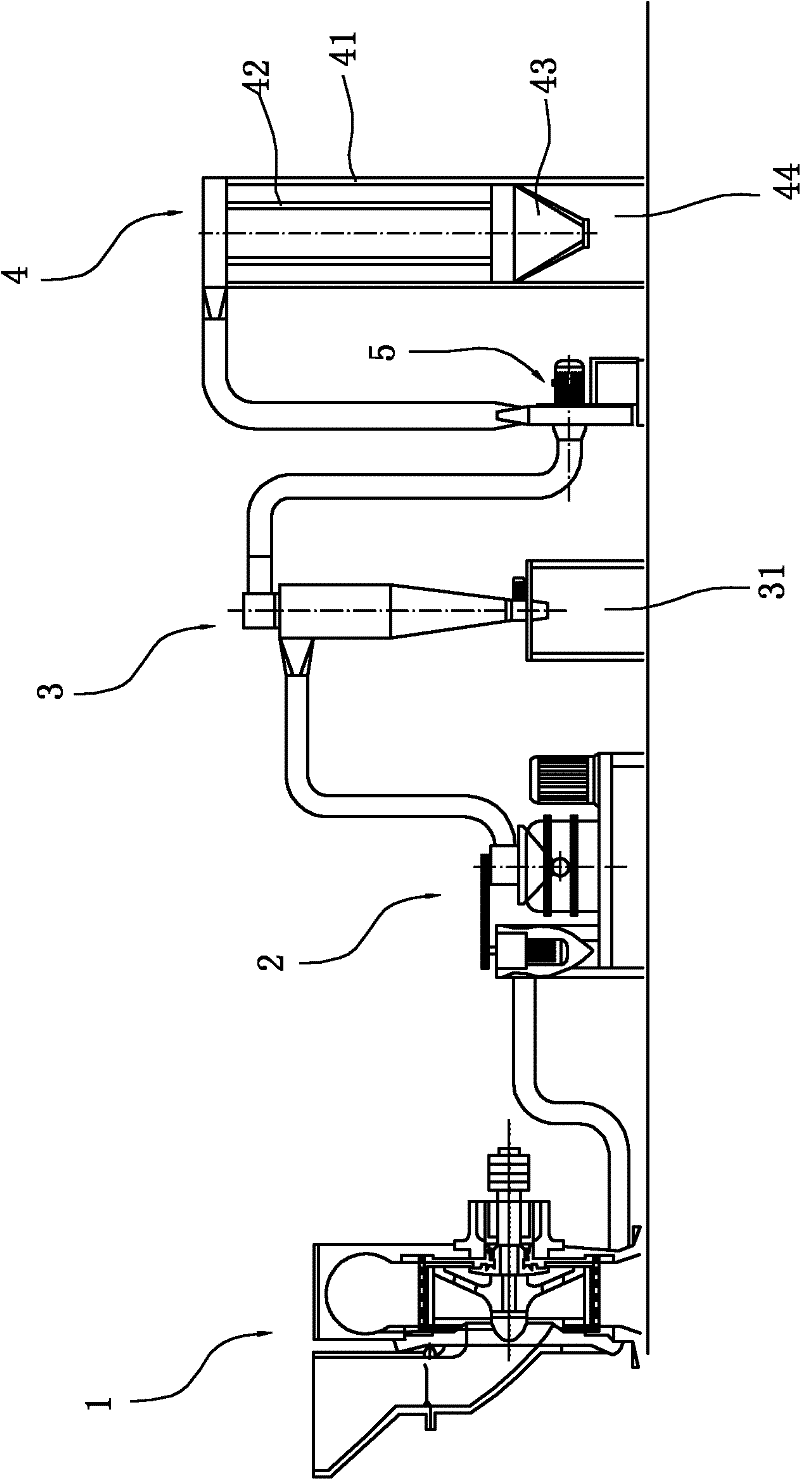

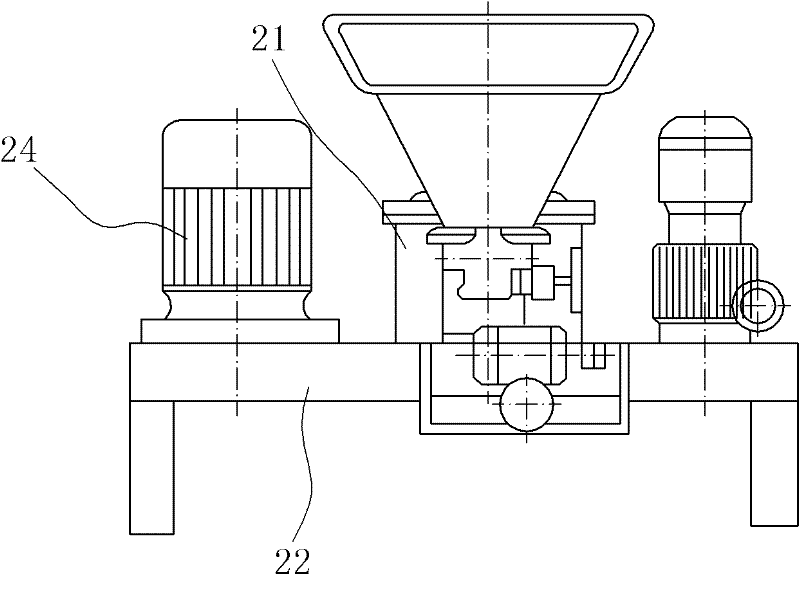

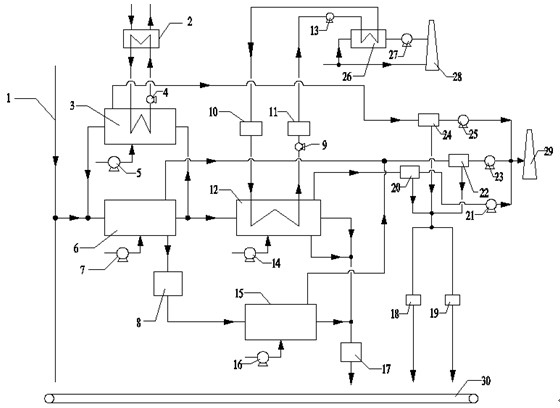

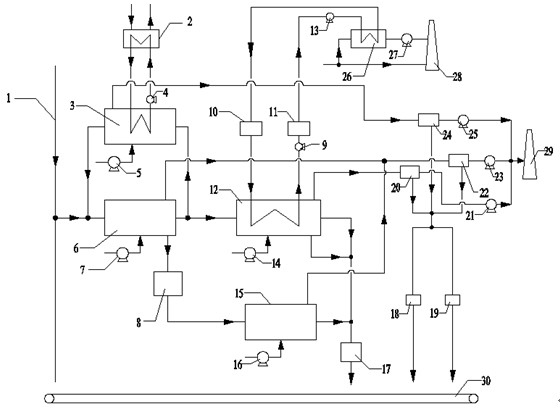

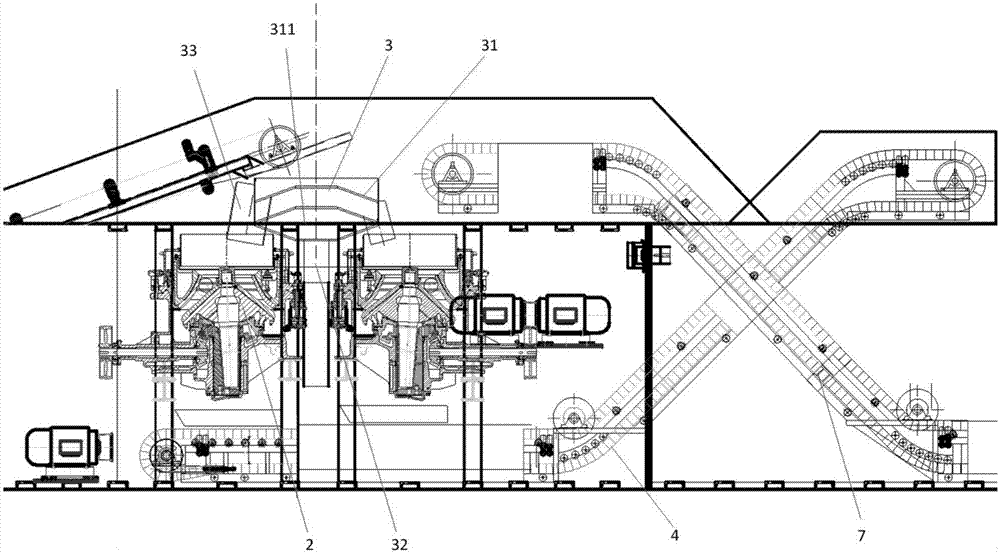

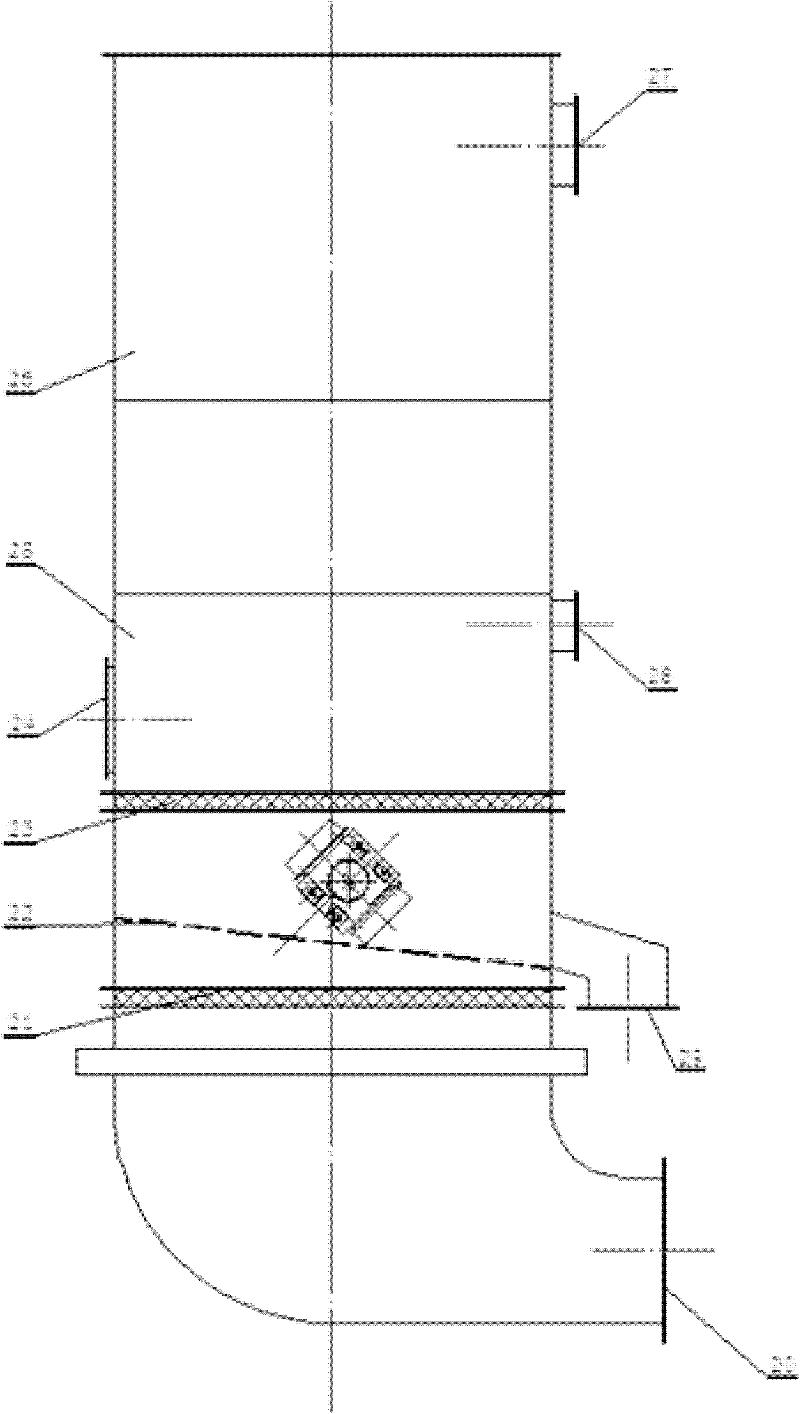

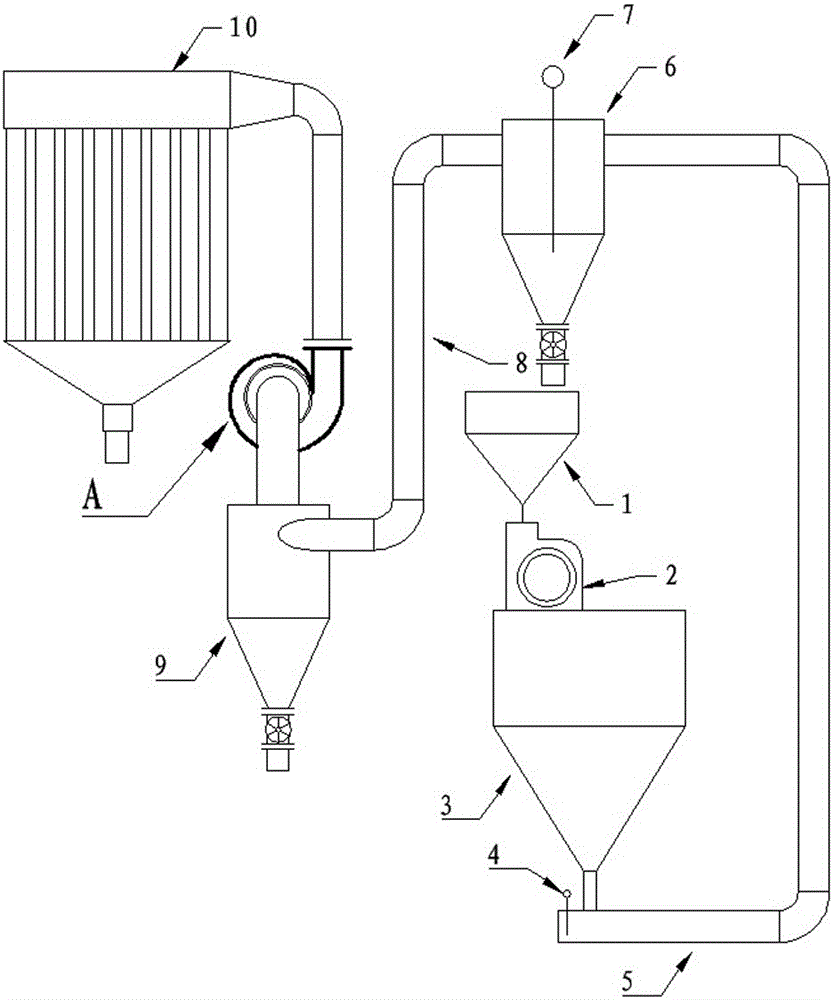

Fine grinding system and grinding method thereof

The invention relates to a fine grinding system and a grinding method thereof. The system is characterized by comprising pre-grinding equipment, fine grinding equipment, a material collector, a dust catcher and a draught fan, wherein the pre-grinding equipment is used for pre-grinding block materials to be grinded, so as to obtain granular grains of the materials to be grinded; the fine grinding equipment is used for further grinding the grains of the materials to be grinded, which are discharged from the pre-grinding equipment; a feeding opening of the material collector is connected with a discharging pipe of the fine grinding equipment through a pipeline and the lower part of the material collector is provided with a first material collection box; the upper part of the material collector is connected with an inlet of the dust catcher through the pipeline and the lower part of the dust catcher is provided with a second material collection box; and the draught fan is used for sequentially sucking the grains of the materials to be grinded into the material collector from the fine grinding equipment and then conveying the grains into the dust catcher. According to the fine grinding system and the grinding method thereof, provided by the invention, the materials are pre-grinded by the pre-grinding equipment and the grains are further grinded and separated by the fine grinding equipment; the grinded grains are collected by the material collector and then are de-dusted by the dust catcher; and therefore, the grinding efficiency is high and the recovery rate of dust is high.

Owner:舟山市金寿机械股份有限公司

Humidifying process for high-moisture charged coking coal

InactiveCN102676193AImprove humidity control performanceWell mixedDrying solid materials with heatCoke ovensLower gradeLow graded

The invention discloses a humidifying process for high-moisture charged coking coal. The process comprises the following steps of: pre-humidifying the high-moisture charged coking coal; sieving coal particles; smashing and separating large-particle coal; humidifying charged coking coal; recycling a low-grade heat source; and dedusting and pelletizing. The humidifying process has the advantages of high humidifying performance, large humidifying range, low energy consumption, low air pollution and convenience for maintaining and repairing.

Owner:WUXI YIEN TECH +1

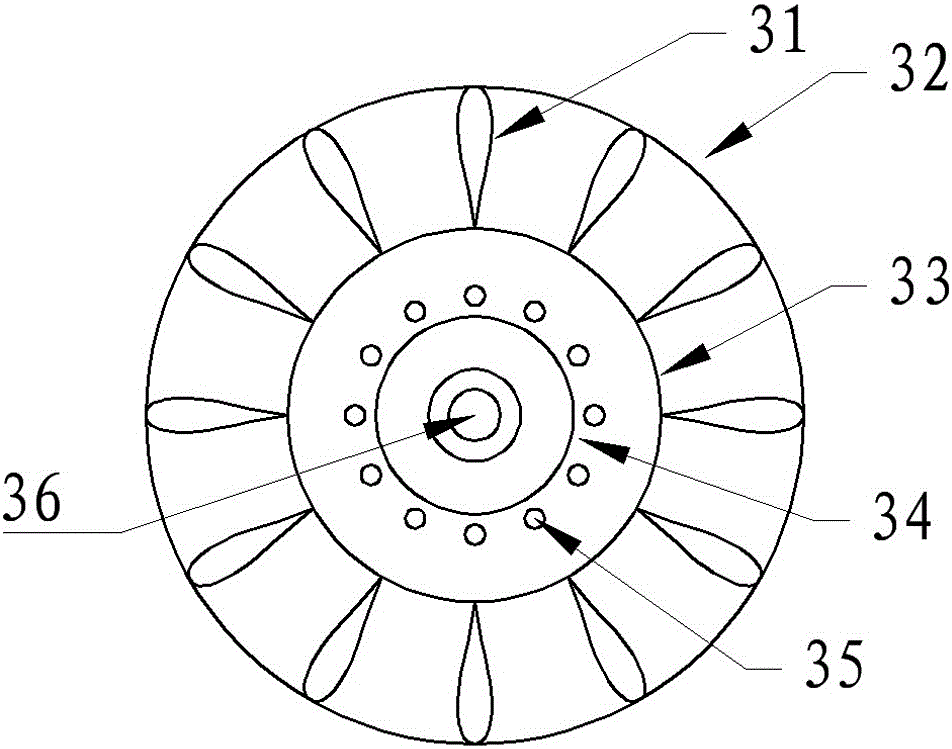

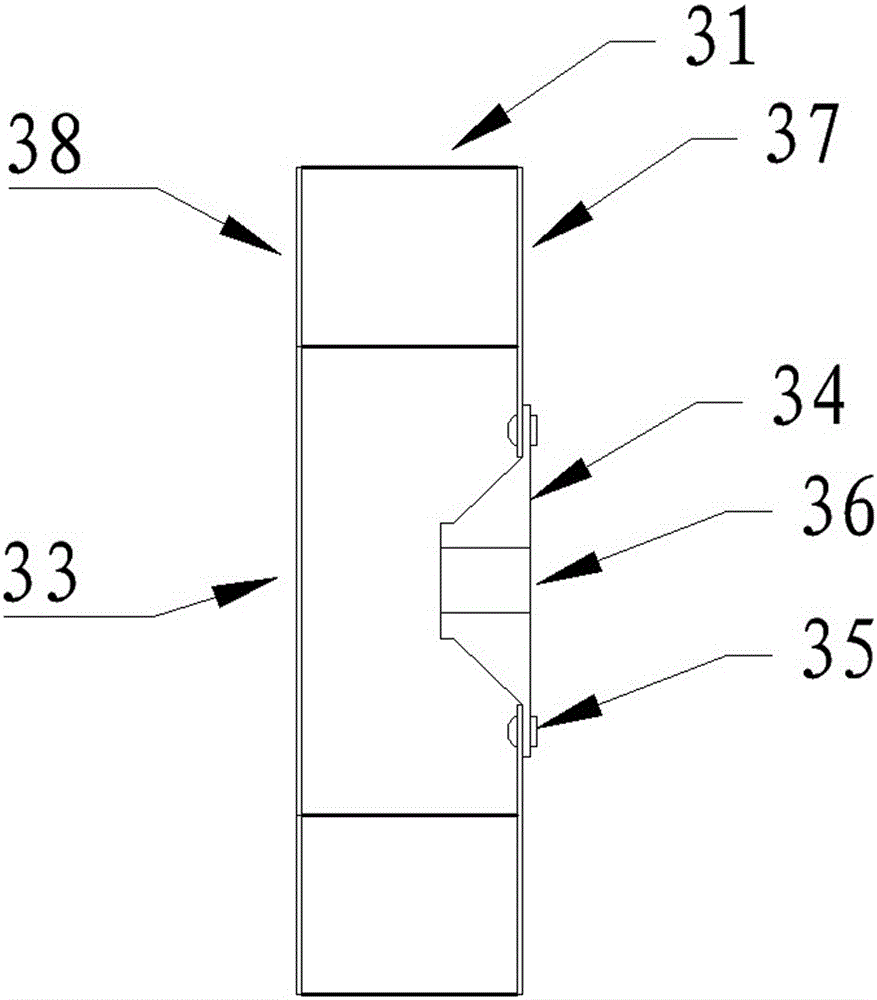

Air suction type grinder for polygonum cuspidatum

InactiveCN105013592AImprove rigidityImprove carrying capacityPump componentsVortex flow apparatusAir volumeInvolute

The invention discloses an air suction type grinder for polygonum cuspidatum. The air suction type grinder for the polygonum cuspidatum comprises a grinder body and an induced draft fan, wherein the discharging end of the grinder body is connected with the induced draft fan through a material storage case, air suction pipes and a cyclone separator; a ventilation door used for adjusting air volume is arranged on one of the air suction pipes; an impeller of the induced draft fan is of a structure with blades in a hollow wedge shape and a backboard in a dish shape; and the shape contour line of the induced draft fan is an involute. By means of the air suction type grinder for the polygonum cuspidatum, sorting of particles and cooling and temperature drop of the material are achieved in the pneumatic transmission process; the return and secondary grinding of the coarse particles are completed in one step, the qualified output of the material is achieved, and meanwhile dust capture is achieved; the timely and smooth discharging of the grinder is guaranteed by an air suction system, the material is prevented from being excessively ground, and electric power is saved; by means of the structure with the blades in the hollow wedge shape and the backboard in a dish shape, the real-time cleaning of dust on the impeller of the induced draft fan and the increase of the strength of the impeller of the draught fan are achieved; the stability is improved, and safety accidents caused by dust accumulation are effectively eradicated; and the application prospect is wide.

Owner:JISHOU UNIVERSITY

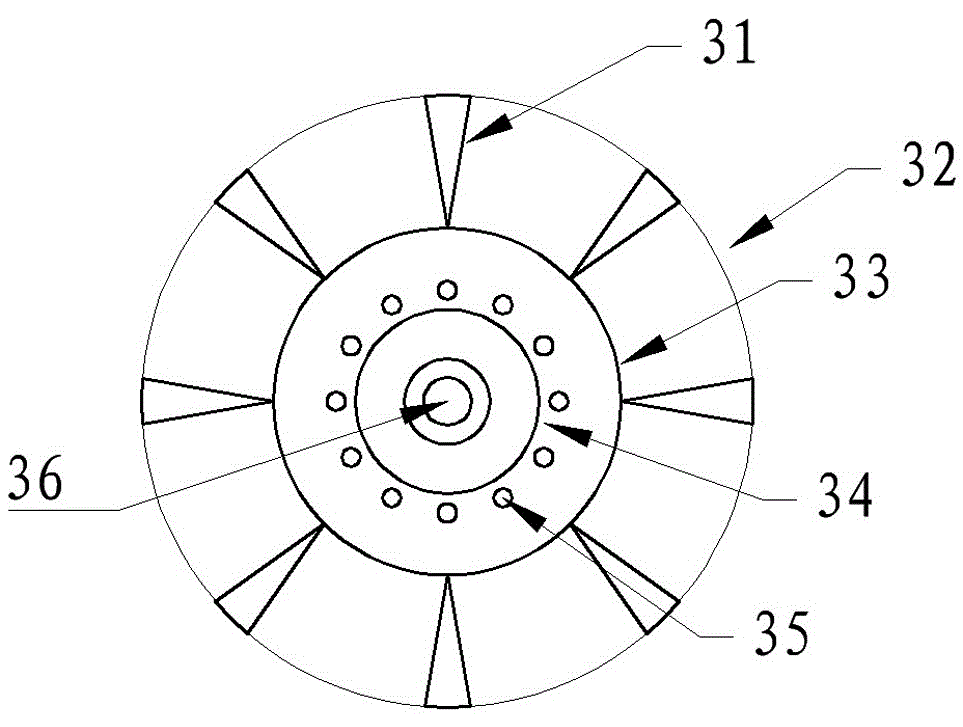

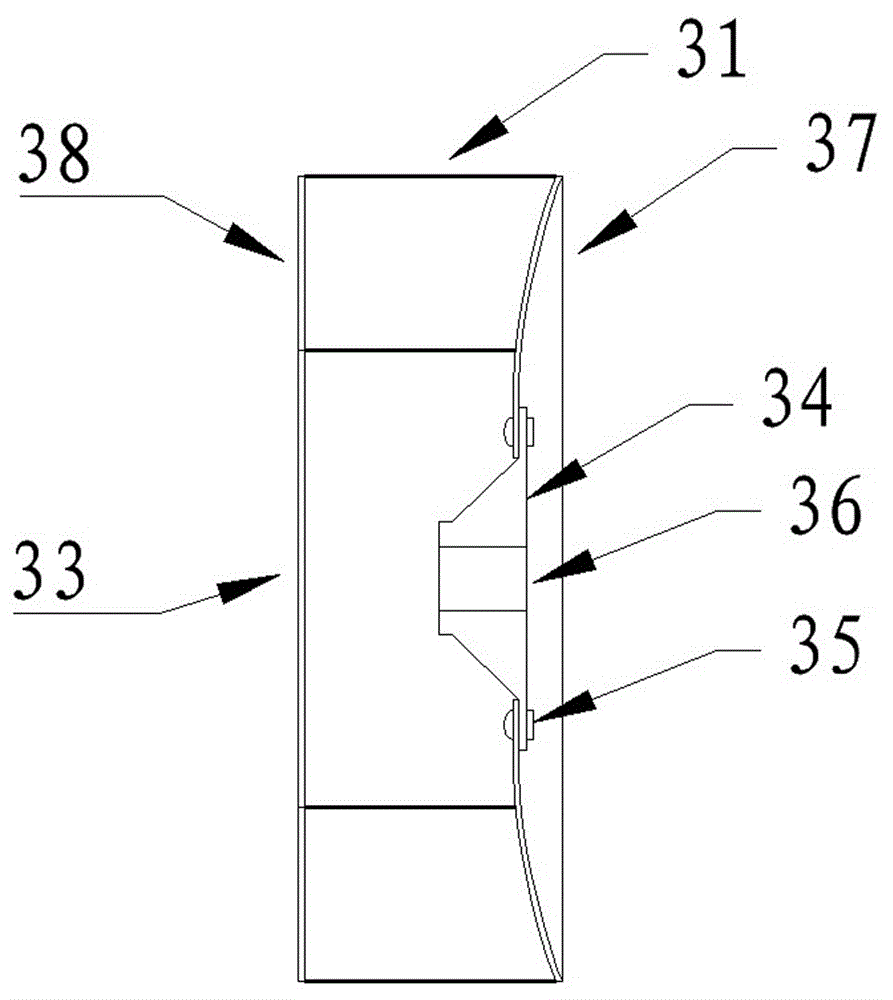

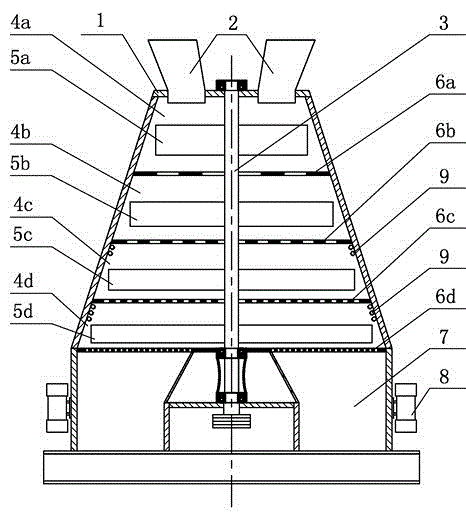

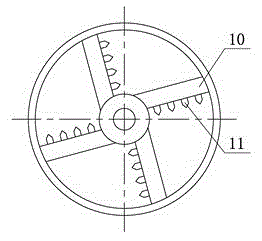

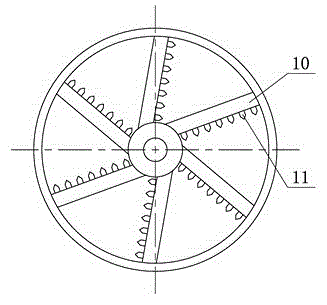

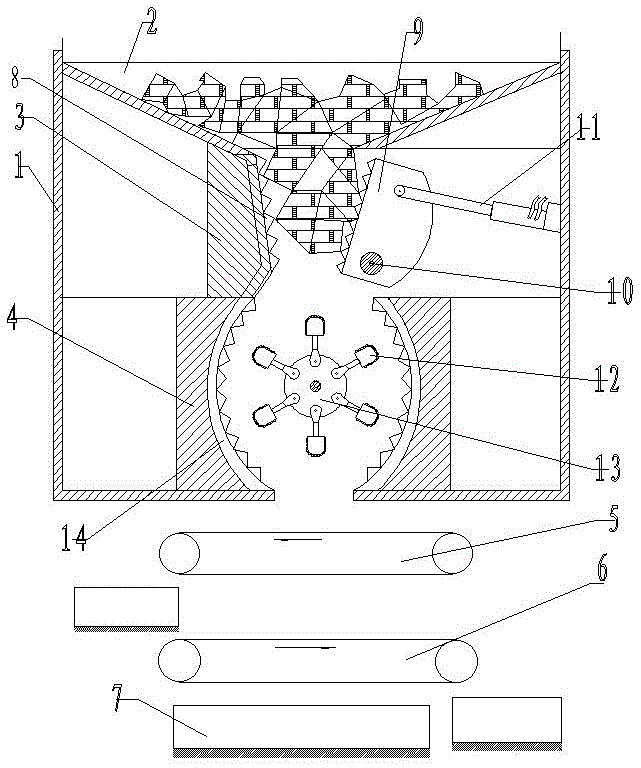

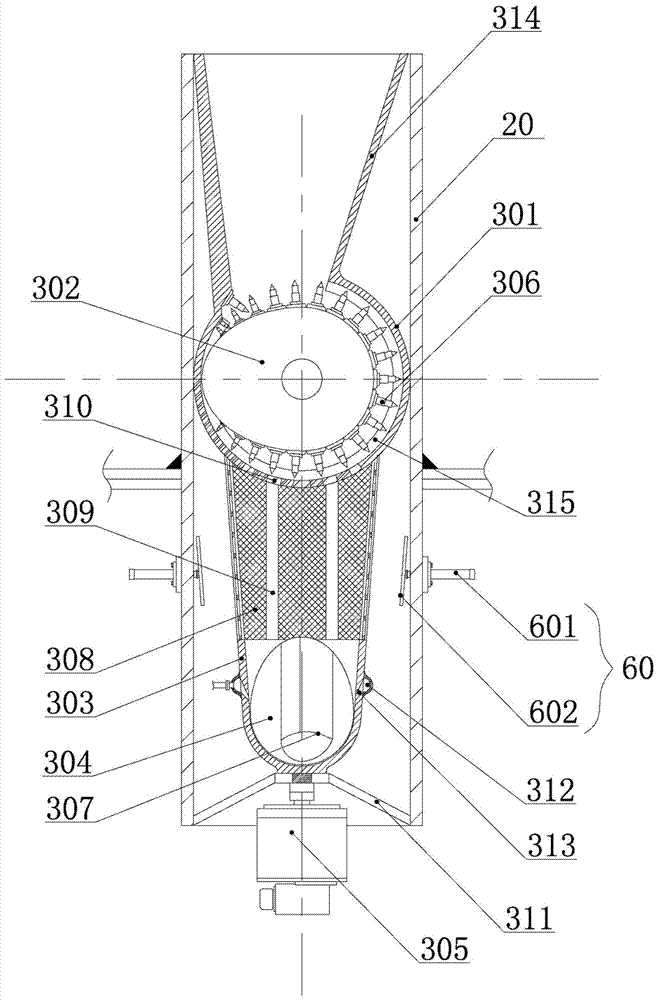

Vertical vibration grading crusher and crushing method

ActiveCN105013566AIncrease dissociationAvoid over crushingCleaning using liquidsGrain treatmentsCoalEngineering

The invention discloses a vertical vibration grading crusher and a crushing method, and is suitable for crushing middle coal selected during coal separation. The crusher adopts a vertical tapered structure. Four crushing chambers are arranged in the crusher, and each crushing chamber is provided with a crushing rotor adopting a wheel hub structure; the four rotors are connected through the same vertical shaft; a sieve plate is arranged under each crushing chamber; under the shearing, squeezing and impact of the crushing rotors, materials are crushed; after the materials in the last crushing chamber are sieved and crushed, the sieved materials enter the next crushing chamber to be further sieved and crushed, and then the sieved materials continue to be crushed and sieved; the final fine materials obtained after being crushed conforming to the requirement for particle size enter a material hopper through the lowest sieve plate; vibration exciters with the function of generating up-down vibration are arranged at the bottom of the crusher. The crusher is simple in structure, low in upper limit to the particle size of crushing, and can perform dry or wet vibration graded crushing on the materials; the materials meeting the requirement for particle size pass through the crusher in advance, so that the over crushing of middle coal is effectively avoided, and the coal separation of the middle coal after crushing is facilitated.

Owner:CHINA UNIV OF MINING & TECH

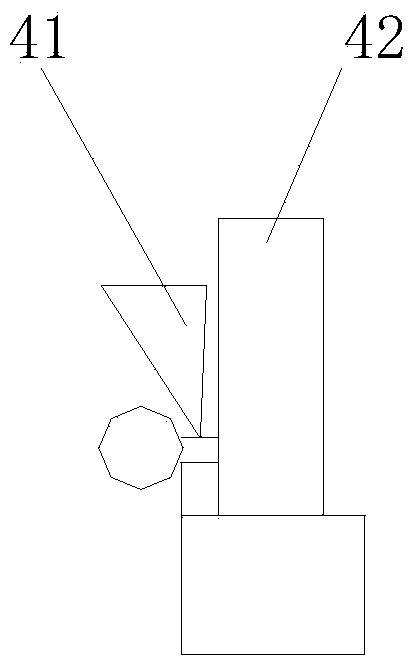

Cyclonic jet mill

The invention discloses a cyclonic jet mill. The jet mill mainly comprises a grader installed on a crushing box; the crushing box is provided with a crushing cavity which is driven by a power unit and is rotatably installed in the crushing box; the crushing cavity comprises an inner column which has a crushing space, an outer column is hermetically installed at the periphery of the inner column, an air flow channel which communicates with a compressed air source is arranged between the inner column and the outer column, an air flow nozzle is provided on the sidewall of the inner column and communicates with the air flow channel and the crushing space. The cyclonic jet mill provided in the invention overcomes the technical problems of formation of a dead space where air flow cannot reach in the crushing space and insufficient crushing of materials, has a reasonable design and is widely applied in ultrafine crushing of raw mineral materials, chemical raw material, heat sensitive substances and the like.

Owner:WEIFANG ZHENGYUAN POWDER ENG EQUIP

Multistage screening mechanism

PendingCN107282257AReduce the burden onReduce workloadDirt cleaningGrain treatmentsEngineeringMachining

The invention relates to the technical field of material crushing, in particular to a multistage screening mechanism. The multistage screening mechanism comprises a first-stage primary crushing unit and a fine crushing unit arranged on the downstream part of the primary crushing unit, wherein the primary crushing unit and the fine crushing unit each comprise a screening structure which is used for screening out materials with a preset grain diameter so as to avoid over crushing of the materials in the units. According to the multistage screening mechanism, the materials with the preset grain diameter can be screened out of the current crushing units timely in the crushing process and can be prevented from being crushed continuously, and therefore over crushing is avoided, and the machining workload is reduced.

Owner:NENGCHENG GRP

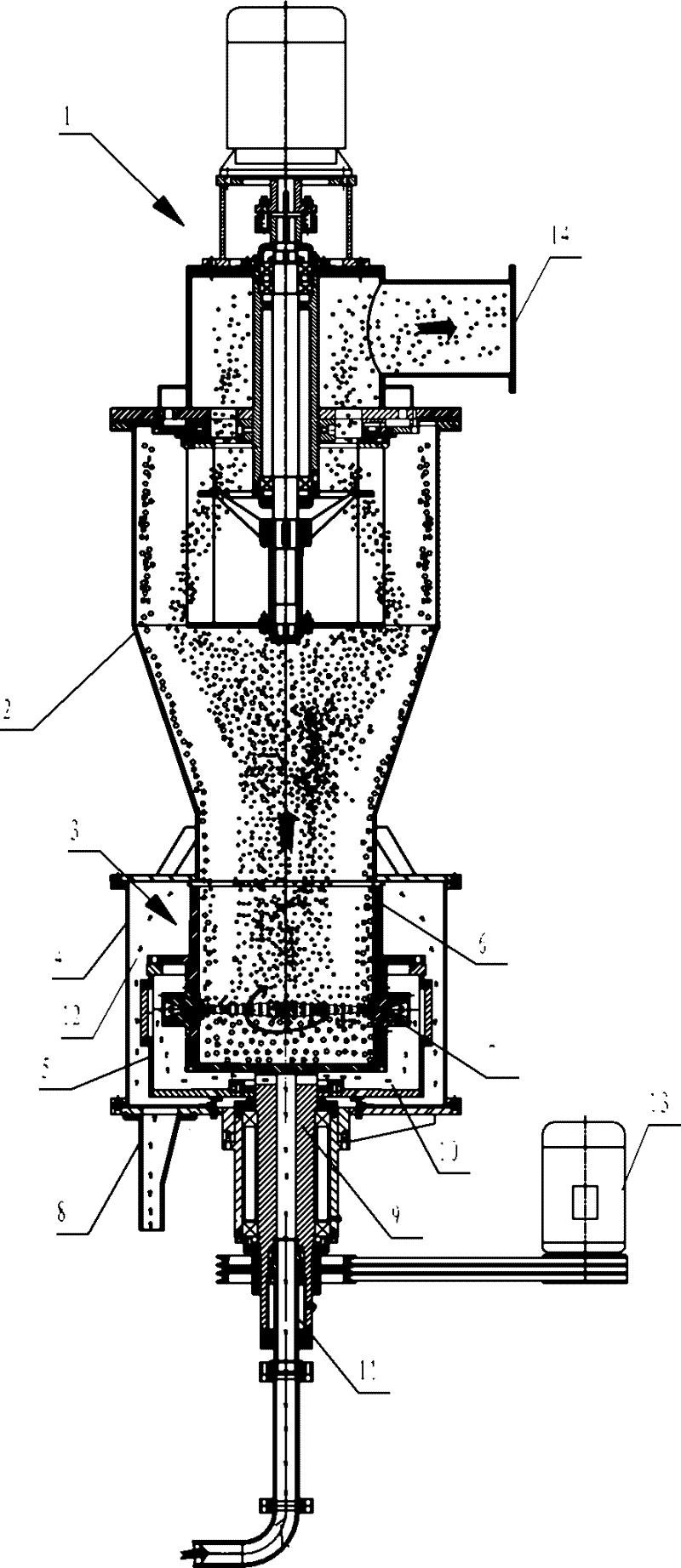

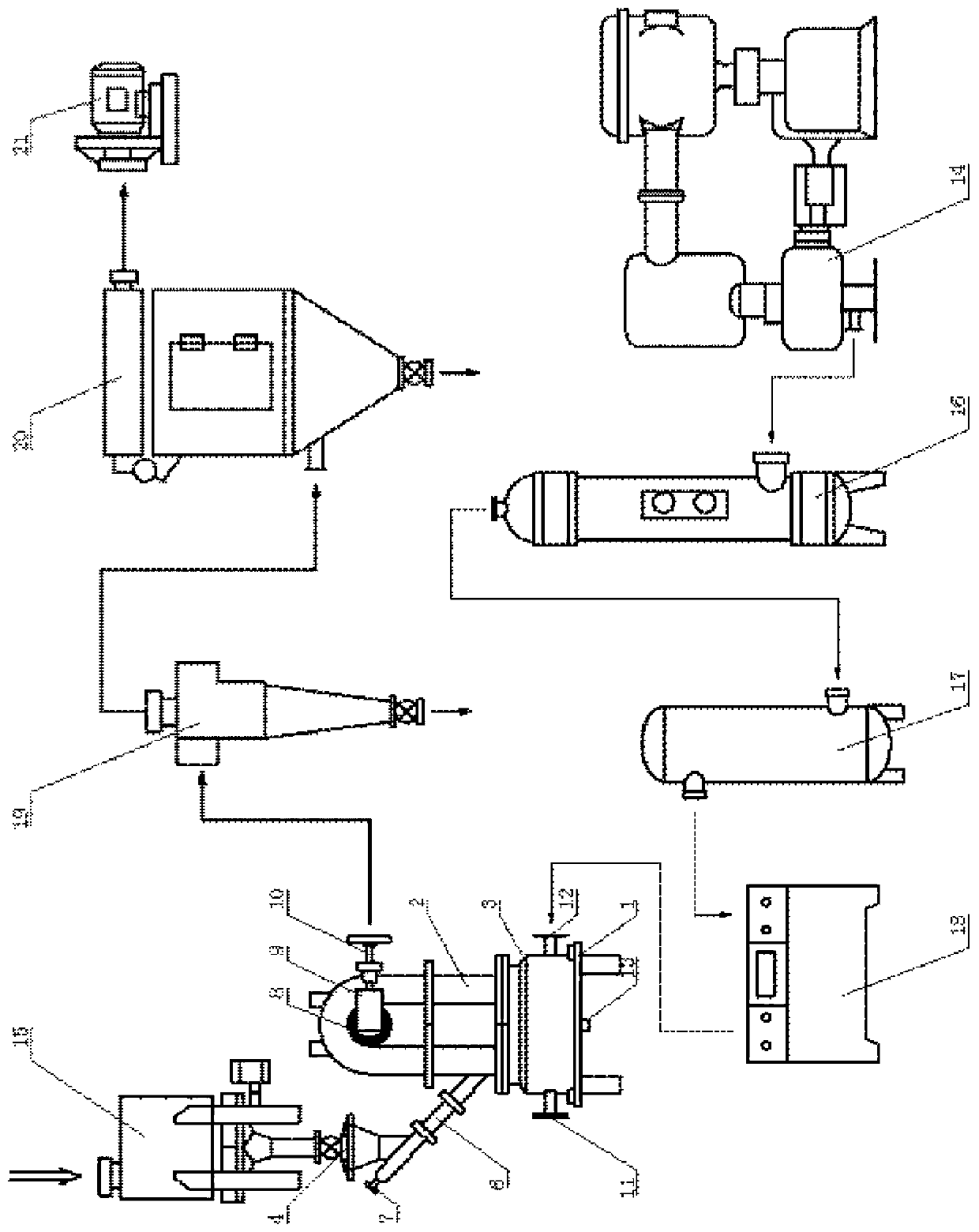

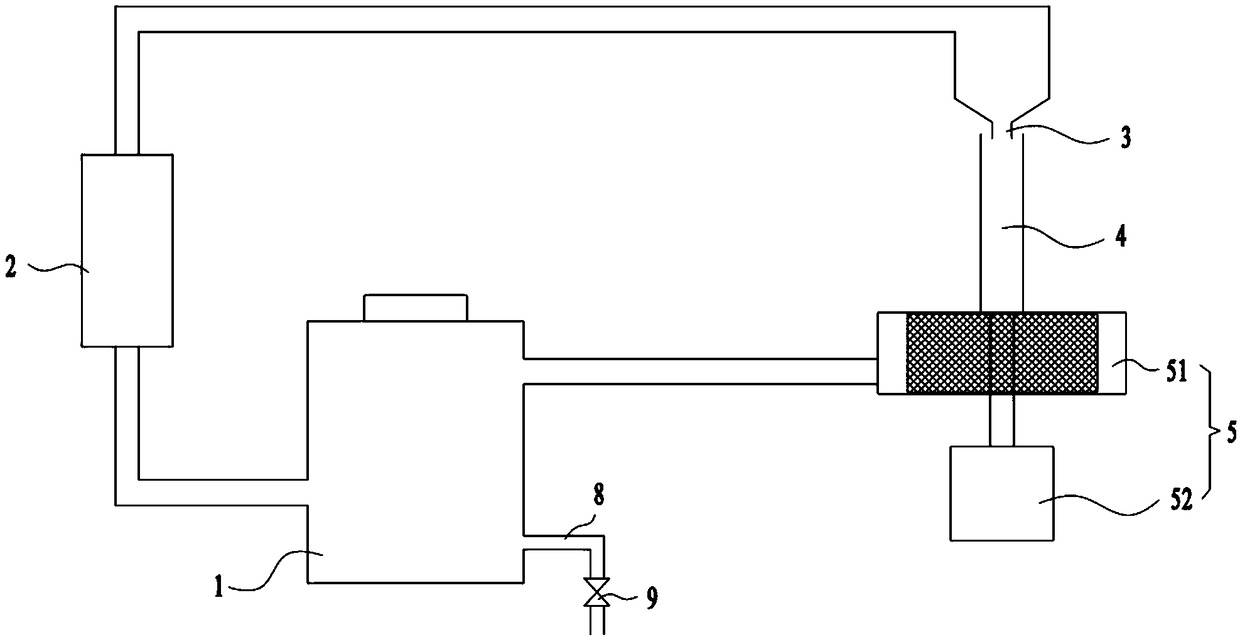

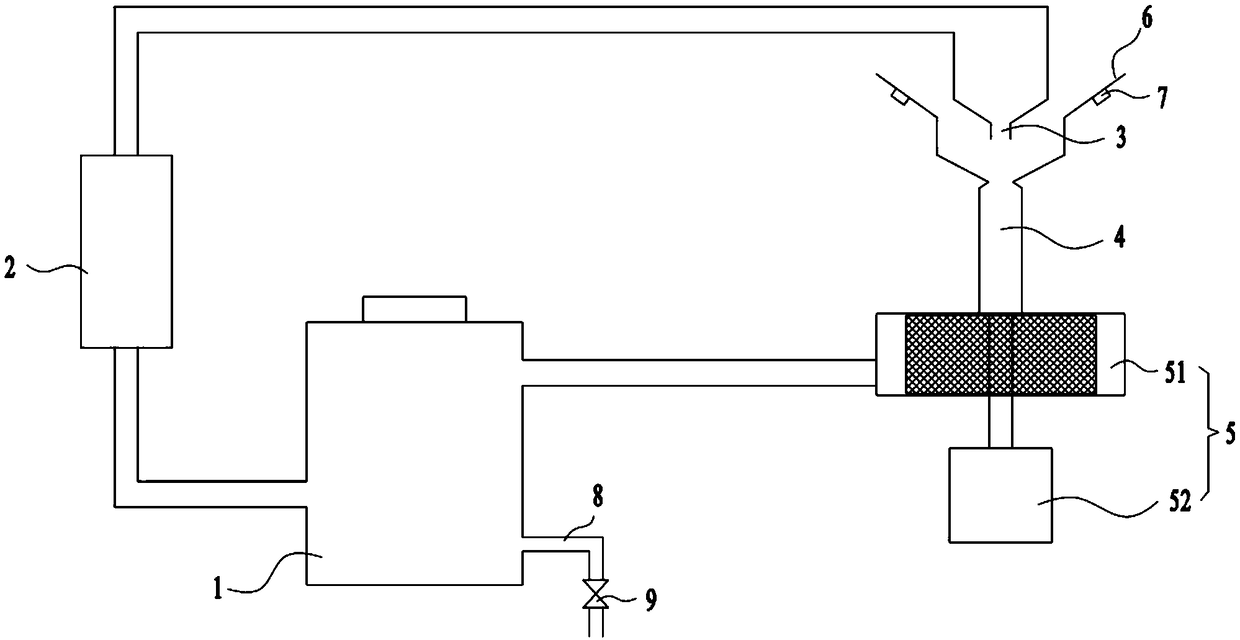

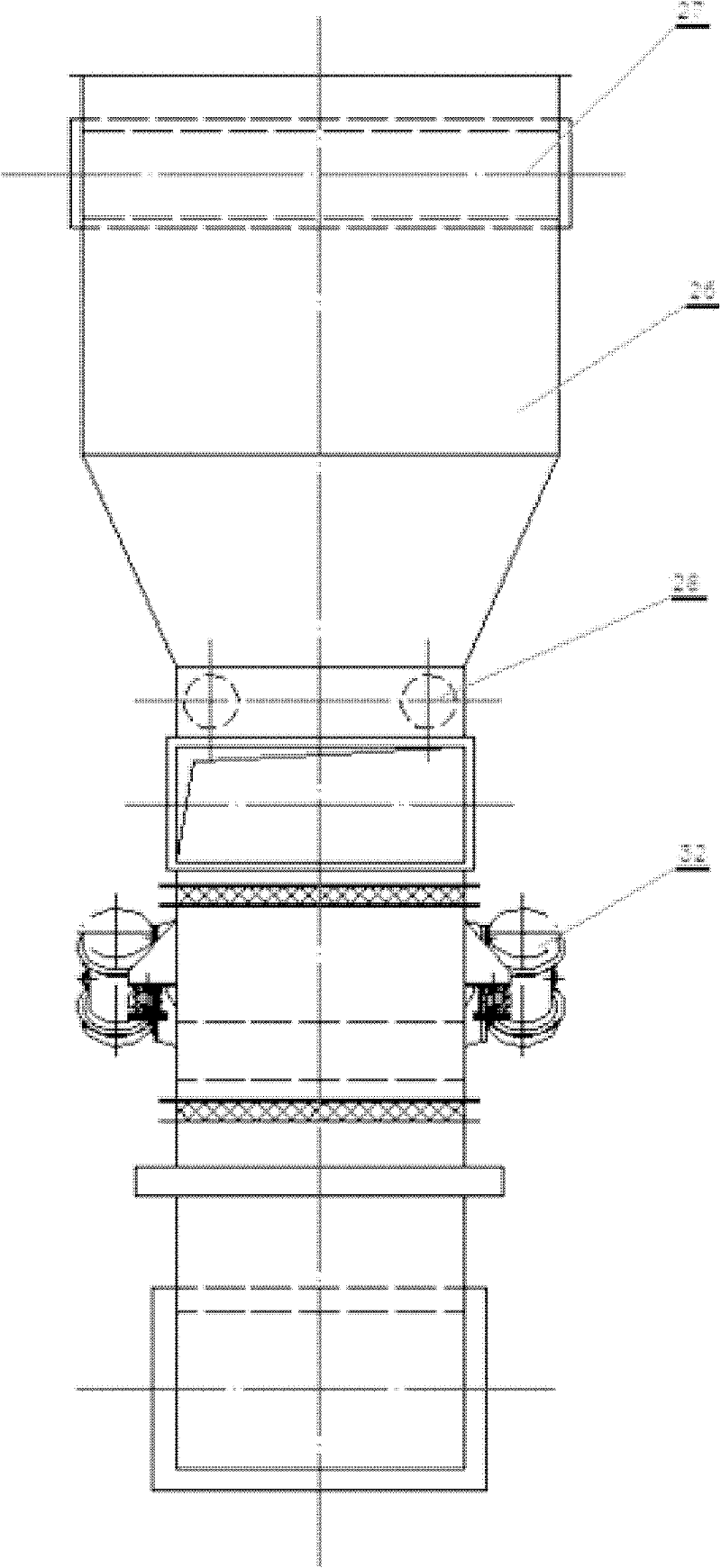

Circulating type jet mill and milling system thereof

InactiveCN102836766AIncrease concentrationIncrease productionGrain treatmentsEngineeringAir compressor

The invention relates to a milling device and system, specifically relates to a circulating type jet mill with convenience in use, high classifying precision and good milling effect, and relates to a milling system matched with the circulating type jet mill. The circulating type jet mill provided by the invention comprises a frame (1), a milling chamber (2) and a compressing air reservoir (3), wherein the milling chamber (2) is arranged on the frame (1); the compressing air reservoir (3) is connected with the lower part of the milling chamber (2); the milling chamber (2) is of annular oval shape; a classifying device is arranged on the upper part of the milling chamber (2); a feeding port (4) and a plurality of milling nozzles (5) are arranged on the lower part of the milling chamber (2); air inlet ends of the milling nozzles (5) are communicated with the compressing air reservoir (3); and air outlet ends of the milling nozzles (5) are respectively in tangential connection with the circles on the lower part of the milling chamber (2). The milling system provided by the invention comprises any circulating type jet mill, a product separating device and an air compressor (14), wherein the product separating device is connected with the outlet end of the classifying device and the air compressor (14) is connected with the compressing air reservoir (3).

Owner:计伟

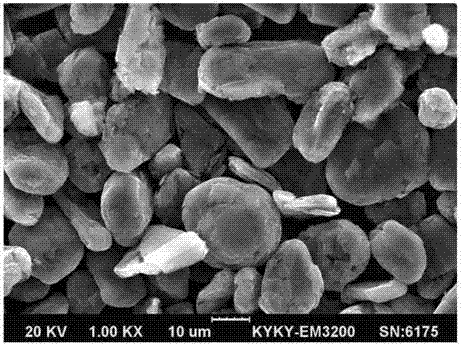

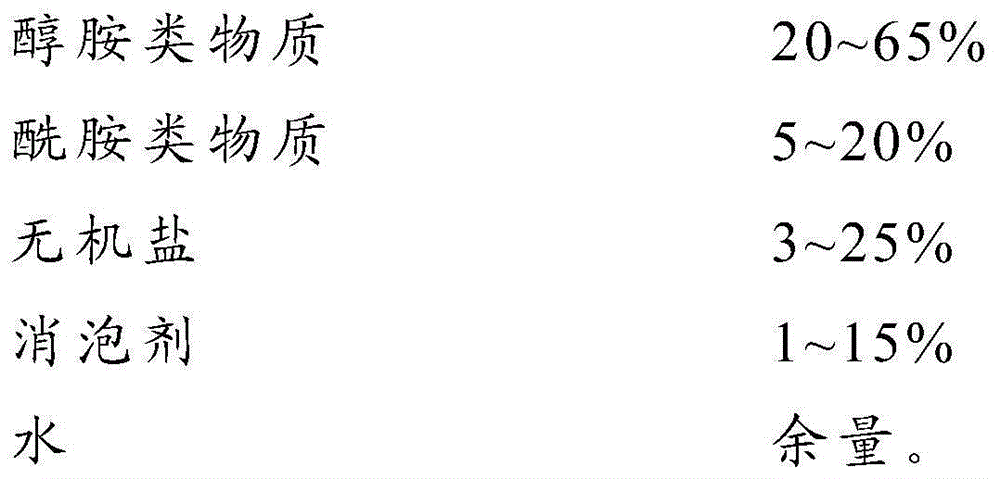

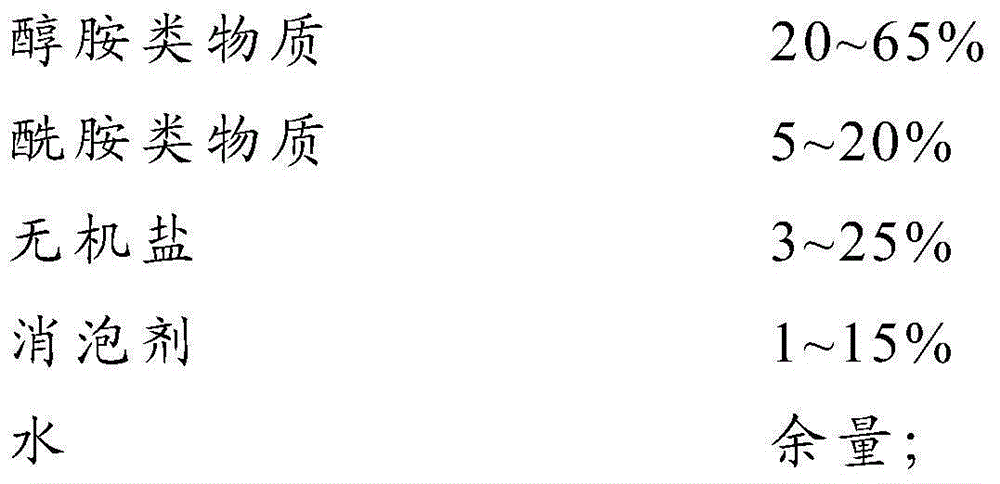

Boron carbide accurate grinding aid and use method thereof

ActiveCN105107609AWide variety of sourcesEasy to prepareOther chemical processesGrain treatmentsInorganic saltsBoron carbide

The invention provides a boron carbide accurate grinding aid and a use method thereof. The accurate grinding aid is prepared by mixing an alcamines substance, an amide substance, inorganic salt, a defoaming agent and any parts of water. The boron carbide accurate grinding aid is added while accurate grinding, can improve slid content of slurry and ore grinding efficiency and enables particle size of the boron carbide to be distributed in a concentration manner.

Owner:中硼科技(牡丹江)有限公司

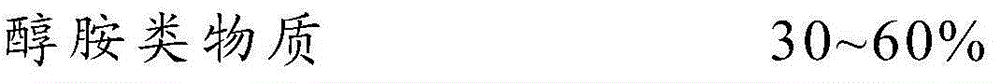

Preparation method of wheat whole wheat flour

InactiveCN110013903AHigh densityImprove crushing efficiencyFood preservationFood dryingWholemeal flourWater content

The invention discloses a preparation method of wheat whole wheat flour. The preparation method of the wheat whole wheat flour comprises the following steps that 1) grinding is performed to obtain non-flour components of wheat bran and wheat germ with part of endosperm and flour; and 2) the non-flour components undergo micronization treatment and then are mixed with the flour components to preparethe whole wheat flour. According to the preparation method, through microwave drying, the water content of the non-flour components is reduced, the enzyme activity of the non-flour components are inactivated and reduced, the easy-to-crush property of the wheat bran is improved, the micronization efficiency and stability of the non-flour components are improved, the micronization energy consumption of the non-flour components is reduced, and the shelf life is prolonged; and meanwhile, through the process that the wheat bran, the wheat germ and the endosperm are properly separated and then micronization is performed, materials needing to be micronized are reduced, the preparation energy consumption of whole wheat flour is further reduced, excessive crushing of the endosperm is avoided, thenatural structure of the protein and the starch is kept, and the basis of the quality of the whole wheat product is laid.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

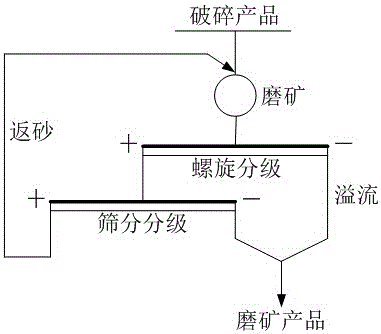

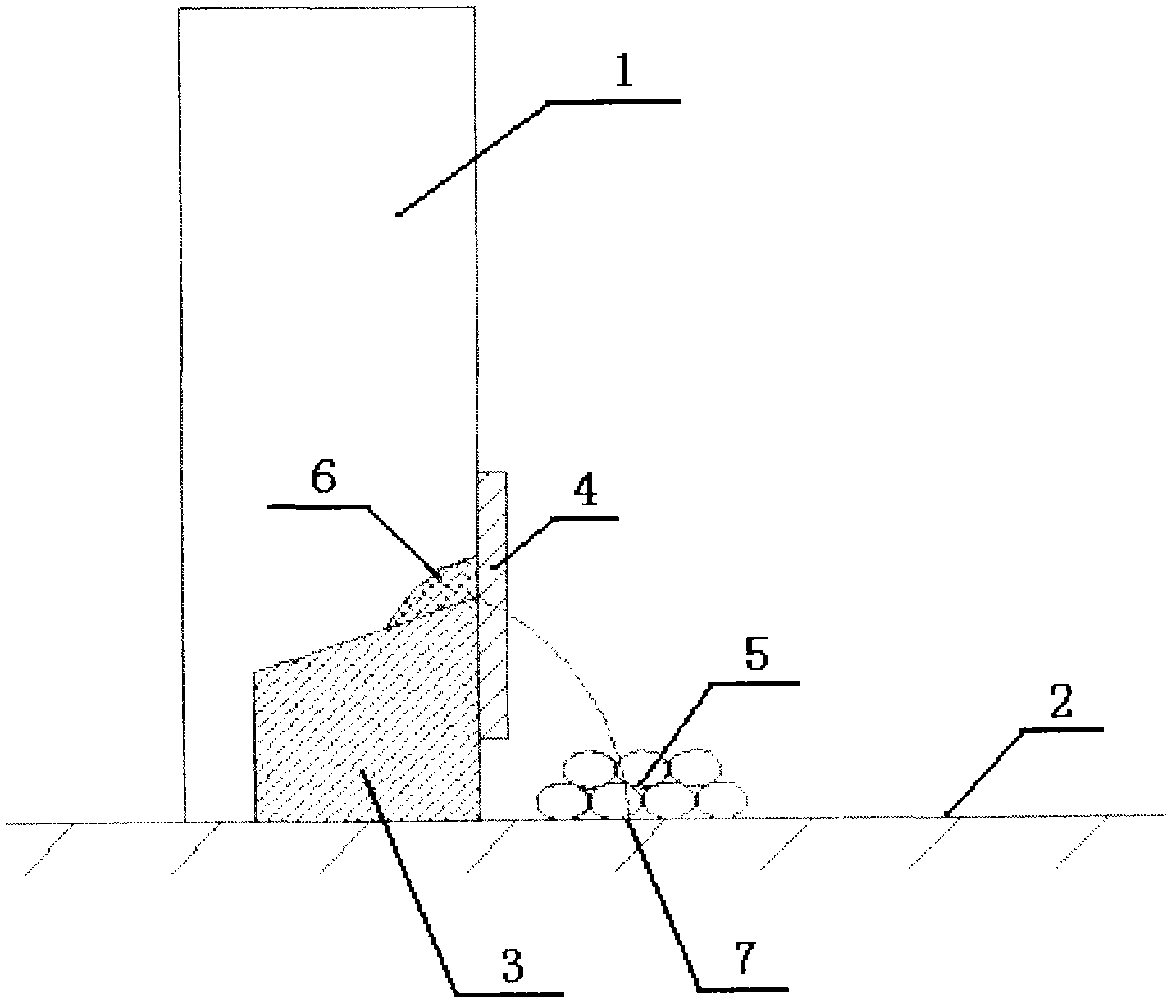

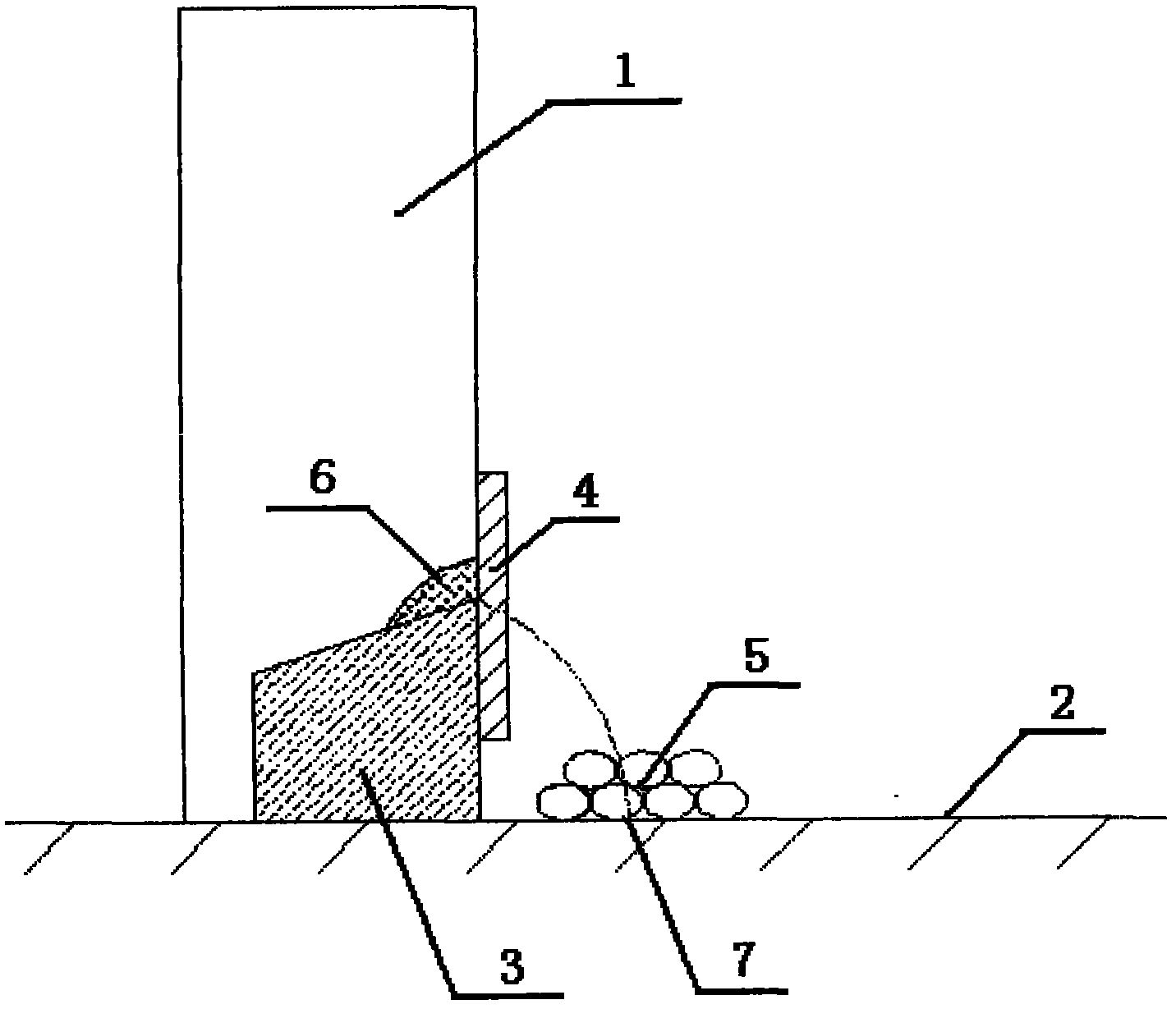

Closed circuit ore grinding classification method

InactiveCN106391298AOvercoming the problem of fine-grained heavy minerals entrained in sand returnAvoid over crushingSievingScreeningMineral SourcesClassification methods

The invention discloses a closed circuit ore grinding classification method and belongs to the field of mineral resource exploitation. The method comprises the steps of feeding a qualified ore grinding raw material into ore grinding equipment, and carrying out ore grinding to produce ore pulp; feeding the produced ore pulp into a spiral classifier, and treating by using the spiral classifier to produce fine particle overflow and coarse particle sand return; enabling the produced overflow to directly enter subsequent production, feeding the produced coarse particle sand return into sieving equipment to sieve and classify to produce undersize fine particles and oversize coarse particles; and enabling the undersize fine particles and the produced overflow to simultaneously enter subsequent production, and returning the oversize coarse particles serving as final sand return to a grinding machine to regrind. The method disclosed by the invention is easily realized on the existing basis, is economic and reasonable in technology and has the characteristics of simple process and high benefit.

Owner:KUNMING UNIV OF SCI & TECH

Multi-stage smashing crusher with screening function

ActiveCN106076583AGood continuous crushingUniform particle sizeGrain treatmentsCoal briquetteGranularity

The invention relates to a multi-stage smashing crusher with a screening function. A collecting tank is arranged on the upper portion of a body of the crusher, a coal briquette outlet in the collecting tank is connected with a first-stage crusher, and coal briquettes directly enter the first-stage crusher to be crushed; a second-stage crusher is arranged below the first-stage crusher, and the coal briquettes crushed by the first-stage crusher enter the second-stage crusher in a natural leakage manner to be further crushed in the second-stage crusher; a large-particle coal briquette screener is arranged below a coal outlet of the second-stage crusher, a middle-particle coal briquette screener is arranged below the large-particle coal briquette screener, and the coal briquettes leaking from the large-particle coal briquette screener enter the middle-particle coal briquette screener; and a small-particle coal briquette collecting tank is arranged below the middle-particle coal briquette screener. Coal briquettes of different sizes can be crushed through the multi-stage smashing crusher, and continuous crushing performance is good; and the granularity of the crushed products is uniform, over crushing is avoided, and overall disassembly, assembly and transportation are convenient.

Owner:江苏亚飞炭素有限公司

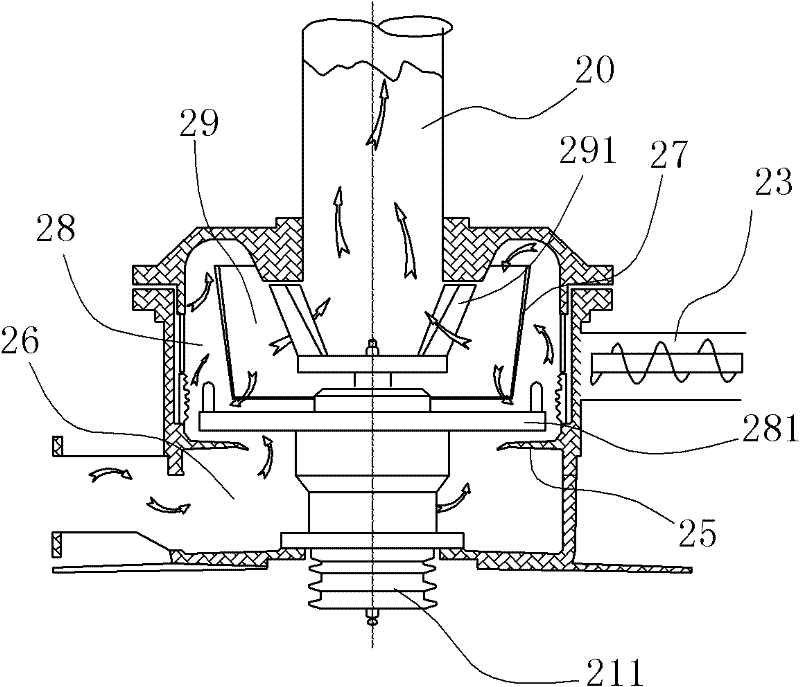

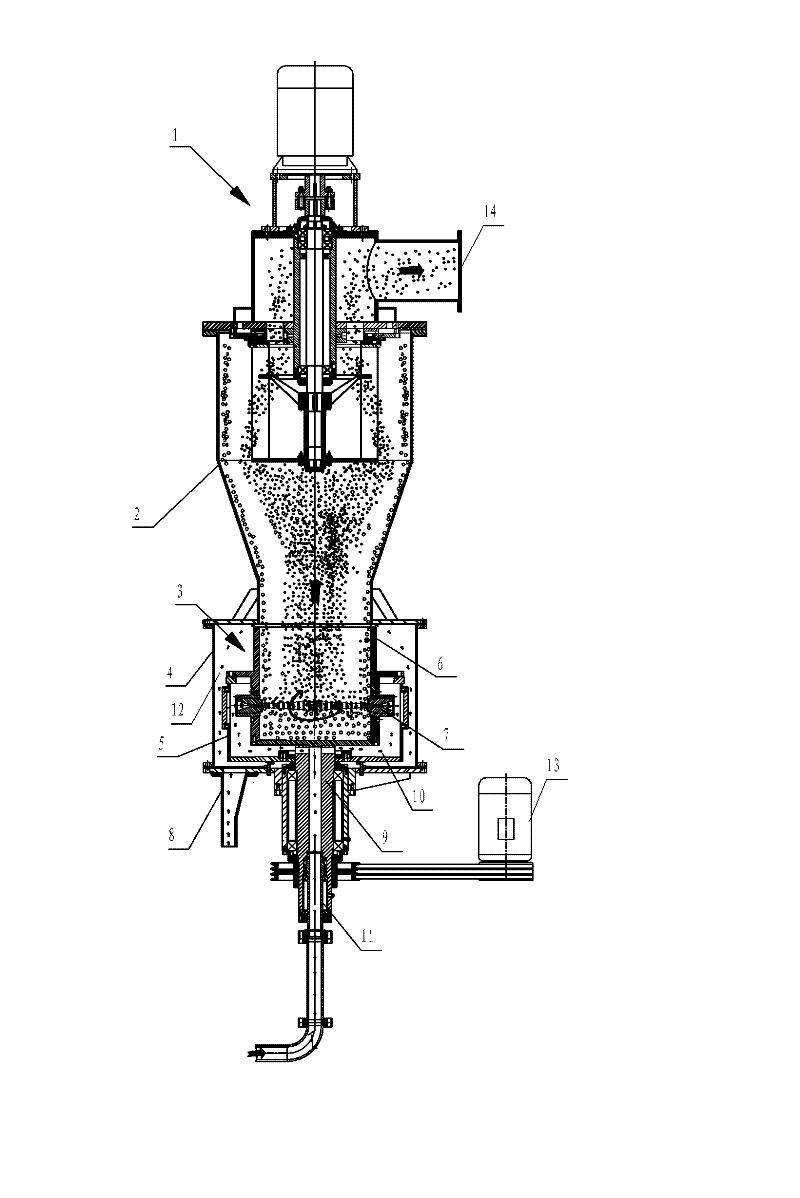

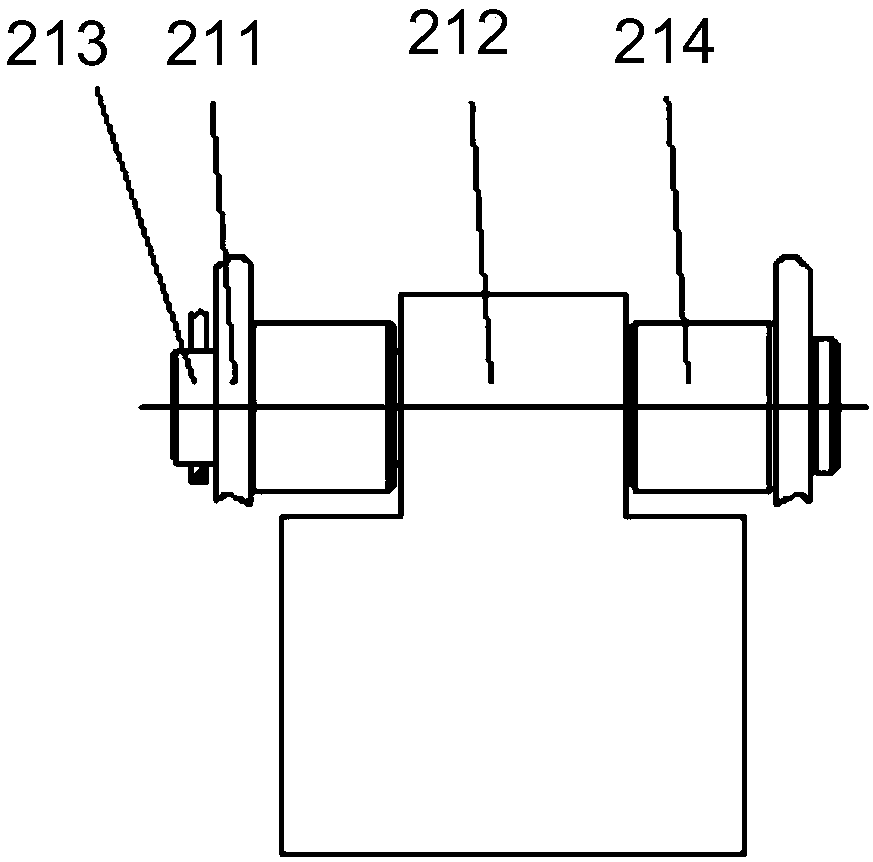

Kitchen waste crushing, pulping and screening integrated treatment equipment

PendingCN109499676ARealization of crushing and pulpingAvoid over crushingGrain treatmentsWaste management

The invention provides kitchen waste crushing, pulping and screening integrated treatment equipment. The equipment comprises a shell, a feeding conveying section, a crushing section and a sundry screening-out section, wherein the feeding conveying section and the crushing section are arranged in the shell and are sequentially connected through the same rotating shaft, the sundry screening-out section is arranged behind the crushing section, under the rotating action of the rotating shaft, the feeding conveying section conveys kitchen waste to the crushing section, moreover, the crushing section performs crushing and pulping on the kitchen waste, the sundry screening-out section screens out sundries in the crushed kitchen waste from the shell. According to the kitchen waste crushing, pulping and screening integrated treatment equipment, the three-section portions are adopted for treatment to realize the function combination; modes of using a hole-free plate in cooperation and arrangingcrushing hammer heads and crushing hammer sheets in an alternate manner are adopted at the front end of the crushing and pulping section, so that crushing and pulping of the materials are realized; amode of using a mesh plate and crushing hammer heads in cooperation is adopted at the rear end of the crushing and pulping section, so that crushing and screening of the materials are realized; all the hammer heads and the hammer sheets are connected in a movable mode, so that excessive crushing of the hammer heads on the materials is avoided, and meanwhile, the damage to equipment is reduced.

Owner:EVERBRIGHT ENVIRONMENTAL TECH EQUIP CHANGZHOU

Grinding machining system

InactiveCN101999742AReduce washoutSeparation in timeFeeding-stuffGrain treatmentsEngineeringMachining system

The invention discloses a grinding machining system in the field of feed machinery. The system comprises a raw material sieve, a sieve-free grinder, a settling chamber, an auger conveyor, a lifter, a powder sieve and a powder collecting bin. The settling chamber is positioned below the grinder; a discharging port of the grinder is connected to one end of the settling chamber; the other end of the settling chamber is connected with an air inlet of a pulse dust catcher; an air outlet of the pulse dust catcher is connected with an inlet of a fan; the auger conveyor is positioned under the settling chamber; a discharging end of the auger conveyor is connected with the lifter; an oversize product outlet of the raw material sieve is conveyed to a feeding port of the sieve-free grinder through a pipeline; an upper-end discharging port of the lifter is connected with a feeding port of the powder sieve; an undersize product outlet of the powder sieve is connected with an inlet of the powder collecting bin; and an oversize product outlet of the powder sieve is conveyed to the feeding port of the sieve-free grinder through the pipeline. The system separates grinding from screening, is high in screening efficiency, is not influenced by a material circulation layer, can effectively reduce the overgrinding phenomenon, improves capacity and saves energy.

Owner:JIANGSU MUYANG GRP CO LTD

Solid-liquid mixing equipment and solid-liquid mixing method

InactiveCN108786509AUniform treatmentAvoid over crushingFlow mixersTransportation and packagingSpray nozzleEngineering

The invention discloses solid-liquid mixing equipment. The solid-liquid mixing equipment comprises a storage tank, a pump body, a spray nozzle, a material receiving pipe and a shearing device, whereina material inlet of the pump body is connected with the storage tank; the tail part of the spray nozzle is connected with a material outlet of the pump body; one end of the material receiving pipe islocated in a feed liquid spraying direction of the spray nozzle; a material inlet of the shearing device is connected to the other end of the material receiving pipe, and a material outlet of the shearing device is connected to the storage tank. The invention also discloses a solid-liquid mixing method. The solid-liquid mixing method comprises the following steps: adding to-be-mixed feed liquid in the storage tank; spraying the feed liquid from the spray nozzle under the driving of the pump body; enabling the feed liquid to enter the shearing device through the material receiving pipe, and enabling the feed liquid to flow into the storage tank after shearing and mixing. According to the solid-liquid mixing equipment disclosed by the invention, the storage tank is separated from the shearing device, solid-liquid mixed materials can be uniformly treated, a phenomenon of doping of large particles cannot occur, and particles can also be prevented from being excessively smashed; through the arrangement of the spray nozzle, ejected fluid is enabled to quickly enter the material receiving pipe, so that negative pressure is formed at the periphery of a pipe opening of the material receiving pipe, and materials can be sucked into the material receiving pipe.

Owner:哈尔滨万鑫石墨谷科技有限公司

Blasting and dismantling special local protecting method of building

The invention relates to a blasting and dismantling special local protecting method of a building. The protecting method comprises the following steps: first, determining a special position of the building to be blasted and dismantled and a collapse touchdown place of the special position according to a blasting notch, a collapse way and a collapse range of a blasting and dismantling design of the building; and then, according to a blasting design, punching a hole by adopting a routine method and equipment, carrying out blasting charge, blocking a blast hole and connecting a detonating network; and finally, binding or putting a flexible material on the special position; or paving a soft material at the collapse touchdown place; or paving the soft material at the collapse touchdown place while binding or putting the flexible material on the special position. By using the blasting and dismantling special local protecting method of the building, not only can the touchdown flyrock of the collapsing building be eliminated, the touchdown shock be decreased and the personnel injury and death and the property loss which are possibly caused be avoided, but also the interference of a material and labor consumption to production, life and traffic and the influence on the environment are also avoided, and the job progress is quickened.

Owner:LANZHOU UNIVERSITY

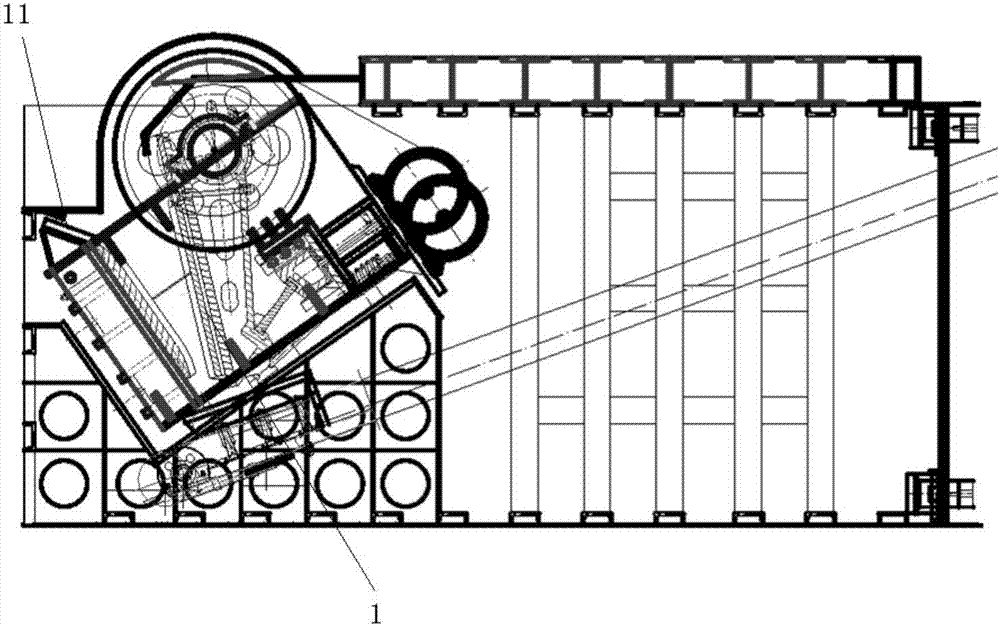

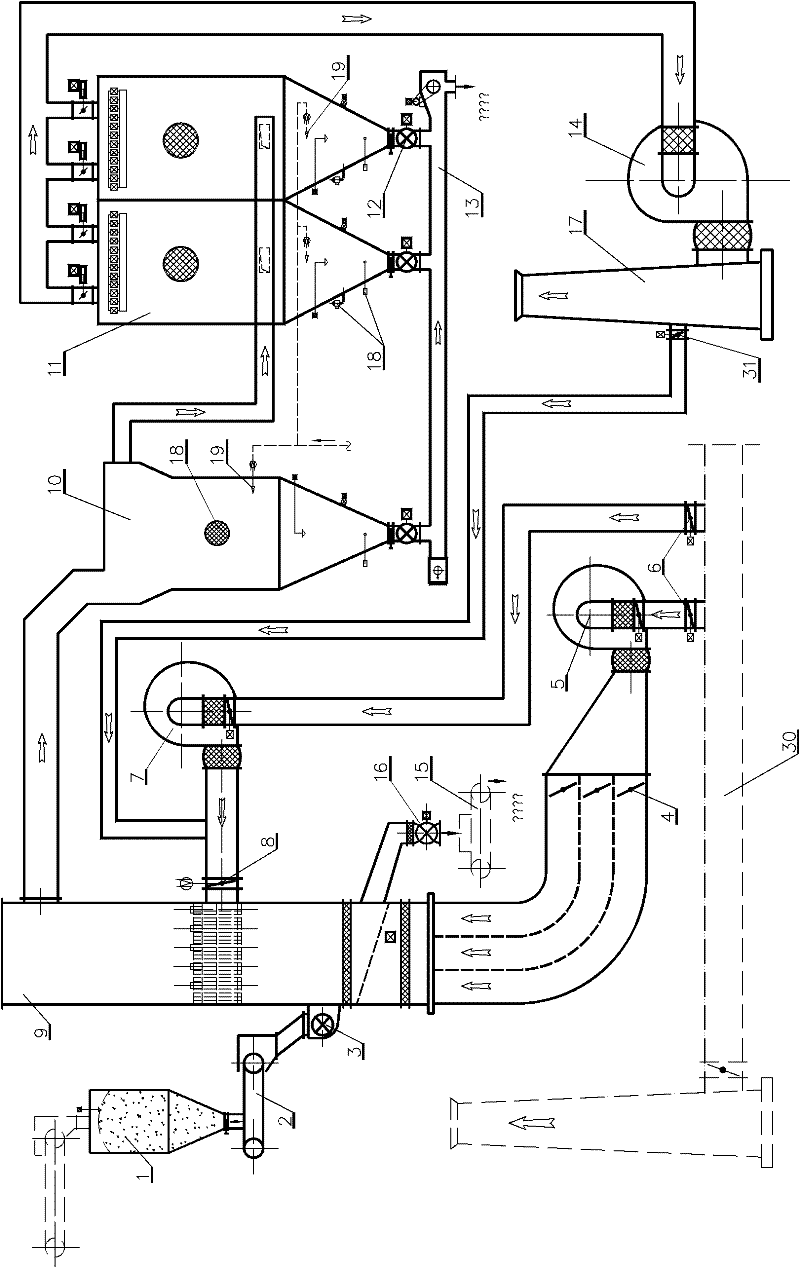

Full-boiling vibration propelled coal moisture control and grading integrated equipment

ActiveCN102304377AImprove energy savingAchieve particle size classificationDrying solid materials with heatCoke ovensFixed bedMoisture

The invention relates to full-boiling vibration propelled coal moisture control and grading integrated equipment, which comprises a primary air inlet section, a secondary air inlet section, and a vibration distribution plate, wherein the primary air inlet section is positioned below the vibration distribution plate, and a sedimentation separation area is positioned in an area above the vibration distribution plate; the vibration distribution plate has an obliquely arranged fluidized bed structure; the top airflow outlet of a grader is connected with a fine particle separation device; the outlet of the fine particle separation device is connected with the inlet of a fine particle recycling device; the upper part of the fine particle recycling device is communicated with a smoke exhaust fanthrough a connecting pipeline; and the smoke exhaust fan is connected with a chimney. Coke oven flue gas is taken as a heat medium; and according to a characteristic that raw material coal has high heat and mass transfer efficiency in a full-boiling fluidized state and low heat and mass transfer efficiency in a fixed bed and half-boiling fluidized state, a coal material can be subjected to moisture control uniformly and efficiently, and can be efficiently graded.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC +1

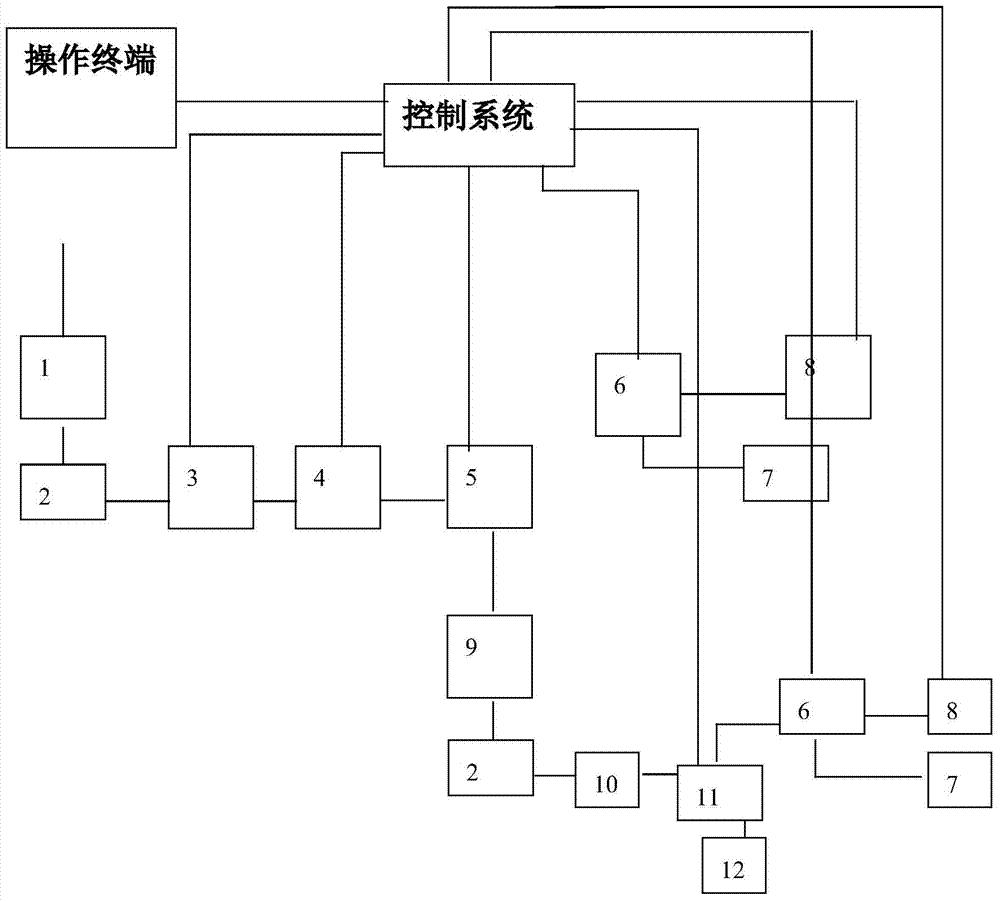

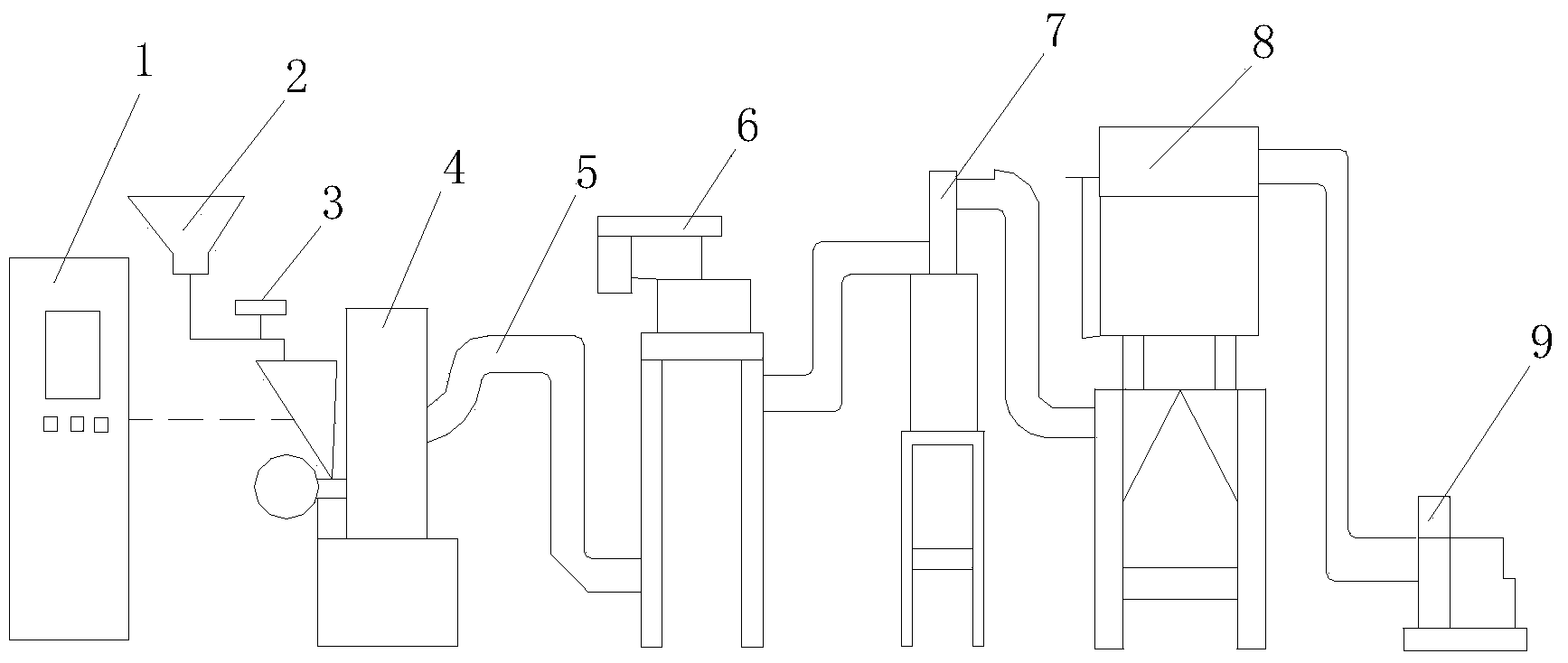

Energy-saving type smash grading device

The invention discloses an energy-saving type smash grading device. The energy-saving type smash grading device comprises an electric control cabinet, a feed bin, an iron separation, an ultrafine grinder, pipelines, an ultrafine grader, a cyclone dust extractor, a dust collector and a fan, wherein the electric control cabinet is arranged on one side of the feed bin, the iron separator is arranged at the other side of the lower part of the feed bin, the ultrafine grinder is arranged blow the iron separator, and the ultrafine grinder, the ultrafine grader, the cyclone dust extractor, the dust collector and the fan are sequentially connected through the pipelines; the electric control cabinet is packaged by a shell, a cooling fin and a solar photovoltaic plate are arranged on the shell, and a storage battery is arranged in the electric control cabinet. The energy-saving type smash grading device has the advantages that the structure is simple, an over-smashing phenomenon is avoided, and the smashing energy consumption is reduced; the energy-saving type smash grading device has strong adaptability to materials and can avoid dust pollution, meanwhile, the materials are simple and convenient to exchange and clean, the energy is saved, and the environment is protected.

Owner:宁夏祺腾数据产业发展有限公司

Air suction type grinder for pseudo-ginseng

InactiveCN105013593ADoes not affect dynamicDoes not affect balancePump componentsPumpsAir volumeInvolute

The invention discloses an air suction type grinder for pseudo-ginseng. The air suction type grinder for the pseudo-ginseng comprises a grinder body and an induced draft fan, wherein the discharging end of the grinder body is connected with the induced draft fan through a material storage case, air suction pipes and a cyclone separator; a ventilation door used for adjusting the air volume is arranged on one of the air suction pipes; and an impeller of the induced draft fan is of a structure with blades in a hollow reverse drop shape, and the shape contour line of the induced draft fan is an involute. By means of the air suction type grinder for the pseudo-ginseng, sorting of particles and cooling and temperature drop of the material are achieved in the pneumatic transmission process; the return and secondary grinding of the coarse particles are completed in one step, the qualified output of the material is achieved, and meanwhile dust capture is achieved; the timely and smooth discharging of the grinder is guaranteed by an air suction system, the material is prevented from being excessively ground, and electric power is saved; by means of the structure with the blades in the hollow reverse drop shape, the real-time cleaning of dust on the impeller of the induced draft fan and the increase of the strength of the impeller of the draught fan are achieved, the stability is improved, and safety accidents caused by dust accumulation are effectively eradicated; and the application prospect is wide.

Owner:JISHOU UNIVERSITY

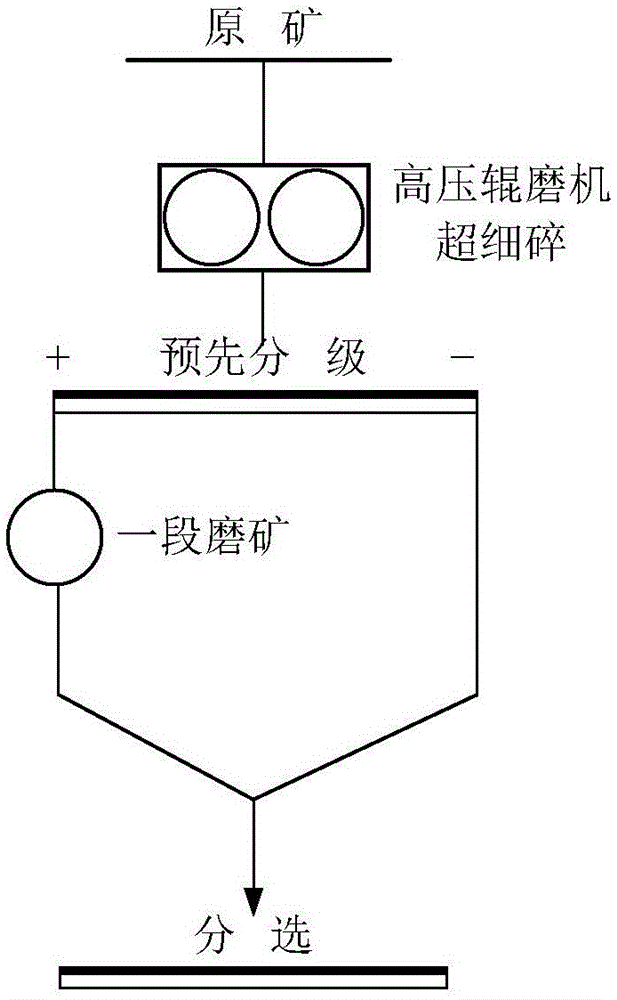

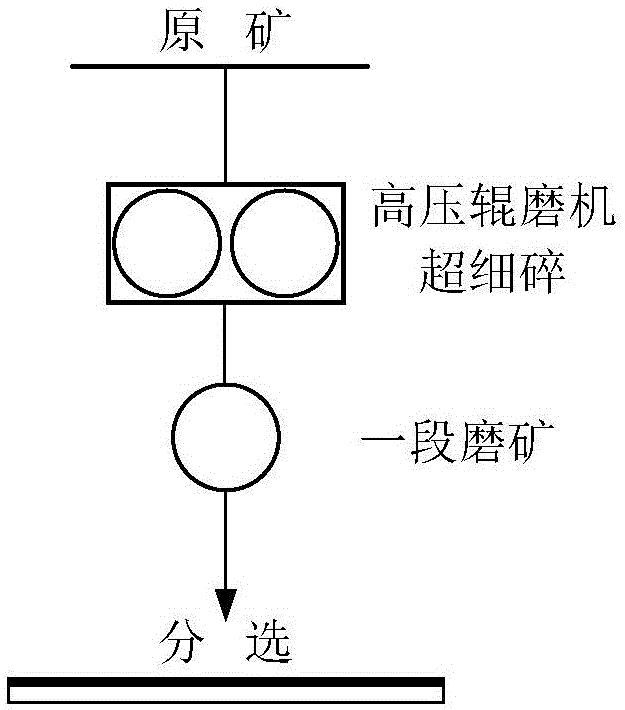

A high-efficiency and low-consumption ultra-fine crushing-grinding process

InactiveCN103934077BAvoid over crushingHigh recovery rateSaving energy measuresGrain treatmentsUltra fineHigh pressure

The invention relates to an efficient low-consumption ultrafine crushing-ore grinding process. The process is characterized in that a high-pressure grinding roller mill is utilized for carrying out ultrafine crushing, wherein the particle sizes of products subjected to the ultrafine crushing are -3.2mm; the products are pre-graded, the pre-graded fine-fraction products directly enter a sorting step without needing a primary grinding step, the pre-graded coarse-fraction products enter the sorting step after being subjected to ore grinding in the primary grinding step. According to the process, by carrying out pre-grading, the over-crushing of the dissociated fine-fraction products in the primary grinding step is avoided, the quantity of ores entering the primary grinding step is remarkably reduced, the processing capability of an ore grinding system is improved, the sorting index of ore concentrate products is improved, and meanwhile, the energy consumption is saved.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Traditional Chinese medicine crushing and grinding device capable of feeding and discharging materials continuously and automatically

ActiveCN107008533AThe overall structure design is reasonableAvoid over crushingGrain treatmentsEngineeringTraditional Chinese medicine

The invention belongs to the technical field of traditional Chinese medicines and discloses a traditional Chinese medicine crushing and grinding device capable of feeding and discharging materials continuously and automatically. The traditional Chinese medicine crushing and grinding device comprises a shell body, a sleeve, a crushing and grinding assembly, a negative pressure exhausting assembly and a discharging assembly. The sleeve is arranged in the middle of the shell body in a sleeving mode. The crushing and grinding assembly is arranged in the sleeve. The negative pressure exhausting assembly is arranged at an air outlet of the shell body. A discharging outlet corresponding to the discharging assembly is formed in the bottom of the shell body. The overall structure design is reasonable; primary crushing and grinding of medicines can be achieved; according to the different grain size requirements, on-line discharging can be achieved by adjusting the magnitude of the wind power of an air blowing opening to prevent the problem of over crushing, so that continuous feeding, grinding and discharging are achieved; and meanwhile by means of the design of the ratio of the section area of the sleeve to the section area of the shell body, timely sedimentation of the grinded medicines can be guaranteed, so that collecting and packing are facilitated.

Owner:山东博济本草阁中医馆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com