Tube chain type loading homogenizing system

A pipe chain and chain technology, applied in the field of pipe chain feeding homogenization system, can solve the problems of complex homogenization treatment steps, influence of polishing powder finished products, high homogenization cost, and achieve reasonable overall structure design and strong practicability. , to ensure the effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

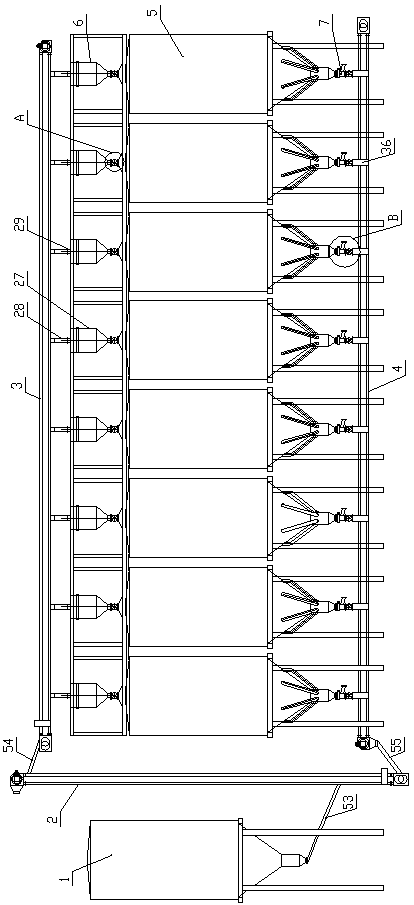

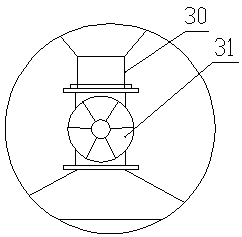

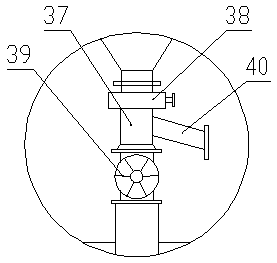

[0028] Such as Figure 1-11 As shown, the pipe chain type feeding and homogenizing system of the present invention includes a raw material warehouse 1, a blending homogenization storehouse and three groups of pipe chain conveying devices. The three groups of pipe chain conveying devices have the same structure, and the three groups of pipe chain conveying devices include The vertical pipe chain conveying device 2, the upper horizontal pipe chain conveying device 3 and the lower horizontal pipe chain conveying device 4, the vertical pipe chain conveying device 2 is vertically arranged on the left side of the blending homogenization warehouse, and the upper horizontal pipe chain conveying device 3 is arranged horizontally Above the blending and homogenizing warehouse, the lower horizontal pipe chain conveying device 4 is horizontally arranged below the blending and homogenizing warehouse; the blending and homogenizing warehouse includes several groups of blending and homogenizing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com