Elevator composite counterweight grinding ultraflat production line

A technology for counterweights and production lines, which is applied to machine tools, grinding frames, and grinding beds suitable for grinding workpiece planes, and can solve occupational health and safety injuries for employees, production quality cannot be guaranteed, and serious pollution at the work site To achieve the effect of reducing labor intensity of workers, controlling product flatness and dimensional accuracy requirements, and reasonable overall structure design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation, structure, features and effects of the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments:

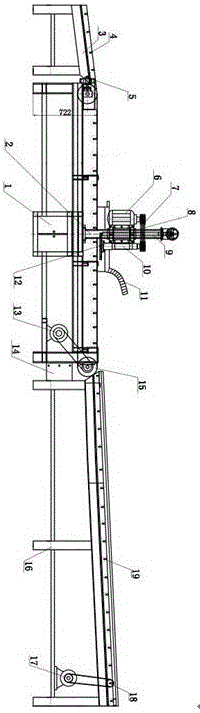

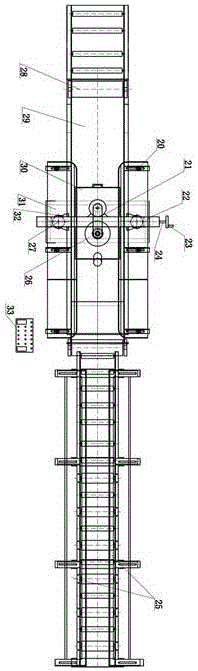

[0020] Such as figure 1 with figure 2 As shown, an elevator composite counterweight grinding ultra-flat production line includes a loading platform, an unloading platform, an operating platform, and an electronic control console 33. The operating platform includes a moving mechanism, a main body 1, a main machine There are guide posts 2 on both sides of the body, bearing seats 12 are arranged on the guide posts, a spindle box 21 is arranged on the bearing seats, a lifting screw 9 and a driving shaft motor 6 are arranged in the spindle box, and the output shaft of the driving shaft motor is arranged There is a pulley 7, which is connected to the main shaft 10 through a power belt 8, and the lower end of the main shaft is provided with a diamond grinding wheel 26; the loading platform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com