Traditional Chinese medicine crushing and grinding device capable of feeding and discharging materials continuously and automatically

A grinding and traditional Chinese medicine technology, applied in grain processing and other directions, can solve the problems of drug effect loss, drug flow, low production efficiency, etc., and achieve the effect of reasonable overall structure design, easy collection and packaging, and guaranteed bagging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings, but the present invention is not limited to these embodiments.

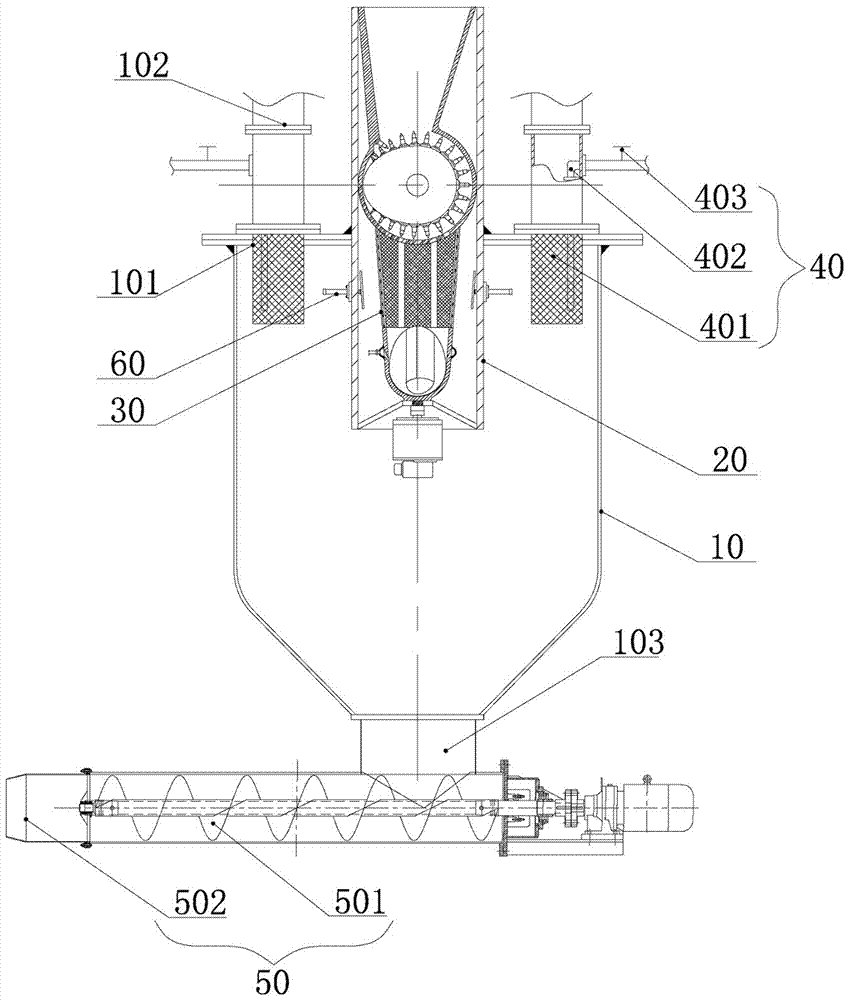

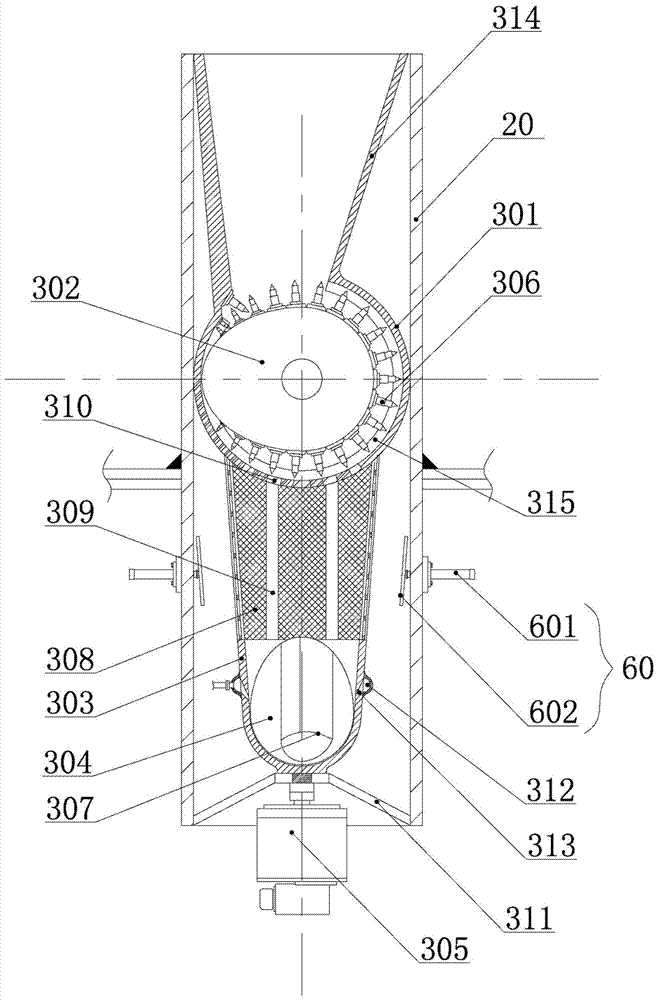

[0021] see figure 1 and figure 2 , a traditional Chinese medicine crushing and grinding device for continuous and uninterrupted automatic supply and discharge, including a housing 10, a sleeve 20, a crushing and grinding assembly 30, a negative pressure exhaust assembly 40 and a discharge assembly 50, and the sleeve 20 is sleeved on the shell In the middle of the body 10, the crushing and grinding assembly 30 is set in the sleeve 20, the negative pressure exhaust assembly 40 is set at the air outlet 101 of the housing 10, and the bottom of the housing 10 is provided with a discharge port 103 corresponding to the discharge assembly 50 Wherein, the crushing and grinding assembly 30 includes a conical feed hopper 314 arranged on the upper half of the sleeve 20, a cylindrical cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com