High-toughness wear-resistant polycrystalline diamond compact and preparation method thereof

A technology of polycrystalline diamond and composite sheet, which is applied in the direction of metal material coating process, ion implantation plating, coating, etc., and can solve the problems of poor adhesion between polycrystalline diamond layer and hard alloy substrate, thermal conductivity, and heat resistance. Anti-oxidation, insufficient chemical inertness, reduced service life of polycrystalline diamond composite sheets, etc., to achieve good sintering promotion, excellent wear resistance, high hardness and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

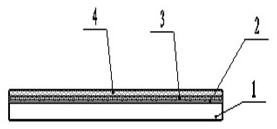

[0041] Such as figure 1 As shown, the high-toughness and wear-resistant polycrystalline diamond compact of this embodiment includes a cemented carbide substrate 1 and Si that is sequentially arranged on the cemented carbide substrate 1. 3 N 4 Coating 2, powder transition layer 3 and polycrystalline diamond layer 4; the polycrystalline diamond layer is composed of the following raw materials in weight percentage: carbon nanotube coated diamond powder 95%, graphene 0.3%, carbon fiber 0.2% and binder 4.5%; the powder transition layer is composed of the following raw materials in weight percentage: 40% cemented carbide powder, 56% carbon nanotube-coated diamond powder, 1.5% graphene and 2.5% binder; Described graphene selects thickness 6~8nm, the graphene nanosheet of wide 5 μ m; 3 N 4 The thickness of the coating is 7 μm; the mass ratio of the powder transition layer and the polycrystalline diamond layer is 0.2:1; the carbon nanotube-coated diamond powder is a chemical vapor p...

Embodiment 2

[0055] The high-toughness and wear-resistant polycrystalline diamond composite sheet of this embodiment includes a cemented carbide substrate and Si that is sequentially arranged on the cemented carbide substrate. 3 N 4 Coating, powder transition layer and polycrystalline diamond layer; The polycrystalline diamond layer is made up of the raw material of following percentage by weight: carbon nanotube coated diamond micropowder 98%, graphene 0.1%, carbon fiber 0.1% and bonding agent 1.8%; the powder transition layer is made up of the following raw materials in weight percentage: 48% of cemented carbide powder, 50% of carbon nanotube-coated diamond powder, 0.5% of graphene and 1.5% of binding agent; the graphene Graphene nanosheets with a thickness of 6-8 nm and a width of 5 μm are selected; the Si 3 N 4 The thickness of the coating is 8 μm; the mass ratio of the powder transition layer and the polycrystalline diamond layer is 0.2:1.5; the carbon nanotube-coated diamond powder...

Embodiment 3

[0069] The high-toughness and wear-resistant polycrystalline diamond composite sheet of this embodiment includes a cemented carbide substrate and Si that is sequentially arranged on the cemented carbide substrate. 3 N 4 coating, powder transition layer and polycrystalline diamond layer; the polycrystalline diamond layer is made up of the following raw materials in weight percentage: carbon nanotube coated diamond powder 96.5%, graphene 0.2%, carbon fiber 0.15% and binding agent 3.15%; the powder transition layer is made up of the following raw materials in weight percentage: 44% of cemented carbide powder, 53% of carbon nanotube-coated diamond micropowder, 1% of graphene and 2% of binding agent; the graphene Graphene nanosheets with a thickness of 6-8 nm and a width of 5 μm are selected; the Si 3 N 4 The thickness of the coating is 6-8 μm; the mass ratio of the powder transition layer and the polycrystalline diamond layer is 0.2:1.2; the carbon nanotube-coated diamond powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com