Sawing and grinding wastewater ultrafiltration membrane (UF)-recovery and treatment system

A technology for grinding wastewater, recycling and treatment, applied in the direction of osmosis/dialysis water/sewage treatment, etc., which can solve the problems of high installation cost, complicated equipment, and difficult treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

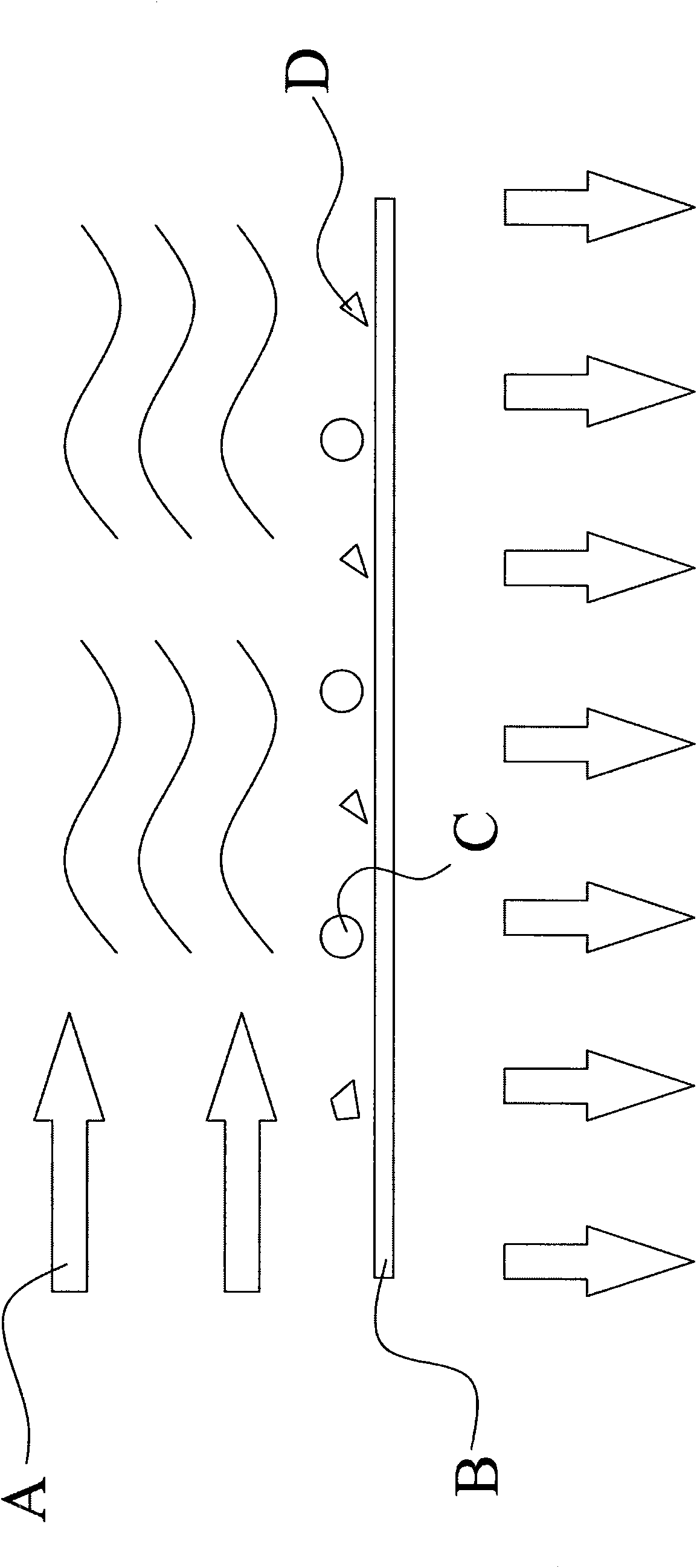

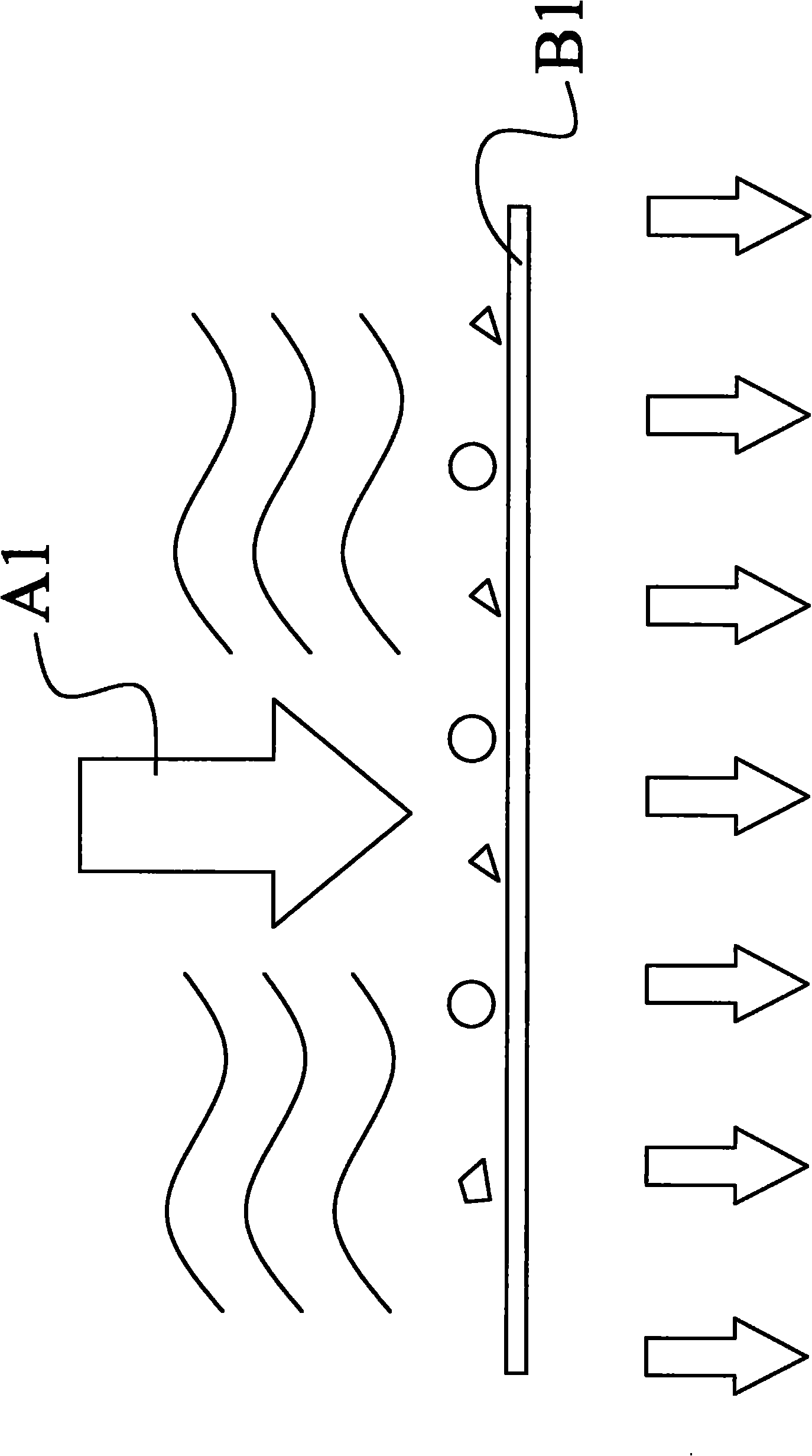

[0027] The UF recovery and treatment system of the cutting and grinding wastewater of the present invention, such as figure 2 As shown, the cutting and grinding waste water is filtered by a dead-end filter system. The full-flow filter system is vertical to the water inlet direction A1 and the UF membrane B1, and cooperates with regular automatic water washing, air washing and chemical washing. The mechanism maintains a better filtration state of the UF membrane, which can increase the recovery rate of wastewater to more than 90%.

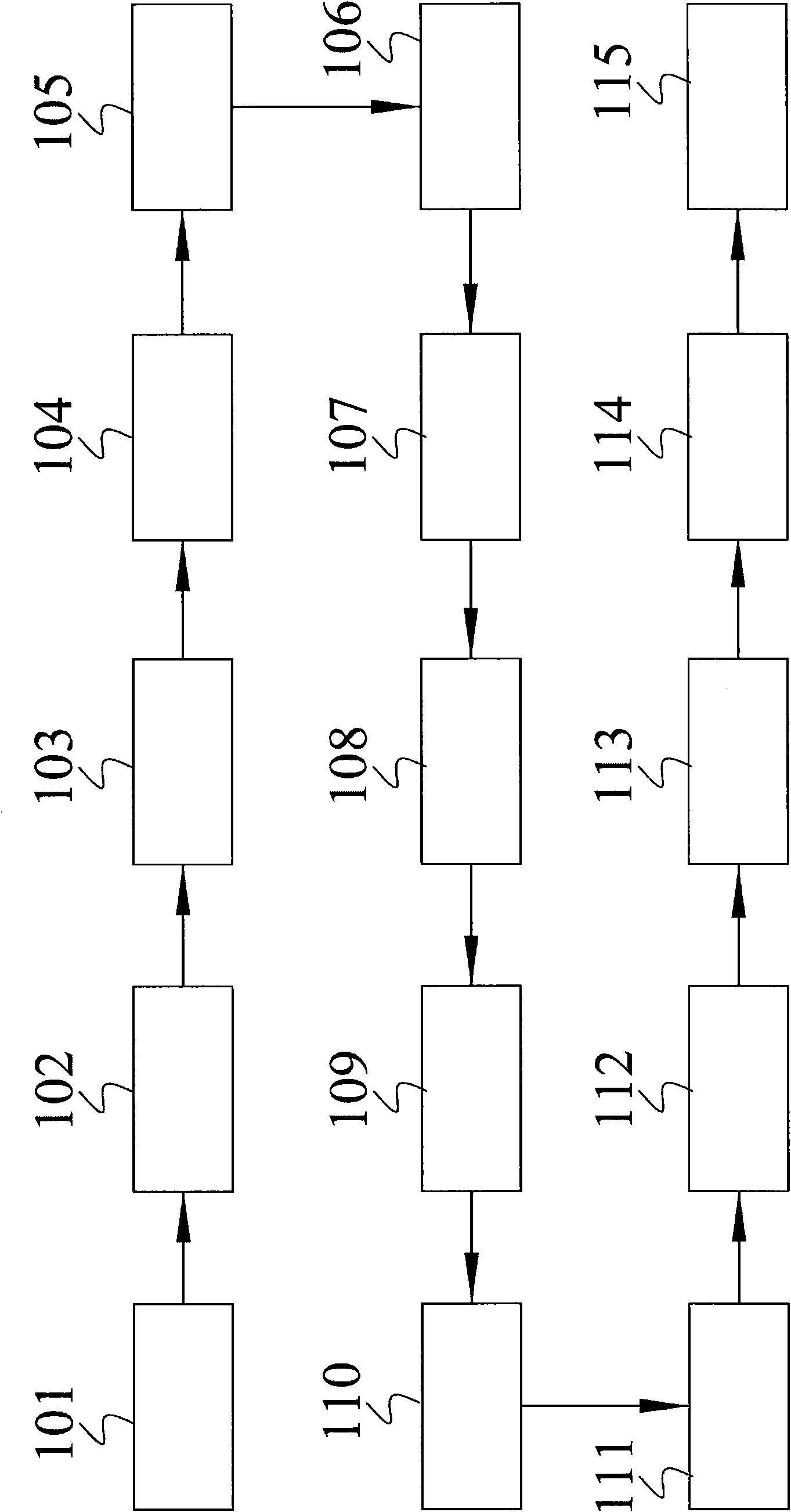

[0028] The UF recovery and treatment system of the cutting and grinding wastewater of the present invention, such as image 3 As shown, the UF recovery treatment system includes: cutting waste water recovery storage tank 100, grinding waste water recovery storage tank 101, self-priming barrel 102, UF water inlet pump 103, primary filter module 104, CDA buffer tank 105, UF filter 106, UF Produced water storage tank 107, RO water supply pump 108, UF...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com