Patents

Literature

44results about How to "Realize flotation separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

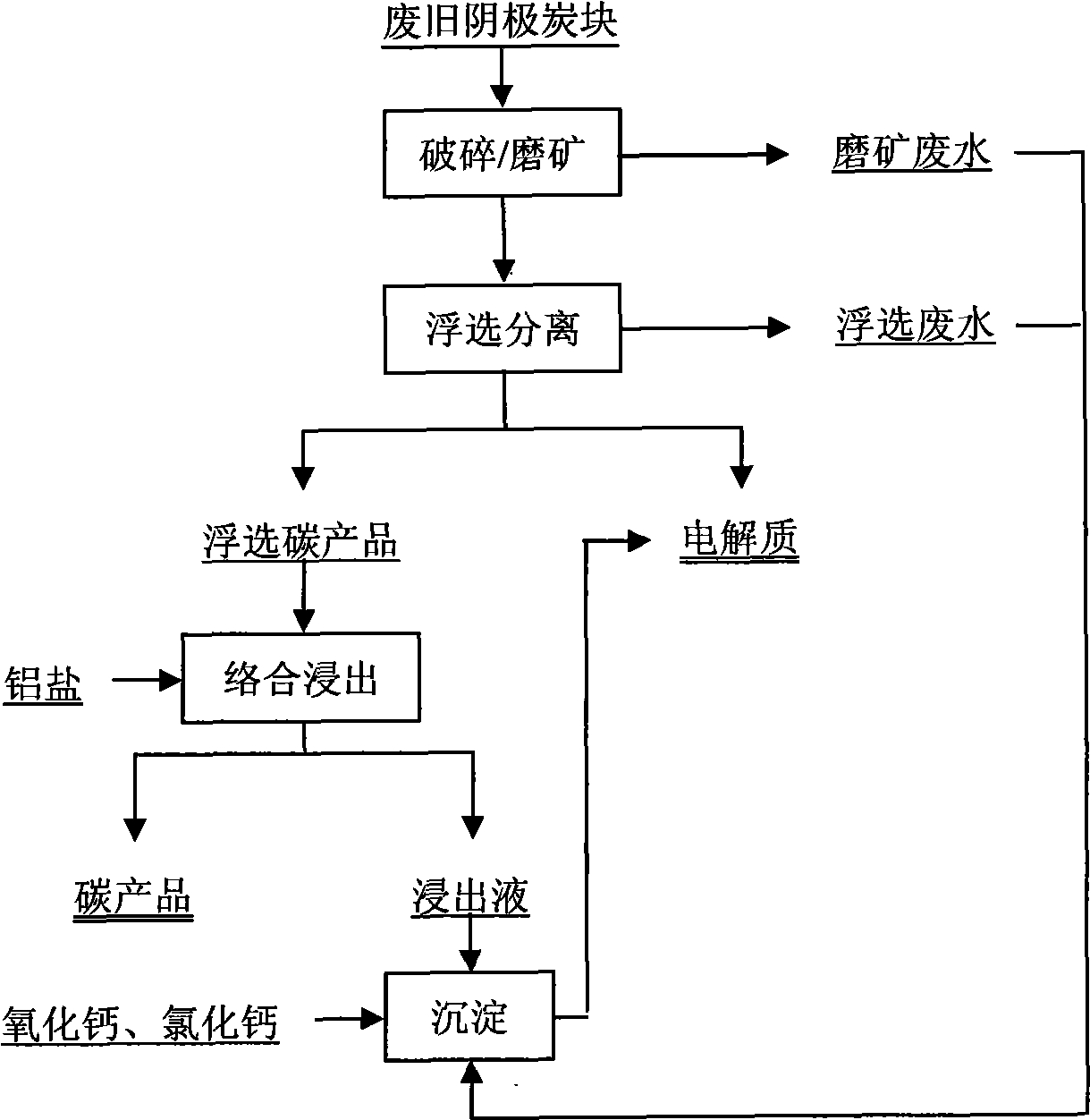

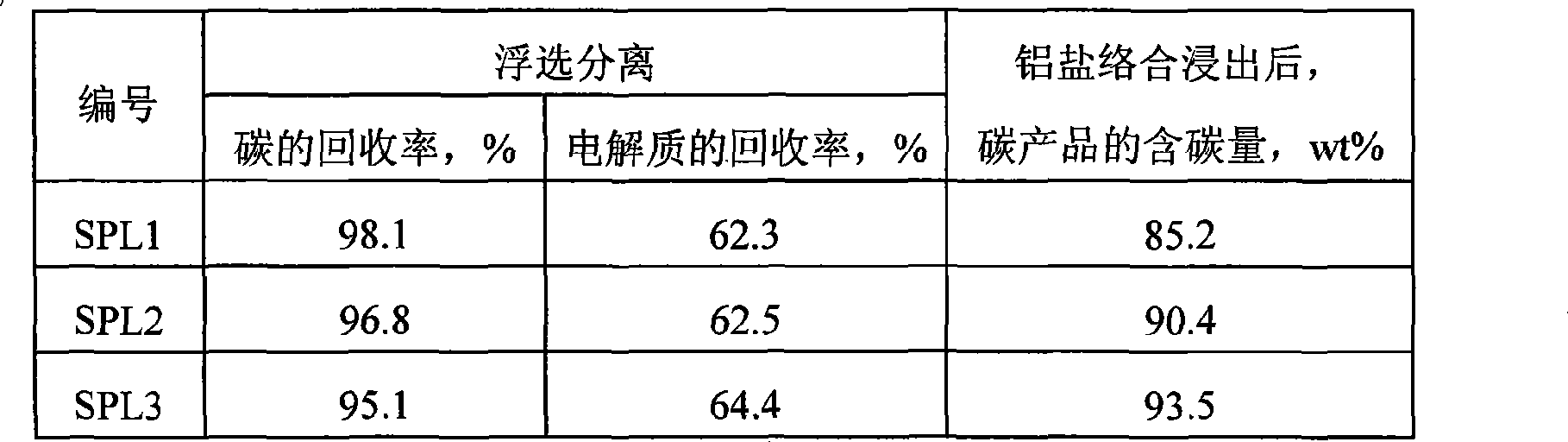

Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

ActiveCN101480658ARealize flotation separationHigh carbon contentFluoride preparationWaste processingPregnant leach solutionHigh carbon

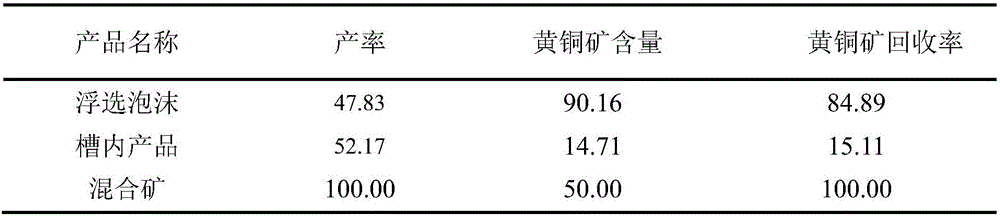

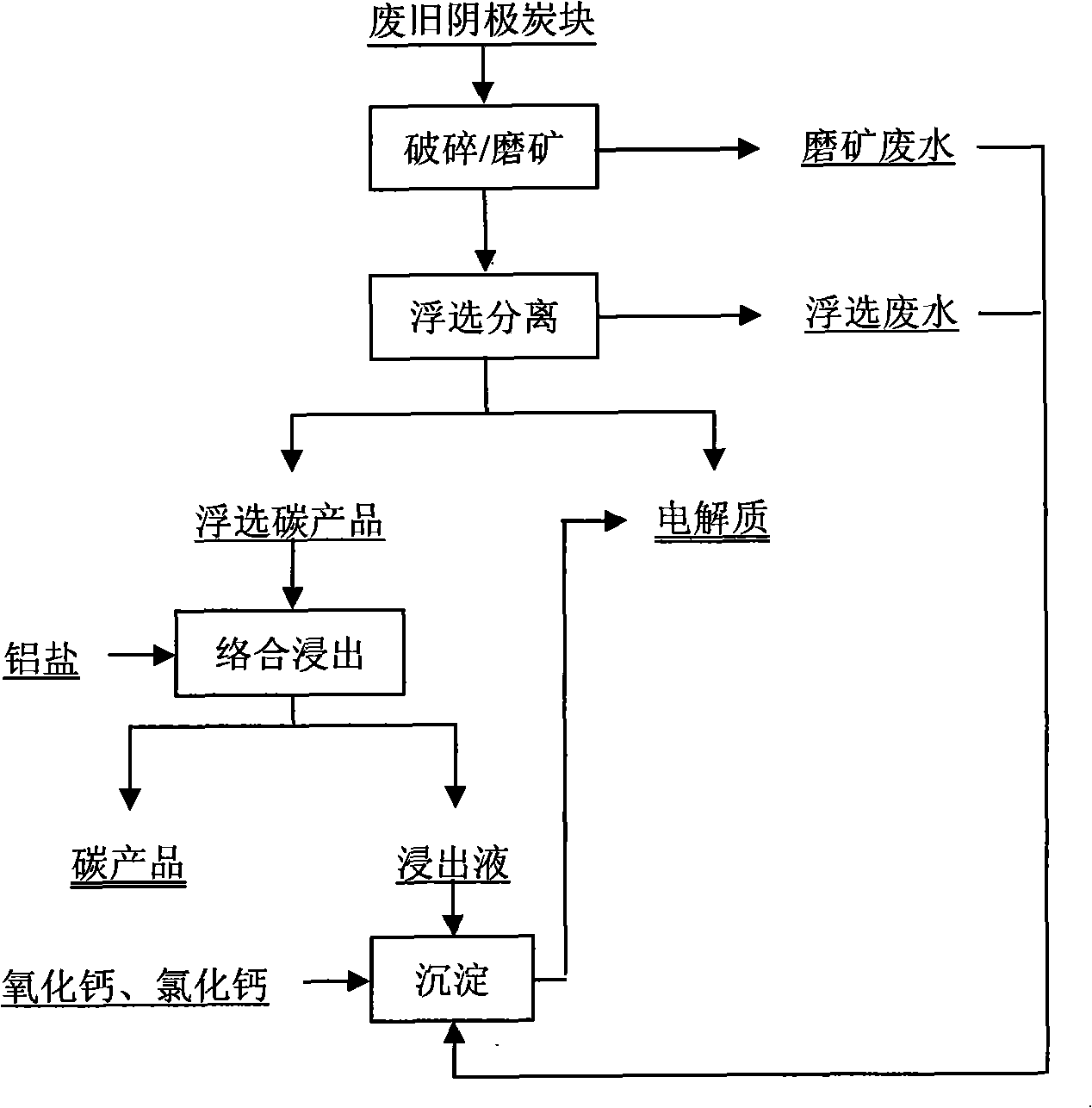

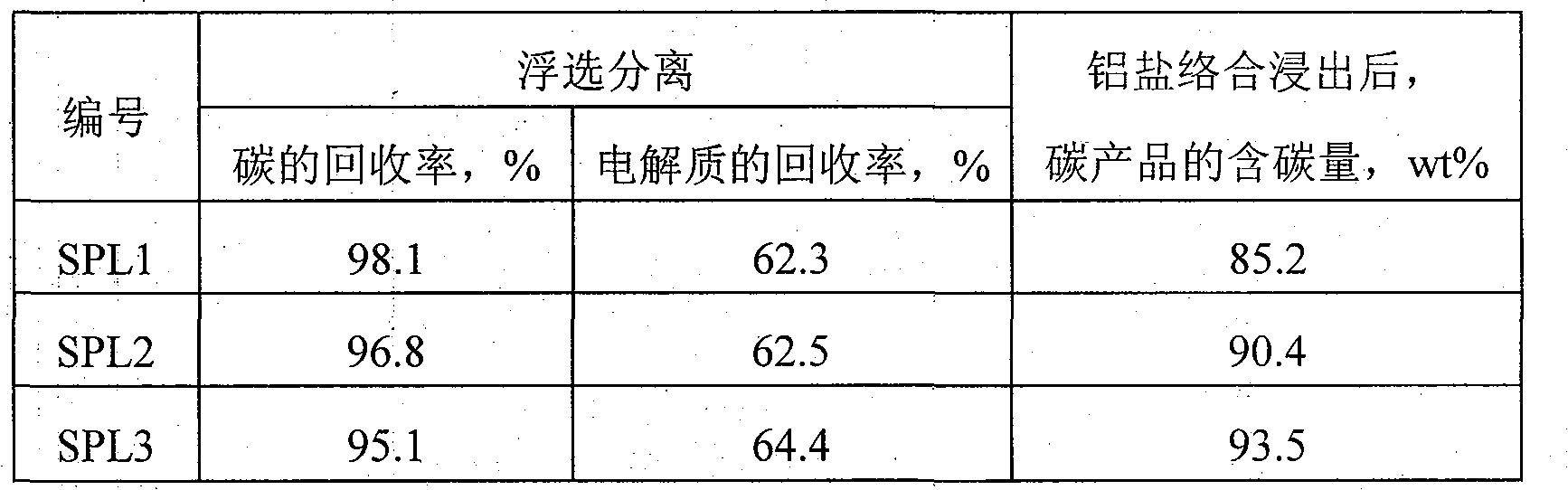

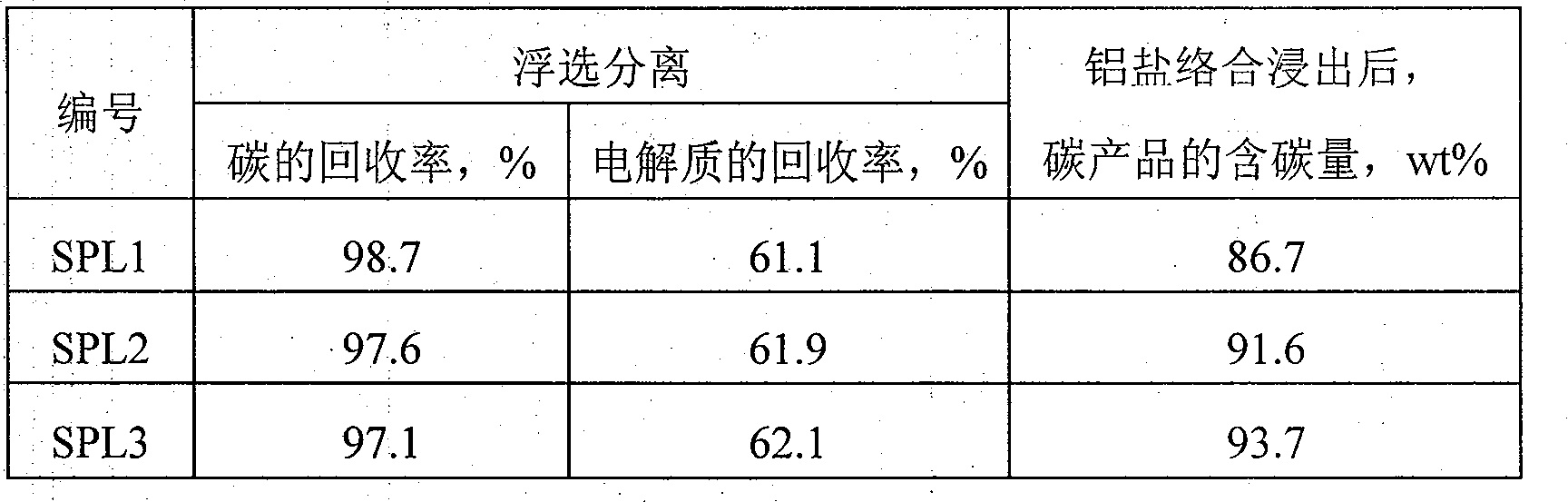

The invention relates to a method for comprehensively using aluminium to electrolyze a waste cathode carbon block, which belongs to the technical field of environment protection and comprises the following steps: crushing and grinding the waste cathode carbon block; adjusting the concentration and the PH value of ore slurry after the grinding, then using floatation equipment to carry out floatation treatment, and separating electrolyte and carbon which are contained in the waste cathode carbon block; using an aluminium salt solution to soak for extracting the electrolyte contained in a carbon product obtained from the floatation, and further improving the grade of a high-carbon product; mixing the grinding waste water, the floatation waste water and the soaking solution, and adding CaO and CaCl2 to precipitate and recover aluminium and fluothane in the mixture. The method for comprehensively using aluminium to electrolyze a waste cathode carbon block has simple operating condition, low energy consumption, high recovery ratio of valuable substances and good application prospect.

Owner:NORTHEASTERN UNIV

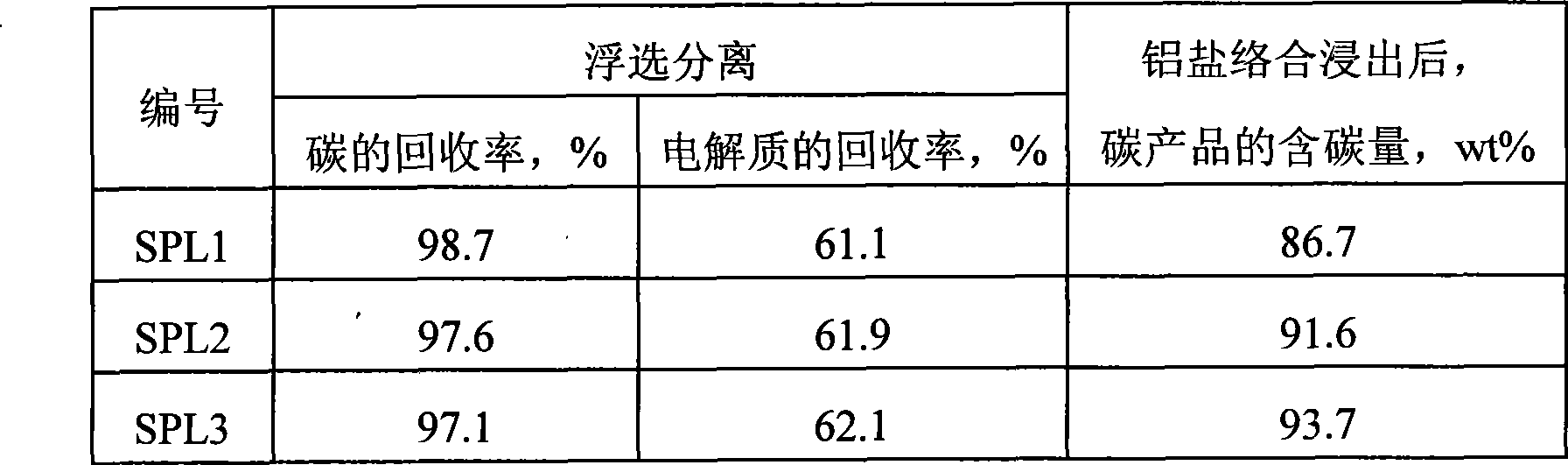

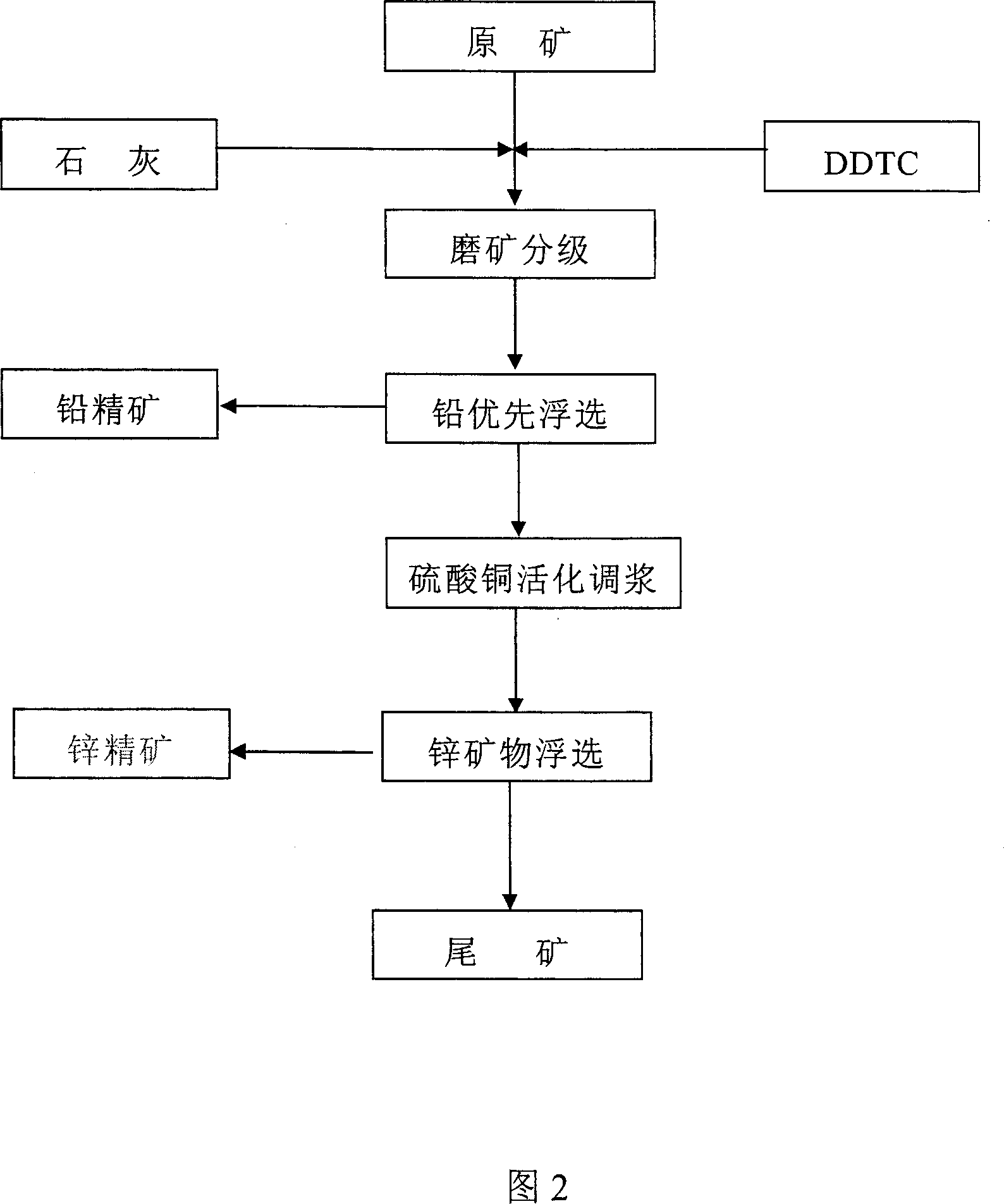

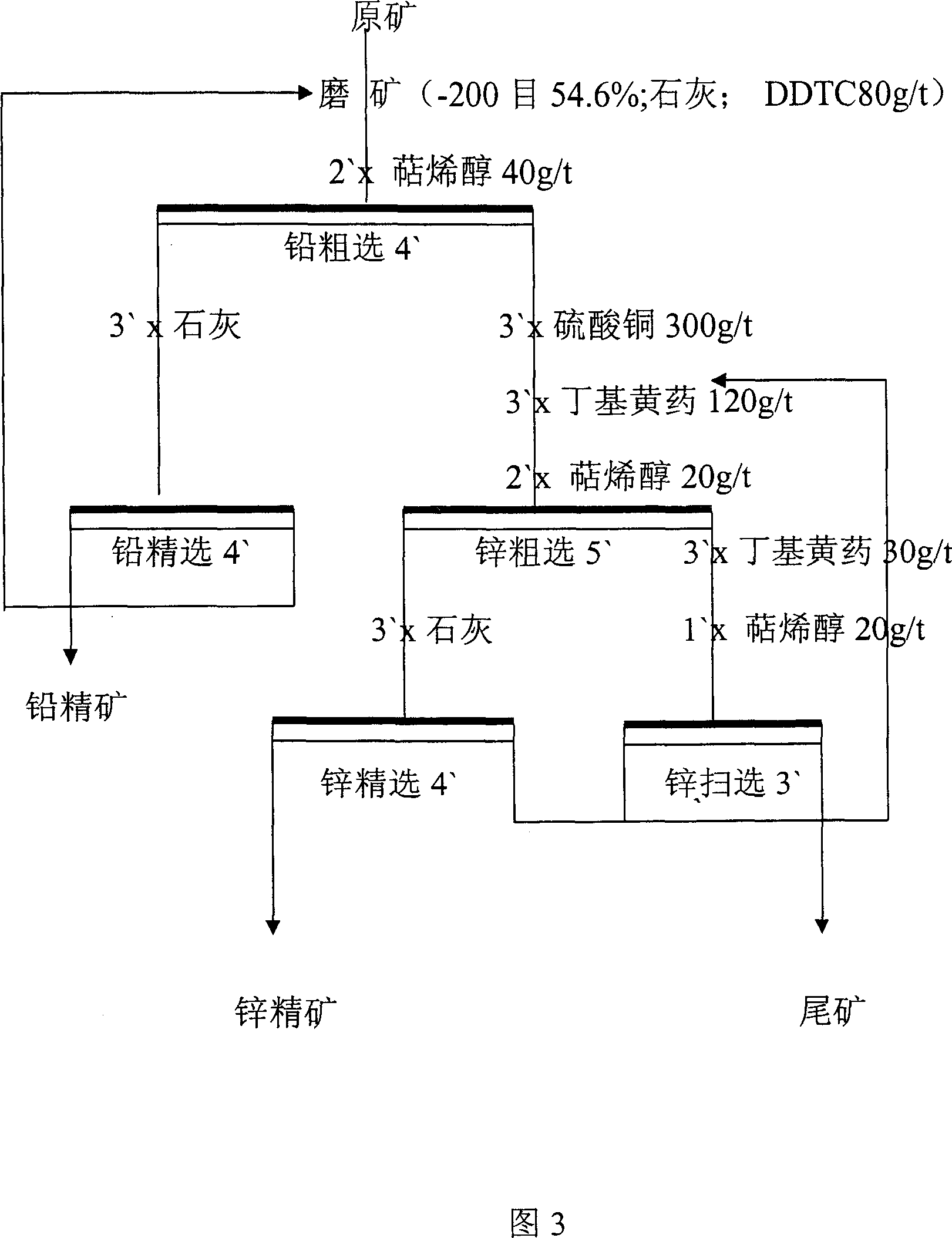

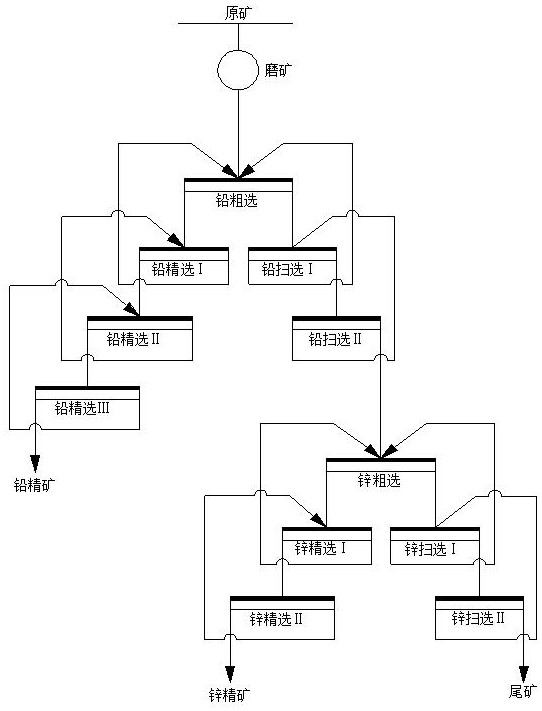

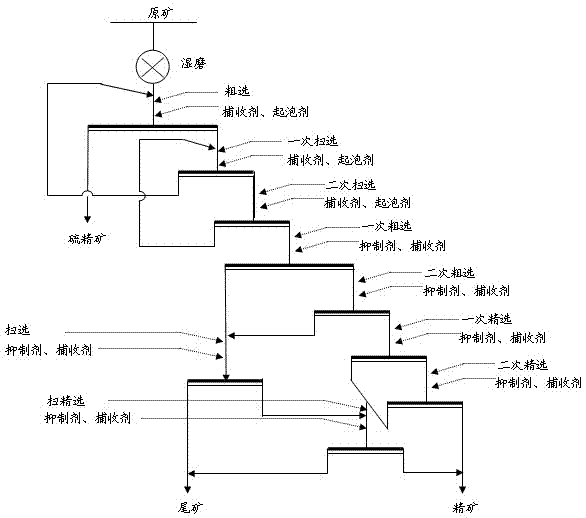

Process for increasing complicated sulfurized-lead-zinc ore dressing recovery rate

The present invention is green process of recovering complicated lead-zinc sulfide ore in high recovering rate. The technological process adopts lime to form high alkalinity and maintain the original potential of lead-zinc sulfide slurry during ore grinding floatation, sodium diethyl dithioamino formate as the selective lead mineral collecting agent, copper sulfate as the sphalerite activating agent and butyl xanthate as the zinc mineral collecting agent for optimized successive fast floatation. The present invention has raised recovering rate, low chemical consumption, simple technological process and low production cost.

Owner:青海西部矿业科技有限公司

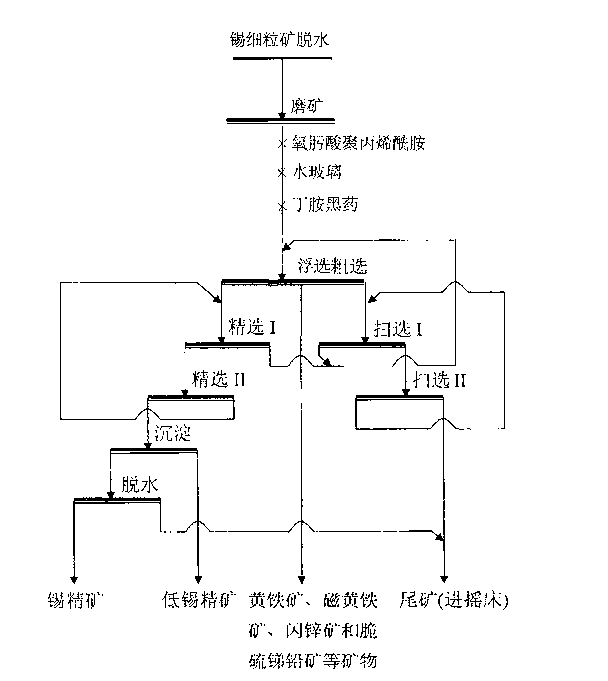

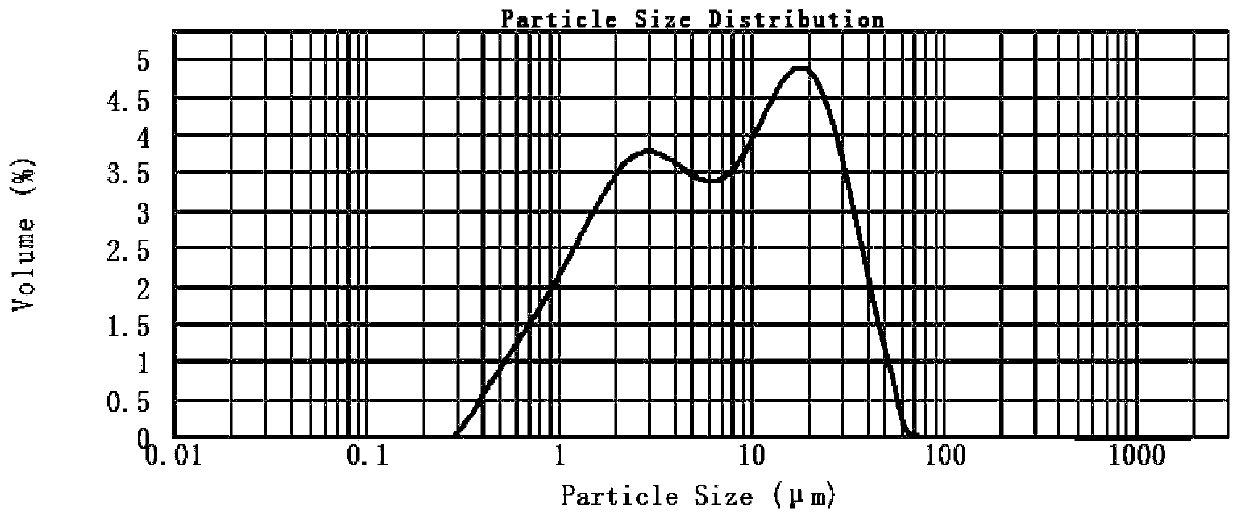

Method for selectively milling cassiterite multi-metal sulfides ores

The invention discloses a method for selectively milling cassiterite multi-metal sulfides ores. In the method, by utilizing the hydrophily / hydrophobicity difference between the surface of cassiterite and the surfaces of sulfides ores such as pyrite, pyrrhotite, blende and jamesonite, and by adding a floating agent in a milling process, floatation separation of cassiterite and the sulfides ores in ores can be realized under a condition of larger milling granularity by using a floatation method. The method disclosed by the invention can be adopted for treating the cassiterite multi-metal sulfides ore which contains 0.5 to 1 percent of Sn and 12 to 17 percent of S; and by adopting the method, the ore milling granularity required in floatation can be decreased, the content of fine-grained cassiterite (with the granularity of minus 0.039 millimeter) is reduced by 20 percent, and over-crushing phenomena of cassiterite are greatly reduced.

Owner:CENT SOUTH UNIV +1

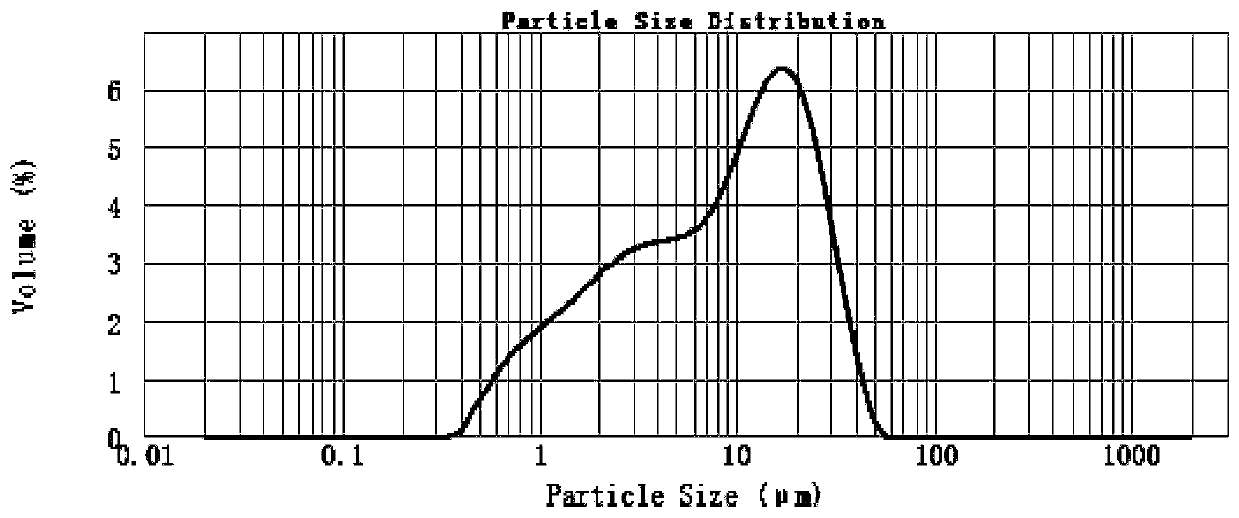

Selective milling-flotation method for cassiterite multi-metal sulfide ore

The invention discloses a selective milling-floatation method for cassiterite multi-metal sulfide ore. In the method, cassiterite multi-metal sulfide ore is selectively milled, so that the surface hydrophilic / hydrophobic properties of cassiterite and sulfide minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like in ore are changed, the surface of cassiterite does not react with a flotation collector but reacts with hydroxamic acid polyacrylamide, and selective flocculation is performed on the surfaces of cassiterite minerals; and surfaces of minerals such as iron pyrite, pyrrhotite, zinc blende, jamesonite and the like do not adsorb hydrophilic substances, and a fresh surface which is obtained by milling ore and dissociating reacts with a flotation collector which is added into an ore mill, so that floatability is realized for the surface hydrophilic property, the problems of low cassiterite floatation efficiency, high tin loss rate and severe environmental pollution caused by excessive smashing of cassiterite with the conventional floatation method in the ore dressing process of cassiterite multi-metal sulfide ore are solved, and the recovery of cassiterite with a subsequent gravity separation technology is facilitated.

Owner:GUANGXI GAOFENG MINE IND

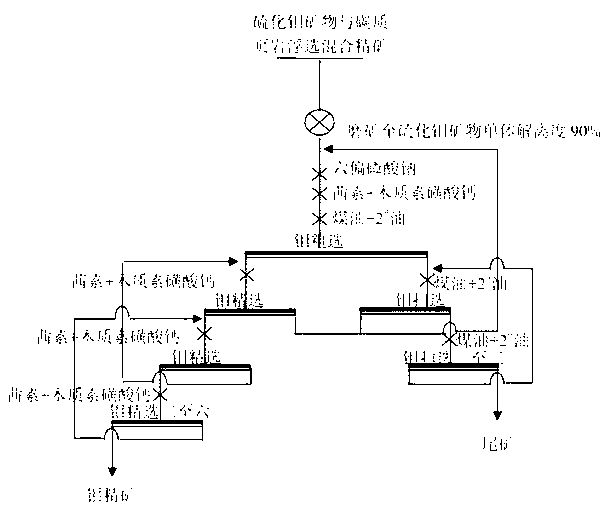

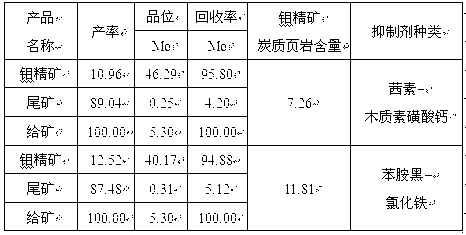

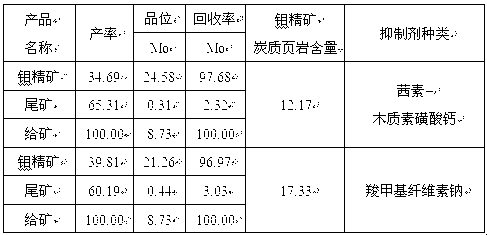

Carbonaceous shale inhibitor and flotation separation method of molybdenum sulfide and carbonaceous shale flotation mixed concentrate

The invention belongs to the technical field of mineral dressing and particularly relates to a carbonaceous shale inhibitor and a flotation separation method of molybdenum sulfide and carbonaceous shale flotation mixed concentrate. The carbonaceous shale inhibitor consists of alizarin and calcium lignosulphonate. The method comprises the following steps that the molybdenum sulfide and carbonaceous shale flotation mixed concentrate is used as raw materials, the alizarin and the calcium lignosulphonate are adopted for inhibiting carbonaceous shale, molybdenum sulfide minerals are subjected to flotation, and the flotation separation of the molybdenum sulfide minerals and the carbonaceous shale is carried out. Carbonyls and hydroxies in the alizarin form hydrophilic complexes with aluminum atoms in the carbonaceous shale, meanwhile, lipophilic groups of the calcium lignosulphonate can be adsorbed on the surface of the carbonaceous shale to generate non-polar solid surface monolayer absorption, and the lipophilic groups at the other end are hydrophilic, so the carbonaceous shale is hydrophilic, and the carbonaceous shale is inhibited. The carbonaceous shale inhibitor and the flotation separation method have the advantages that the technological process of the molybdenum sulfide and carbonaceous shale flotation separation is simplified, and a good separation effect is obtained.

Owner:HUNAN RES INST FOR NONFERROUS METALS

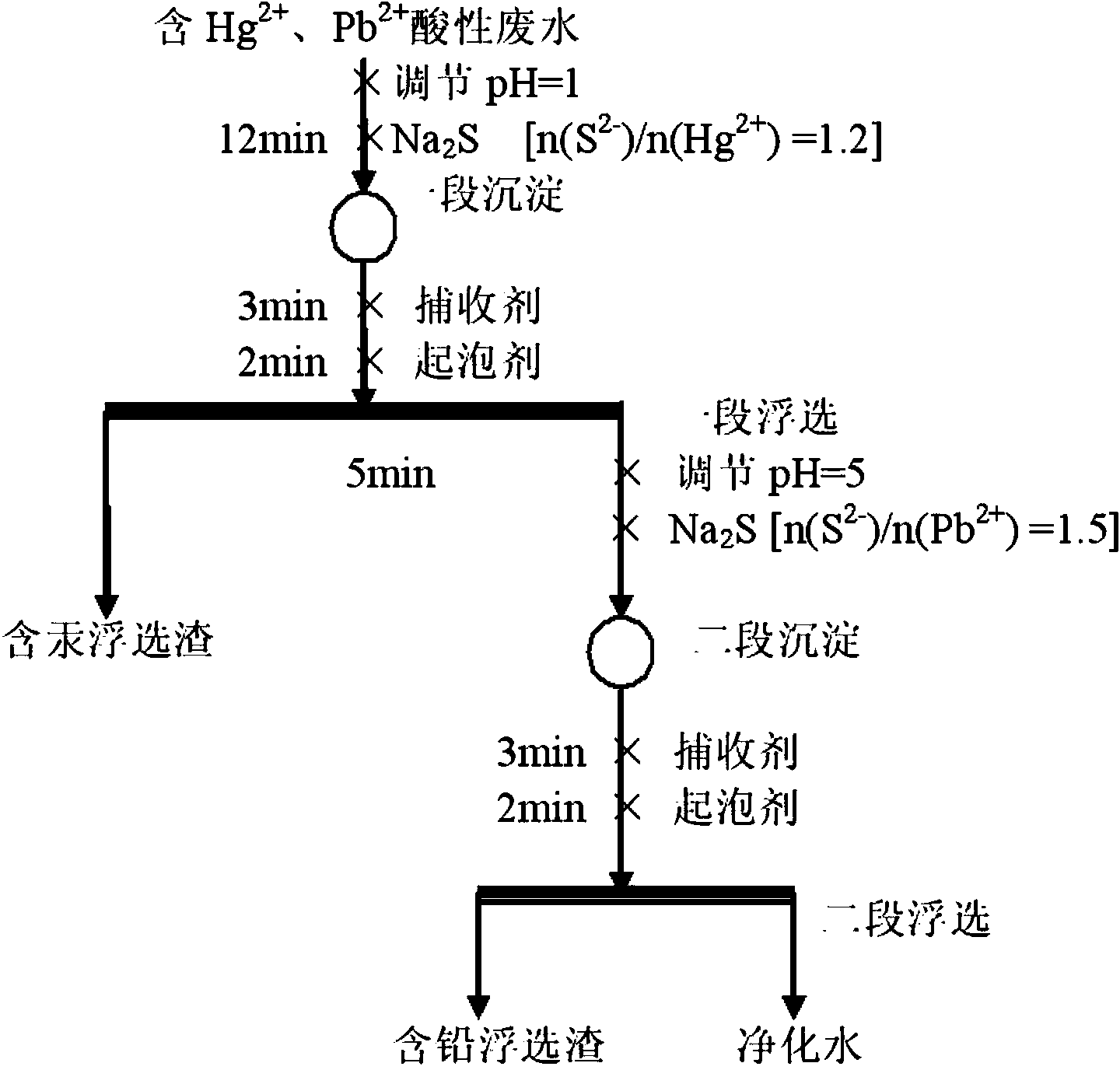

Method for recycling lead and mercury from acidic wastewater

ActiveCN104108810APrevent grade influenceRealize flotation separationMultistage water/sewage treatmentProcess efficiency improvementSlagWastewater

The invention discloses a method for recycling lead and mercury from acidic wastewater. The method comprises a two-section precipitation flotation step that is used to process acidic wastewater containing mercury ions and lead ions. Through controlling the concentration of S<2-> in wastewater and the pH vale of wastewater, the mercury-containing flotation slag and lead-containing flotation slag can be individually separated in a form of sulfide precipitate by the flotation technology. The method has the advantages of simple technology process and low cost, and can high efficiently separate lead ions and mercury ions in wastewater. The contents of residual heavy metals in the wastewater which has been processed by the method all reach the A level standard of GB8979-1996 'Integrated Wastewater Discharge Standard'. The mercury grade in the separated mercury concentrate slag and the lead grade in the separated lead concentrate slag are high, and the resources are comprehensively utilized.

Owner:CENT SOUTH UNIV

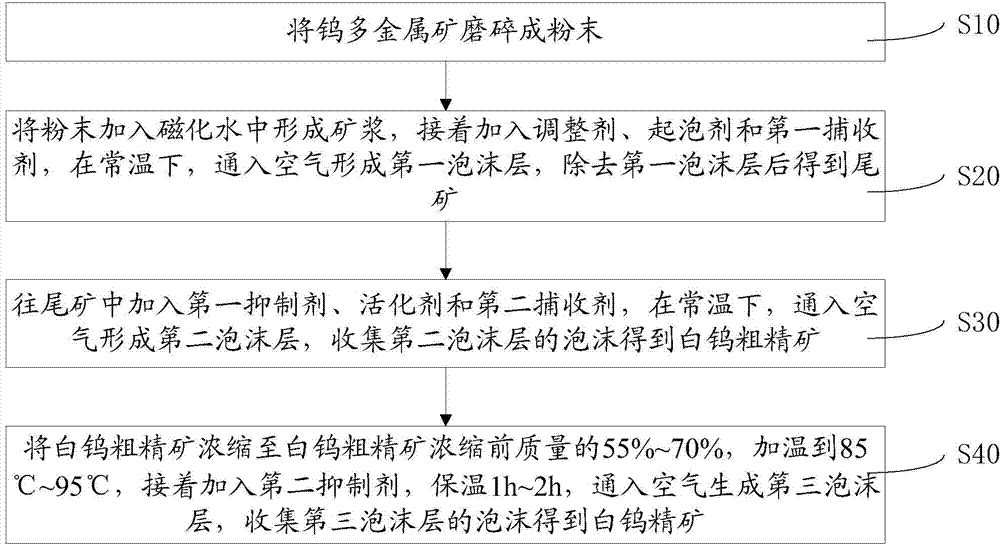

Beneficiation method for tungsten polymetallic ore

InactiveCN103934113AIncrease floatability differenceRealize flotation separationFlotationFoaming agentCalcite

The invention discloses a beneficiation method for tungsten polymetallic ore. The beneficiation method comprises the following steps of (1) grinding the tungsten polymetallic ore to form powder, (2) adding the powder to magnetized water to form ore pulp, then, adding regulators, foaming agents and first collecting agents, feeding in air to form a first foam layer, obtaining tailings after removing the first foam layer, (3) adding first inhibitors, activators and second collecting agents to the tailings, feeding in air to form a second foam layer, collecting the second foam layer to obtain white tungsten rough concentrate, and (4) concentrating the white tungsten rough concentrate till the mass of the white tungsten rough concentrate ranges from 55% to 70% of the mass of the white tungsten rough concentrate before concentration, heating the white tungsten rough concentrate to the temperature which ranges from 85 DEG C to 95 DEG C, adding second inhibitors, feeding in air to generate a third foam layer, and collecting the third foam layer to obtain white tungsten concentrate. According to the beneficiation method for the tungsten polymetallic ore, the magnetized water is used in the technological process, difference between floatability of the white tungsten ore and floatability of calcium minerals can be increased, flotation separation of the white tungsten ore and the calcium minerals such as fluorite and calcite is achieved, and the recovery rate of the white tungsten ore is increased.

Owner:HUNAN YOUSE TECH DEV

Method for flotation separation of lead sulfide and zinc sulfide minerals

The invention relates to a method for flotation separation of lead sulfide and zinc sulfide minerals and belongs to the technical field of mineral flotation separation. The method comprises the stepsthat the pH value of ore pulp is regulated to be 8.5-10.5, zinc sulfate, sodium carbonate and ferricyanide are adopted as an inhibitor of blende, ethyl thio carbamate, xanthate and aerofloat are adopted as a collecting agent of galena, 2<#> oil is adopted as a foaming agent, and a qualified lead concentrate product is separated from the minerals; and then, copper sulfate is adopted as an activating agent of the blende, the xanthate is adopted as a collecting agent, a qualified zinc concentrate product is obtained through flotation, and thus a lead mineral and a zinc mineral are effectively separated. According to the method for flotation separation of the lead sulfide and zinc sulfide minerals, the galena and the blende can be separated through a flotation method, a reagent system is simple, the procedure is reasonable in structure, and the grade and the recovery rate of the lead and zinc minerals can be effectively increased; and a combined reagent containing the ferricyanide is adopted to inhibit the zinc mineral, the advantages of good selectivity, high inhibitive capacity, less dosage and the like are achieved, the ferricyanide is stable and has little influence on the environment, the zinc content in lead concentrates is effectively decreased under the premise of saving the reagent cost and under the precise of the low-alkali environment, and the lead mineral and the zincmineral are efficiently separated.

Owner:KUNMING UNIV OF SCI & TECH

Pyroxene peridotite type ilmenite depressing agent and preparation method thereof

InactiveCN103721853AResolve recovery rateSolve the technical problem of low concentrate gradeFlotationPhysical chemistryIlmenite

The invention belongs to the ilmenite flotation technology, and particularly relates to a pyroxene peridotite type ilmenite depressing agent and a preparation method of the pyroxene peridotite type ilmenite depressing agent. The preparation method of the pyroxene peridotite type ilmenite depressing agent comprises the step of carrying out oscillation, stir and curing on a mixed solution formed by sodium silicate, ferric nitrate and sulfuric acid to obtain the pyroxene peridotite type ilmenite depressing agent, wherein oscillation, stir and curing are carried out for 30-40min. The obtained pyroxene peridotite type ilmenite depressing agent comprises, by weight, 5-15 parts of the sodium silicate, 5-15 parts of the ferric nitrate and 1-10 parts of the sulfuric acid. The pyroxene peridotite type ilmenite depressing agent obtained through the preparation method has a good selective depressing effect on olivine and pyroxene, and has extremely important significance in obtaining of good technical indexes of titanium flotation of pyroxene peridotite type ilmenite.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI +1

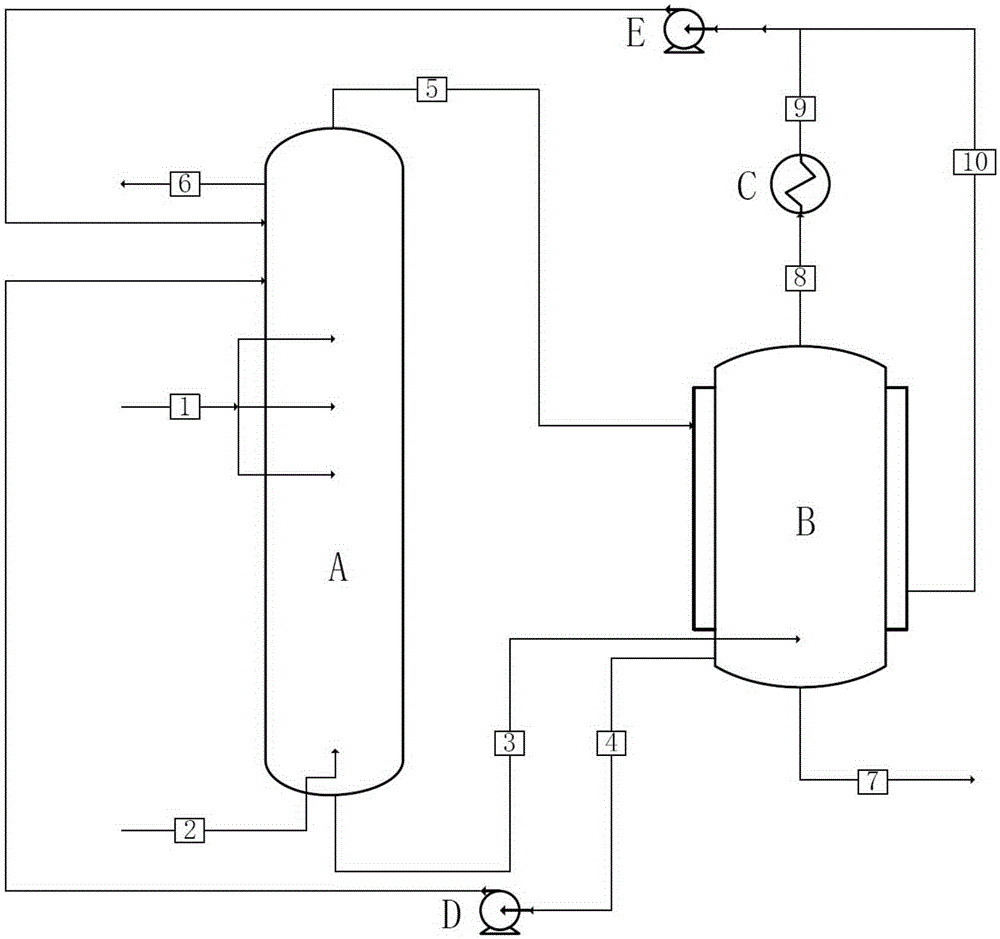

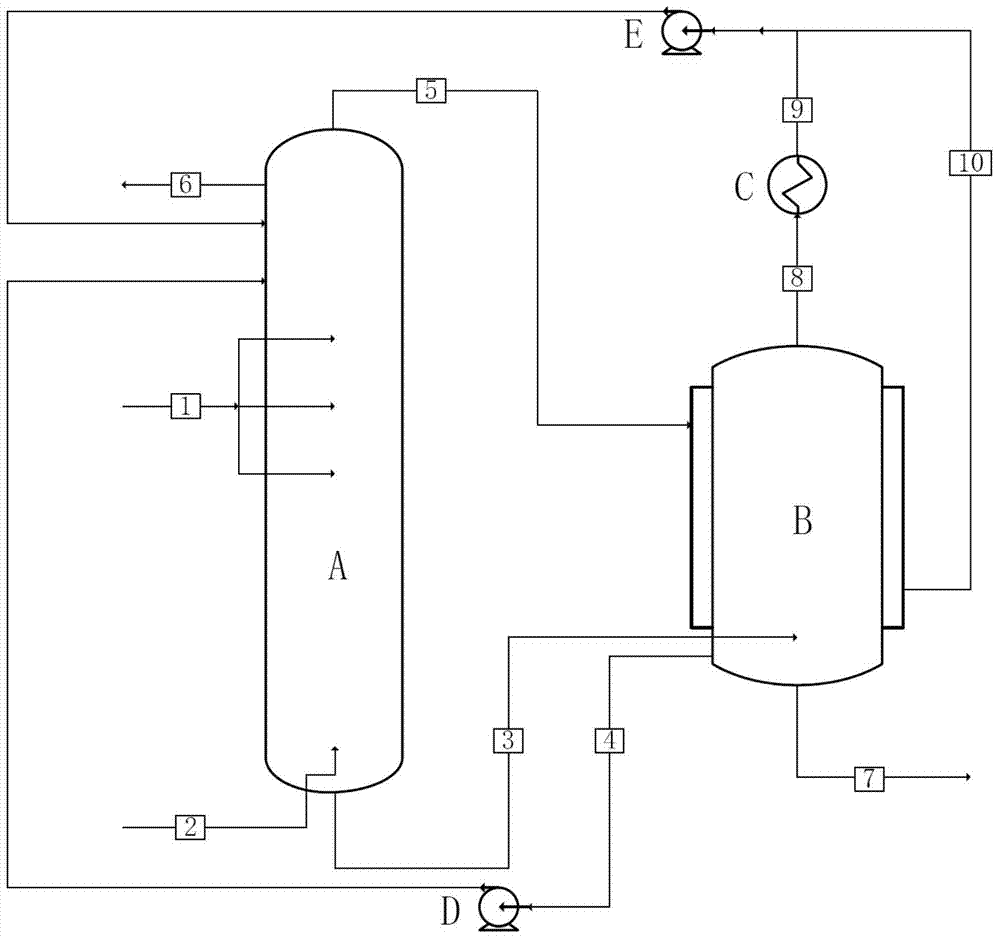

Alkylate waste sulfuric acid resourceful treatment device and method

ActiveCN105217654AGood economic and social benefitsSave time in method flow and handlingChemical industryAmmonia compoundsAmmonium sulfateChemistry

The invention relates to an alkylate waste sulfuric acid resourceful treatment device and method. The device is composed of a reaction flotation tower, a crystallizer, a heat exchanger, a mother solution circulation pump, a condensate pump and connecting pipelines between the components. Alkylate waste sulfuric acid and ammonia gas serve as inlet materials of the reaction flotation tower, and a high-temperature and high-pressure ammonium sulfate mother solution generated at the bottom of the tower enters a crystallizer; low-pressure steam generated by the reaction flotation tower is extracted from the top of the tower and enters an outer jacket of the crystallizer; polymerization oil in the alkylate waste sulfuric acid is subjected to floatation and extraction in reaction and floatation integrated equipment to obtain polymerization oil; the normal-pressure saturated ammonium sulfate mother solution crystallized in the crystallizer returns the reaction flotation tower through the mother solution circulation pump; generated crystals are extracted to serve as ammonium sulfate crystals; the normal-pressure steam generated in the crystallizer is condensed through the heat exchanger and then returns to the reaction flotation tower through the condensate pump; condensation water generated in the outer jacket of the crystallizer returns to the reaction flotation tower through the condensate pump. The method process is simplified, the operation time is shortened, and the method is environmentally friendly.

Owner:TIANJIN RUYOU TECH CO LTD

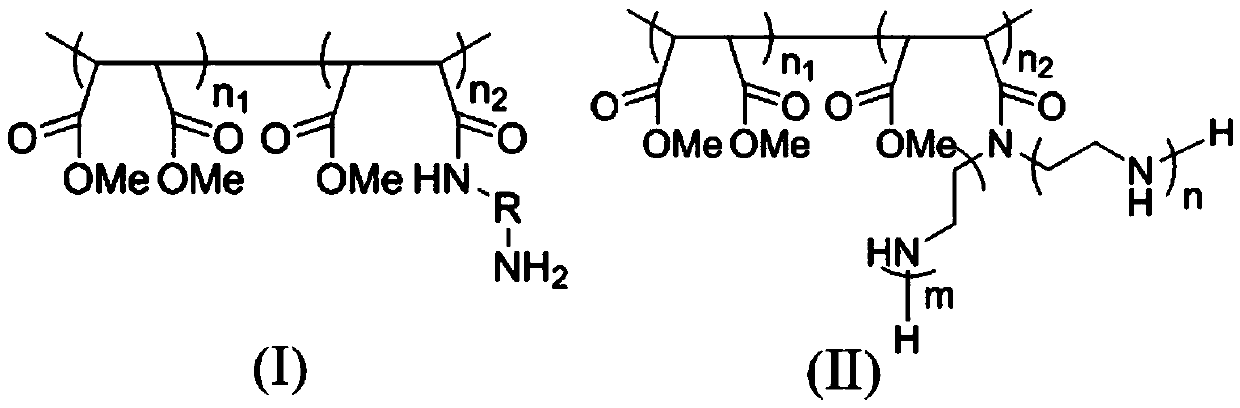

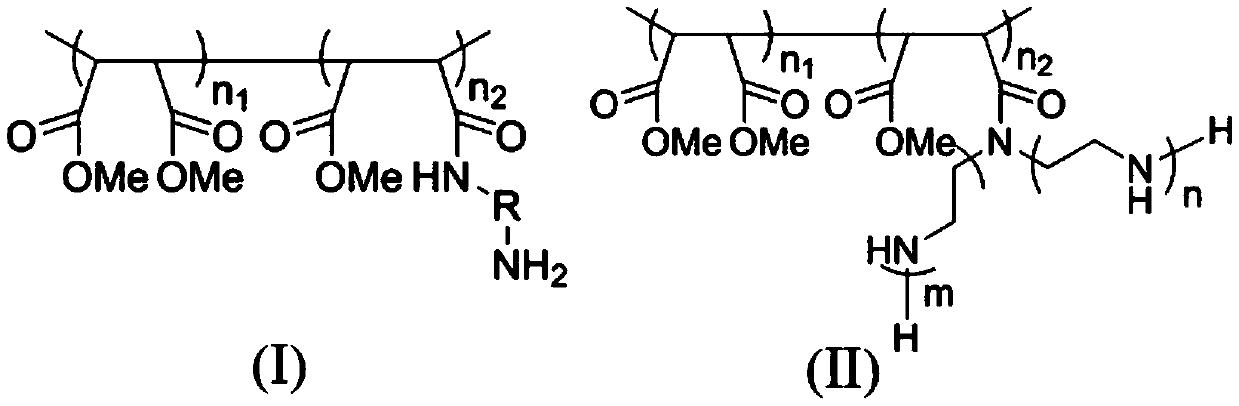

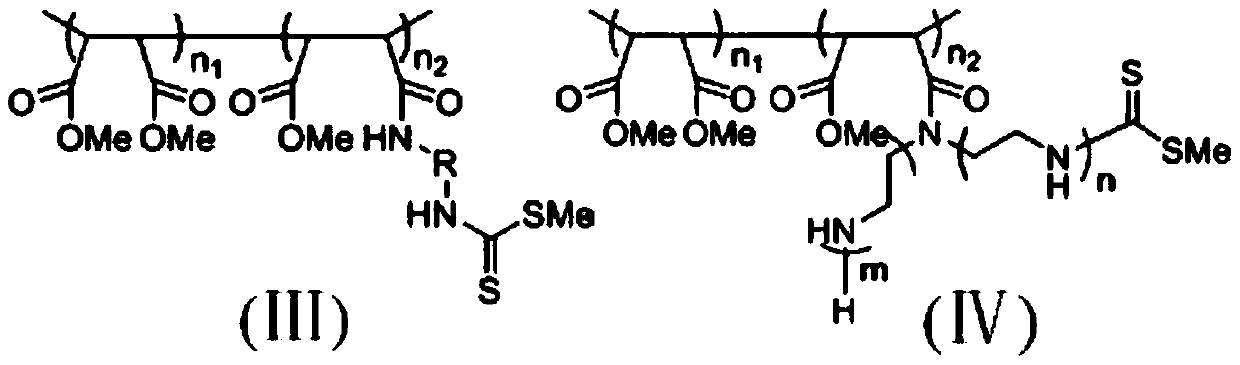

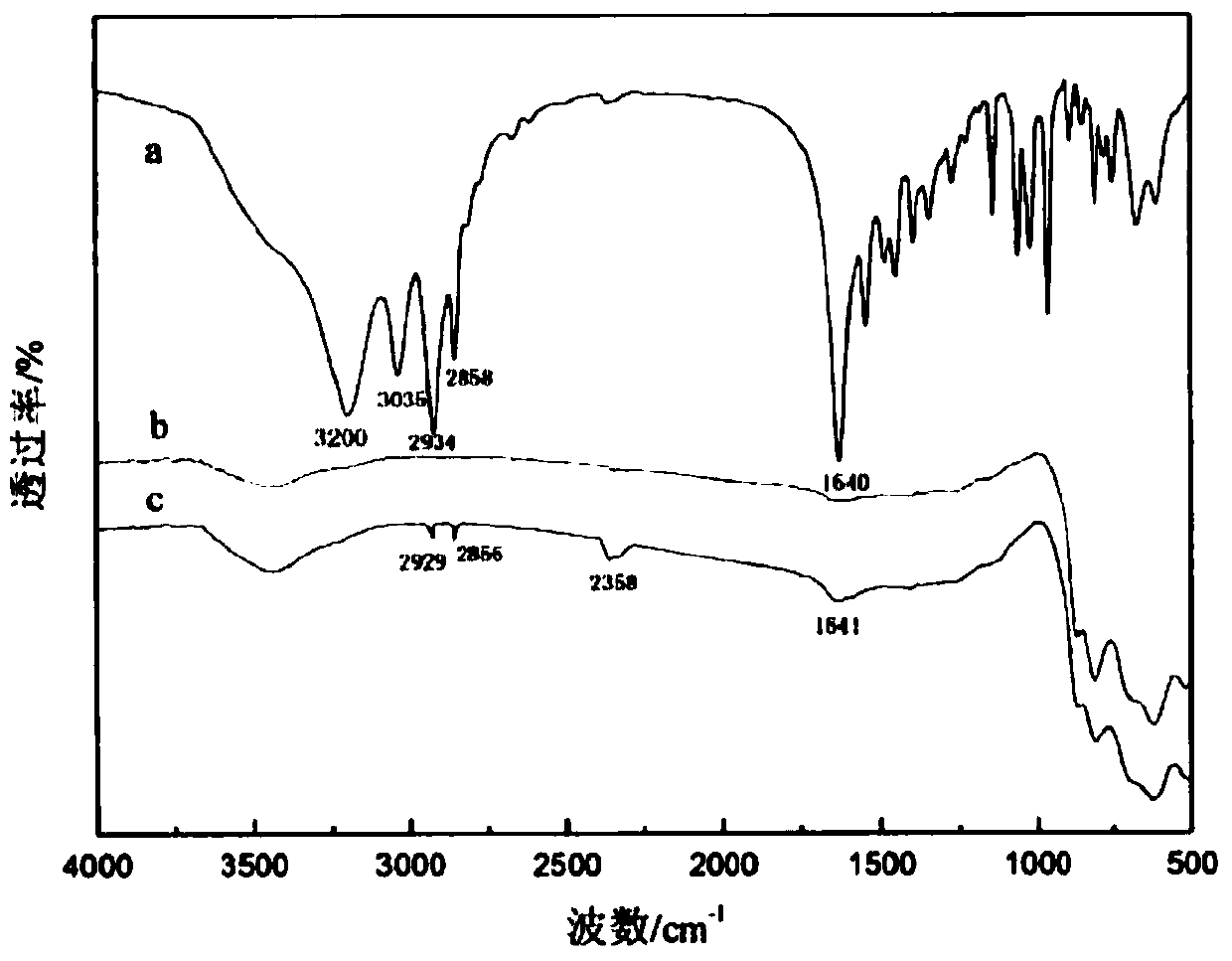

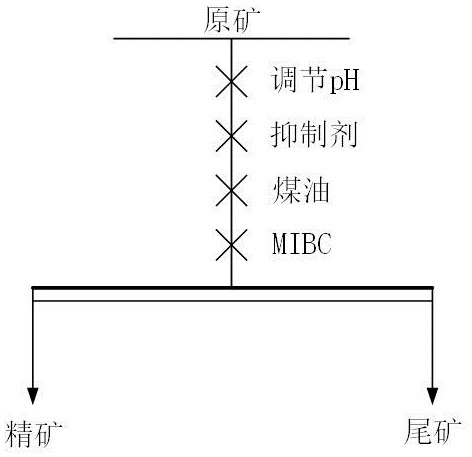

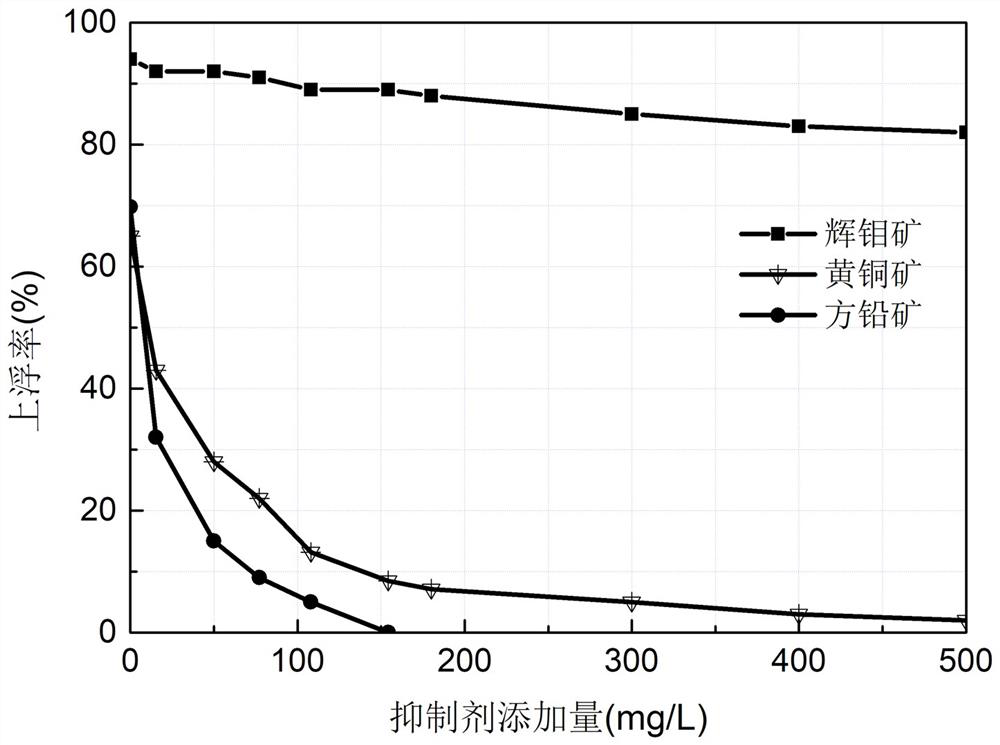

Polymetallic sulfide ore flotation separation inhibitor and flotation separation method thereof

The invention discloses a polymetallic sulfide ore flotation separation inhibitor and a flotation separation method thereof; polymaleic anhydride reacts with an organic compound containing a pluralityof amino groups to obtain an intermediate M, and then the intermediate M reacts with carbon disulfide in an alkaline solution to obtain a polymetallic sulfide ore flotation separation inhibitor. Themulti-metal sulfide ore flotation separation inhibitor provided by the invention is simple in preparation process and mild in reaction condition, has the advantages of safety in use, convenience in addition, easiness in obtaining raw materials and the like, also has the technical advantages of low toxicity, environmental friendliness, small dosage and good inhibition effect, and can effectively replace a traditional inhibitor. The multi-metal sulfide ore flotation separation inhibitor can effectively inhibit impurity minerals such as galena, chalcopyrite, sphalerite, pyrite and bismuthite, canbe widely applied to the flotation separation process of multi-metal sulfide ores such as copper lead, lead zinc, molybdenum lead, molybdenum sulfur, molybdenum bismuth, copper molybdenum and copperlead molybdenum, and is beneficial to improving the separation index.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

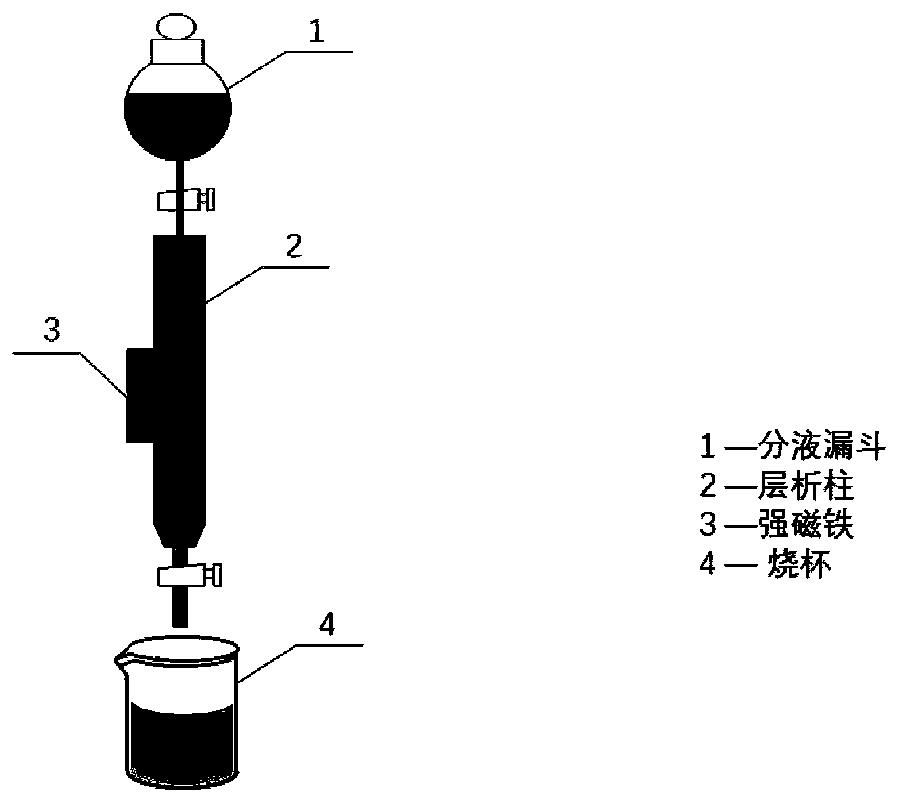

Charged magnetic hydrophobic material and preparation method and application thereof in separation of micro-fine-particle minerals

The invention discloses a charged magnetic hydrophobic material and a preparation method and application thereof in separation of micro-fine-particle minerals. The material includes magnetic particlesand a metal organic complex loaded on the surface, has strong magnetism, is positively charged on the surface, and has high electrostatic adsorption capacity for anions and high physical adsorption performance for hydrophobic micro-fine-particle minerals, and therefore, after micro-fine-particle minerals in ore pulp are subjected to surface hydrophobic and anion modification, the micro-fine-particle minerals can be adsorbed and agglomerated by utilizing the material, then the micro-fine-particle minerals are efficiently separated from gangue minerals through magnetic separation, thus solvinga difficult problem of separation and purification of ultrafine minerals. A preparation process of the charged magnetic hydrophobic material is simple and cheap and meets industrial production requirements.

Owner:CENT SOUTH UNIV

Marmatite inhibitor preparation method

InactiveCN104437881ASuppressed flotation separationInhibition of buoyancyFlotationSolubilityPollution

The invention discloses a marmatite inhibitor preparation method. The method comprises the steps that (1) bark is weighed and obtained according to the mass percent ranging from 1:1 to 1:1.5, the bark is smashed and screened, and a mixture A is obtained; (2) the mixture A and sodium carbonate or sodium sulfide are mixed according to the mass percent ranging from 1:3 to 1:4 and are added with water to form a solution with the mass percentage concentration ranging from 30% to 35%, the solution is made to stand, and is heated and cooked, and a substance B is obtained after water is completely evaporated; (3) the substance B and sodium humate are mixed according to the mass percent ranging from 1:2 to 1:2.5 and added with water to form a solution, the solution is stirred for 2 h to 3 h, then is cooked at 65 DEG C to 75 DEG C, and finally a marmatite inhibitor is obtained after water is completely evaporated. The marmatite inhibitor can achieve flotation separation for jamesonite and marmatite on the natural pH condition, medicament dosage is mall, the marmatite inhibitor is good in solubility, innocuous and free of pollution, the flotation technological process in the prior art is simplified, operation is easier, and meanwhile the technological cost is reduced.

Owner:广西华锡集团股份有限公司 +1

Combined inhibitor for flotation separation of lead-zinc sulfide ore and application

PendingCN113477410AEfficient flotationImprove flotation levelFlotationOre concentrateInorganic chemistry

The invention discloses a combined inhibitor for flotation separation of lead-zinc sulfide ore and application. The combined inhibitor comprises zinc sulfate and iminodisuccinic acid. The combined inhibitor is used as a sphalerite inhibitor for flotation separation of galena and sphalerite. The method comprises the steps of conducting ore grinding and pulp mixing on raw ore, obtaining ore pulp to be floated, sequentially adding a combined inhibitor, quick lime, a collecting agent and a foaming agent into the ore pulp for lead flotation operation, obtaining lead concentrate and lead flotation tailings, sequentially adding an activating agent, the collecting agent and the foaming agent into the lead flotation tailings for zinc flotation operation, and obtaining zinc concentrate and tailings. The combined inhibitor has a strong inhibition effect on sphalerite, flotation separation of galena and sphalerite is effectively achieved, the combined inhibitor can be naturally degraded and is environmentally friendly, and the dosage of zinc sulfate can be reduced by adding iminodisuccinic acid, so that the mineral separation cost is reduced.

Owner:YILIANG CHIHONG MINING IND +1

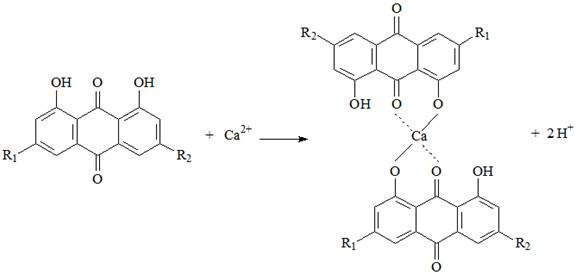

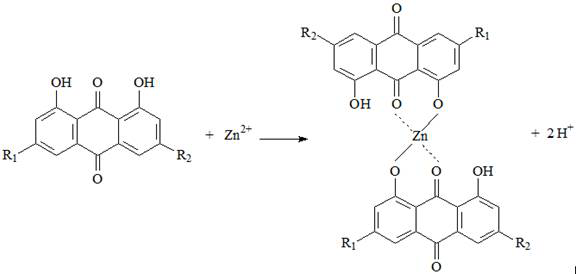

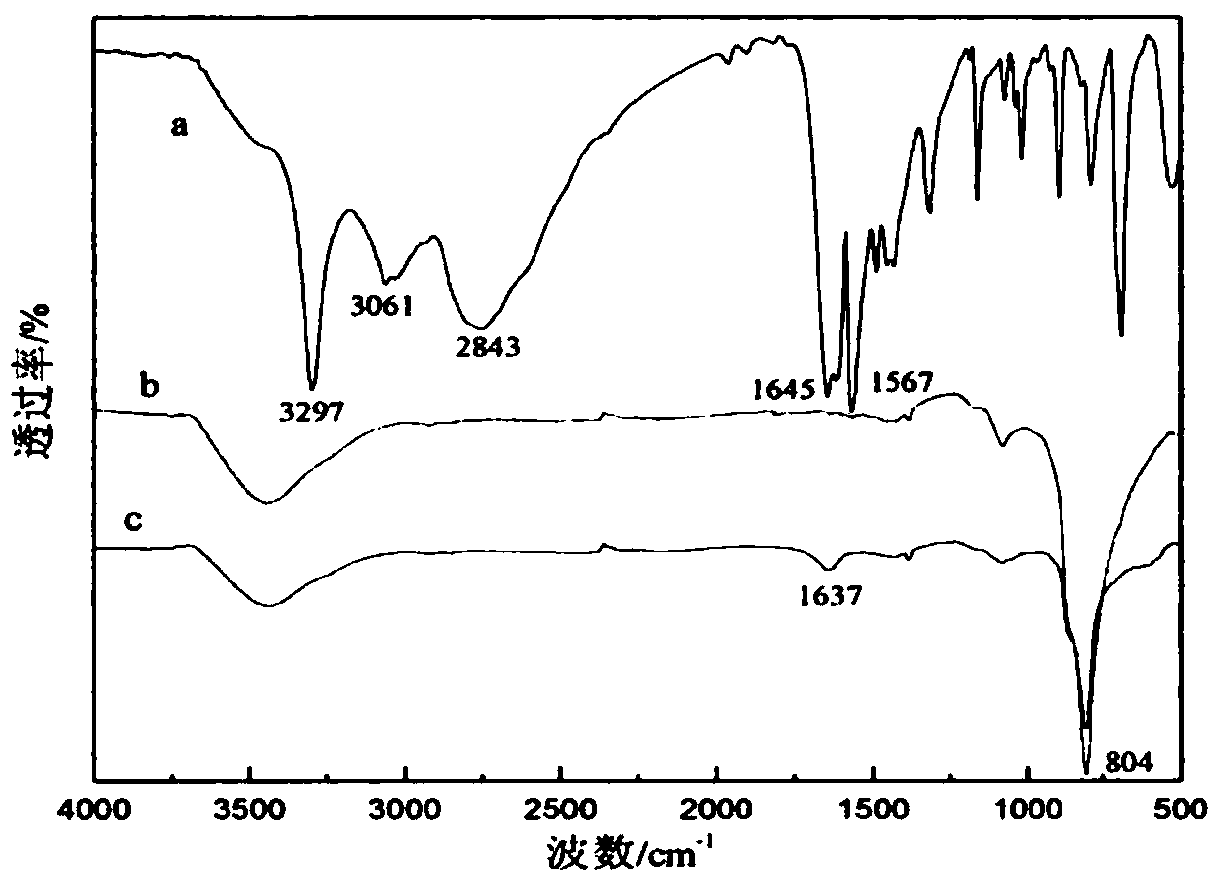

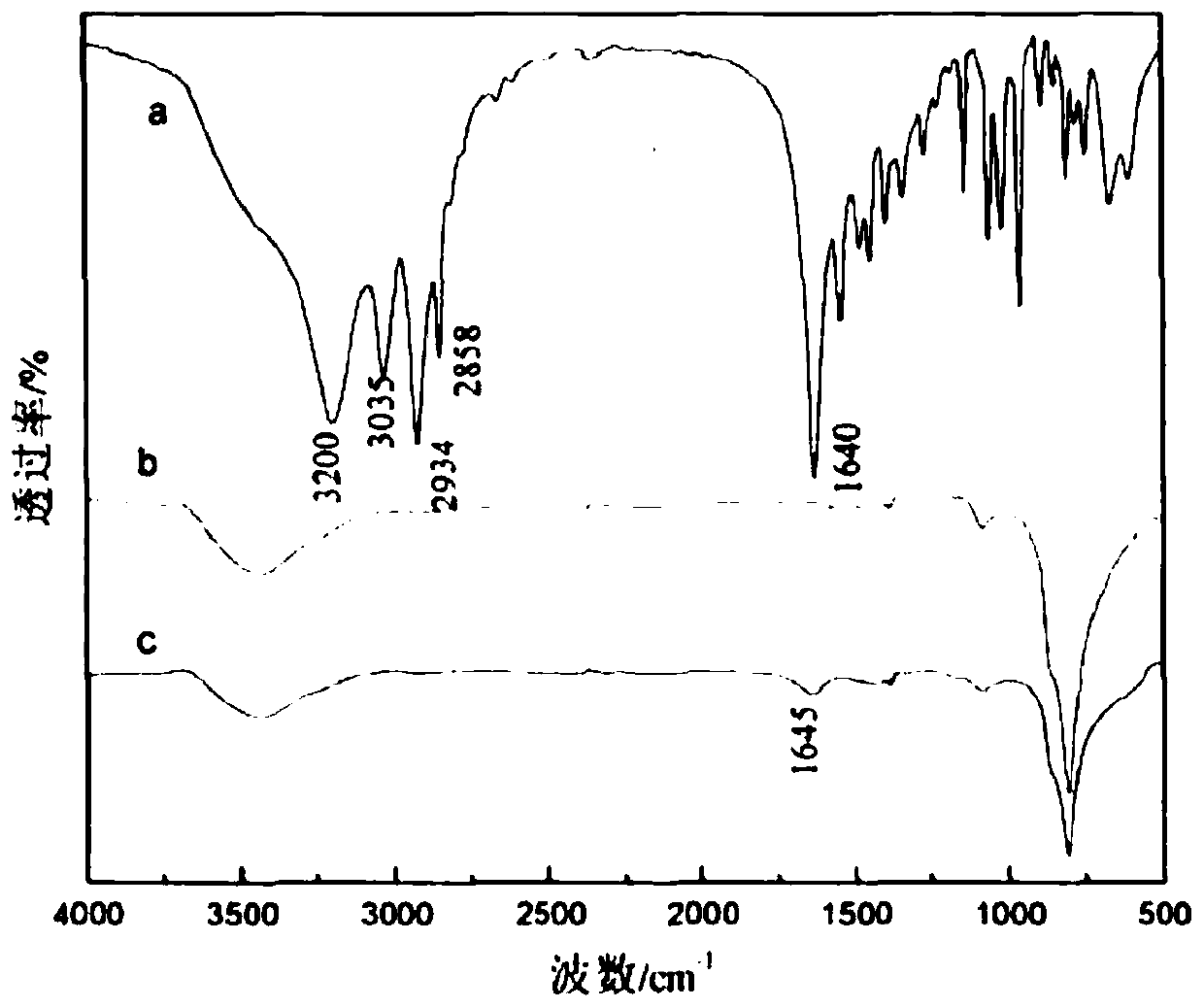

Sphalerite flotation composite inhibitor and application thereof

The invention discloses a sphalerite flotation composite inhibitor and application thereof, and belongs to the technical field of sphalerite flotation. The composite inhibitor comprises an organic inhibitor and an inorganic inhibitor, the organic inhibitor is composed of one or two of emodin, chrysophanol, aloe-emodin and rheinic acid, and the inorganic inhibitor is composed of ZnSO4 and any one of CaO, Na2CO3, Na2S2O5 and Ca(ClO)2. Compared with a single inhibitor, the composite inhibitor has the advantages that a complex formed by the composite inhibitor in ore pulp can be adsorbed to the surface of sphalerite, the hydrophilicity of the sphalerite is improved, and the floatability of the sphalerite is reduced. The composite inhibitor can be used in a low-alkalinity environment, can selectively inhibit sphalerite, and basically has no inhibition effect on chalcopyrite; the composite inhibitor is stable in property, small in dosage, safe, non-toxic, easy to add and capable of effectively achieving flotation separation of sphalerite and chalcopyrite.

Owner:KUNMING UNIV OF SCI & TECH

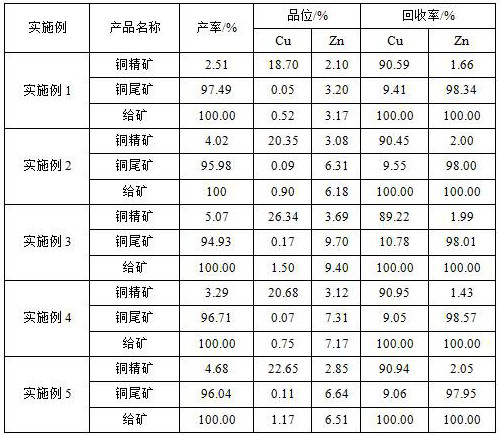

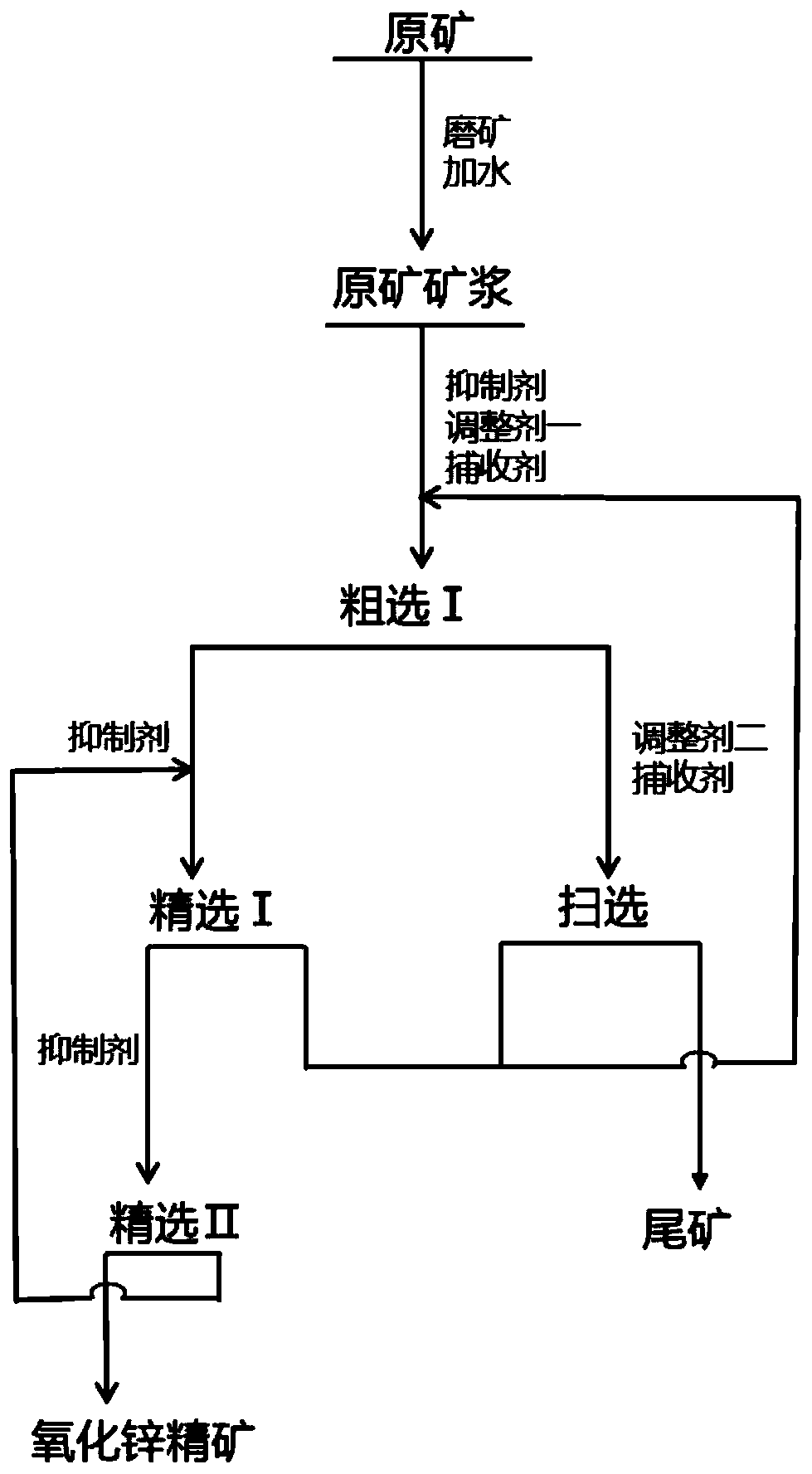

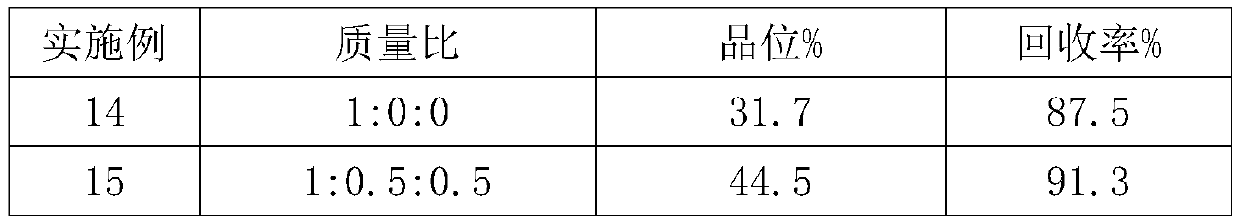

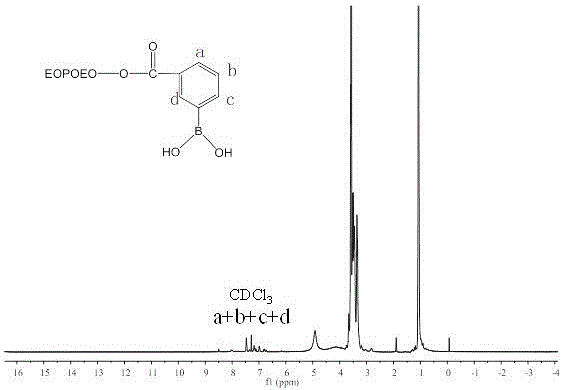

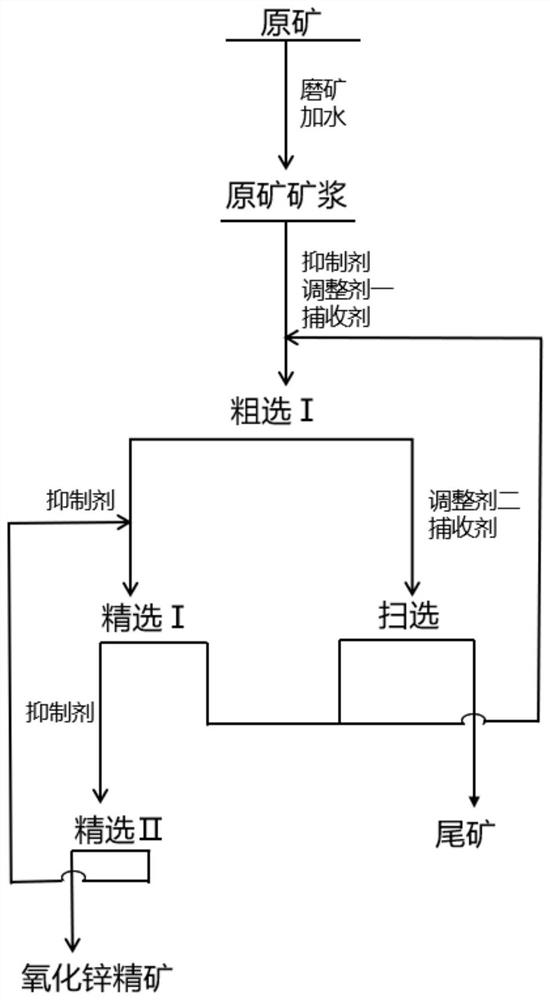

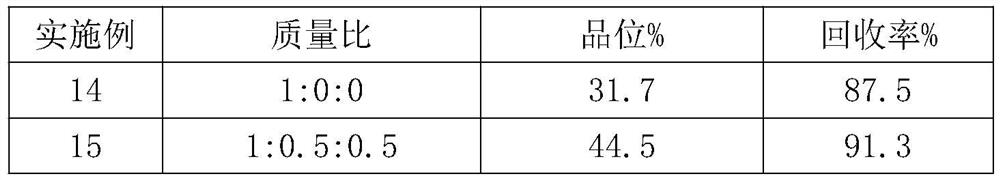

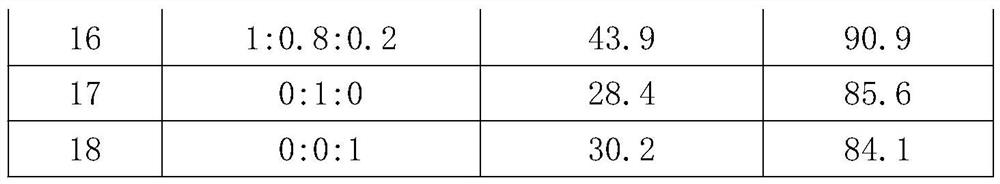

Flotation method for zinc oxide in sulphide ore tailings

The invention discloses a flotation method for zinc oxide in sulphide ore tailings. Sodium hexametaphosphate and sodium silicate which have a remarkable inhibiting effect on gangue minerals such as quartz, calcium magnesium carbonate and magnesium silicate and slime in sulfide ore tailings are used as a combined inhibitor, and meanwhile a combined collecting agent formed by mixing CA-1, N-nitroso-benzene nuclear ammonium salt and E-5 according to the proportion of 1: (0.5-0.8): (0.2-0.5) is used. The combined collecting agent is adopted, a one-roughing, two-concentrating and one-sweeping closed-loop non-desliming direct flotation process flow is adopted, the dosage ratio of the inhibitor to the regulator in the flotation process is reasonably optimized, the flotation reagent consumption can be effectively reduced, the separation index is improved, and the recovery rate and the grade of the zinc oxide concentrate in the sulphide ore tailings are remarkably improved, so that the zinc oxide concentrate of which the zinc grade is 46.7% and the zinc recovery rate is as high as 92.4% is obtained, and efficient utilization of low-grade refractory zinc oxide ore resources in the sulphide ore tailings is realized.

Owner:NANHUA UNIV

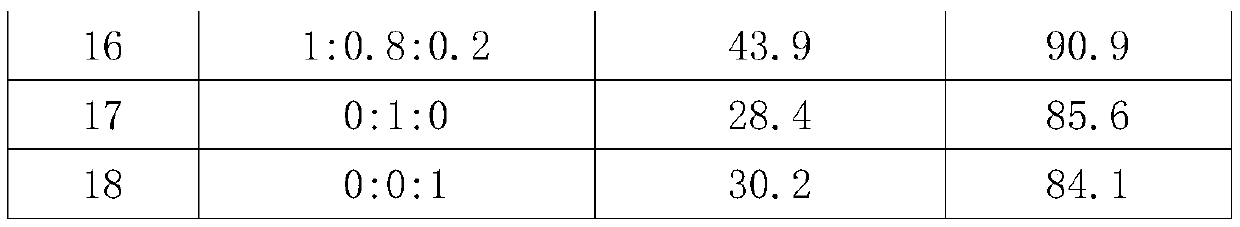

Method for separating and purifying o-hydroxyl compound

ActiveCN106278852AHigh enrichment factorHigh purityIon-exchange process apparatusIon-exchanger regenerationPhenylboronic acidNatural product

The invention relates to a method for separating and purifying an o-hydroxyl compound, and belongs to the field of natural product separation and purification. The method comprises the steps that firstly, alizarin red and K2HPO4 are added into a colorimetric tube, then phenylboronic acid functionalized PEO20PPO60PEO20 is added, the solution is diluted with distilled water, full shaking is carried out, and the mixture is mixed to be uniform; the mixture is poured into a flotation column after still standing, then normal propyl alcohol is added, gas flowing speed is regulated, and flotation is started; after the system is divided into two phases, the volume of the upper phase is recorded, and the alizarin red concentration in the upper phase is measured. The double aqueous phase flotation system is set up for flotation separation of o-hydroxyl compound alizarin red; synthesized phenylboronic acid functionalized PEO20PPO60PEO20 is added to serve as a complementing agent and can be effectively combined with alizarin red, meanwhile, functionalized PEO20PPO60PEO20 can be effectively adsorbed on a hydrophobic bubble interface, and flotation separation of water-soluble alizarin red is achieved; obtained alizarin red is large in the enrichment factor and high in purity, and the yield of the product can be increased.

Owner:JIANGSU UNIV

Method for flotation separation of potassium feldspar and quartz

InactiveCN108126825ARealize flotation separationNo pollution in the processFlotationHydrofluoric acidMalonic acid

The invention belongs to the technical field of flotation separation methods, and particularly relates to a method for flotation separation of potassium feldspar and quartz. A regulator malonic acid capable of replacing HF in a traditional hydrofluoric acid method can be found, the using effect of malonic acid is equivalent to that of HF, the requirement for the pH value in the flotation separation process is lowered, no pollution is caused to the environment, and the flotation separation process is simplified.

Owner:CHANGCHUN GOLD RES INST

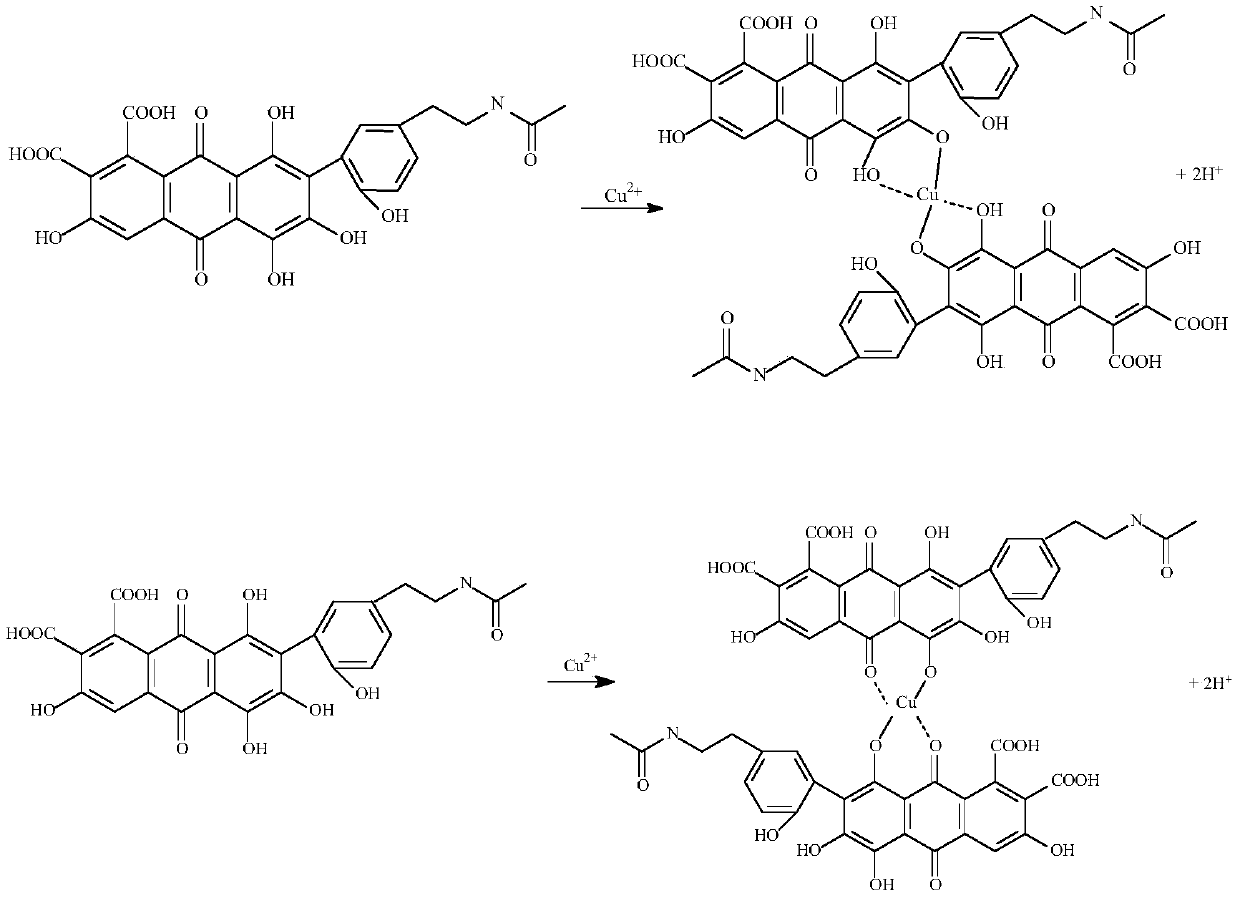

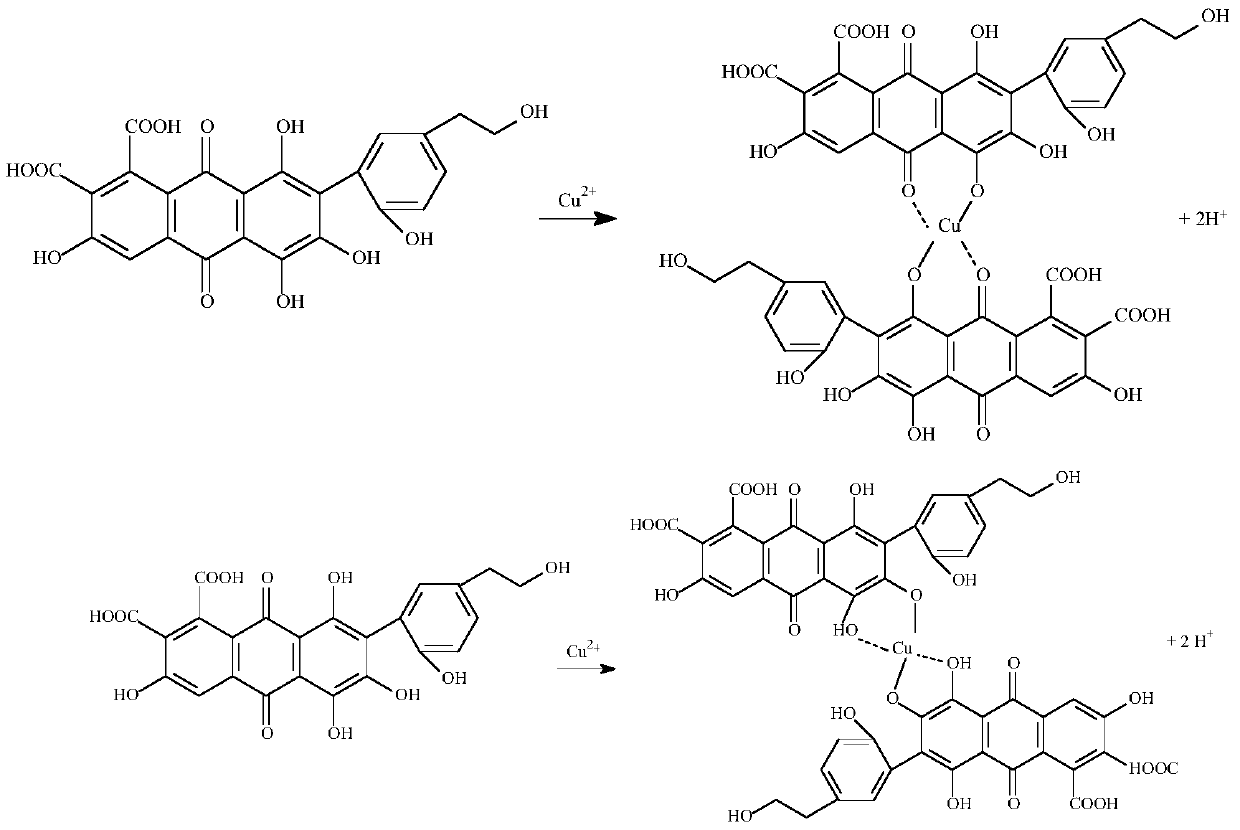

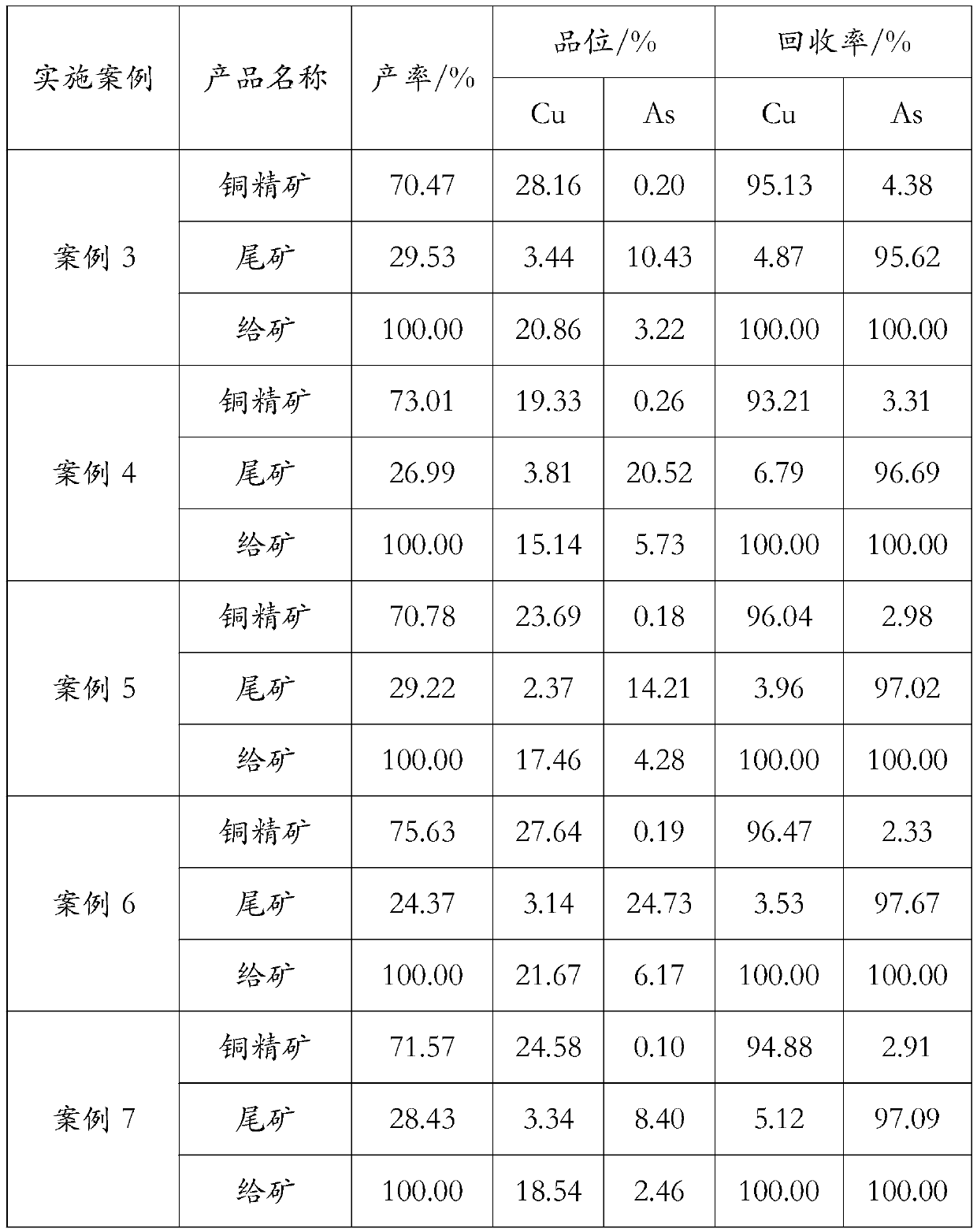

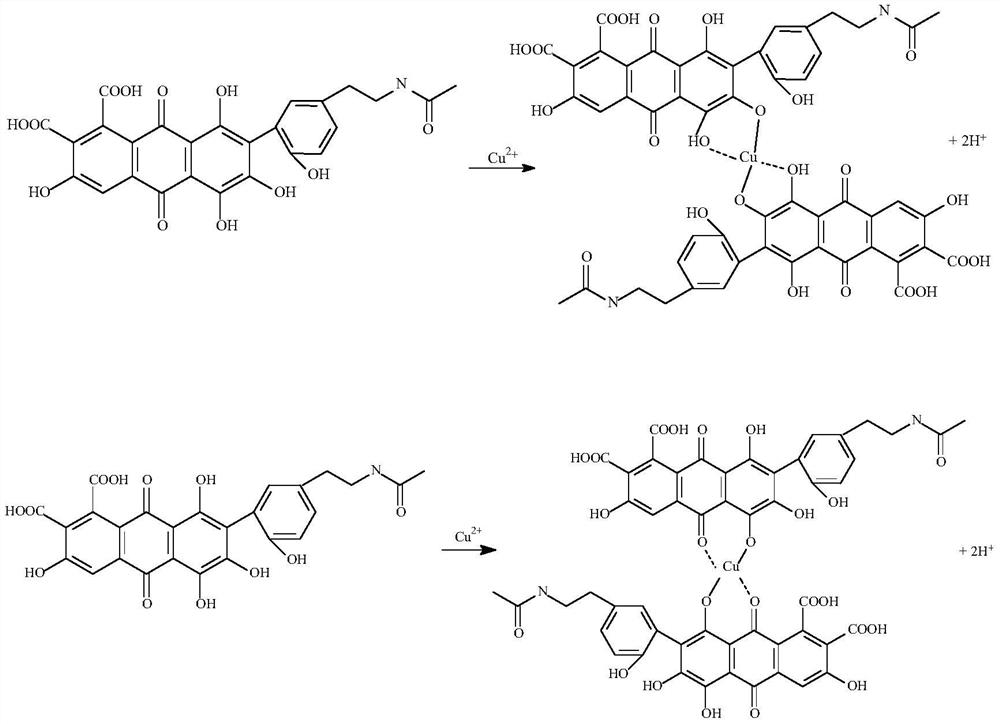

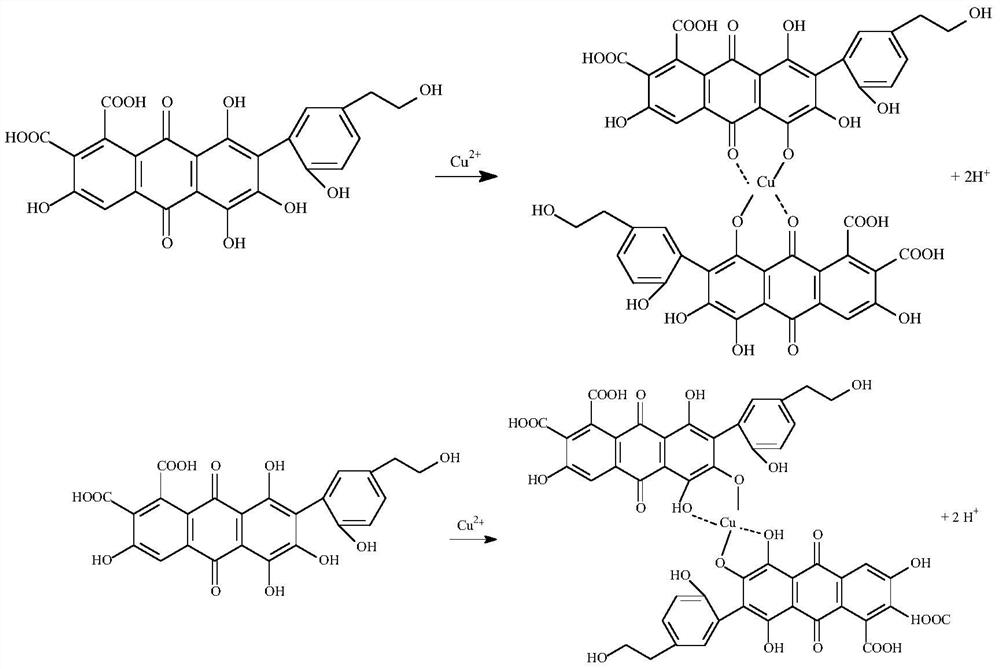

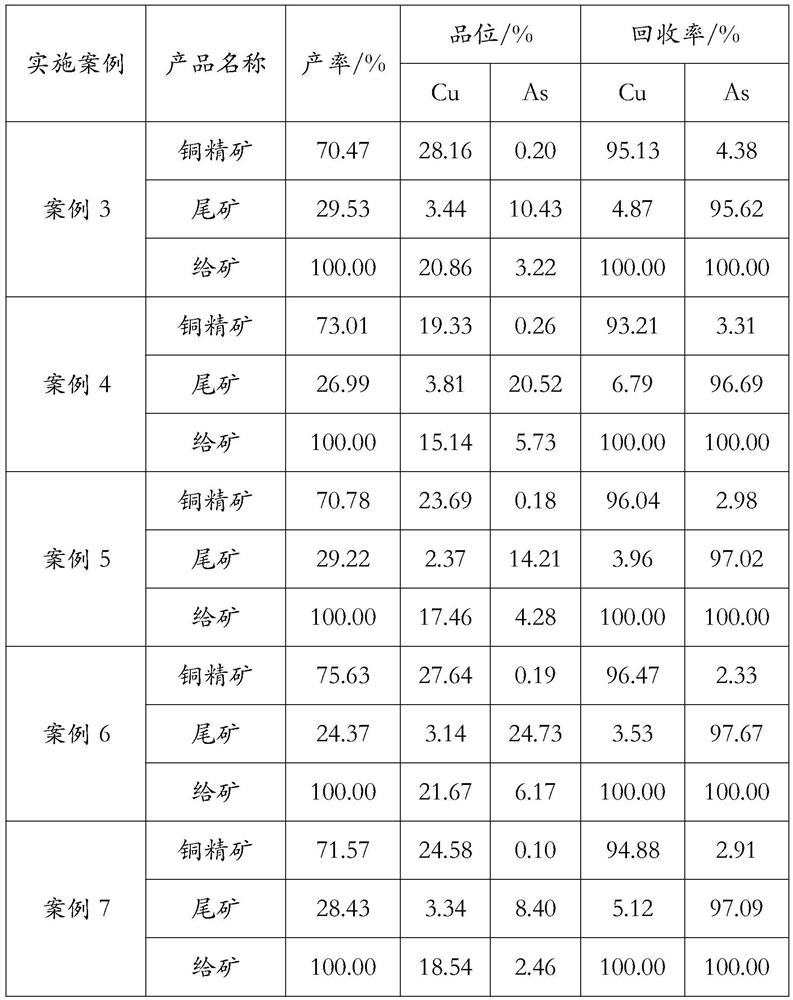

Arsenopyrite combined inhibitor and application thereof

The invention belongs to the technical field of flotation separation of arsenopyrite and copper sulfide ores, and particularly relates to an arsenopyrite combined inhibitor and an application thereof.The combined inhibitor comprises an organic inhibitor and an inorganic inhibitor. The organic inhibitor and Cu<2+> form a complex, and the complex is adsorbed on the surface of arsenopyrite, so the hydrophilicity of the surface of the arsenopyrite is enhanced, the floatability of the arsenopyrite is reduced, and the inhibition effect on the arsenopyrite is enhanced. Compared with single inhibitors, the combined inhibitor can greatly reduce the adsorbing capacity of a collecting agent on the surface of the arsenopyrite ore. The combined inhibitor has a high inhibition selectivity on arsenopyrite, and basically has no inhibition effect on the copper sulfide ore. The combined inhibitor has a high adaptability, and can effectively inhibit arsenopyrite in copper sulfide concentrate containingchalcopyrite and schreyerite. The combined inhibitor also has the advantages of small dosage, safety, non-toxicity, environmental friendliness, good stability, good water solubility, easiness in preparation and addition, convenience in use, effective achieving of flotation separation of the arsenopyrite and copper sulfide ores, and wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

A kind of arsenopyrite combined inhibitor and its application

The invention belongs to the technical field of flotation separation of arsenopyrite and copper sulfide ores, and particularly relates to an arsenopyrite combined inhibitor and an application thereof.The combined inhibitor comprises an organic inhibitor and an inorganic inhibitor. The organic inhibitor and Cu<2+> form a complex, and the complex is adsorbed on the surface of arsenopyrite, so the hydrophilicity of the surface of the arsenopyrite is enhanced, the floatability of the arsenopyrite is reduced, and the inhibition effect on the arsenopyrite is enhanced. Compared with single inhibitors, the combined inhibitor can greatly reduce the adsorbing capacity of a collecting agent on the surface of the arsenopyrite ore. The combined inhibitor has a high inhibition selectivity on arsenopyrite, and basically has no inhibition effect on the copper sulfide ore. The combined inhibitor has a high adaptability, and can effectively inhibit arsenopyrite in copper sulfide concentrate containingchalcopyrite and schreyerite. The combined inhibitor also has the advantages of small dosage, safety, non-toxicity, environmental friendliness, good stability, good water solubility, easiness in preparation and addition, convenience in use, effective achieving of flotation separation of the arsenopyrite and copper sulfide ores, and wide application prospect.

Owner:KUNMING UNIV OF SCI & TECH

A metal ion complex collector and its preparation method and application

The invention discloses a metal ion complex collecting agent and a preparation method and application of the metal ion complex collecting agent. The metal ion complex collecting agent is formed by a ligand and metal ions in a coordination manner. The preparation method of the metal ion complex collecting agent comprises the step that soluble metal salt is added into a solution with the ligand for a reaction, and the metal ion complex collecting agent is obtained. The method is simple and low in cost. The prepared metal ion complex collecting agent has extremely high selective collecting capacity on tungsten-containing minerals, rare earth, cassiterite and the like, the tungsten-containing minerals, the cassiterite, the rear earth and the like can be selectively separated from calcic gangue minerals in the absence of a calcic mineral inhibitor, and the problem that calcic minerals are hard to separate is fundamentally solved. The metal ion complex collecting agent is good in selective collecting effect, stable in performance, low in use level, low in cost and capable of being widely applied to the floatation and separation process of the tungsten-containing minerals, the cassiterite and the rear earth, and the quality of concentrates is effectively improved.

Owner:CENT SOUTH UNIV +1

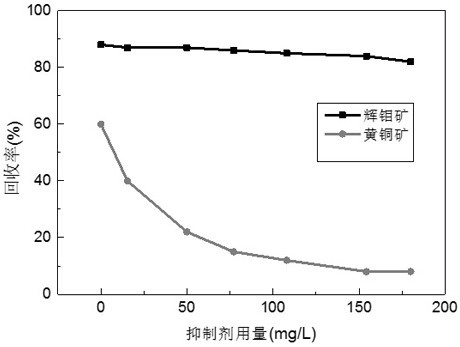

A kind of non-molybdenum sulfide ore flotation inhibitor and its application

A kind of sulfide ore flotation inhibitor disclosed by the present invention, chemical name is: DL dithiothreitol; Its structural formula is: provide a kind of application method of non-molybdenum sulfide ore flotation inhibitor simultaneously, comprise the following steps: ( 1) The mineral is mixed with water to obtain a pulp, and the pH of the pulp is adjusted; (2) The DL-dithiothreitol aqueous solution is added to the pH-adjusted pulp; (3) Inflatable flotation to obtain foam products and tailings, this scheme The sulfide ore flotation inhibitor has an inhibitory effect on primary copper sulfide, secondary copper sulfide and galena in molybdenum concentrate, and can realize the separation of molybdenite and non-sulfide minerals, with less consumption, low price, Pollution is small.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A charged electromagnetic hydrophobic material and its preparation method and application

The invention discloses a charged magnetic hydrophobic material and a preparation method and application thereof in separation of micro-fine-particle minerals. The material includes magnetic particlesand a metal organic complex loaded on the surface, has strong magnetism, is positively charged on the surface, and has high electrostatic adsorption capacity for anions and high physical adsorption performance for hydrophobic micro-fine-particle minerals, and therefore, after micro-fine-particle minerals in ore pulp are subjected to surface hydrophobic and anion modification, the micro-fine-particle minerals can be adsorbed and agglomerated by utilizing the material, then the micro-fine-particle minerals are efficiently separated from gangue minerals through magnetic separation, thus solvinga difficult problem of separation and purification of ultrafine minerals. A preparation process of the charged magnetic hydrophobic material is simple and cheap and meets industrial production requirements.

Owner:CENT SOUTH UNIV

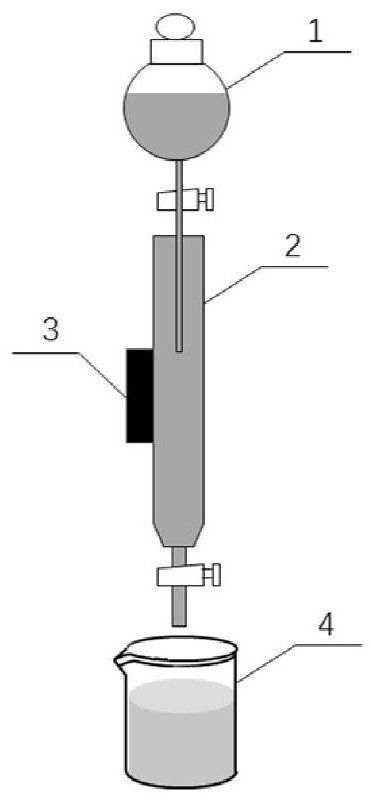

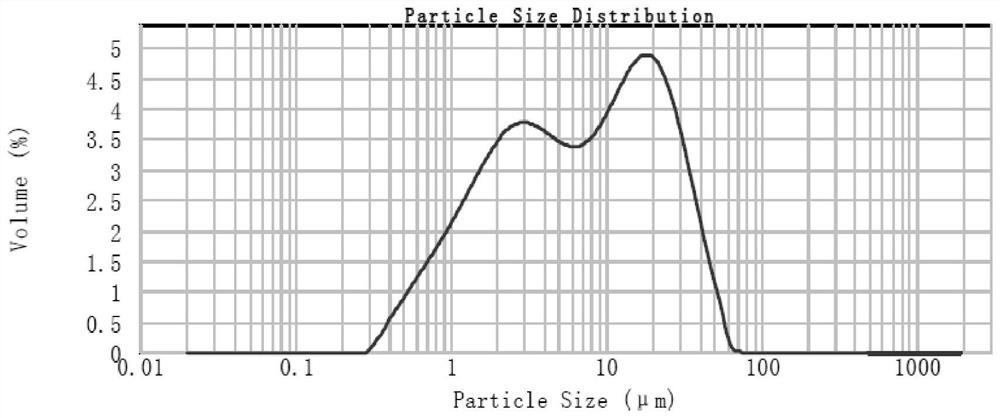

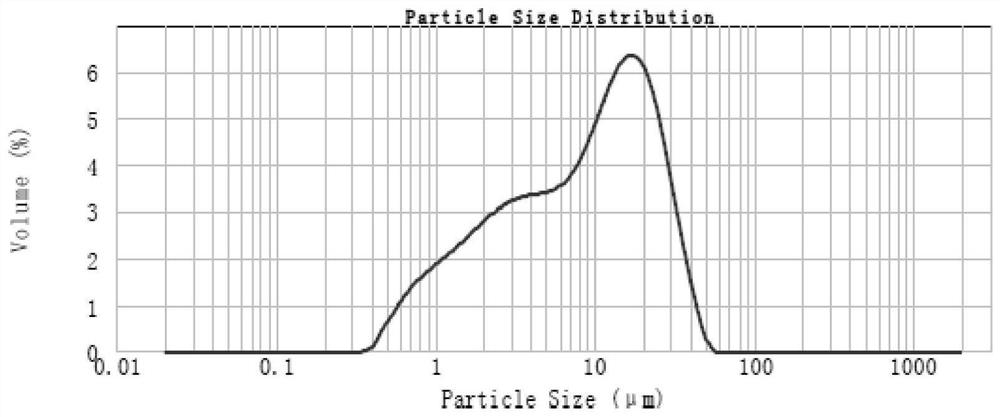

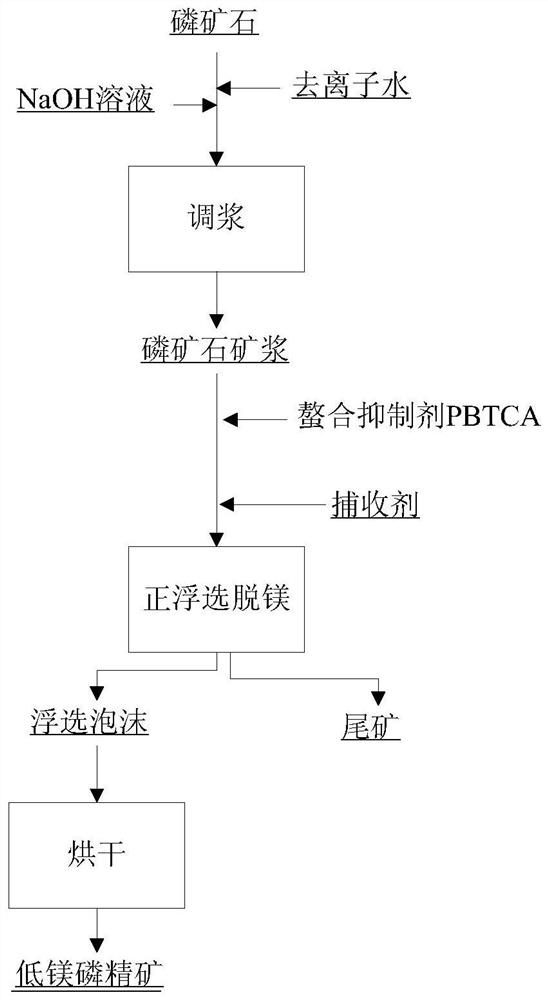

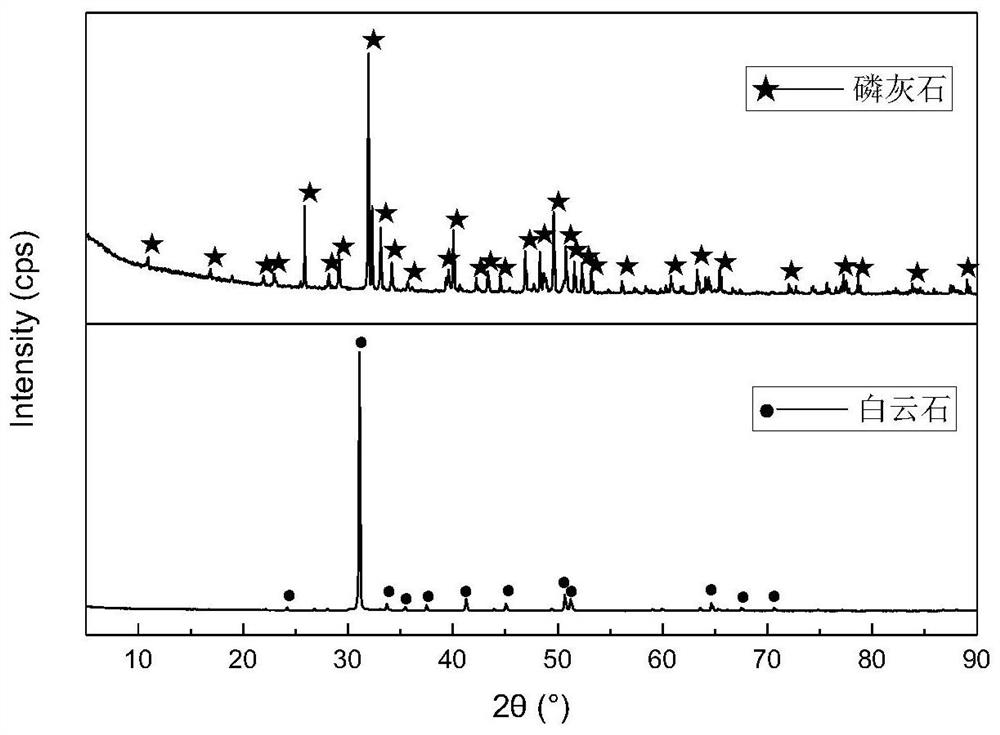

A kind of method that uses chelation inhibitor PBTCA to carry out phosphate rock flotation to remove magnesium

InactiveCN111036410BSuppressed flotation separationRealize the purpose of positive flotation magnesium removalFlotationMagnesium phosphateMining engineering

A method of flotation demagnesization of phosphate rock using chelating inhibitor PBTCA, which belongs to the field of flotation separation of salt minerals. This method uses water to adjust the slurry and pH value, and then adds the chelating inhibitor PBTCA (2-phosphonobutane-1,2,4-tricarboxylic acid) to perform positive flotation and remove magnesium, and the obtained flotation product is dried dry to obtain low magnesium phosphate concentrate, whose P 2 O 5 The recovery rate is 77.54% to 84.31% by weight, and the removal rate of MgO in the low magnesium phosphate concentrate is 74.06% to 83.08% by weight. This method selectively inhibits dolomite flotation by adding the chelating inhibitor PBTCA, expands the difference in flotation performance between apatite and dolomite, and uses positive flotation method to achieve effective separation of apatite and dolomite. In addition, the chelating inhibitor PBTCA is biodegradable, non-toxic, highly selective, low-cost, and easy to obtain commercially, and can achieve the goal of flotation demagnesization of high-magnesium and low-grade phosphate ores.

Owner:NORTHEASTERN UNIV LIAONING

A kind of flotation method of zinc oxide in sulfide ore tailings

The invention discloses a method for flotation of zinc oxide in sulfide ore tailings. By using a six-component zinc oxide with remarkable inhibitory effect on gangue minerals and slimes such as quartz, calcium magnesium carbonate and magnesium silicate in sulfide ore tailings, Sodium metaphosphate and sodium silicate are combined inhibitors, and a combination of CA-1, N-nitroso-phenylnuclear ammonium salt, and E-5 is used in the ratio of 1:0.5~0.8:0.2~0.5 Collector; by adopting the above-mentioned combined collector, and through a closed-circuit non-desliming direct flotation process of one coarse, two fine and one sweep, and rationally optimizing the dosage ratio of inhibitor and regulator in the flotation process, it can effectively Reduce the dosage of flotation agents, improve the separation index, and significantly increase the recovery rate and grade of zinc oxide concentrate in sulfide ore tailings, thus obtaining a zinc oxide concentrate with a zinc grade of 46.7% and a zinc recovery rate of 92.4%. It has realized the efficient utilization of low-grade refractory zinc oxide ore resources in sulfide ore tailings.

Owner:NANHUA UNIV

Flotation method for desulfurization and desilication of high-silicon bauxite

InactiveCN102228869BRealize flotation separationImprove the efficiency of flotation separationFlotationEngineeringReverse flotation

The present invention provides a flotation method for desulfurization and desilication of high-silicon bauxite, which separately employs direct flotation desulfurization and reverse flotation desilication processes for simultaneous desulfurization and desilication and comprises the following steps of: firstly ball-milling high-silicon bauxite with a ball mill and then carrying out direct flotation through direct flotation desulfurization and reverse flotation desilication. The flotation reagent used in the floatation method is conducive to direct flotation desulfurization and reverse flotation desilication. When the bauxite to be floated has a sulfur content larger than 1% and an aluminum / silicon ratio larger than 5.5, the aluminum / silicon ratio of the flotation concentrate can reach morethan 10, the sulfur content in the concentrate is less than 0.3%, the recovery rate of Al2O3 is more than 80%, and the utilization of bauxite is greatly improved.

Owner:KUNMING UNIV OF SCI & TECH

A device and method for recycling waste sulfuric acid from alkylation

ActiveCN105217654BSave operating timeAvoid strong corrosiveChemical industryAmmonia compoundsCondensate pumpAmmonia gas

The invention relates to an alkylate waste sulfuric acid resourceful treatment device and method. The device is composed of a reaction flotation tower, a crystallizer, a heat exchanger, a mother solution circulation pump, a condensate pump and connecting pipelines between the components. Alkylate waste sulfuric acid and ammonia gas serve as inlet materials of the reaction flotation tower, and a high-temperature and high-pressure ammonium sulfate mother solution generated at the bottom of the tower enters a crystallizer; low-pressure steam generated by the reaction flotation tower is extracted from the top of the tower and enters an outer jacket of the crystallizer; polymerization oil in the alkylate waste sulfuric acid is subjected to floatation and extraction in reaction and floatation integrated equipment to obtain polymerization oil; the normal-pressure saturated ammonium sulfate mother solution crystallized in the crystallizer returns the reaction flotation tower through the mother solution circulation pump; generated crystals are extracted to serve as ammonium sulfate crystals; the normal-pressure steam generated in the crystallizer is condensed through the heat exchanger and then returns to the reaction flotation tower through the condensate pump; condensation water generated in the outer jacket of the crystallizer returns to the reaction flotation tower through the condensate pump. The method process is simplified, the operation time is shortened, and the method is environmentally friendly.

Owner:TIANJIN RUYOU TECH CO LTD

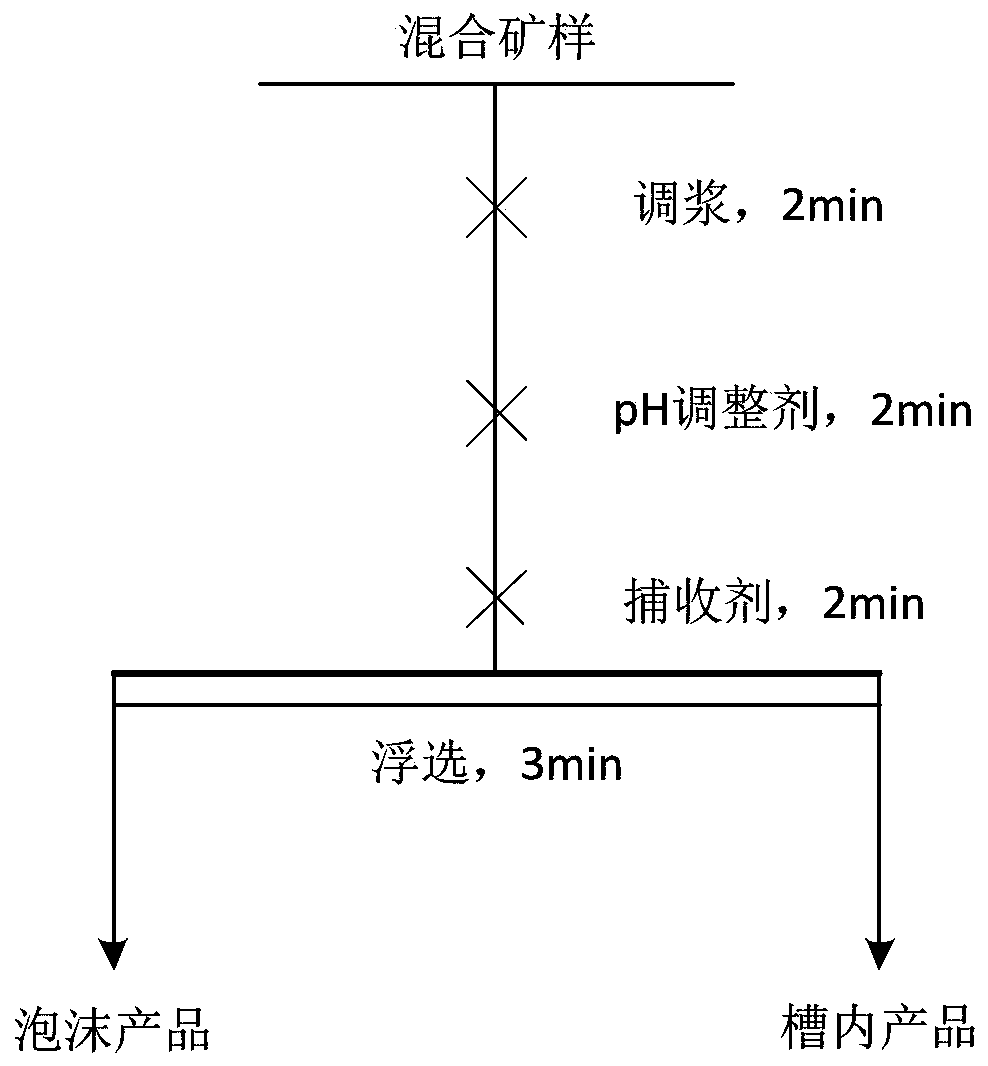

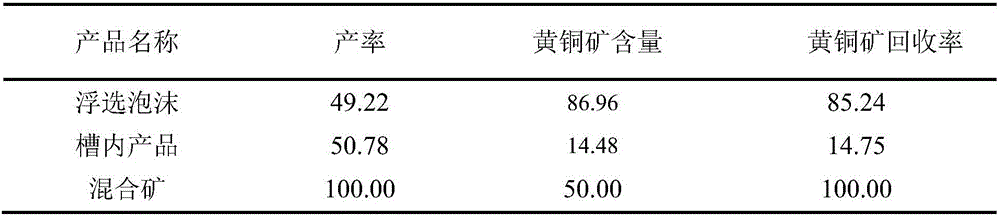

A method for flotation purification of hemimorphite from quartz

The invention relates to a method for flotation and purification of hemimorphite from quartz, specifically to a flotation separation method for hemimorphite and quartz, and belongs to the technical field of mineral flotation separation in the field of mineral processing engineering. A method for flotation and purification of hemimorphite from quartz. Mix the mixed mineral sample of hemimorphite and quartz to be processed with deionized water, and add a collector to the evenly stirred slurry. The amount of collector is 750 ~900g / t; stir the slurry added with the collector evenly and then perform flotation, wherein the collector is sodium N,N'-bis-fatty acyl ethylenediamine dipropionate. The process proposed by the present invention for flotation and purification of hemimorphite from quartz has a simple process flow, simple chemical system, convenient operation, and good industrial feasibility prospects.

Owner:NORTHEASTERN UNIV LIAONING

Method for separating chalcopyrite from talc with tragacanth

The invention provides a method for separating chalcopyrite from talc with tragacanth and belongs to the field of separating copper sulfide minerals from hydrophobic silicate gangue. The method comprises the steps that the chalcopyrite and the talc are levigated and put into a flotation tank of a hanging trough flotator, an appropriate amount of water is added into the flotation tank, and stirring and slurry mixing are conducted; pH of slurry is adjusted with a pH adjustment agent; the tragacanth which is an inhibitor, butyl xanthate which is a collecting agent and 2 # oil which is a foaming agent are added into the flotation tank, and stirring is conducted for 1-5min; air flotation is conduced, and concentrate and a tailings product are obtained; and the products are dried, weighed and tested. The tragacanth, the efficient inhibitor, can be adsorbed on the surface of the hydrophobic silicate gangue, so that a selective inhibiting effect is achieved on the hydrophobic silicate gangue; and meanwhile, the tragacanth is non-toxic, easy to degrade and low in cost.

Owner:JIANGXI UNIV OF SCI & TECH

Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

ActiveCN101480658BRealize flotation separationHigh carbon contentWaste processingFluoride preparationAluminium electrolysisWastewater

The invention relates to a method for comprehensively using aluminium to electrolyze a waste cathode carbon block, which belongs to the technical field of environment protection and comprises the following steps: crushing and grinding the waste cathode carbon block; adjusting the concentration and the PH value of ore slurry after the grinding, then using floatation equipment to carry out floatation treatment, and separating electrolyte and carbon which are contained in the waste cathode carbon block; using an aluminium salt solution to soak for extracting the electrolyte contained in a carbonproduct obtained from the floatation, and further improving the grade of a high-carbon product; mixing the grinding waste water, the floatation waste water and the soaking solution, and adding CaO and CaCl2 to precipitate and recover aluminium and fluothane in the mixture. The method for comprehensively using aluminium to electrolyze a waste cathode carbon block has simple operating condition, low energy consumption, high recovery ratio of valuable substances and good application prospect.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com