Self-cleaning and filtering device and filtering method thereof

A self-cleaning filtration and liquid clearing technology, which is applied in the field of filtration devices and filtration, filtration devices and filtration with self-cleaning function, can solve the problems of difficult regeneration, low filtration efficiency, incomplete regeneration, etc., to avoid excessive equipment load uniformity, increase driving force, and improve self-cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

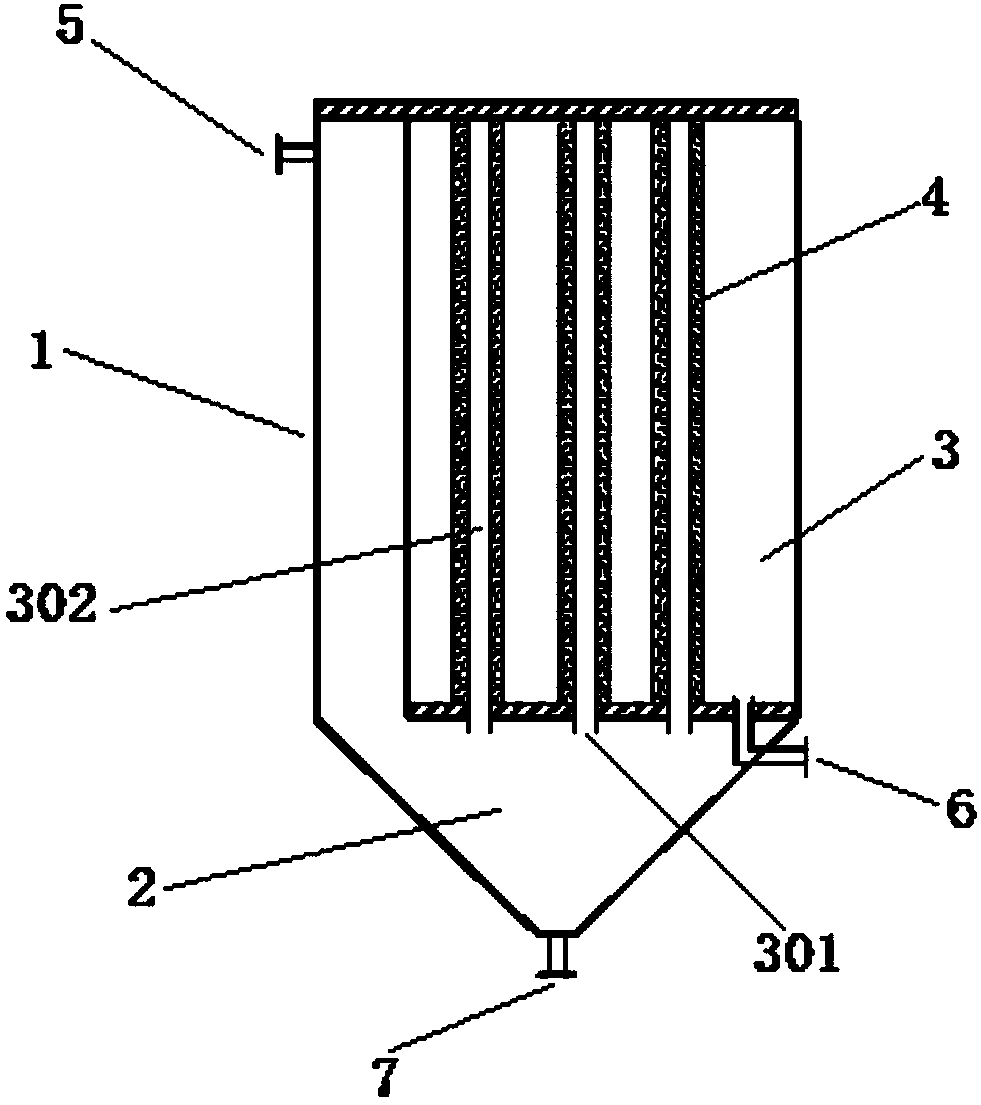

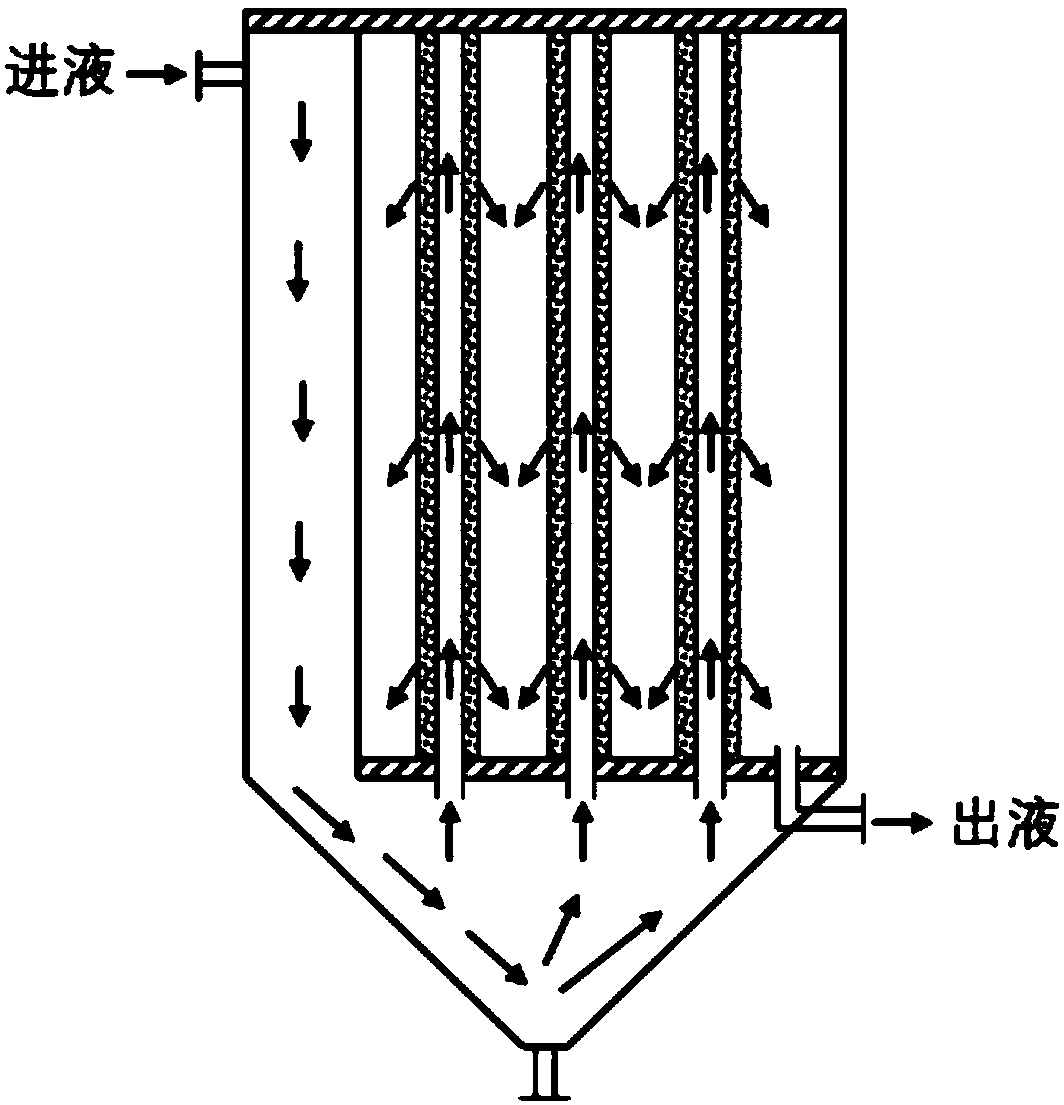

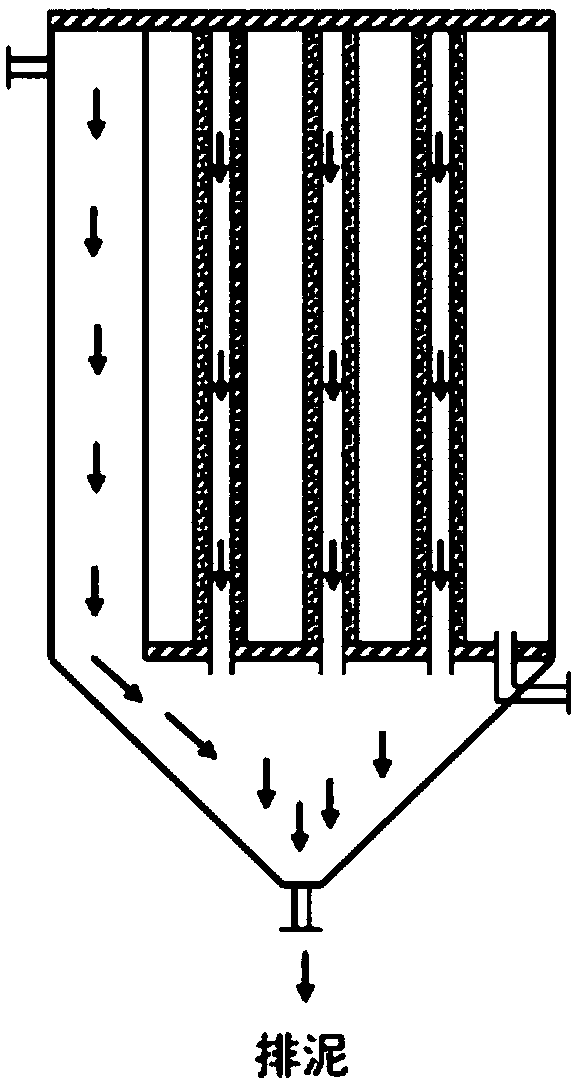

[0073] like figure 1 As shown, a self-cleaning filter device includes a housing 1 , a thick liquid chamber 2 , a clear liquid chamber 3 , a filter membrane 4 , a liquid inlet 5 , a liquid outlet 6 , and a slag discharge port 7 . Wherein: the concentrated liquid chamber 2 and the clear liquid chamber 3 are located in the housing 1 . The filter membrane 4 is set in the clear liquid chamber 3 . A concentrated liquid inlet 301 is provided at the bottom of the clear liquid chamber 3 , and the concentrated liquid inlet 301 communicates with the concentrated liquid chamber 2 . The dope inlet 301 and the filter membrane 4 form a filter channel 302 . The liquid inlet 5 is arranged on the top or side wall of the thick liquid chamber 2 and communicates with the thick liquid chamber 2 . The liquid outlet 6 is arranged on the bottom or the side wall of the clear liquid chamber 3 and communicates with the clear liquid chamber 3 . The slag outlet 7 is arranged at the bottom of the concen...

Embodiment 2

[0075] like Figure 4 As shown, embodiment 1 is repeated, except that the device also includes a buffer cavity 8 . The buffer chamber 8 is arranged on the top of the clear liquid chamber 3 and communicates with the top of the filter channel 302 . The device also includes a pressure detection device 9 . The pressure detection device 9 is arranged on the top of the housing 1 and detects the pressure in the buffer chamber 8 . The section of the buffer chamber 8 is a tapered structure. The sections of the buffer cavity 8 and the filter channel 302 are funnel-shaped.

Embodiment 3

[0077] Example 2 is repeated, except that the device includes 8 filter channels 302, and all filter channels 302 are arranged in parallel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com