Selective milling-flotation method for cassiterite multi-metal sulfide ore

A multi-metal and sulfide ore technology, applied in flotation, solid separation, etc., can solve the problems of high tin loss rate, low cassiterite flotation efficiency, environmental pollution, etc., and achieve the effect of avoiding excessive crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

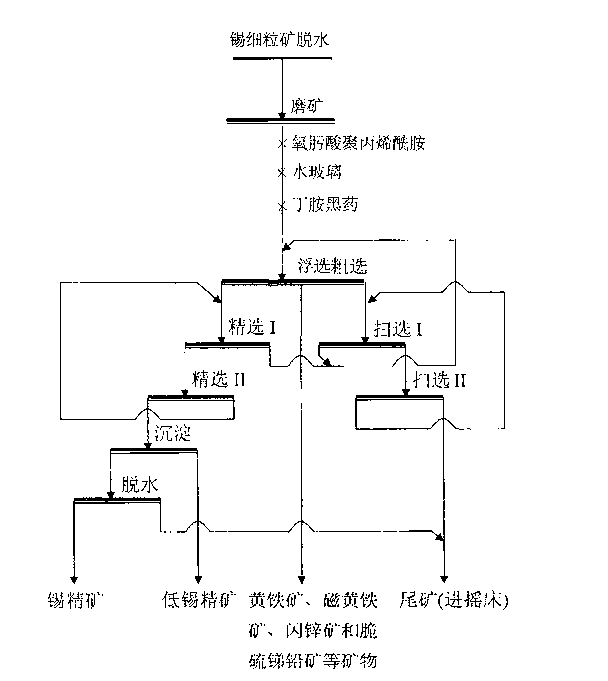

Embodiment 1

[0026] Example 1: Treatment of a cassiterite polymetallic sulfide ore in Guangxi containing 1.0% Sn and 21.2% S, the process system is: the particle size of the ore to be ground is less than 20mm, the grinding condition is a grinding concentration of 57%, and the pH of the grinding system is controlled When the pH is 7; the ore and flotation agents (dispersant, inhibitor and collector) are added to the ore mill for grinding. The type and dosage of the flotation agent added to the rod mill are: hydroxamic acid polypropylene Amide 75-85 grams per ton raw ore, water glass 190-220 grams per ton raw ore, flotation collector butylamine black medicine 70-100 grams per ton raw ore. The particle size of the ore grinding product is +0.039mm, and -0.074mm accounts for 29.5%. After flotation to remove sulfide minerals, the tin grade (Sn) in the remaining ore is 2.88%, and the S content is 2.65%. Through the particle size analysis, the -0.039 The occupancy rate of tin metal in mm particle ...

Embodiment 2

[0027]Embodiment 2: processing a certain cassiterite polymetallic sulfide ore in Guangxi containing 1.5.0% Sn and 18.0% S, the process system is: the particle size of the ore entering the grinding is less than 20mm, the grinding condition is a grinding concentration of 52%, the grinding system The pH is controlled at pH 7.5; the ore and flotation agents (dispersant, inhibitor and collector) are added to the ore mill for grinding. The type and dosage of the flotation agent added to the rod mill are: hydroxamic acid Polyacrylamide 75-85 grams per ton raw ore, water glass 190-220 grams per ton raw ore, flotation collector butylamine black medicine 70-100 grams per ton raw ore. The particle size of the grinding product is +0.035mm, and -0.070mm accounts for 30.1%. After the sulfide minerals are removed by flotation, the tin grade (Sn) in the remaining ore is 3.50%, and the S content is 2.30%. Through the particle size analysis, the -0.039 The occupancy rate of tin metal in mm part...

Embodiment 3

[0028] Example 3: Treatment of a cassiterite polymetallic sulfide ore in Guangxi containing 0.8% Sn and 23.4% S, the process system is: the particle size of the ore to be ground is less than 20mm, the grinding condition is a grinding concentration of 48%, and the pH of the grinding system is controlled When the pH is 8; the ore and flotation agents (dispersant, inhibitor and collector) are added to the grinding machine for grinding. The type and dosage of the flotation agent added to the rod mill are: hydroxamic acid polypropylene Amide 75-85 grams per ton raw ore, water glass 190-220 grams per ton raw ore, flotation collector butylamine black medicine 70-100 grams per ton raw ore. The particle size of the ore grinding product is +0.039mm, and -0.074mm accounts for 27.5%. After flotation to remove sulfide minerals, the tin grade (Sn) in the remaining ore is 2.53%, and the S content is 2.75%. Through the particle size analysis, the -0.039 The occupancy rate of tin metal in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com