Method used for purifying slightly polluted drinking water

A drinking water treatment and micro-pollution technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low water supply load and poor circulation, and save land occupation area, reduce energy consumption, and ensure biological safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

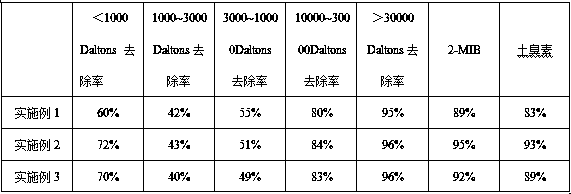

Embodiment 1

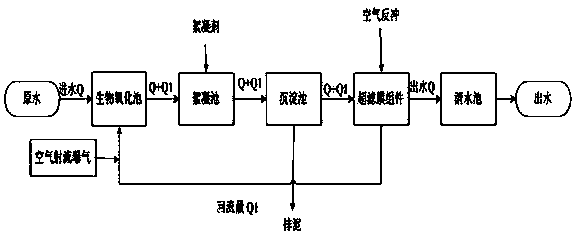

[0029] A treatment process for purifying organic polluted water, the purification process is:

[0030] (1) The raw water enters the biological oxidation tank, and the sludge concentration on the filler is maintained at 2.5KgMLSS / m 2 , The hydraulic retention time is 2h, and the dissolved oxygen is maintained at about 2mg / L;

[0031] (2) The effluent from the biological oxidation tank enters the flocculation tank, the polyaluminum chloride is used as the flocculant, the dosage is 3mg / L, and the flocculation stirring time is 15min;

[0032] (3) The effluent from the flocculation tank enters the inclined tube sedimentation tank with a hydraulic retention time of 1.5h;

[0033] (4) The effluent of the sedimentation tank is pumped into the ultrafiltration membrane equipment for cross-flow ultrafiltration. The membrane flux of the ultrafiltration membrane is 50L / (m) 2 ·H), the backwash intensity is 13 / m 2 ·S, the recoil duration is 5min, and the recoil interval is 3h;

Embodiment 2

[0035] A treatment process for purifying organic polluted water, the purification process is:

[0036] (1) The raw water enters the biological oxidation tank, and the sludge concentration on the filler is maintained at 3KgMLSS / m 2 , The hydraulic retention time is 2h, and the dissolved oxygen is maintained at about 2.5mg / L;

[0037] (2) The effluent from the biological oxidation tank enters the flocculation tank, the polyaluminum chloride is used as the flocculant, the dosage is 3mg / L, and the flocculation stirring time is 15min;

[0038] (3) The effluent from the flocculation tank enters the inclined tube sedimentation tank with a hydraulic retention time of 1.5h;

[0039] (4) The effluent of the sedimentation tank is pumped into the ultrafiltration membrane equipment for cross-flow ultrafiltration. The membrane flux of the ultrafiltration membrane is 50L / (m) 2 ·H), the backwash intensity is 16 / m 2 ·S, the recoil duration is 5min, and the recoil interval is 2h;

Embodiment 3

[0041] A treatment process for purifying organic polluted water, the purification process is:

[0042] (1) The raw water enters the biological oxidation tank, and the sludge concentration on the filler is maintained at 3.5KgMLSS / m 2 , The hydraulic retention time is 2h, and the dissolved oxygen is maintained at about 2.5mg / L;

[0043] (2) The effluent from the biological oxidation tank enters the flocculation tank, the polyaluminum chloride is used as the flocculant, the dosage is 3mg / L, and the flocculation stirring time is 15min;

[0044] (3) The effluent from the flocculation tank enters the inclined tube sedimentation tank with a hydraulic retention time of 1.5h;

[0045] (4) The effluent of the sedimentation tank is pumped into the ultrafiltration membrane equipment for cross-flow ultrafiltration. The membrane flux of the ultrafiltration membrane is 50L / (m) 2 ·H), the backwash intensity is 16 / m 2 ·S, the recoil duration is 5min, and the recoil interval is 1.5h;

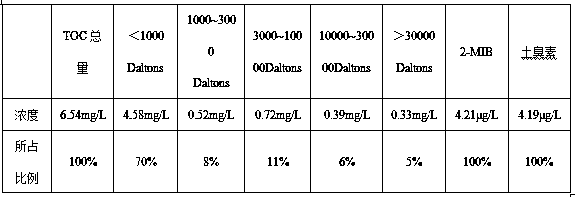

[0046] The results...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com