Patents

Literature

66 results about "Dead end filtration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

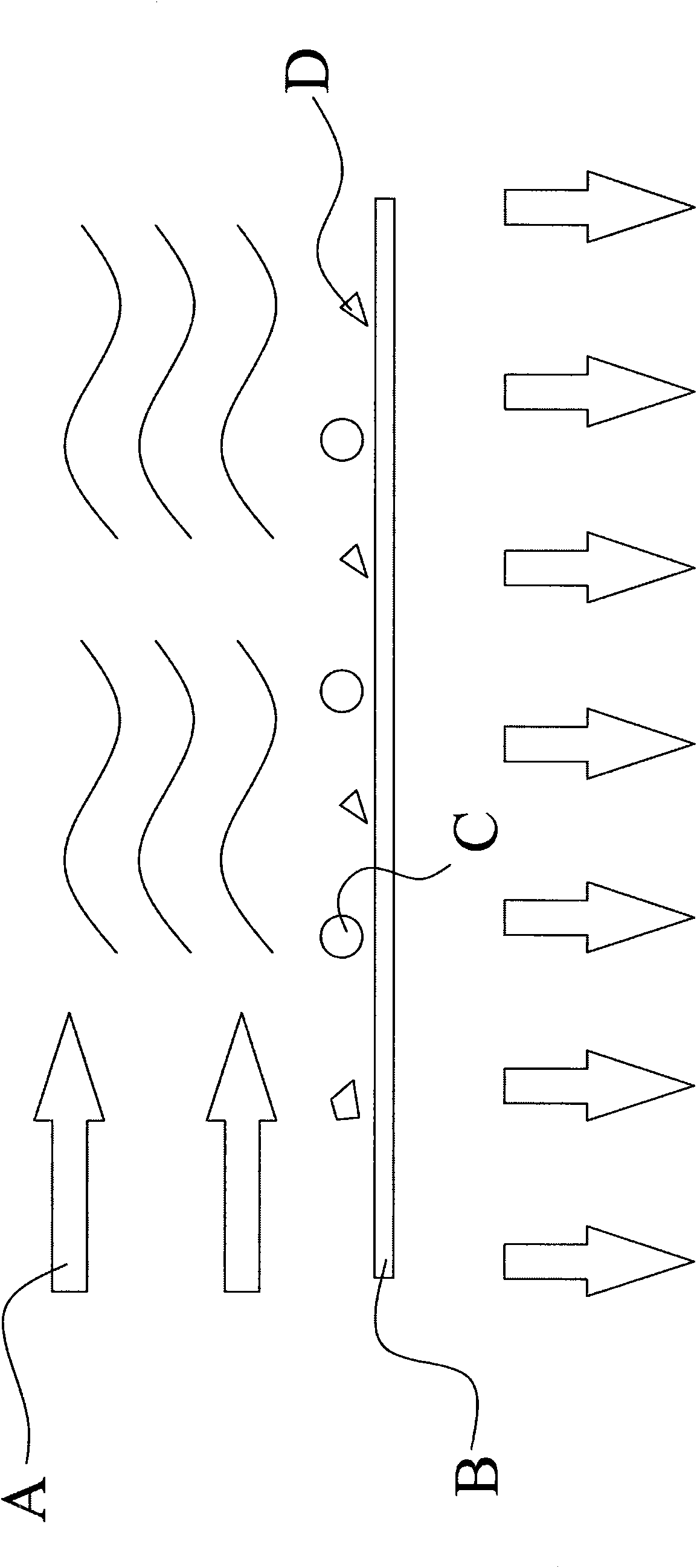

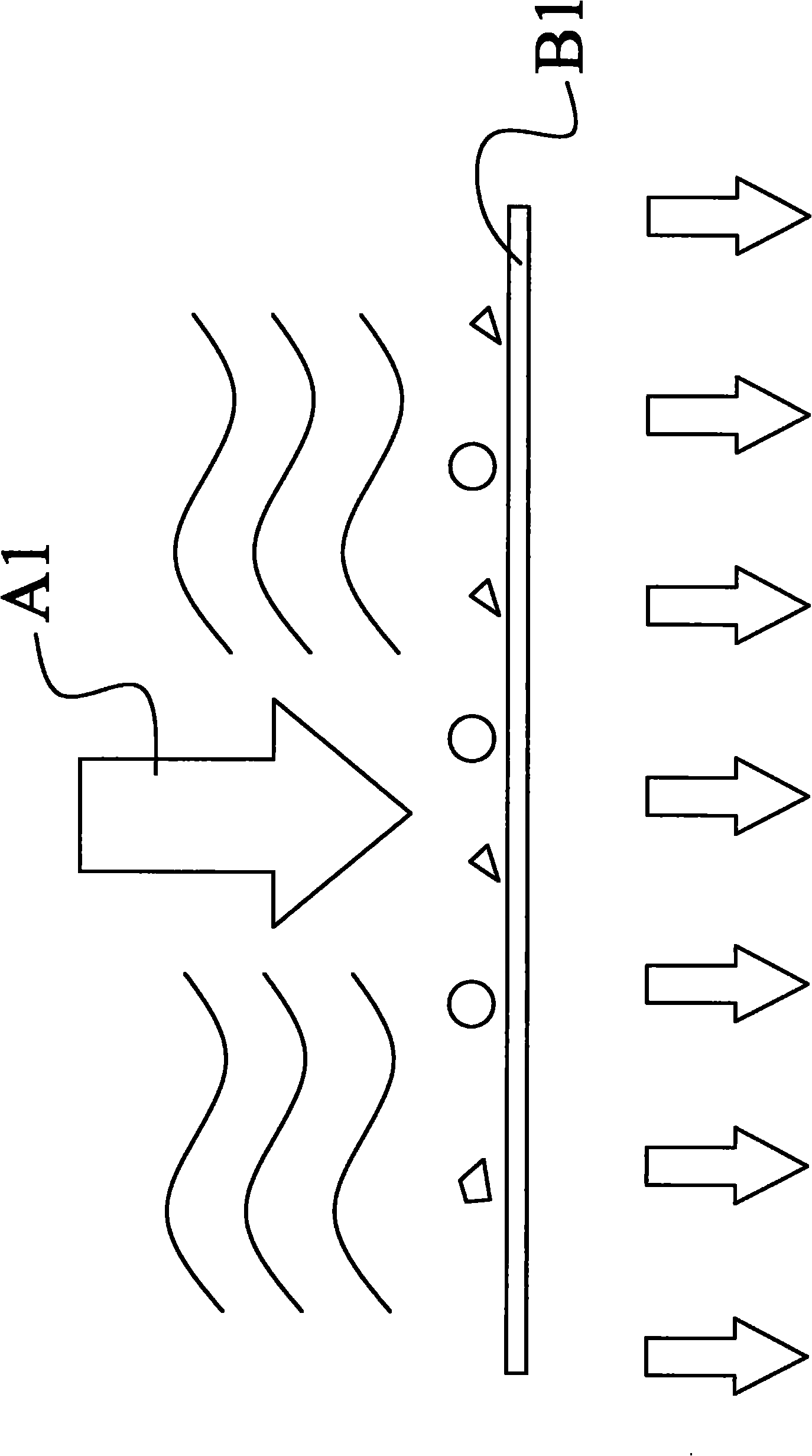

Dead end filtration. Dead end filtration is when flow is applied perpendicular to the membrane surface. Particles smaller than the effective pore size pass through as filtrate, and particles that are larger build up as a cake layer on the membrane surface.

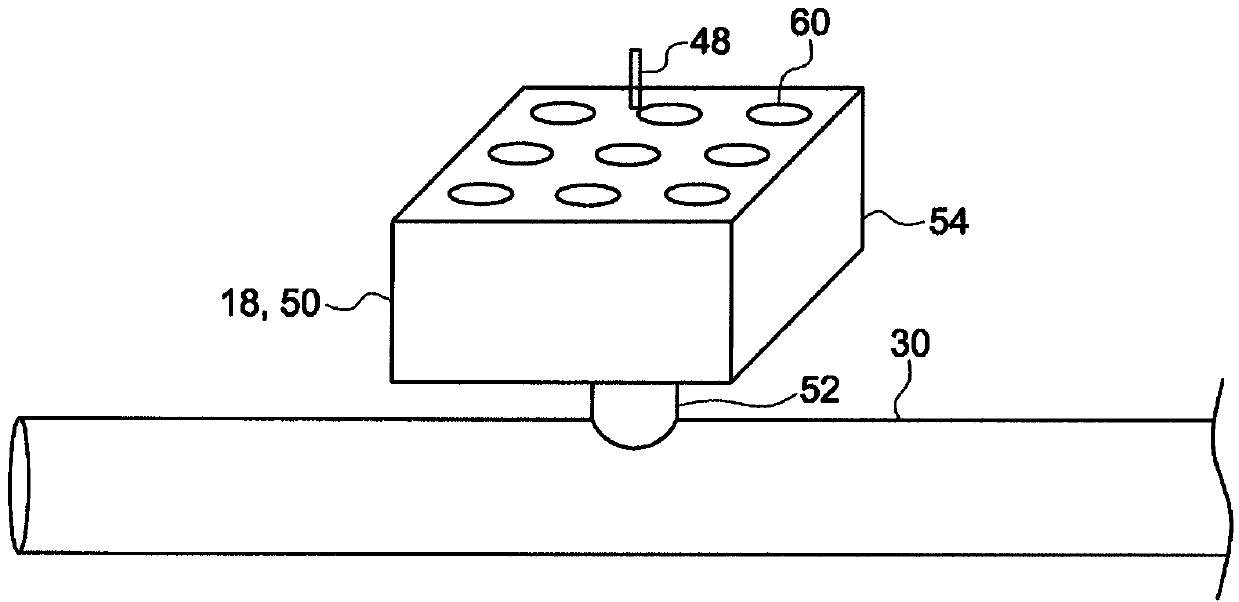

Electrochemical carbon nanotube filter and method

ActiveUS20120234694A1Minimize flow resistanceImprove stabilityMaterial nanotechnologyFrom normal temperature solutionsPorous carbonFiltration

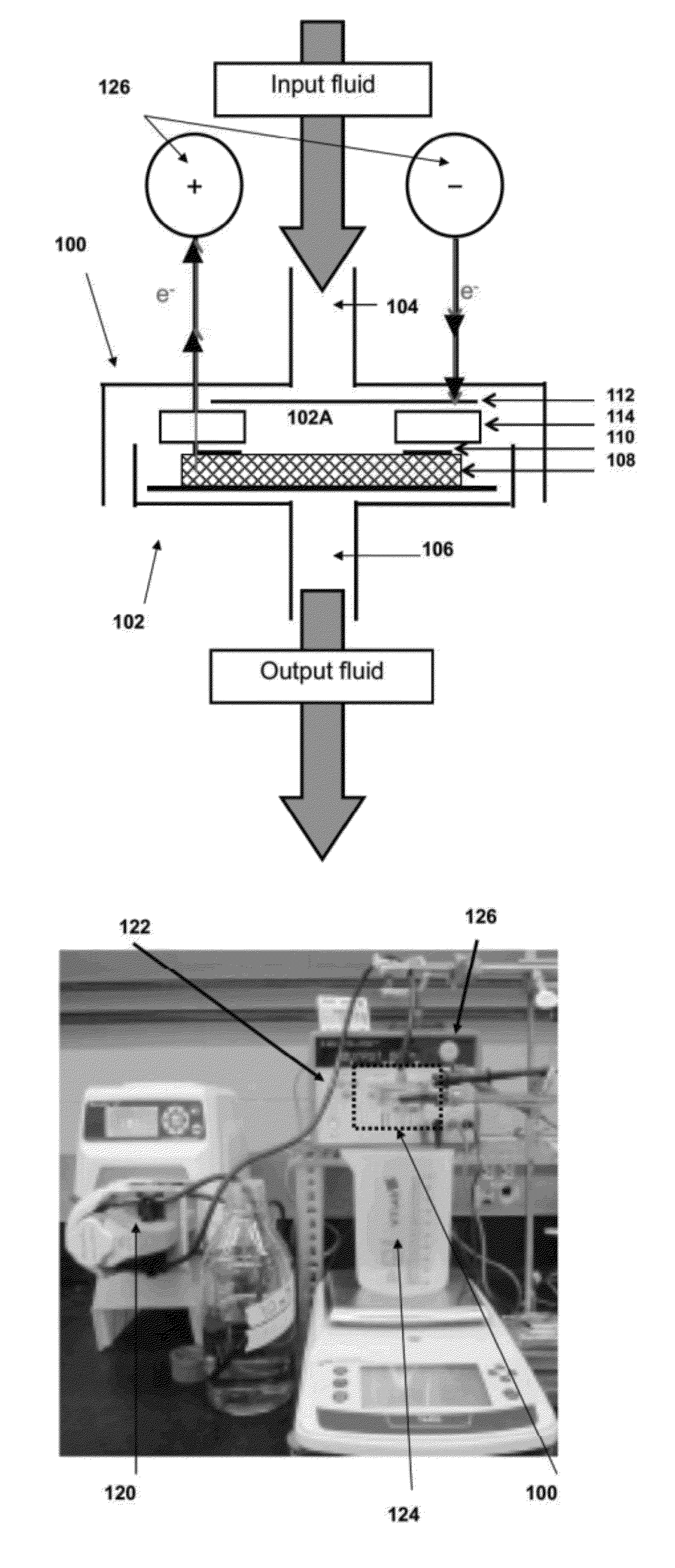

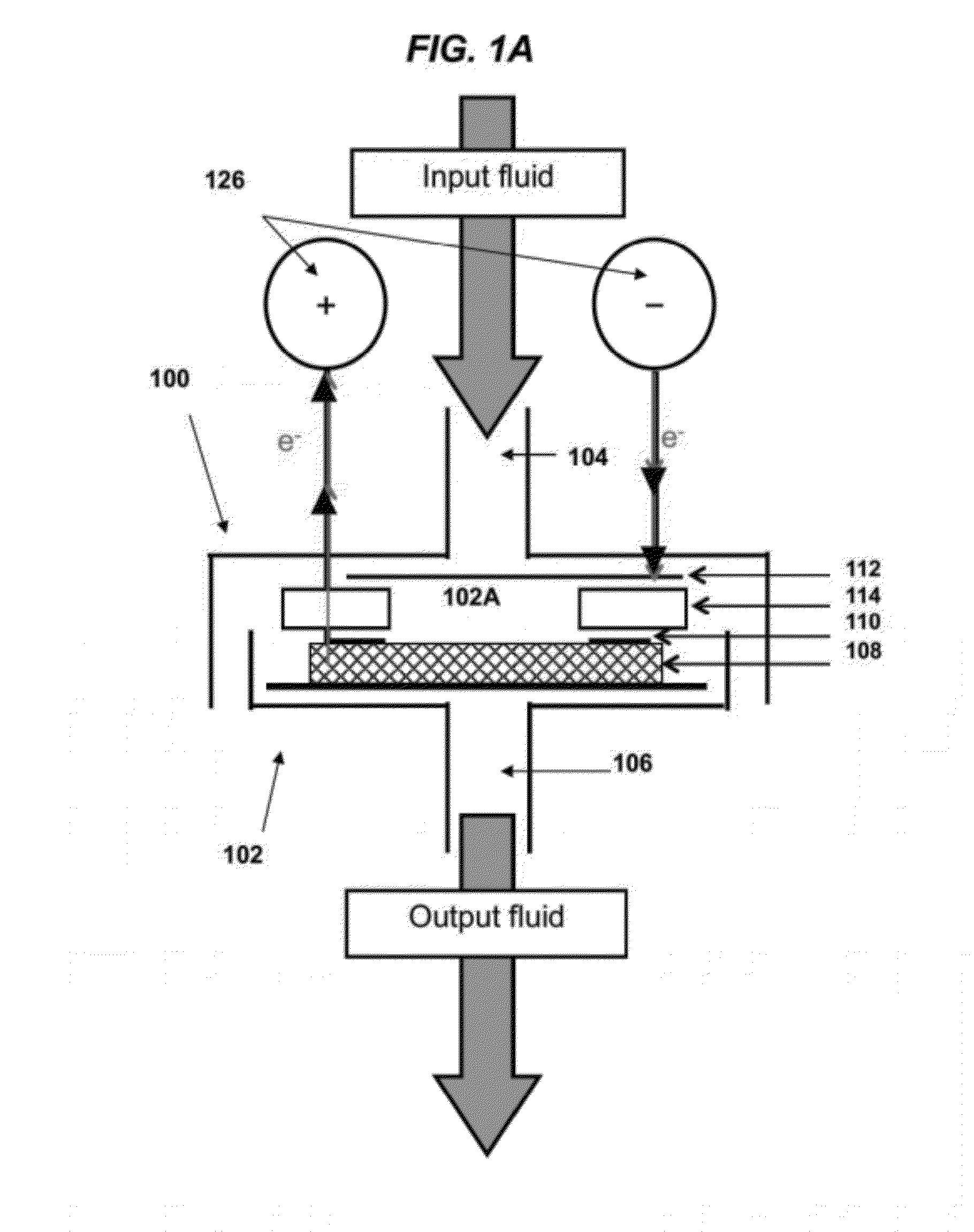

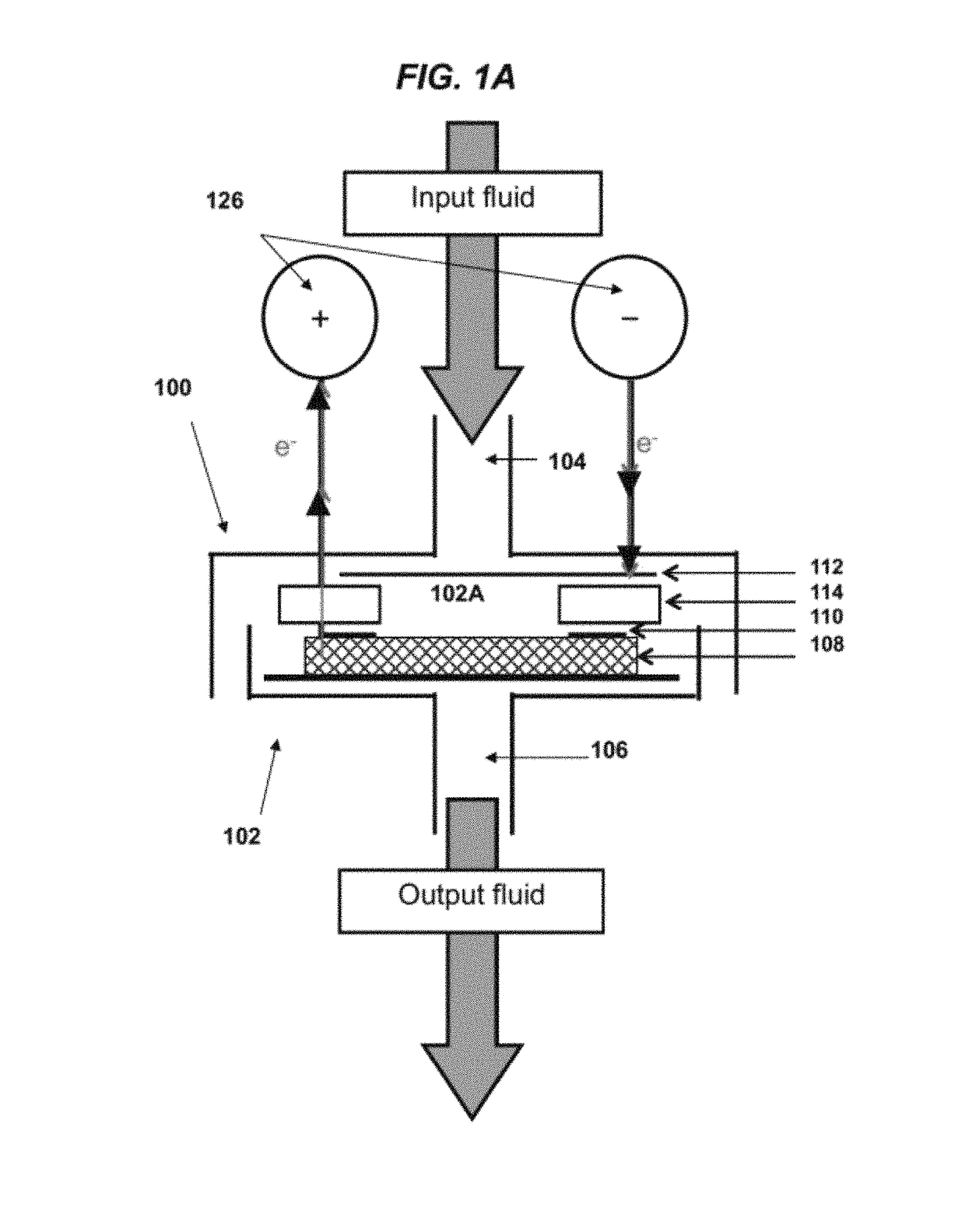

A filtration apparatus and filtration method can be used to reduce at least one contaminant (e.g., organic molecules, ions and / or biological microorganisms) in an aqueous fluid. The filtration apparatuses and methods of the invention can separate at least one contaminant from an aqueous fluid and / or oxidize at least one contaminant. In operation, an aqueous fluid is flowed through a filtration apparatus comprising a porous carbon nanotube filter material at an applied voltage. In some embodiments, the filtration apparatus described herein can be used for dead-end filtration. In some embodiments, the filtration apparatus described herein can be used for cross-over filtration.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Method for determining HDL concentration from whole blood or plasma

ActiveUS7087397B2Avoid flowEasy and fast assemblyAnalysis using chemical indicatorsMicrobiological testing/measurementReaction layerCholesterol

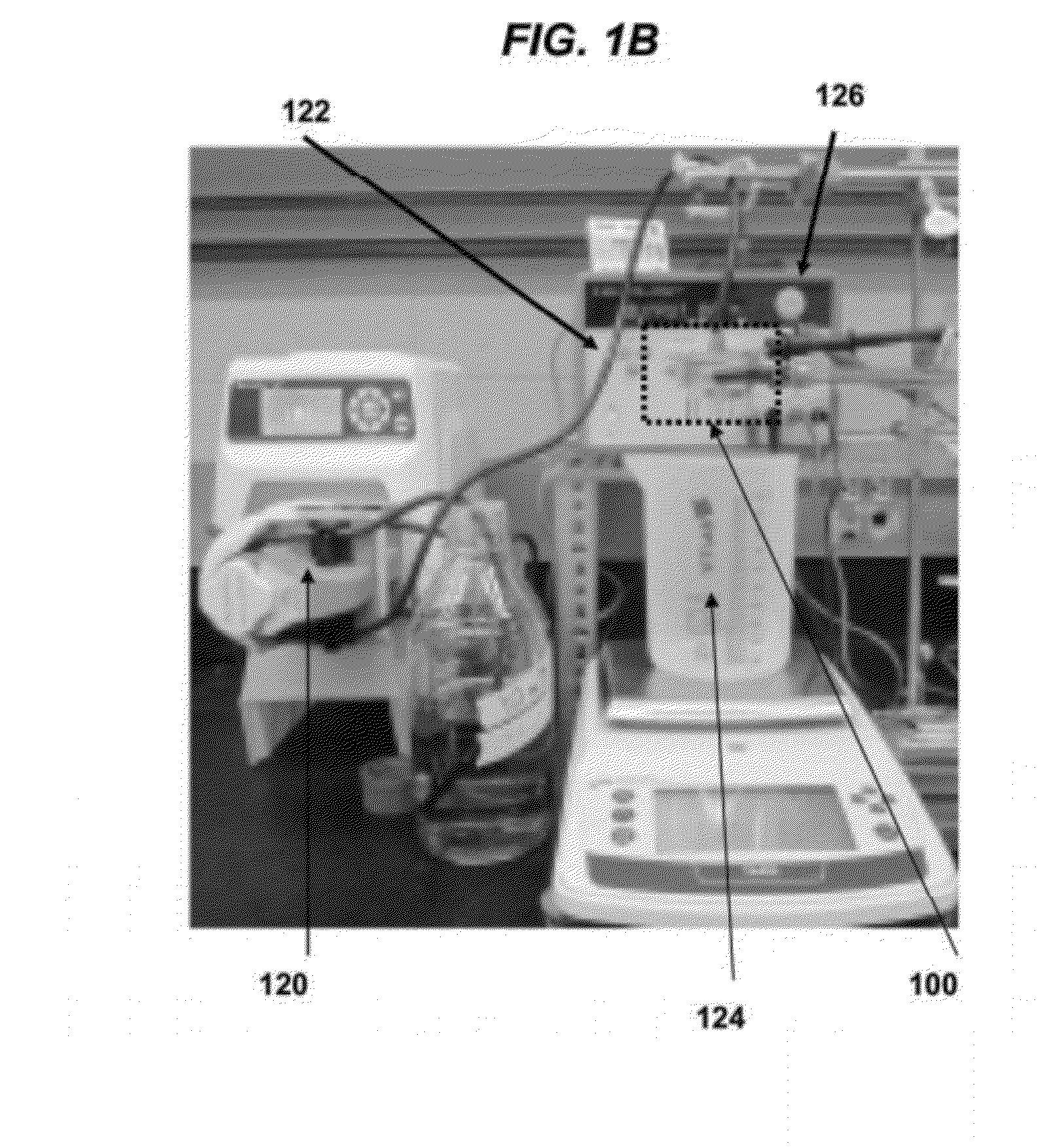

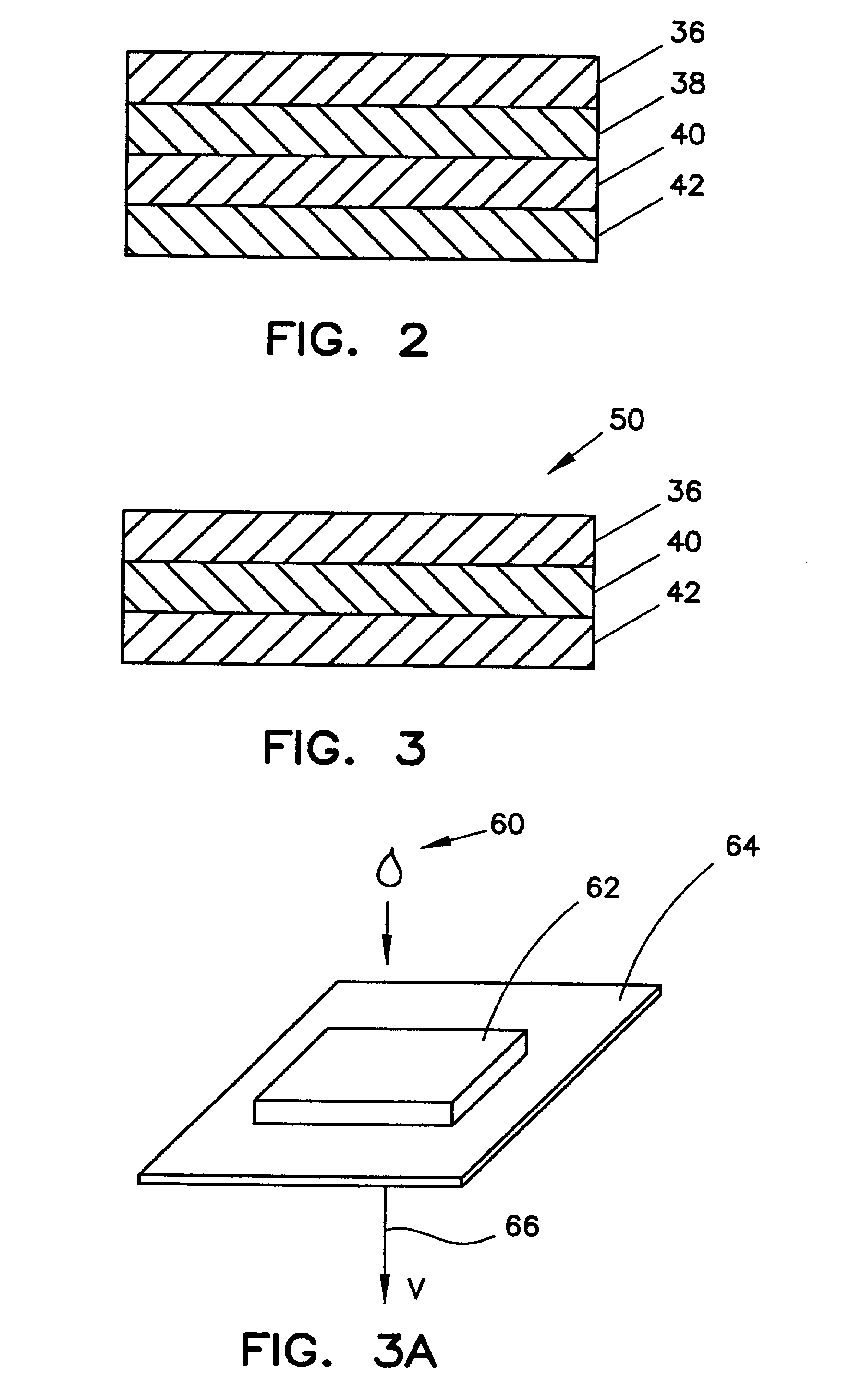

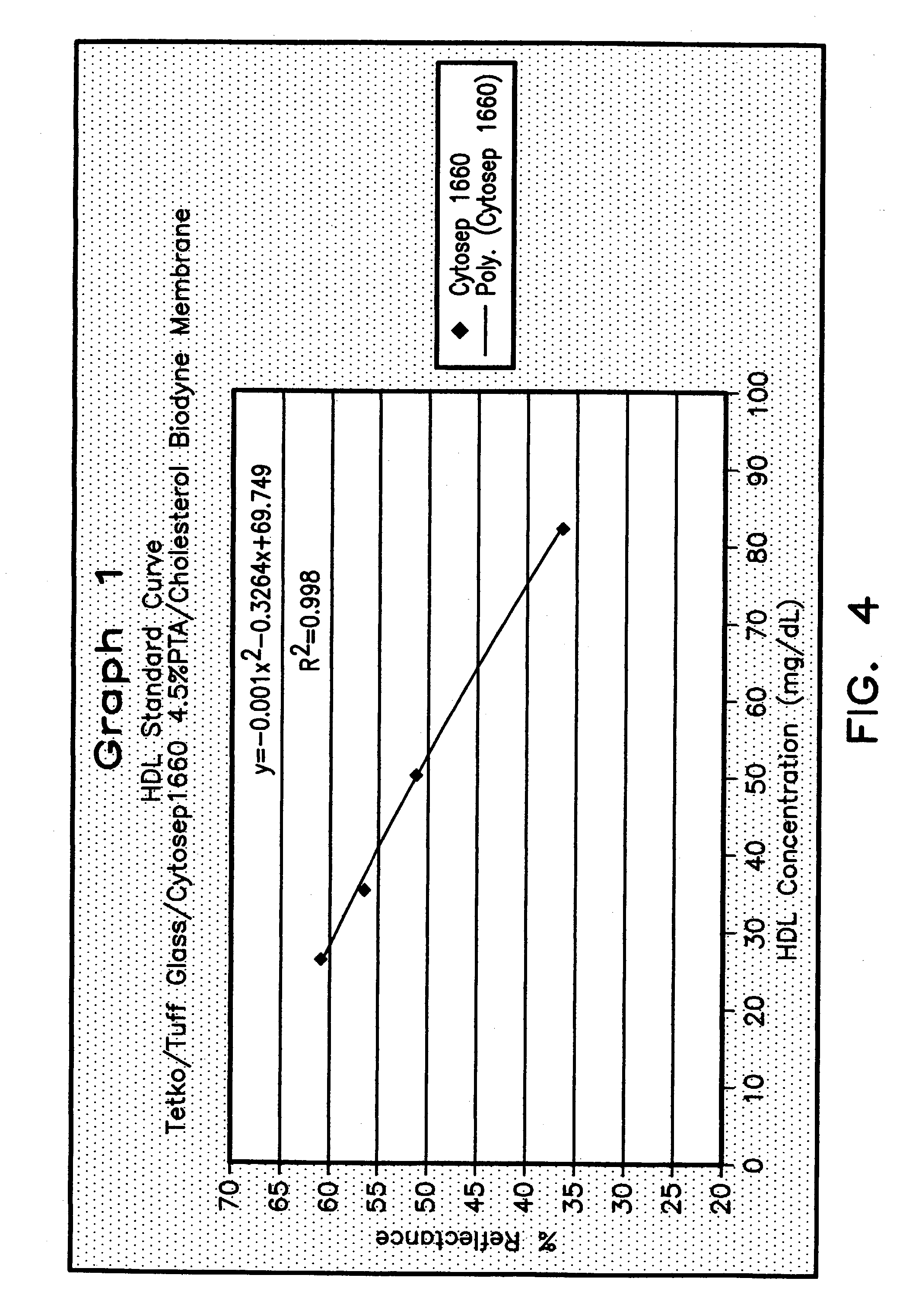

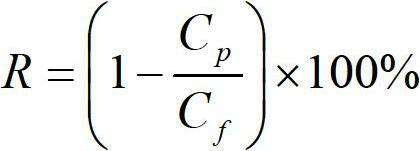

A multilayer test strip and method of using the test strip for determining concentration of HDL cholesterol in a whole blood sample. The inventive test strip includes a two-stage blood separation mechanism, including a first glass fiber matrix which separates most of the blood cells and an adjacent, second matrix preferably also containing glass fibers that separates the remainder of the blood cells. The second layer also precipates and retains non-HDL cholesterol, thereby providing plasma that is substantially free of red blood cells and substantially free of non-HDL cholesterol to a reaction layer. Precipitation and retention on non-HDLs takes place by a vertical or dead-end filtration in a single layer. The reaction layer produces a color, the intensity of which is proportional to the concentration of HDL cholesterol in the blood sample which is applied to the test strip. Advantageously, the inventive test strip is a vertical flow device, which can be made more compact and operates more efficiently than a lateral flow device.

Owner:POLYMER TECH SYST

Preparation method of polyelectrolyte self-assembled composite nonafiltration membrane based on coordination

InactiveCN102688701AImprove stabilityStrong swelling resistanceSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolyelectrolytePhysical chemistry

The invention relates to a preparation method of a polyelectrolyte self-assembled composite nonafiltration membrane based on coordination. The preparation method comprises the following steps of: respectively preparing a polyanion electrolyte solution containing transition metal ions and a polycation electrolyte solution easy to form a complex together with the transition metal ions; enabling the polyanion electrolyte solution or the polycation electrolyte solution to flow through the surface of a base membrane in a cross flow way at the pressure of 0-0.5MPa, and self-assembling on the surface of the base membrane to form a polyelectrolyte lamellar membrane; washing surplus polyelectrolyte solution on the surface of the membrane by water; enabling the polyion electrolyte solution with charges opposite to the charges of the upper-layer polyion electrolyte solution to flow through the surface of the base membrane in a cross flow way, and enabling polycation electrolyte and polyanion electrolyte to undergo self-assembled reaction on the surface of the membrane through the coordination of the metal ions to form a polyelectrolyte composite membrane; washing surplus polyelectrolyte solution on the surface of the membrane by using water; and repeating the operations to enable polyelectrolyte with opposite charges to be alternatively deposited and assembled on the surface of the base membrane to obtain the polyelectrolyte self-assembled composite nonafiltration membrane. A cross flow flowing way is adopted in the method, and thus, the phenomenon that gel is easy to form in a dead-end filtration way is avoided, and a product is high in stability, strong in impact resistance and swelling resistance, simple in process, low in preparation cost and friendly to production environment...

Owner:OCEAN UNIV OF CHINA

Method for removing smelly substances in water

InactiveCN103121732APollution controlReduce concentrationWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisNano catalystHollow fibre

The invention discloses a method for removing smelly substances in water, which comprises the following steps: 1. preparing an inorganic nano catalyst, an organic high-polymer basal film material, additives, a solvent and the like into a film casting solution at certain temperature, and preparing a flat or hollow-fiber or tubular inorganic-organic hybrid photocatalytic separation film; and 2. putting the inorganic-organic hybrid photocatalytic separation film on a film filter unit, and filtering smelly-substance-containing water to be treated in a dead end filtering or cross-flow filtering mode under the conditions of a proper light source. The photocatalytic unit and the film separation unit which are mutually independent are organically fused into one unit for operation, and thus, the invention can simultaneously have the advantages of both photocatalysis and film separation. The method disclosed by the invention has the advantages of simple technique, no need of reagents, high operation reliability, compact equipment and easy automatic control; and the method can effectively remove smelly substances in water, reduce the film pollution, prolong the service life of the film, and lower the technological cost.

Owner:SHANGHAI JIAO TONG UNIV

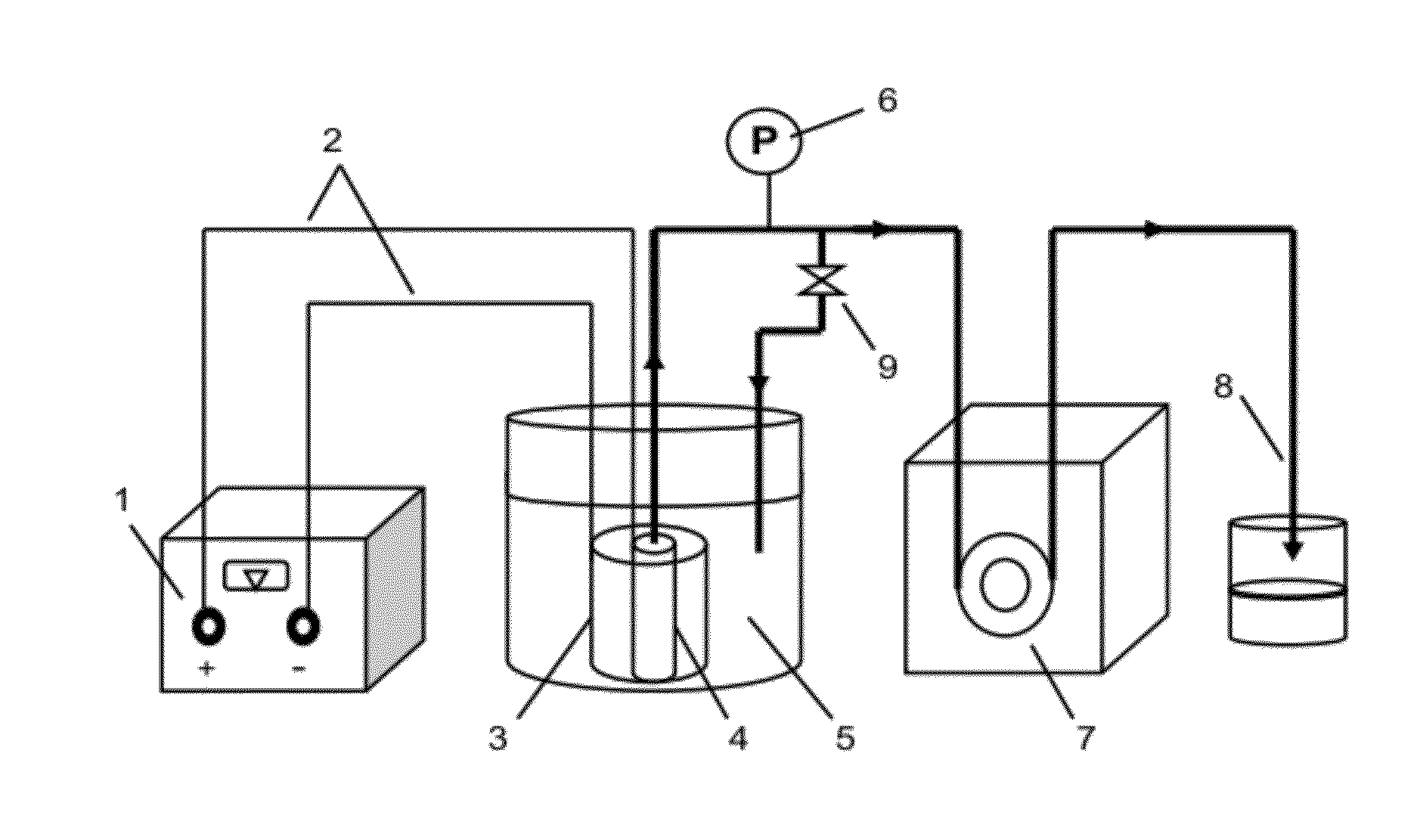

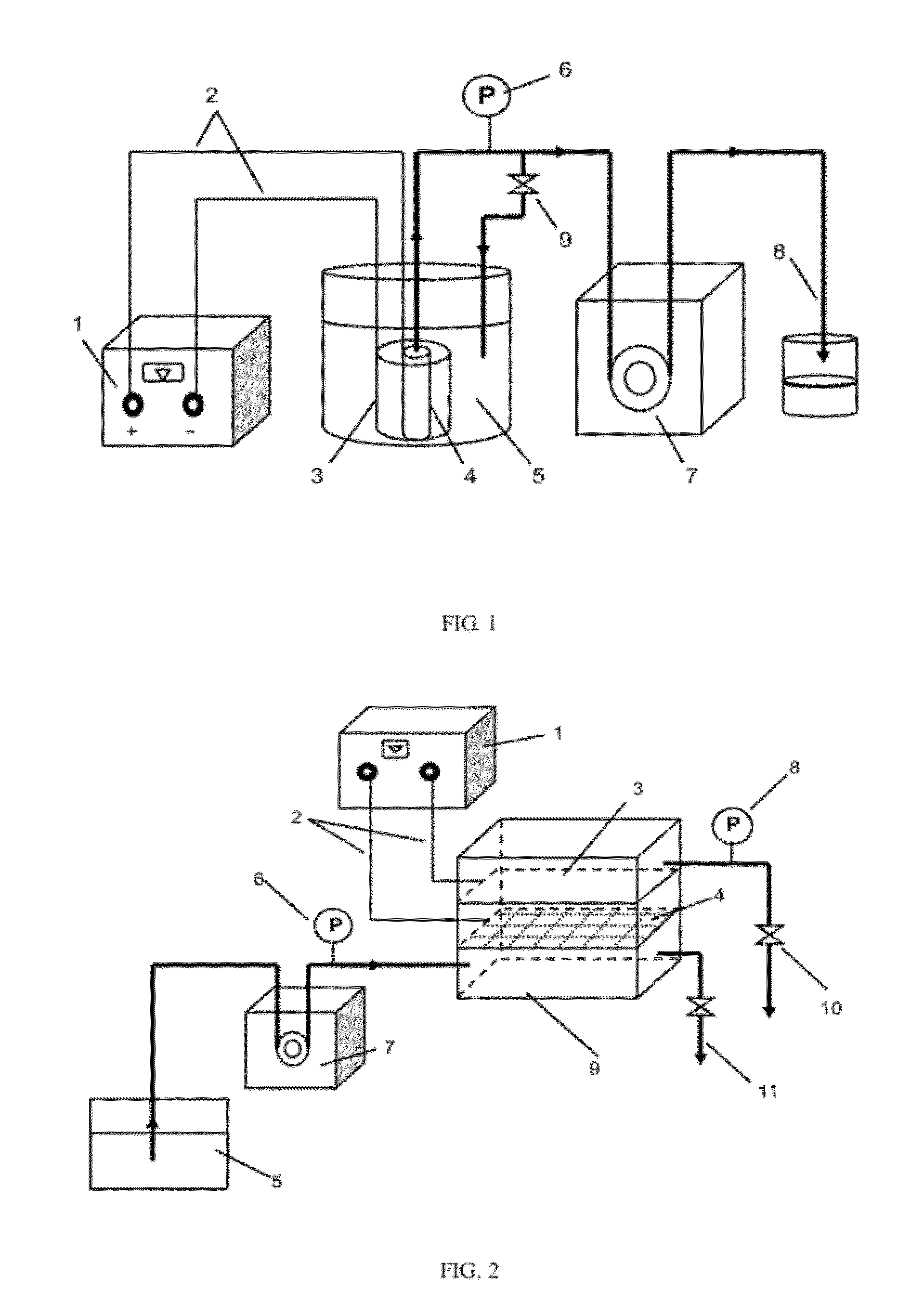

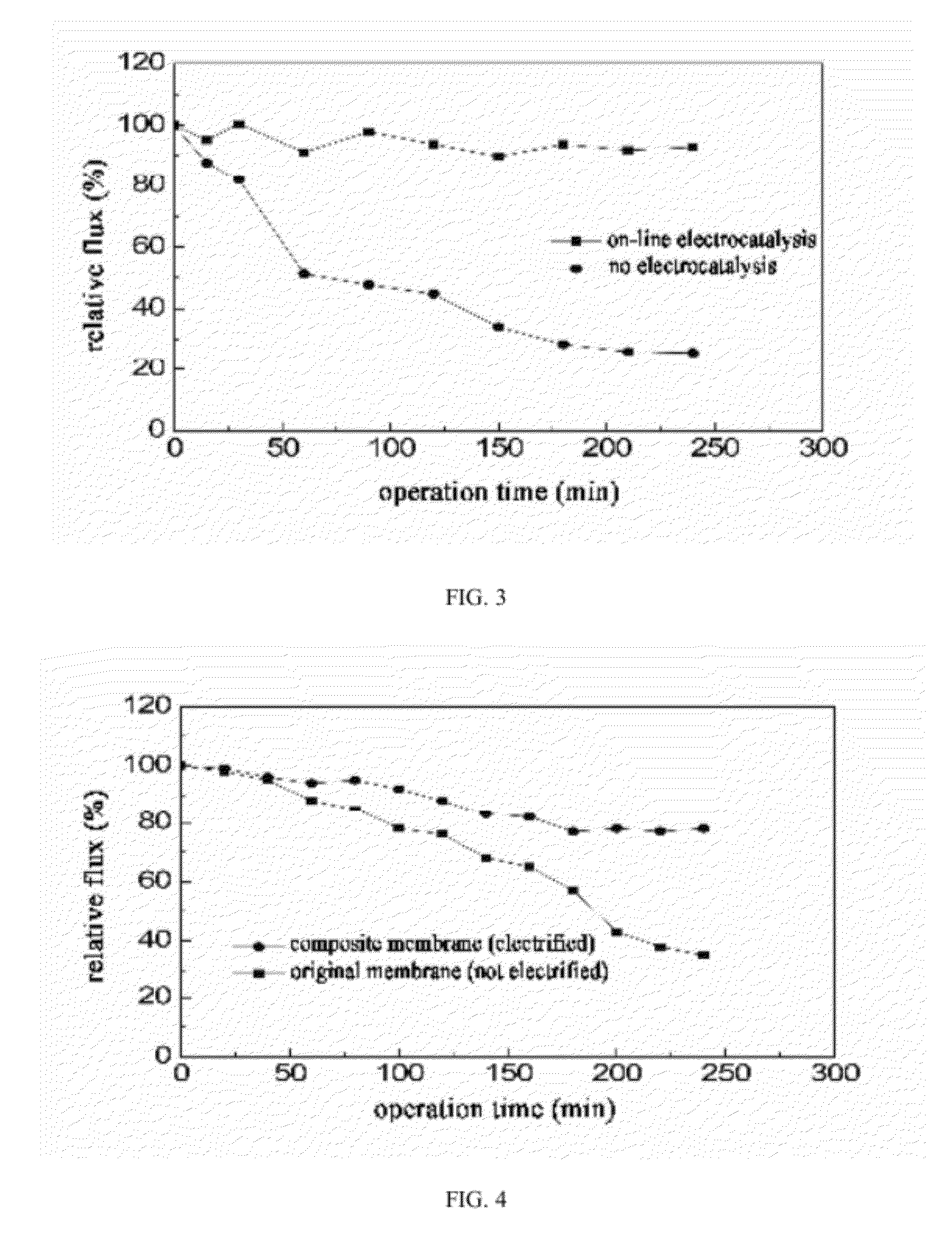

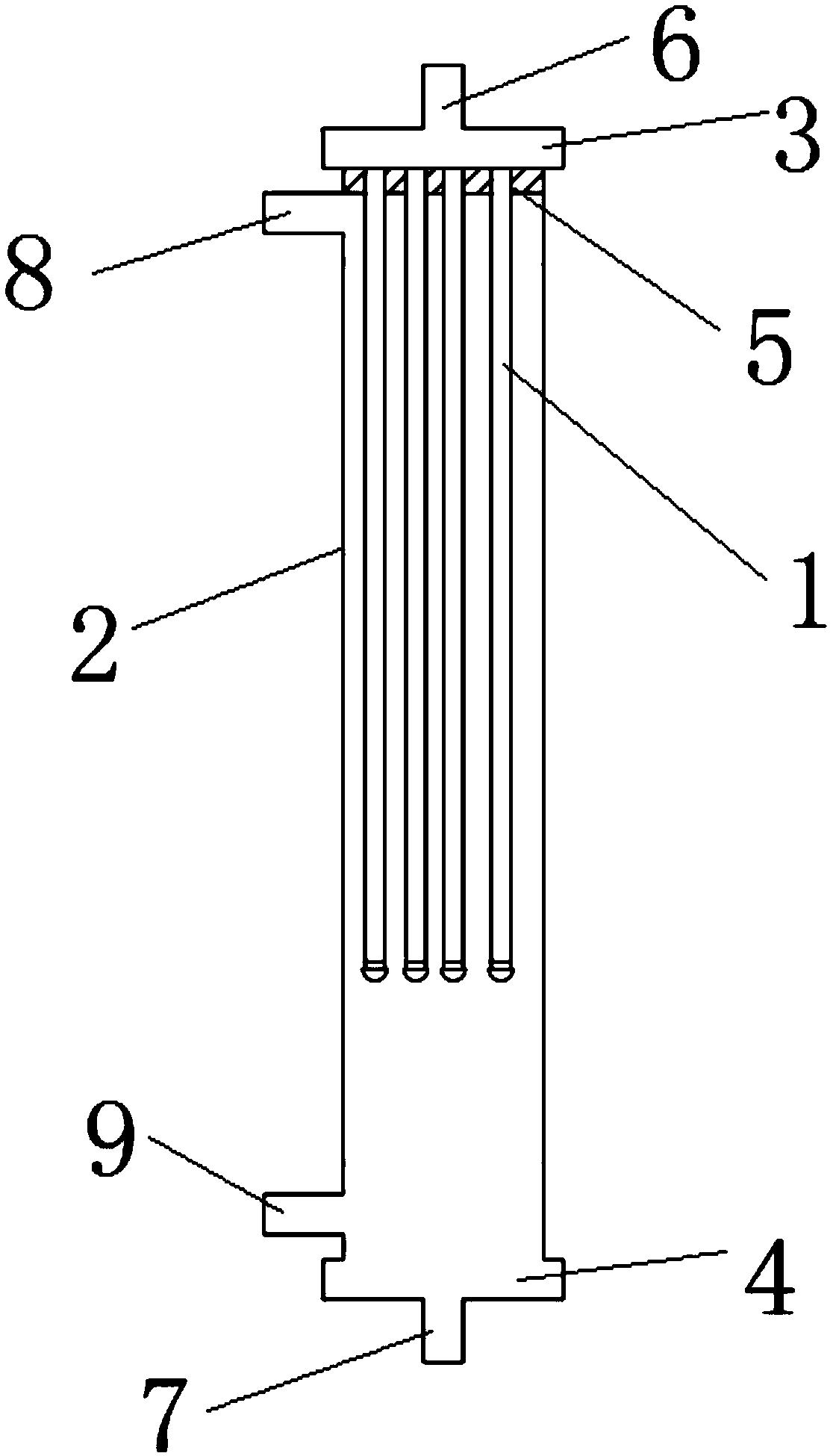

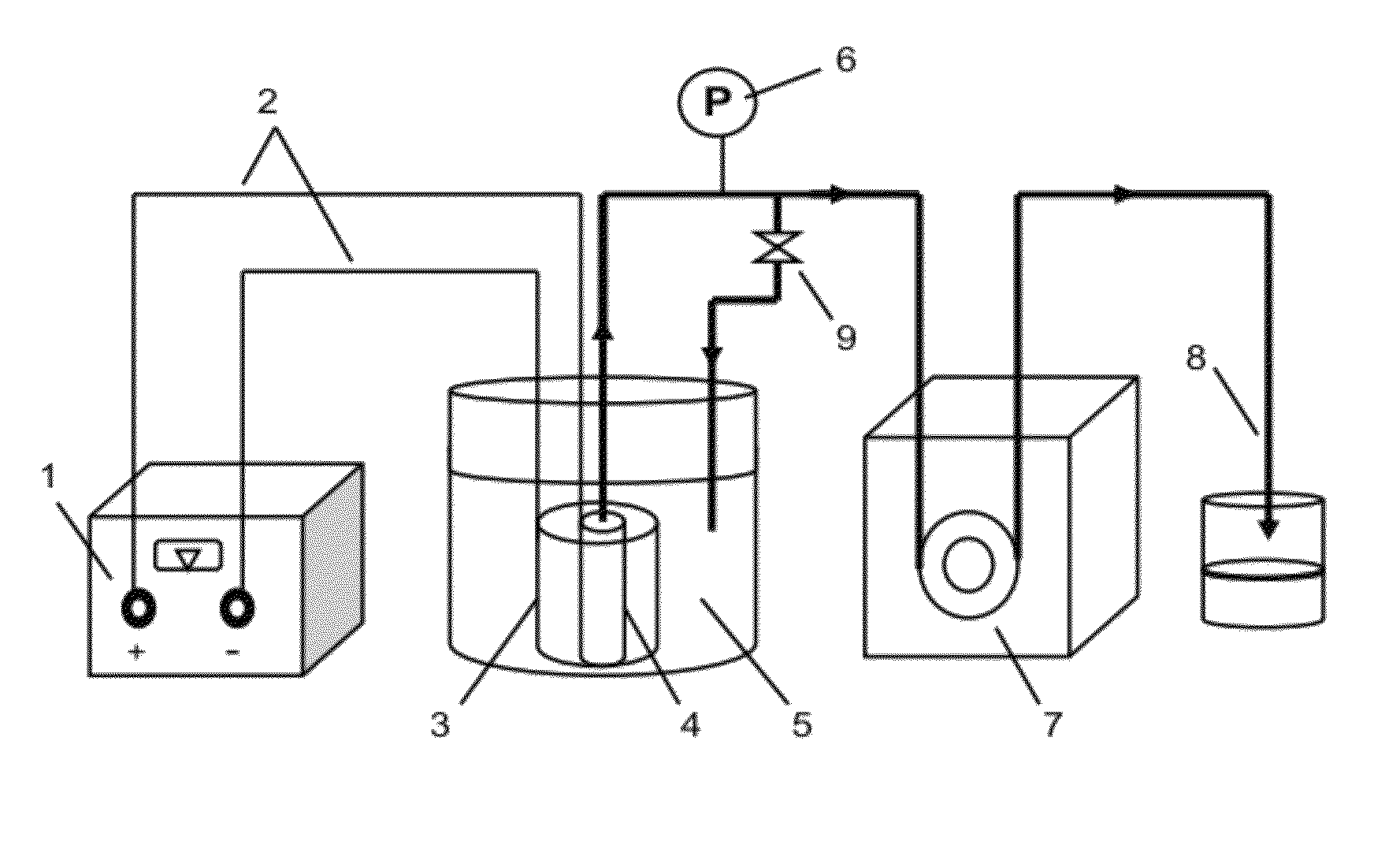

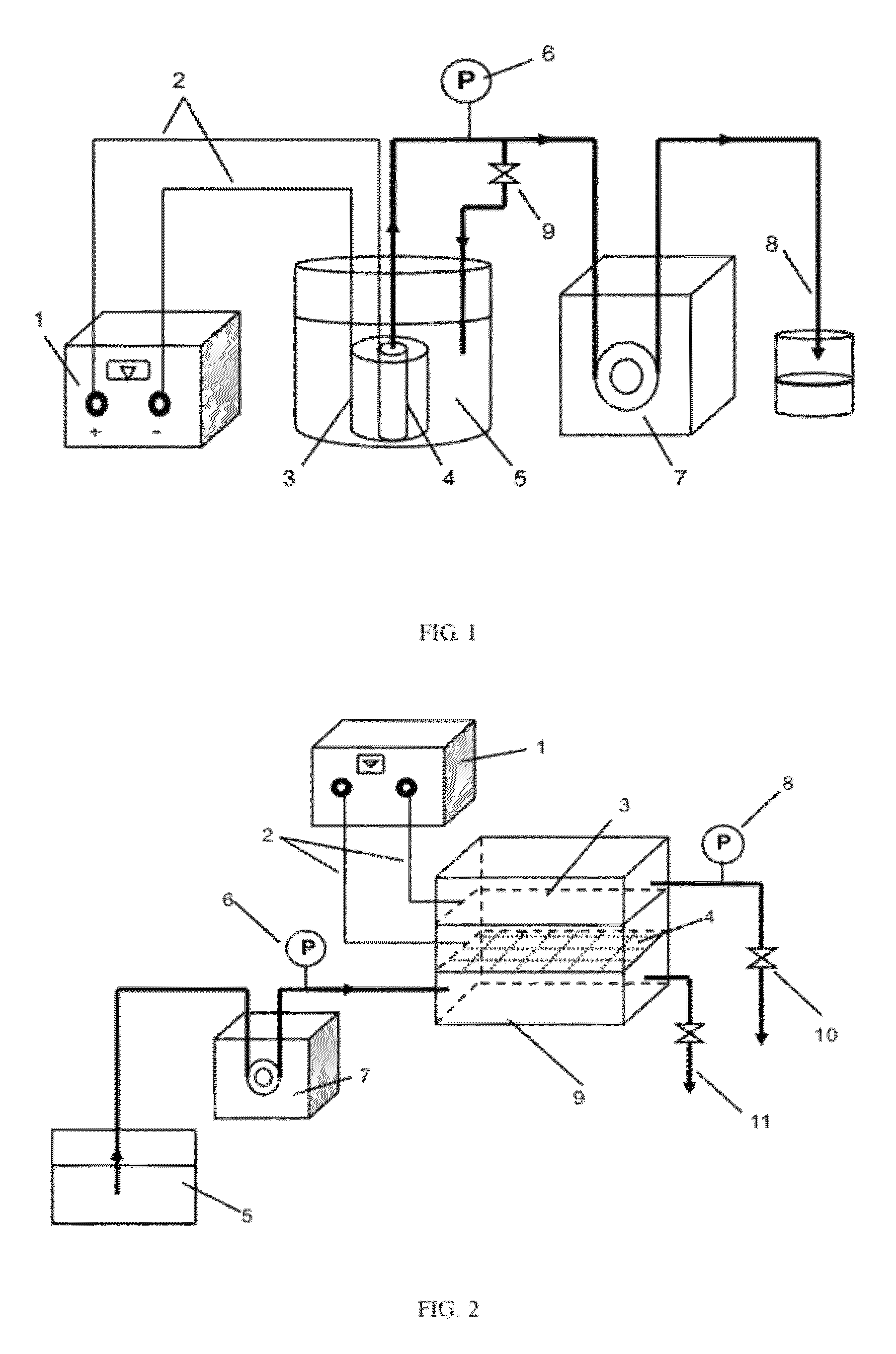

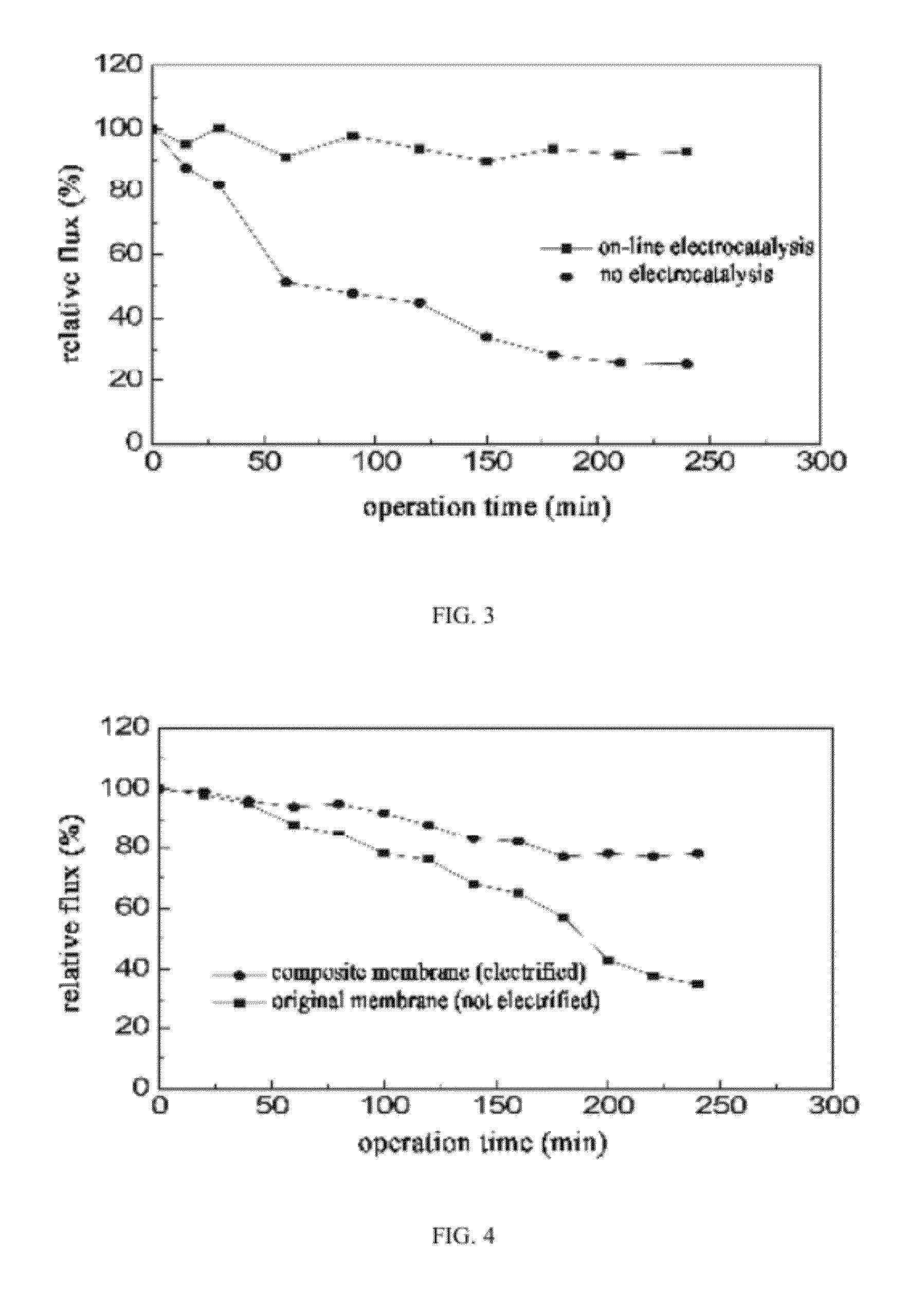

Anti-pollution electrocatalysis composite membrane and membrane reactor

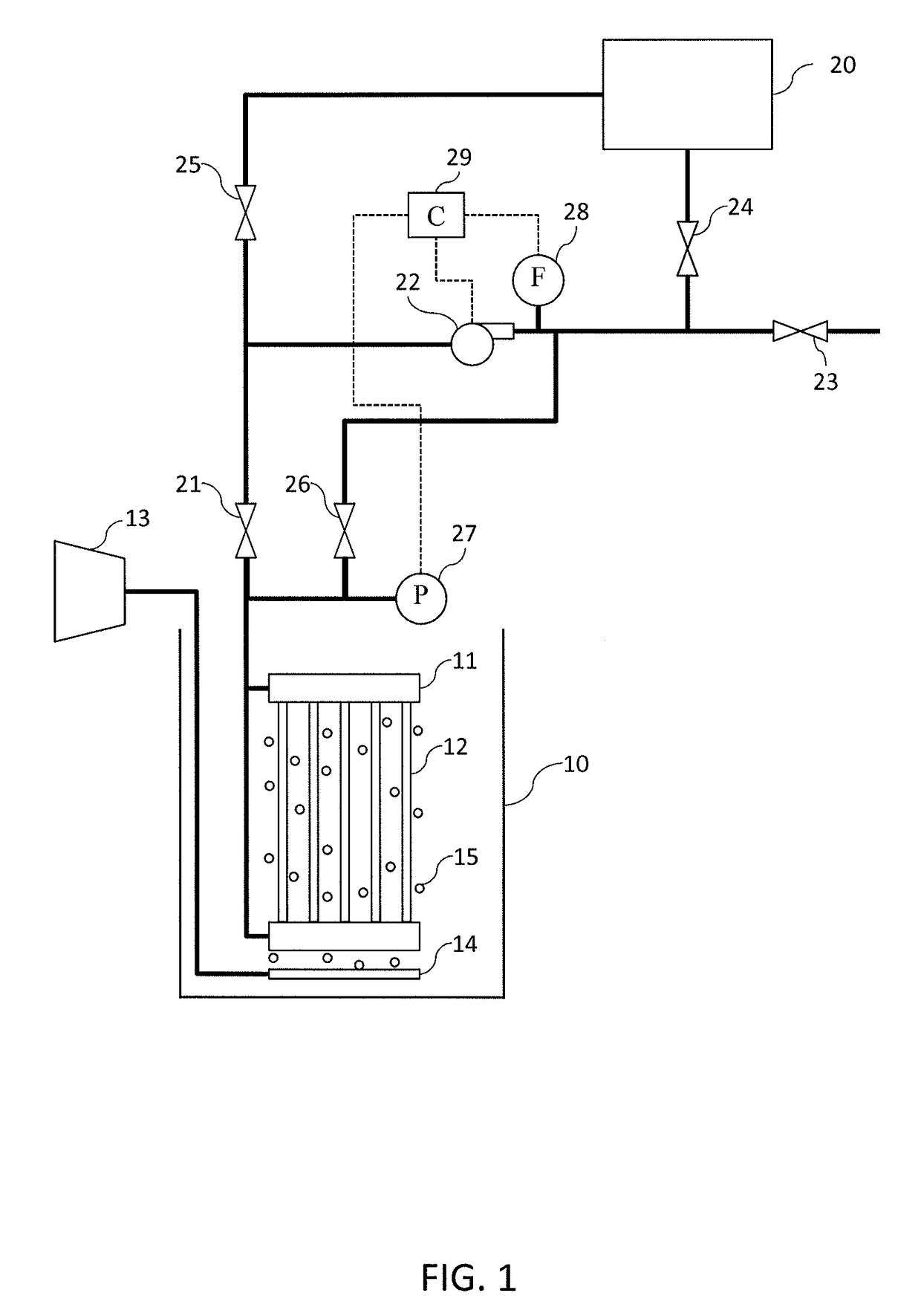

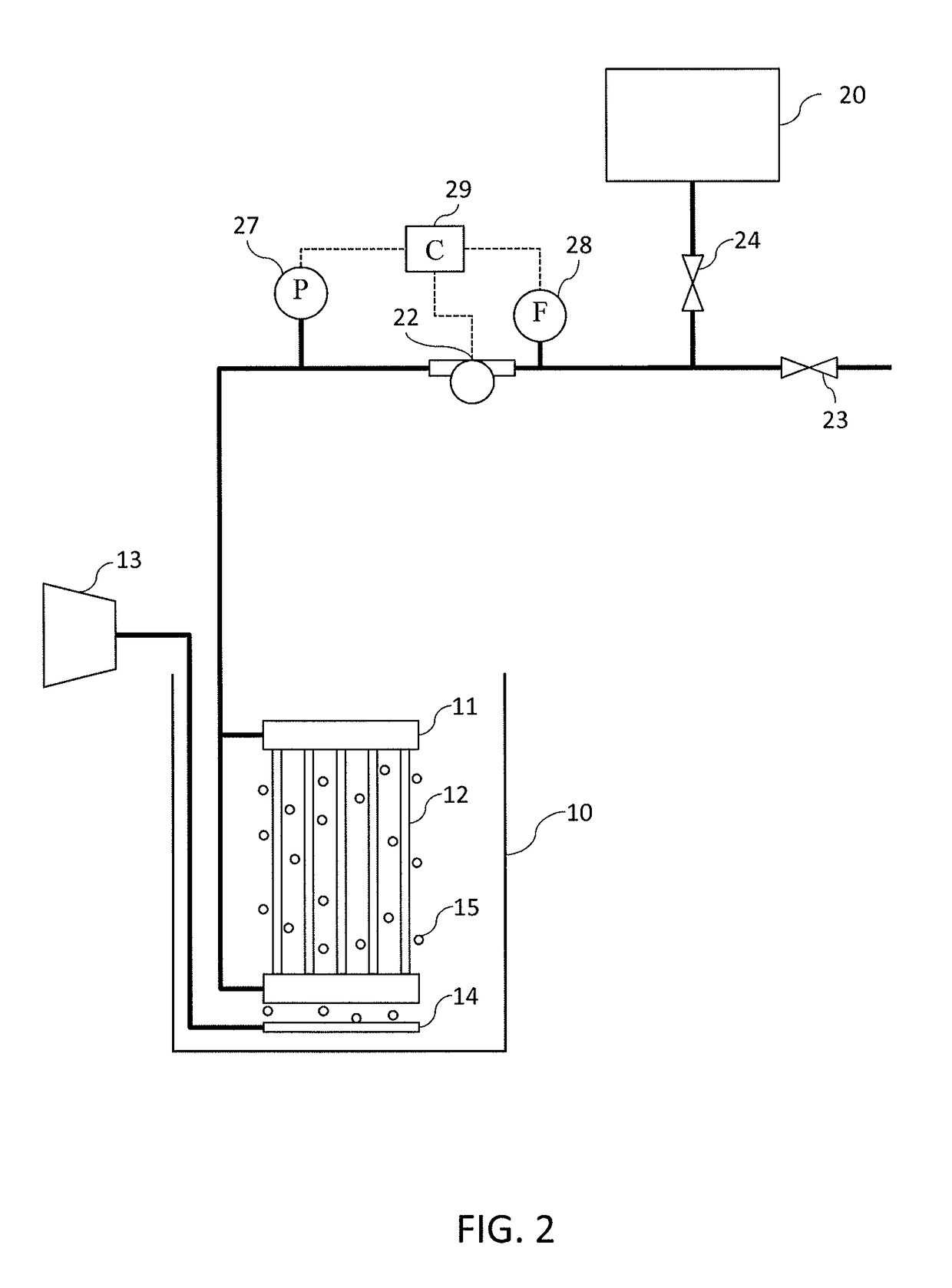

ActiveUS20120090988A1Improve antifouling performanceImprove electrocatalytic activityCellsSemi-permeable membranesElectrolysisConductive coating

The present invention relates an antifouling electrocatalytic composite membrane and a membrane reactor. The electrocatalytic composite membrane (3) consists of a substrate and a catalytic coating, wherein the substrate is selected from a conductive substrate or a nonconductive substrate coated with a conductive coating, and the substrate is a porous support having supporting, conducting and separating functions. The catalytic coating is supported or coated on the surface and in the pores of the conductive substrate or the conductive coating so as to increase the electrocatalytic activity of the substrate. The membrane reactor provides a trans-membrane pressure as the membrane separation power generated by a pump (7) and dead-end filtration or cross-flow filtration is applied, then the feed liquid permeates through the membrane from one side to the other to achieve the separation of the liquid; meanwhile, an electrocatalytic composite membrane (3) as anode and an auxiliary electrode (4) as cathode are connected to a power supply (1) separately by conducting wires (2) so that an electrolysis apparatus is formed. The electrocatalytic composite membrane (3) has a self-cleaning function and achieves the pollution-free operation during the membrane separation.

Owner:TIANJIN POLYTECHNIC UNIV

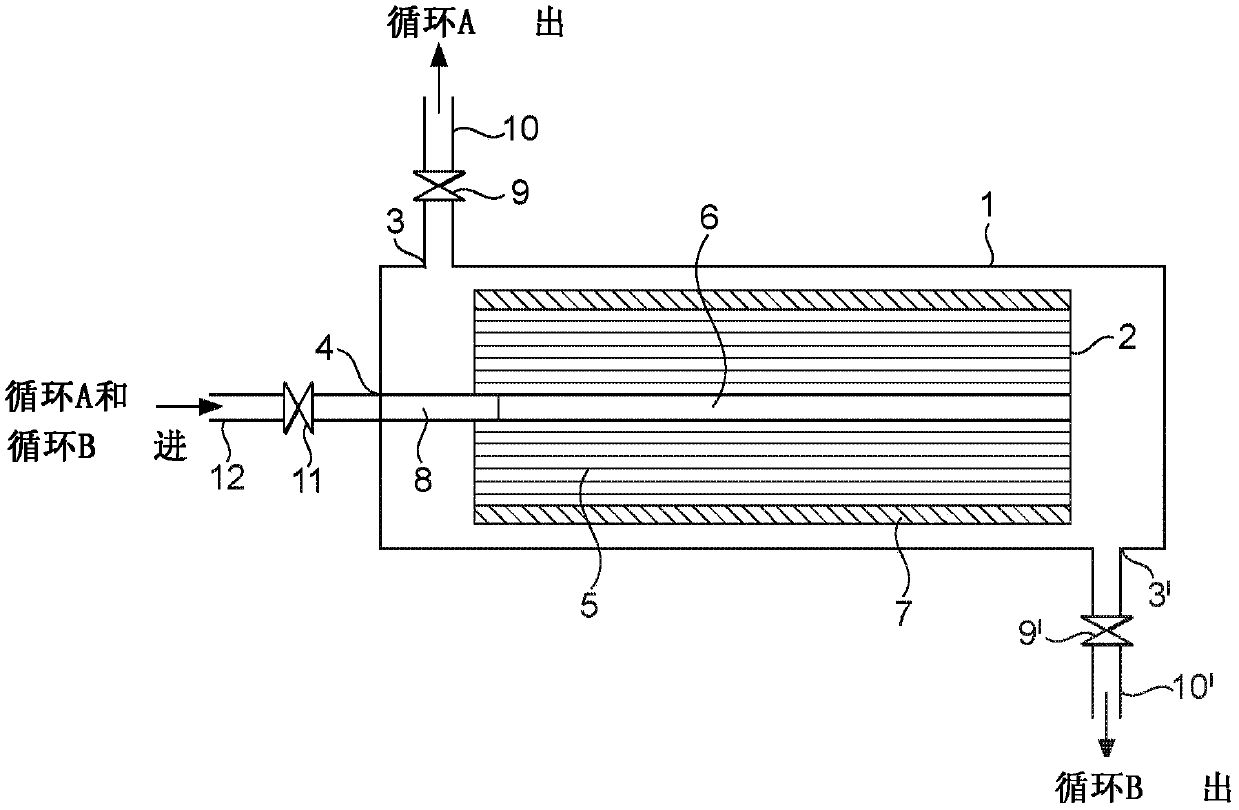

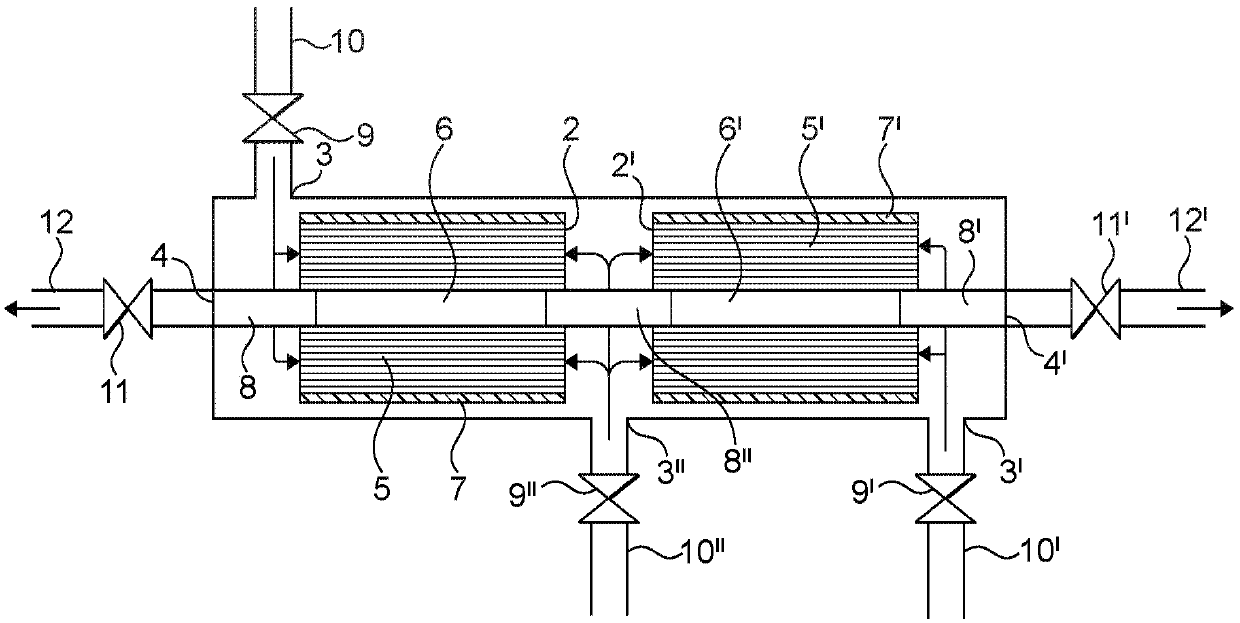

In-line filtration systems

InactiveUS20090057210A1Inhibition formationIncrease effective operation timeMembranesSpecific water treatment objectivesCounter flowIndustrial systems

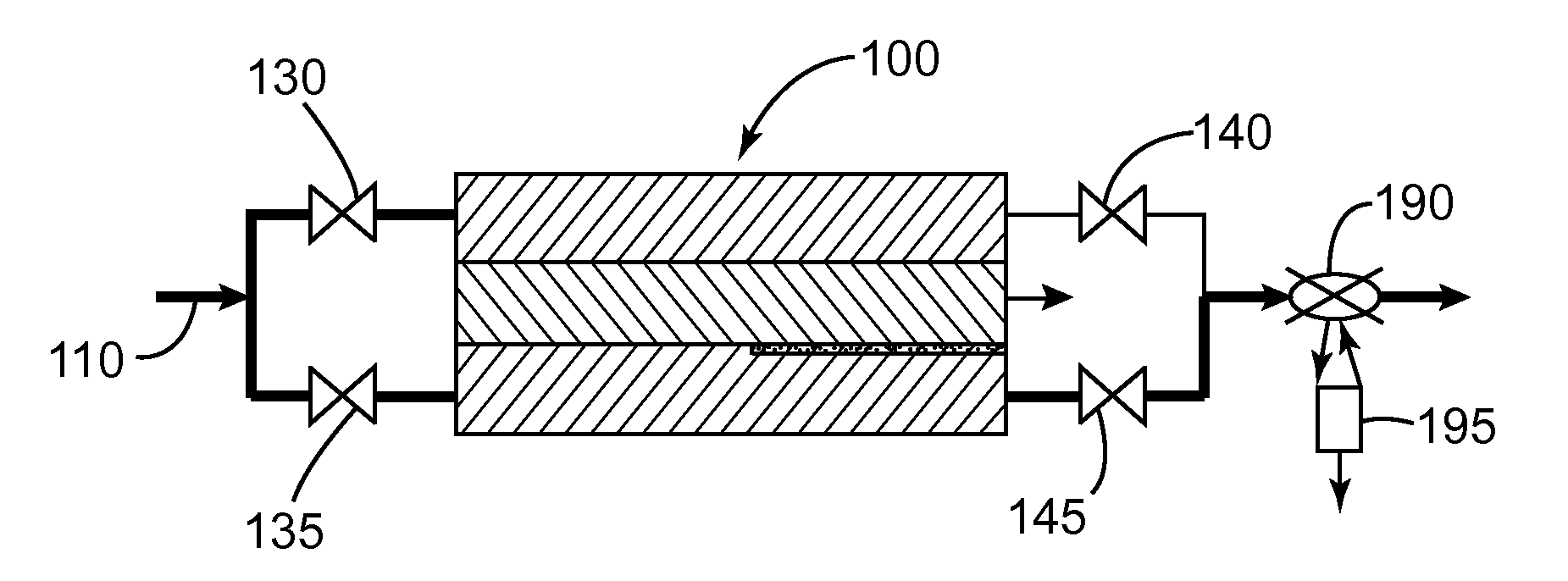

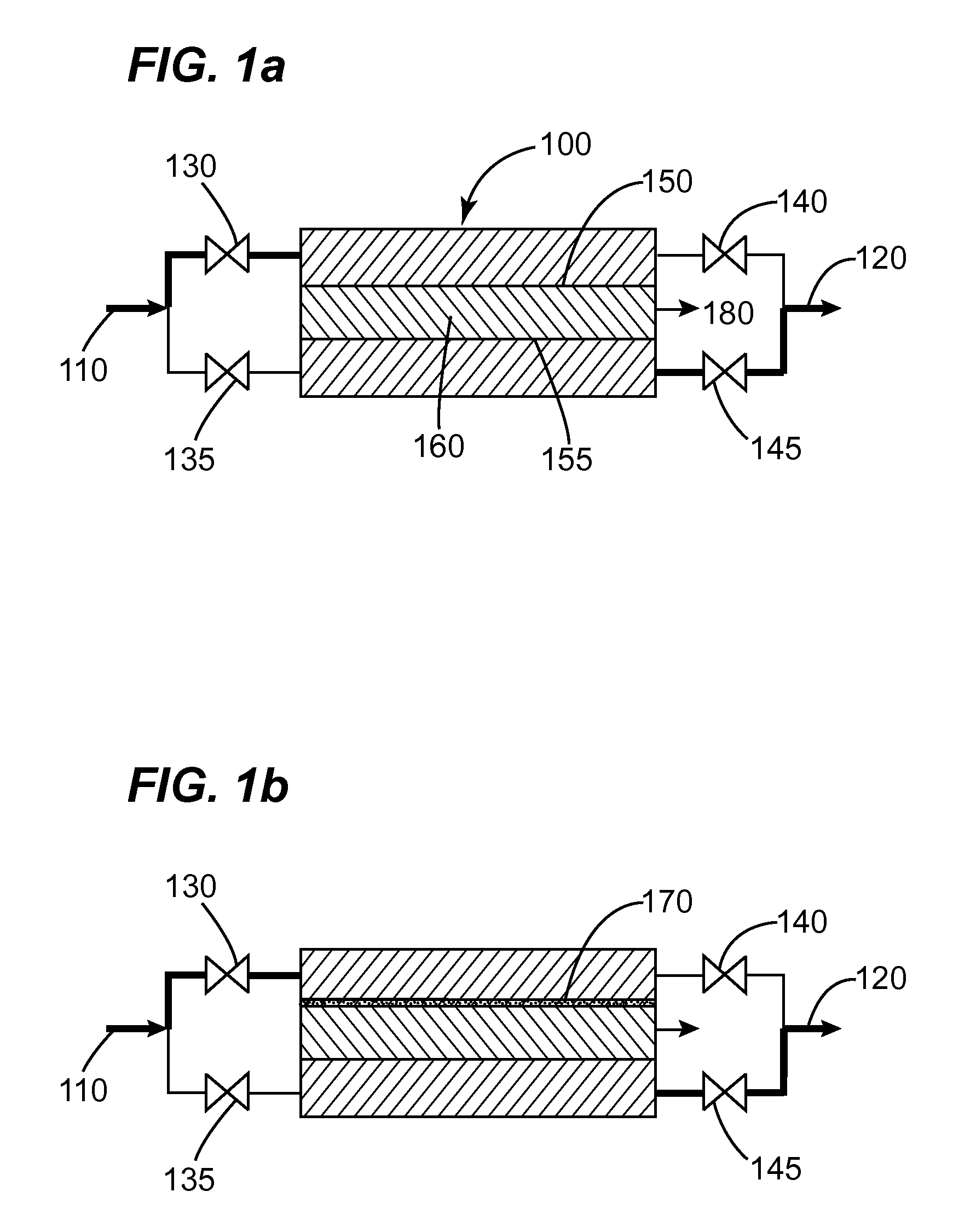

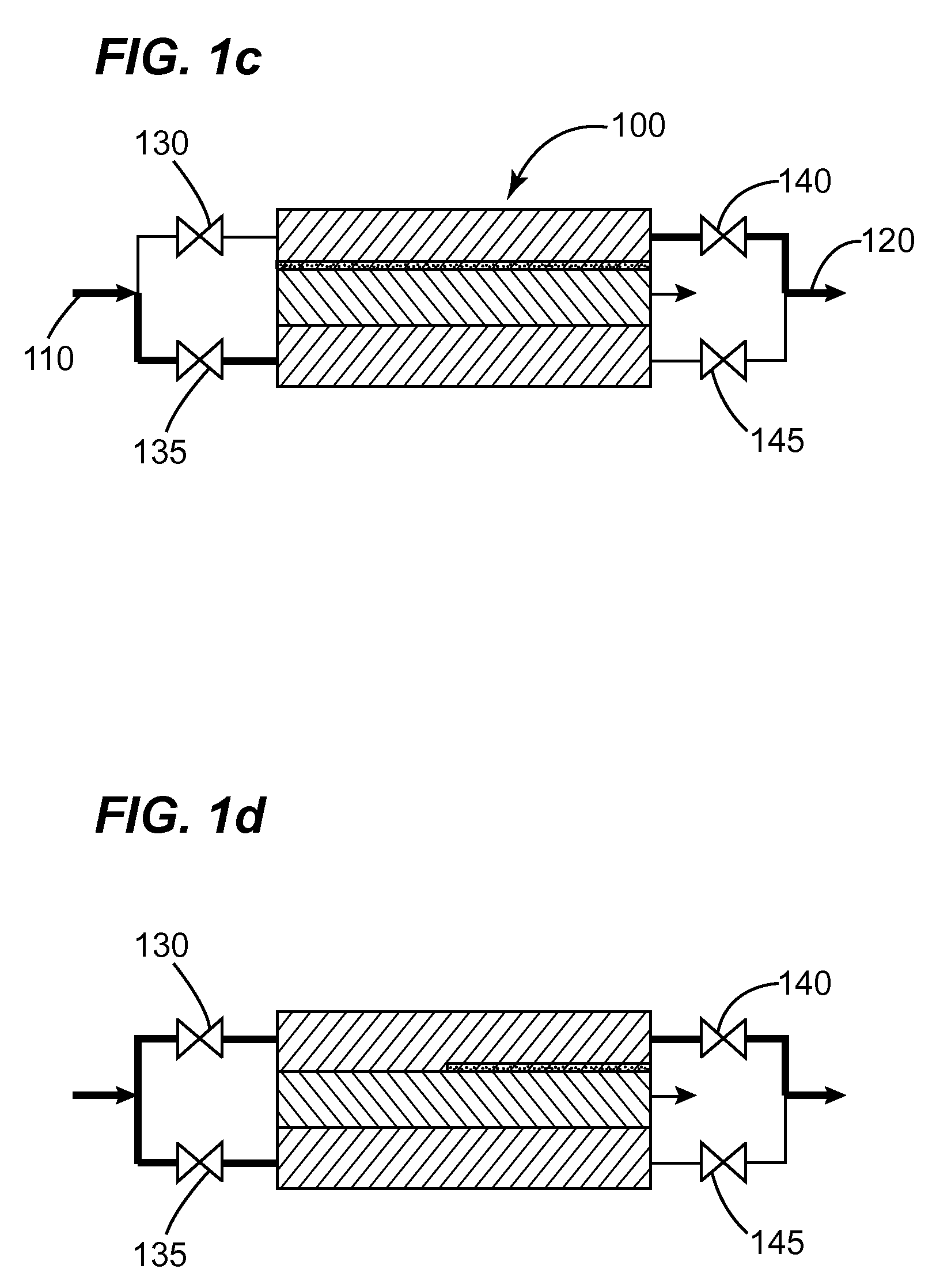

A filtration system is disclosed that uses a combination of dead end filtration across opposing membranes with a sample take-off in the middle and cross-flow to prevent cake formation on these opposing filters. In one embodiment is a system that uses opposing filters with a central collection chamber that flips flow back and forth between the sides at a frequency that minimizes filter cake formation. In another embodiment, a combination flip-flip, cross flow system is disclosed. An additional embodiment discloses an actuator valve driven sampling system, in which valves collect the cross flow / counter flow filter cake samples as they are liberated from a filter surface and a quick through filter fluid pulse loosens the sample cake from the filter material. The invention increases effective operation time, allows for continuous filtration operation without interruption, and provides filtered samples that accurately represent the concentration of macromolecular species in industrial systems.

Owner:GENERAL ELECTRIC CO

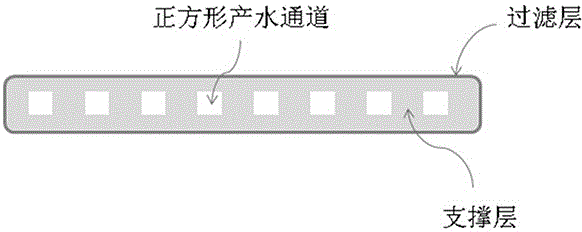

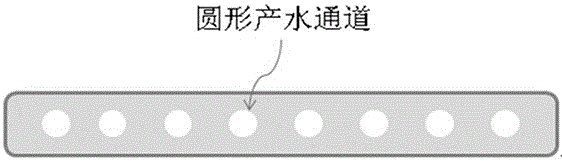

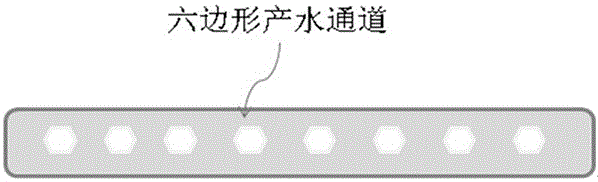

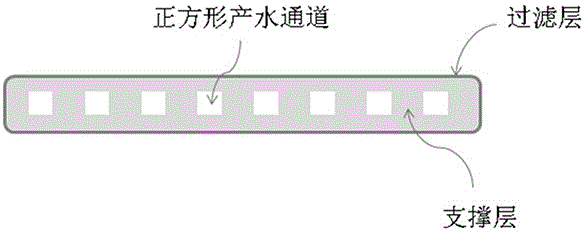

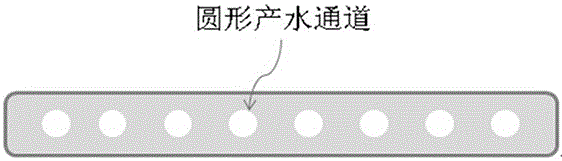

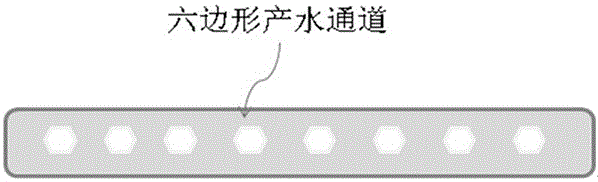

Production method of nucleus micropore filtering film of optimizing flow passage

ActiveCN101249386AImprove retention efficiencySpeed up filteringSemi-permeable membranesPorosityMicropore Filter

The invention discloses a manufacturing method of a nucleopore filtration film to optimize flow passages in the technology field of liquid filtration. The manufacturing method is that a heavy ion accelerator or a reactor is used to radiate an insulation film and radiation damage is formed inside the insulation material; a solvent type release layer is coated on the insulation film; an alkalifast adhesive film is compounded on the surface of the release layer at low temperature to form a composite film; subsequently, under the optimized etching condition, the composite film is etched on one side under the protection of the adhesive film, thus forming non-biconical micropores; the release layer is stripped off at ordinary temperature; the microporous film is washed in de-ionized water before the composite film is dried. The microporous film made by using the method can have the thickness more than 10 micrometers, the opening rate on the upper surface of the film less than 1 percent and the porosity on the lower surface more than 10 percent. When the microporous film is used for liquid filtration, the flow resistance is small, the flow is large, granules are unlikely to be absorbed and cause dead end filtration. The method provided by the invention is applicable for producing films in batch; the process is well-developed; product quality is controlled easily and the cost is low.

Owner:TSINGHUA UNIV

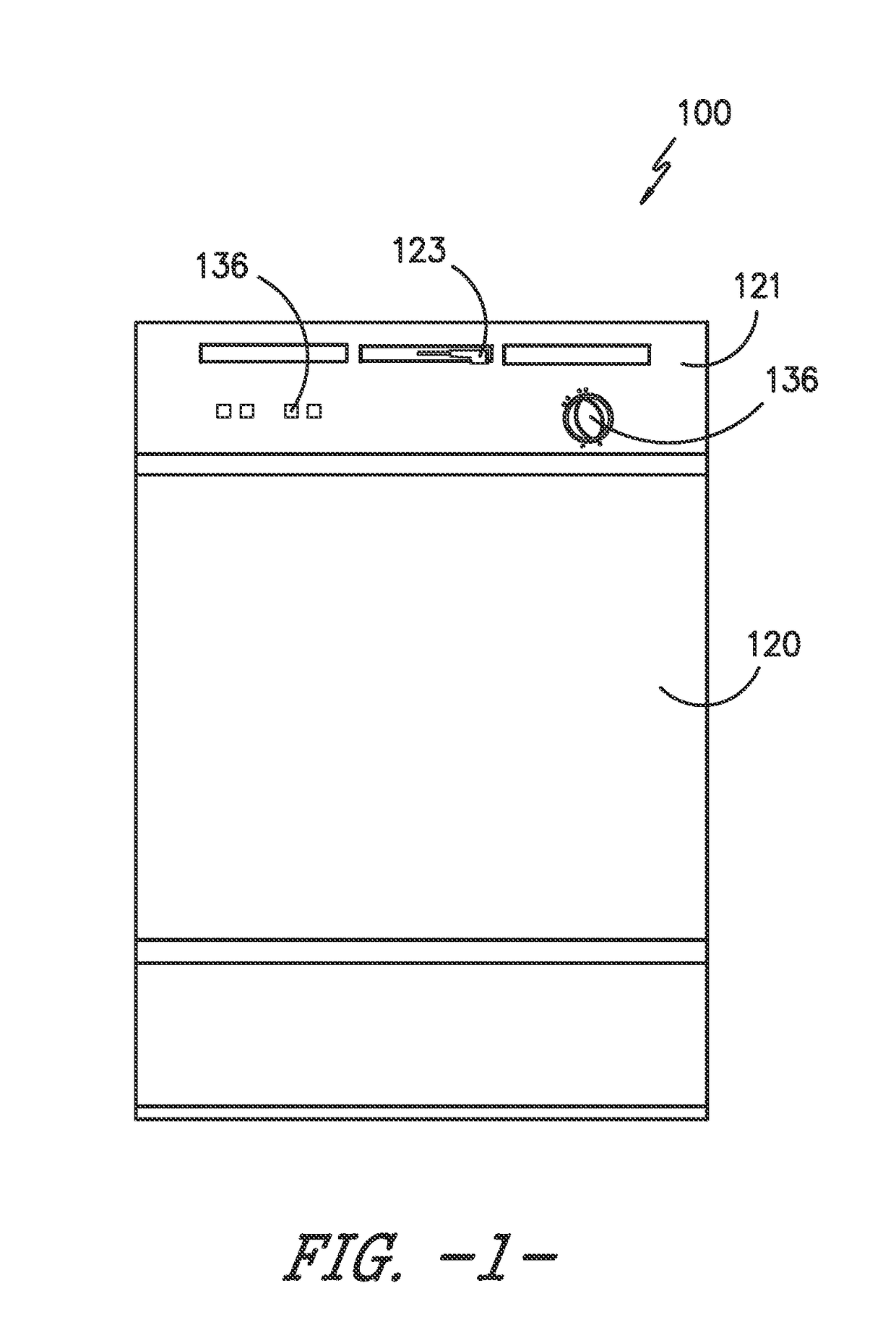

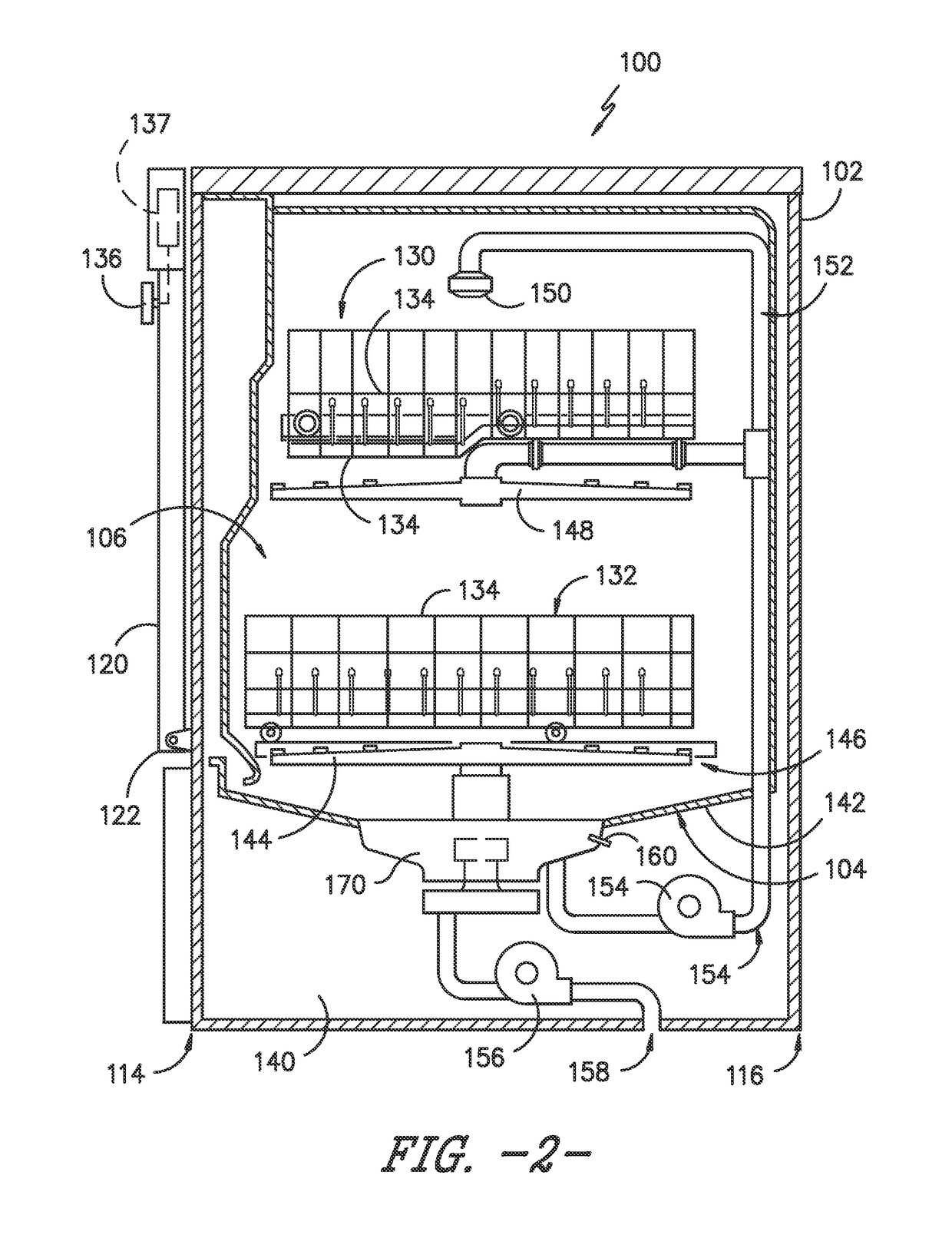

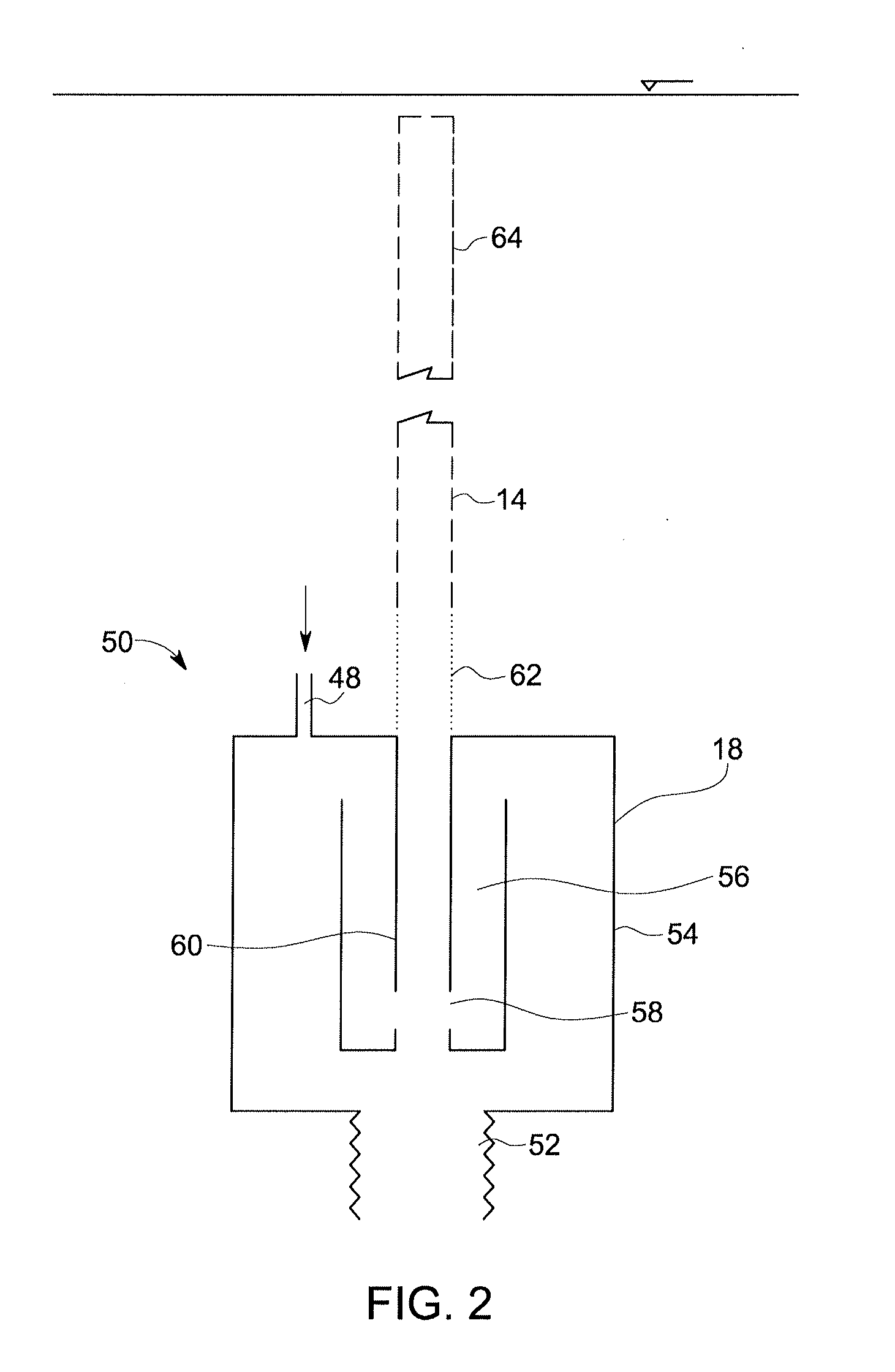

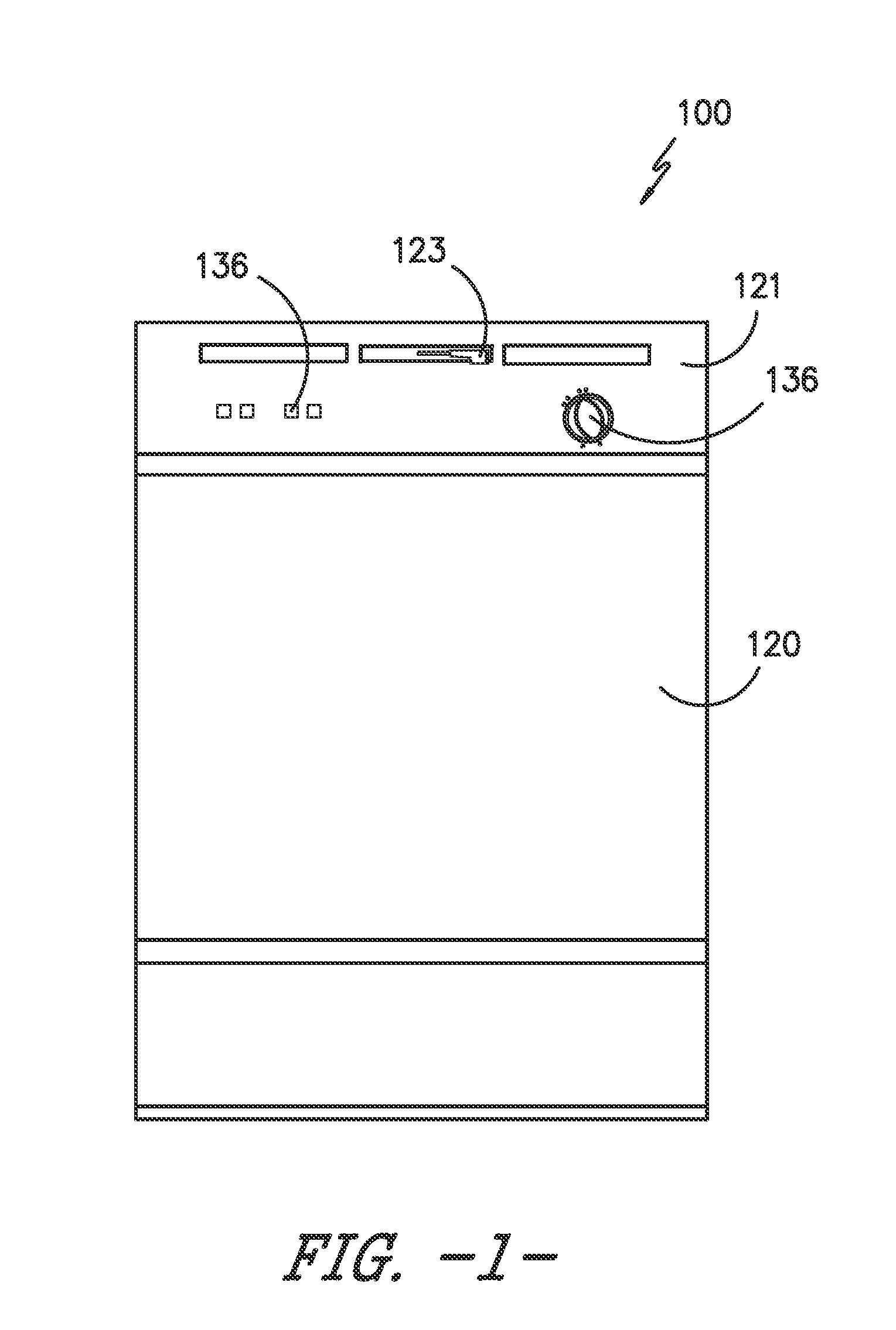

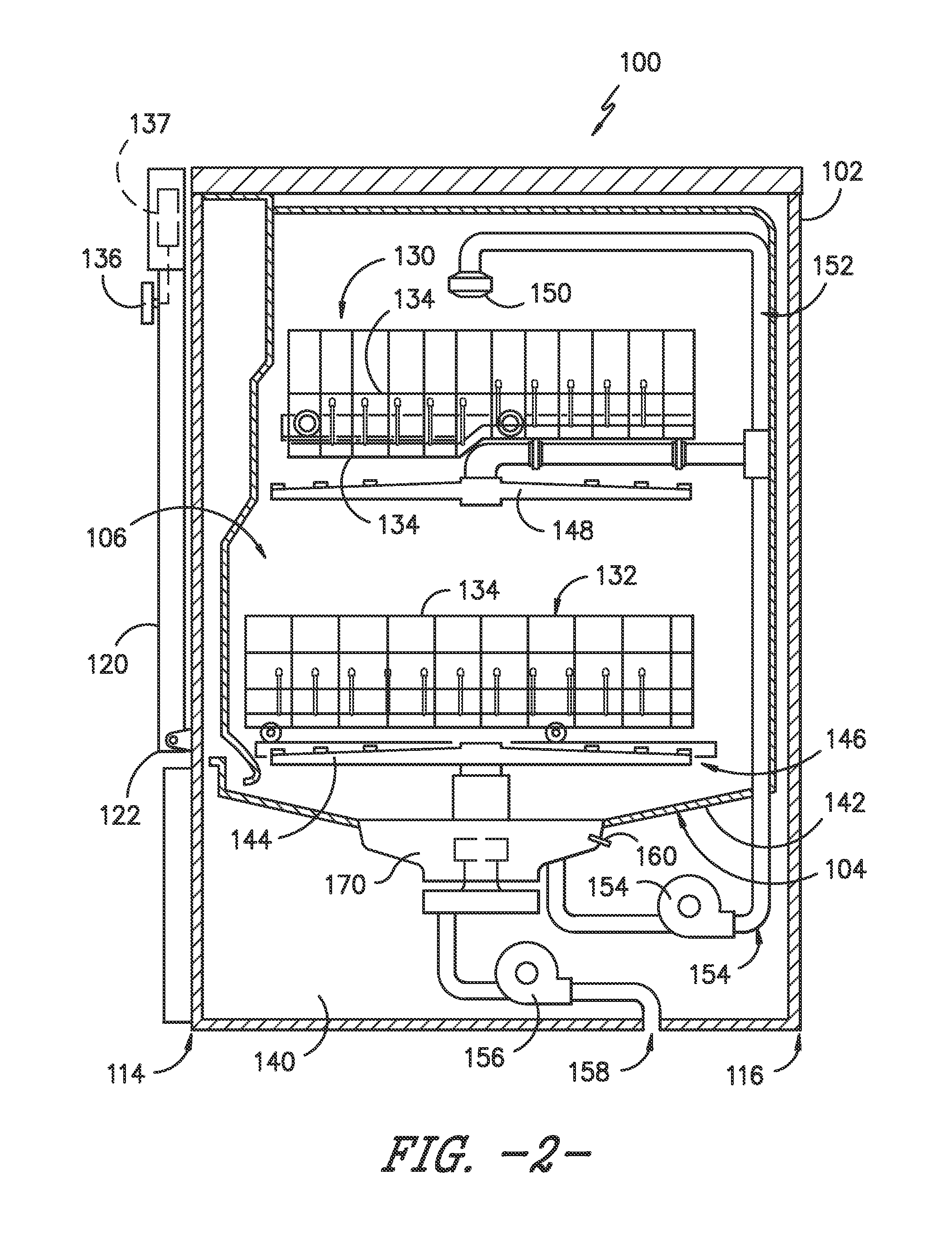

Dishwasher appliance and a method for operating the same

ActiveUS9968236B2Tableware washing/rinsing machine detailsCleaning equipmentSubject matterEngineering

The present subject matter provides a method for operating a dishwasher appliance. The method includes finely filtering wash fluid with a fine filtration medium via cross-flow filtration and coarsely filtering wash fluid with a coarse filtration medium via dead-end filtration. The finely filtered wash fluid is directed to a spray assembly of the dishwasher appliance. A related dishwasher appliance is also provided.

Owner:HAIER US APPLIANCE SOLUTIONS INC

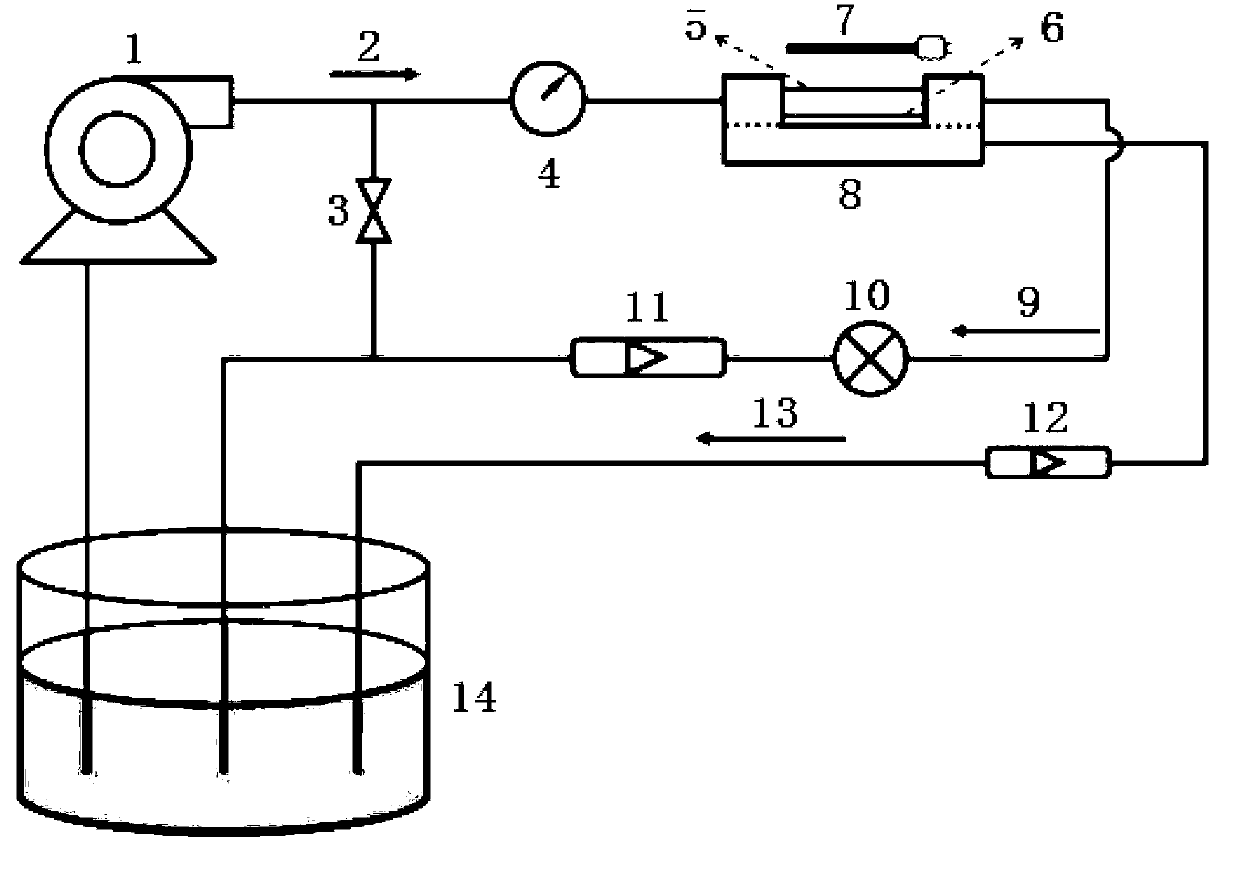

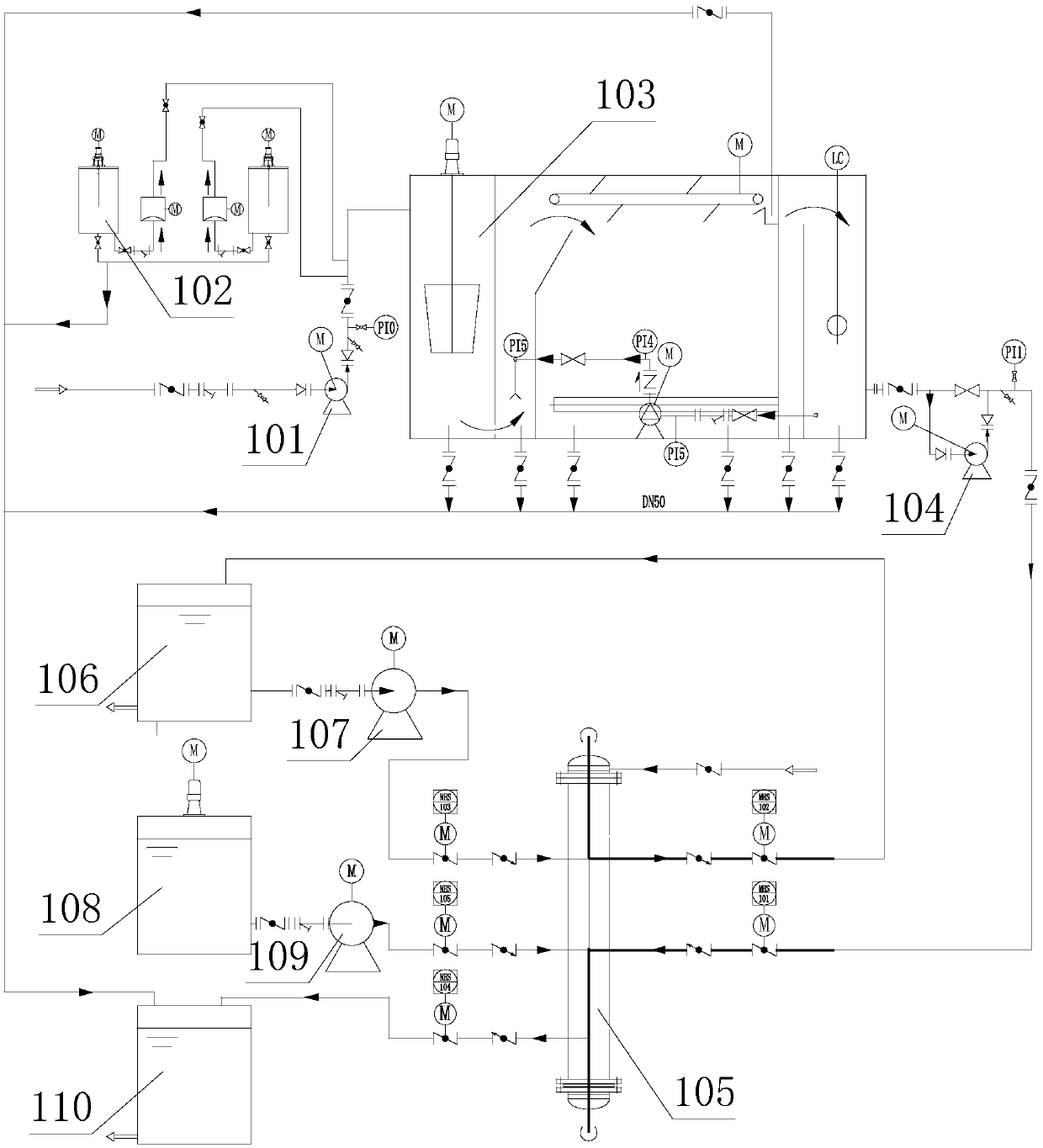

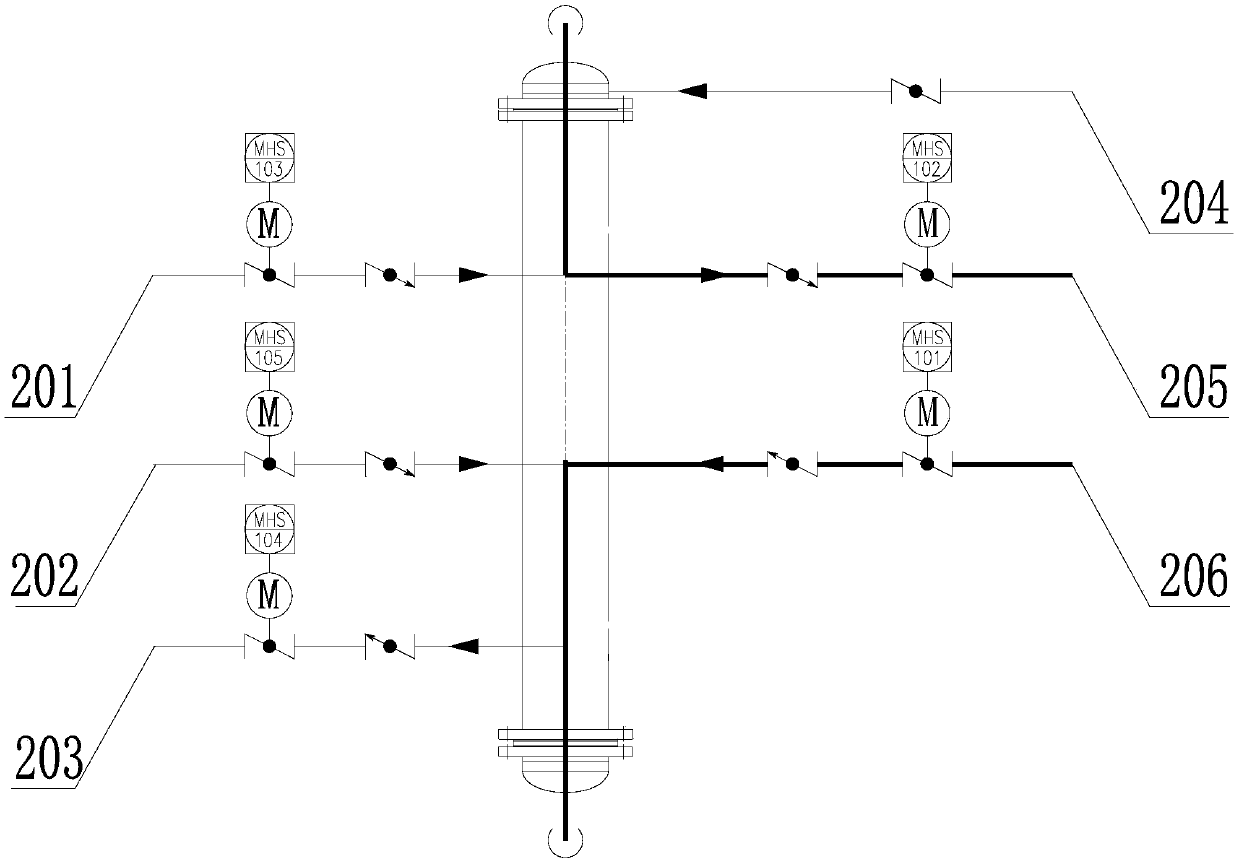

Sawing and grinding wastewater ultrafiltration membrane (UF)-recovery and treatment system

InactiveCN102070227AEffective interceptionReduce turbidityWater/sewage treatment bu osmosis/dialysisHollow fibreUltrafiltration

The invention discloses a sawing and grinding wastewater ultrafiltration membrane (UF)-recovery and treatment system, which adopts a dead-end filtration system, utilizes a vertical hollow fibrous membrane and combines periodical water-washing, gas-washing and medicament-washing mechanisms so as to increase the recovery rate under low setting cost and low loss in a simple flow, and prolong the service life of the UF membrane.

Owner:SHANGHAI HANHUA WATER TREATMENT ENG CO LTD

Method for removing natural organism and heavy metal simultaneously from water

InactiveCN101555048AImprove anti-pollution performanceReduced anti-pollution abilityWater/sewage treatment bu osmosis/dialysisHollow fibreAutomatic control

The invention relates to a method for removing natural organism and heavy metal simultaneously from water, belonging to the technical field of water treatment. The method comprises the steps as follows: Step One, a hydrophilic ultrafiltration membrane is modified to a hydrophilic charged ultrafiltration membrane, wherein shape of the hydrophilic charged ultrafiltration membrane is one selected from flatbed, roll type, hollow fibre type and tube type; Step Two, the hydrophilic charged ultrafiltration membrane is placed on an ultrafiltration device and dead-end filtration or cross-flow filtration is employed to carry out ultrafiltration to water to be treated which comprises natural organism and heavy metal. The method of the invention is simple in process and free of medicine addition; the method has reliable operation, compact device, and easy automatic control, which can reduce membrane pollution, prolong membrane service life and reduce process cost.

Owner:SHANGHAI JIAO TONG UNIV

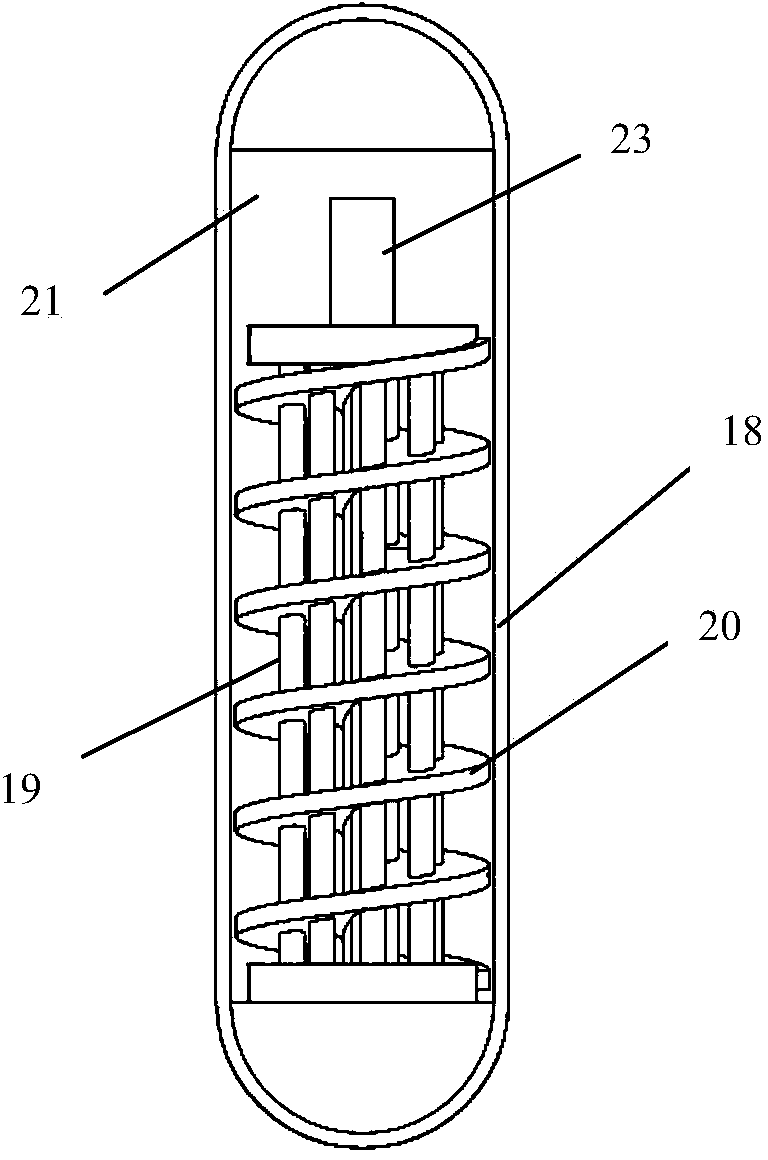

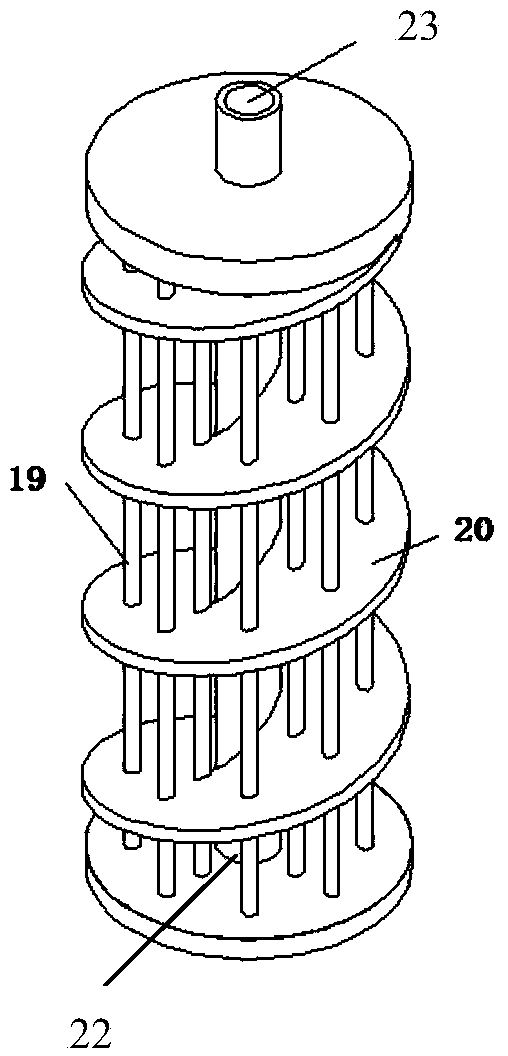

Intermittent spiral cross-flow membrane filtering device and method thereof

ActiveCN103638818AReduce pollutionReduce dosageSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisFiberAutomatic control

The invention discloses an intermittent spiral cross-flow membrane filtering device and a method thereof. The filtering device comprises a membrane component and a water circulation system, wherein the membrane component comprises a shell body, a hollow fiber external press film and a spiral baffle plate, the spiral baffle plate is arranged in the shell body, a reserved water storage zone is arranged above the spiral baffle plate, a spiral channel is formed between the spiral baffle plate and the shell body, the hollow fiber external press film goes through the spiral baffle, a cross-flow water inlet is arranged in the lower end of the shell body, a cross-flow water outlet is arranged in the upper end of the shell body, the cross-flow water inlet is corresponding to the inlet of the spiral channel, the outlet of the spiral channel is communicated to the cross-flow water outlet through the reserved water storage zone; the water circulation system comprises a water reservoir, a circulation water pump, and a pulse water flow generator, wherein the water reservoir, the circulation water pump and the pulse water flow generator are orderly connected through pipelines, the pulse water flow generator is communicated with the cross-flow water inlet pipeline, and the water inlet of the water reservoir is connected to the cross-flow water outlet pipeline. The device carries out cross-flow filtration and dead end filtration in turns. The device has the advantages of convenience, energy reduction, and easy automatic control, can effectively slow down the membrane pollution accumulation, and prolongs the service life of the membrane.

Owner:SOUTH CHINA UNIV OF TECH

Cross-flow ceramic membrane filter in field of petrochemical engineering

ActiveCN112057942AImprove chemical production efficiencyFiltration separationRefining by filtrationPetrochemicalCeramic membrane

The invention discloses a cross-flow type ceramic membrane filter in the field of petrochemical engineering, which comprises a feeding box body, a filtering box body and an impurity removal box body;the feeding box body, the filtering box body and the impurity removal box body are all of cuboid structures, the filtering box body is positioned between the feeding box body and the impurity removalbox body, and a communicating pipe I and a communicating pipe II are communicated between the feeding box body and the filtering box body; one end of the first communicating pipe is communicated withthe side wall of the feeding box body, the other end of the first communicating pipe is communicated with the top of the filtering box body, petroleum flows into the feeding box body through the liquid inlet pipe and then is discharged into the filtering box body through the first communicating pipe and the second communicating pipe, and the petroleum flowing into the feeding box body through thefirst communicating pipe makes contact with the ceramic membrane to be filtered at the dead end. Petroleum flowing into the feeding box body through the second communicating pipe makes contact with the ceramic membrane for cross-flow filtration; when filter cakes are accumulated on the surface of the ceramic membrane, the flowing speed of the petroleum flowing into the mounting shell through the third communicating pipe is low, the amount of the petroleum flowing into the filtering box body through the second communicating pipe is increased, and dead end filtration is converted into cross-flowfiltration.

Owner:大庆惠博普石油机械设备制造有限公司

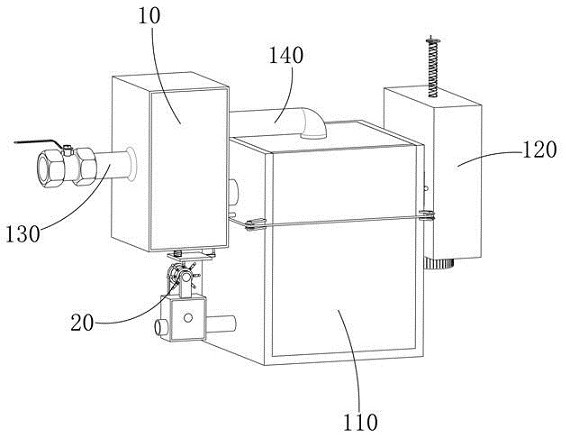

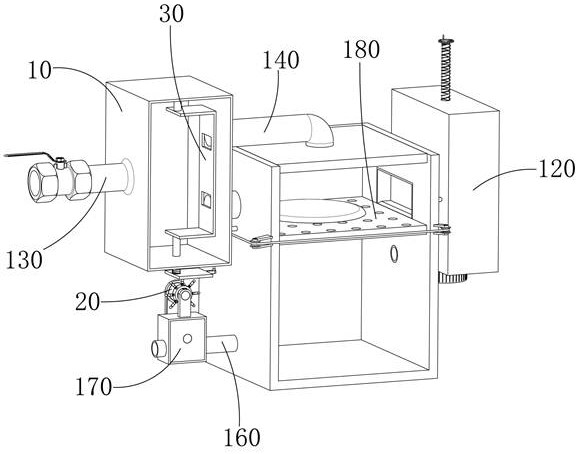

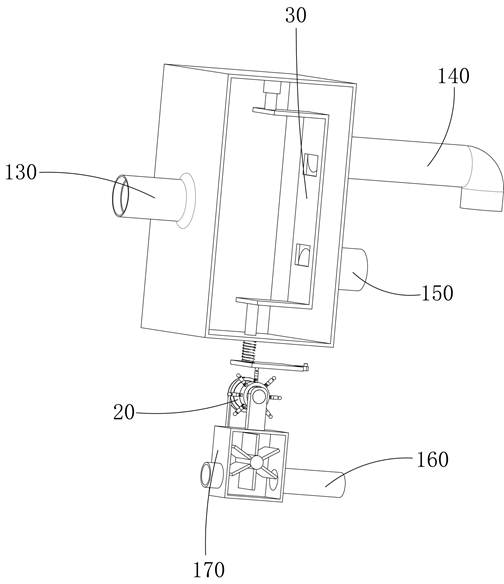

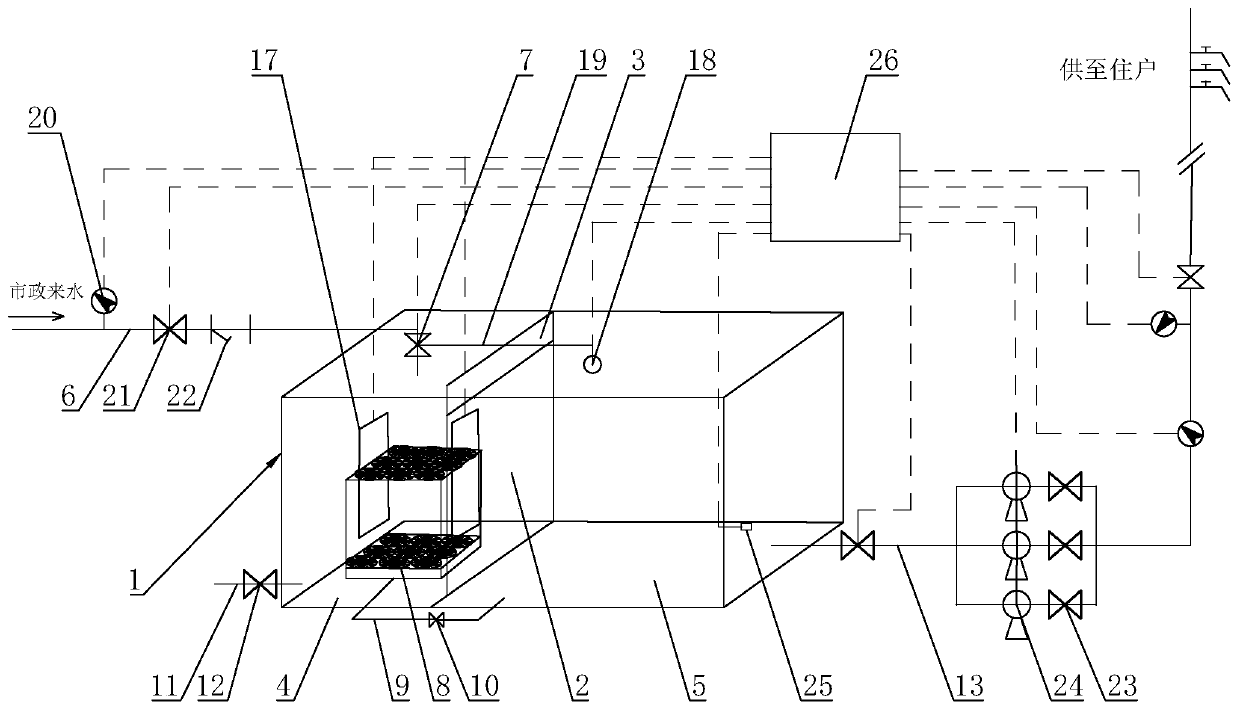

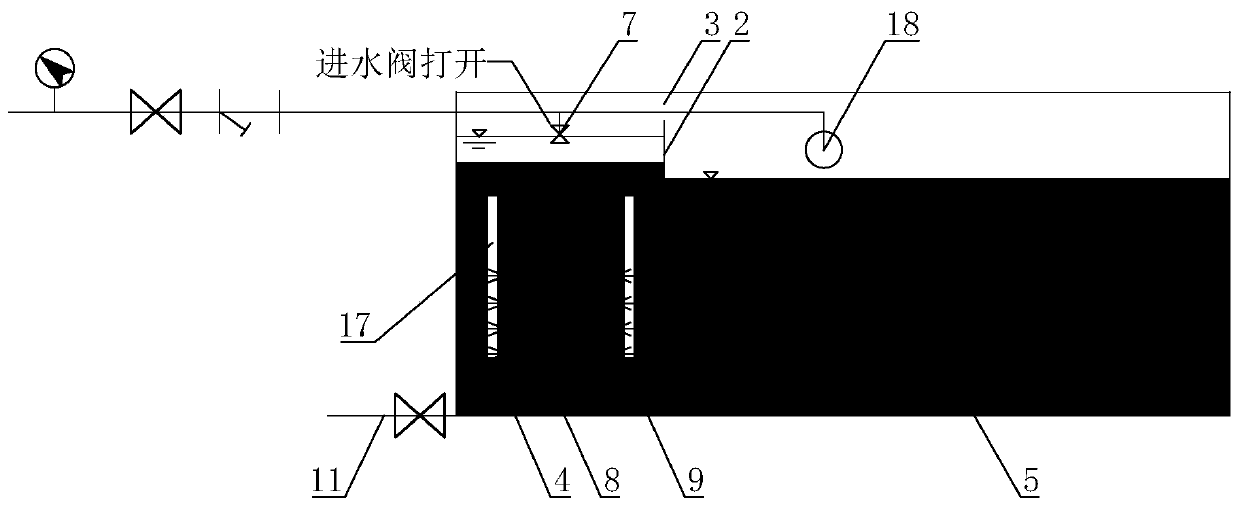

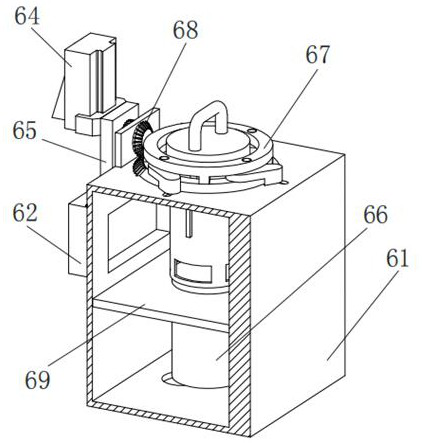

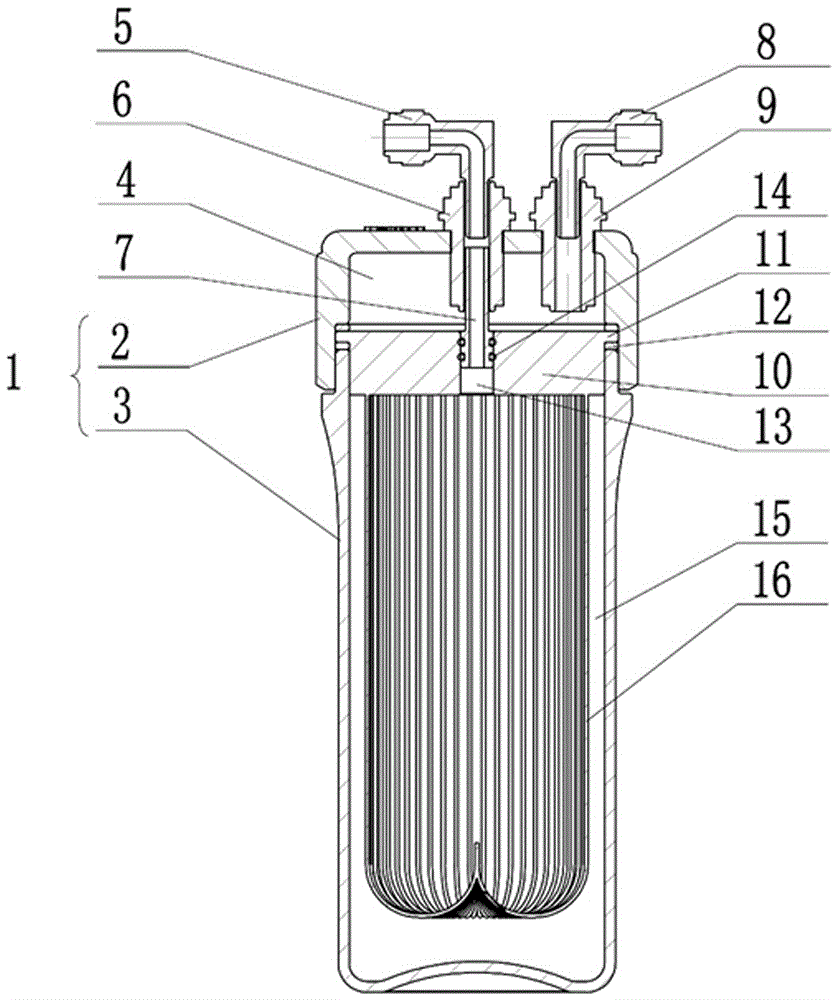

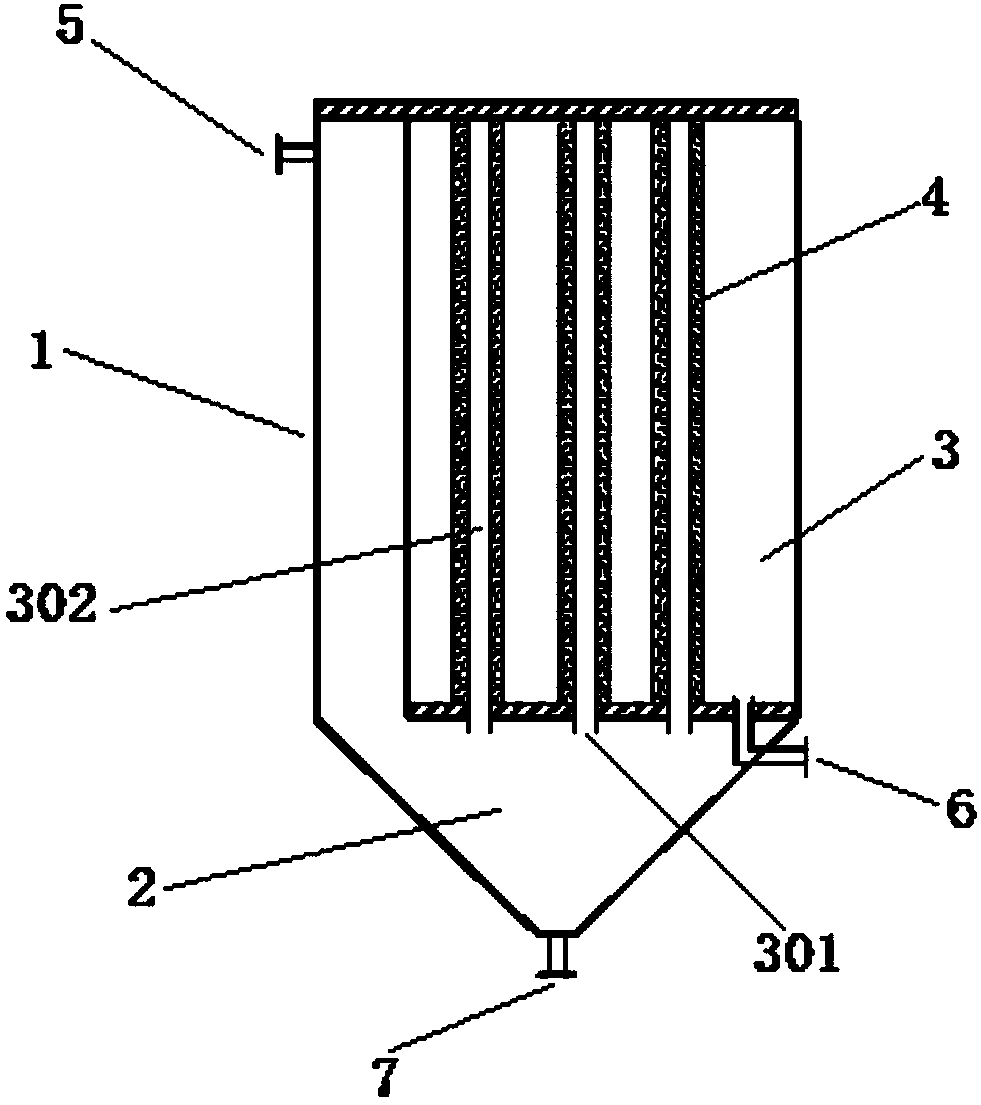

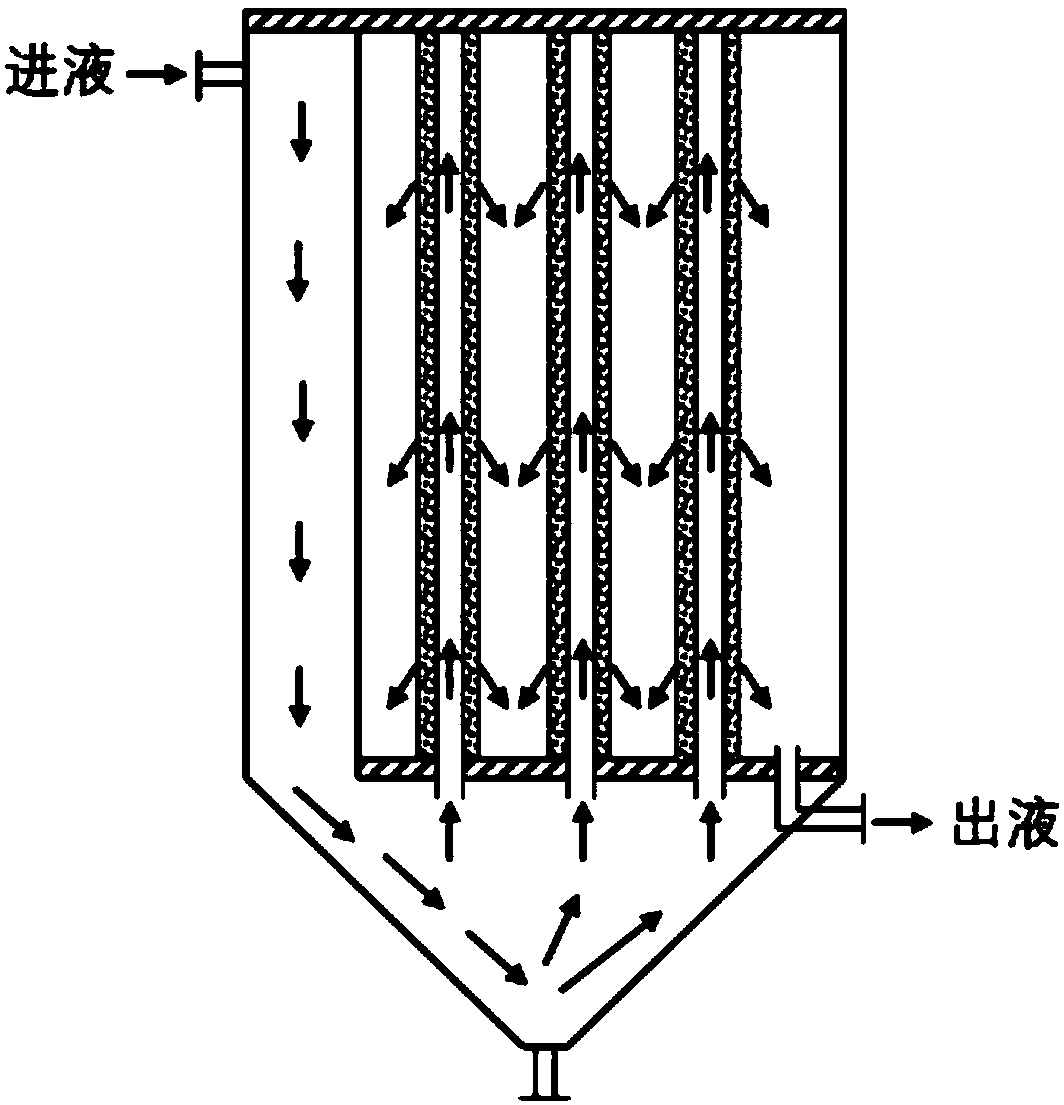

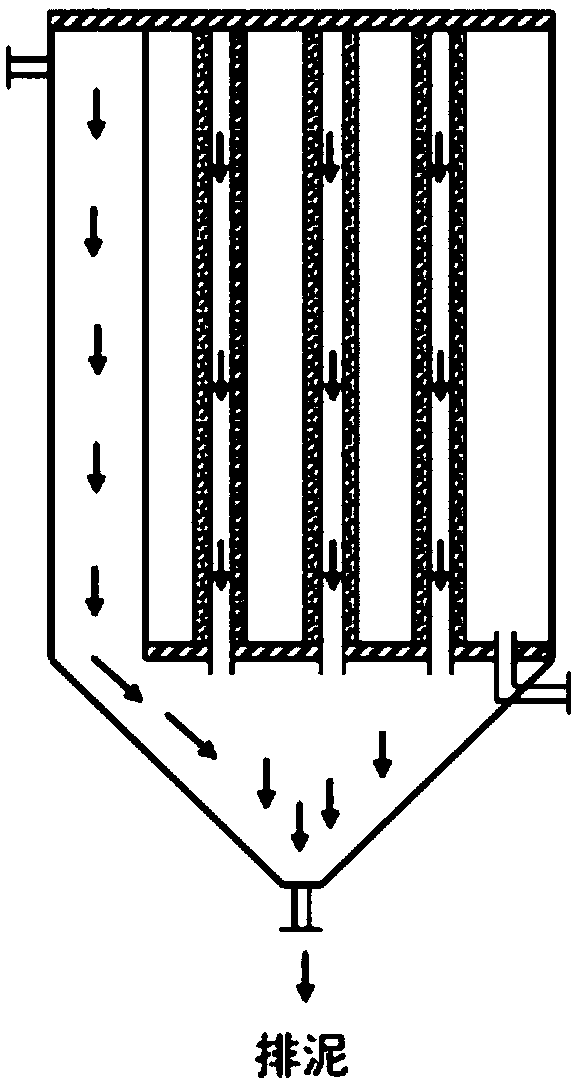

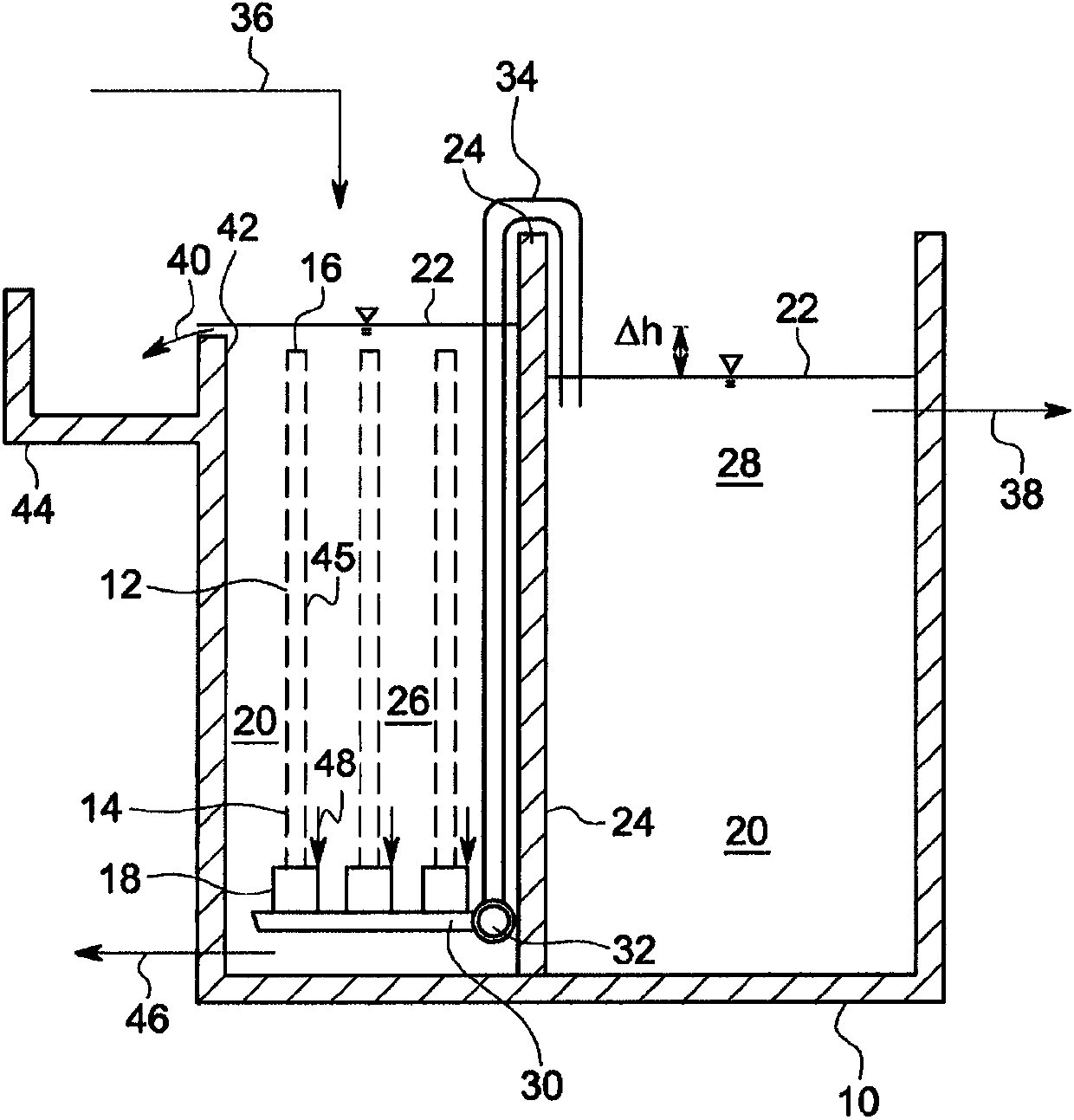

Secondary water supply water tank with dead end filtration and self-cleaning functions and secondary water supply method

PendingCN111236363ARaise the liquid levelGuaranteed filtering effectTreatment involving filtrationMultistage water/sewage treatmentTap waterInlet valve

The invention discloses a secondary water supply water tank with dead end filtration and self-cleaning functions and a secondary water supply method. The water tank comprises a water tank body and ischaracterized in that a baffle is vertically arranged in the water tank body, an overflow channel is formed between the top end of the baffle and the top wall of the water tank body, the baffle divides the water tank body from front to back into a first water tank and a second water tank, the first water tank is connected with a municipal water pipeline, a water inlet valve is arranged on the municipal water pipeline, a filtering device is arranged in the first water tank, water enters from the side surface of the filtering device, is filtered and flows out from the bottom, the filtering device communicates with the second water tank through a bottom connecting pipeline, a blow-off pipeline is arranged at the bottom end of the first water tank, and a liquid level detection mechanism for controlling the opening and closing of a water inlet valve of the first water tank is arranged in the second water tank. The secondary water supply water tank has the advantages that municipal tap wateris subjected to primary sedimentation, then is subjected to dead end filtration, secondary pollutants of water supply are removed, the filtering device can be automatically cleaned, and normal watersupply for households is guaranteed while self cleaning is carried out.

Owner:浙江富莱迪环境设备有限责任公司

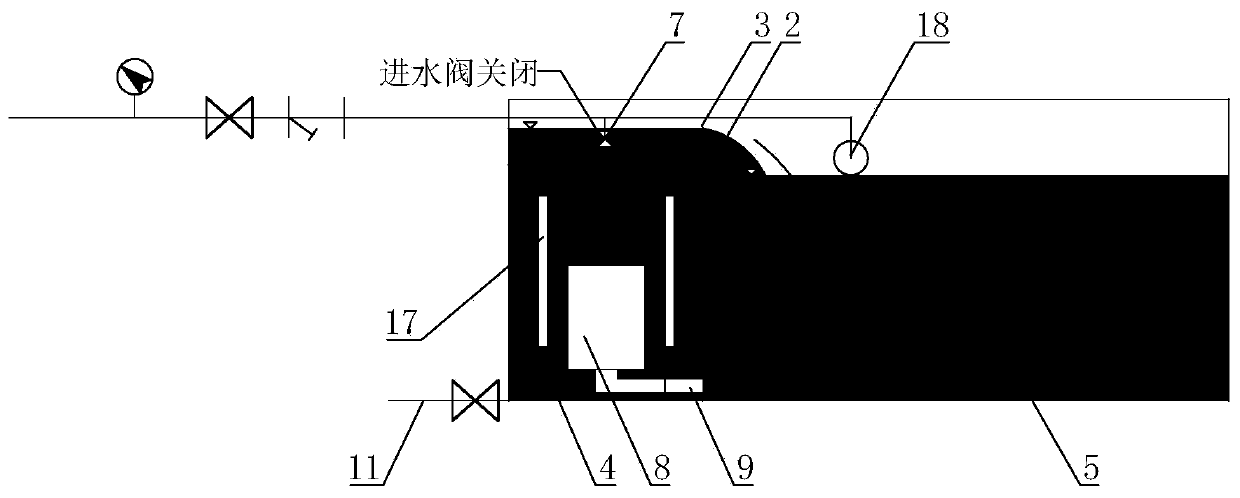

Method used for purifying slightly polluted drinking water

InactiveCN109179880APrevent leakageEfficient retentionTreatment using aerobic processesSpecific water treatment objectivesLiquid wasteWater discharge

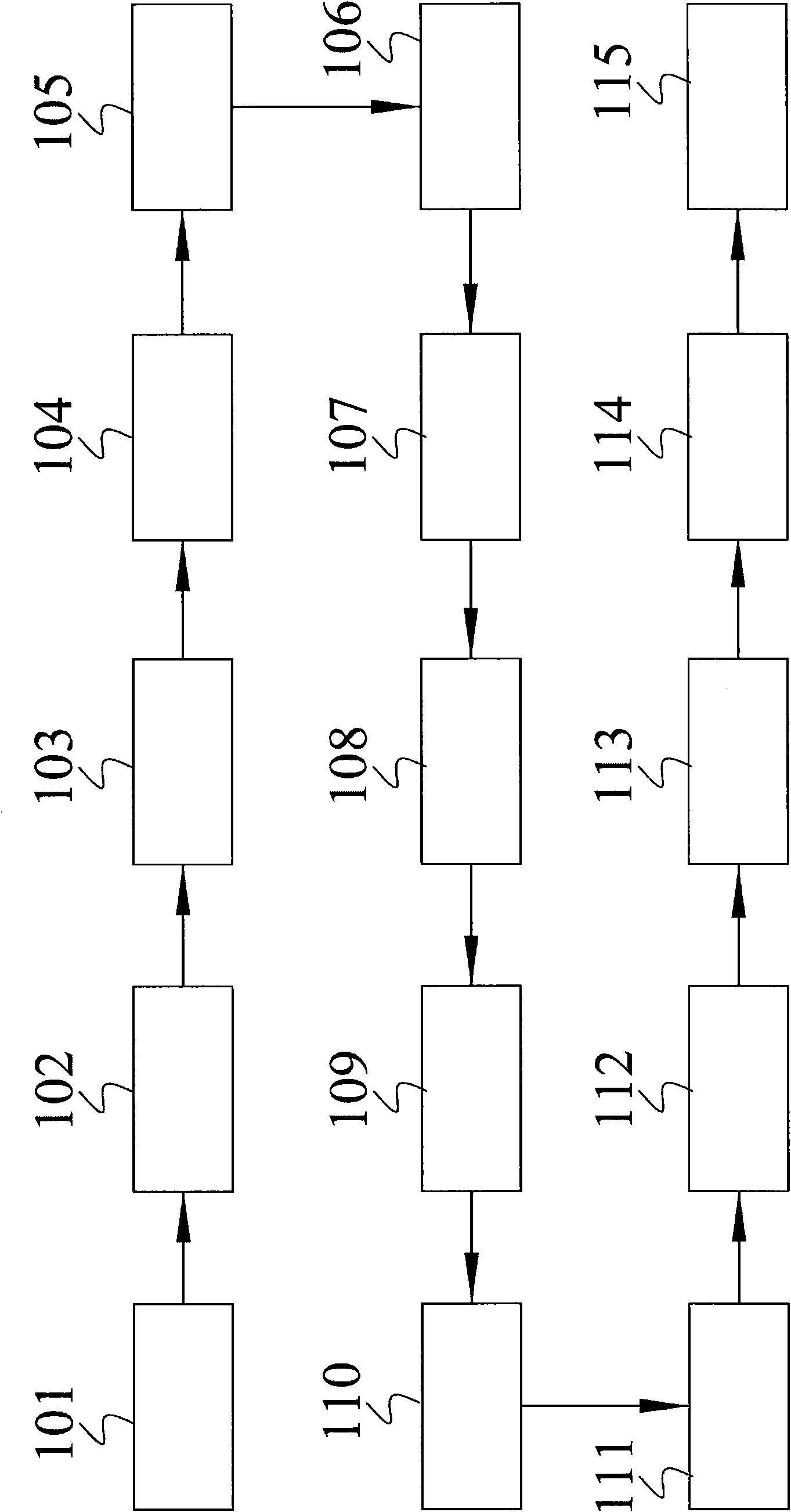

The invention discloses a method used for purifying slightly polluted drinking water. According to the method, raw water is introduced into a high load biological oxidation pool for complete biodegradation; discharged water is introduced into a flocculation basin and a sedimentation basin successively; an obtained supernatant is pumped into an ultrafilter membrane assembly for crossflow filtration; ultrafiltration discharged water is introduced into a clean water tank for chlorine disinfection and discharging, a concentrate and a backwash waste liquid from the ultrafilter membrane assembly arerecycled back into the biological oxidation pool for circulation processing. According to the method, organic combination of biological oxidation and crossflow untrafiltration is adopted, and a conventional biological oxidation is optimized so as to solve problems in the prior art that water feeding processing load capacity is low, routine dead end filtration water discharge amount is low, and energy consumption is high; the method is capable of increasing removing effect on small molecular dissolvable organic matters, ensuring the biological safety of discharged water, reducing land occupation area, and reducing water production energy consumption. The specific flow is disclosed in a graph in the invention.

Owner:JINAN JIANDA ENVIRONMENTAL PROTECTION TECH CO LTD

Electrochemical carbon nanotube filter and method

A filtration apparatus and filtration method can be used to reduce at least one contaminant (e.g., organic molecules, ions and / or biological microorganisms) in an aqueous fluid. The filtration apparatuses and methods of the invention can separate at least one contaminant from an aqueous fluid and / or oxidize at least one contaminant. In operation, an aqueous fluid is flowed through a filtration apparatus comprising a porous carbon nanotube filter material at an applied voltage. In some embodiments, the filtration apparatus described herein can be used for dead-end filtration. In some embodiments, the filtration apparatus described herein can be used for cross-over filtration.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE

Method of treating discharged sewage of circulating water plant through precoated membrane filtration technology

InactiveCN110803792AImprove anti-pollution performanceHydrophilicTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisCoated membraneSludge

The invention discloses a method of treating discharged sewage of a circulating water plant through a precoated membrane filtration technology. The method comprises the specific processes that (1) anagent-adding coagulation air floatation unit pretreats wastewater; and (2) a precoated membrane filtration unit performs deep treatment on air floatation produced water, wherein the precoated membranefiltration unit adopts the operation process of "backwashing membrane explosion-membrane coating-filtration", a 316L stainless steel powder sinteredporous inert membrane tube is adopted as a membranebase, and dead end filtration is performed. According to the method, the treatment effect of the discharged sewage, which contains oil and high-viscosity sludge, of the circulating water plant of a petrochemical enterprise is good, the oil content and suspended matter content in effluent are greatly lowered, and the treated sewage can be reused as circulating water or enter a conventional biochemical treatment system for treatment.

Owner:青岛海晏环境技术工程有限公司

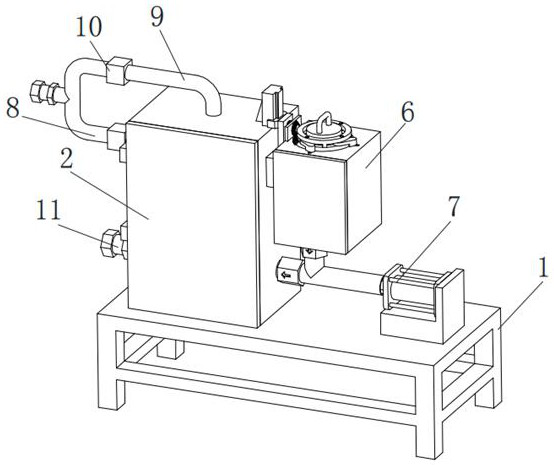

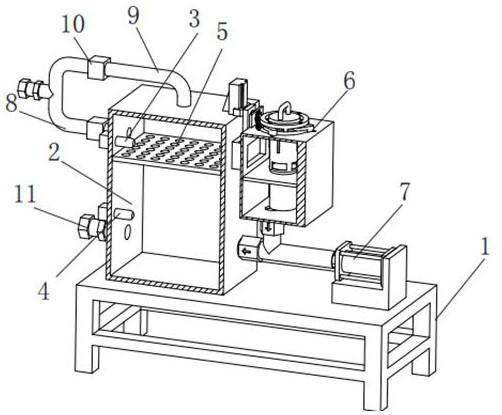

Silicon carbide ceramic membrane filtering device

ActiveCN113368698AImprove filtering effectImprove filtration efficiencySemi-permeable membranesCarbide siliconCeramic membrane

The invention discloses a silicon carbide ceramic membrane filtering device, and belongs to the technical field of filtering equipment, wherein the silicon carbide ceramic membrane filtering device comprises a workbench, a filtering box, a first water pressure sensor, a second water pressure sensor, a silicon carbide ceramic membrane, impurity removal equipment and backflow equipment. When the device works, dead-end filtering is firstly carried out, if the pressure borne by the first water pressure sensor is far larger than that borne by the second water pressure sensor, it is indicated that impurities block the silicon carbide ceramic membrane after long-time filtering, and at the moment, the first water pressure sensor and the second water pressure sensor transmit signals to carry out cross-flow filtering; impurities in the silicon carbide ceramic membrane can be taken out through cross-flow filtration, then waste water carries the impurities to enter the impurity removal equipment, then the impurities are recycled by the impurity removal equipment, the remaining liquid returns to the filtering box again through the backflow equipment, and cleaning of the silicon carbide ceramic membrane is completed; and after cleaning of the silicon carbide ceramic membrane is completed, the whole device can continue to return to a dead-end filtering state, so that the filtering efficiency is improved.

Owner:山东浦创流体技术有限公司

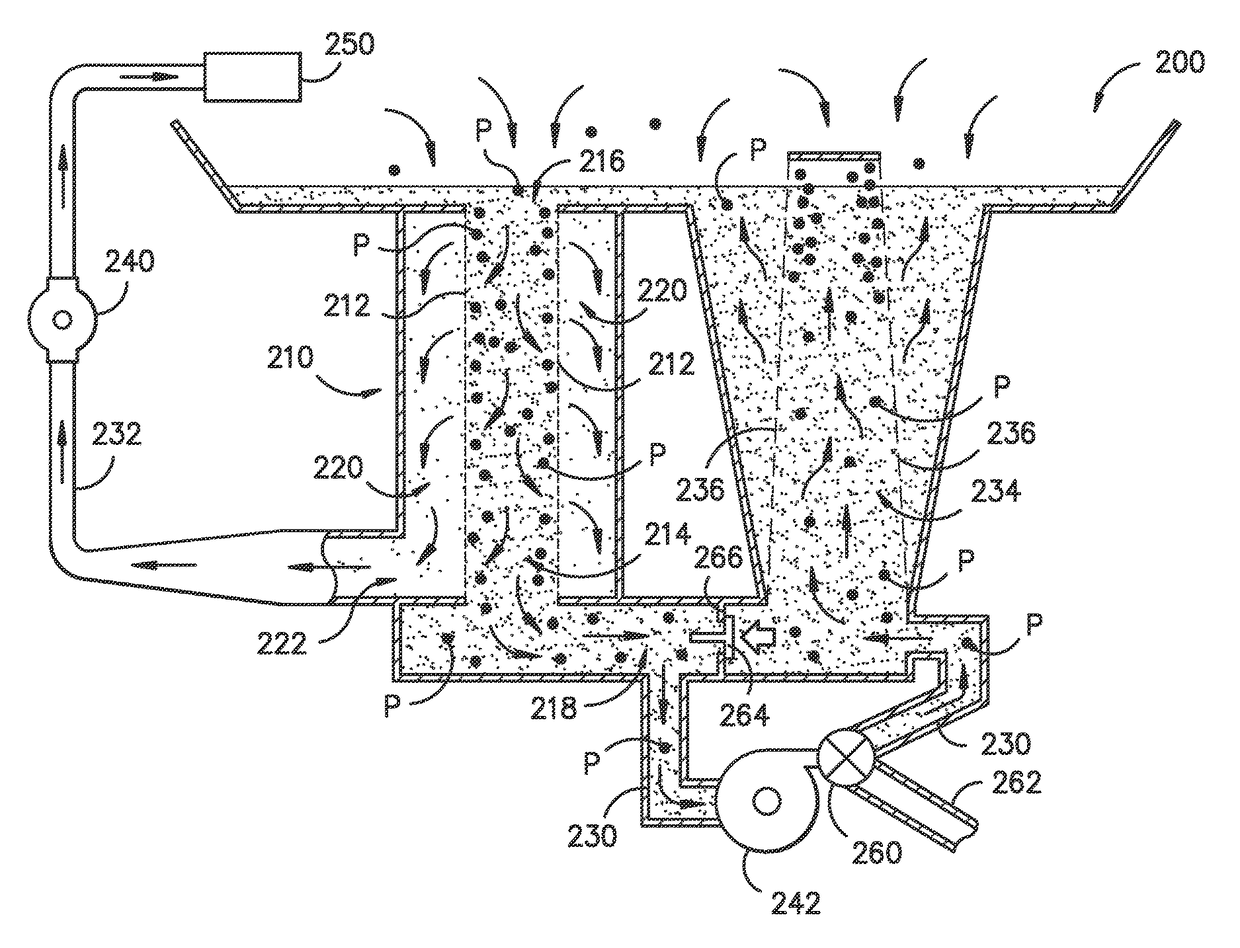

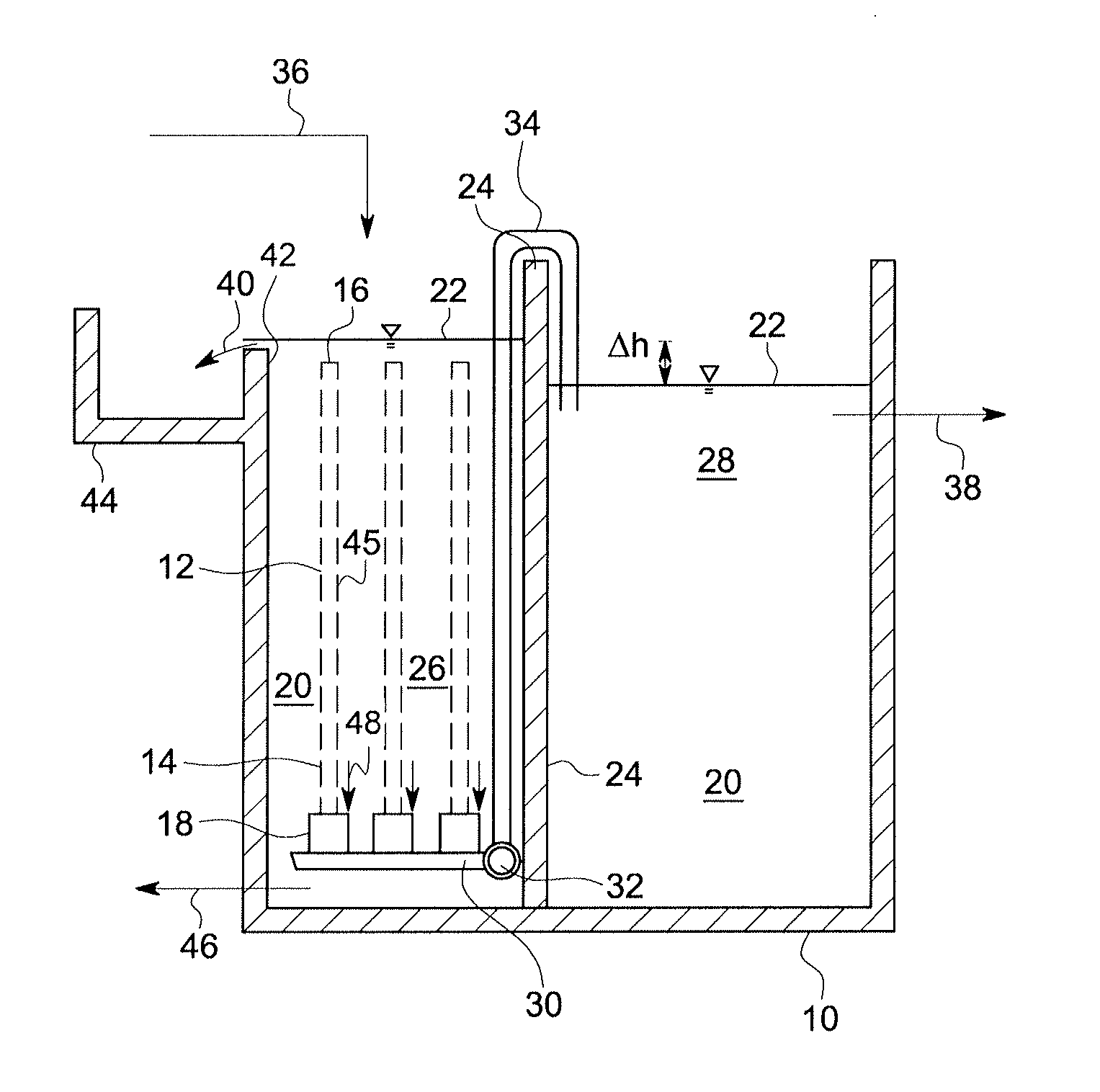

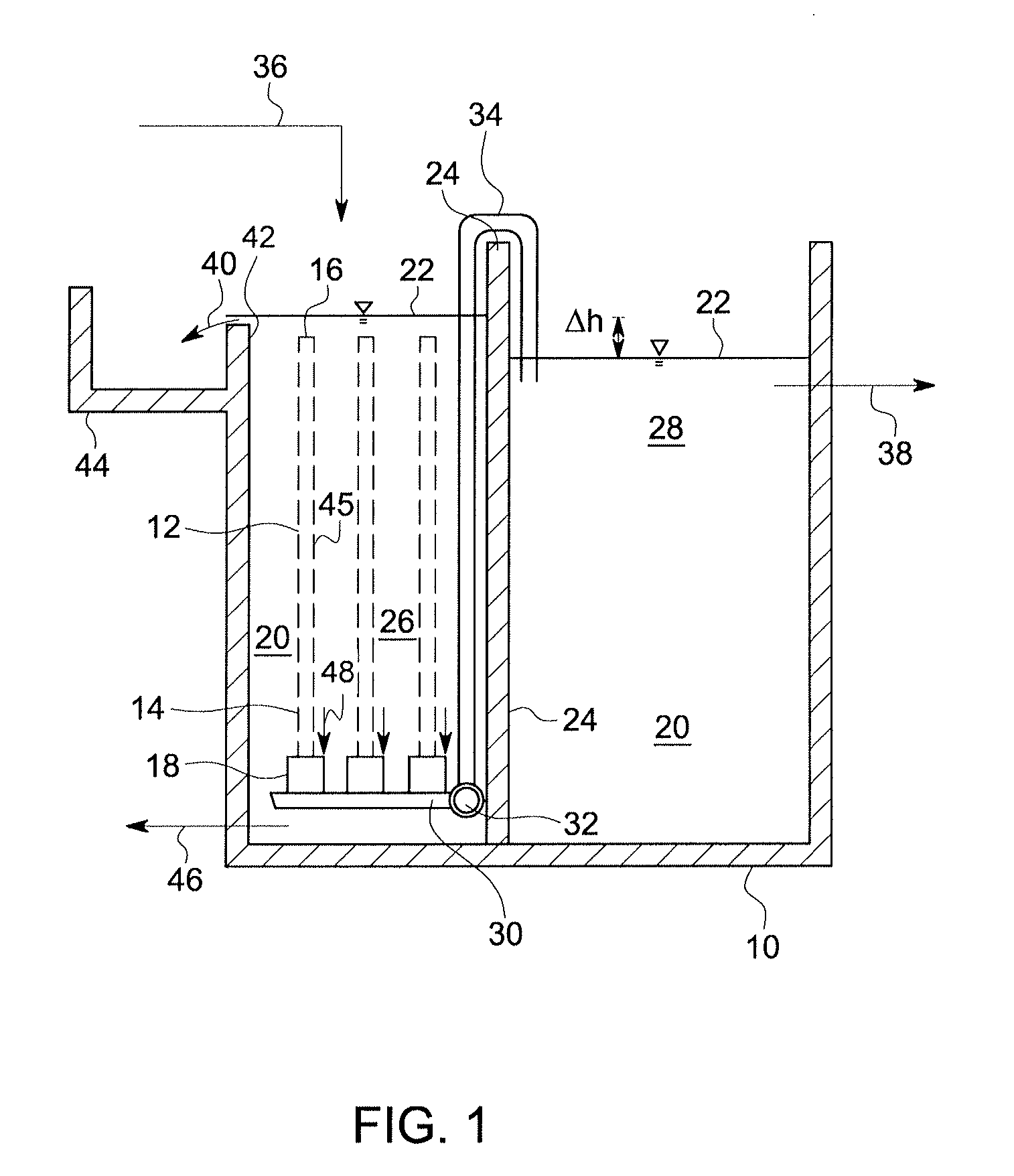

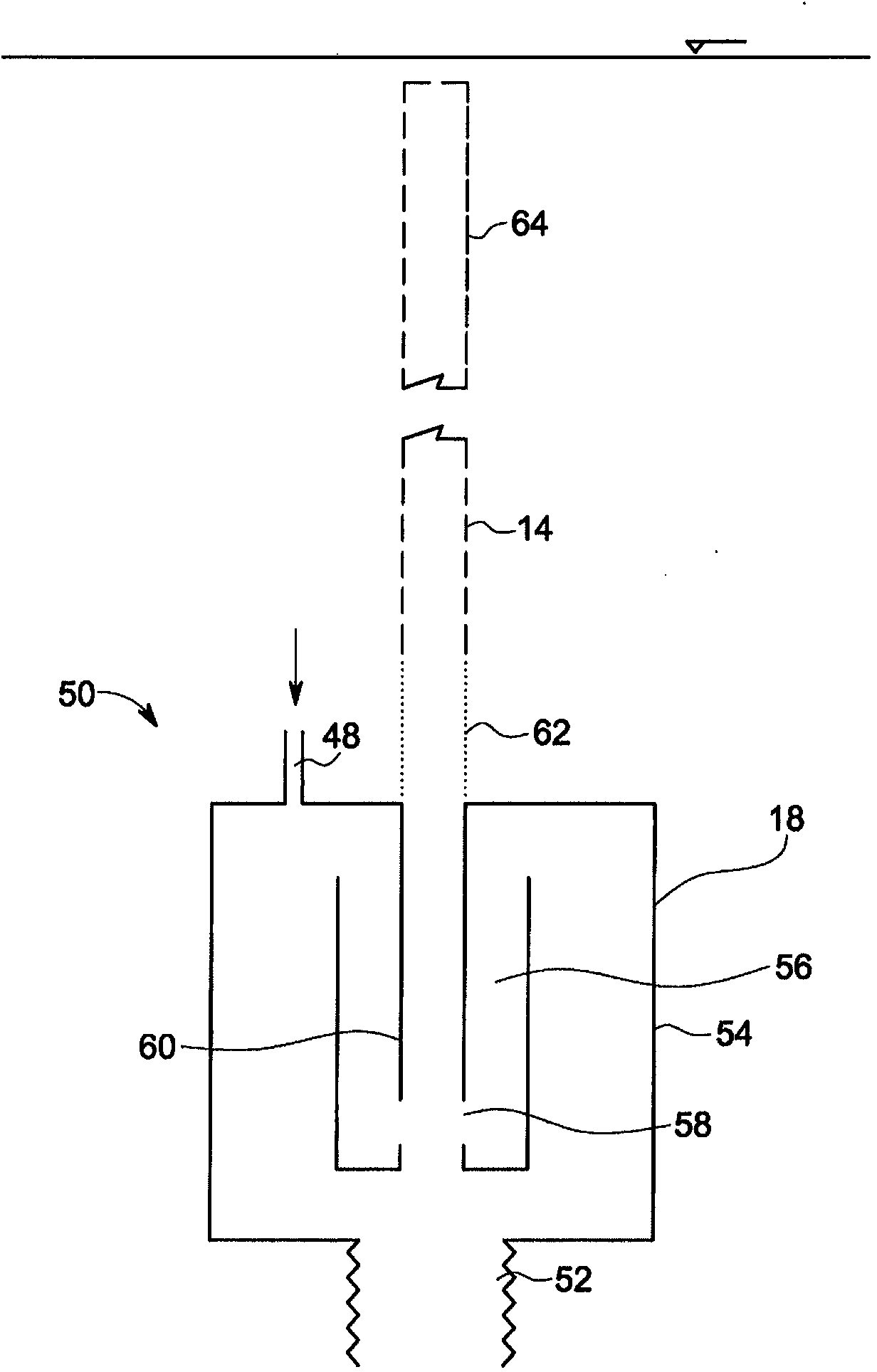

Immersed screen and method of operation

InactiveUS20130146548A1Mild backwashCapital costTransportation and packagingLoose filtering material filtersWastewaterWater flow

A static screen has a plurality of screening bodies and a plurality of aeration devices downstream of the screening bodies. Each aeration device is associated with a set of one or more of the screening bodies. Each aeration device may be a pulsing aerator. The pulsing aerators do not all release air at the same time. Each screening body works through periods of dead end filtration separated by backwashing events. The backwashing events comprise introducing a slug or pulse of air into the bottom of the screening body. Flow through the static screen continues at all times because the screening bodies are not all backwashed at the same time. The static screen may be used to remove trash from water flowing to an immersed membrane unit. Alternatively, the static screen may be used to provide primary wastewater treatment.

Owner:GENERAL ELECTRIC CO

Dishwasher appliance and a method for operating the same

ActiveUS20160073851A1Tableware washing/rinsing machine detailsCleaning equipmentSubject matterEngineering

The present subject matter provides a method for operating a dishwasher appliance. The method includes finely filtering wash fluid with a fine filtration medium via cross-flow filtration and coarsely filtering wash fluid with a coarse filtration medium via dead-end filtration. The finely filtered wash fluid is directed to a spray assembly of the dishwasher appliance. A related dishwasher appliance is also provided.

Owner:HAIER US APPLIANCE SOLUTIONS INC

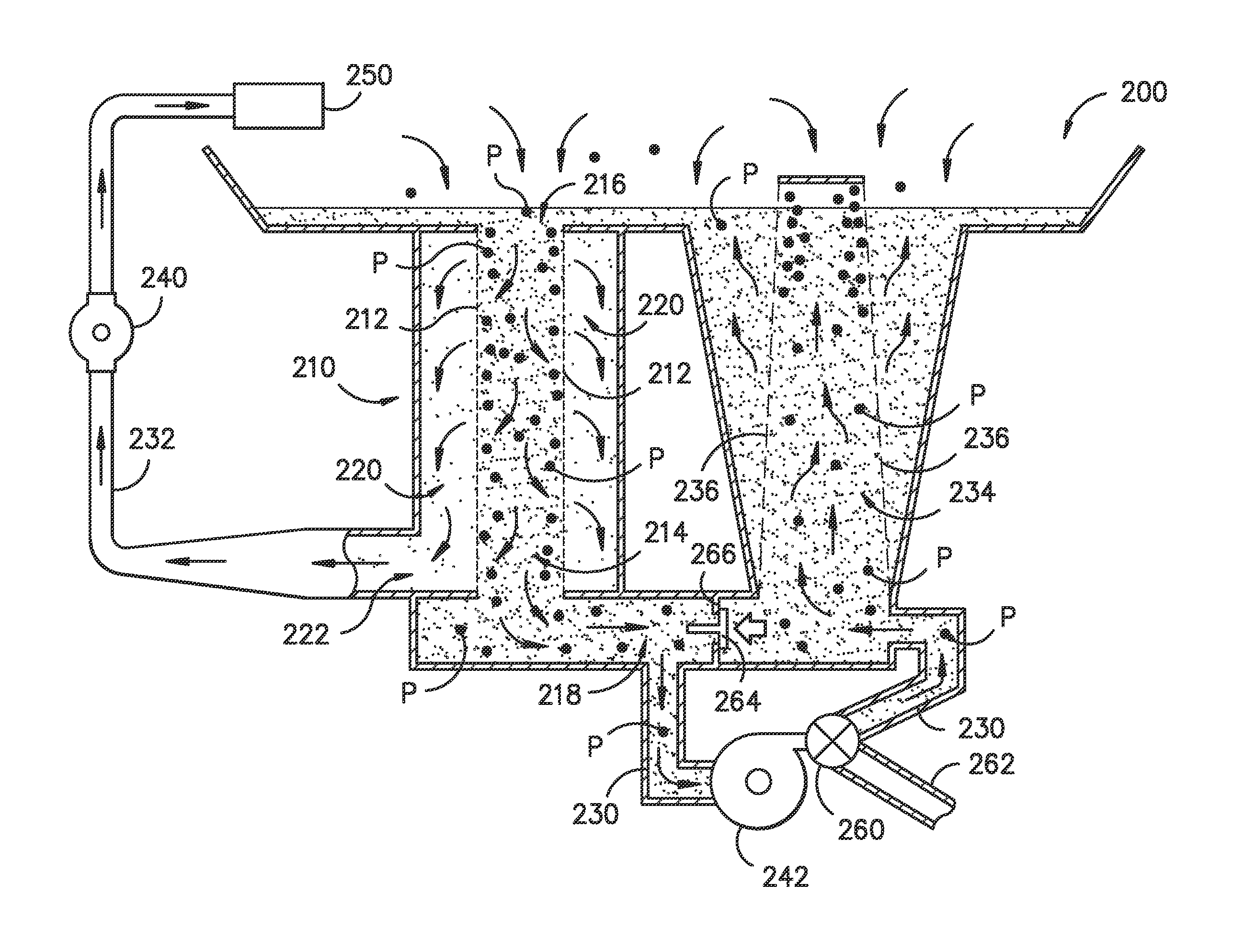

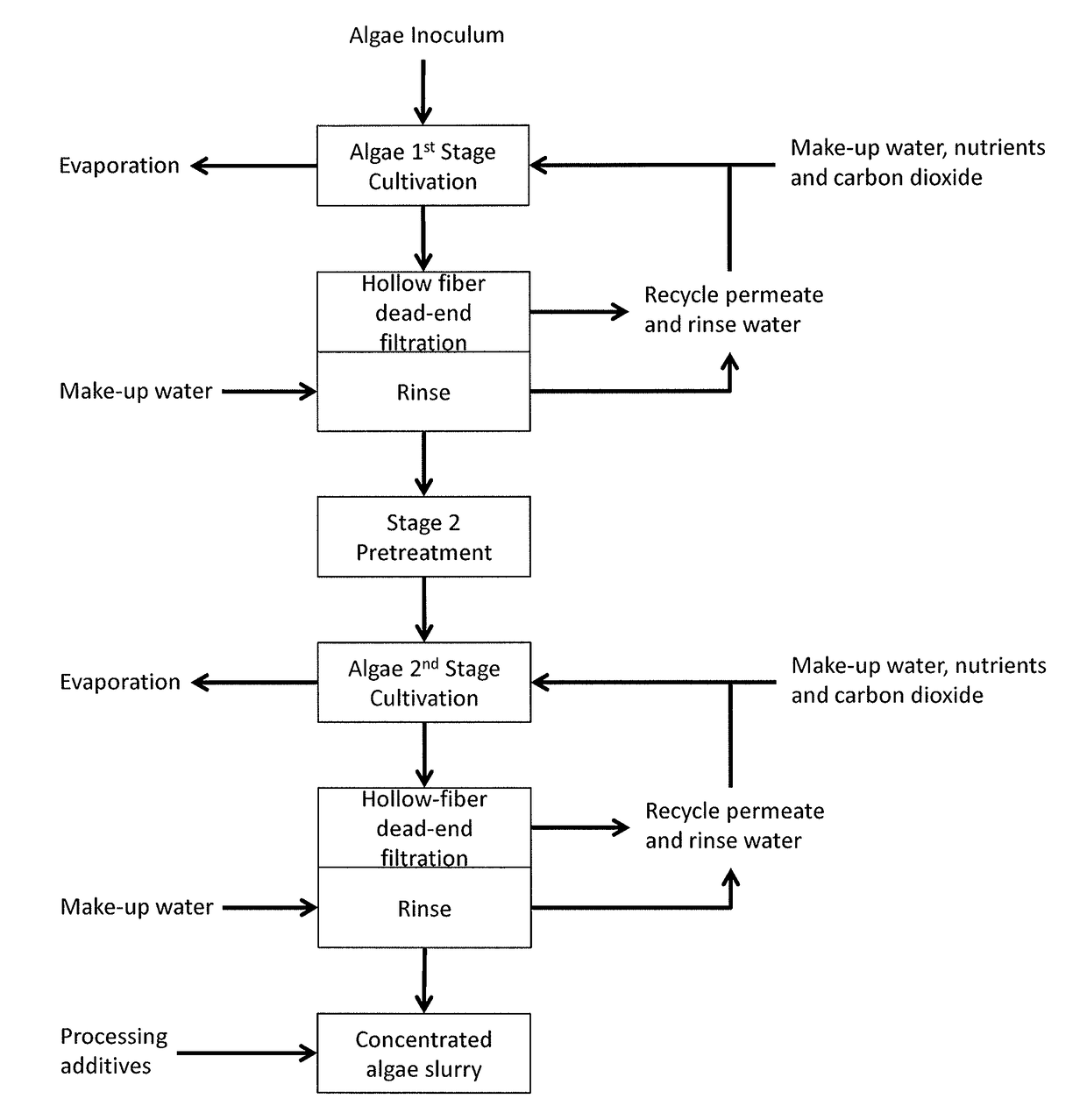

Biological and algae harvesting and cultivation systems and methods

ActiveUS20170321182A1Reduce complexityLow costBioreactor/fermenter combinationsBiological substance pretreatmentsHigh concentrationFishery

Algae harvesting and cultivating systems and methods for producing high concentrations of algae product with minimal energy. In an embodiment, a dead-end filtration system and method includes at least one tank and a plurality hollow fiber membranes positioned in the at least one tank. An algae medium is pulled through the hollow fiber membranes such that a retentate and a permeate are produced.

Owner:GLOBAL ALGAE TECH LLC

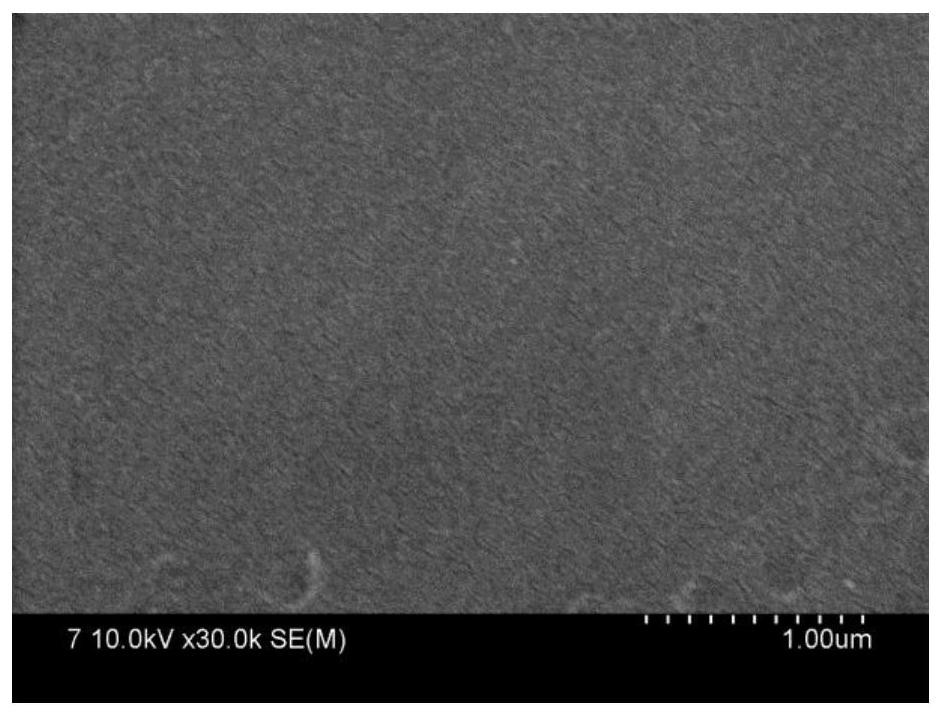

Nanofiltration membrane for extracting lithium from salt lake as well as preparation method and application of nanofiltration membrane

ActiveCN114177775AEfficient separationSimple preparation processMembranesReverse osmosisAdsorption effectMagnesium ion

The invention discloses a nanofiltration membrane based on membrane separation-adsorption synergistic salt lake lithium extraction and a preparation method and application thereof, a polyimide nanofiltration membrane is modified in situ by using an amino polymer one-step method through an immersion precipitation phase inversion technology, and a loose polyimide nanofiltration membrane with positive electricity is prepared. And fixing the lithium ion sieve adsorbent on the support layer of the loose polyimide nanofiltration membrane through a dead-end filtration technology, wherein the average pore size of the finally obtained nanofiltration membrane for extracting lithium from the salt lake is less than 1t. The composite material prepared by the preparation method has excellent retention performance on magnesium ions and has specific adsorption and permeation effects on lithium ions, so that the permeation rate of the lithium ions is improved. Therefore, the screening effect of the nanofiltration membrane is cooperated with the adsorption effect of the lithium ion sieve adsorbent, so that the magnesium-lithium separation efficiency is greatly improved; in addition, the nanofiltration membrane for extracting lithium from the salt lake is simple in preparation process, has more stable lithium extraction efficiency, and can be widely applied to but not limited to the fields of seawater, geothermal water and salt lake brine.

Owner:江苏巨之澜科技有限公司

High-temperature-condensed-water oil removing technology

ActiveCN105923804AImprove throughputStrong anti-pollutionWater/sewage treatmentMultistage water/sewage treatmentActivated carbon filtrationWater quality

The invention provides a high-temperature-condensed-water oil removing technology. The high-temperature-condensed-water oil removing technology comprises a carrier-type membrane assembly filtering stage and an active carbon filter oil removing stage and includes the specific following steps that 1, high-temperature condensed water is injected into a carrier-type membrane assembly from a raw water tank through a circulating pump; 2, the carrier-type membrane assembly filtering stage is carried out in a cross flow filtration mode, wherein the membrane face flow speed is 0.1 m / s to 5 m / s, the transmembrane pressure difference is 0.01 MPa to 0.3 MPa, the filtering accuracy of the membrane assembly is 0.001 micron to 100 microns, and the recirculation ratio is 80% to 99%; 3, the active carbon filter oil removing stage is carried out in a dead-end filtration mode, wherein the filtering speed is 3 m / s to 5 m / s. Compared with the existing high-temperature-condensed-water oil removing technology, the high-temperature-condensed-water oil removing technology has the advantages that cost is low, oil removing efficiency is high, and produced water meets the requirement for boiler feedwater and stable in quality.

Owner:ZHEJIANG CATHAYRIPE ENVIRONMENTAL ENG

Outer-layer coating tubular microfiltration membrane as well as preparation method and assembly thereof

PendingCN108043250AHigh strengthSolution to short lifeUltrafiltrationVolumetric Mass DensityProduced water

The invention discloses an outer-layer coating tubular microfiltration membrane. The outer coating tubular microfiltration membrane comprises a macromolecular microporous filter tube, wherein one endof the macromolecular microporous filter tube is sealed, and only the outer layer and micropores of the macromolecular microporous filter tube are coated with tubular microfiltration membranes adopting an anchored structure. The outer-layer coating tubular microfiltration membrane has the advantages of high strength, long service life, high filling density and the like. An assembly of the outer-layer coating tubular microfiltration membrane is operated in external pressure type and dead-end filtration manners, the proportion of concentrated water to produced water can be adjusted, backwashingand aeration can be conducted periodically, the chemical cleaning cycle of the membrane assembly can be prolonged, and the energy consumption and the wastewater treatment cost can be reduced.

Owner:SUZHOU KAHO POLYMER TECH CO LTD

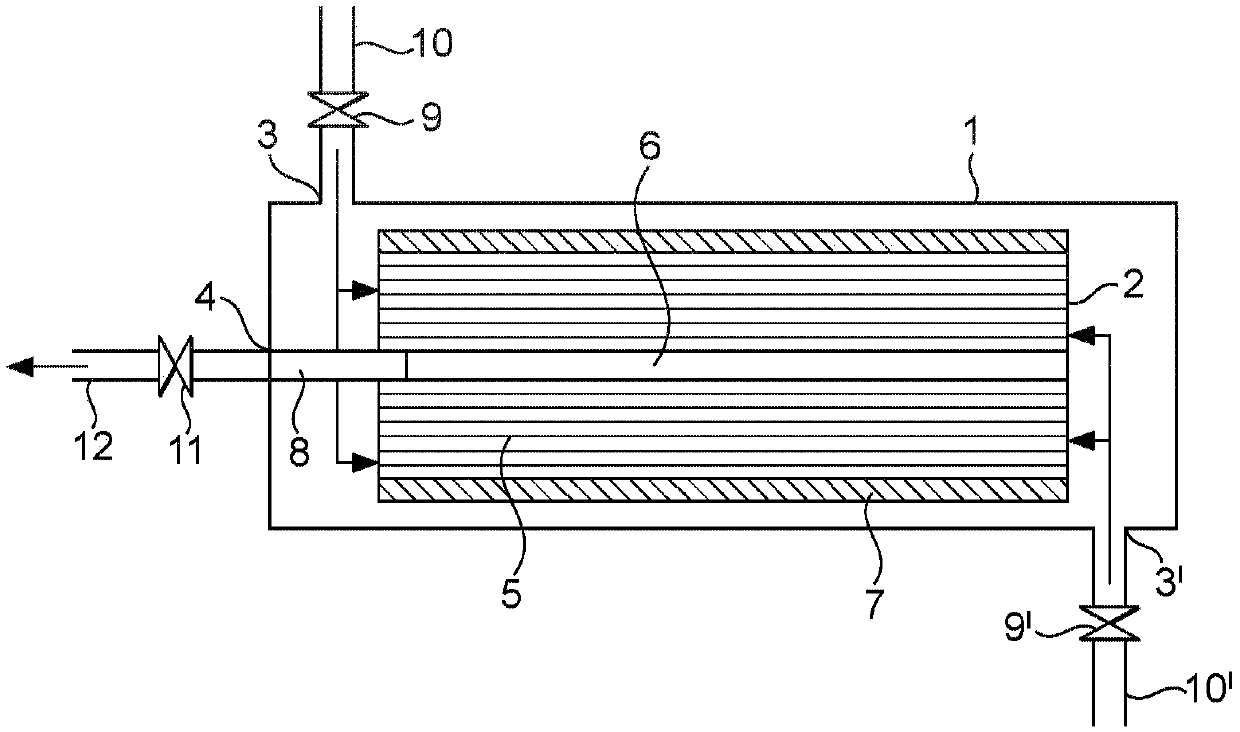

Anti-pollution electrocatalysis composite membrane and membrane reactor

ActiveUS9162905B2Improve antifouling performanceImprove electrocatalytic activitySemi-permeable membranesMembranesElectrolysisConductive coating

The present invention relates an antifouling electrocatalytic composite membrane and a membrane reactor. The electrocatalytic composite membrane (3) consists of a substrate and a catalytic coating, wherein the substrate is selected from a conductive substrate or a nonconductive substrate coated with a conductive coating, and the substrate is a porous support having supporting, conducting and separating functions. The catalytic coating is supported or coated on the surface and in the pores of the conductive substrate or the conductive coating so as to increase the electrocatalytic activity of the substrate. The membrane reactor provides a trans-membrane pressure as the membrane separation power generated by a pump (7) and dead-end filtration or cross-flow filtration is applied, then the feed liquid permeates through the membrane from one side to the other to achieve the separation of the liquid; meanwhile, an electrocatalytic composite membrane (3) as anode and an auxiliary electrode (4) as cathode are connected to a power supply (1) separately by conducting wires (2) so that an electrolysis apparatus is formed. The electrocatalytic composite membrane (3) has a self-cleaning function and achieves the pollution-free operation during the membrane separation.

Owner:TIANJIN POLYTECHNIC UNIV

Detachable ultrafiltration filter

InactiveCN105771659AImprove athletic abilityReduce foulingUltrafiltrationWater/sewage treatment bu osmosis/dialysisWater dischargeChinese characters

The invention relates to a detachable ultrafiltration filter, belonging to the technical field of water treatment equipment. The detachable ultrafiltration filter comprises an ultrafiltration tank, a membrane head and ultrafiltration membrane filaments, wherein the membrane head is fixedly arranged on the inner wall of the ultrafiltration tank, and divides the inner cavity of the ultrafiltration tank into a water producing cavity and a water inlet cavity, and the ultrafiltration membrane filaments are arranged in the water inlet cavity in a filamentous shape. The ultrafiltration membrane filament is of a structure shaped like a Chinese character hui in a disturbed state, so that the moveability of the membrane filaments is improved, the membrane surface scaling is reduced, and membrane filament sewage blocking is reduced. The detachable ultrafiltration filter adopts a dead-end filtration way, and a concentrated water discharge port is not arranged, so that the problem that the membrane operating pressure change is large can be avoided; a pressure control valve is not needed, so that the structure is simple and the operation is convenient.

Owner:浙江至美环境科技有限公司

Green and safe wastewater treatment method for methyl tin mercaptide

InactiveCN105967368ASemi-permeable membranesTin organic compoundsActivated carbon filtrationAqueous solution

The invention relates to a wastewater treatment method for organic tin substances, in particular to a green and safe wastewater treatment method for methyl tin mercaptide. The green and safe wastewater treatment method comprises the following steps: (1) performing tin mineralization; (2) synthesizing, namely, adding an obtained methyl tin chloride aqueous solution into isooctyl thioglycolate, adding a second catalyst, stirring for a reaction for 0.2-0.4 hour at 5-15 DEG C, further adding an alkali liquid, continuously stirring for a reaction till the pH value of the reaction system is 7-9, and heating to 60-70 DEG C for a reaction; (3) washing with water; (4) distilling. A process for treating wastewater generated in the preparation process comprises a carrier type membrane module filtering procedure and an activated carbon filter oil removing procedure. The process comprises the following steps: (1) feeding the wastewater into a carrier type membrane module via a circulation pump from a raw water tank; (2) implementing the carrier type membrane module filtering procedure in a cross flow filtration mode; (3) implementing the activated carbon filter oil removing procedure in a dead end filtration mode. The wastewater treatment method provided by the invention has the advantages of low cost and high treatment efficiency.

Owner:ANHUI SHENGHUA XINAOTE CHEM CO LTD

Self-cleaning and filtering device and filtering method thereof

PendingCN108744655AEfficient self-cleaningAchieve compactionStationary filtering element filtersSludgeEngineering

The invention combines the advantages of cross flow filtration and dead end filtration, an intercepted material is concentrated along the flowing direction of a solution, and is enriched at the top ofa filter; then the principle that a vacuum is created after the concentrated solution is emptied and then a flexible filtering material (cloth bag) is shrunk and pressed flat is combined, and the sludge in the filter is compacted and falls off under the effect of gravity. Therefore, the filter is efficiently self-cleaned.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Method of filtration and backwashing using hollow fibre membrane elements

A method of operating a filtration unit comprising a filtration vessel containing at least one dead-end filtration element, the or each filtration element comprised of a plurality of hollow fibre microfiltration or ultrafiltration membranes wherein: during filtration, feed water containing suspended particulate material is fed simultaneously to the inside of the hollow fibres through both ends thereof and filtrate is removed from the outside of the hollow fibres through an outlet of the filtration element(s); and during back-washing, back-wash water is fed to outside of the hollow fibres through the outlet of the filtration element(s) and, in a first back-wash cycle, back-wash water containing entrained particulate material is discharged from the inside of the hollow fibres from one end thereof; and, in a second back-wash cycle, back-wash water containing entrained particulate material is discharged from the inside of the hollow fibres from the other end thereof; and wherein the firstand second back-wash cycles may be performed in either order.

Owner:BP EXPLORATION OPERATING CO LTD

Immersed screen and method of operation

Owner:GENERAL ELECTRIC CO

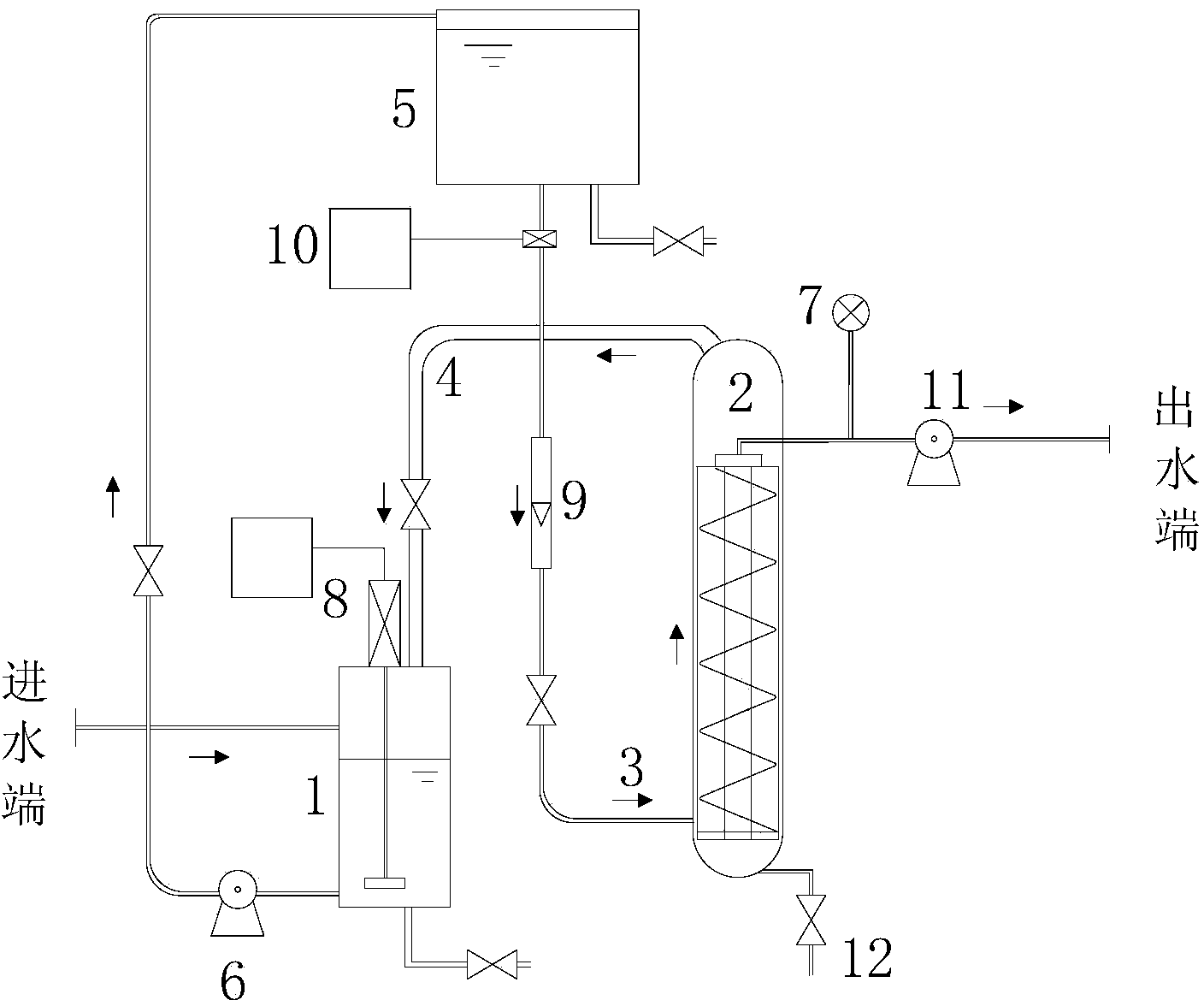

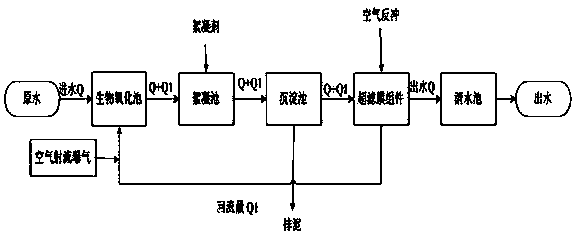

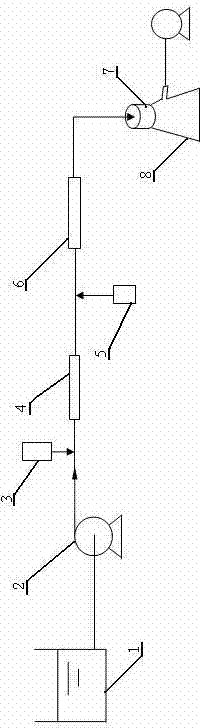

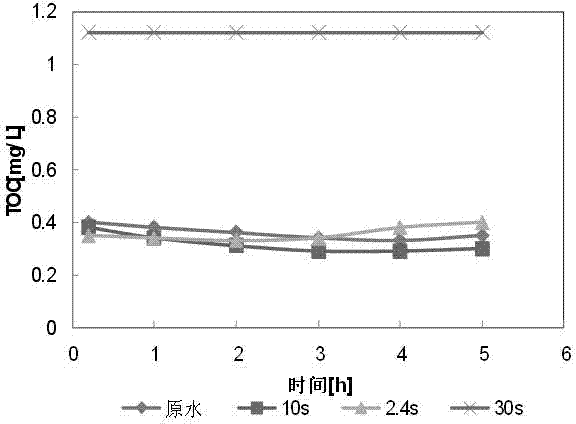

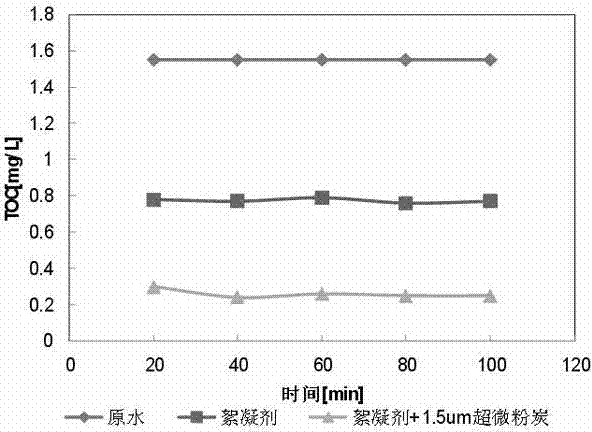

Microfiltration water inlet ultrafine powder activated carbon pretreatment method

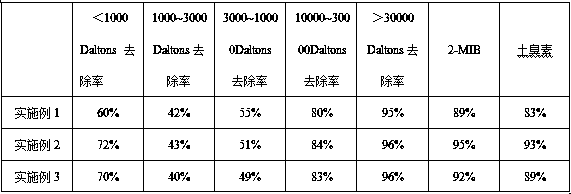

InactiveCN103803742AHigh removal rateMultistage water/sewage treatmentPretreatment methodEnvironmental engineering

The invention discloses a microfiltration water inlet ultrafine powder activated carbon pretreatment method which comprises the following steps: mixing inflow water in a feeding tank (1) with 1.5um ultrafine powder activated carbon from an activated carbon storage tank (3) in a tubular reactor (4) for 10 seconds through a feeding pump (2), and adding a flocculating agent polyaluminium chloride from a flocculating agent tank (5); mixing through a static mixer (6), entering a ceramic film dead-end filter, and obtaining contributing water, wherein the addition amount of the ultrafine powder carbon is 5mg / L, and the addition amount of the polyaluminium chloride is 3.5mg-Al / L; the flow of the inflow water is kept to be 60L / (m2.h). After the microfiltration inflow water is pretreated by adopting the method, the removal rate of TOC is 82 percent, and after the inflow water treated by powdered activated carbon treatment is subjected to microfiltration, the removal rate of TOC is 50 percent. The removal rate of TOC in the inflow water subjected to ultrafine powder activated carbon pretreatment is obviously increased.

Owner:XUCHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com