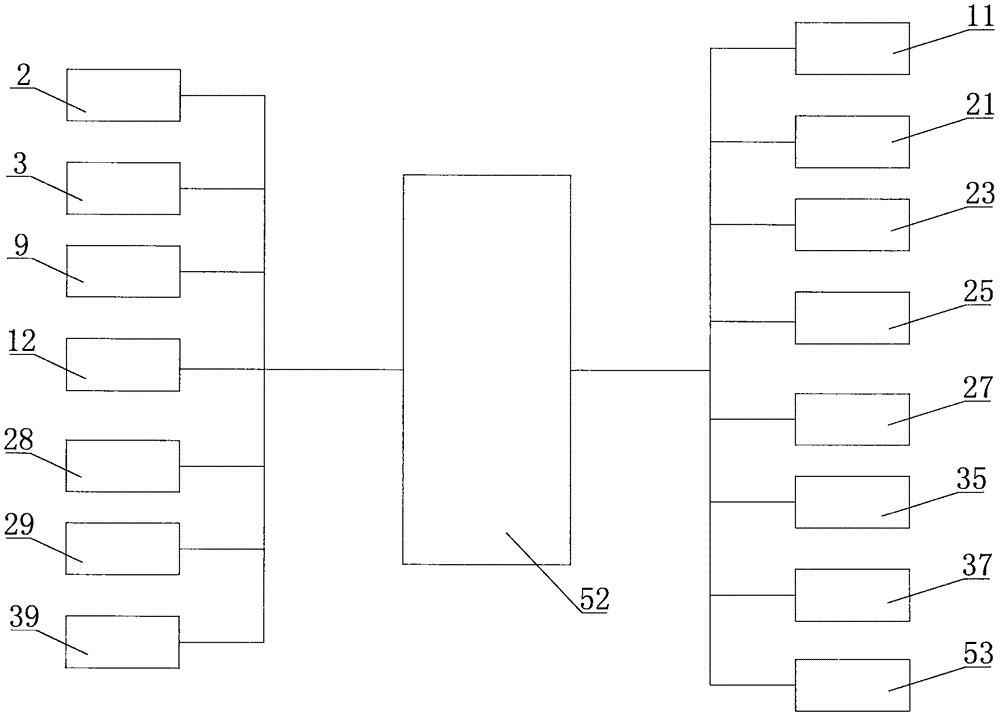

Patents

Literature

33results about How to "Achieve reunion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

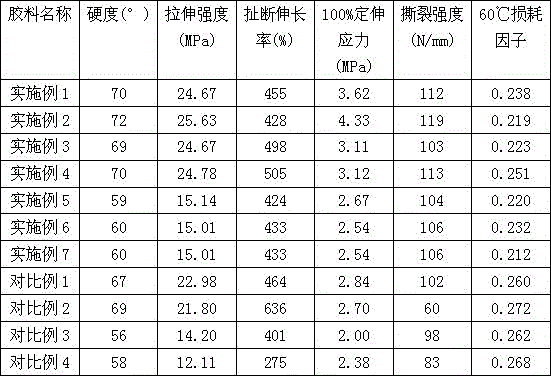

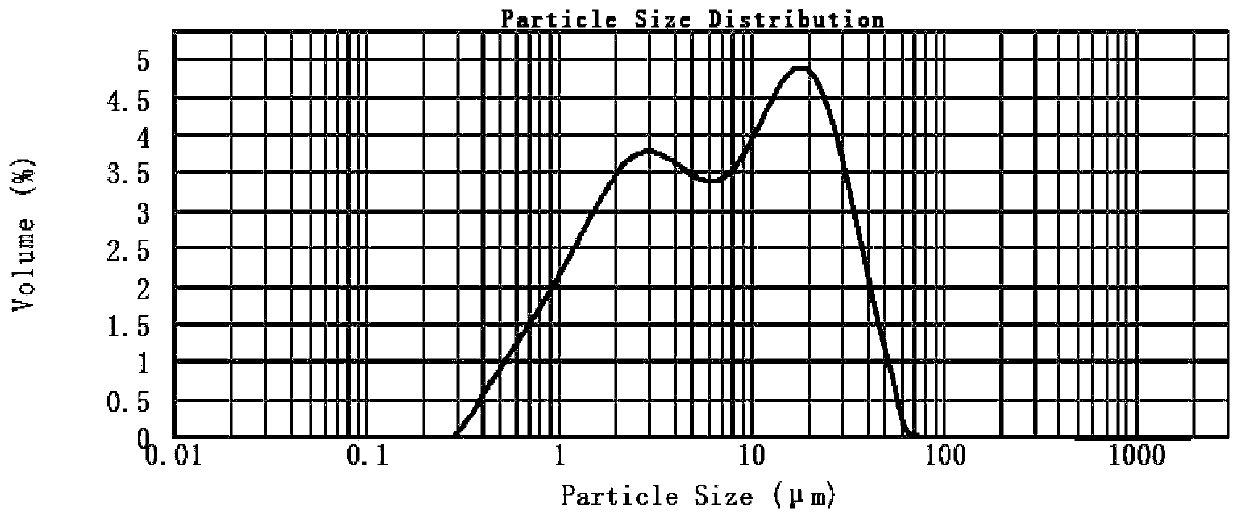

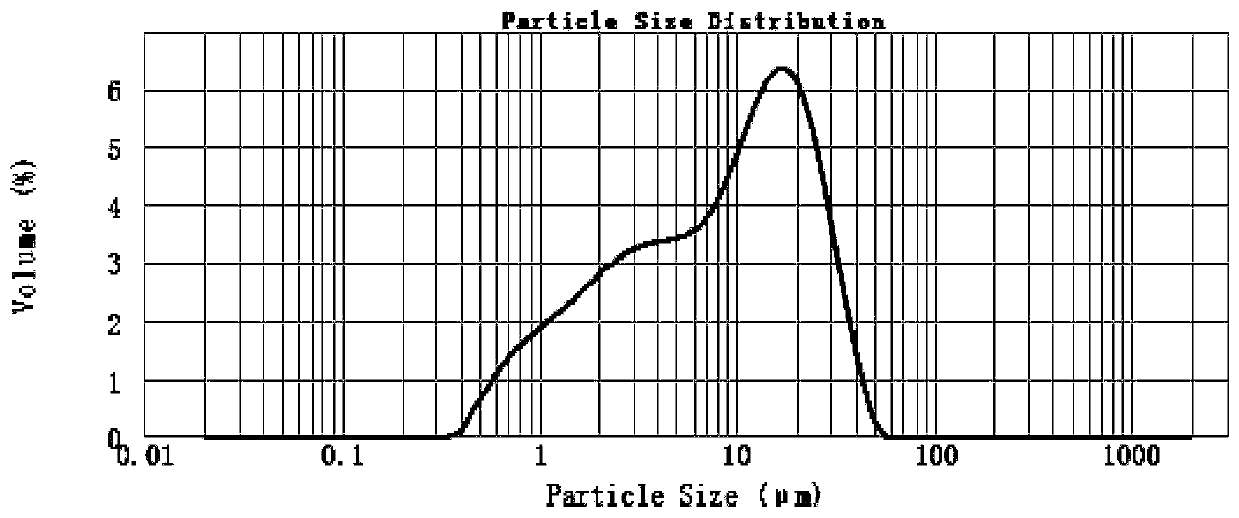

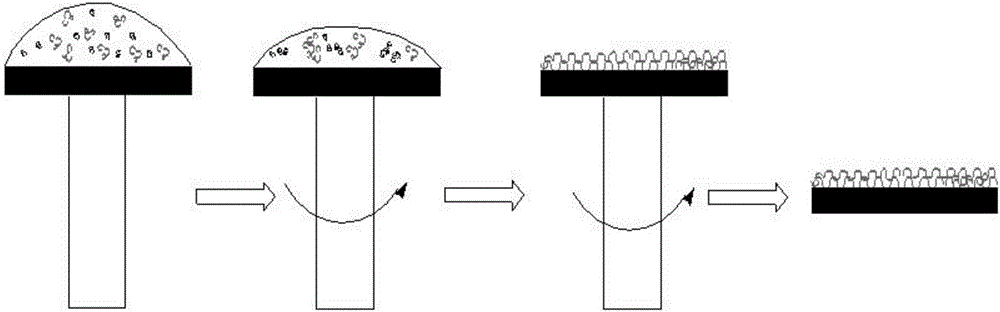

Method and production device for preparing graphene micro-plate pre-dispersion master batch

The invention relates to the technical field of technologies for processing rubber, in particular to a method and a production device for preparing graphene micro-plate pre-dispersion master batch. The method includes stirring and mixing graphene micro-plate dispersion liquid and latex with each other by the aid of a high-speed stirring machine to obtain mixed materials, adding flocculating agents into the mixed materials and coagulating the mixed materials to obtain pulp; dehydrating and drying the pulp to obtain the master batch. The method and the production device have the advantages that technologies are simple, the method and the production device are safe in operation, the graphene micro-plate pre-dispersion master batch can be continuously produced on a large scale, and the production efficiency can be improved as compared with original preparation technologies by the aid of batch processes; graphene micro-plates in the master batch prepared by the aid of the method can be highly dispersed as compared with melt processing methods; quick mixing and condensation can be implemented as compared with previous methods, drying and dehydrating phases are combined with squeezing drying and oven-drying modes, accordingly, the drying time can be shortened, rubber materials can be prevented from being aged, and the graphene micro-plate pre-dispersion master batch with excellent performance can be prepared by the aid of the method and the production device.

Owner:青岛蓝湾烯碳材料科技有限责任公司

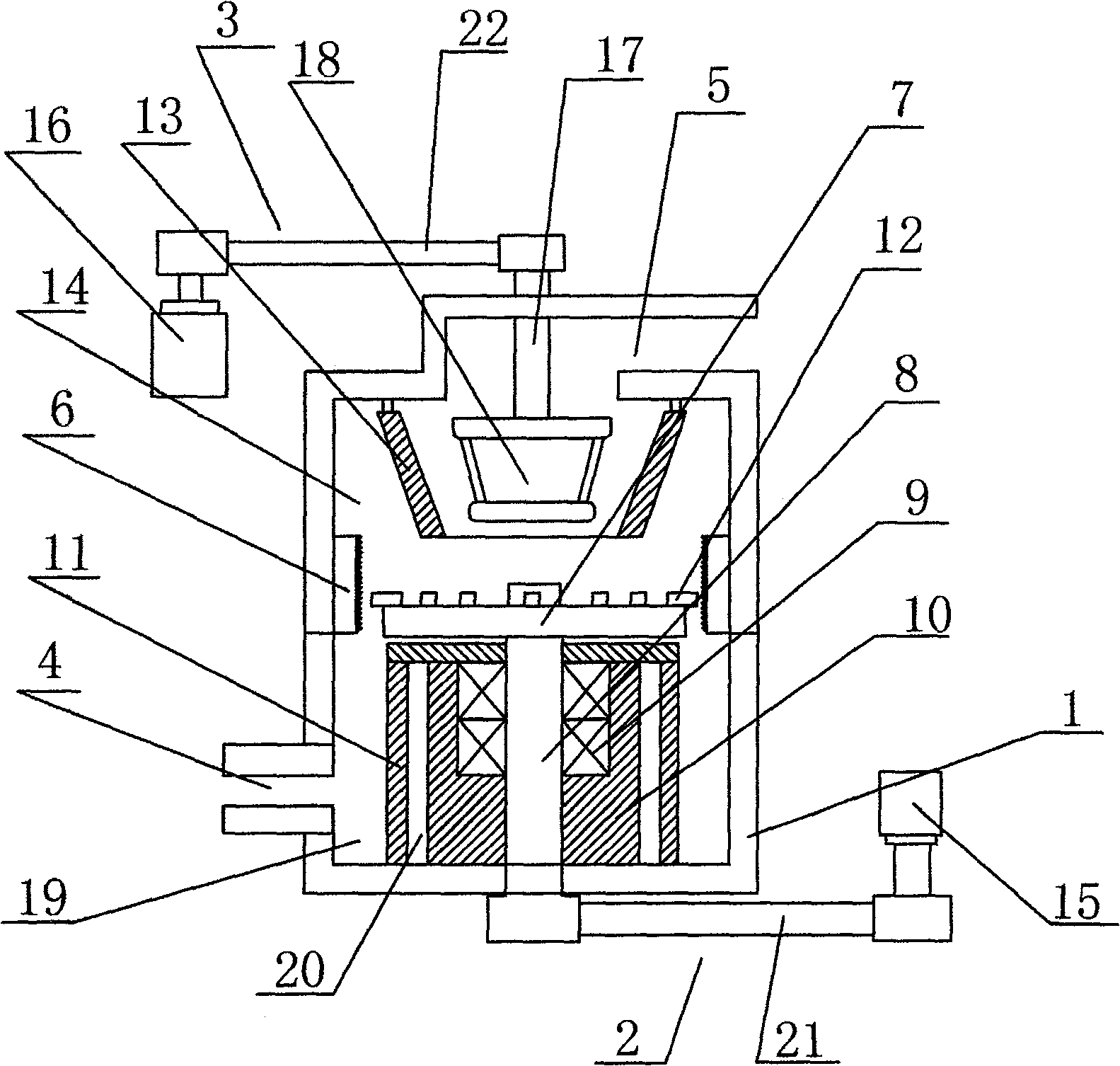

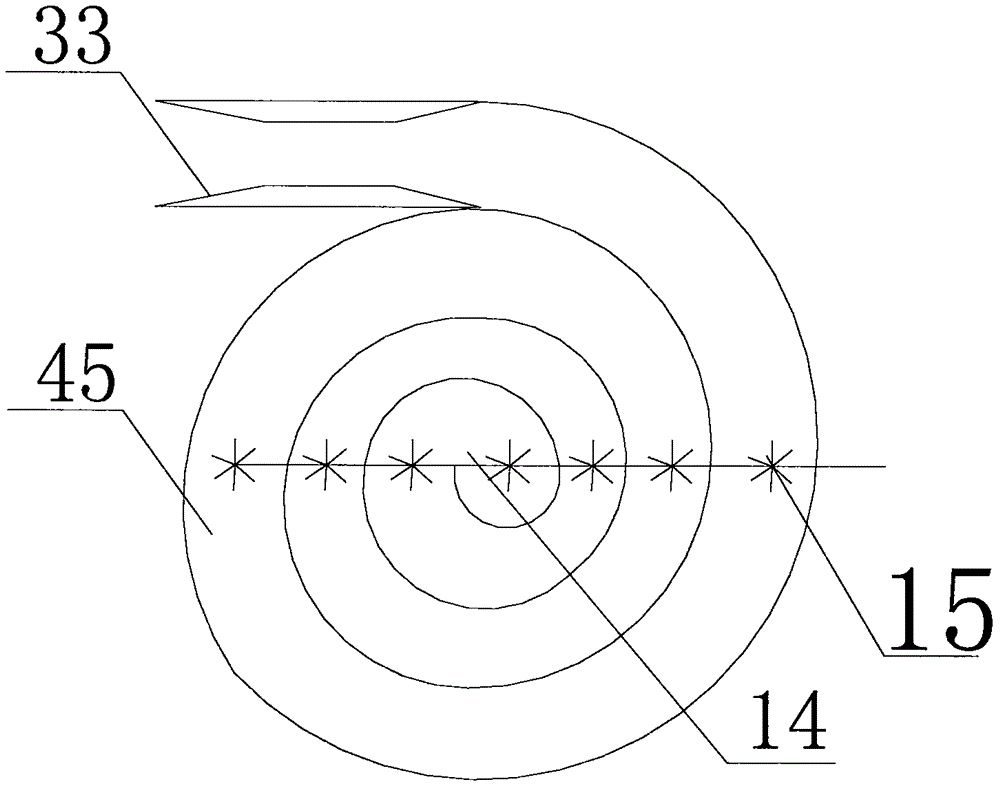

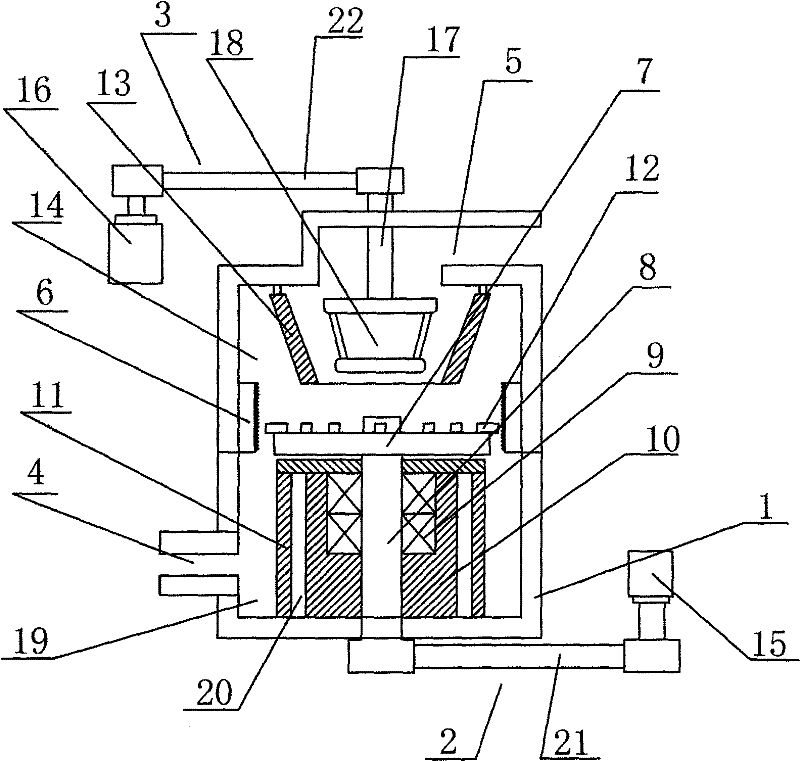

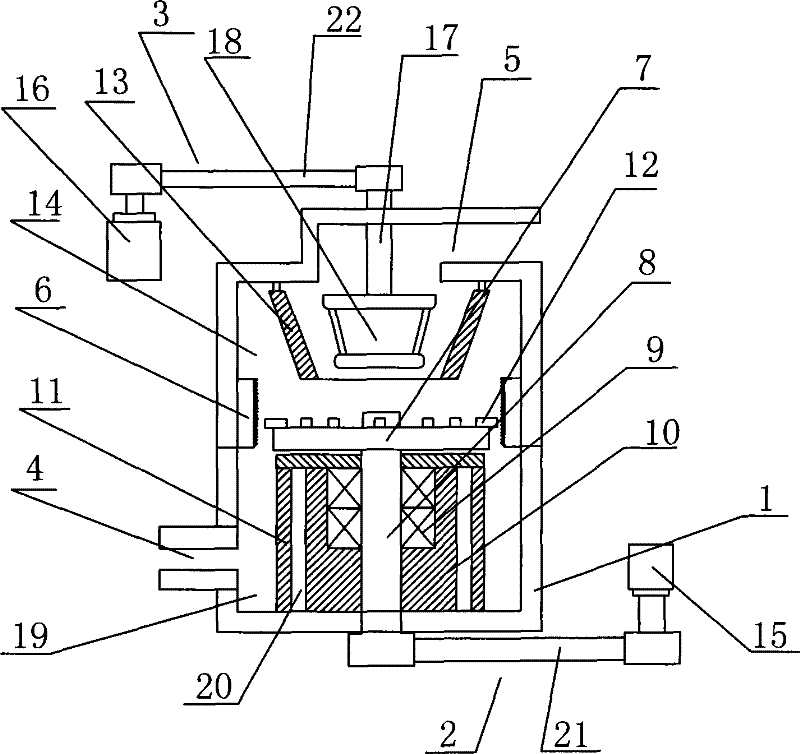

Air-flow vortex balling machine for producing spherical graphite

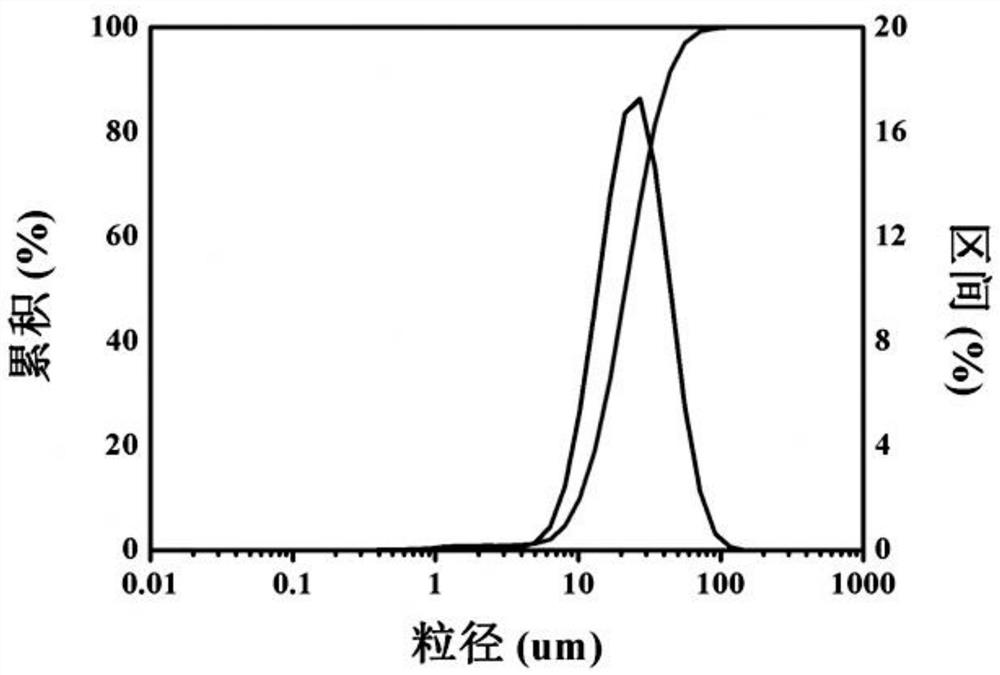

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling process and a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

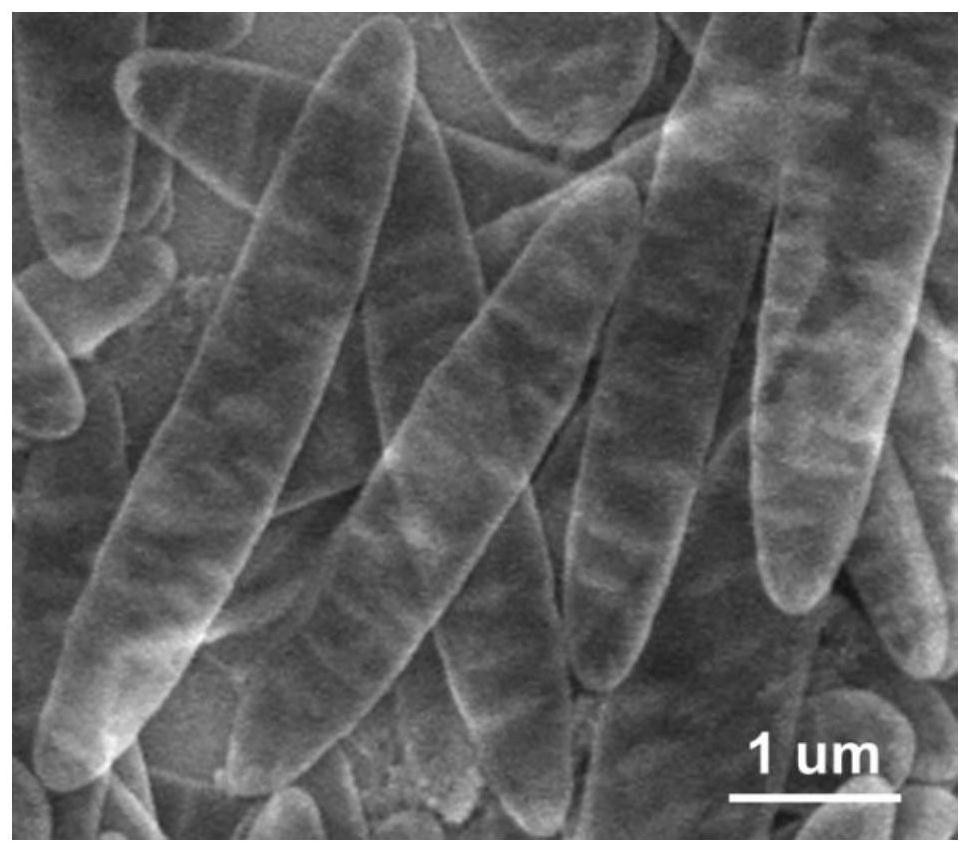

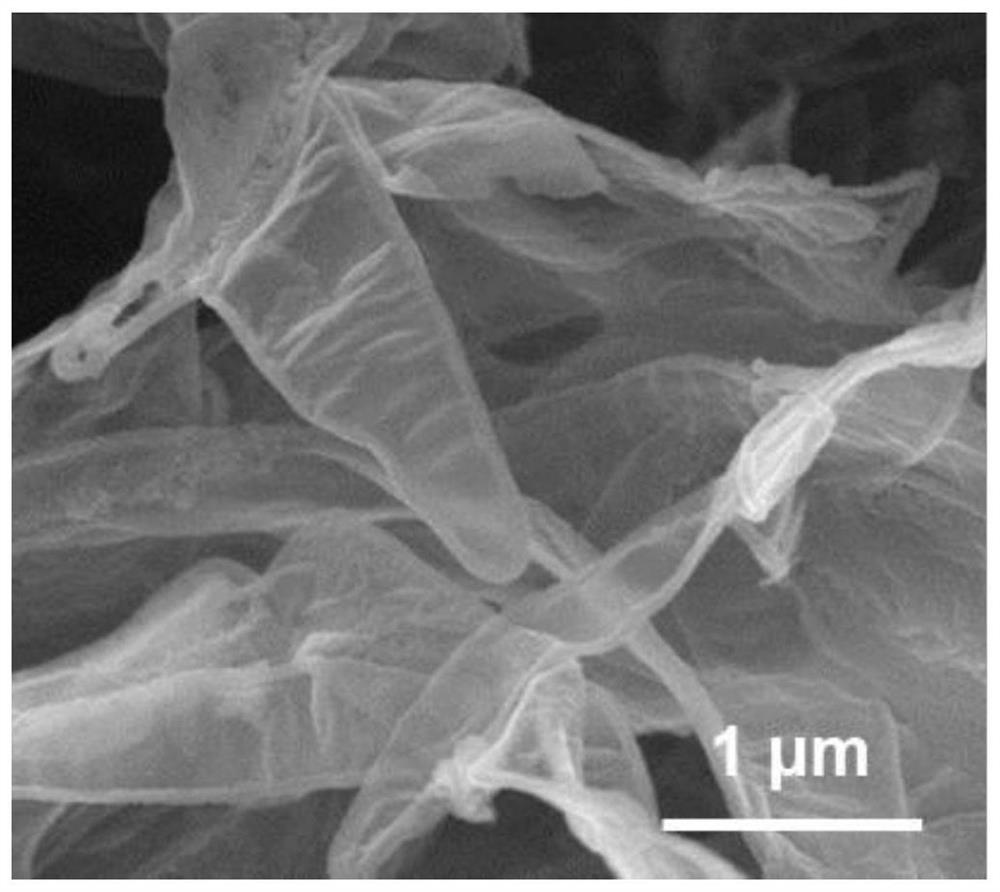

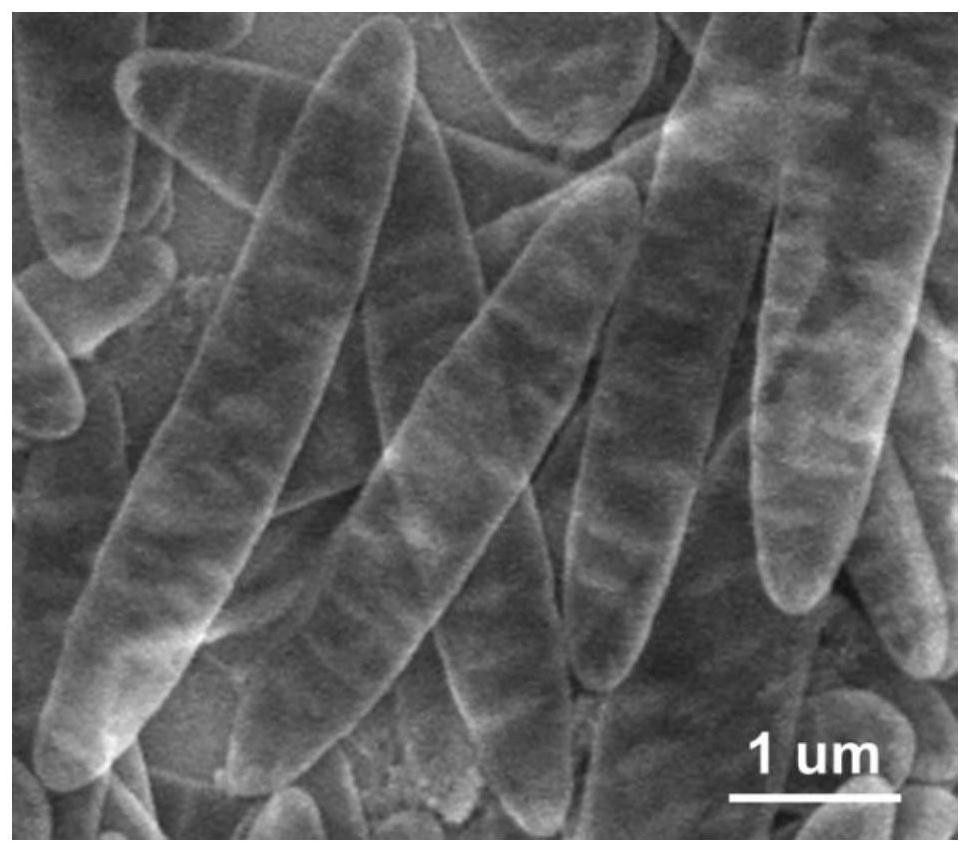

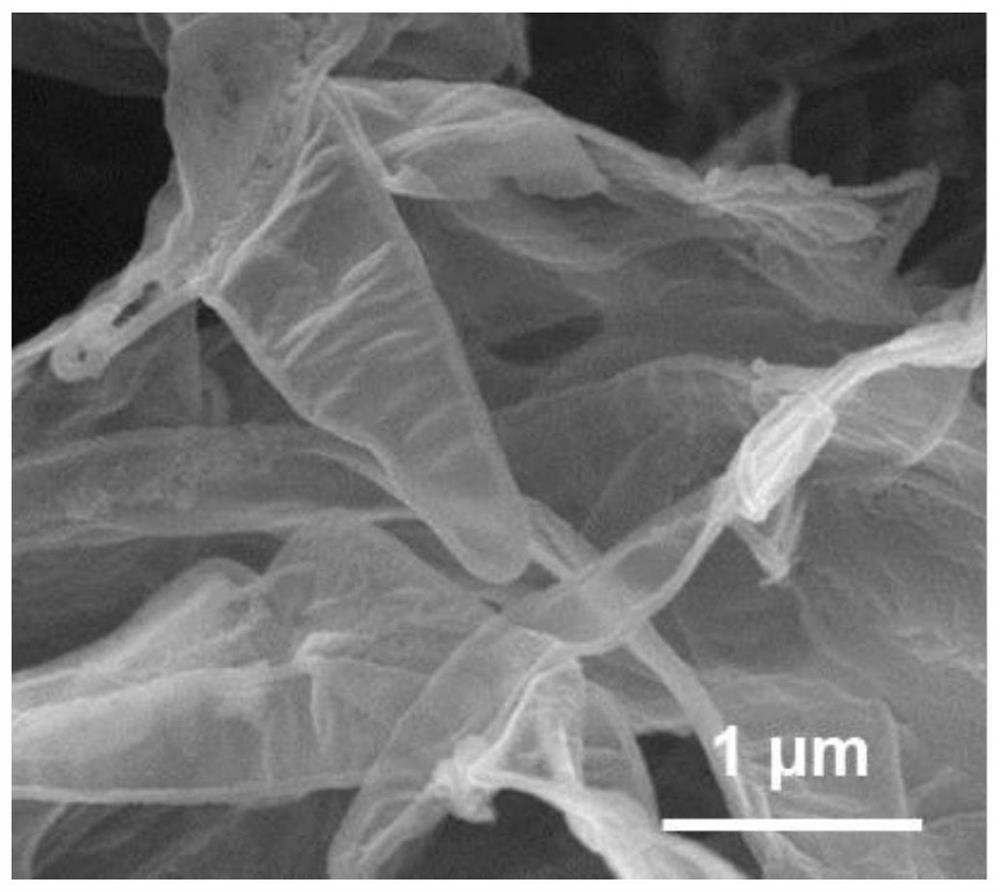

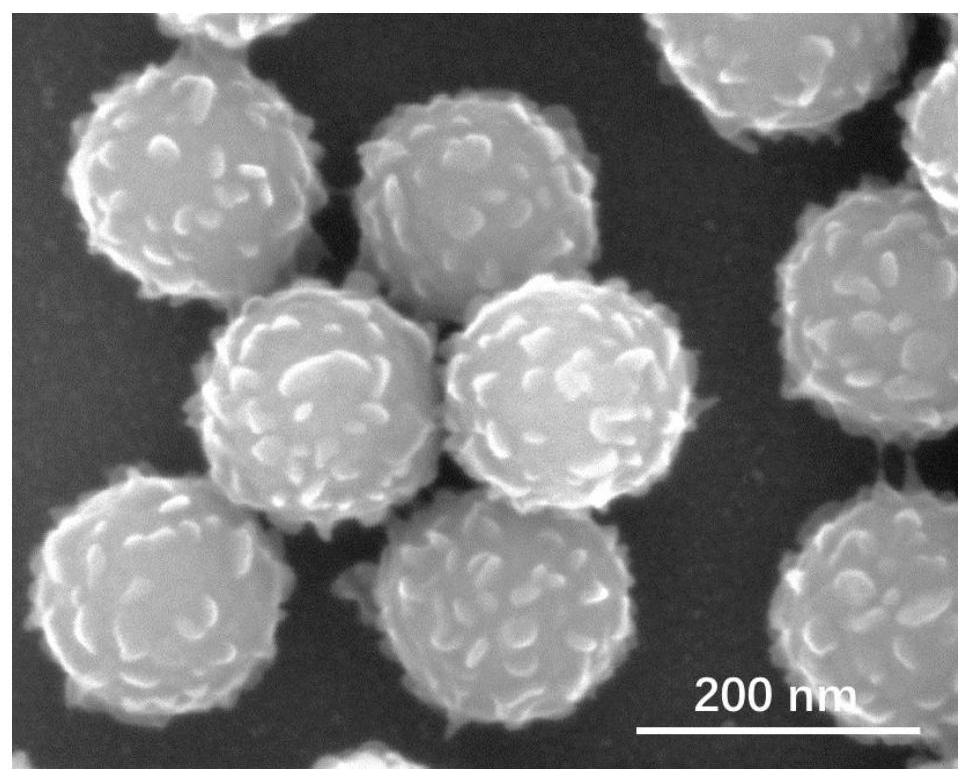

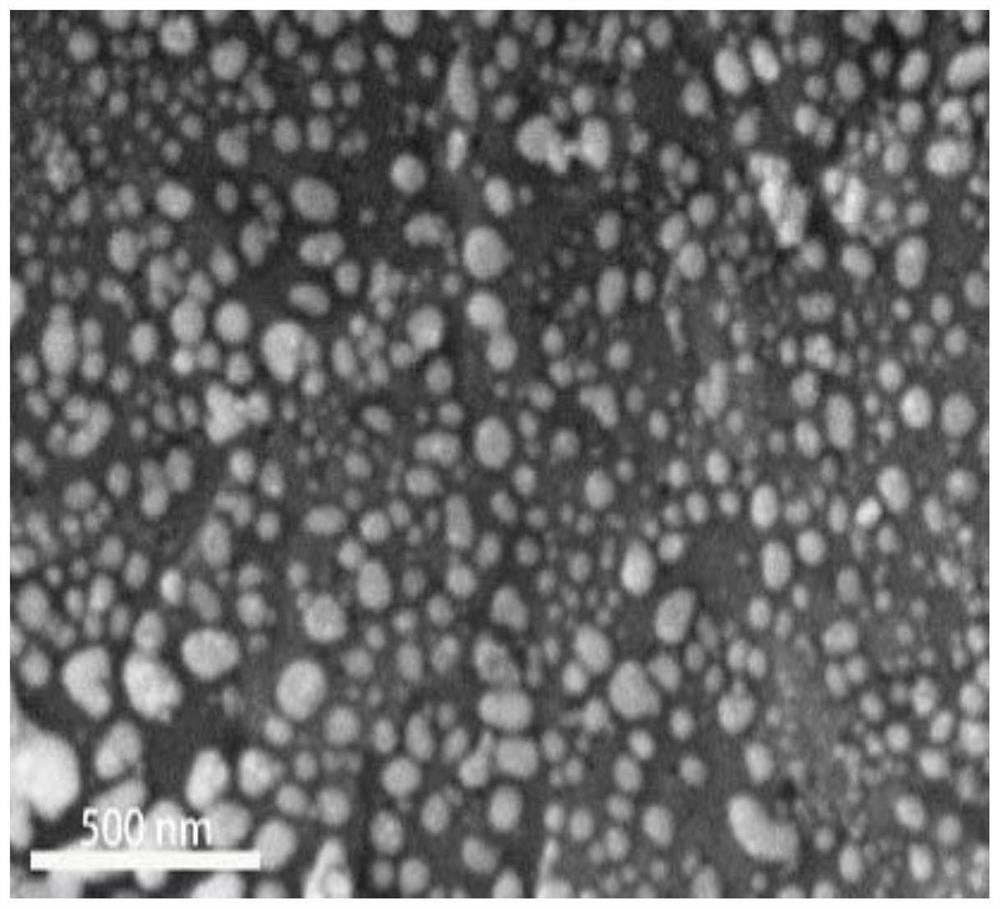

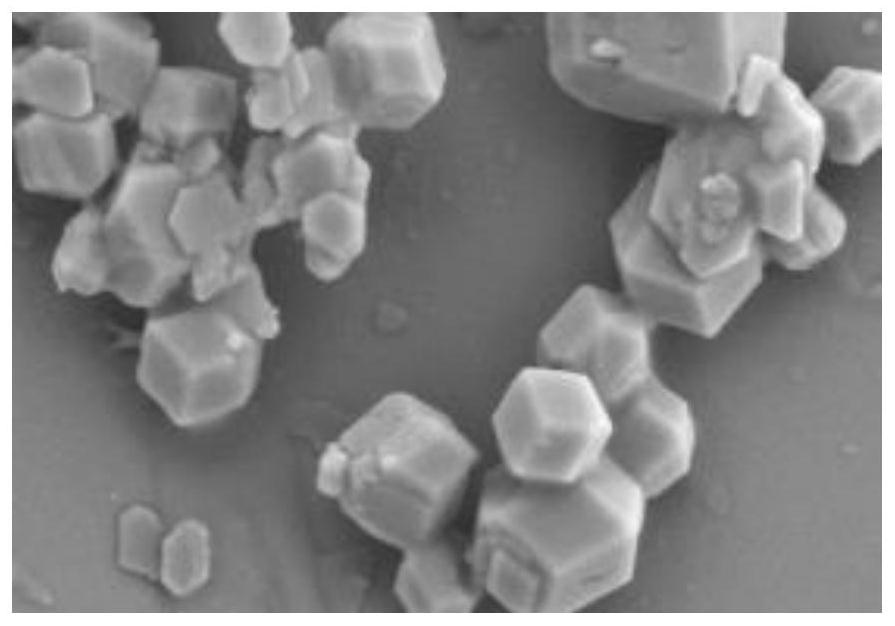

Polymer composite material with rough surface, nano carbon material, preparation method and application

ActiveCN112592451AChange quantityChange heightPhysical/chemical process catalystsOther chemical processesEtchingPtru catalyst

The invention relates to a polymer composite material with a rough surface, a nano carbon material, a preparation method and application. The preparation method comprises the following steps: mixing aphenolic compound, a carbonyl compound, an amino compound and a colloid template solution, performing sequential polymerization by utilizing dynamic difference of polycondensation reaction, Schiff base reaction and Mannich reaction on a micelle interface, and generating nano islands or nano particles on the surface or the edge of a nano material, thereby constructing a rough structure on the surface of the nano material. The method does not need additional etching and deposition processes, and the process is simple and controllable. The adsorbent prepared by the method can realize rapid diffusion of gas, and the diffusion rate is 5-10 times that of a commercial adsorbent; and by utilizing the catalyst carrier prepared by the invention, metal active particles can be anchored, migration andagglomeration of active components under a high-temperature condition are inhibited, and the stability of the catalyst is effectively improved.

Owner:DALIAN UNIV OF TECH

Preparation method and application of coix seed extract

InactiveCN109170532AInhibit blood sugar riseImprove starch removal rate and degreasing rateOther chemical processesCombustible gas purificationIonic strengthEmulsion

The invention relates to a preparation method of a coix seed extract. The method comprises the steps as follows: S1, drying and crushing coix seeds to obtain coix seed flour; S2, removing starch and fat in the coix seed flour through acid treatment and addition of a degreasing agent; S3, performing dynamic superhigh-pressure microfluidization treatment on coix seed pulp to promote dissolution extraction of polysaccharide and protein in the coix seed pulp; S4, adjusting the mass concentration of the coix seed pulp, adding an ionic strength regulator to regulate the ionic strength of the coix seed pulp, and adjusting the pH of the coix seed pulp; S5, adding an organic polymer adsorbent to the coix seed pulp to adsorb protein and polysaccharide agglomerates; S6, performing standing and filtration, collecting a filtered-out organic polymer adsorbent, and sequentially eluting polysaccharide and protein; and S7, removing starch and grease again through low-temperature settlement and centrifugal degreasing to finally prepare a coix seed emulsion containing polysaccharide and protein. The prepared coix seed emulsion is compounded into instant compound coix seed flour.

Owner:福建拓天生物科技有限公司

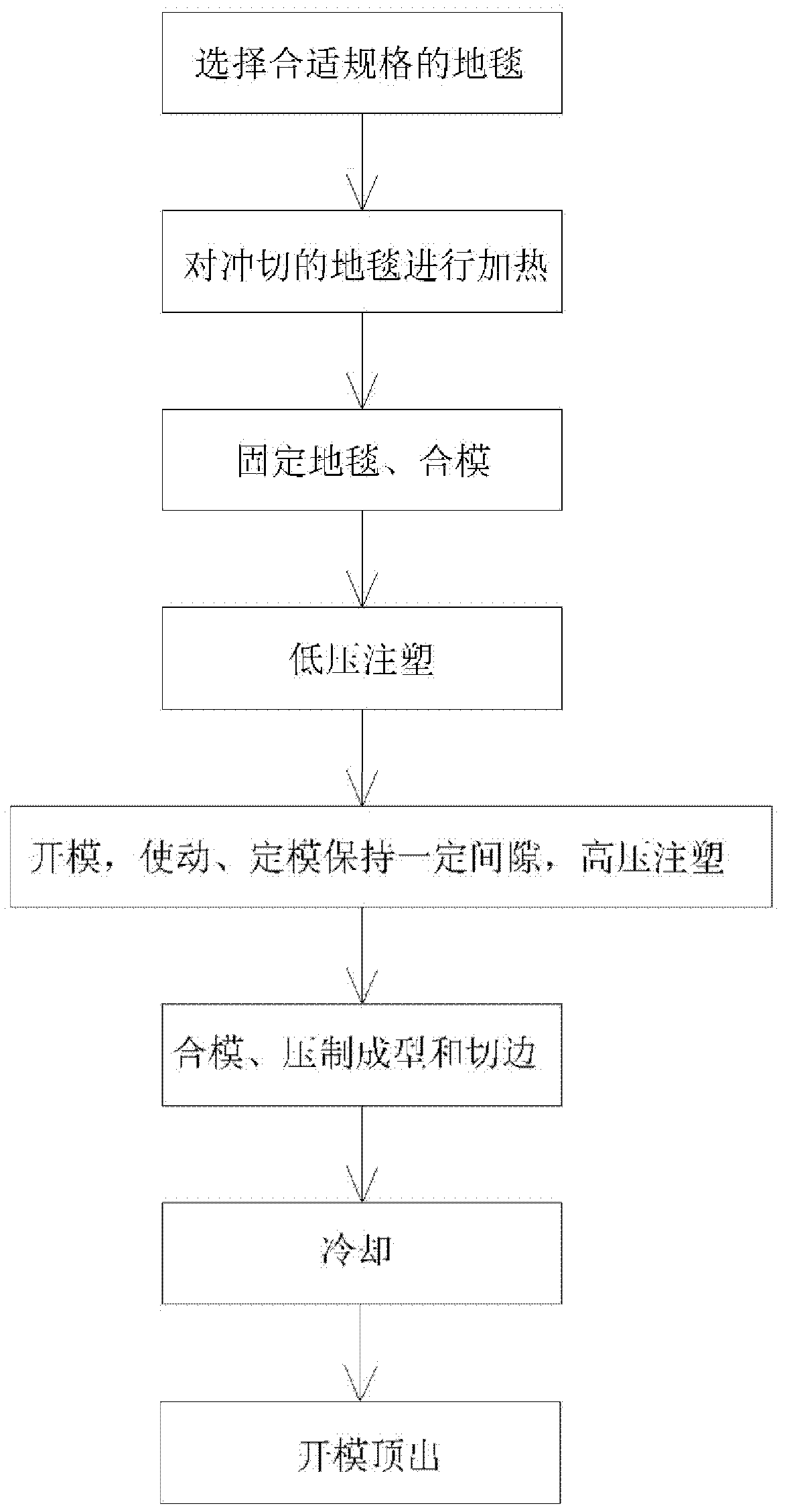

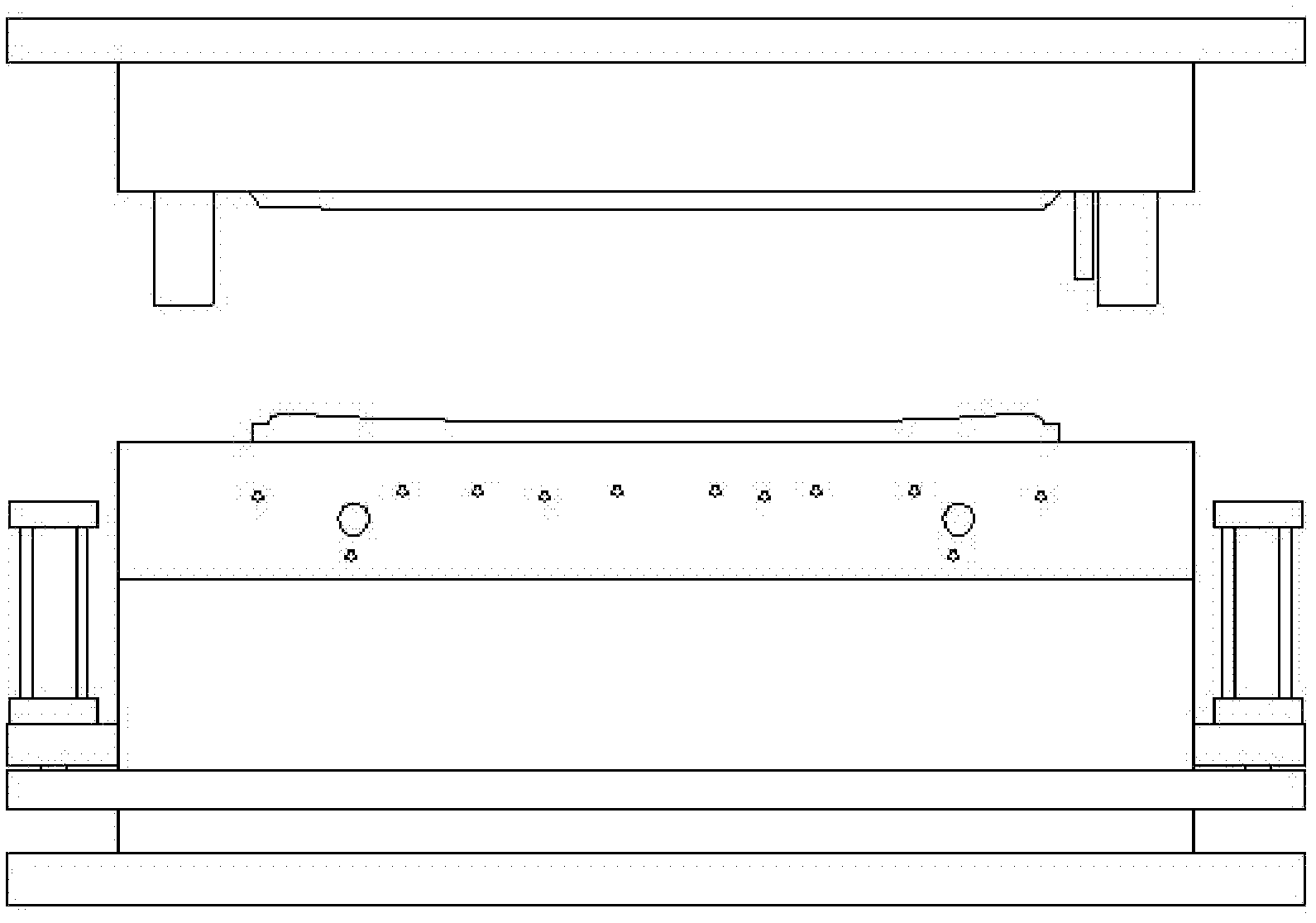

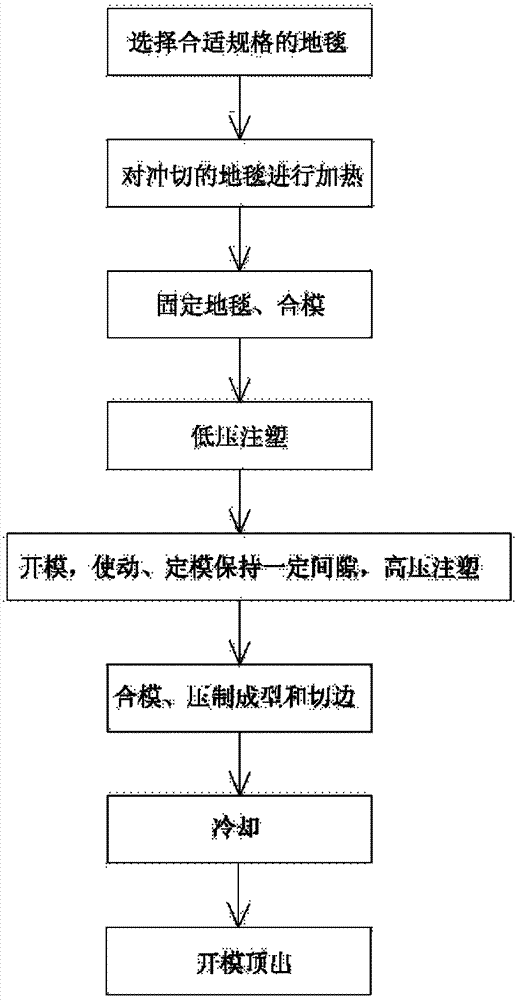

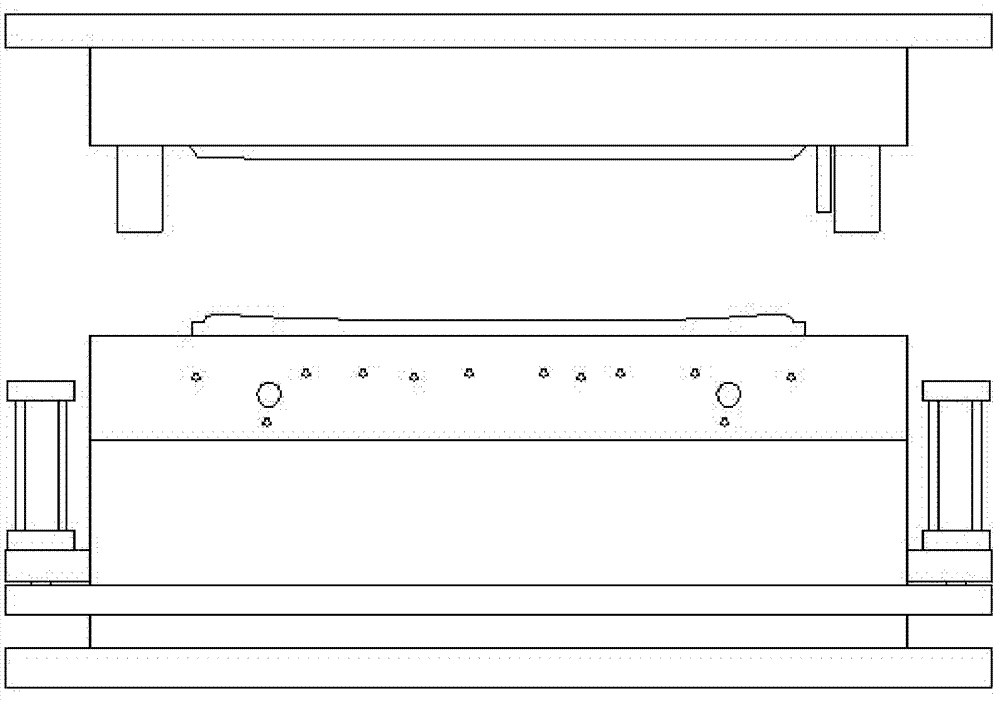

Injection molding and compression molding method of composite tufted carpet plastic interior ornament

The invention discloses an injection molding and compression molding method of a composite tufted carpet plastic interior ornament. The method comprises the following steps of: a, selecting a composite tufted carpet; b, heating the composite tufted carpet; c, opening a mold, fixing the composite tufted carpet in the injection mold, and then closing the mold; d, injecting plastic in an amount which is 10 to 20 percent of the required injection molding total amount under low pressure at a low speed by an injection molding machine through a plurality of hot runners; e, opening the injection moldto reserve certain clearance between a movable mold and a fixed mold, and starting the injection molding machine to inject the rest plastic of the required injection molding total amount under high pressure at a high speed; f, closing the mold, forming the composite tufted carpet plastic interior ornament by pressing, and simultaneously cutting the redundant edge and cooling; and g, opening the mold, and taking out the composite tufted carpet plastic interior ornament. The method is low in production condition requirement, good in product quality and high in production efficiency, the required equipment is cheap, and the produced product can be popularized in a large range.

Owner:NINGBO SUNLIGHT MOTOR PARTS

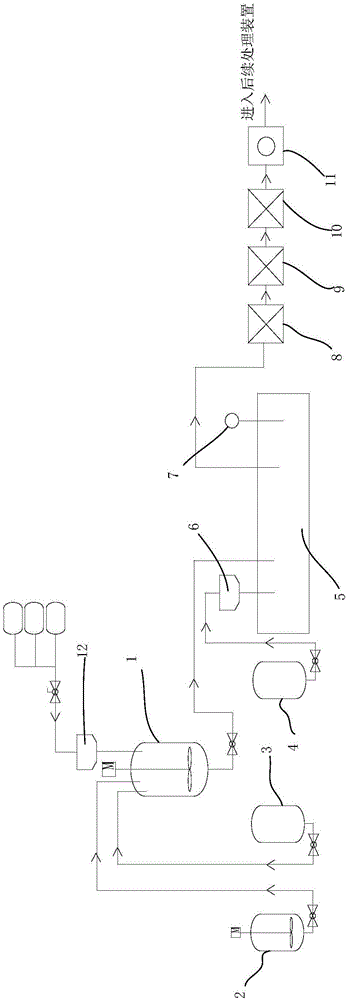

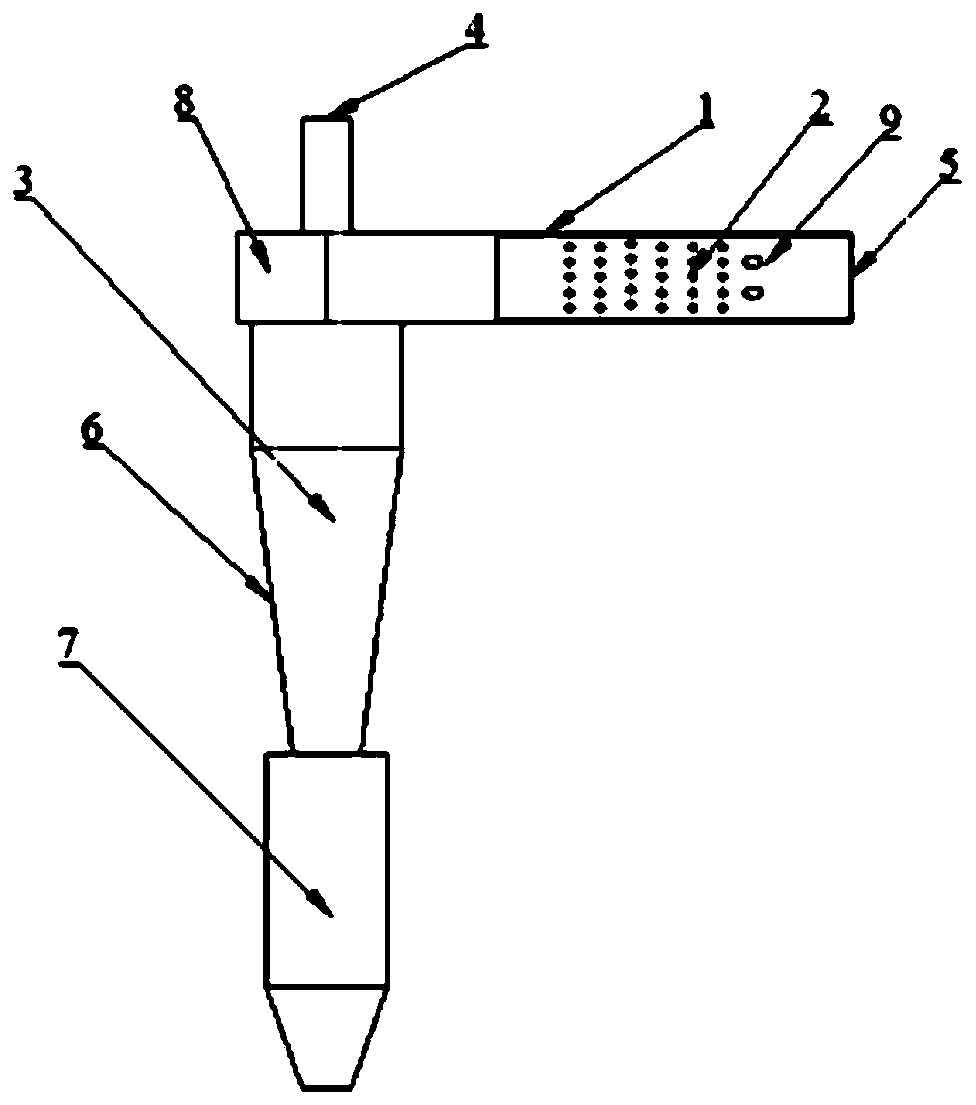

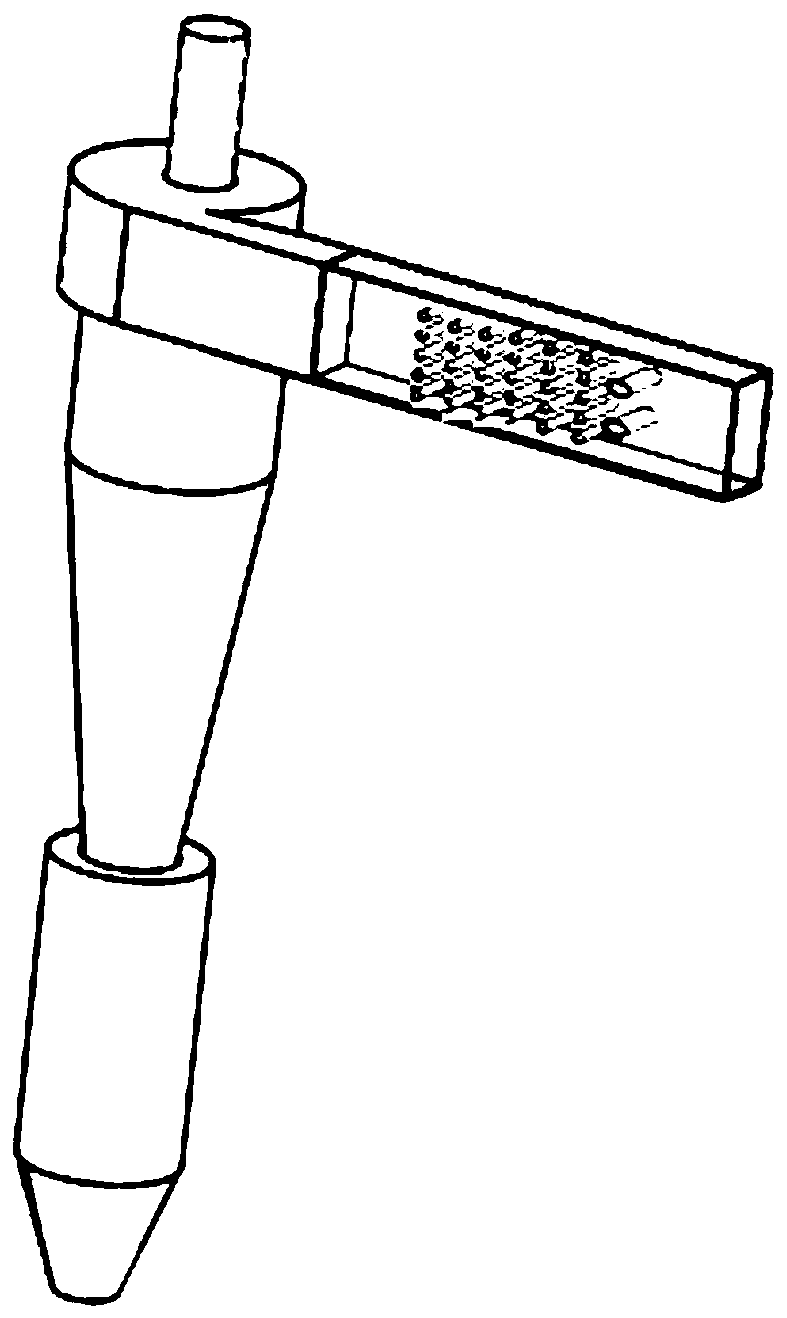

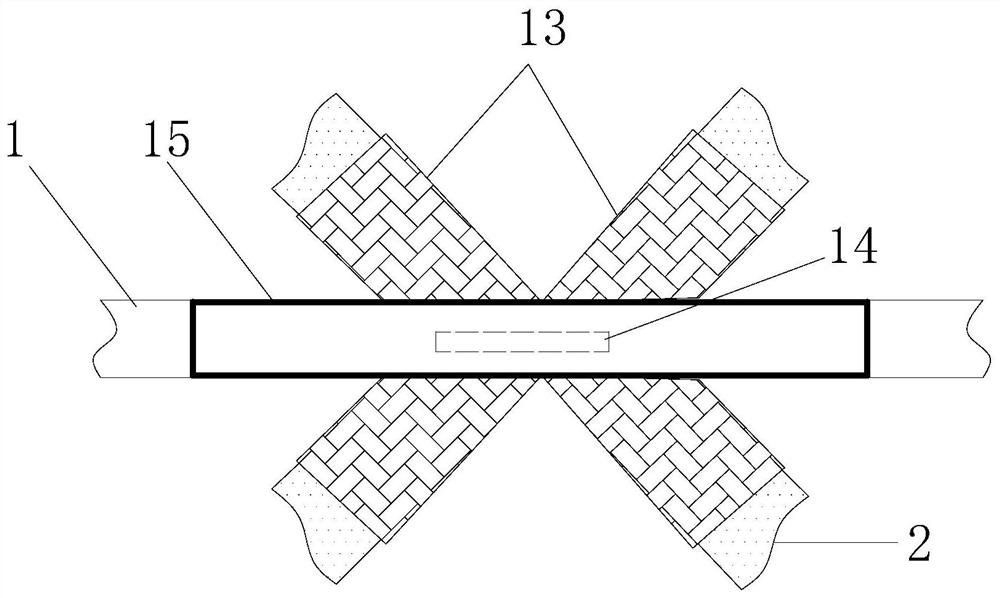

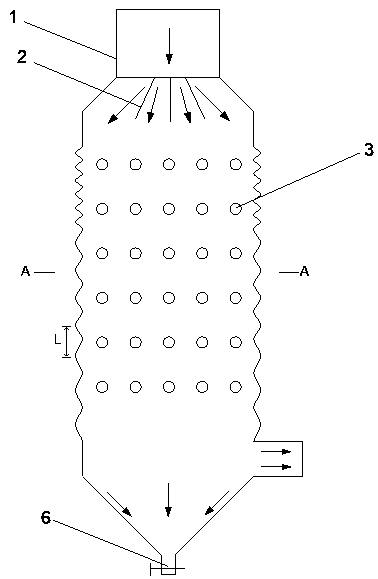

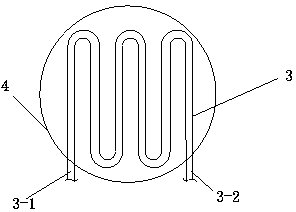

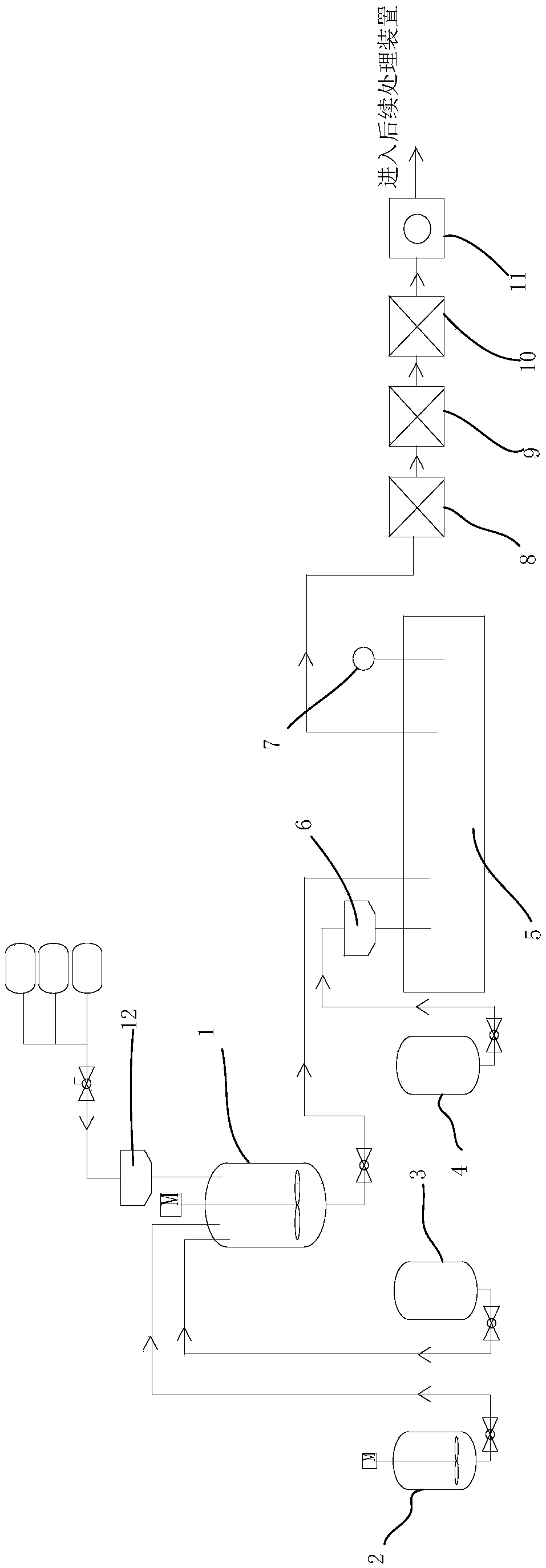

Ultrafine particle separation system under coupling mechanism

PendingCN111558256AAchieve reunionNo lossDispersed particle separationCyclonic separationEngineering

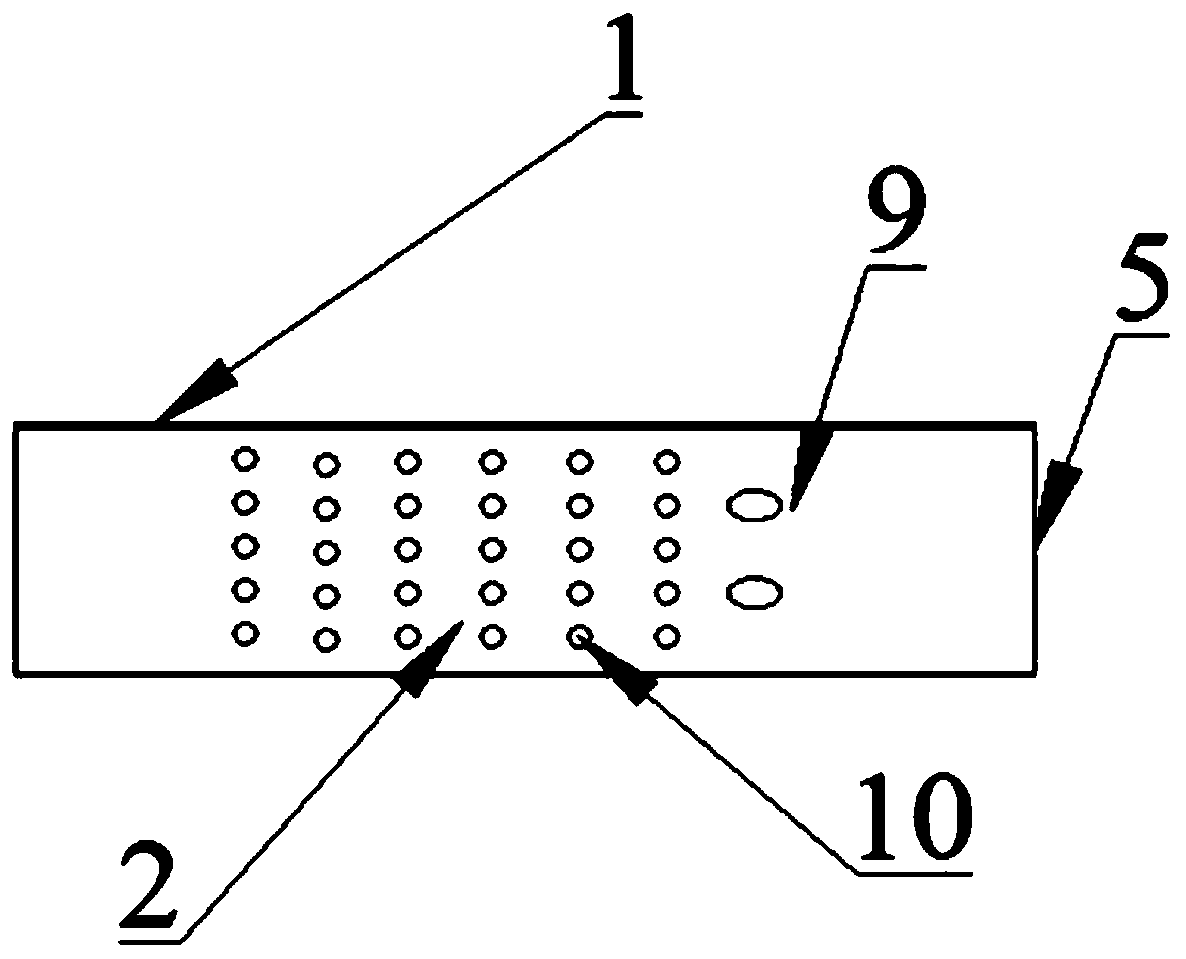

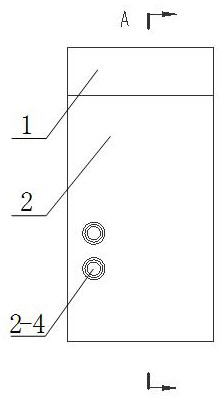

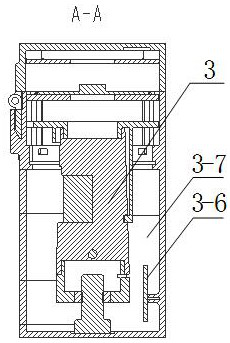

The invention aims to provide an ultrafine particle separation system under a coupling mechanism. A turbulence coalescer of a pure mechanical structure and cyclone separation equipment are directly and sequentially installed together, efficient separation of ultrafine particles is achieved by means of a coupling mechanism, the ultrafine particle separation effect is good, and the system is simplein structure, safe and reliable in equipment, wide in application range, and suitable for various ultrafine particle separation processes. The system comprises a cyclone separator, the turbulence coalescer is arranged at an inlet of the cyclone separator, the turbulence coalescer comprises a shell, the shell comprises an inlet and an outlet, the outlet of the shell is connected with the inlet of the cyclone separator, the cross section of the shell is rectangular, a turbulence column device is arranged in the shell, and a plurality of guide vanes are further arranged in the upstream directionof the turbulence column device.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

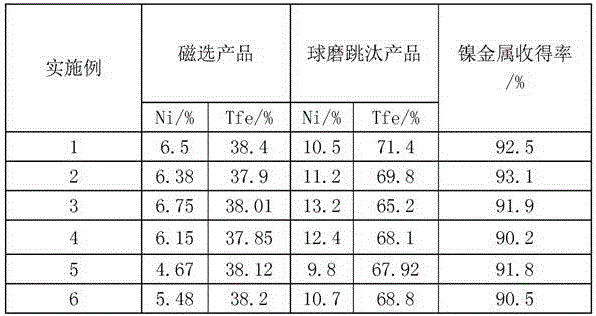

Method for producing ferronickel through reduction smelting of laterite-nickel ore flash furnace

The invention relates to the technical field of pyrometallurgy, in particular to a method for producing ferronickel through reduction smelting of a laterite-nickel ore flash furnace, which is short inflash reduction smelting time, high in speed, high in production efficiency, energy-saving and environment-friendly, and the reduction time is within one minute. Iron in the slag is reduced to prepare the iron-containing semi-steel alloy; remelting of said alloy is carried out to form qualified molten steel, meanwhile, submerged arc furnace slag is also obtained; the submerged arc furnace slag can serve as cement clinker to be conveyed to a cement plant to produce high-quality cement. The process is simple, the flow is short, qualified molten steel can be smelted and recycled, cement can be manufactured, economic benefits are good, environmental protection is facilitated, and hot materials subjected to multi-stage cyclone drying and pre-reduction directly enter a rotary kiln to be roasted; on one hand, the material buffering effect is achieved, and the material blocking problem caused when the hot materials directly enter the rotary kiln can be avoided; and on the other hand, throughfurther pre-reduction roasting of the rotary kiln, agglomeration of the materials can be achieved, and equipment and operation safety problems caused by direct feeding of the powdery materials into the furnace is avoided.

Owner:QINGDAO ZHONGZI ZHONGCHENG GROUP CO LTD

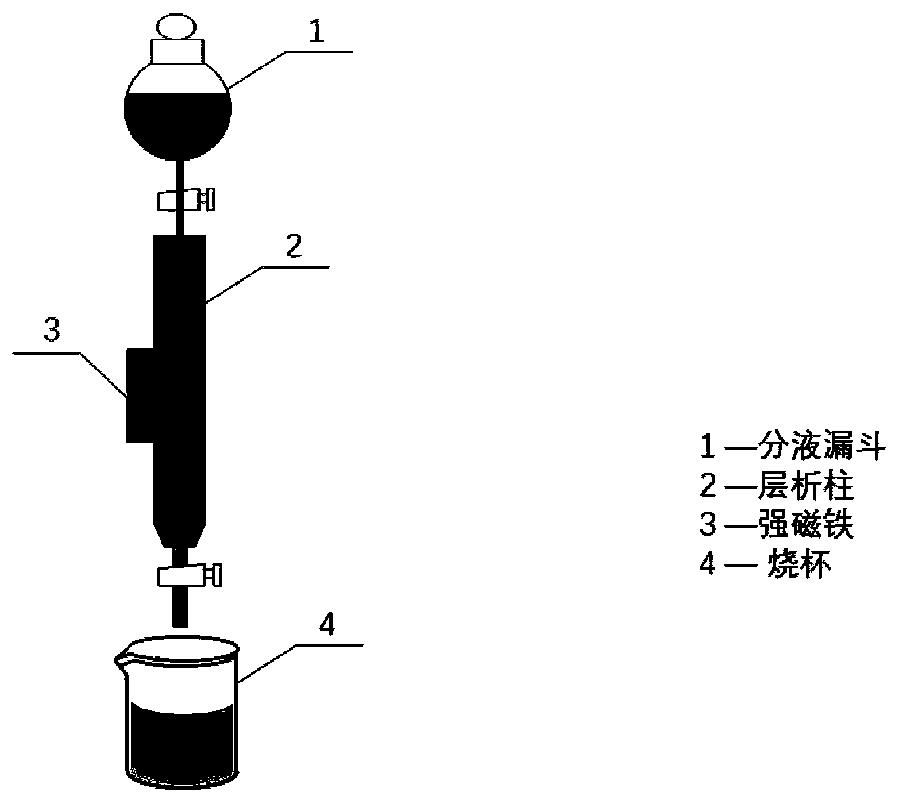

Charged magnetic hydrophobic material and preparation method and application thereof in separation of micro-fine-particle minerals

The invention discloses a charged magnetic hydrophobic material and a preparation method and application thereof in separation of micro-fine-particle minerals. The material includes magnetic particlesand a metal organic complex loaded on the surface, has strong magnetism, is positively charged on the surface, and has high electrostatic adsorption capacity for anions and high physical adsorption performance for hydrophobic micro-fine-particle minerals, and therefore, after micro-fine-particle minerals in ore pulp are subjected to surface hydrophobic and anion modification, the micro-fine-particle minerals can be adsorbed and agglomerated by utilizing the material, then the micro-fine-particle minerals are efficiently separated from gangue minerals through magnetic separation, thus solvinga difficult problem of separation and purification of ultrafine minerals. A preparation process of the charged magnetic hydrophobic material is simple and cheap and meets industrial production requirements.

Owner:CENT SOUTH UNIV

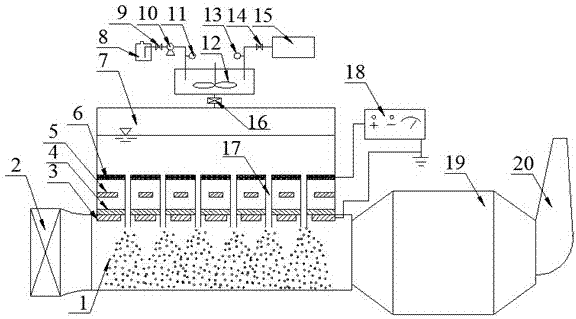

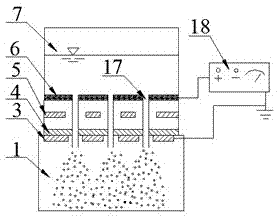

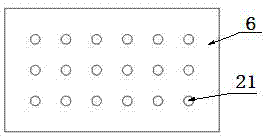

Array electrostatic-atomization ultrafine particulate matter coalescence equipment and method

ActiveCN104258674AImprove adsorption capacityImprove surface activityCombination devicesParticulatesCapillary Tubing

The invention discloses array electrostatic-atomization ultrafine particulate matter coalescence equipment and an array electrostatic-atomization ultrafine particulate matter coalescence method. The array electrostatic-atomization ultrafine particulate matter coalescence equipment is characterized in that an array electrostatic-atomization device which comprises a liquid storage chamber, base plate electrodes, adjusting hole plates, insulating panels, metal plate grounding electrodes and a plurality of metal capillary tubes is arranged at the upper part of an electrostatic-atomization agglomeration chamber, wherein an agglomeration agent solution is stored in the liquid storage chamber, a base plate of the liquid storage chamber is formed by the base plate electrodes connected with a negative high voltage electrostatic generator, the adjusting hole plates are arranged right below the base plate electrodes, the insulating panels clinging to the outer wall of the top of the electrostatic-atomization agglomeration chamber are arranged right below the adjusting hole plates, and the metal plate grounding electrodes are arranged on the inner wall of the top of the electrostatic-atomization agglomeration chamber; each metal capillary tube stretches into the electrostatic-atomization agglomeration chamber from top to bottom; the top of the liquid storage chamber is connected with a stirring mixing chamber through a one-way valve, and the stirring mixing chamber is connected with an agglomeration agent storage tank and a water supply system through pipelines. According to the array electrostatic-atomization ultrafine particulate matter coalescence equipment, liquid containing an agglomeration agent is subjected to electrostatic atomization by virtue of a contact charging method, and the adsorption capacity of fog drops to ultrafine dust (such as PM2.5) is enhanced.

Owner:WUXI SHENKANG MECHANICAL EQUIP

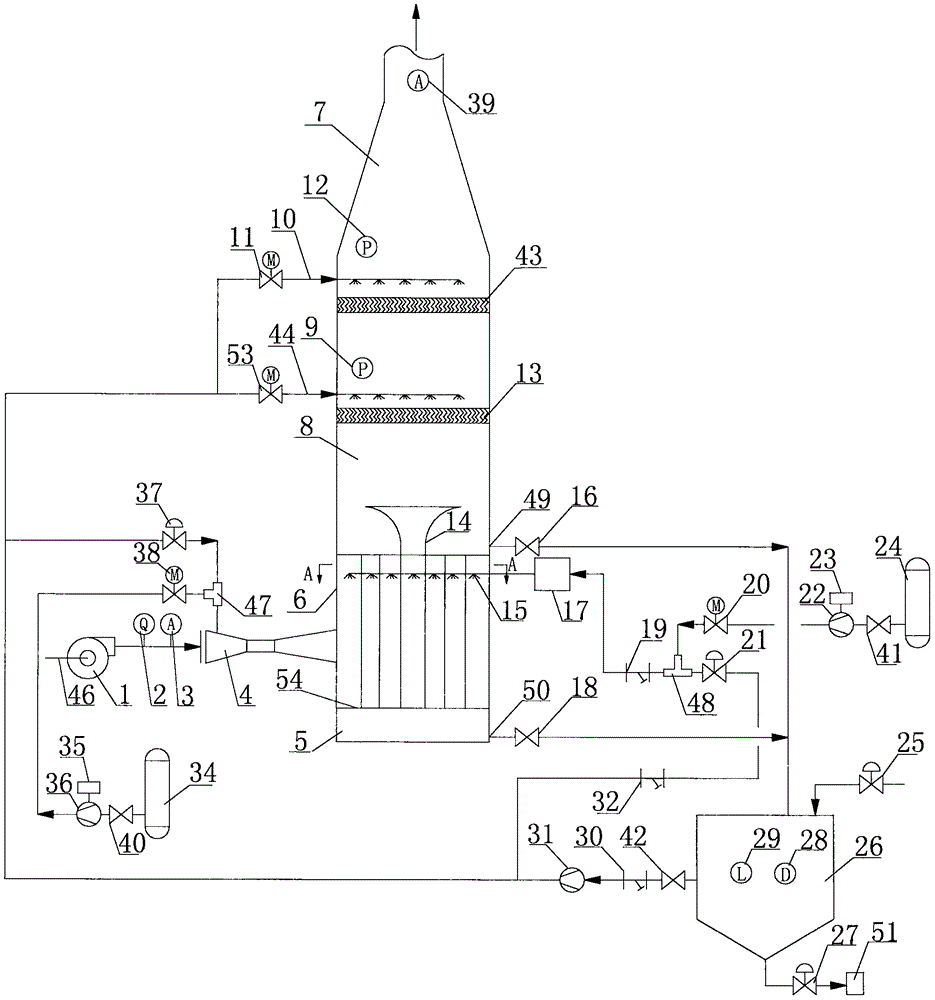

Labyrinth type cyclone dedusting device and dedusting method

ActiveCN106669347AAchieve reunionLower emission standardsHuman health protectionCombination devicesCycloneSmall footprint

The invention belongs to a labyrinth type cyclone dedusting device and a dedusting method. The device comprises a mechanical part and a control part, wherein the mechanical part comprises a dedusting device, an induced draft fan, a surfactant storage tank, a circulating water tank and a foam storage tank; the dedusting device comprises a casing, and a chimney, an upper-layer flushing pipeline, an upper-layer demister, a lower-layer flushing pipeline, a lower-layer demister, a settling demisting tower, a labyrinth type cyclone device and a grey waster chamber are arranged in the casing; the control part comprises a controller, a signal input end of the controller is connected with a smoke flow detection sensor, a smoke dust concentration analyzer, a second pressure detector, a first pressure detector, a circulating water densitometer, a liquid level meter and an outside exhausted smoke concentration detector. The device has the advantages that the device is simple in structure, low in investment and low in operation cost, operates stably, occupies a small area and has a desulfurization function.

Owner:HENAN XINLIANXIN FERTILIZER

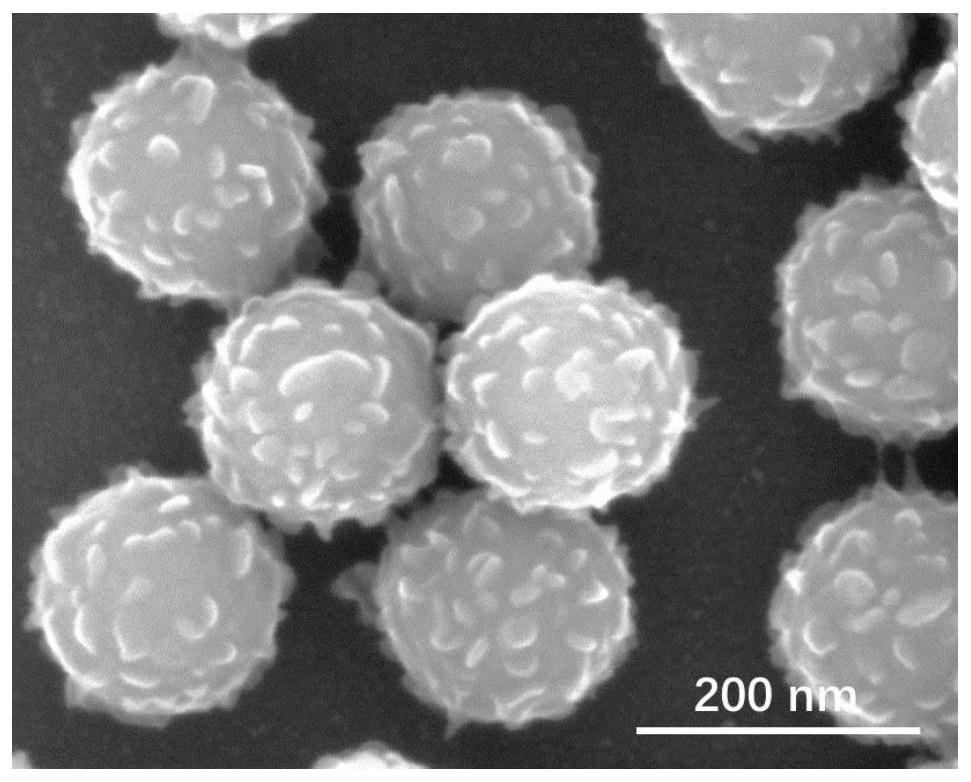

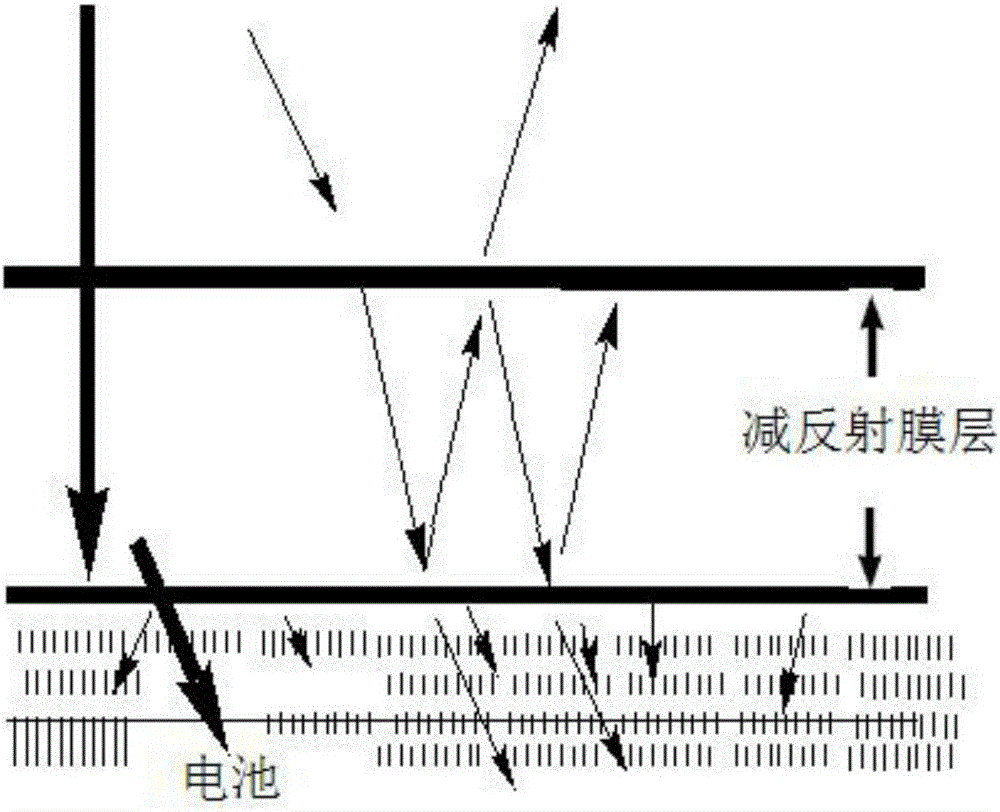

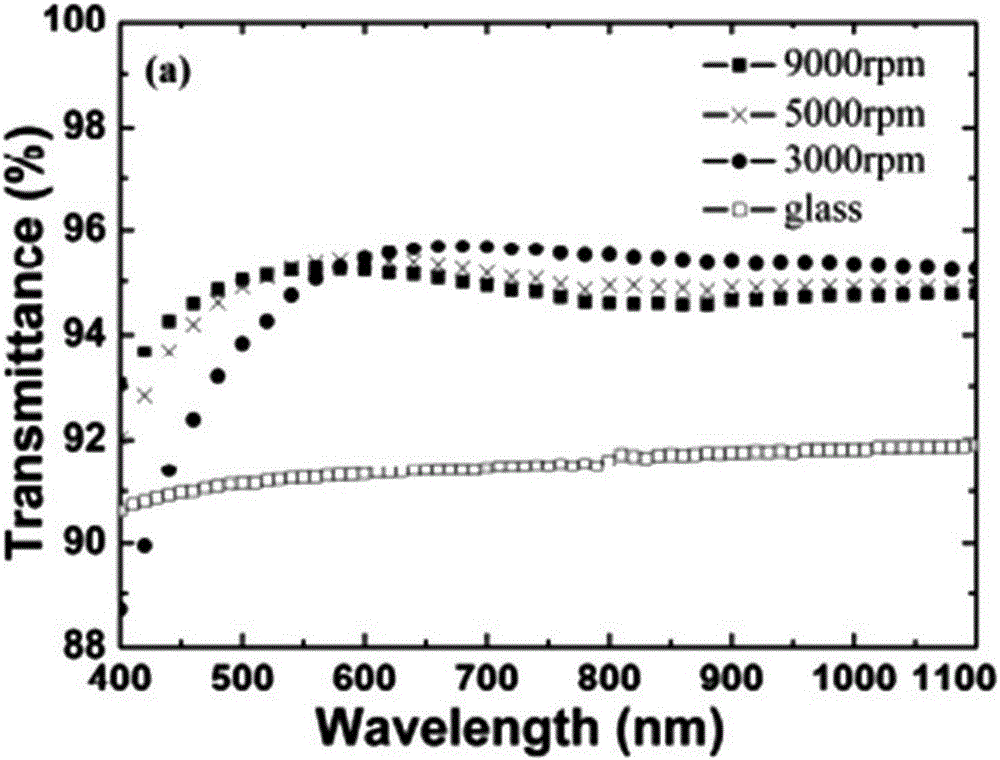

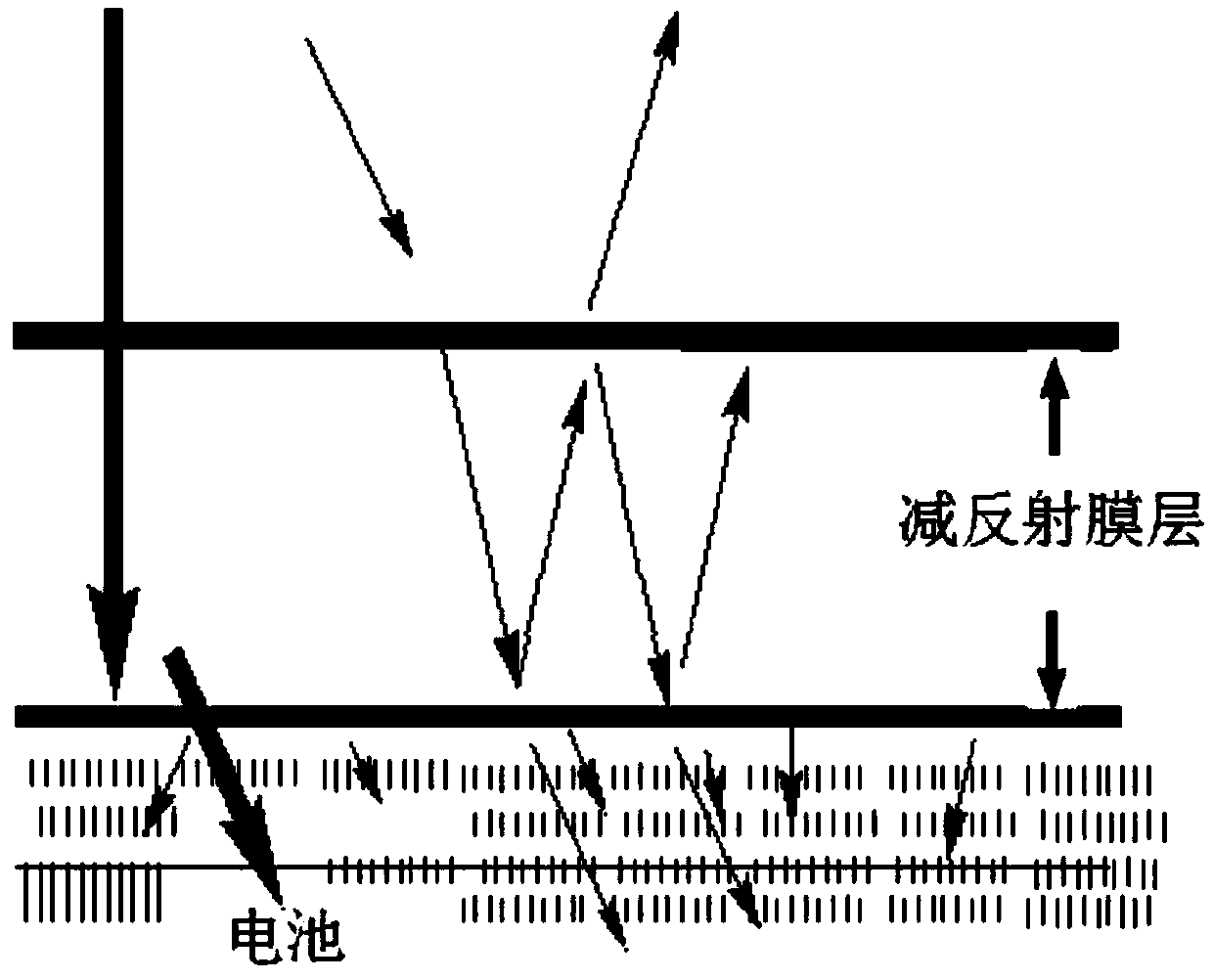

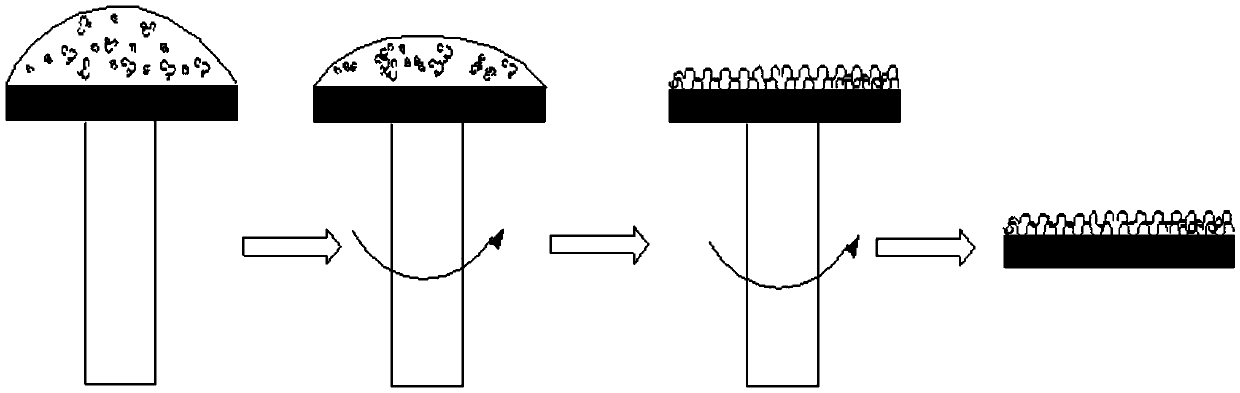

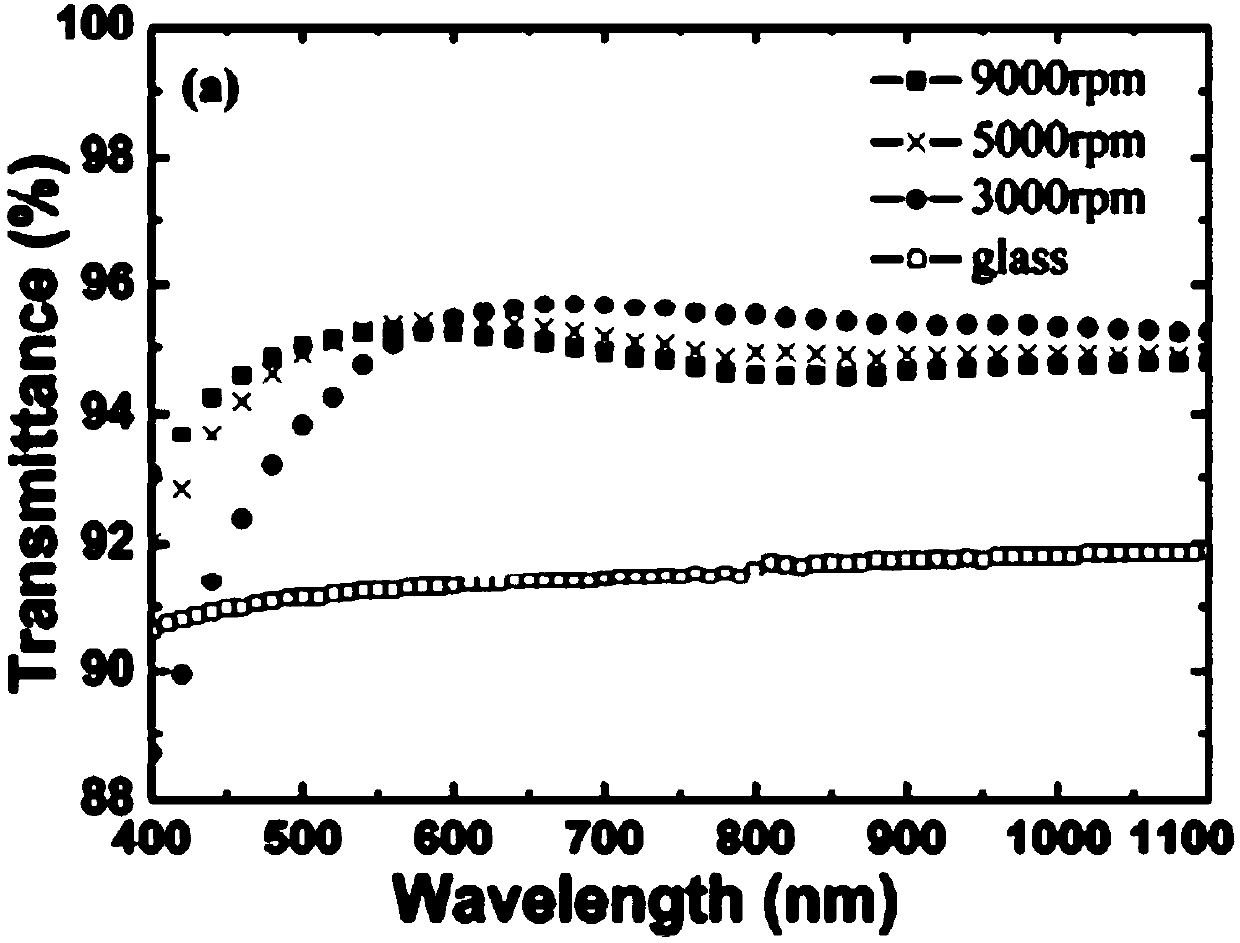

Preparation method of high-transmittance anti-reflection membrane of solar cell

ActiveCN106206759AIncrease short circuit currentReduce thicknessFinal product manufacturePhotovoltaic energy generationRefractive indexLuminous flux

The invention relates to a high-transmittance anti-reflection membrane of a solar cell. The thickness of the anti-reflection membrane is 70-90 nanometers, the pore size of the anti-reflection membrane is smaller than 200 nanometers, and the raw material of the anti-reflection membrane comprises a solvent and a polymer. In the anti-reflection membrane, uniformly coating is performed on the solar cell by a rotation gluing machine, and the anti-reflection membrane with relatively thin thickness and relatively small pore size is formed. By means of mobility performance of an organic polymer material, the agglomeration of the polymer material is achieved; meanwhile, the solvent liable to volatilize is separated during the high-speed rotation process, and pores are formed in the anti-reflection membrane; by adjusting the rotational speed, the time and a solvent formula, the adjustment of the sizes of nanometer pores is achieved, and finally, the reflectivity of the anti-reflection membrane is changed; and through a test, the short-circuit current of the cell is effectively increased, the luminous flux of sunlight on a cell surface is improved, and the conversion efficiency is improved.

Owner:TIANJIN LANTIAN SOLAR TECH

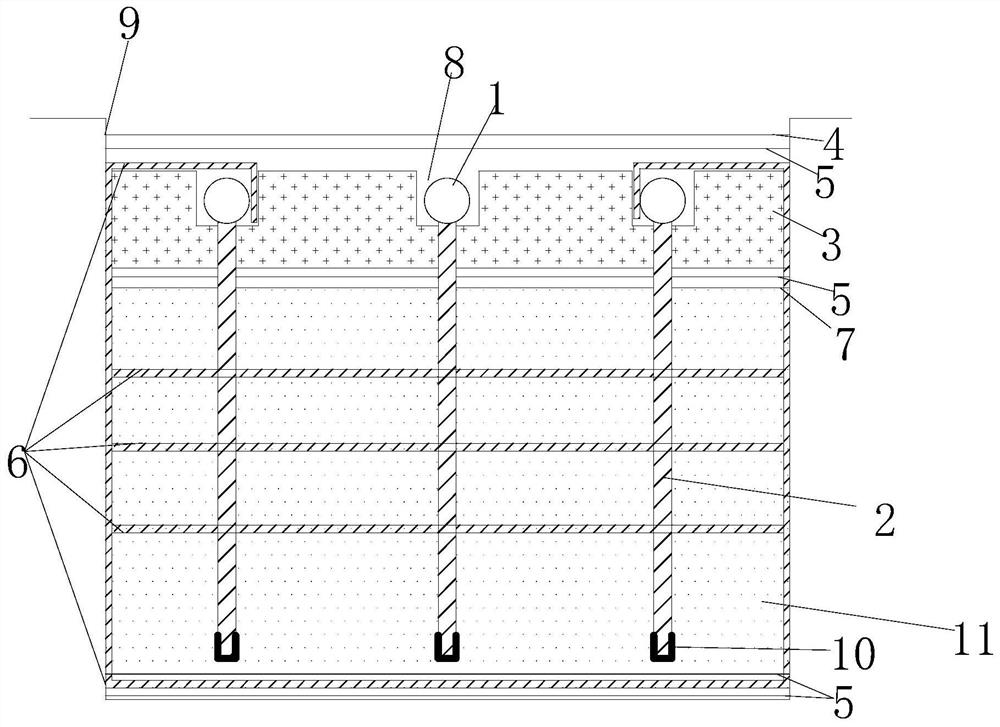

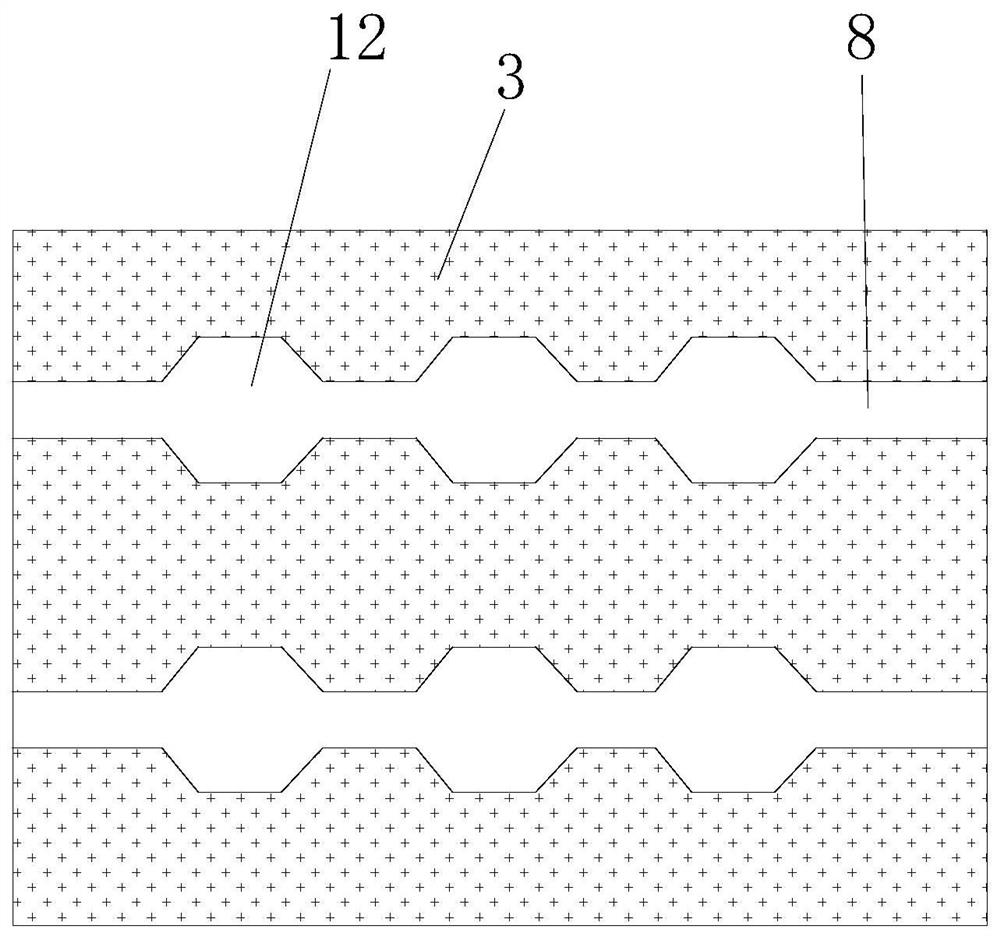

Waste mud dehydration and solidification treatment method

ActiveCN112499920ASpeed up the consolidationShorten the drainage pathSludge treatment by de-watering/drying/thickeningFixation/solidifcation sludge treatmentSlurryDehydration

The invention discloses a waste mud dehydration and solidification treatment method which adopts a multi-layer vacuum treatment method, and a plurality of layers of horizontal plastic drainage platesand a plurality of rows of vertical plastic drainage plates are laid in a mud pit, so that the problem of insufficient lower-layer mud treatment effect is solved, and the solidification speed is increased; multi-layer horizontal drainage can be achieved only by filling slurry and precipitating in batches, multi-layer vacuum is formed in the slurry through the multi-layer horizontal drainage system, the drainage path is shortened, and the drainage effect is better; moreover, the flocculating agent is also adopted, so that the vacuum dehydration effect and the solidification speed can be improved, meanwhile, a curing agent is added, soil solidification is realized while vacuum dehydration is performed, and further treatment is not needed; by adopting the method, the treatment speed of the waste mud can be rapidly increased, and the curing effect of the waste mud is enhanced.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +2

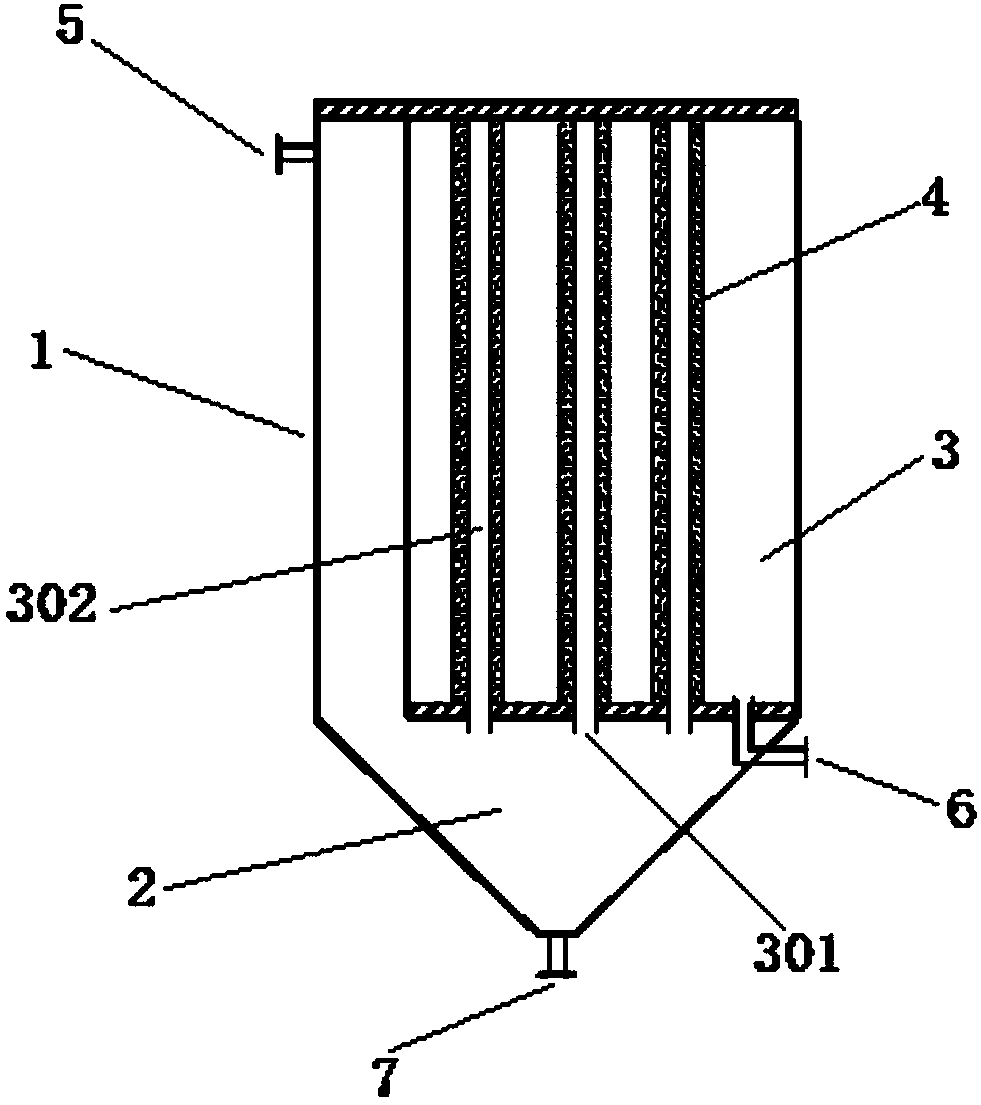

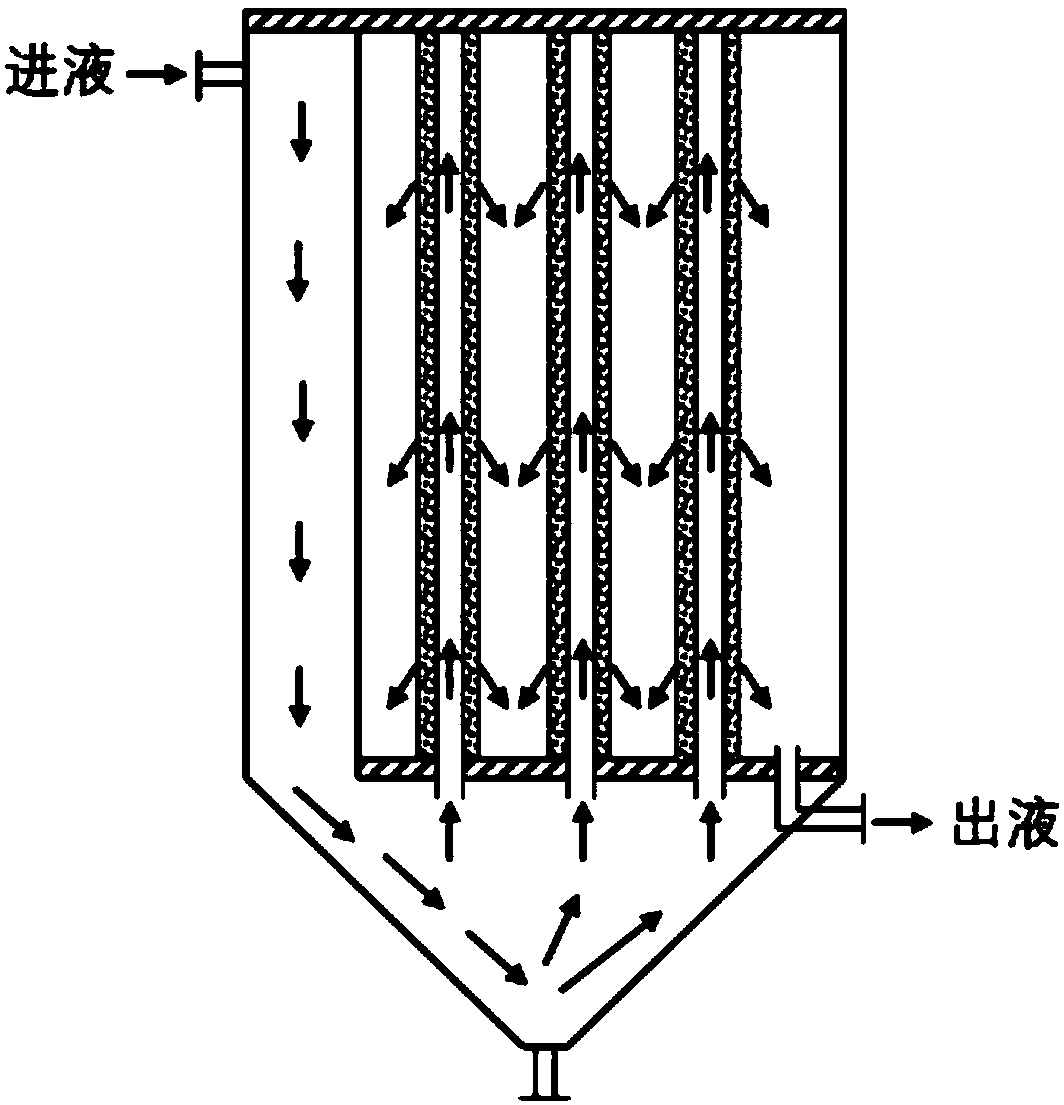

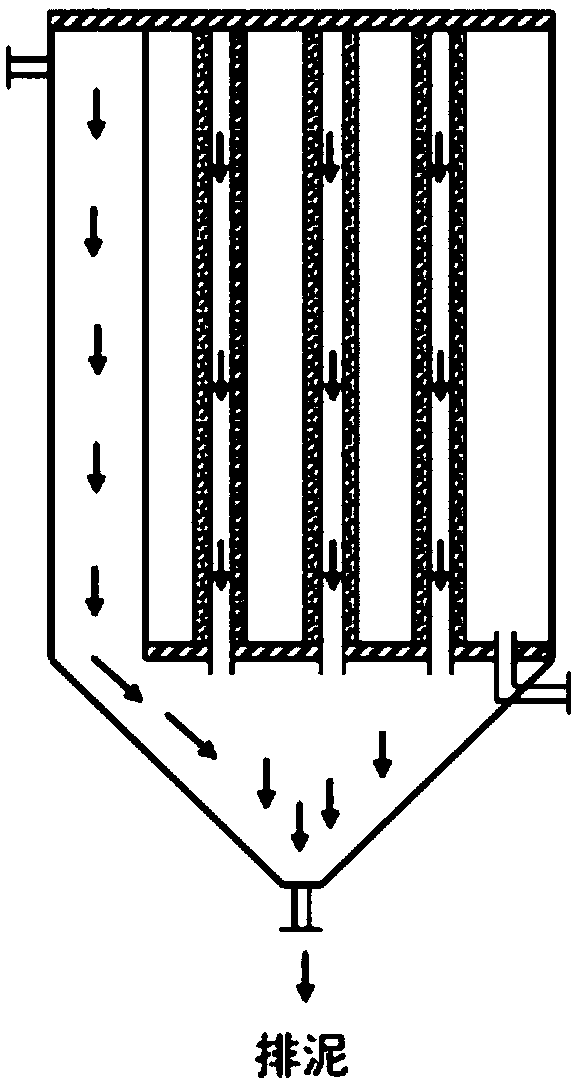

Self-cleaning and filtering device and filtering method thereof

PendingCN108744655AEfficient self-cleaningAchieve compactionStationary filtering element filtersSludgeEngineering

The invention combines the advantages of cross flow filtration and dead end filtration, an intercepted material is concentrated along the flowing direction of a solution, and is enriched at the top ofa filter; then the principle that a vacuum is created after the concentrated solution is emptied and then a flexible filtering material (cloth bag) is shrunk and pressed flat is combined, and the sludge in the filter is compacted and falls off under the effect of gravity. Therefore, the filter is efficiently self-cleaned.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

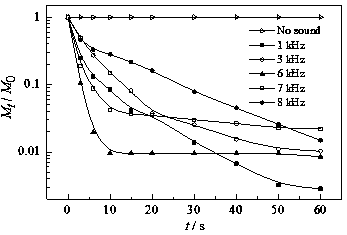

Water lifting and white smoke removal device and water lifting and white smoke removal method thereof

PendingCN110292828ALess investmentShort construction periodCombination devicesGas treatmentSmoke plumeEngineering

The invention discloses a water lifting and white smoke removal device and a water lifting and white smoke removal method thereof, and belongs to the field of white smoke removal devices. The device comprises a shell, the shell is provided with a smoke inlet and a smoke outlet, and flow dividing plates connected with the smoke inlet are arranged in the shell; the shell is a bellows-type shell; smoke heat-exchange pipes are arranged at the portion, between the lower positions of the flow dividing plates and the smoke outlet, in the shell; a drainage port is formed in the bottom of the shell. According to the water lifting and white smoke removal device, the temperature of high-temperature smoke is reduced through cooling water, so that the water in the smoke is condensed and separated out;meanwhile, when flowing through the bellows-type shell, the smoke regularly shrinks and expands, sound waves with a specific frequency and suitable for droplet agglomeration can be given out to agglomerate droplets, and the agglomerated droplets fall off under the effect of gravity and are drained out of the device through the drainage port. Gas-liquid separation is achieved, energy is sufficiently utilized, water lifting is efficient, besides, the generation of white smoke plume is effectively lowered, and the purpose of removing white smoke is achieved. The device is low in investment and simple in structure, does not cause secondary pollution, and is suitable for application and popularization.

Owner:CHINA JILIANG UNIV

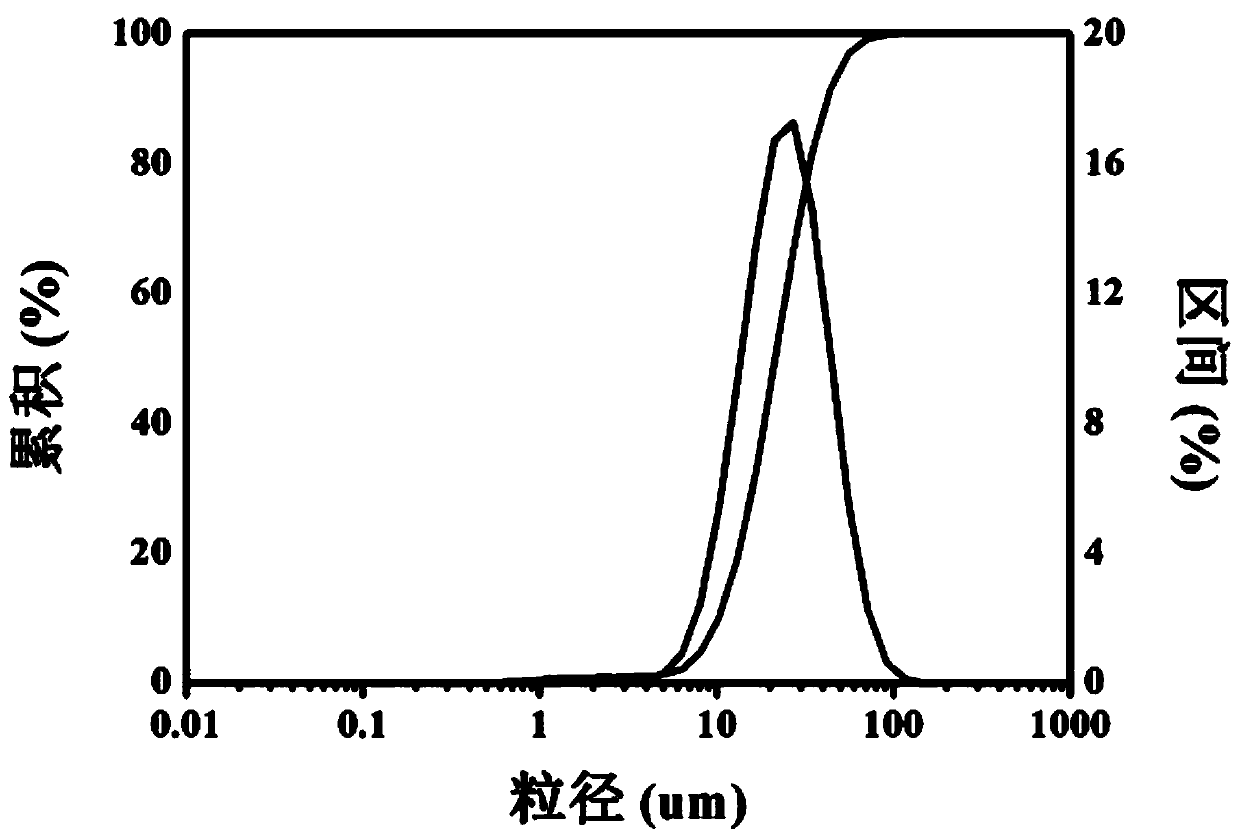

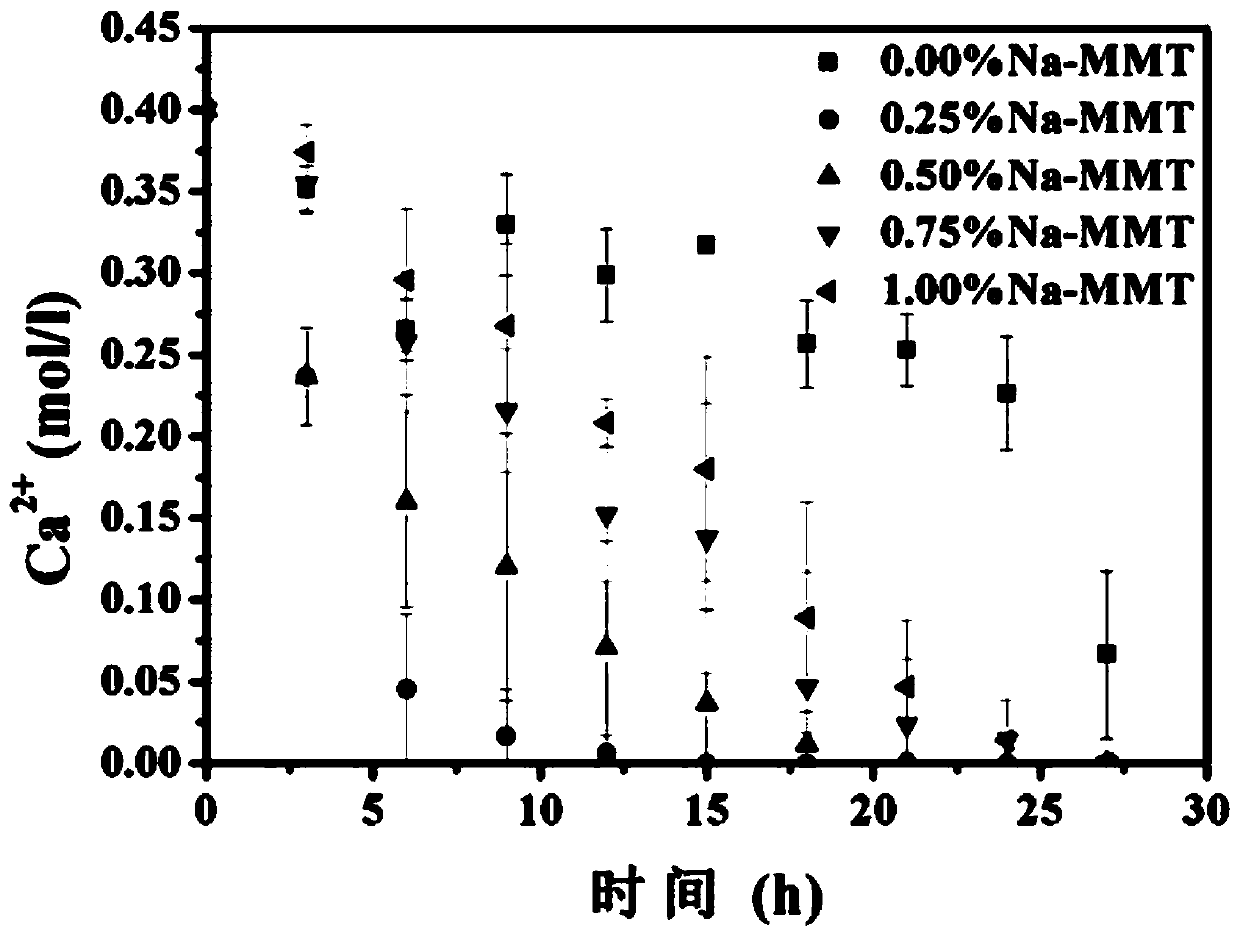

Method for inducing precipitation of calcium carbonate by using microorganisms

InactiveCN111411127AImprove adsorption capacityConducive to precipitationContaminated soil reclamationMicroorganism based processesEnvironmental chemistryPrecipitated calcium carbonate

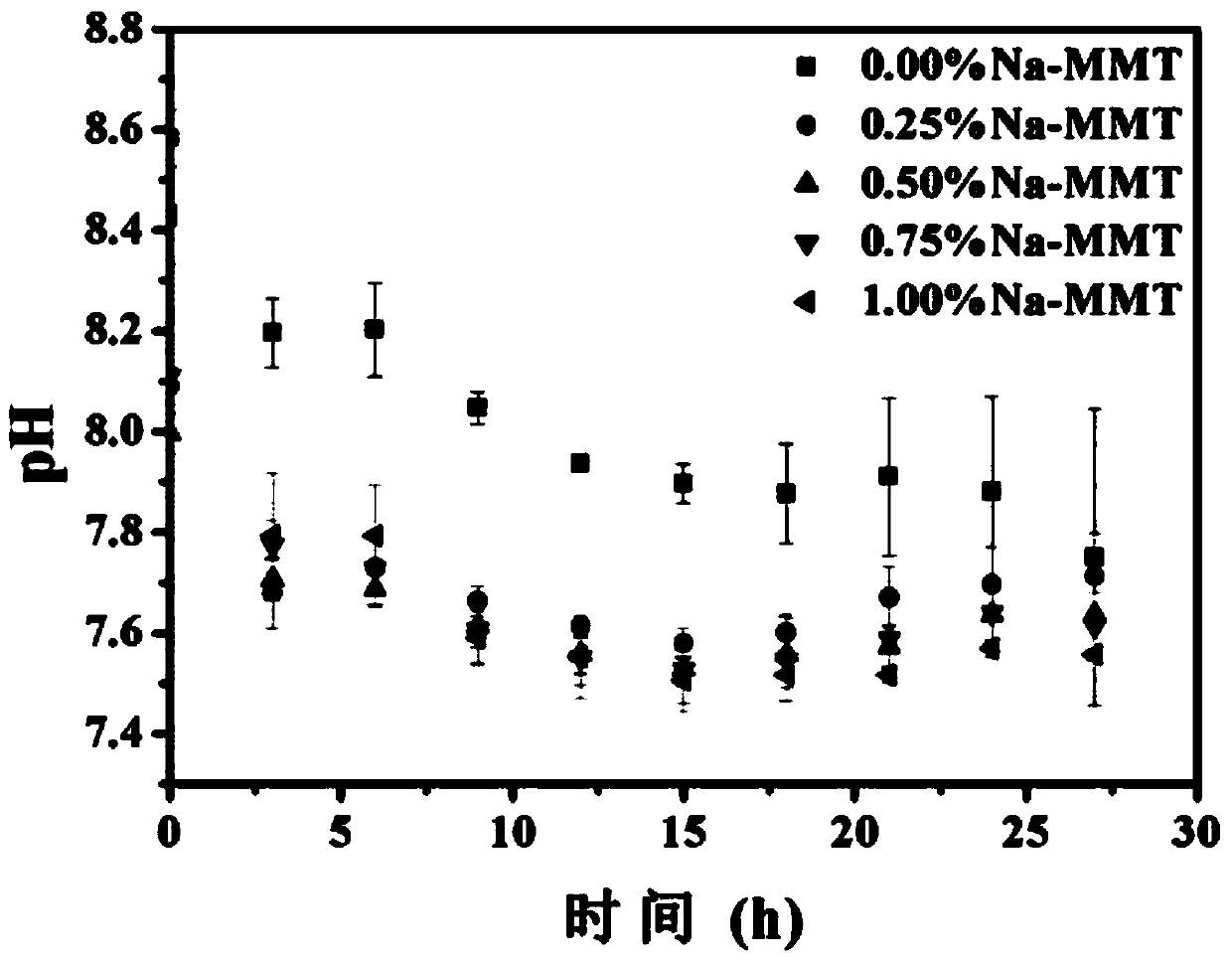

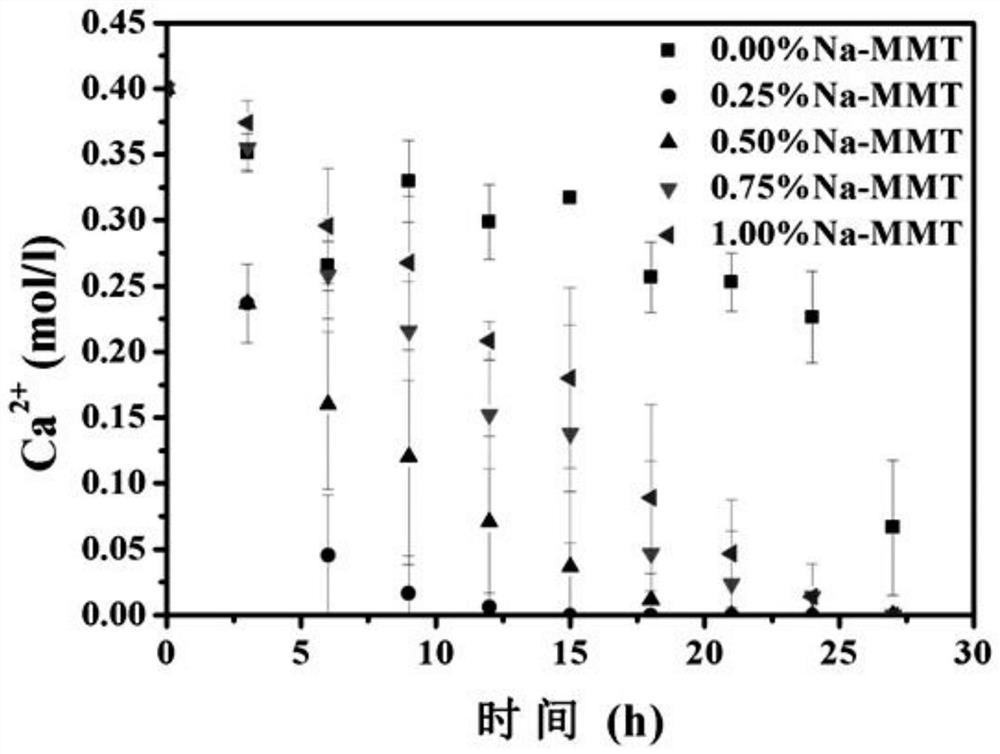

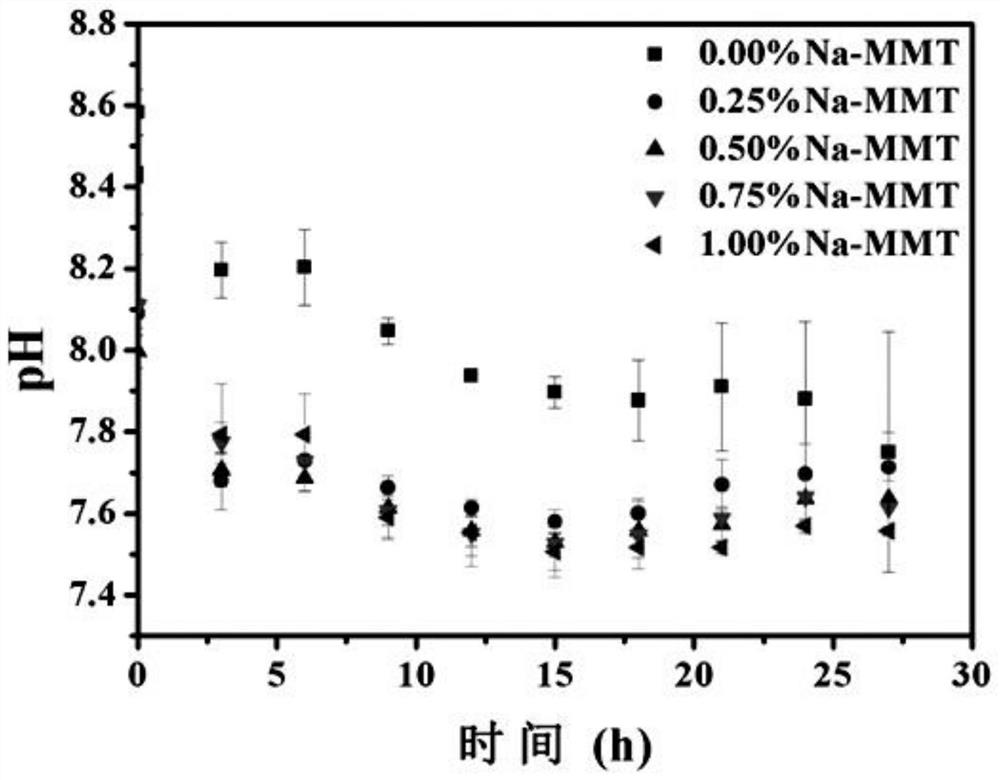

The invention provides a method for inducing precipitation of calcium carbonate by using microorganisms. The method comprises the following steps: mixing a bacterial suspension with a calcium reactionsolution to obtain a total gel solution, and adding sodium montmorillonite into the gel solution to carry out calcium carbonate precipitation, wherein the sodium montmorillonite accounts for 0.25-1%of the total gel solution by mass. According to the method, the sodium montmorillonite is added, and under the condition of interaction of the sodium montmorillonite, the reaction solution and urea, precipitation of calcium ions is accelerated, and the calcium ions can achieve the effect of complete precipitation, so that the reaction efficiency is obviously improved, and the method has a higher practical application value; and under the condition of more reaction solutions, the reaction can be carried out in the forward direction, the calcium ions are completely precipitated, and the precipitation amount of calcium carbonate in the reaction is obviously increased.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

High-toughness wear-resistant polycrystalline diamond compact and preparation method thereof

ActiveCN112059193AImpact toughnessImprove wettabilityVacuum evaporation coatingSputtering coatingFiberCarbon fibers

The invention relates to a high-toughness wear-resistant polycrystalline diamond compact and a preparation method thereof. The diamond compact comprises a hard alloy matrix, and a Si3N4 coating, a powder transition layer and a polycrystalline diamond layer which are sequentially arranged on the hard alloy matrix; and the polycrystalline diamond layer is prepared from the following raw materials of, in percentage by weight, 95 %-98 % of carbon nanotube coated diamond micro-powder, 0.1 % -0.3 % of graphene, 0.1 %-0.2 % of carbon fiber and 1.8 %-4.5 % of binding agent. According to the diamond compact and the method, the carbon nanotube coated diamond micro-powder with double characteristics of diamond and carbon nanotube is adopted, the Si3N4 coating is deposited on the surface of the hard alloy matrix, and the powder transition layer is arranged between the coating and the polycrystalline diamond layer, so that the excellent performance of the polycrystalline diamond layer is ensured, and meanwhile, the bonding strength between the hard alloy matrix and the polycrystalline diamond layer is greatly enhanced, and then the diamond compact has wear resistance and excellent impact toughness.

Owner:ZHONGNAN DIAMOND CO LTD

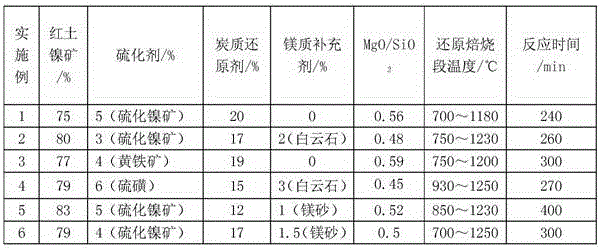

Process for producing nickel iron particles by carrying out reducing calcination on laterite-nickel ore through rotary kiln one-step method

The present invention discloses a process for producing nickel iron particles by carrying out reducing calcination on laterite-nickel ore through a rotary kiln one-step method. According to the present invention, at a material preparing and ball producing stage, the MgO / SiO2 in raw materials is more than or equal to 0.54, and the whole melting point of the material is increased by adding dolomite or magnesia and other magnesium-based supplements during insufficiency, such that the mixing pellet is in the solid state at a high temperature of 1250 DEG C at a reducing calcination stage so as not to cause the ringing of the rotary kiln, and the service life of the fireproof material of the rotary kiln is prolonged due to the decreasing of the maximum temperature of the reducing calcination stage; the FeS in the vulcanizing agent in the mixing pellet preferentially reacts with the NiO in the laterite-nickel ore to achieve the agglomeration of the reduced metal particles, such that the metal achieves the high yield.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

A kind of preparation method of solar cell high transmittance anti-reflection film

ActiveCN106206759BIncrease short circuit currentReduce thicknessFinal product manufacturePhotovoltaic energy generationRefractive indexLuminous flux

The invention relates to a high-transmittance anti-reflection membrane of a solar cell. The thickness of the anti-reflection membrane is 70-90 nanometers, the pore size of the anti-reflection membrane is smaller than 200 nanometers, and the raw material of the anti-reflection membrane comprises a solvent and a polymer. In the anti-reflection membrane, uniformly coating is performed on the solar cell by a rotation gluing machine, and the anti-reflection membrane with relatively thin thickness and relatively small pore size is formed. By means of mobility performance of an organic polymer material, the agglomeration of the polymer material is achieved; meanwhile, the solvent liable to volatilize is separated during the high-speed rotation process, and pores are formed in the anti-reflection membrane; by adjusting the rotational speed, the time and a solvent formula, the adjustment of the sizes of nanometer pores is achieved, and finally, the reflectivity of the anti-reflection membrane is changed; and through a test, the short-circuit current of the cell is effectively increased, the luminous flux of sunlight on a cell surface is improved, and the conversion efficiency is improved.

Owner:TIANJIN LANTIAN SOLAR TECH

Air-flow vortex balling machine for producing spherical graphite

The invention discloses an air-flow vortex balling machine for producing spherical graphite, which consists of a machine body, a balling drive device and an internal classification machine drive device, wherein an internal classification machine, a powder balling module and a cooling system are arranged in the machine body. In the invention, an internal balling module and a classification module are rationally arranged, and thus, the air-flow vortex balling machine for producing the spherical graphite is provided. The air-flow vortex balling machine can ensure that the graphite powder undergoes the physical processes of thinning, shearing, collision, friction, coiling, uniting and densification in an air-flow vortex balling room or can realize the combination of a physical balling processand a mechanical powder thinning process to prepare the spherical product. The indexes, such as sphericity, grain fineness distribution, tap density, apparent density, actual density and special surface area, of the spherical graphite powder can be controlled in the range of pre-determined values; the quality is stable; the yield can be improved by over three times; and over 50 percent of energy consumption can be reduced.

Owner:LUOYANG GUANQI INDAL & TRADE

Rough surface polymer composite material, nano-carbon material, preparation method and application

ActiveCN112592451BChange quantityChange heightPhysical/chemical process catalystsOther chemical processesEtchingPtru catalyst

The invention relates to a polymer composite material with a rough surface, a nano-carbon material, a preparation method and an application. By mixing phenolic compounds, carbonyl compounds, amino compounds and colloidal template solutions, sequential polymerization is carried out by using the kinetic differences of polycondensation reaction, Schiff base reaction and Mannich reaction at the interface of micelles to generate nanomaterials on the surface or edge of nanomaterials. Islands or nanoparticles, thus building a rough structure on the surface of nanomaterials. The method does not require additional etching and deposition processes, and the process is simple and controllable. The adsorbent prepared by the present invention can realize rapid diffusion of gas, and the diffusion rate is 5-10 times that of commercial adsorbents; the catalyst carrier prepared by the present invention can anchor metal active particles and inhibit active components under high temperature conditions Migration and agglomeration effectively improve the stability of the catalyst.

Owner:DALIAN UNIV OF TECH

Injection molding and compression molding method of composite tufted carpet plastic interior ornament

The invention discloses an injection molding and compression molding method of a composite tufted carpet plastic interior ornament. The method comprises the following steps of: a, selecting a composite tufted carpet; b, heating the composite tufted carpet; c, opening a mold, fixing the composite tufted carpet in the injection mold, and then closing the mold; d, injecting plastic in an amount which is 10 to 20 percent of the required injection molding total amount under low pressure at a low speed by an injection molding machine through a plurality of hot runners; e, opening the injection moldto reserve certain clearance between a movable mold and a fixed mold, and starting the injection molding machine to inject the rest plastic of the required injection molding total amount under high pressure at a high speed; f, closing the mold, forming the composite tufted carpet plastic interior ornament by pressing, and simultaneously cutting the redundant edge and cooling; and g, opening the mold, and taking out the composite tufted carpet plastic interior ornament. The method is low in production condition requirement, good in product quality and high in production efficiency, the required equipment is cheap, and the produced product can be popularized in a large range.

Owner:NINGBO SUNLIGHT MOTOR PARTS

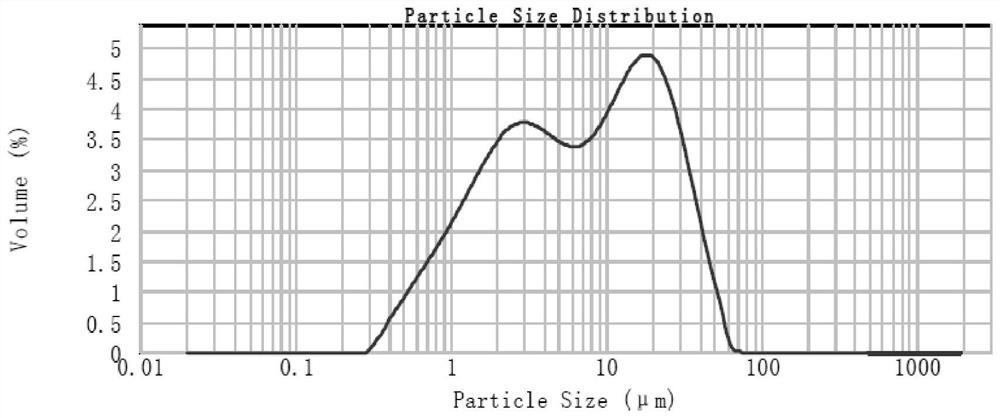

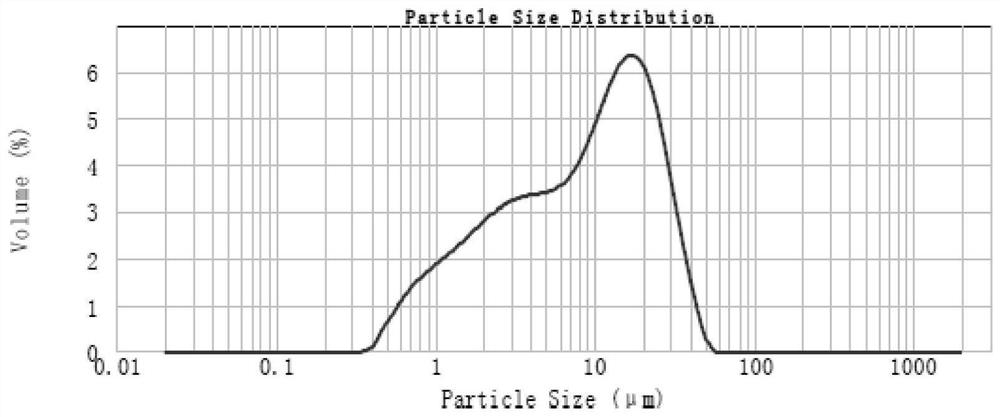

Preparation method and production device of graphene microchip pre-dispersed masterbatch

The invention relates to the technical field of technologies for processing rubber, in particular to a method and a production device for preparing graphene micro-plate pre-dispersion master batch. The method includes stirring and mixing graphene micro-plate dispersion liquid and latex with each other by the aid of a high-speed stirring machine to obtain mixed materials, adding flocculating agents into the mixed materials and coagulating the mixed materials to obtain pulp; dehydrating and drying the pulp to obtain the master batch. The method and the production device have the advantages that technologies are simple, the method and the production device are safe in operation, the graphene micro-plate pre-dispersion master batch can be continuously produced on a large scale, and the production efficiency can be improved as compared with original preparation technologies by the aid of batch processes; graphene micro-plates in the master batch prepared by the aid of the method can be highly dispersed as compared with melt processing methods; quick mixing and condensation can be implemented as compared with previous methods, drying and dehydrating phases are combined with squeezing drying and oven-drying modes, accordingly, the drying time can be shortened, rubber materials can be prevented from being aged, and the graphene micro-plate pre-dispersion master batch with excellent performance can be prepared by the aid of the method and the production device.

Owner:青岛蓝湾烯碳材料科技有限责任公司

A charged electromagnetic hydrophobic material and its preparation method and application

The invention discloses a charged magnetic hydrophobic material and a preparation method and application thereof in separation of micro-fine-particle minerals. The material includes magnetic particlesand a metal organic complex loaded on the surface, has strong magnetism, is positively charged on the surface, and has high electrostatic adsorption capacity for anions and high physical adsorption performance for hydrophobic micro-fine-particle minerals, and therefore, after micro-fine-particle minerals in ore pulp are subjected to surface hydrophobic and anion modification, the micro-fine-particle minerals can be adsorbed and agglomerated by utilizing the material, then the micro-fine-particle minerals are efficiently separated from gangue minerals through magnetic separation, thus solvinga difficult problem of separation and purification of ultrafine minerals. A preparation process of the charged magnetic hydrophobic material is simple and cheap and meets industrial production requirements.

Owner:CENT SOUTH UNIV

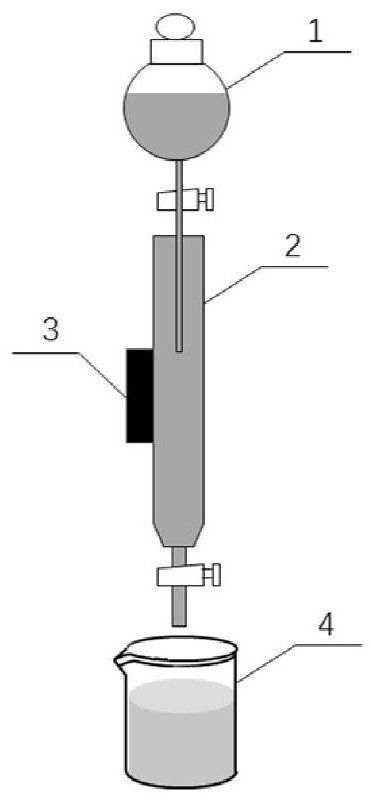

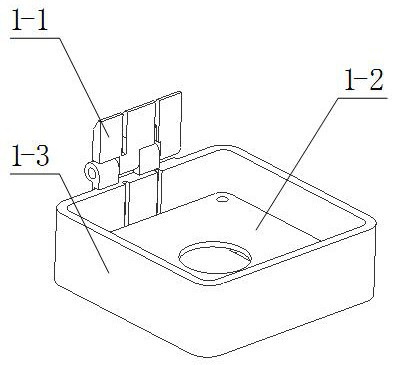

Portable multifunctional visual microfluid equipment based on electric field regulation and control

ActiveCN114210377AMake up for the problem of power-on difficultyAchieve reunionLaboratory glasswaresMicroscopesCurrent electricElectrical battery

The invention discloses portable multifunctional visual microfluid equipment based on electric field regulation and control, the microfluid equipment comprises a replaceable top cover assembly, an equipment shell assembly and a display transmission assembly, the replaceable top cover assembly is composed of a power transmission board, an electric field regulation and control PCB and a top cover; the shell assembly is composed of a shell, a power transmission probe, a detachable window plate and a button switch. The display transmission assembly is composed of a chip base, a copper column, a movable support, an adjustable microscope, a focusing bolt, an image transmission PCB, a battery and a micro-fluidic chip. The device is good in reliability, compact in structure, light in weight, good in portability and modularized, different top cover assemblies can be replaced according to different needs, electric field regulation and control can be conducted on microfluid, and the device can be applied to electric field regulation and control besides the basic functions of dielectrophoresis, induced charge electroosmosis, alternating-current electroosmosis, direct-current electric heating, alternating-current electric heating and the like. And the functions of agglomeration, sorting, deflection, microfluid mixing and the like of particles or cells can be realized.

Owner:HARBIN INST OF TECH

A kind of method utilizing microorganism to induce calcium carbonate precipitation

InactiveCN111411127BIncrease sedimentationAccelerated precipitationContaminated soil reclamationMicroorganism based processesMicroorganismSoil science

The invention provides a method for using microorganisms to induce precipitation of calcium carbonate. The method is to mix the bacterial suspension with the calcium reaction solution to obtain the total gel solution, and add sodium montmorillonite to the gel solution to precipitate calcium carbonate; the mass percentage of the sodium montmorillonite in the total gel solution is 0.25%. ~1%. The present invention accelerates the precipitation of calcium ions through the addition of sodium montmorillonite, under the condition of interaction between sodium montmorillonite, reaction solution and urea, and enables calcium ions to achieve complete precipitation, which significantly improves the The efficiency of the reaction has greater practical application value; and under the condition of more reaction liquid, the reaction can be carried out forward, the calcium ions can be completely precipitated, and the precipitation amount of calcium carbonate in the reaction can be obviously increased.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

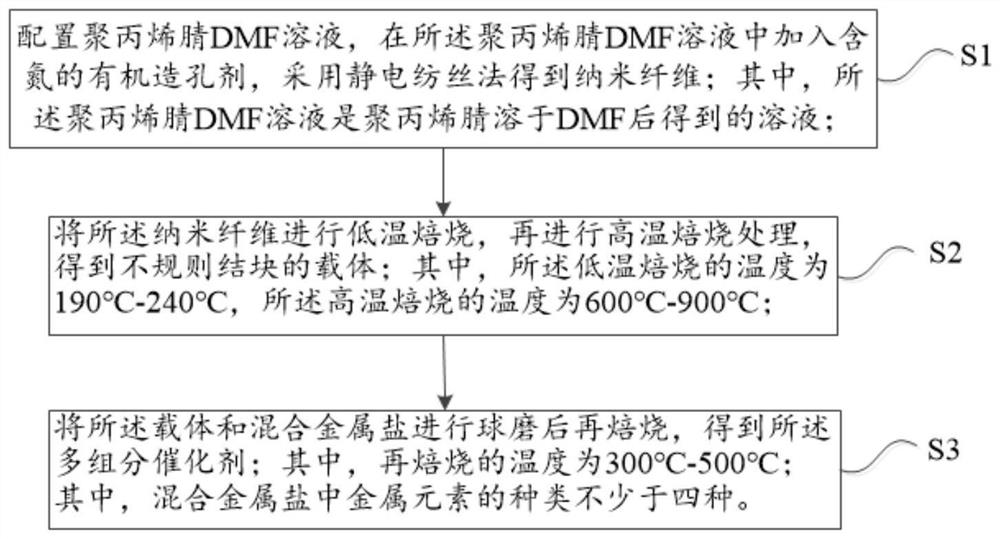

Preparation method of multi-component catalyst, multi-component catalyst and application of multi-component catalyst

ActiveCN114700075AGood dispersionImprove conversion rateHydrogenOrganic chemistryPtru catalystOrganic liquids

The invention provides a preparation method of a multi-component catalyst, the multi-component catalyst and application of the multi-component catalyst, and the preparation method of the multi-component catalyst comprises the following steps: step 1, preparing a polyacrylonitrile DMF solution, adding a nitrogen-containing organic pore-forming agent into the polyacrylonitrile DMF solution, and obtaining nanofibers by adopting an electrostatic spinning method; step 2, carrying out low-temperature roasting on the nanofiber, and then carrying out high-temperature roasting treatment to obtain an irregular caked carrier; 3, the carrier and the mixed metal salt are subjected to ball milling and then roasted, and the multi-component catalyst is obtained, wherein the variety of metal elements in the mixed metal salt is not less than four, and by adopting the preparation method disclosed by the invention, multi-component metals are combined together without using a surfactant, and the multi-component catalyst with relatively good activity, high conversion rate and high selectivity can be obtained; and the obtained multi-component catalyst can be used in hydrogenation and dehydrogenation reaction processes of a nitrogen heterocyclic organic liquid hydrogen storage carrier.

Owner:陕西氢易能源科技有限公司

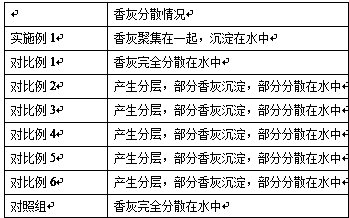

Incense ash agglomeration type incense stick and preparation method thereof

InactiveCN109010886AImprove adhesionImprove adsorption capacityBiocideFungicidesPotassium nitrateIxonanthes

The invention discloses an incense ash agglomeration type incense stick and a preparation method thereof. Raw materials comprise traditional Chinese medicine powder, sandalwood powder, modified Ixonanthes chinensis powder, potassium nitrate and distilled water. The preparation method concretely comprises the following steps: 1) mixing the traditional Chinese medicine powder, sandalwood powder, modified Ixonanthes chinensis powder and potassium nitrate, and crushing the obtained mixture to obtain a mixed powder; 2) adding the distilled water to the mixed powder, and performing stirring and mixing; 3) pouring the obtained slurry into a mold after the stirring is completed, and shaping the slurry to prepare an incense stick body; and 4) transferring the incense stick body into an oven, and drying the incense stick body to obtain the incense ash agglomeration type incense stick. The incense stick prepared in the invention has the advantages of simple preparation process, low cost, excellent air sterilization and purification effects, realization of aggregation of ash generated after combustion, reduction of the escaping of the ash, reduction of the pollution to the environment, and wide application prospect.

Owner:王灯生

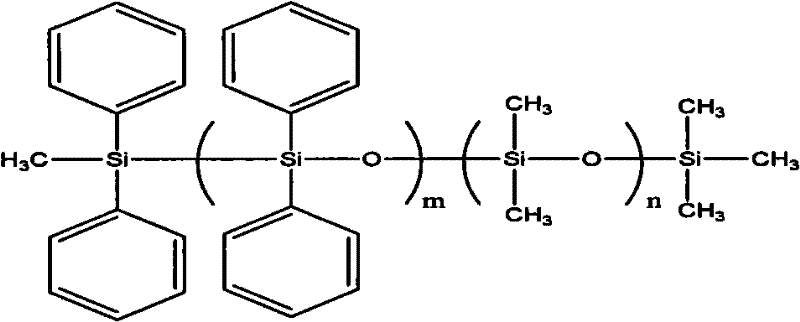

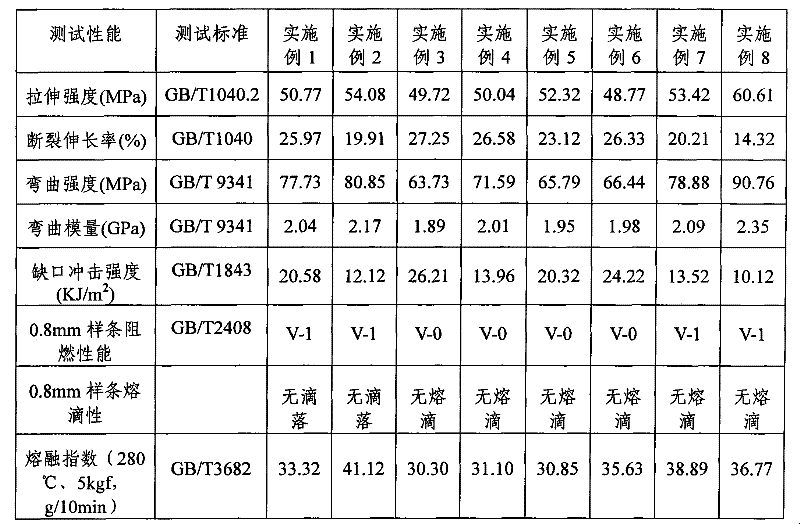

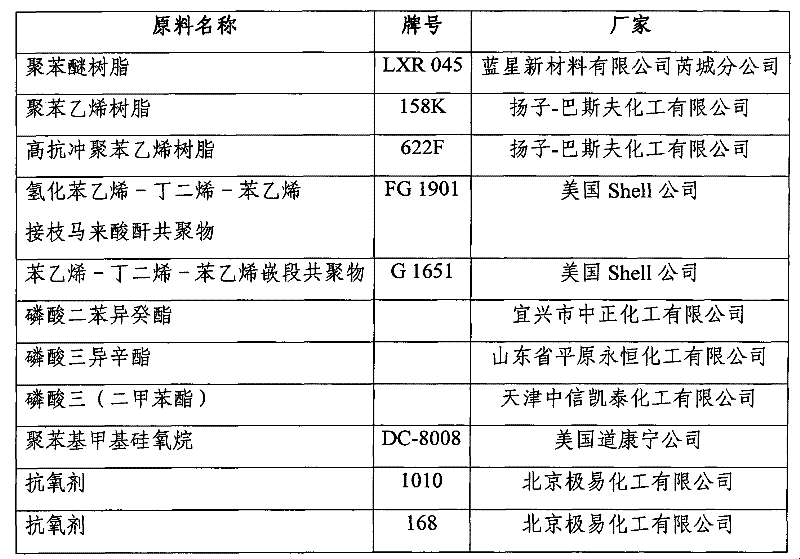

Halogen-free fire-retardant polyphenyl ether compound and method for preparing same

Owner:BEIJING UNIV OF CHEM TECH

A kind of high-toughness and wear-resistant polycrystalline diamond composite sheet and its preparation method

ActiveCN112059193BImpact toughnessImprove wettabilityVacuum evaporation coatingSputtering coatingFiberCarbon fibers

Owner:ZHONGNAN DIAMOND CO LTD

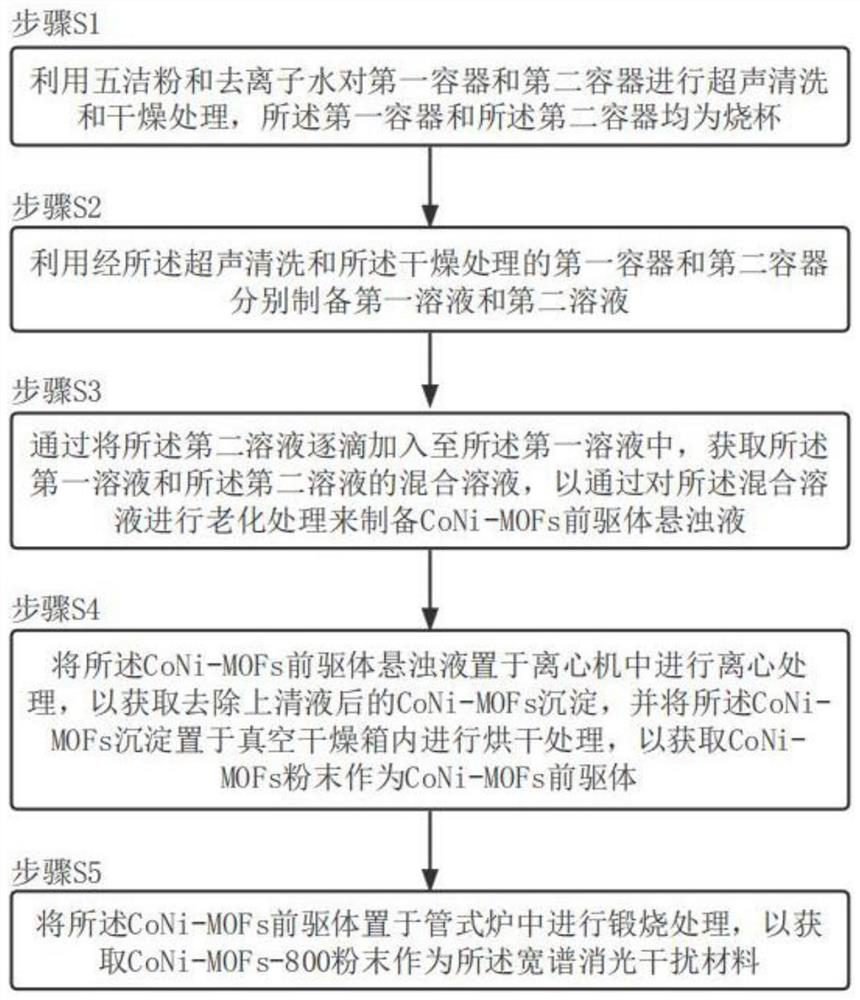

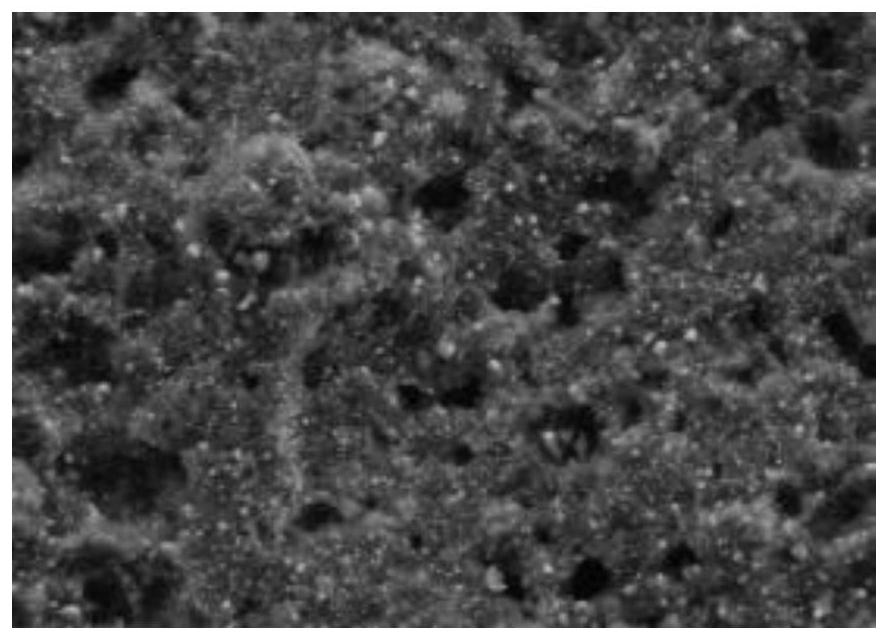

Wide-spectrum extinction interference material and preparation method thereof

PendingCN114590845AImprove performanceHigh specific surface areaTransportation and packagingChemical industryChemistryTube furnace

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com