Method for electrolyzing waste and old cathode carbon block by comprehensive utilization of aluminum

A waste cathode carbon block and aluminum electrolysis technology, which is applied in the removal of solid waste, waste treatment, alumina/aluminum hydroxide, etc., can solve the problems of low electrolyte recovery rate, difficult fluoride recovery, and poor separation effect, etc. Achieve the effect of good application prospect, high recovery rate and simple operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

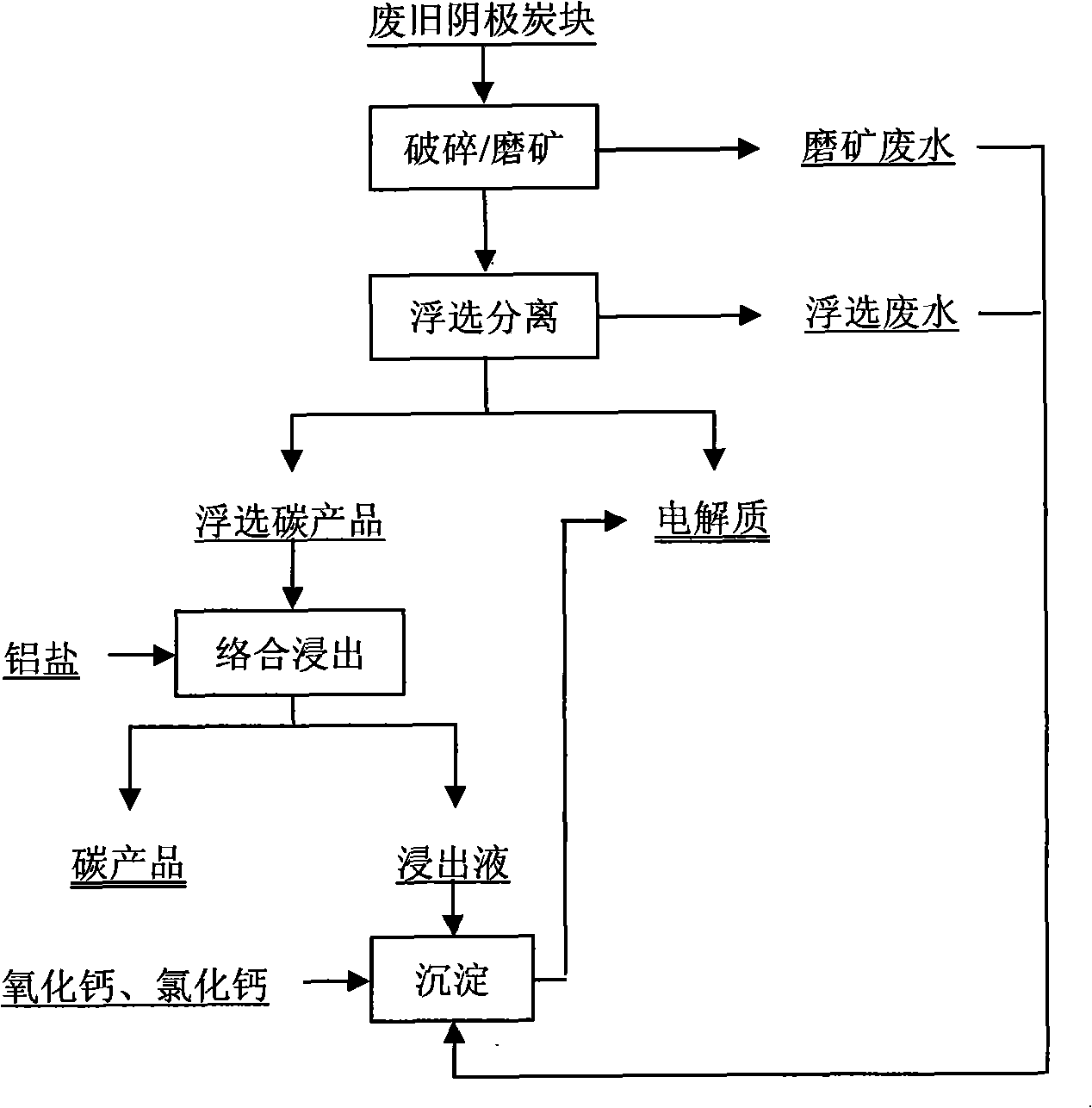

Method used

Image

Examples

Embodiment 1

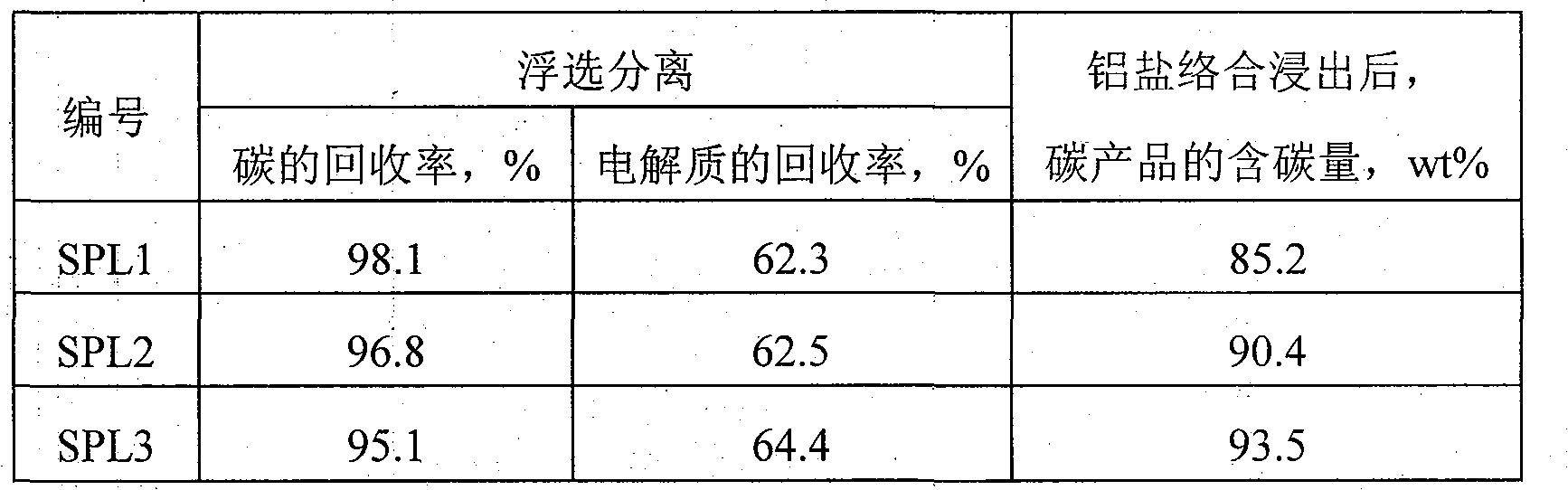

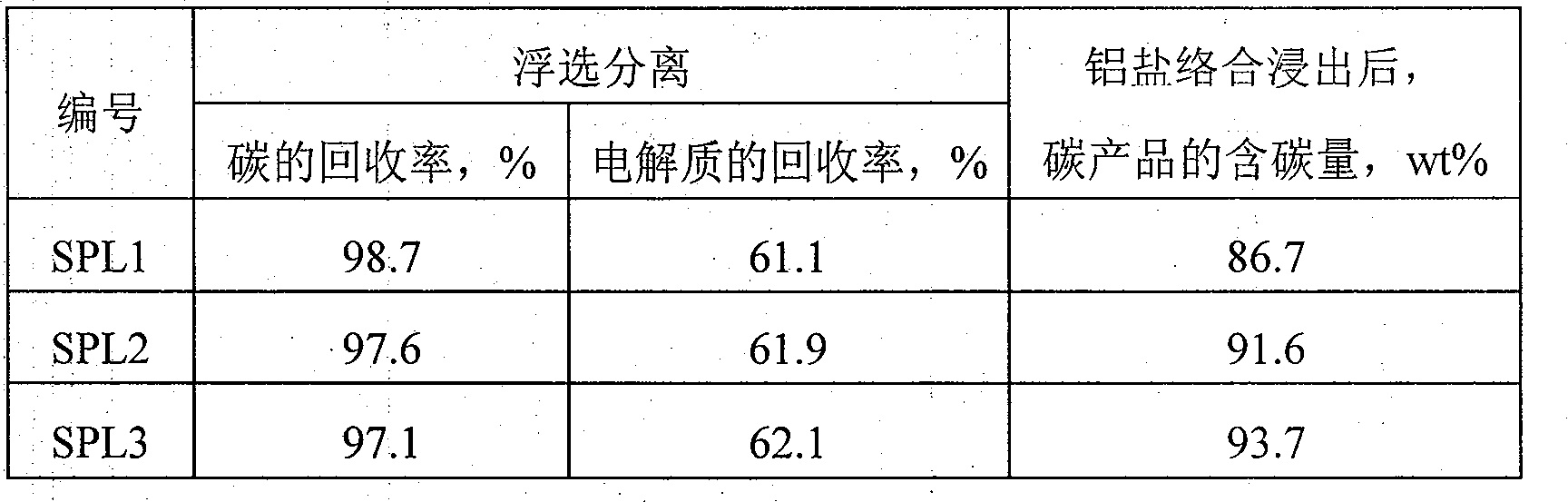

[0027] Three kinds of waste cathode carbon blocks with different carbon contents were crushed respectively, and the ore grinding equipment was used for grinding treatment, until the part of the waste cathode carbon blocks with a particle size less than 0.075mm accounted for 40wt%.

[0028] After ore grinding, adjust the pulp concentration to be 10wt%, and adjust the pH value of the pulp to 9 with inorganic acid and alkali; then put it into the flotation equipment, adopt No. 2 oil (pine alcohol oil) as a foaming agent, and kerosene as a collector , where the amount of foaming agent terpineol oil is 30g per ton of waste cathode carbon block; the amount of collector kerosene is 50g per ton of waste cathode carbon block. 3-stage grinding is adopted.

[0029] Use aluminum nitrate solution with a concentration of 0.5mol / L to leach the electrolyte of the carbon product obtained by flotation, and the addition amount is 10:1 according to the liquid-solid ratio. The relevant processing...

Embodiment 2

[0034] Three kinds of waste cathode carbon blocks with different carbon content were crushed, and the ore grinding equipment was used for grinding treatment, until the part of the waste cathode carbon blocks with a particle size less than 0.075mm accounted for 71wt%. After grinding, adjust the pulp concentration to 20wt%, and adjust the pH value of the pulp to 11 with inorganic acids and bases; then put it into the flotation equipment, adopt No. 2 oil (pine alcohol oil) as a foaming agent, and kerosene as a collector , wherein the amount of foaming agent terpineol oil is 200g per ton of waste cathode carbon block; the amount of collector kerosene is 300g per ton of waste cathode carbon block. 3-stage grinding is adopted.

[0035] An aluminum chloride solution with a concentration of 1.0 mol / L is used to leach the electrolyte of the carbon product obtained by flotation, and the addition amount is 8:1 according to the liquid-solid ratio. The relevant processing results are show...

Embodiment 3

[0040] Three kinds of waste cathode carbon blocks with different carbon contents were crushed respectively, and the ore grinding equipment was used for grinding treatment, until the part of the waste cathode carbon blocks with a particle size less than 0.075mm accounted for 78wt%.

[0041] After grinding, adjust the concentration of the pulp to 30wt%, and adjust the pH value of the pulp to 14 with inorganic acid and alkali; then put it into the flotation equipment, adopt No. 2 oil (pine alcohol oil) as a foaming agent, and kerosene as a collector , where the amount of foaming agent terpineol oil is 300g per ton of waste cathode carbon block; the amount of collector kerosene is 500g per ton of waste cathode carbon block. 3-stage grinding is adopted.

[0042] An aluminum chloride solution with a concentration of 1.5 mol / L is used to leach the electrolyte of the carbon product obtained by flotation, and the addition amount is 5:1 according to the liquid-solid ratio. The relevant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com