Polymetallic sulfide ore flotation separation inhibitor and flotation separation method thereof

A technology for sulfide ores and polymetals, applied in flotation, solid separation and other directions, can solve the problems of poor ore adaptability, high environmental protection pressure, poor inhibition effect, etc., and achieve the effect of convenient addition, safe use and strong inhibition effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

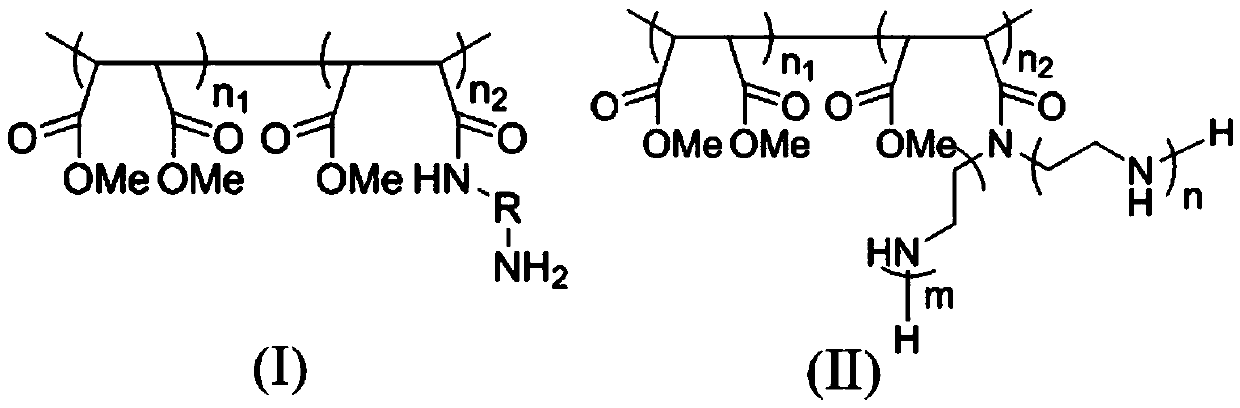

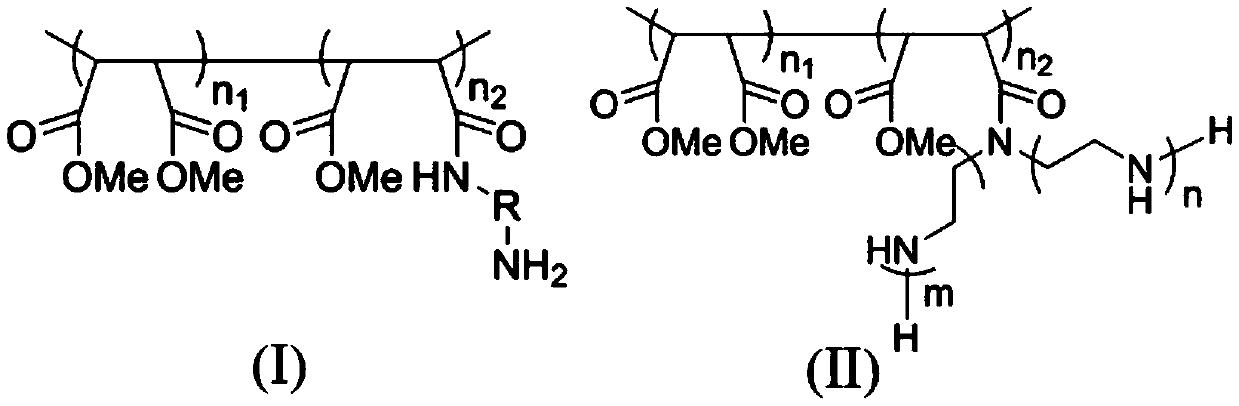

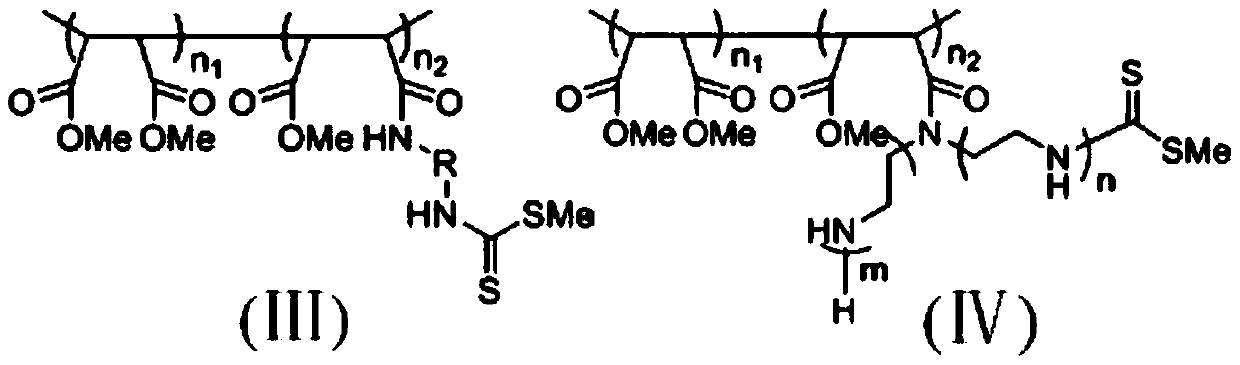

Method used

Image

Examples

Embodiment 1

[0028] The polymetallic sulfide ore flotation separation inhibitor is prepared by the following steps:

[0029] Put 12.0g of polymaleic anhydride (maleic anhydride content 0.1mol) in a 100ml three-necked bottle, then add 40ml of water, after stirring thoroughly, add 0.74g of propylenediamine (0.01mol of propylenediamine) at one time, and fully React for 3 hours; then add 20.0 g of 40% sodium hydroxide solution (containing 0.2 mol of sodium hydroxide), stir to make it fully dissolved, gradually warm up to 40 ° C, and then add 0.90 g of carbon disulfide (0.012 mol of carbon disulfide) , fully stirred for 2 hours, then heated up to 60° C., and continued to react for 3 hours. After the reaction was completed, a light yellow polymetallic sulfide ore flotation separation inhibitor solution with a mass concentration of about 25% was obtained.

Embodiment 2

[0031] The polymetallic sulfide ore flotation separation inhibitor is prepared by the following steps:

[0032] Put 12.0g of polymaleic anhydride (maleic anhydride content 0.1mol) in a 100ml there-necked bottle, then add 40ml of water, after stirring fully, add 1.03g of diethylenetriamine (0.01mol of diethylenetriamine) at one time, 30 ℃ fully reacted for 3 hours; then add 20.0g of 40% sodium hydroxide solution (containing 0.2mol of sodium hydroxide), stir to make it fully dissolved, gradually warm up to 40°C, then add 0.90g of carbon disulfide (0.012mol of carbon disulfide), fully stirred for 2 hours, then heated up to 60° C., and continued to react for 3 hours. After the reaction was completed, an orange to reddish-brown polymetallic sulfide ore flotation separation inhibitor solution with a mass concentration of about 25% could be obtained.

Embodiment 3

[0034] The mineral raw material is 2.0g of chalcopyrite and galena pure mineral artificial mixed ore with a mass ratio of 2:3. The flotation separation test is carried out in the XFG5-35 hanging tank flotation machine, 40ml of water is added, and the flotation machine speed is adjusted to 1754r / min, then adjust the pH in the tank to 8-9 with sodium hydroxide, then add the polymetallic sulfide ore flotation separation inhibitor prepared in Example 1 of the present invention, the consumption is 2mg / L, using O-isopropyl -N-ethylthiocarbamate is chalcopyrite collector, methyl isobutyl carbinol is used as foaming agent, the amount of collector and foaming agent is 10mg / L, and the flotation time is 4min. Copper concentrate with a copper grade of 28.9%, lead content of 12.1%, and a recovery rate of 93.1% was obtained through roughing, and lead concentrate with a lead grade of 80.6%, copper content of 1.5%, and a recovery rate of 90.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com