A kind of preparation method of solar cell high transmittance anti-reflection film

A technology of anti-reflection film and solar cell, which is applied in the direction of circuits, electrical components, photovoltaic power generation, etc., can solve the problems of complex preparation process, surface etching of battery structure, large pore size, etc., to improve luminous flux, improve conversion efficiency, and improve Effect of short circuit current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the high transmittance anti-reflection film for the above solar cell comprises the following steps:

[0033] (1) Under the protective atmosphere of inert gas, the ambient temperature is 12-28 degrees Celsius: select any one of chloroform, ethanol, acetone or propanol and mix it with nonane to obtain a solvent;

[0034] (2) Under the protective atmosphere of inert gas, select any one, any two or all three of acrylic resin, polyethylene acetate or polyvinyl alcohol as a polymer, add it to the solvent prepared in step (1), and stir for 1~ After 4 hours, let stand for 15 to 120 minutes and filter out the precipitate to obtain a solution;

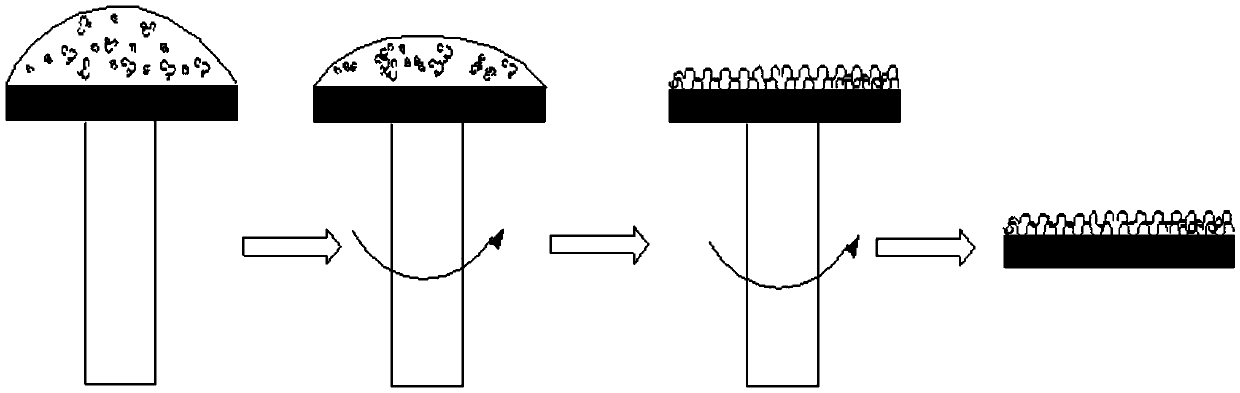

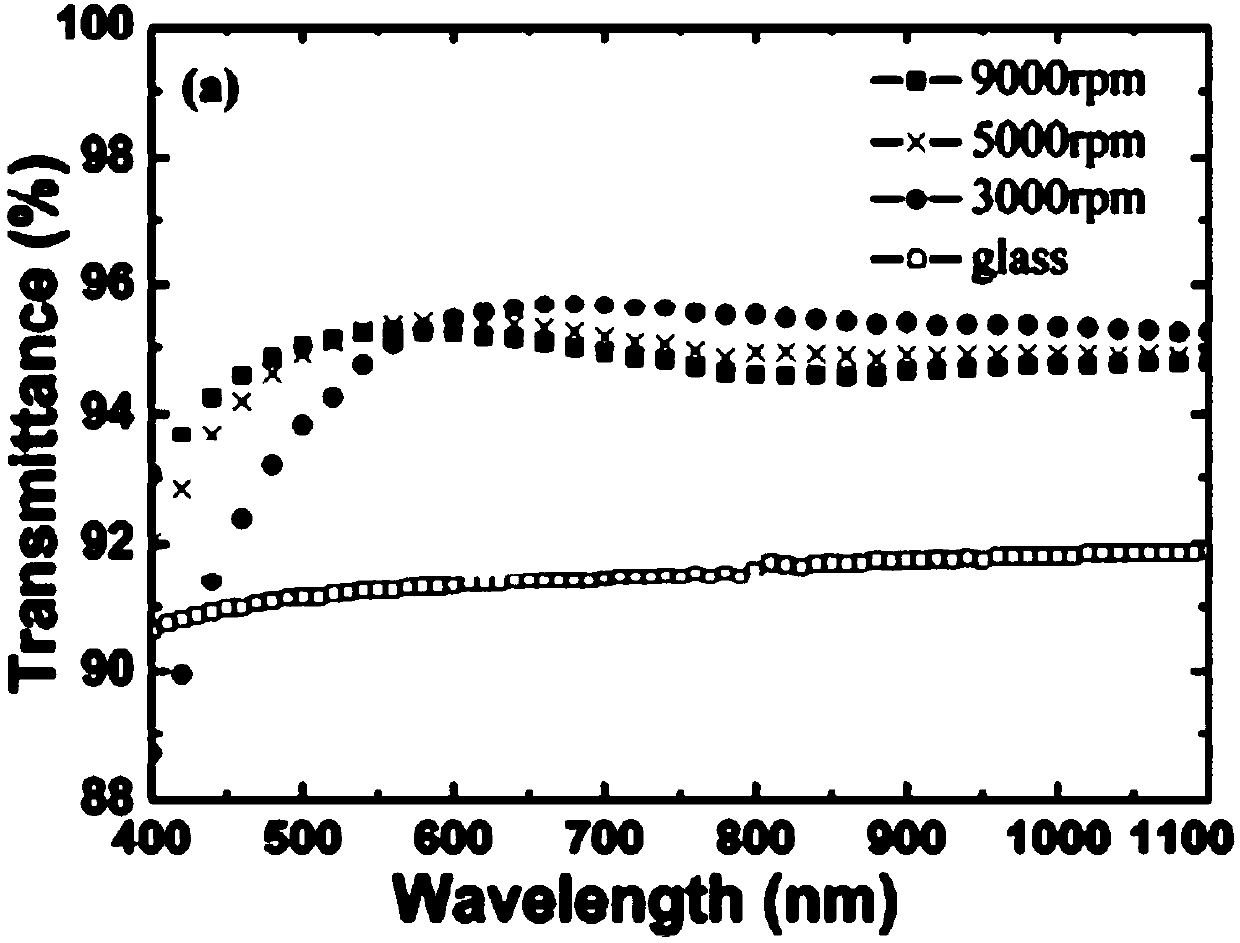

[0035] (3) Under a protective atmosphere of inert gas, use a spin coating machine to evenly coat the solution in step (3) on the upper surface of the solar cell at a speed of 5000-12000r / min. The spin-coating time is 15-60 seconds. The temperature is kept at 20-125 degrees Celsius, and then the anti-reflection f...

Embodiment

[0038] 1. In N 2 Under the protective atmosphere of the environment temperature of 20 degrees Celsius, acetone and nonane are mixed uniformly according to the volume of 1:0.015;

[0039]2. Add PMMA granular material to the solvent at a volume ratio of 1:2, mix and stir for 2 hours, then let it stand for 40 minutes, the existing residue precipitates out, and the solution is obtained after filtration;

[0040] 3. Use the glue coating machine to evenly coat the solution on the amorphous silicon battery at a speed of 9000r / min. The spin coating time is kept at 30 seconds. After coating, the solar battery is vacuum-dried at 100 degrees Celsius for 40 minutes. Finally, a stable and cured anti-reflection film is formed.

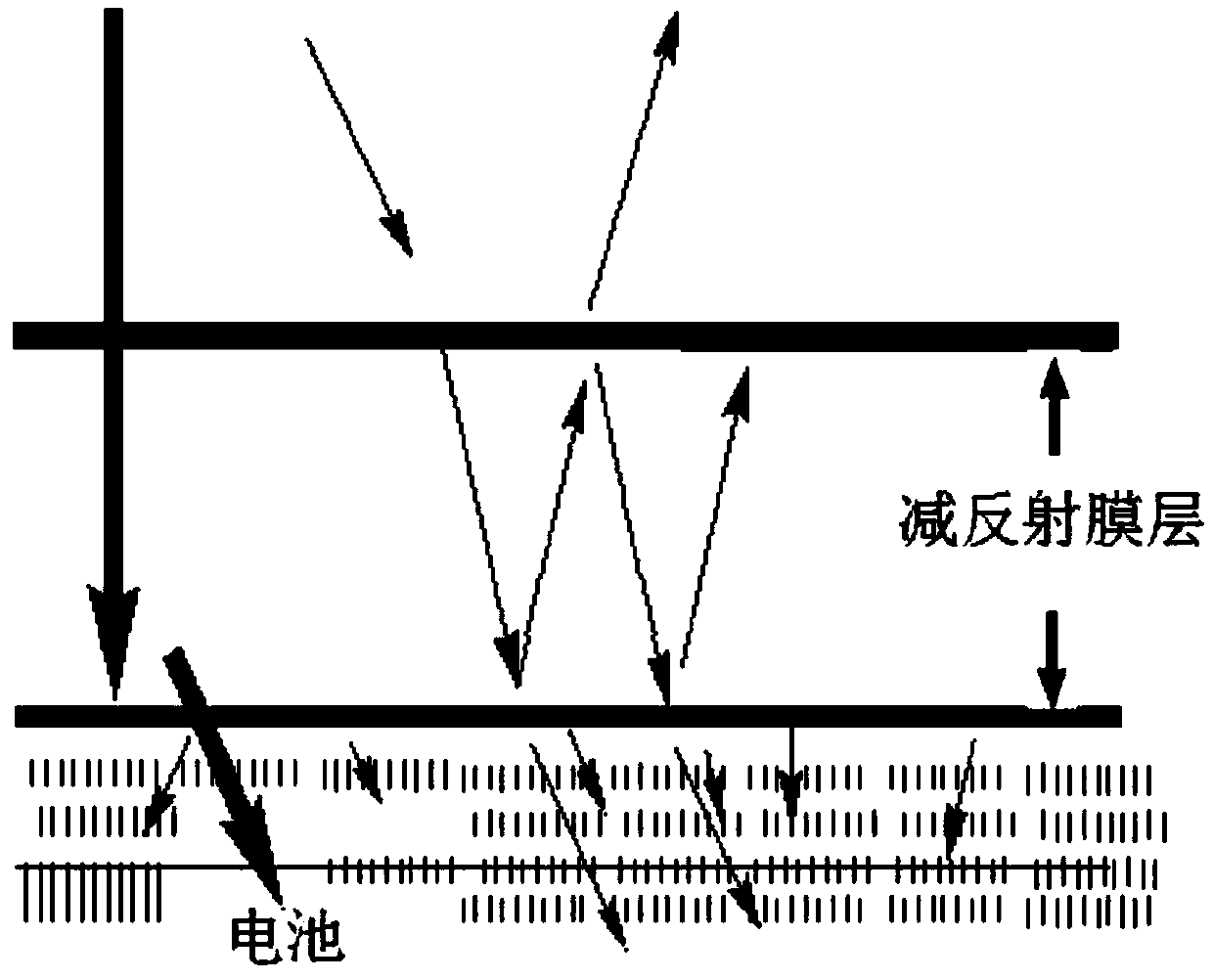

[0041] figure 1 It is a schematic diagram of the structure of a solar cell with a nanoporous anti-reflection film. The layered structure of the anti-reflection film is between the two black filled lines. When irradiated on the solar cell, the transmittance is imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com