Fine grinding system and grinding method thereof

A micro-grinding and pre-grinding technology, which is applied in the direction of grain processing, etc., can solve the problems of low efficiency, indoor air pollution, excessive dust, etc., and achieve the effects of high crushing efficiency, high recovery rate, and high airflow classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

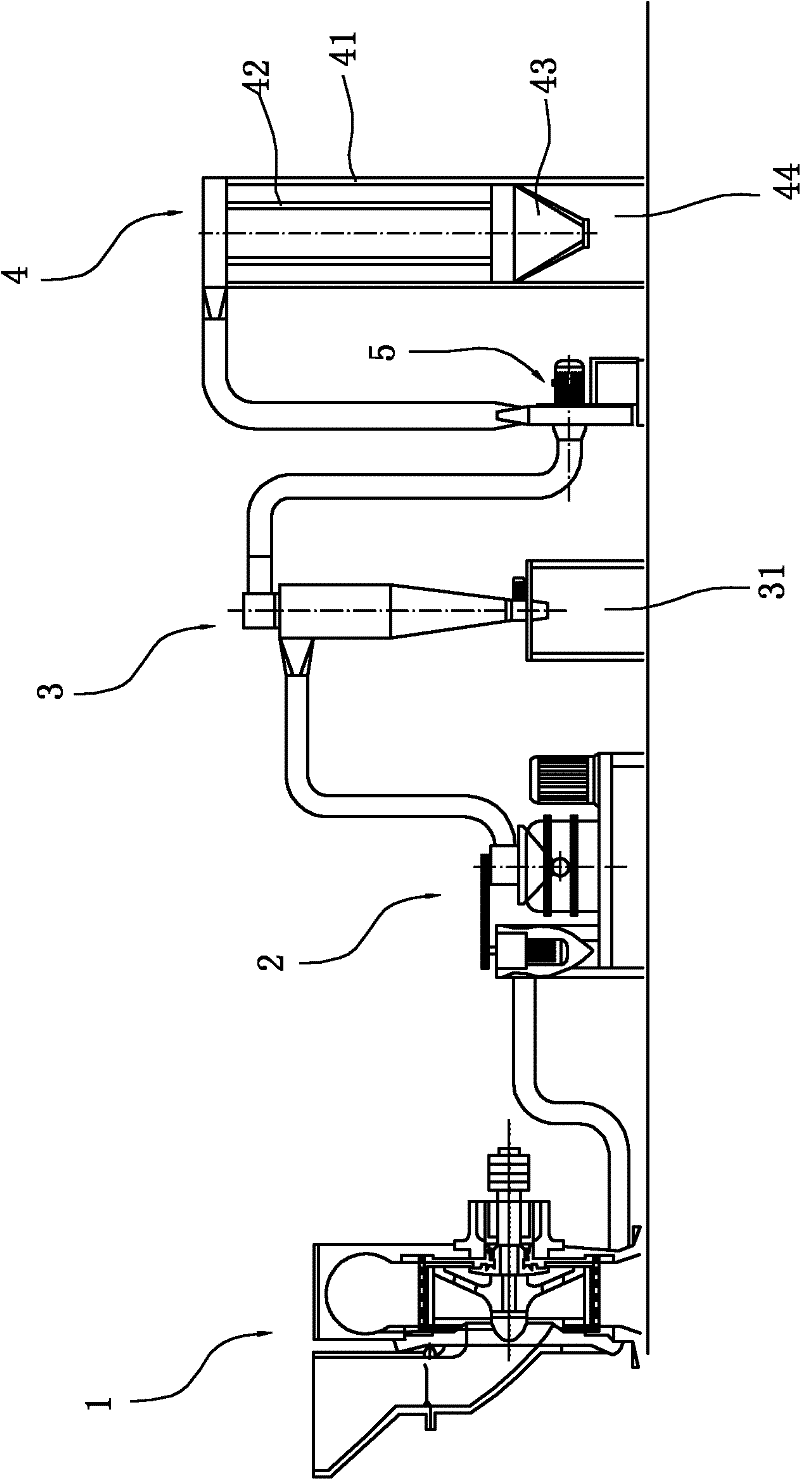

[0040] see figure 1 The micro-grinding system shown, it comprises

[0041] Pre-crushing equipment 1, used for pre-crushing the agglomerated material to be crushed, so as to obtain granular material particles to be crushed;

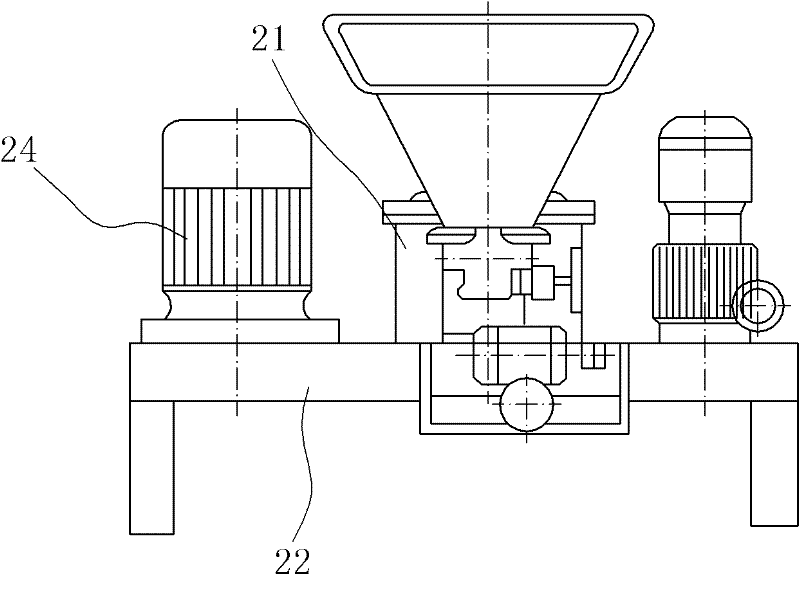

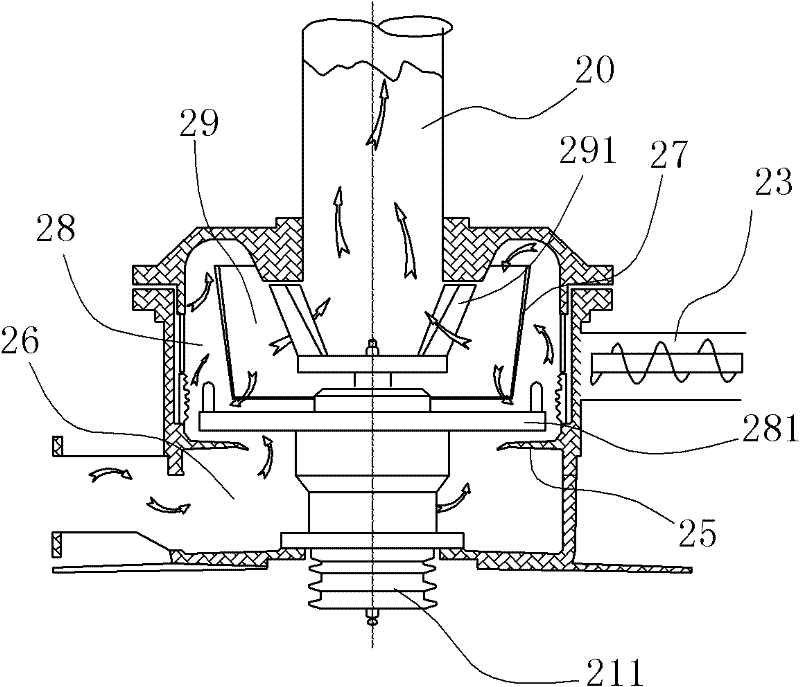

[0042] Micro-grinding equipment 2, for further pulverizing the material particles to be pulverized discharged from the pre-grinding equipment;

[0043] A material collector 3, the feed port of the material collector is connected to the discharge pipe of the micro-grinding equipment through a pipeline, and the first collecting box 31 is arranged at the lower part of the material collector;

[0044] Dust collector 4, the upper part of the collector is connected to the inlet of the dust collector through a pipeline, and the second collection box 44 is arranged at the lower part of the dust collector;

[0045] The induced draft fan 5 is used to suck the particles of the material to be pulverized from the micro pulverization equipment to the collector and the...

Embodiment 2

[0054] Different from the embodiment, the dust collector 4 also includes a solenoid valve controlled by a pulse controller, and the induced draft fan is installed outside the air outlet of the dust collector, and the solenoid valve is connected to the filter bag exit. see Figure 6 shown.

[0055] During the crushing process, when the dust blocked on the outer wall of the filter bag continues to increase, the resistance of the dust collector will continue to increase. In order to ensure that the resistance of the dust collector is controlled within the specified range, the pulse controller sends out a control signal at a fixed interval to turn on the electromagnetic The valve makes the filter bag expand instantly and then shrink sharply, so that the excess dust particles accumulated on the outer wall of the filter bag are eliminated, and the falling dust enters the second collection box through the outlet of the ash hopper for collection, so that the filter bag can be obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com