A device and method for recycling waste sulfuric acid from alkylation

A technology of alkylation of waste sulfuric acid and recycling, applied in chemical instruments and methods, ammonia compounds, inorganic chemistry, etc., can solve problems such as phase difference of ammonium sulfate crystals, intermittent operation, difficult recovery of polymerized oil, etc., and achieve saving method flow and operating time, good economic and social benefits, and remarkable energy-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

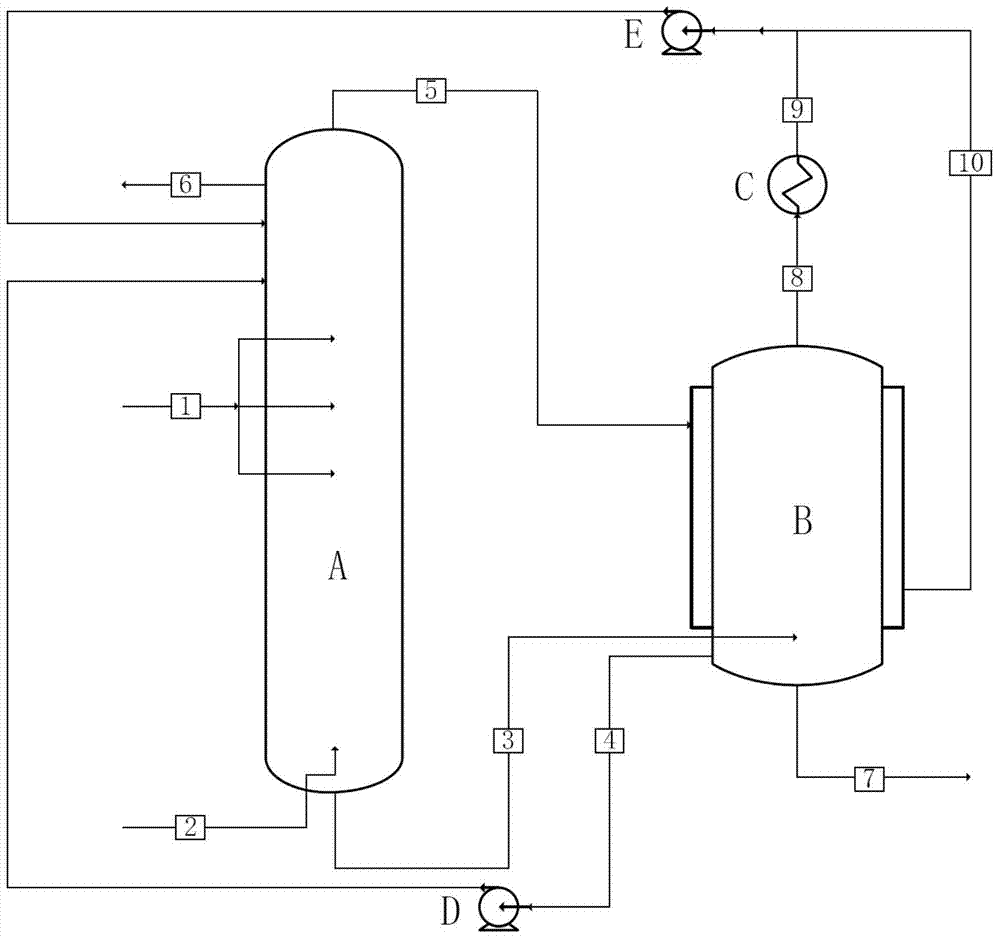

[0026] Describe in detail below in conjunction with accompanying drawing:

[0027] Such as figure 1 Shown: a kind of alkylation waste sulfuric acid recycling treatment device of the present invention:

[0028] It is composed of reaction flotation tower A, crystallizer B, heat exchanger C, mother liquid circulation pump D, condensate water pump E and connecting pipelines in between. The bottom liquid outlet of reaction flotation tower A passes through high temperature and high pressure ammonium sulfate mother liquid pipeline 3 It is connected with the liquid phase inlet of the lower part of the crystallizer B, and enters the liquid in the lower part of the crystallizer B; the bottom solution outlet of the crystallizer B is connected with the upper solution inlet of the reaction flotation tower A through the normal pressure saturated ammonium sulfate mother liquor pipeline 4 and the mother liquor circulation pump D , into the upper liquid phase of the reaction flotation tower A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com