Method for separating chalcopyrite from talc with tragacanth

A technology of chalcopyrite and tragacanth, applied in solid separation, flotation, etc., can solve the problem that chalcopyrite cannot be separated by efficient flotation of talc, and achieve the effects of low cost, significant economic benefits, and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

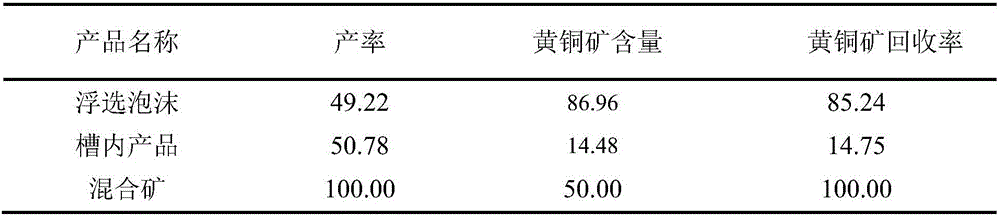

[0016] Grind chalcopyrite and talc until the particle size is less than 74um, take 1g of chalcopyrite and 1g of talc into the flotation cell of the hanging cell flotation machine, add 40mL of water and stir to obtain a uniform slurry, adjust the resulting slurry with a pH regulator The pH is 5, add 100mg / L concentration of 1% inhibitor tragacanth gum and stir for 5min, 20mg / L concentration of 5% collector butyl xanthate and stir for 3min, 10mg / L foaming agent No. 2 oil and stir for 1min , and then inflated flotation to obtain the flotation foam and the product in the tank, and the product is dried, weighed and tested. The results of the beneficiation test are shown in the table below.

[0017] Flotation test index (wt%)

[0018]

Embodiment 2

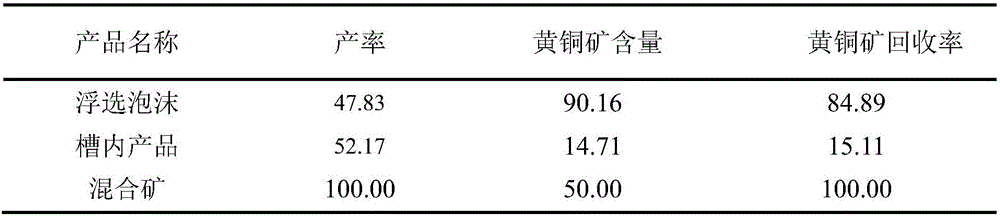

[0020] Grind chalcopyrite and talc until the particle size is less than 74um, take 1g of chalcopyrite and 1g of talc into the flotation cell of the hanging cell flotation machine, add 40mL of water and stir to obtain a uniform slurry, adjust the resulting slurry with a pH regulator The pH is 5, add 100mg / L concentration of 3% inhibitor tragacanth gum and stir for 5min, 40mg / L concentration of 5% collector butyl xanthate and stir for 3min, 10mg / L foaming agent No. 2 oil and stir for 1min , and then inflated flotation to obtain the flotation foam and the product in the tank, and the product is dried, weighed and tested. The results of the beneficiation test are shown in the table below.

[0021] Flotation test index (wt%)

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com