Patents

Literature

93 results about "No removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

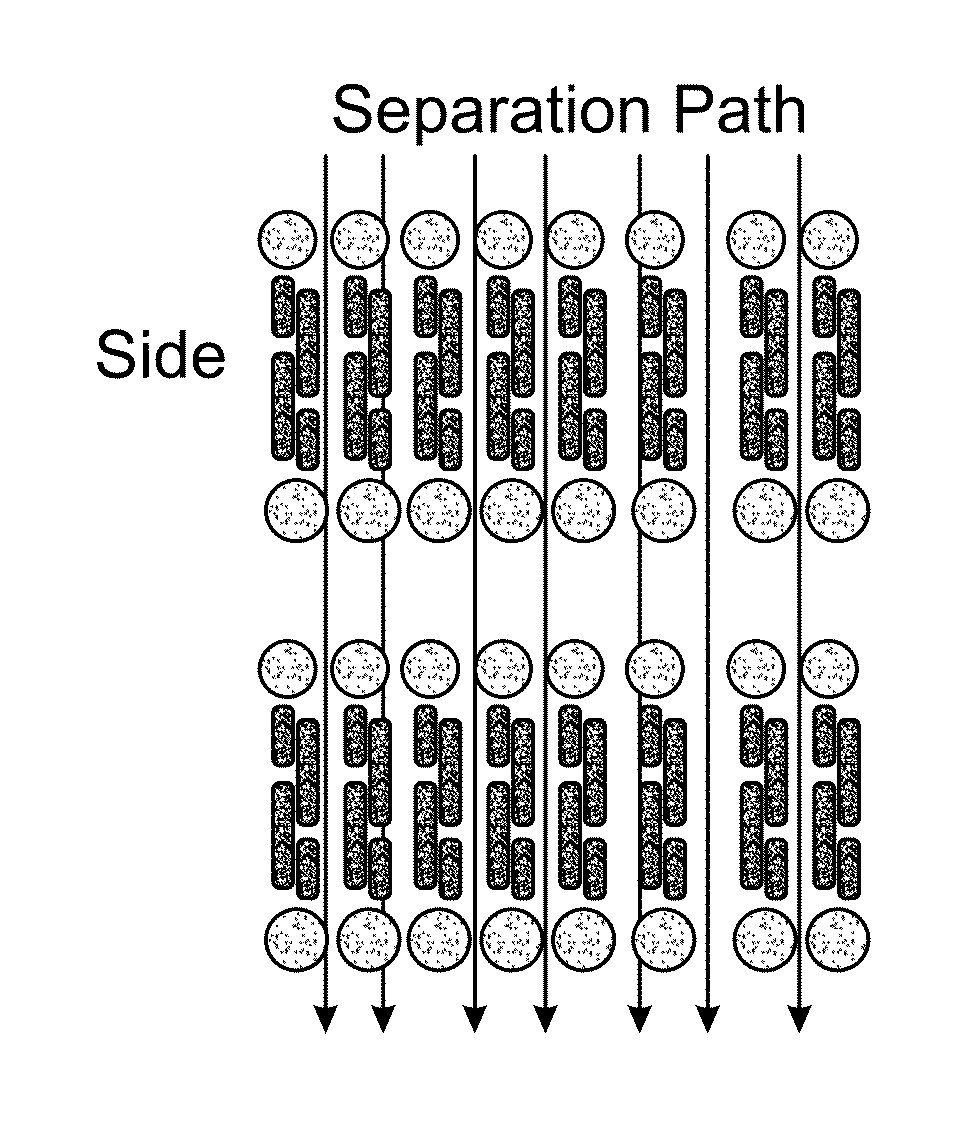

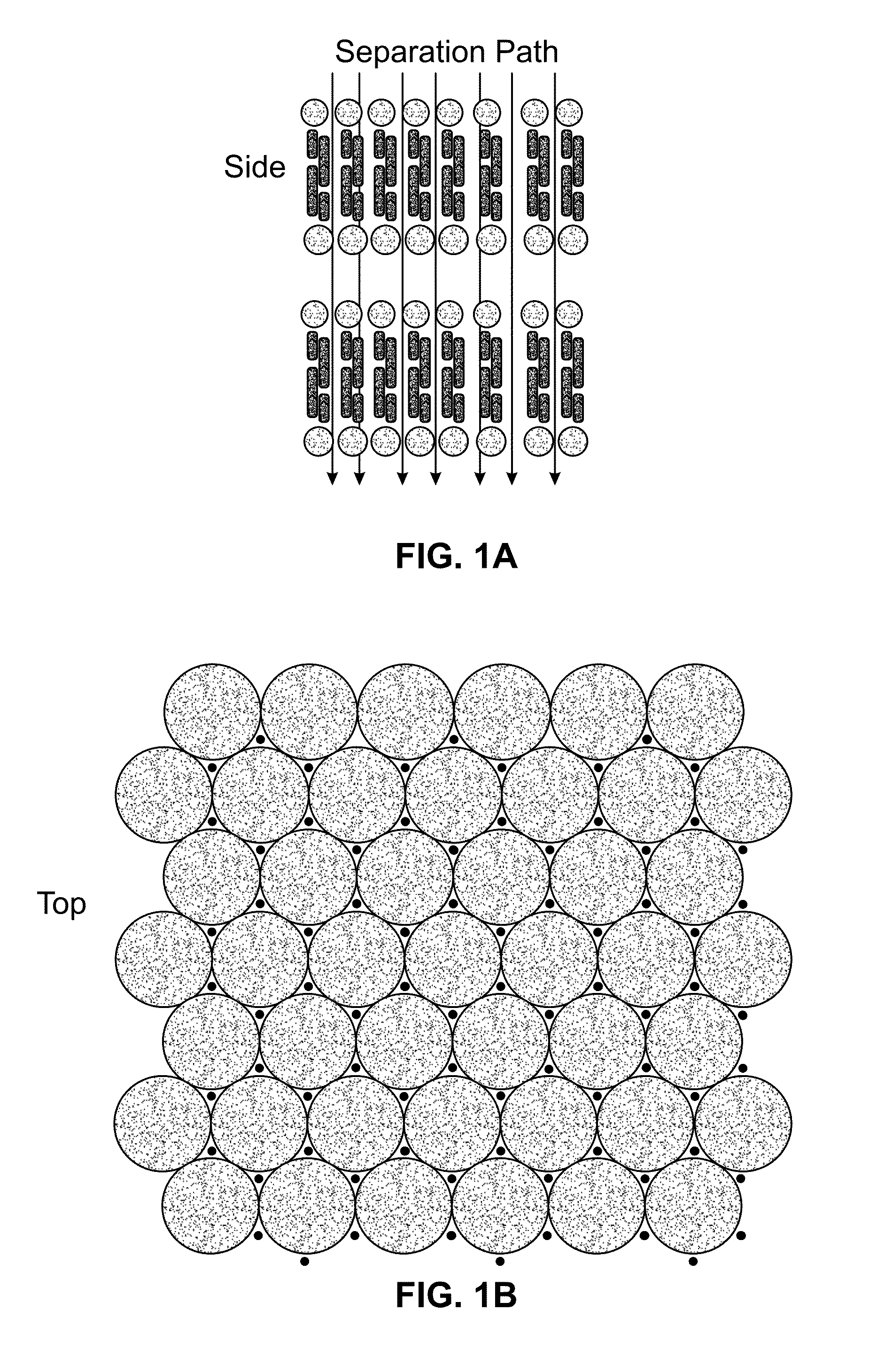

Self-Assembled Surfactant Structures

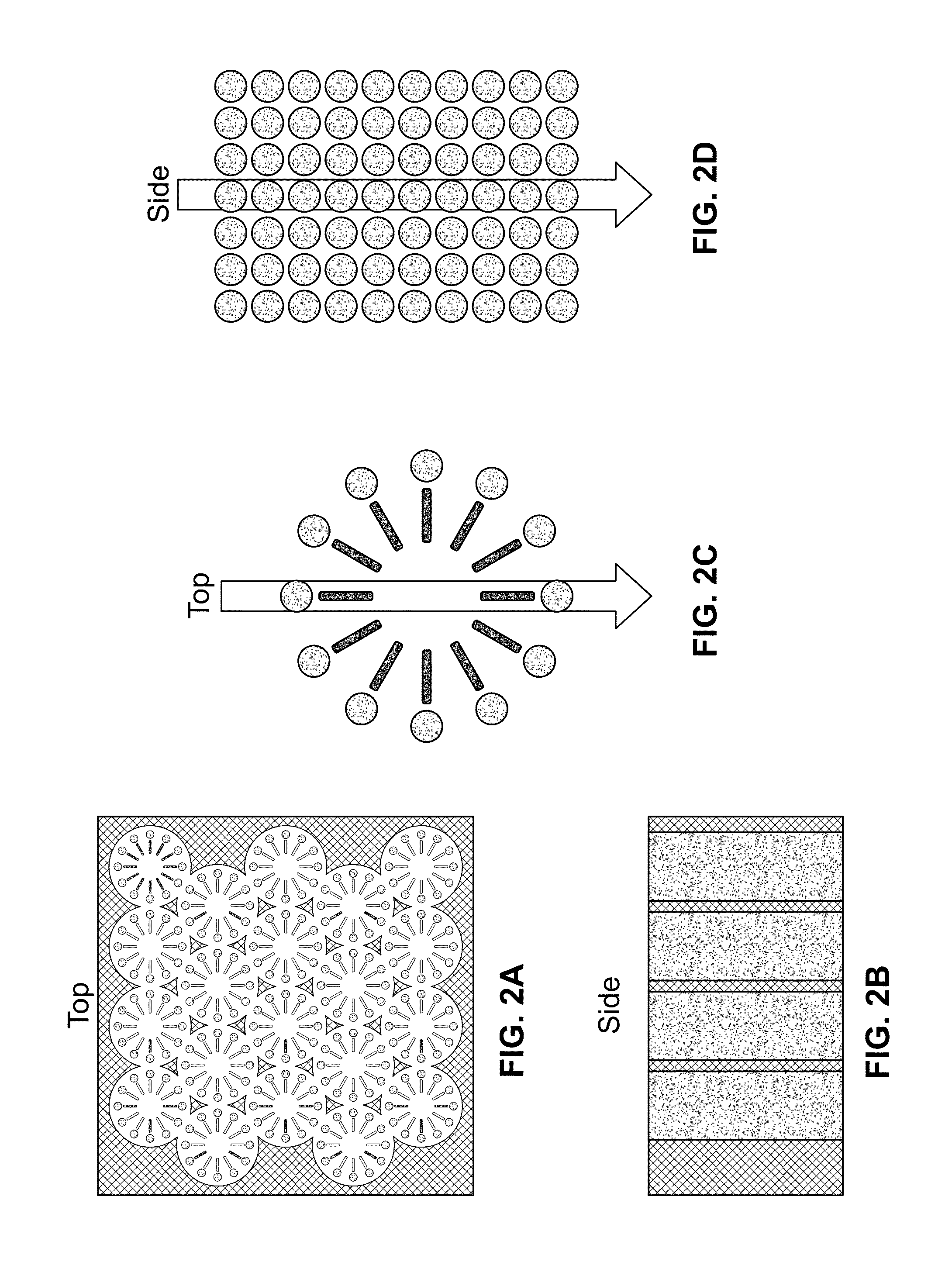

ActiveUS20110284456A1Small apertureSolid electrolytesSemi-permeable membranesEvaporationSpiral wound

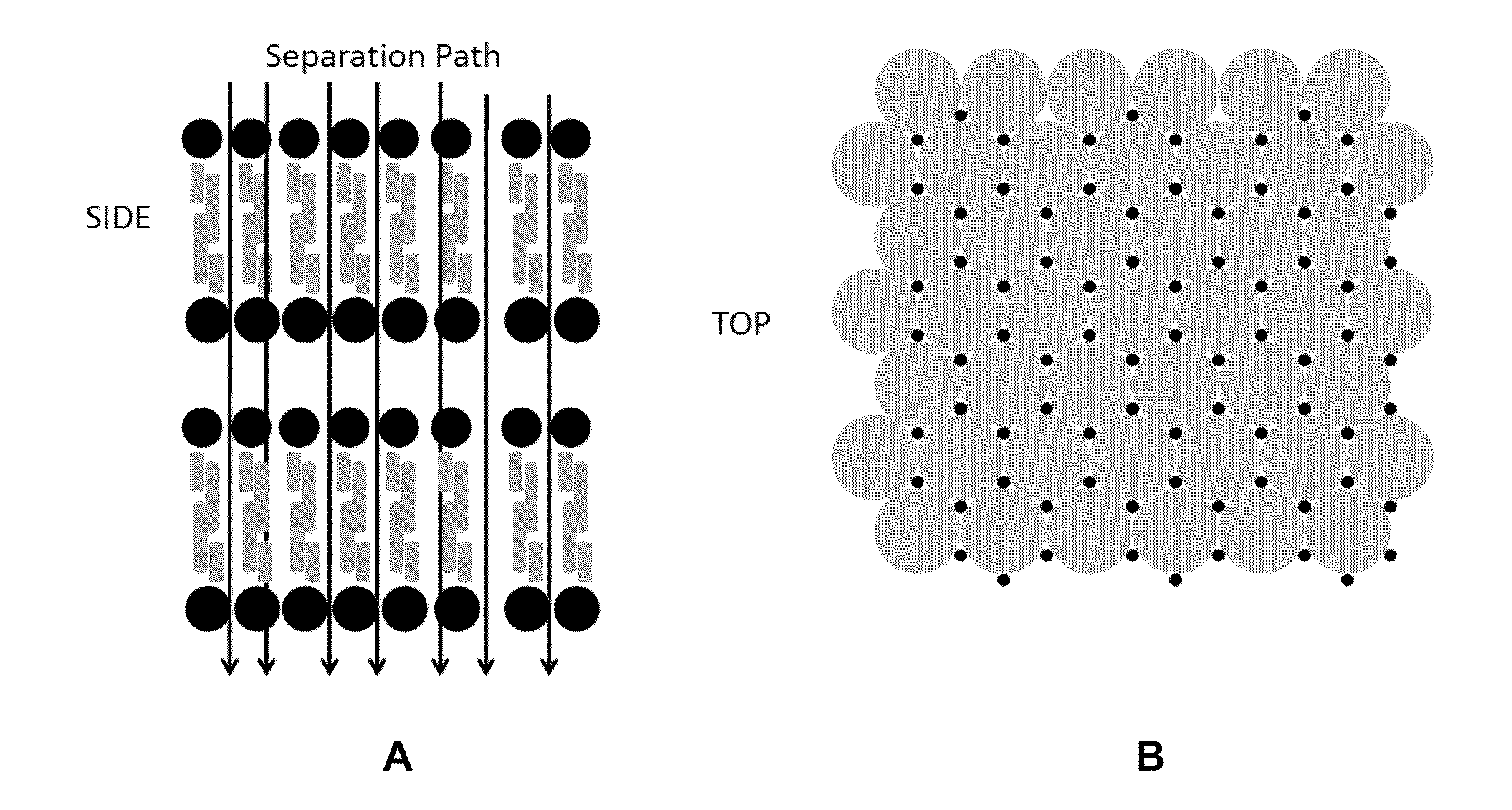

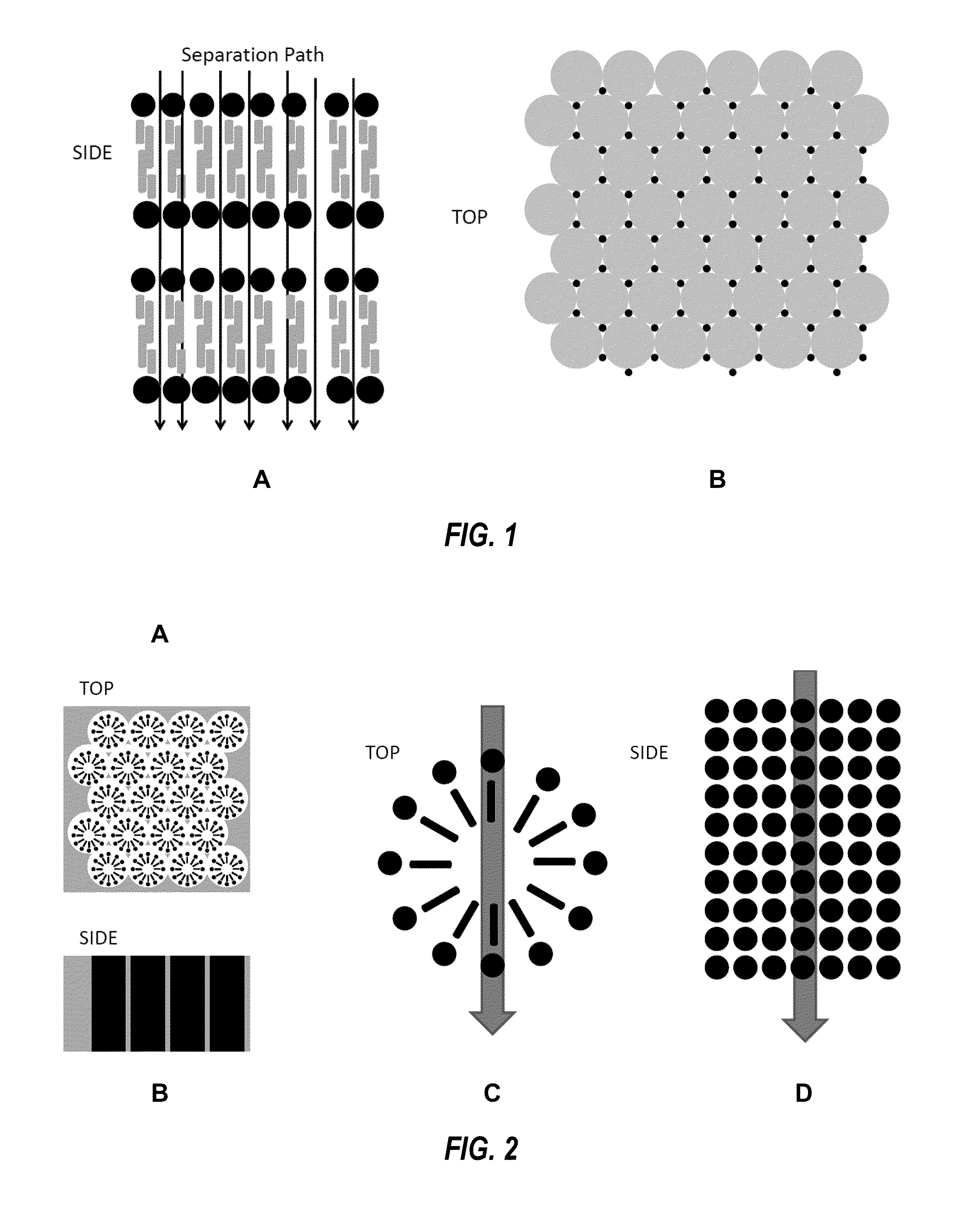

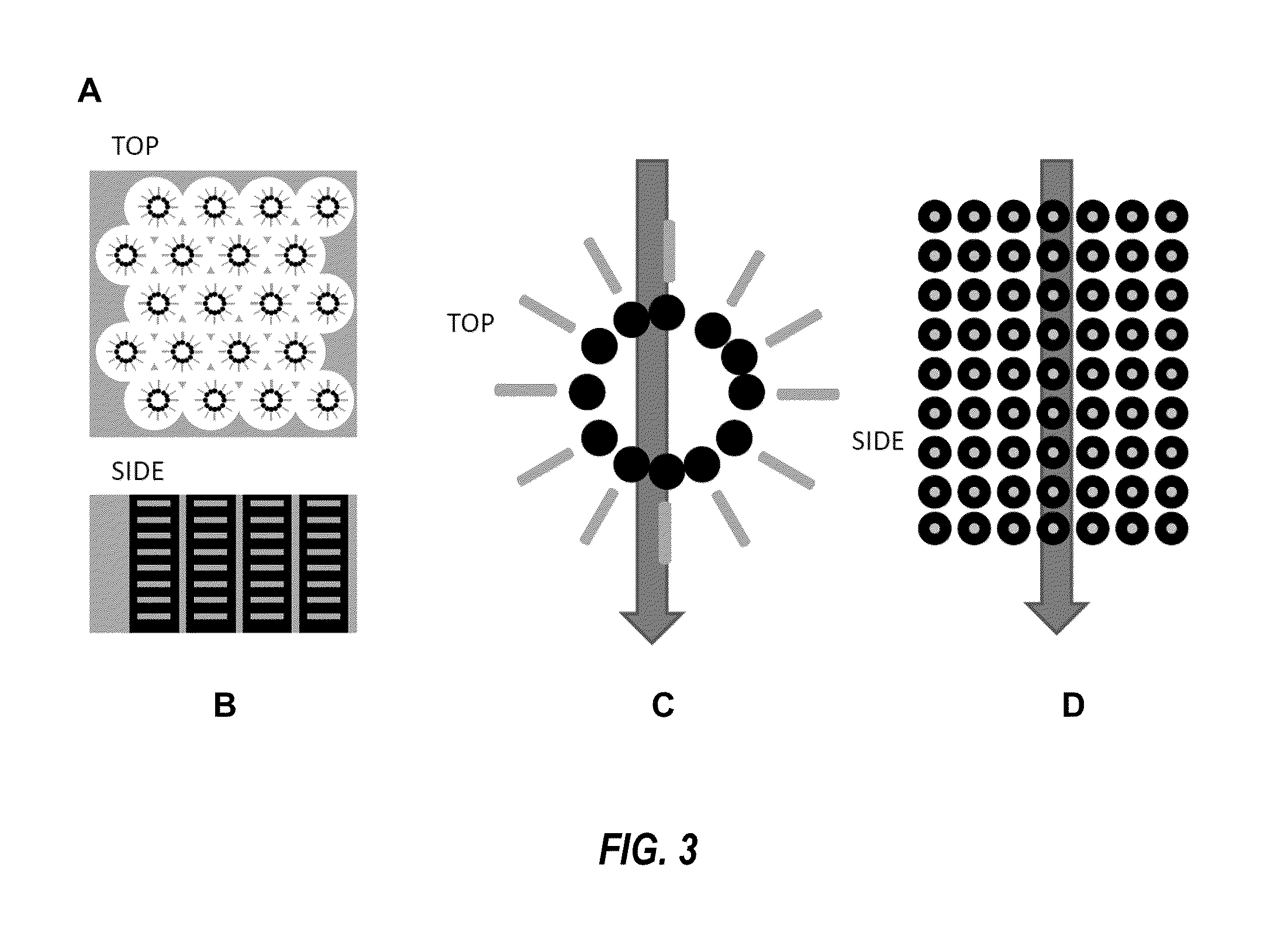

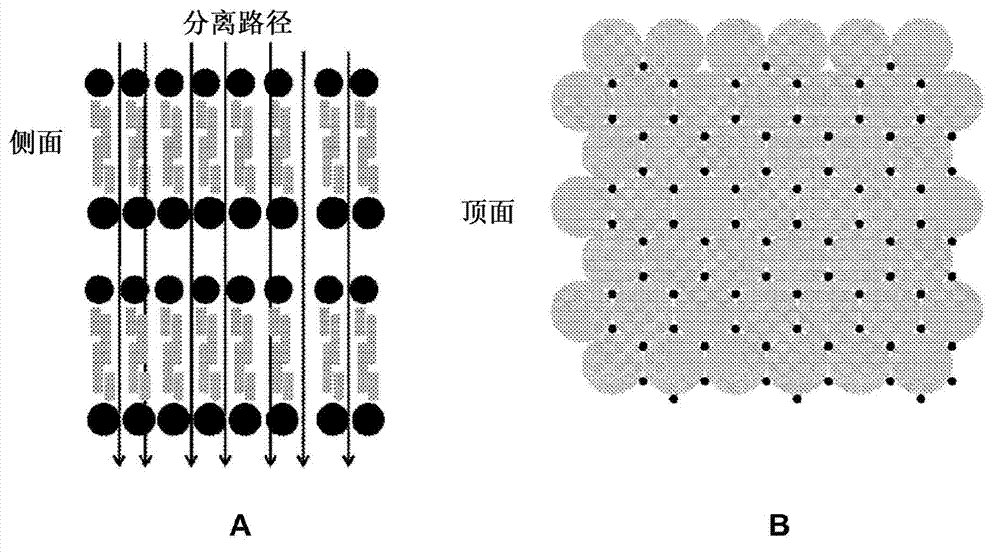

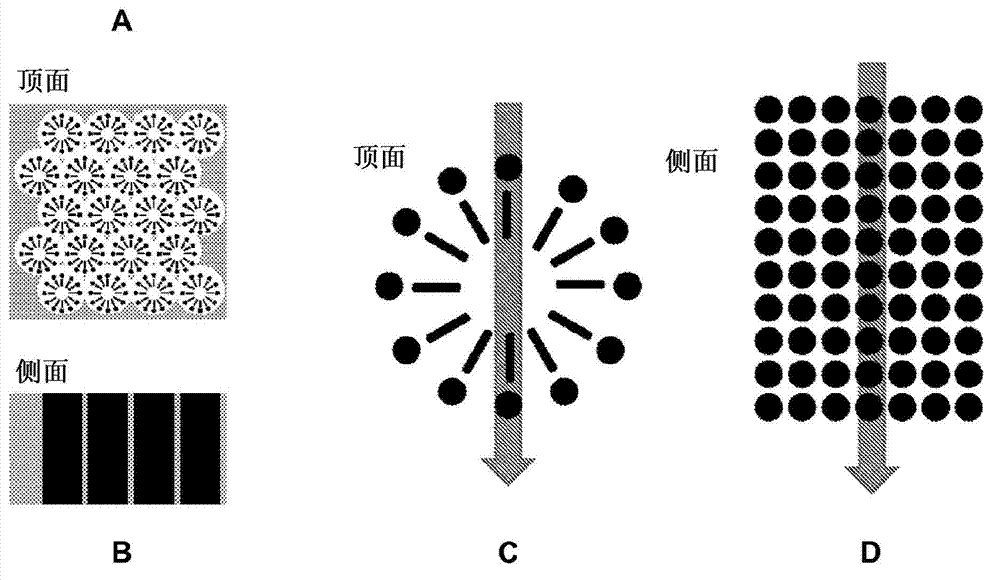

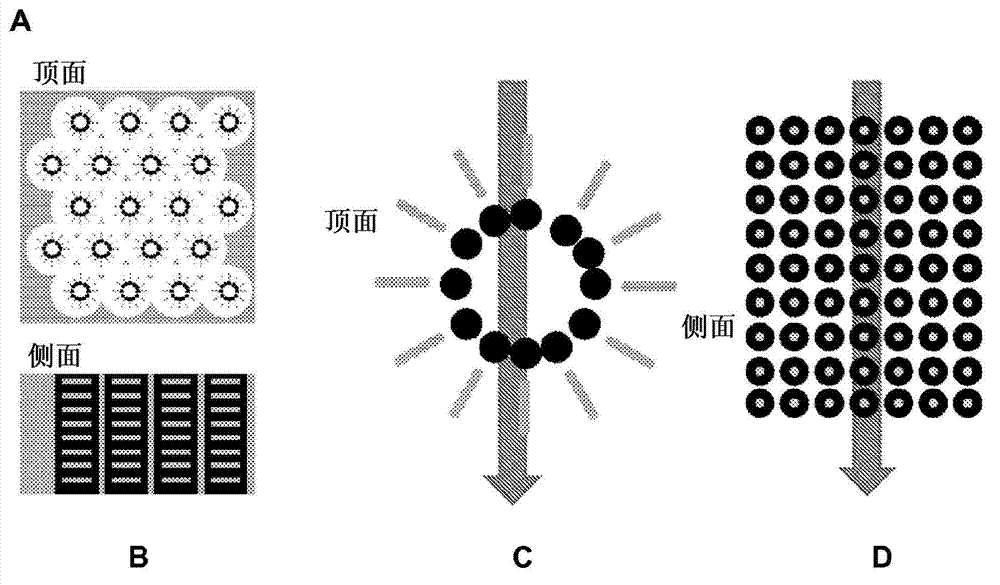

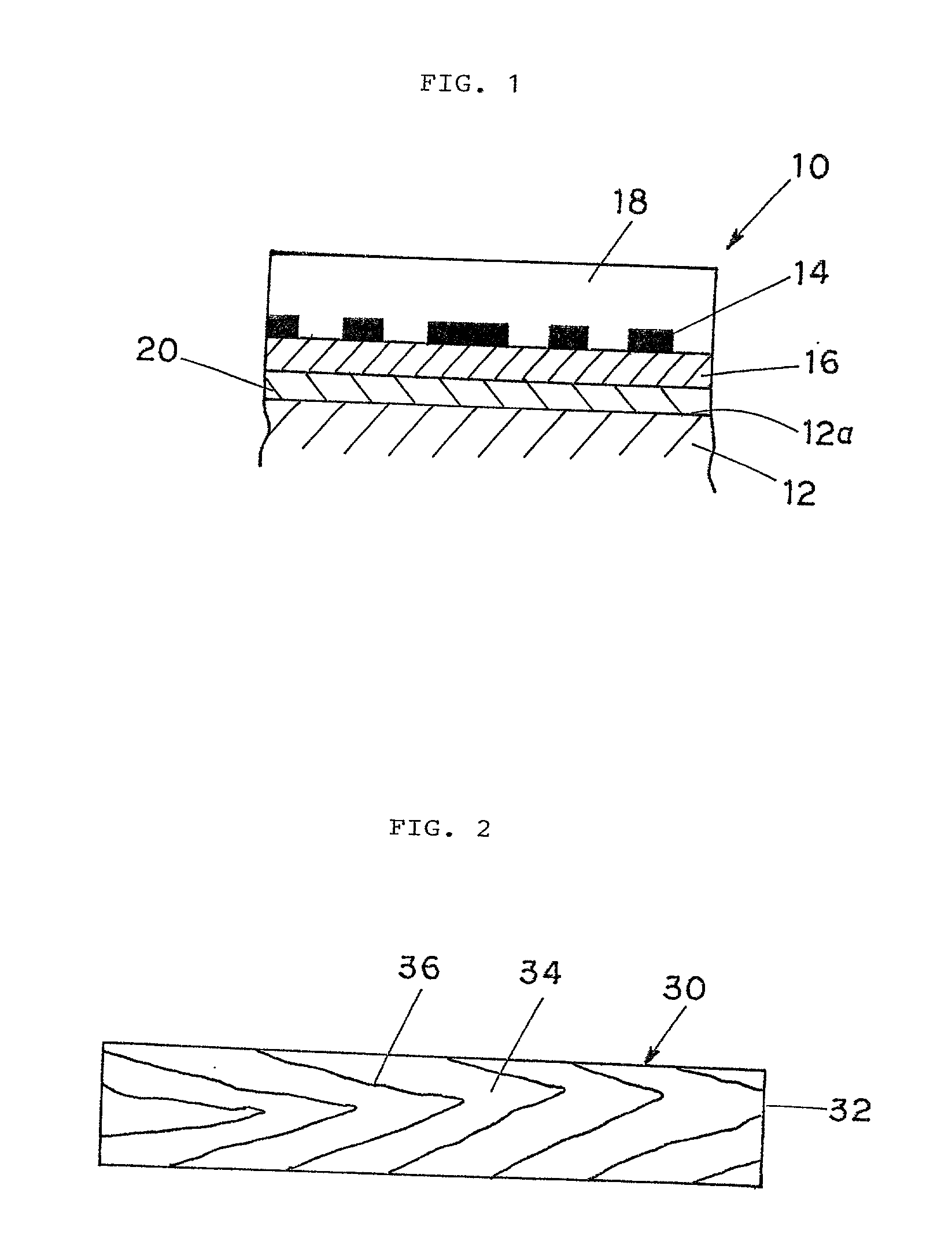

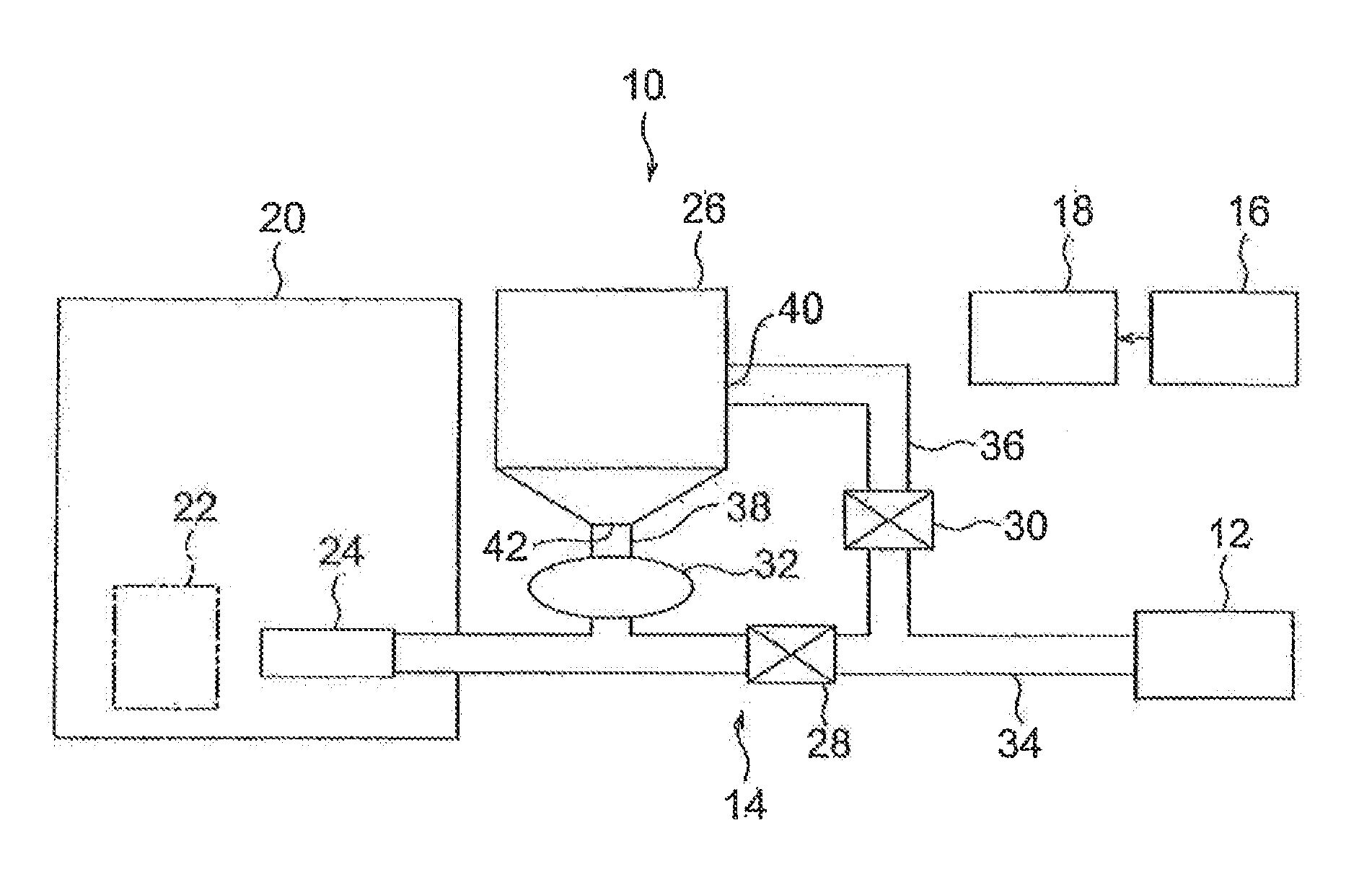

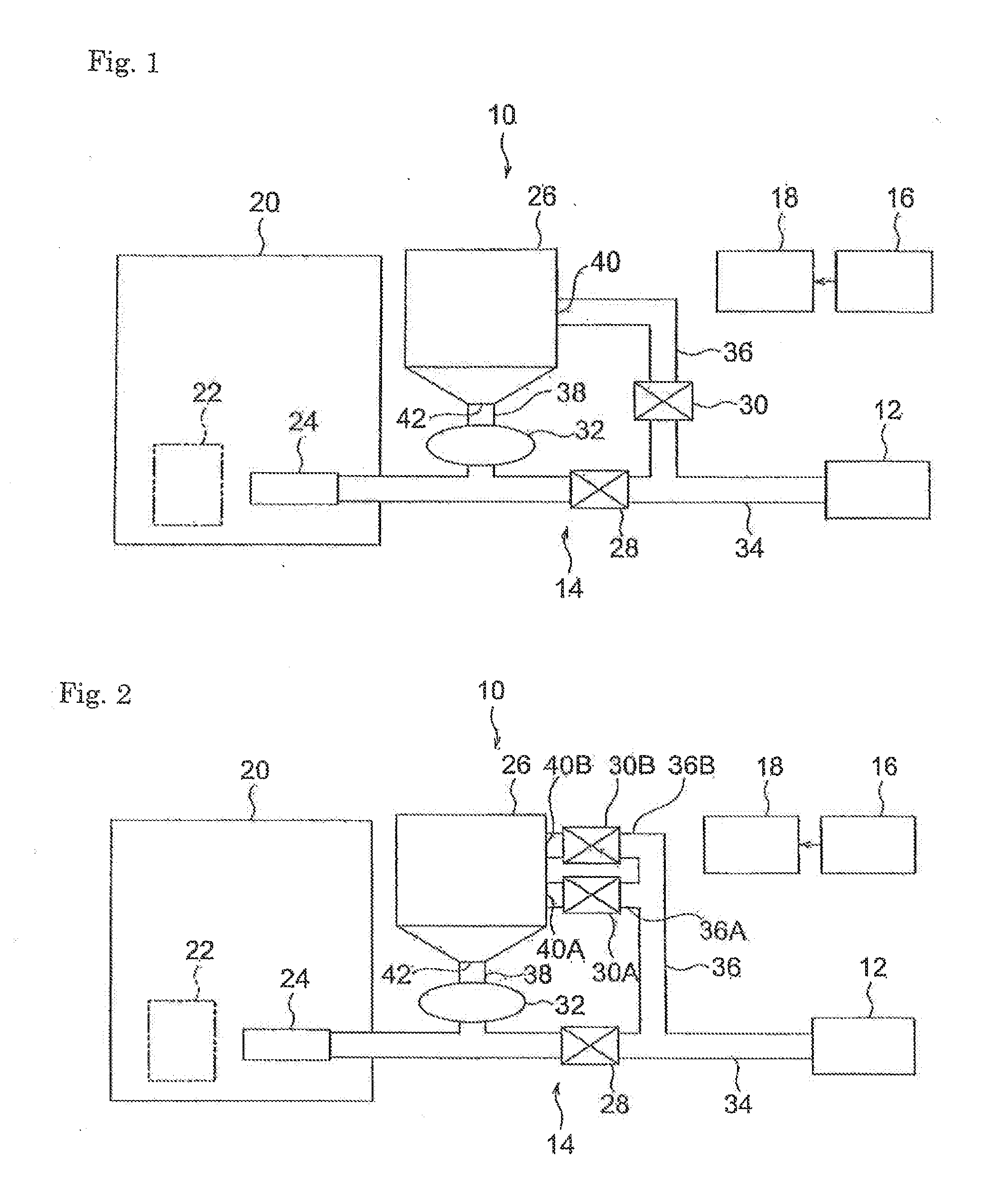

Stabilized surfactant-based membranes and methods of manufacture thereof. Membranes comprising a stabilized surfactant mesostructure on a porous support may be used for various separations, including reverse osmosis and forward osmosis. The membranes are stabilized after evaporation of solvents; in some embodiments no removal of the surfactant is required. The surfactant solution may or may not comprise a hydrophilic compound such as an acid or base. The surface of the porous support is preferably modified prior to formation of the stabilized surfactant mesostructure. The membrane is sufficiently stable to be utilized in commercial separations devices such as spiral wound modules.

Owner:ZNANO LLC +1

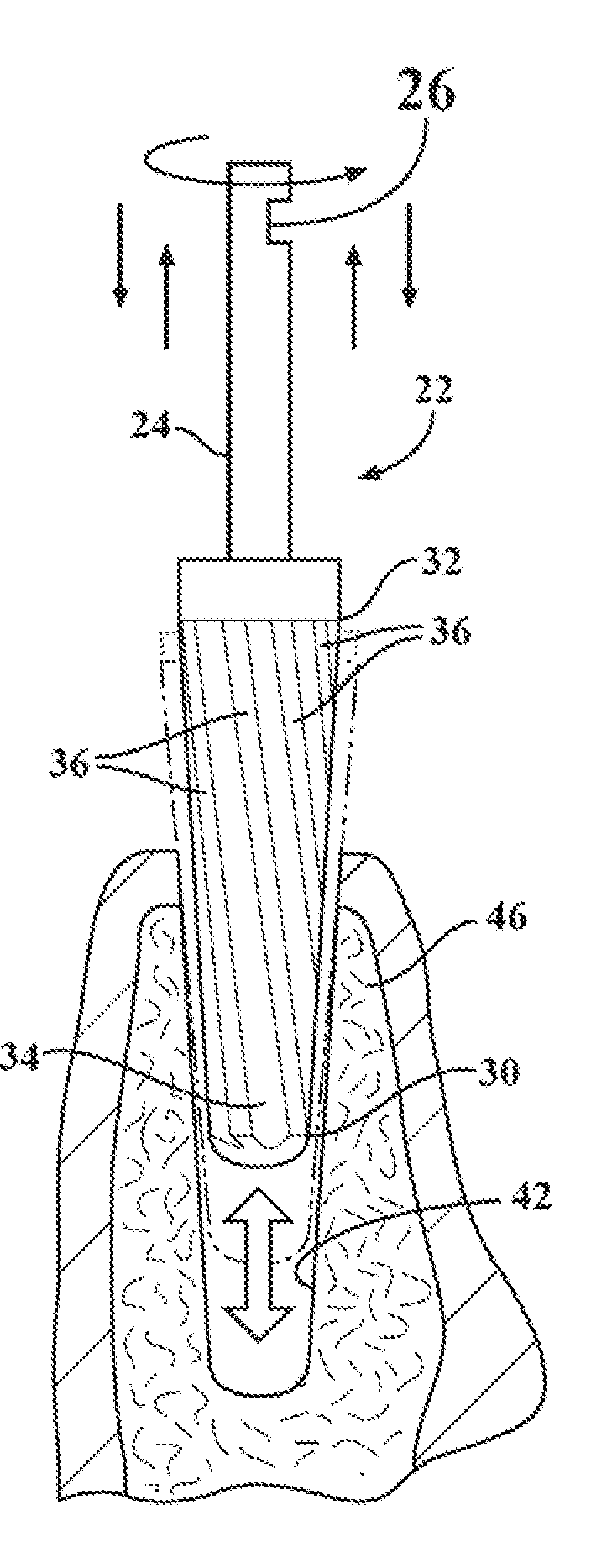

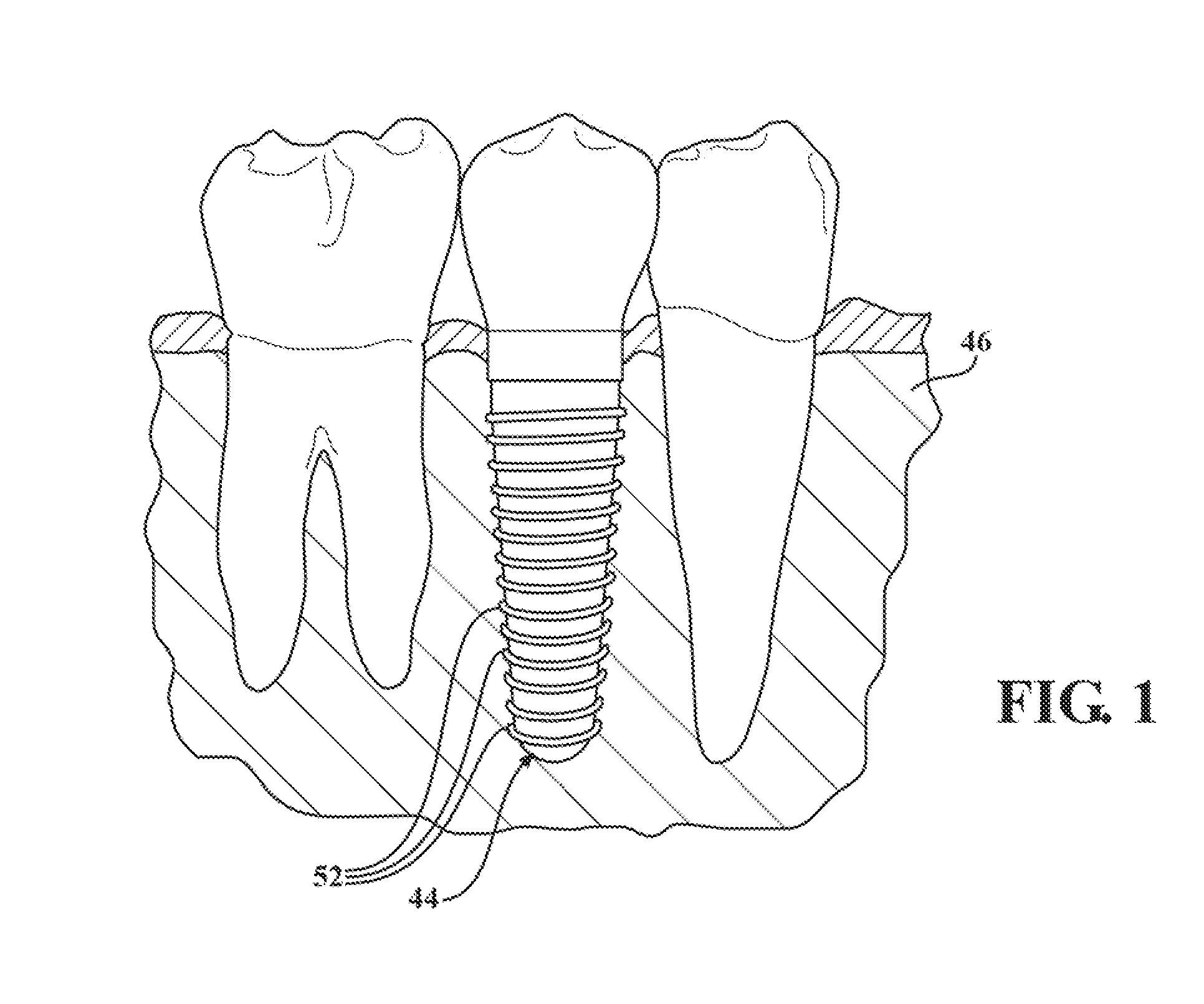

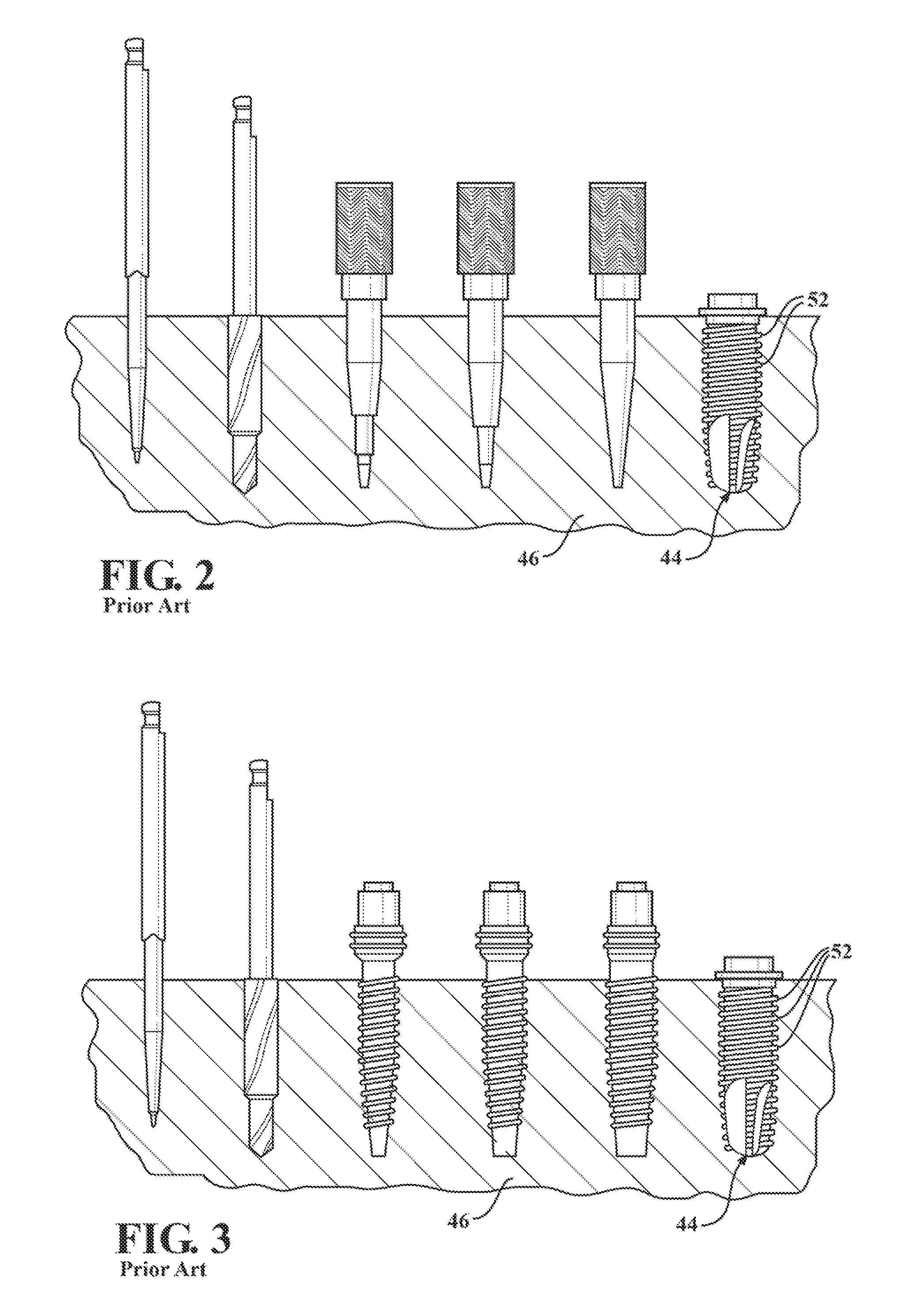

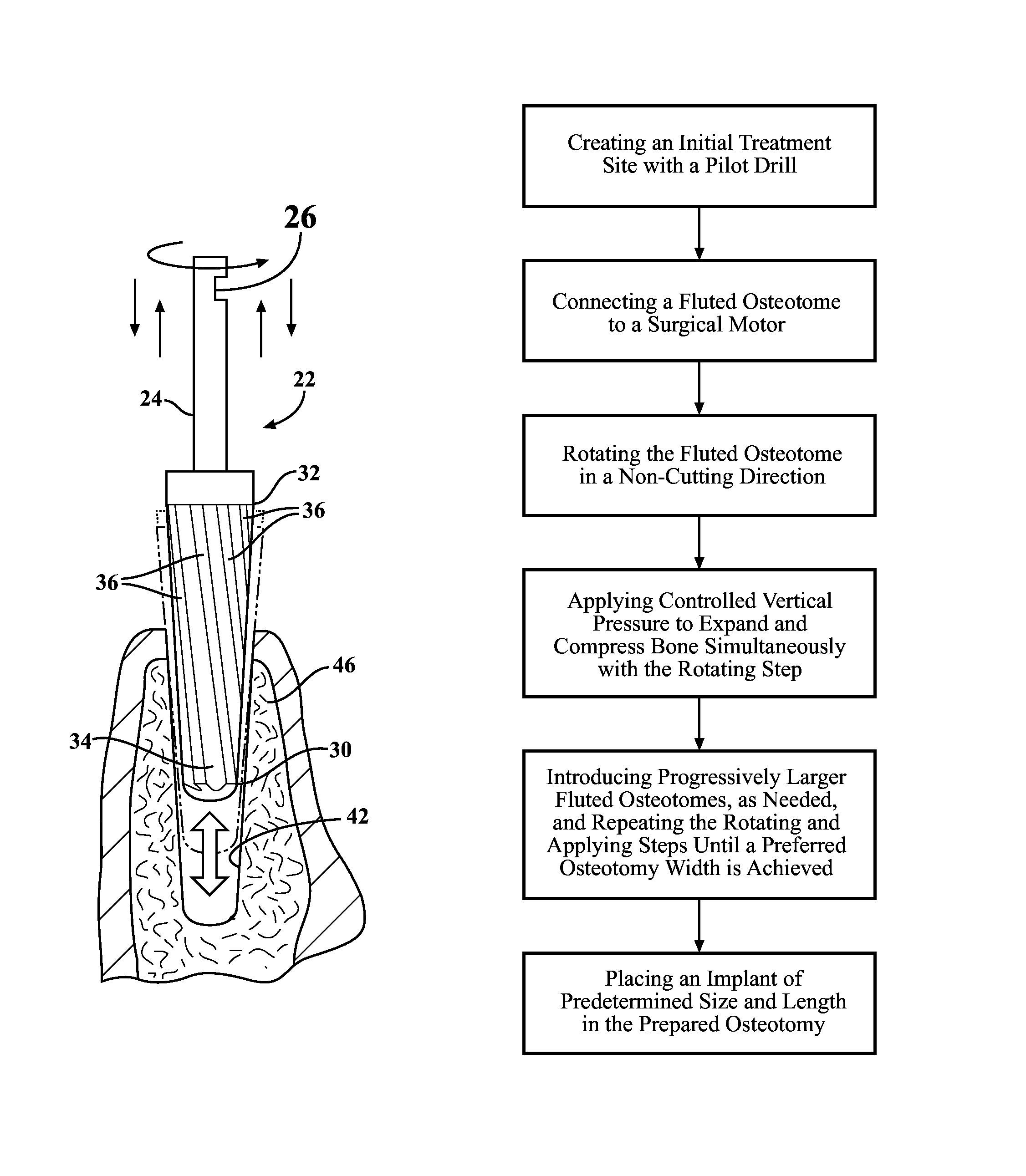

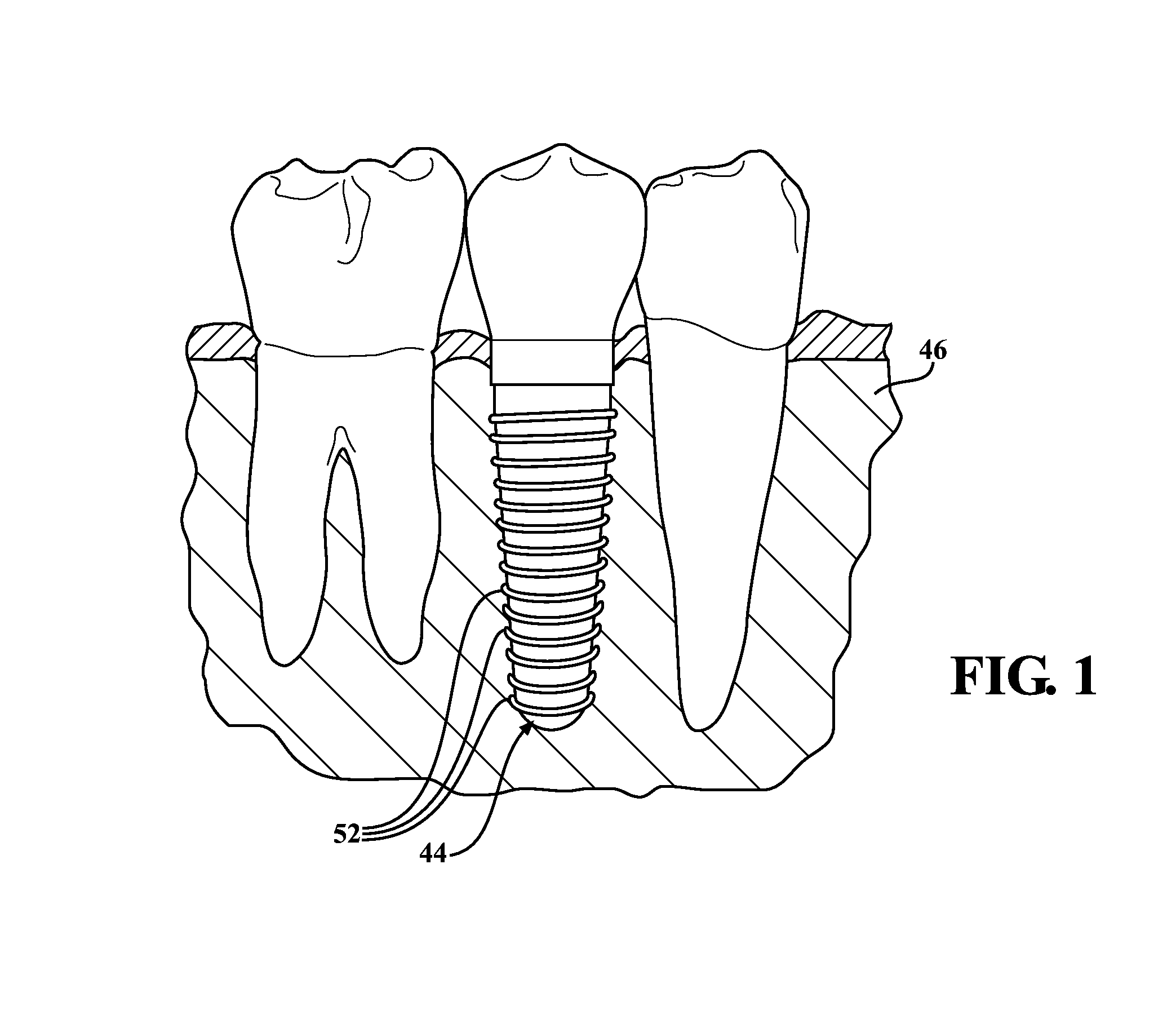

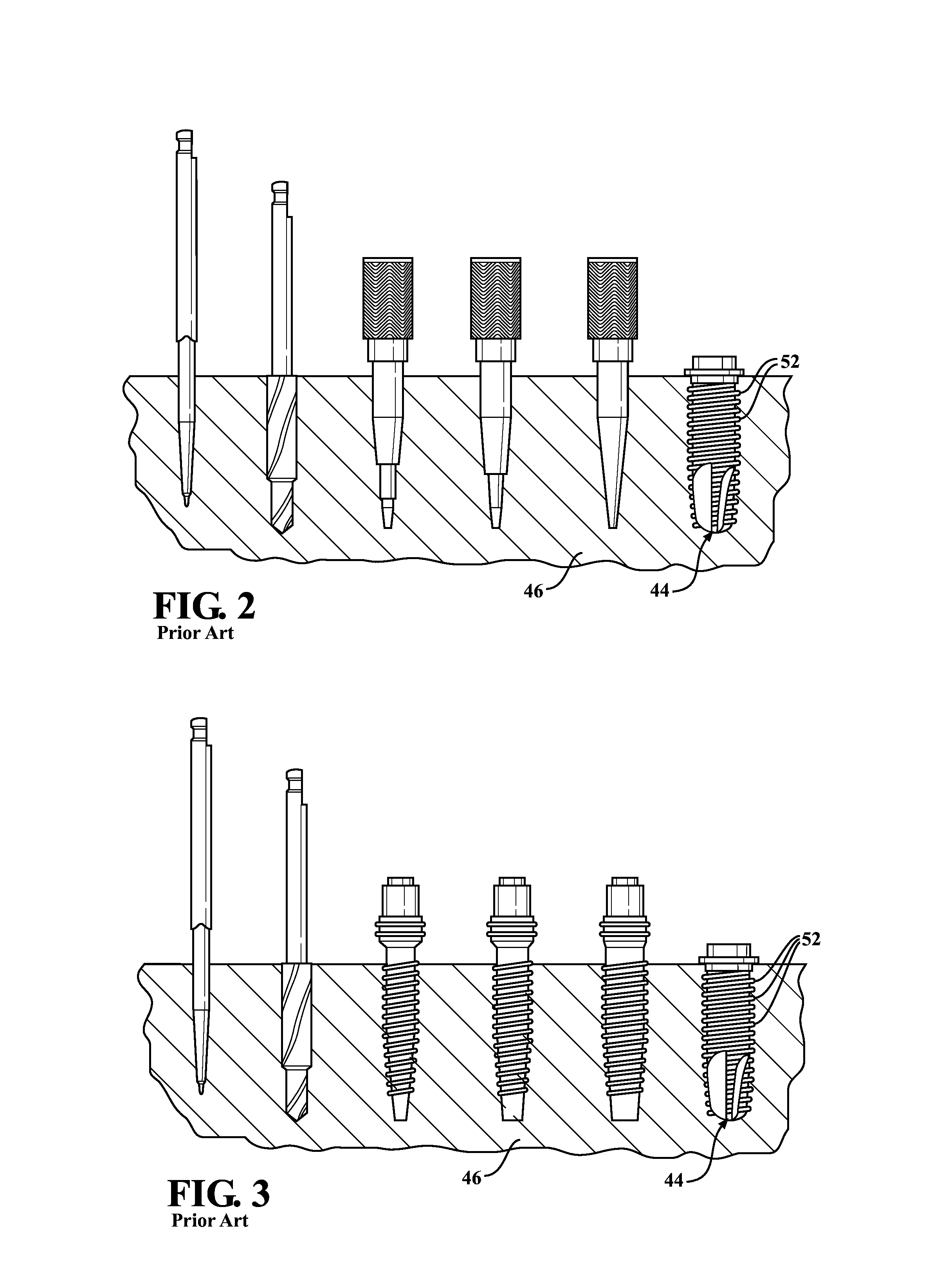

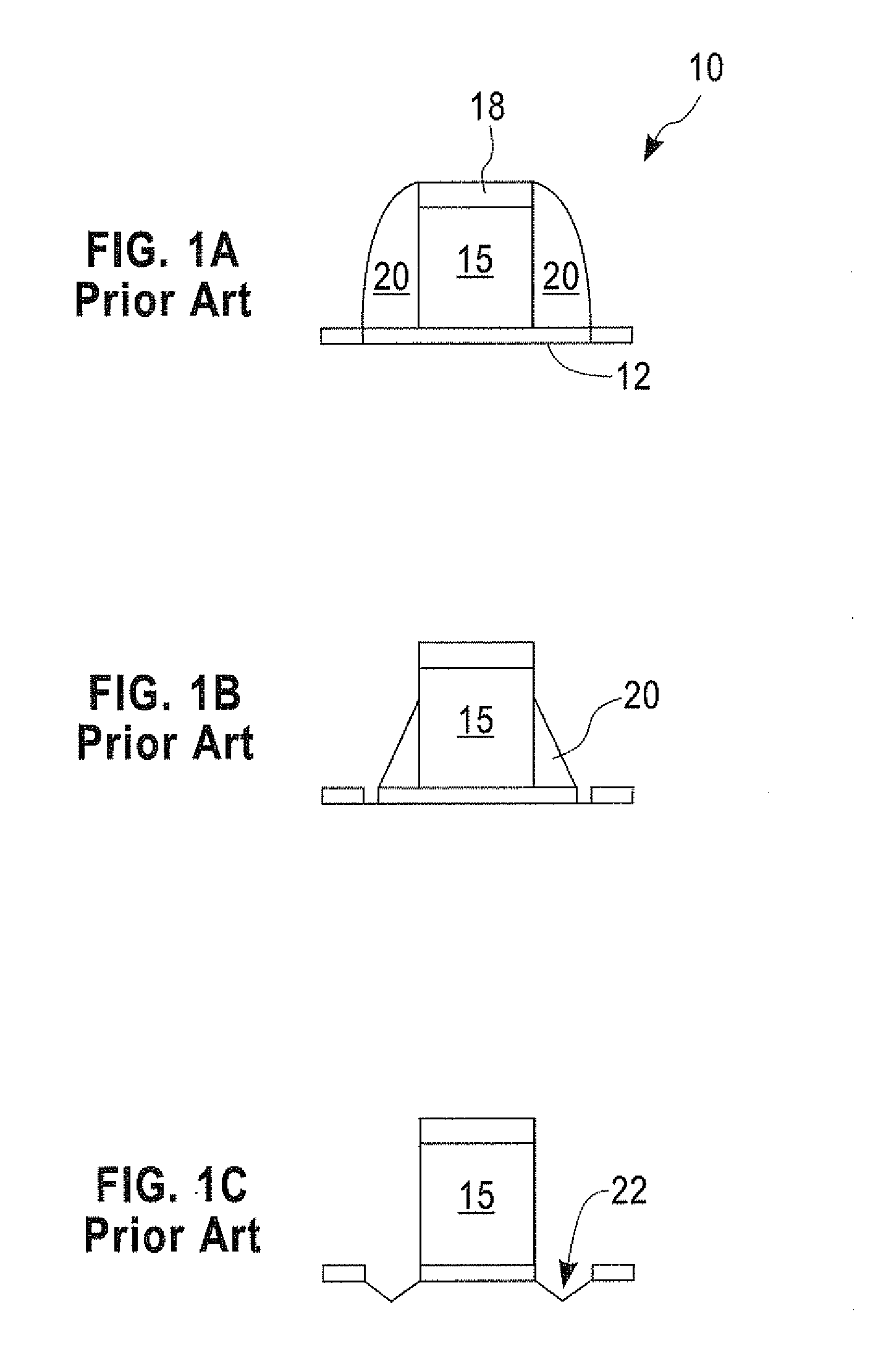

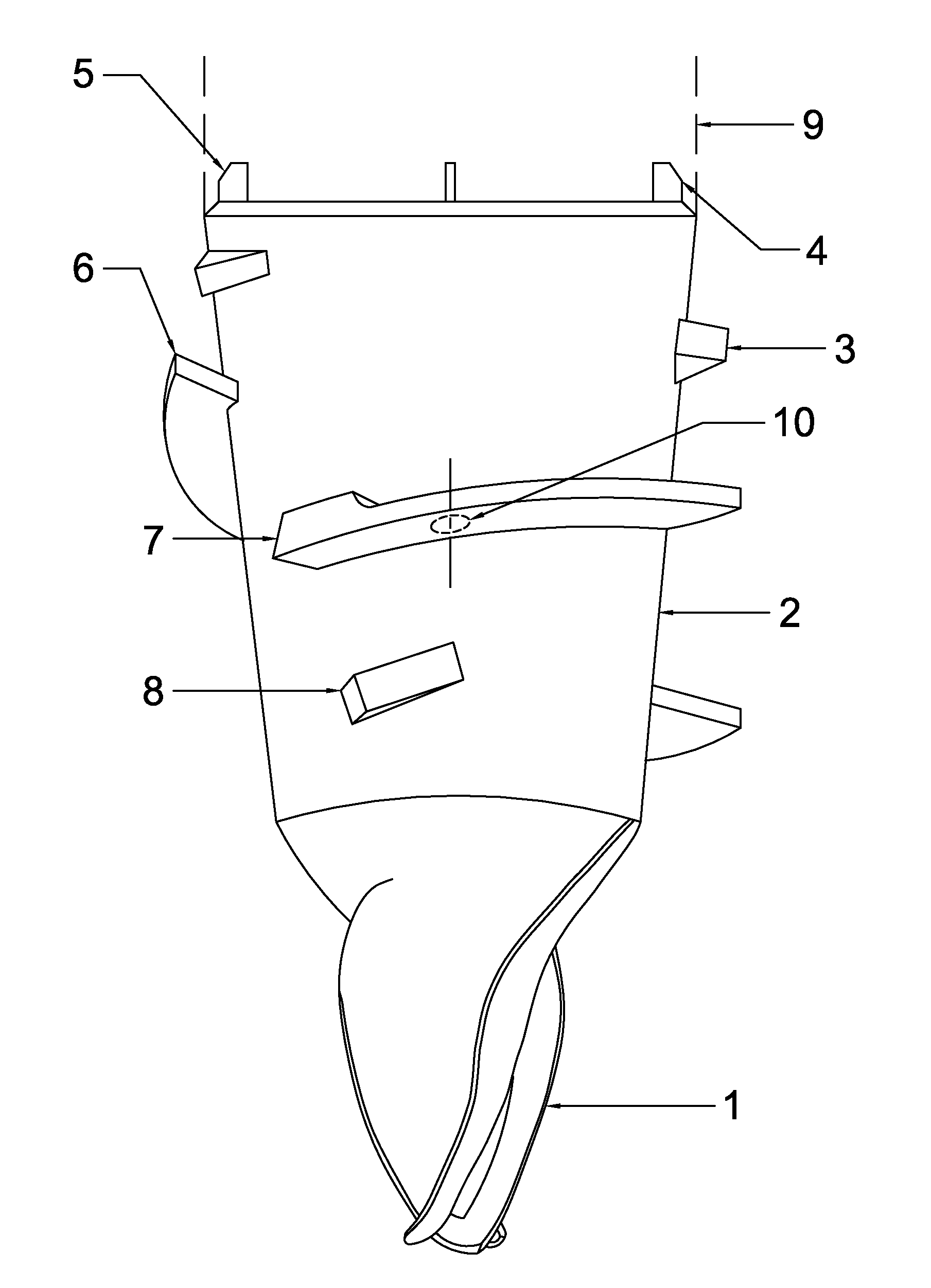

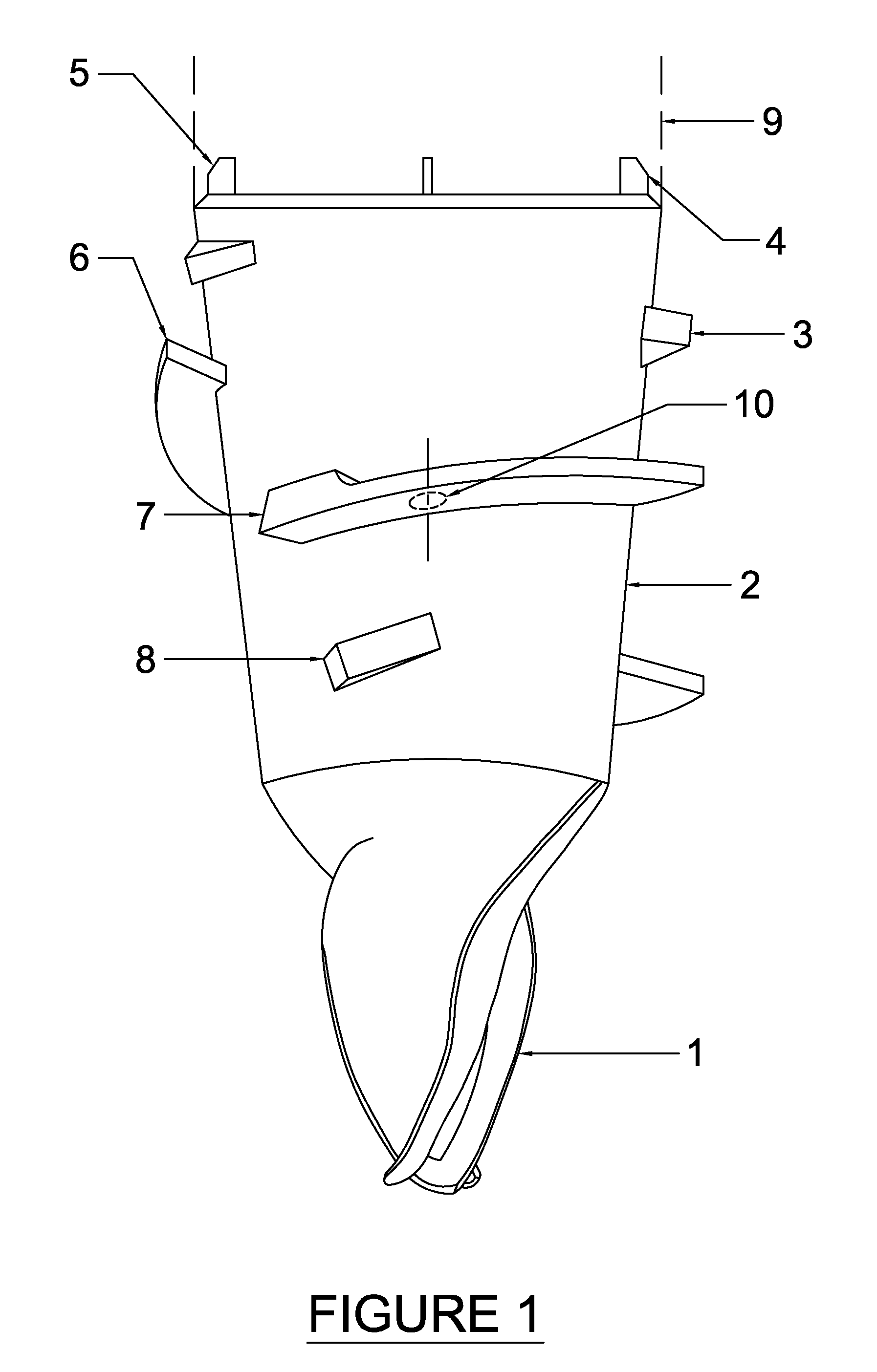

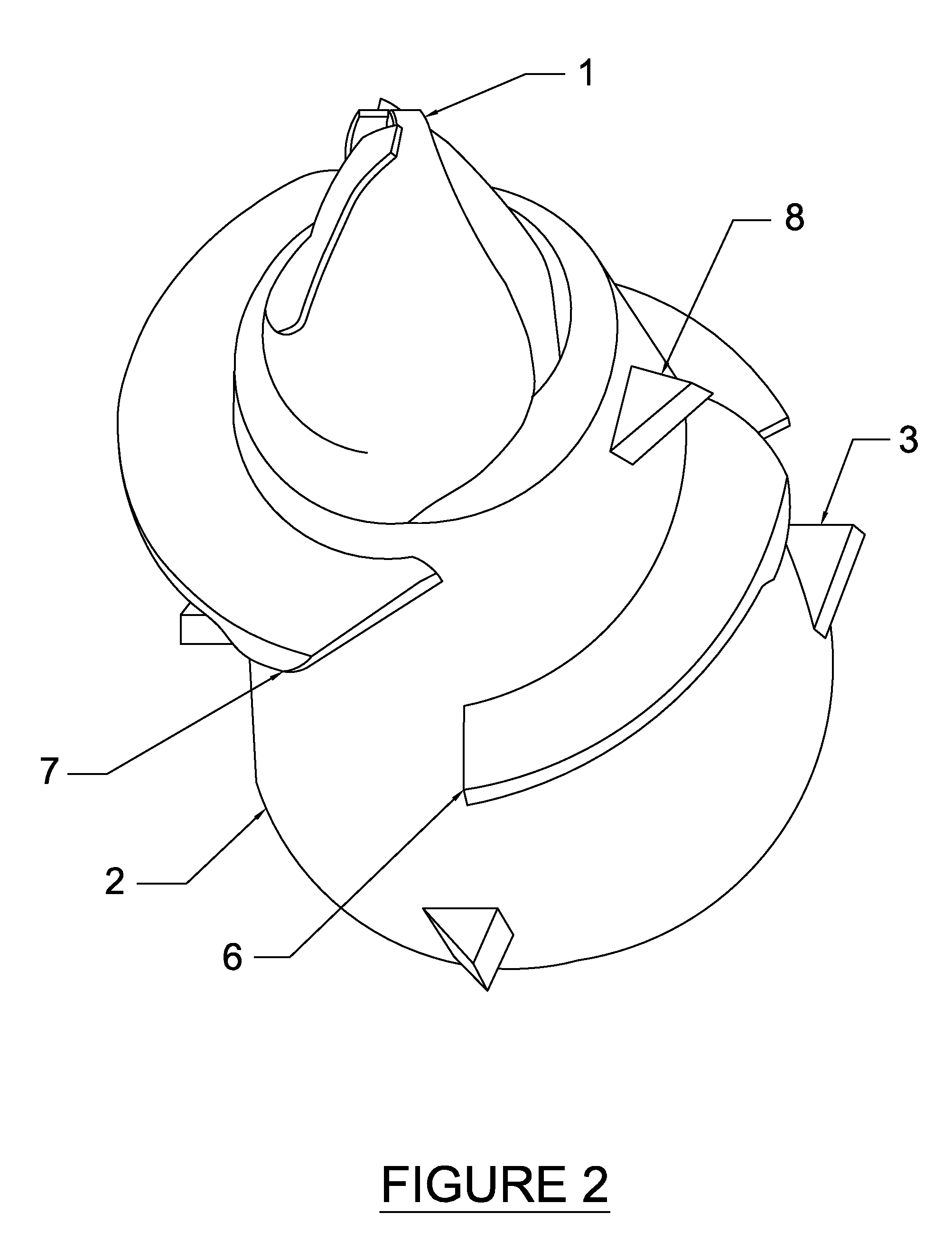

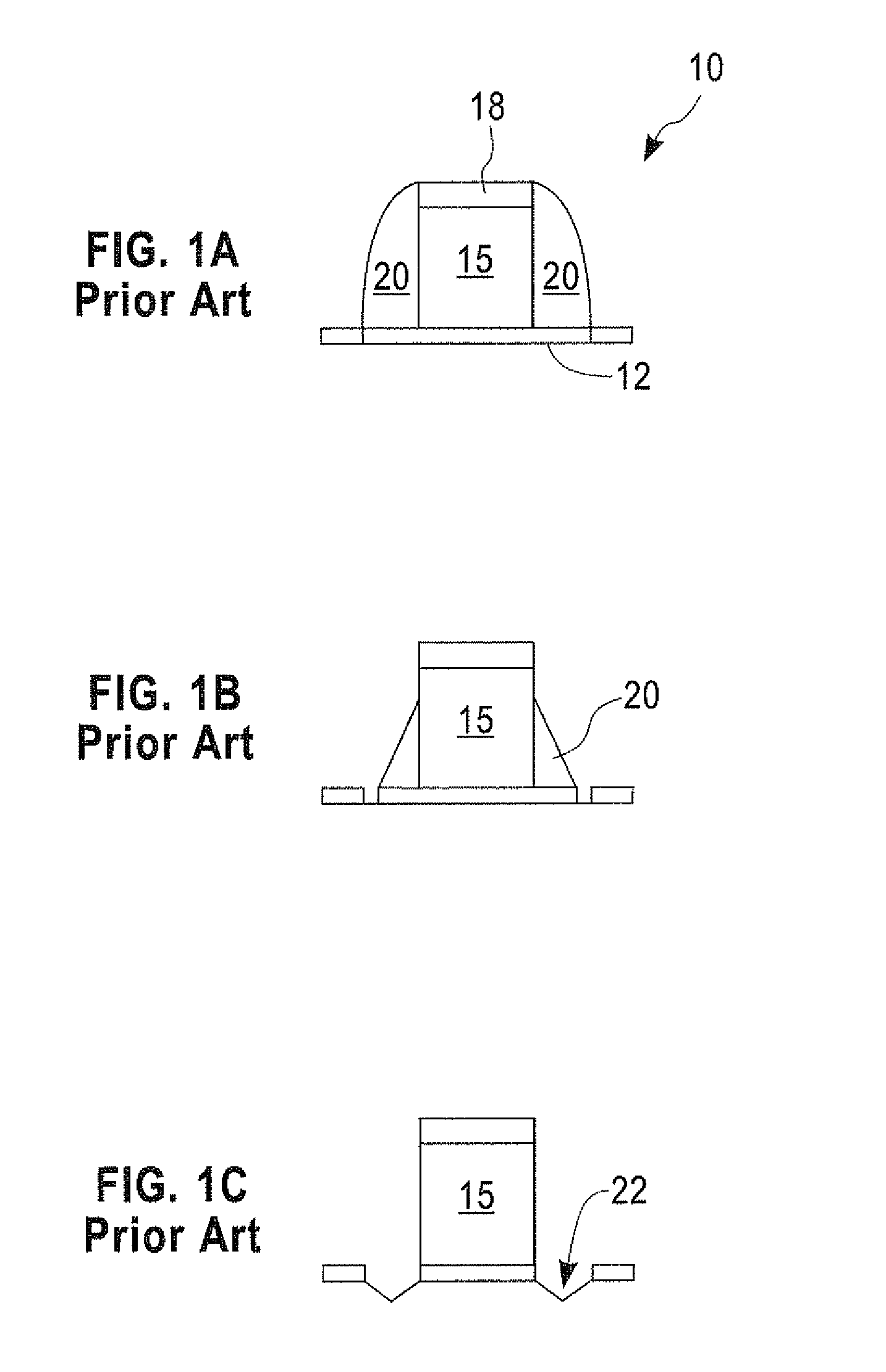

Fluted osteotome and surgical method for use

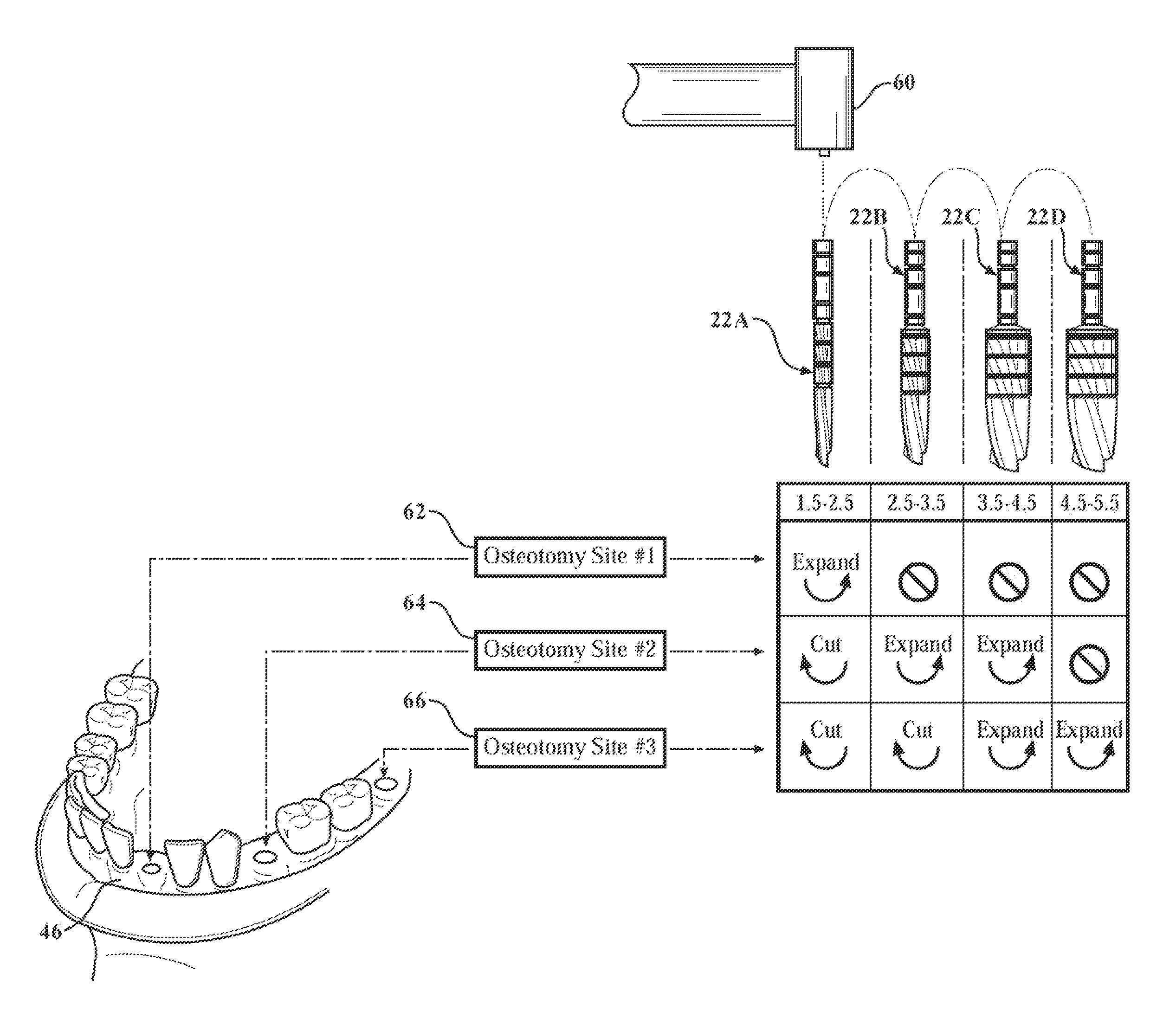

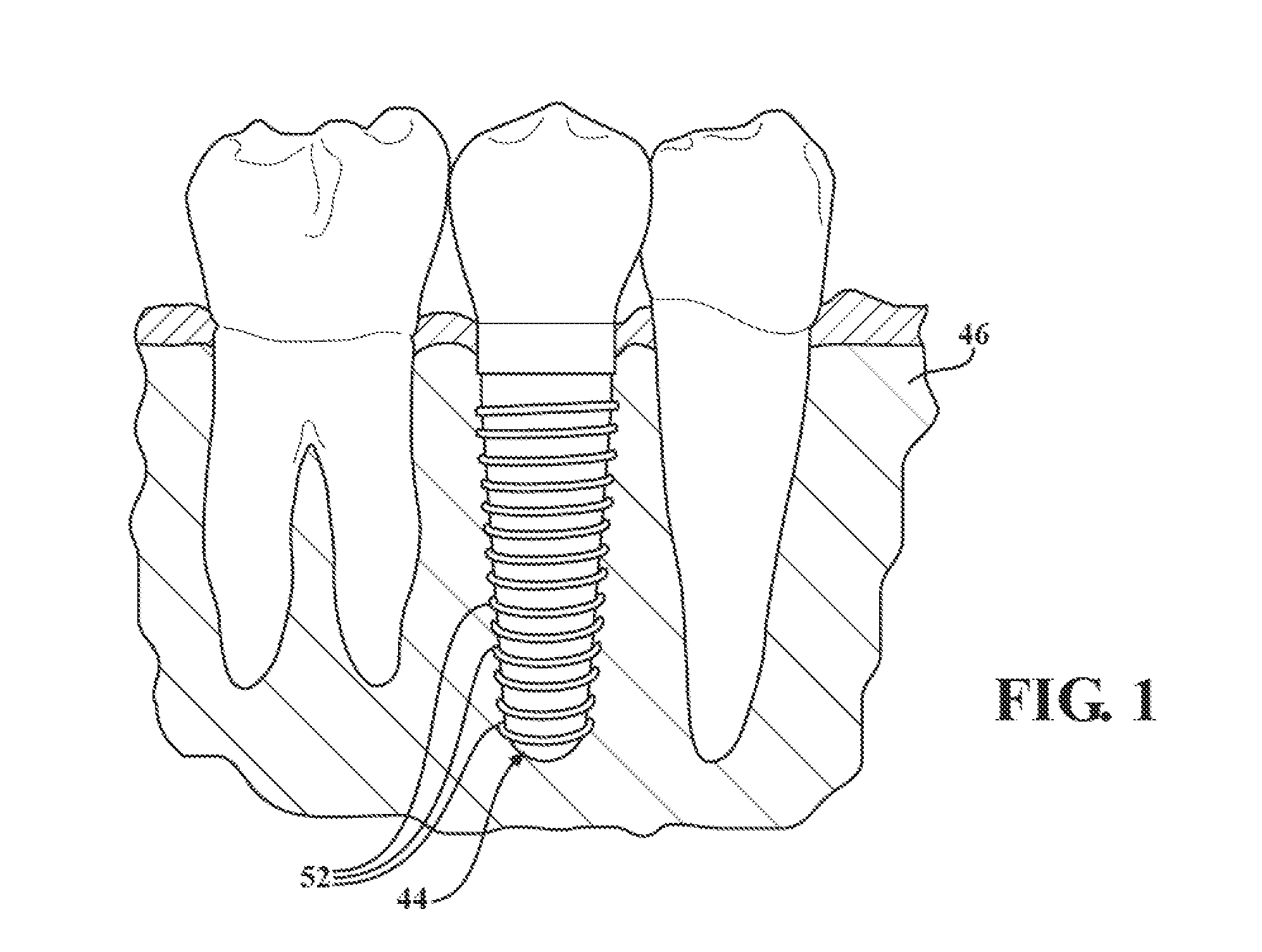

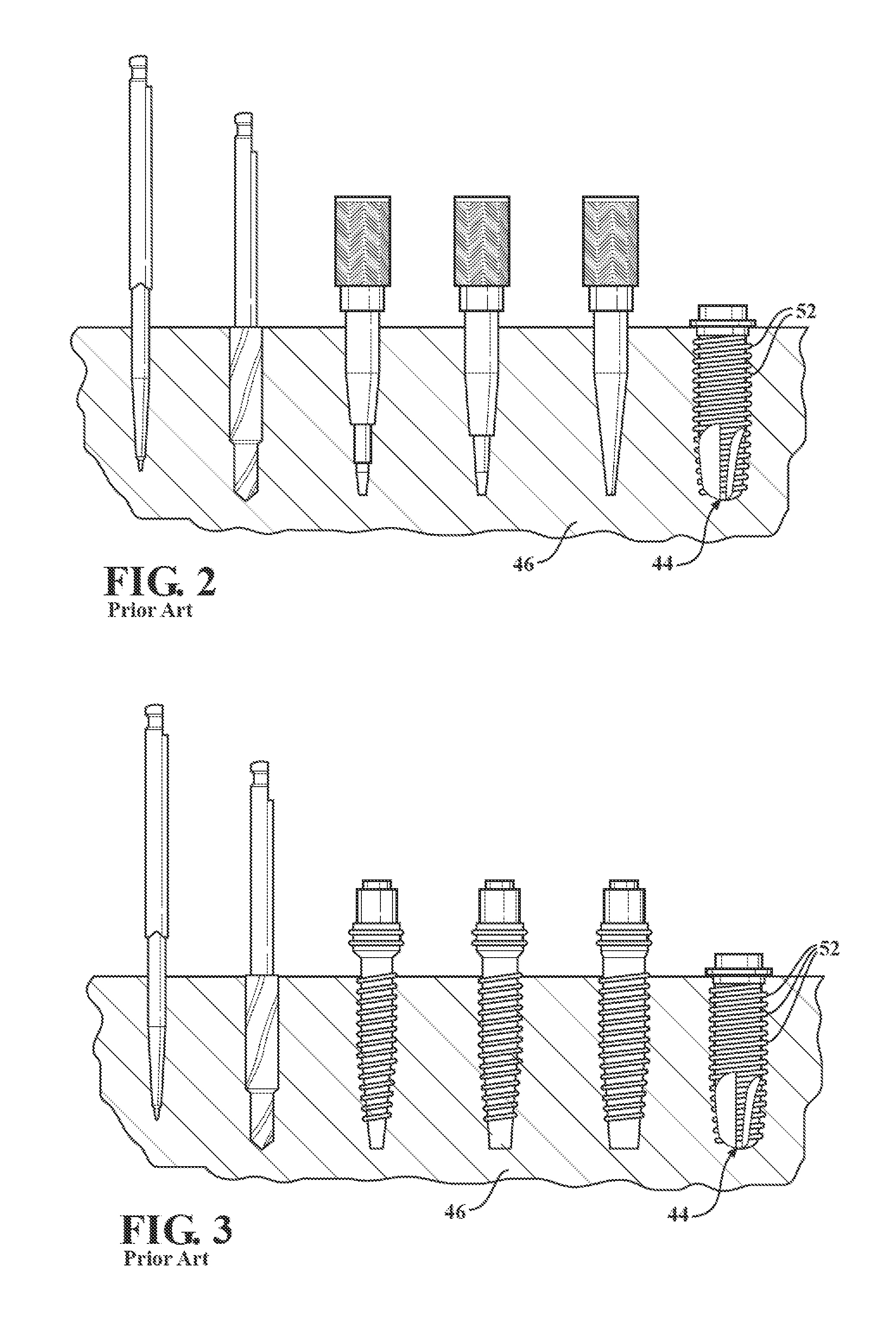

ActiveUS20120244497A1Effective expansionEasy to controlDental implantsDental toolsEngineeringNo removal

A surgical method and tool for expanding an initial osteotomy (42) to receive a dental implant (44). An osteotome (22) having a tapered working end (28) is inserted into the initial osteotomy (42). The initial osteotomy (42) is enlarged by simultaneously rotating and pushing the working end (28) of the tapered osteotome (22) into the osteotomy (42). One or more burnishing edges (40) concentrate the pushing and rotational force in outward normal and tangential component forces against the interior surface of the osteotomy (42) to incrementally expand the osteotomy (42) with little to no removal of bone material (46). The inserting and enlarging steps are repeated, as needed, with progressively larger tapered osteotomes (22) until an osteotomy (42) of predetermined size is achieved. Finally, a fixture portion of a dental implant (44) is installed into the expanded osteotomy (42).

Owner:HUWAIS IP HLDG

Catalyst for low-temperature denitration of flue gas and preparation method thereof

InactiveCN101468314AIncrease oxygen vacanciesImprove adsorption capacityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsFlue gasActive component

The invention discloses a catalyst for low-temperature flue gas denitration, and a preparation method thereof. The method adopts a selective catalytic reduction (SCR) technique, takes vanadium oxide as an active component and titanium oxide as a carrier, and substitutes fluorine for partial oxygen in an oxide catalyst, so as to prepare the catalyst, wherein the vanadium oxide as the active component is loaded on the carrier by an impregnation method; the titanium oxide as the carrier is prepared by a sol-gel method; and the substitution of fluorine for oxygen can be carried out when the titanium oxide as the carrier is prepared, or when the vanadium oxide as the active component is loaded, or when the titanium oxide as the carrier is prepared and the vanadium oxide as the active component is loaded. The catalyst remarkably improves low-temperature denitration activity and catalytic capability, can reach the NO removal rate of over 90 percent at a temperature over 200 DEG C, has strong industrial application value, and can be widely applied to the NH3 selective catalytic reduction of nitrogen oxides in flue gas.

Owner:NANJING UNIV OF SCI & TECH

Self-Assembled Surfactant Structures

Stabilized surfactant-based membranes and methods of manufacture thereof. Membranes comprising a stabilized surfactant mesostructure on a porous support may be used for various separations, including reverse osmosis and forward osmosis. The membranes are stabilized after evaporation of solvents; in some embodiments no removal of the surfactant is required. The surfactant solution may or may not comprise a hydrophilic compound such as an acid or base. The surface of the porous support is preferably modified prior to formation of the stabilized surfactant mesostructure. The membrane is sufficiently stable to be utilized in commercial separations devices such as spiral wound modules. Also a stabilized surfactant mesostructure coating for a porous material and filters made therefrom. The coating can simultaneously improve both the permeability and the filtration characteristics of the porous material.

Owner:ZNANO LLC +1

Fluted osteotome and surgical method for use

ActiveUS20130004918A1Effective expansionEasy to controlDental implantsOsteosynthesis devicesSurgical approachEngineering

A surgical method and tool for expanding an initial osteotomy (42) to receive a bone implant (44). An osteotome (22) having a tapered working end (28) is inserted into the initial osteotomy (42). The initial osteotomy (42) is enlarged by simultaneously rotating and pushing the working end (28) of the tapered osteotome (22) into the osteotomy (42). When rotated in one direction the burnishing edges (40) concentrate the pushing and rotational force in outward normal and tangential component forces against the interior surface of the osteotomy (42) to incrementally expand the osteotomy (42) with little to no removal of bone material (46). When rotated in the opposite direction the burnishing edges cut the interior surface of the osteotomy. Progressively larger tapered osteotomes (22) are used until an osteotomy (42) of predetermined size is achieved.

Owner:HUWAIS IP HLDG

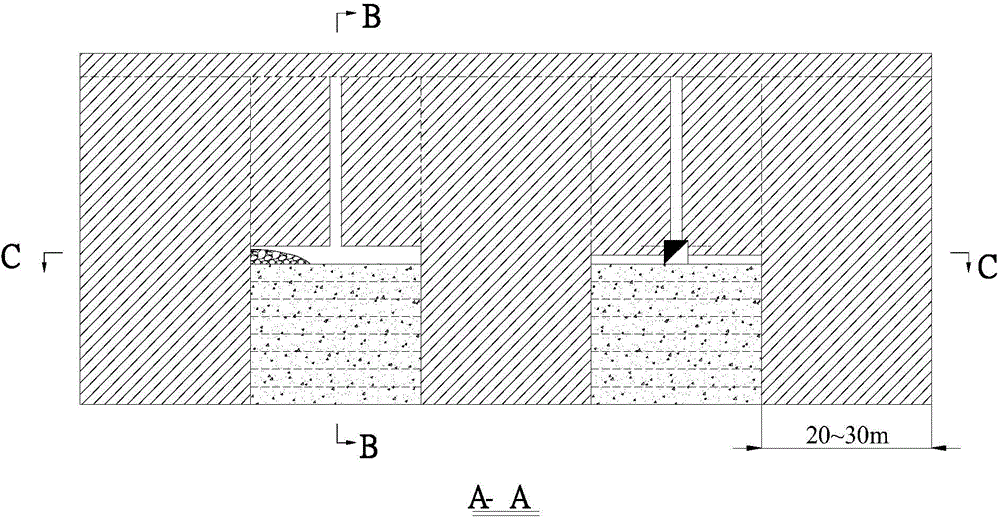

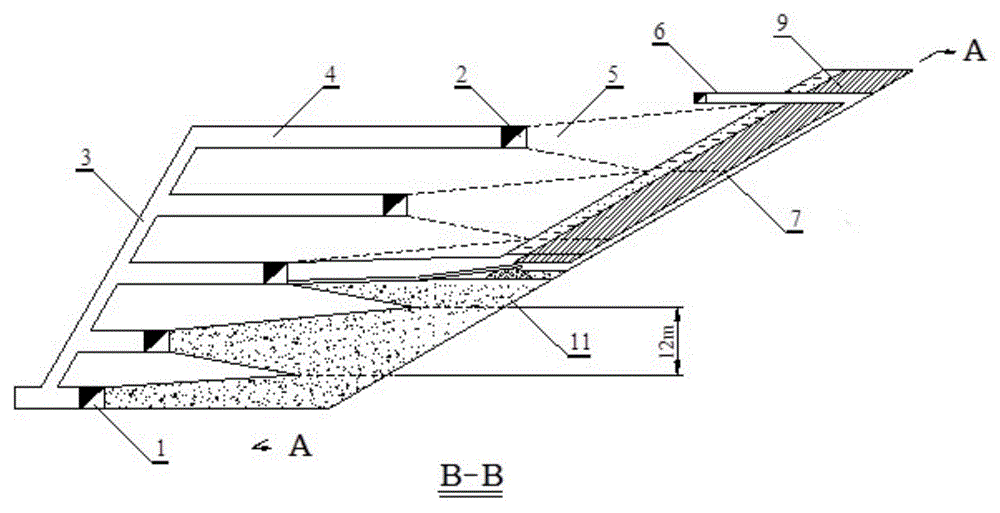

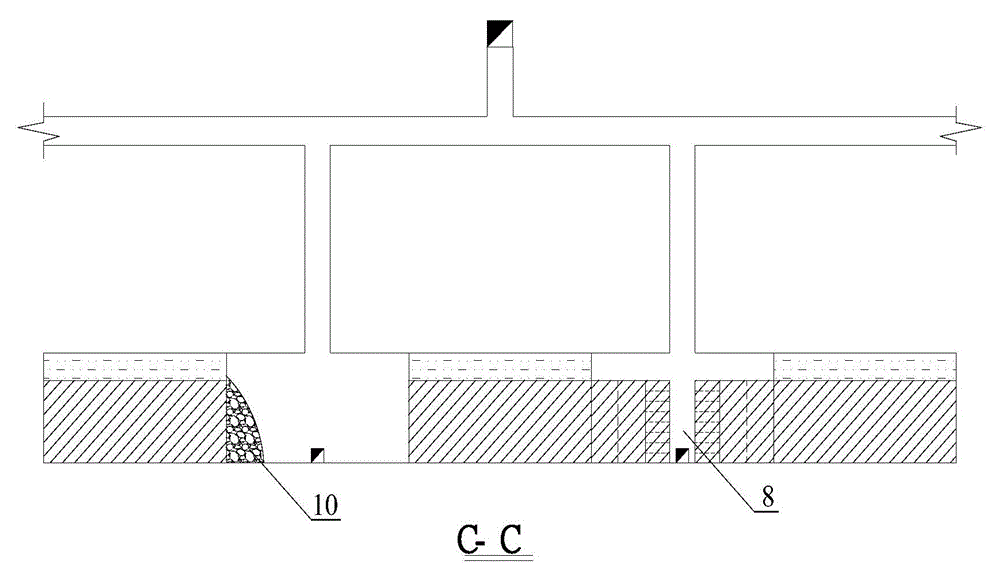

Divided mining method for inclined medium-thick ore body with unstable false roof

ActiveCN104018836AOut of stopeReduce the dilution loss rateUnderground miningSurface miningEngineeringNo removal

The invention discloses a divided mining method for an inclined medium-thick ore body with an unstable false roof. The ore body is divided into panels along the strike, ore pillars of chambers are divided in the panels and a top pillar is reserved during stoping; an outside-vein slice drift, a layered linking roadway and a trackless stope preparation project of a chute mine are distributed on the upper panel of the ore body, and an upward air roadway is filled and is distributed at a position at the center of the ore pillars of the chambers and close to the lower panel; chambers are mined firstly and the ore pillars are mined secondly in the panels, and the chambers and the ore pillars are mined in an up-down layering manner; the stoping is performed from an ore removal crossdrift, the false roof and the ore body are mined in sequence, after ores are conveyed out by a carry-scraper, the false roof at the lower sub-layer is subjected to caving in advance by shallow holes, waste stones of the false roof are reserved in a stoping field, and the ore breaking compensation height is compensated in a layering filling manner, the stoping is performed on the lower sub-layer, and the laying caving is performed on the false roof after layering ore breaking and ore conveyed out, the operation is repeated for multiple times until the stoping field is stoped completely, and the bottom layer of the stoping field is filled to close to the back. By using the method, the operating safety, high mechanical degree, no removal of the waste stones of the false roof, low production cost, and low ore dilution loss can be realized.

Owner:CENT SOUTH UNIV

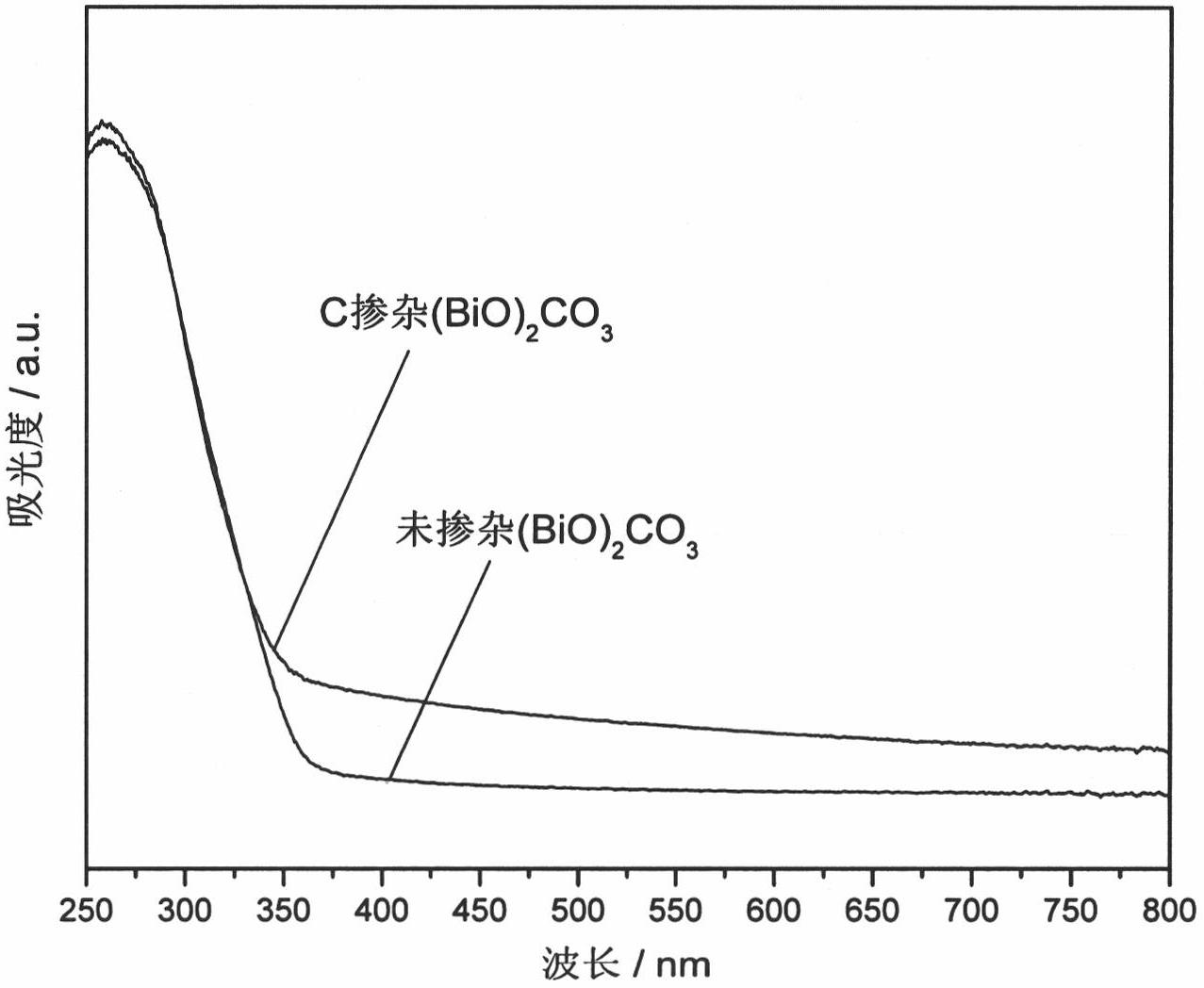

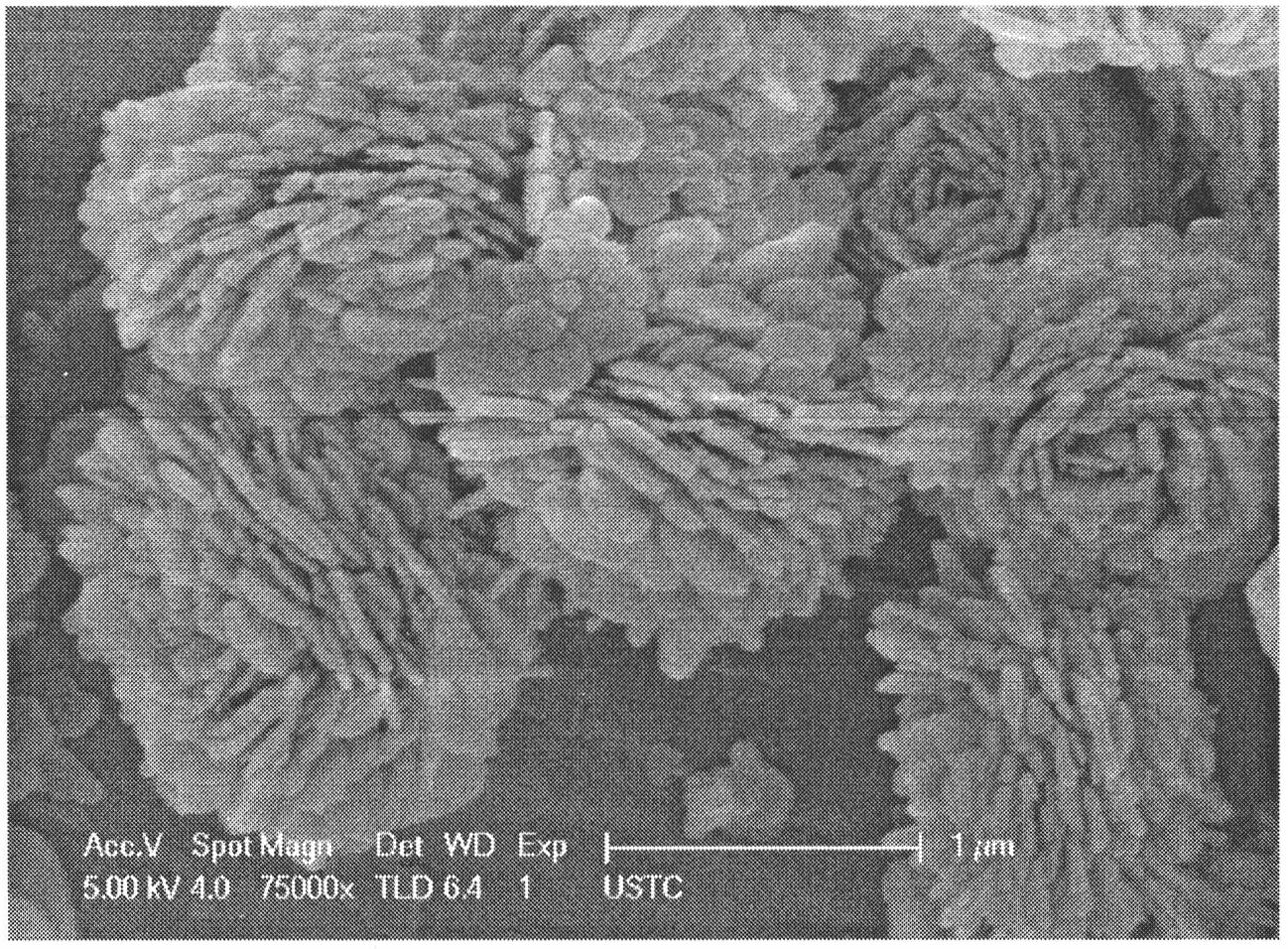

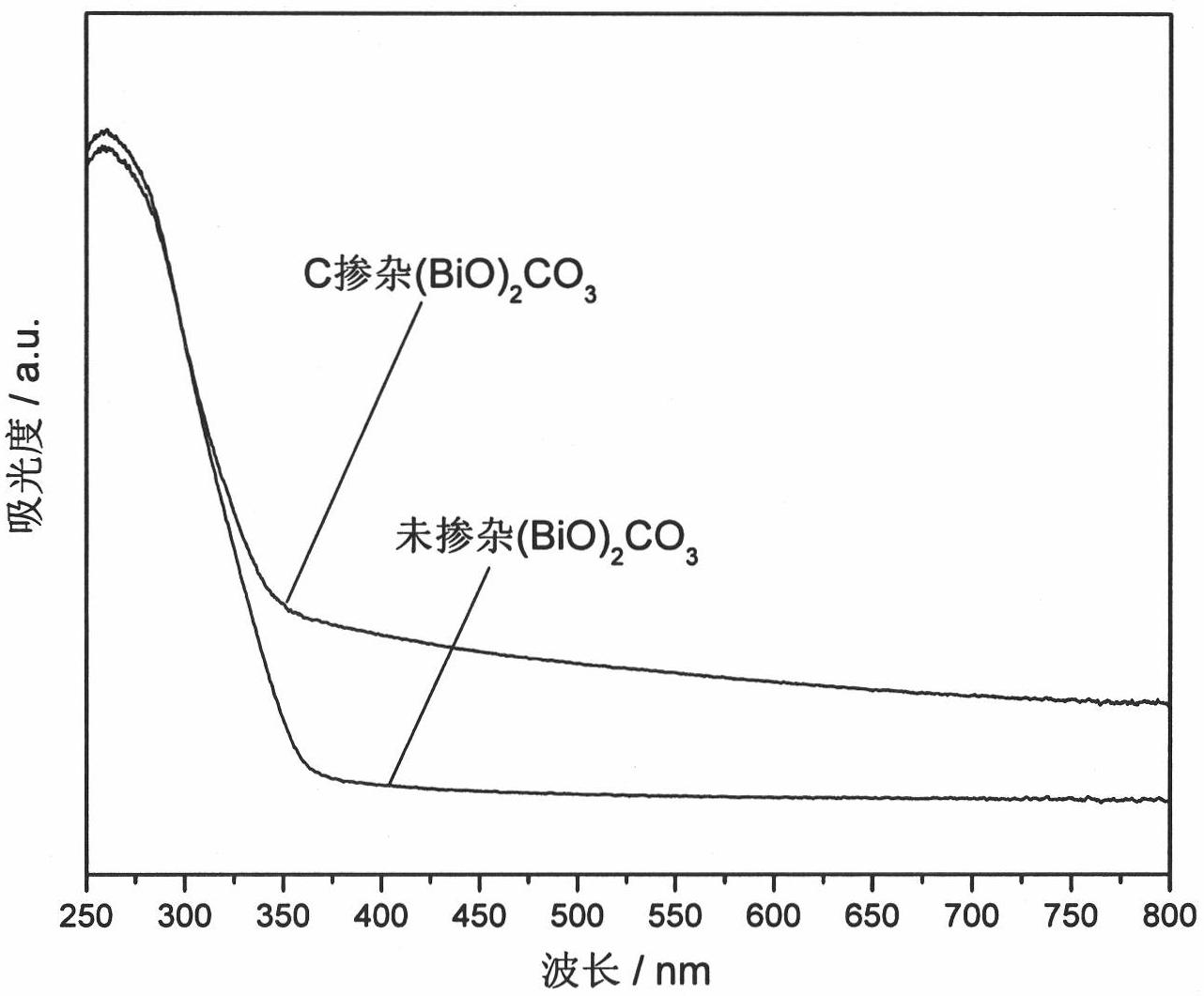

Preparation method of nanosheet self-assembled C-doped (BiO)2CO3 microsphere visible light catalyst

ActiveCN102671683AReduce defectsEasy to separatePhysical/chemical process catalystsDispersed particle separationMicrosphereHigh pressure

The invention discloses a preparation method of a nanosheet self-assembled C-doped (BiO)2CO3 microsphere visible light catalyst, which comprises the following steps: (1) dissolving a bismuth-containing precursor, a soluble carbonate and a doping carbon source in a water solution, stirring for 30 minutes, transferring the obtained mixed solution into a high-pressure hydrothermal kettle, and carrying out hydrothermal reaction at 120-250 DEG C for 3-100 hours; and (2) after the hydrothermal reaction finishes, cooling, filtering out the precipitate, respectively washing the precipitate with deionized water and ethanol, and drying to obtain the nanosheet self-assembled C-doped (BiO)2CO3 microspheres. According to the C-doped (BiO)2CO3 prepared by the method disclosed by the invention, the doping C element reduces the energy gap of (BiO)2CO3, and the (BiO)2CO3 has visible light catalytic activity. The experimental result proves that the NO removal rate of the bismuthyl carbonate photocatalyst disclosed by the invention is 30-45%, which indicates that the bismuthyl carbonate photocatalyst has high visible light catalytic activity.

Owner:江苏碧峰环保科技有限公司

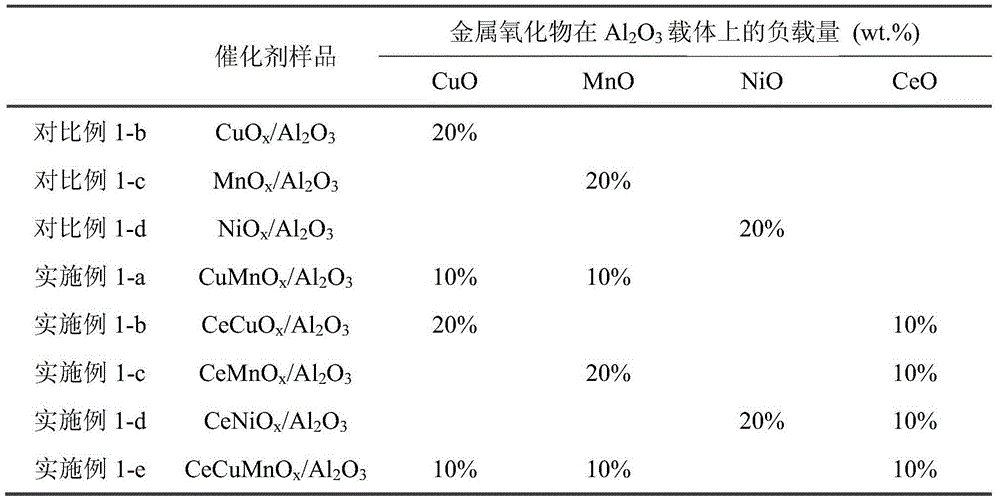

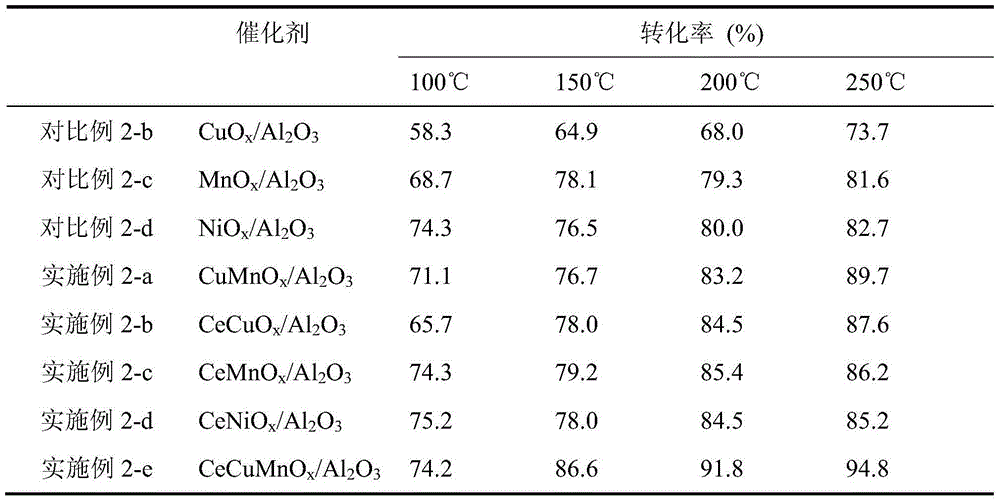

Method for denitrifying NO by directly decomposing NO catalytically by using supported metal oxide catalyst

ActiveCN104474890AImprove removal efficiencyNo secondary pollutionDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDecompositionCerium

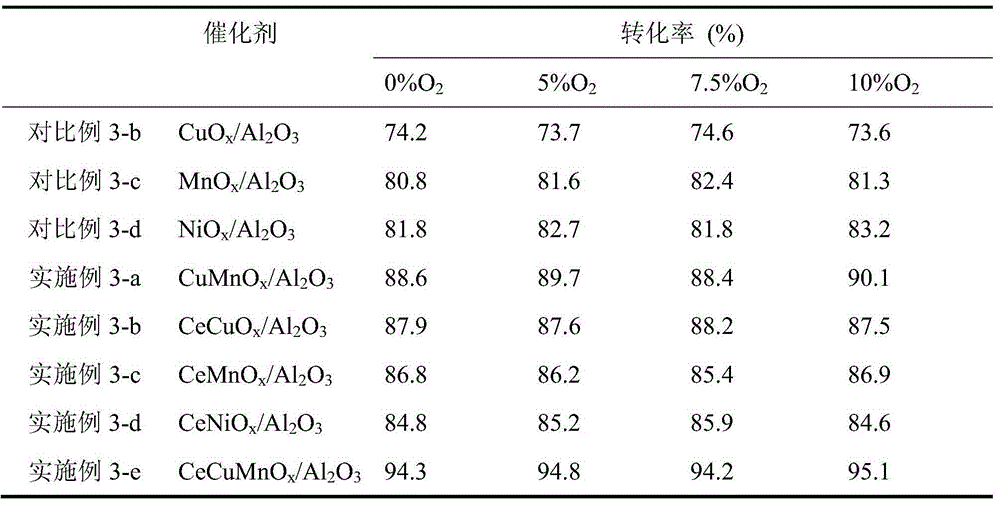

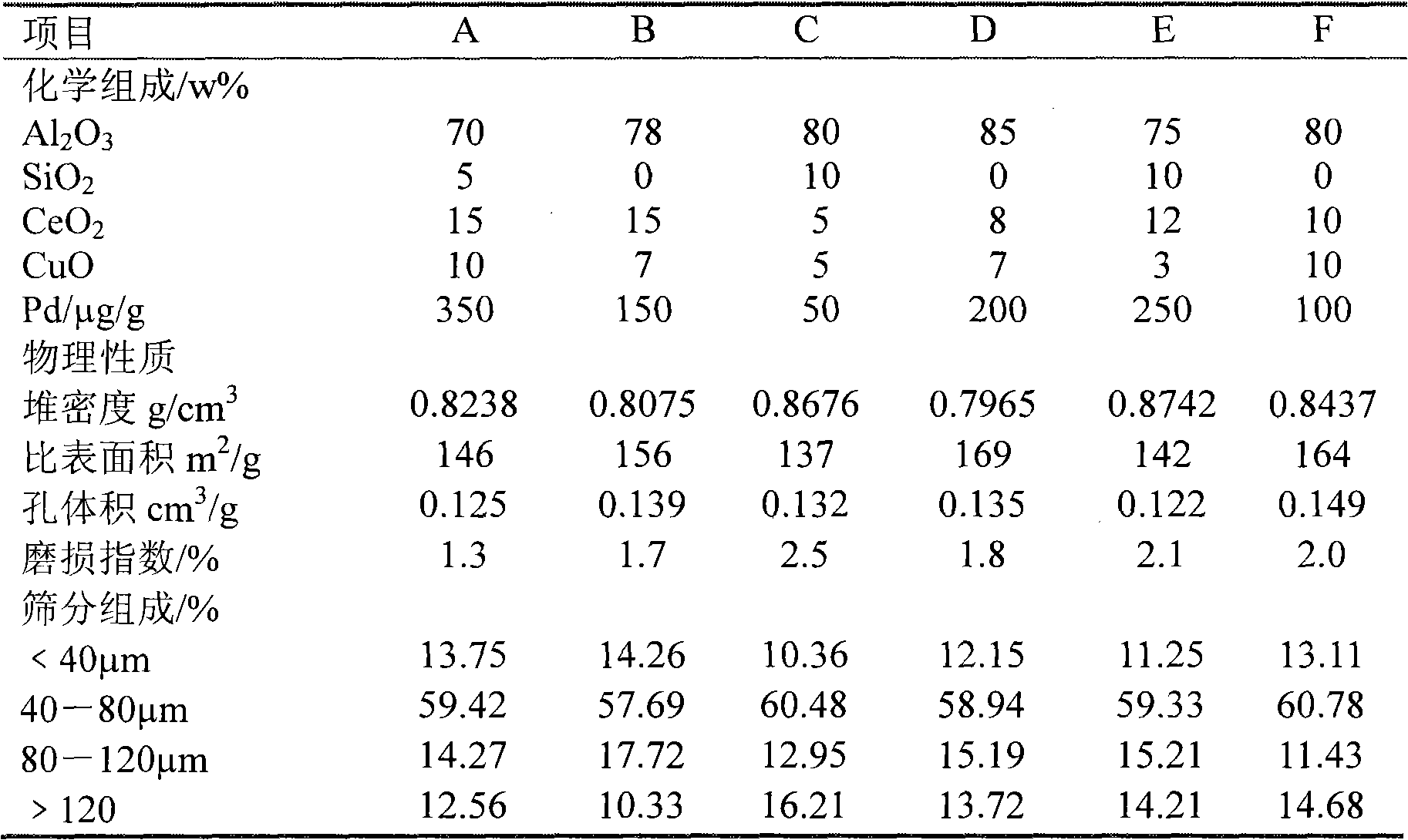

The invention provides a method for denitrifying NO by directly decomposing NO catalytically by using a supported metal oxide catalyst. The method is carried out in a microwave field. The catalyst is a supported mixed metal oxide catalyst which is characterized in that a mixed metal oxide MOx is supported on an Al2O3 carrier, wherein M is selected from two or three of cerium, copper, manganese and nickel; preferably, the catalyst is selected from CeCuOx / Al2O3, CeMnOx / Al2O3, CeNiOx / Al2O3 and CeCuMnOx / Al2O3. The method has the advantages that secondary pollution is avoided through microwave catalytic direct NO decomposition reaction; the process is simple, is convenient to operate and easy to control, is high in NO removal efficiency (the NO conversion rate can be 95.1%), strong in oxidation resistance and low in operating temperatures, is energy-saving and environment-friendly and is low in operating cost; the flue gases or waste gases treated by using the method can be directly up to the national emission standard.

Owner:XIANGTAN UNIV

Adhesion layer for adhesive tape as well as preparation method and application thereof

ActiveCN109306252AHigh elastic plasticityImprove cohesionMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolytetramethylene terephthalatePolyolefin

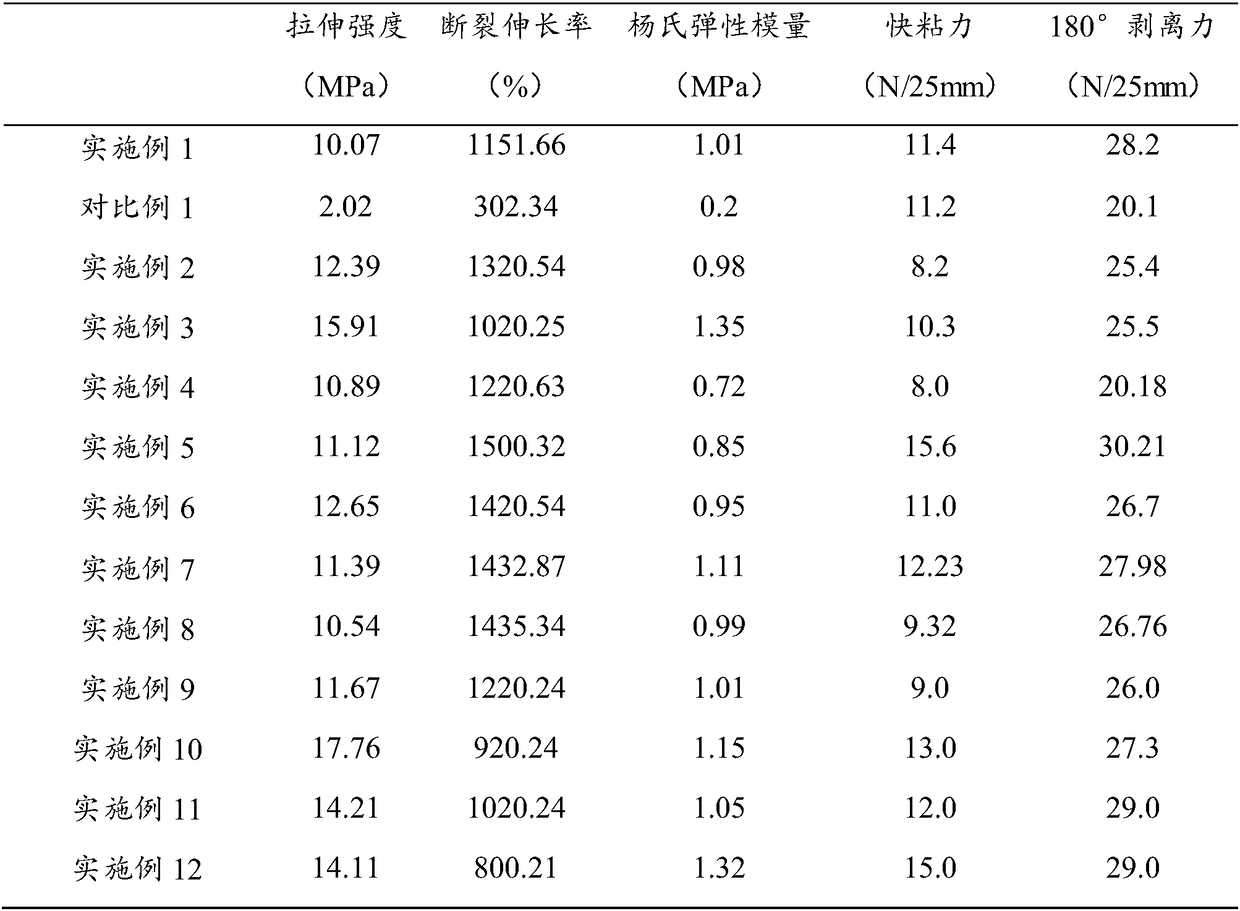

The invention provides an adhesion layer for an adhesive tape. The adhesion layer is prepared from the following raw materials in parts by weight: 40 to 60 parts of a thermoplastic elastomer, 40 to 60parts of tackifying resin, 10 to 20 parts of a reinforcing agent, 10 to 25 parts of a softening agent, 0.2 to 5 parts of an antioxidant and 0.1 to 5 parts of filler, wherein the thermoplastic elastomer is selected from one or more of a styrene block copolymer, a polyolefin block copolymer, an acrylic block copolymer, polyisobutene, thermoplastic polyurethane, butyl rubber and ethylene propylene diene monomer; the reinforcing agent is selected from one or more of polystyrene, polyphenylene ether, polyethylene glycol terephthalate and polybutylene terephthalate. According to the adhesion layerprovided by the invention, the components with specific content are adopted to realize a good compatible effect; the cohesion force is improved on the basis that the adhesion layer has high-elasticityplasticity, so that the adhesion layer has the properties of high peeling force, high temperature resistance, tension without breaking and no removal of residual glue.

Owner:安徽屹珹新材料科技有限公司

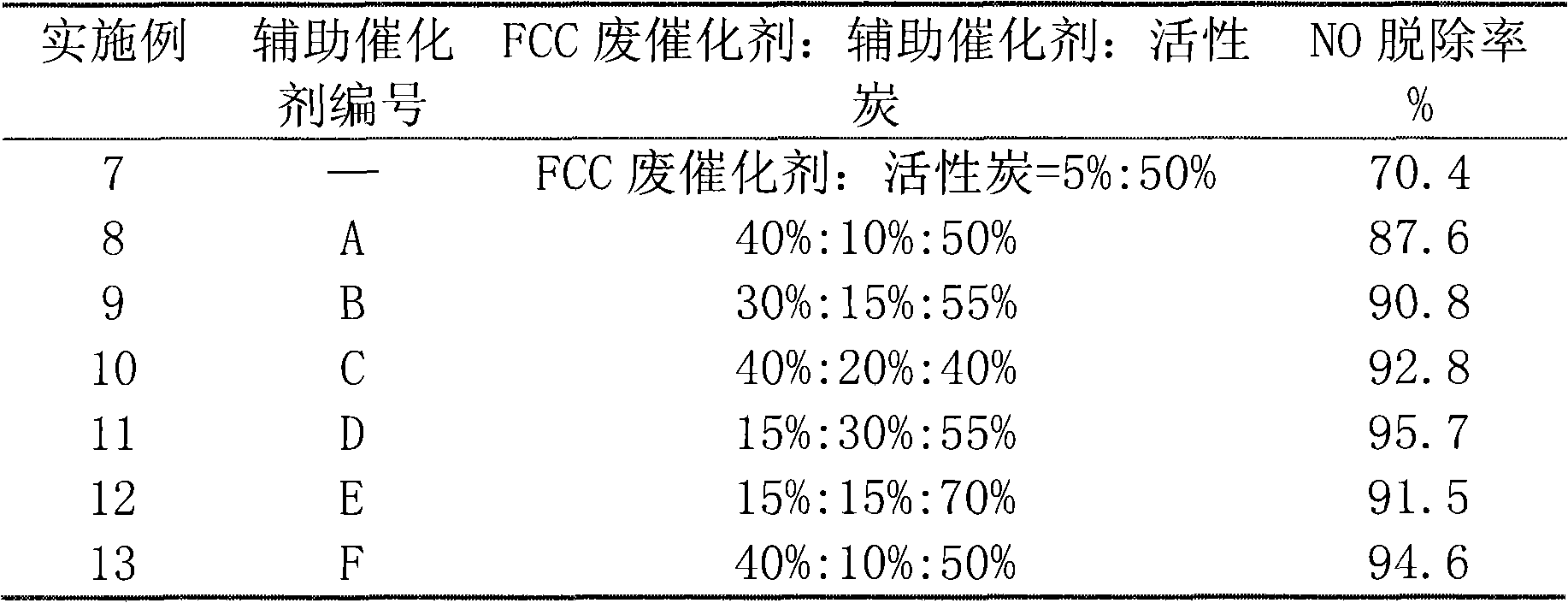

Method for removing NO (nitric oxide) in flue gas

ActiveCN102631838AHigh removal rateWide reaction temperature rangeNitrous oxide captureDispersed particle separationActivated carbonFlue gas

The invention discloses a method for removing NO (nitric oxide) in flue gas. Gas containing the NO flows through a reactor with the reaction temperature ranging from 400 DEG C to 800 DEG C at airspeed of 1000-10000h-1, from 10 to 40% of main catalyst, from 5 to 30% of auxiliary catalysts and from 30 to 70% of activated carbon are filled in the reactor by total weight of catalyst, and shortcomings that NO removal rate is low and a removal process is complex in the prior art are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

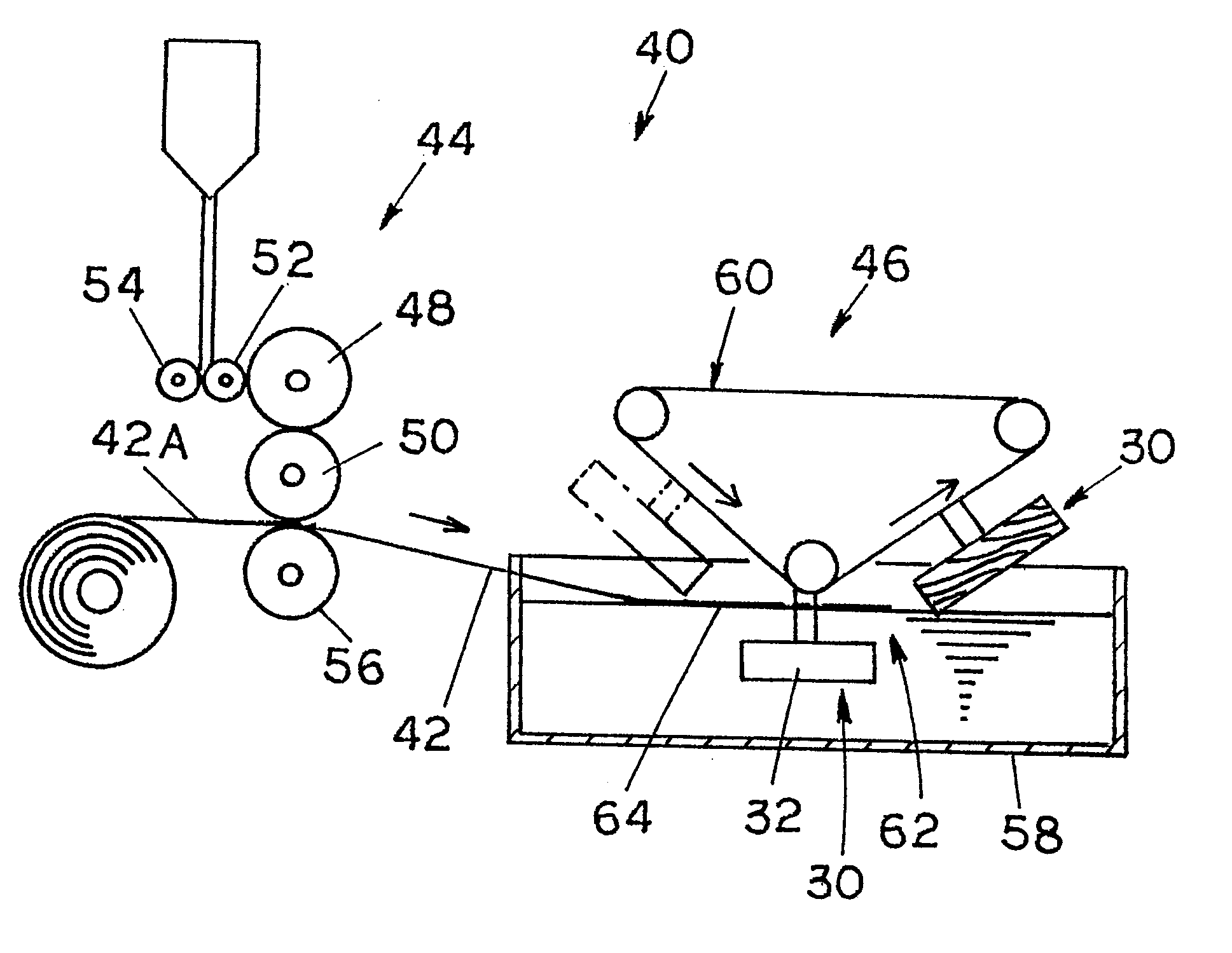

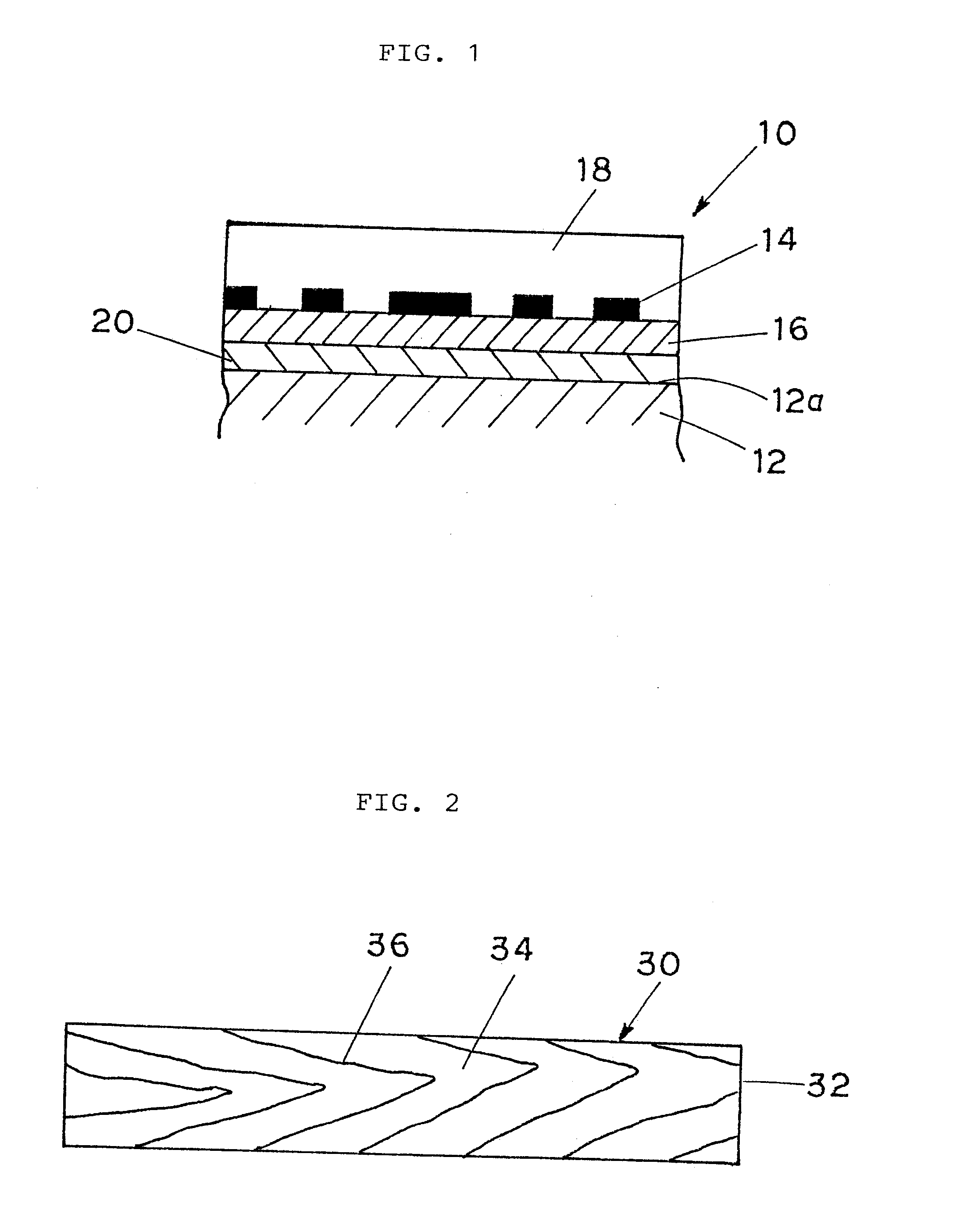

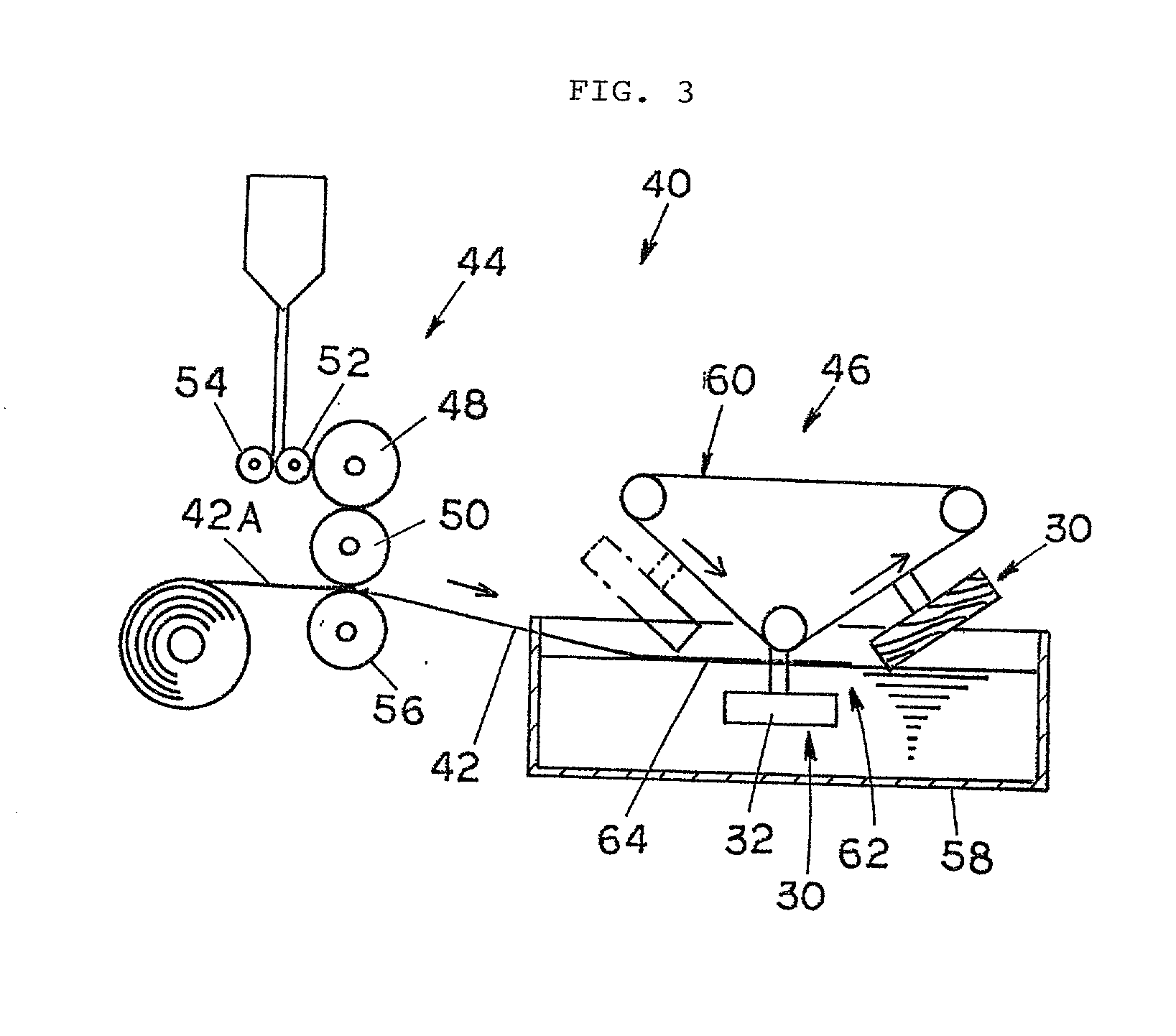

Method of transferring a print pattern composed of a fluoropolymer resin and an inorganic pigment onto an objective body using liquid pressure

InactiveUS6554940B2Inhibit deteriorationExcellent stateDecorative surface effectsPattern printingWeather resistanceColor printing

A pattern-transferring film having a print pattern provided on an upper surface thereof is floated on a liquid surface within a transferring bath and an objective body is immersed into a liquid within the transferring bath together with the pattern transferring film under a liquid pressure so as to transfer the print pattern onto the objective body. The print pattern is obtained by being printed by using an optional printing ink or inks of blue, yellow, red black and white inks or an ink or inks prepared by blending the printing inks. The liquid pressure pattern-transferring ink or inks comprise at least a resin ingredient and a color pigment. The resin ingredient of each of the color inks is composed of a fluoropolymer resin and the color pigment of each of the color inks is an inorganic pigment. In this manner, with liquid pressure pattern-transferring ink comprising the resin ingredient of the fluoropolymer resin and the inorganic pigment in spite of its color, all the color printing inks have a weather resistance of 5000 hours or more determined by a JIS based sunshine weather meter. Thus, there occurs no removal of the transferred pattern out of the objective body which tends to be caused by a deterioration of the resin ingredient, if otherwise and the color of the transferred pattern neither changes nor fades, which enables the article to have its life span maintained for a longer period.

Owner:TAICA

Fluted osteotome and surgical method for use

ActiveUS9028253B2Effective expansionEasy to controlDental implantsOsteosynthesis devicesEngineeringNo removal

A surgical method and tool for expanding an initial osteotomy (42) to receive a bone implant (44). An osteotome (22) having a tapered working end (28) is inserted into the initial osteotomy (42). The initial osteotomy (42) is enlarged by simultaneously rotating and pushing the working end (28) of the tapered osteotome (22) into the osteotomy (42). When rotated in one direction the burnishing edges (40) concentrate the pushing and rotational force in outward normal and tangential component forces against the interior surface of the osteotomy (42) to incrementally expand the osteotomy (42) with little to no removal of bone material (46). When rotated in the opposite direction the burnishing edges cut the interior surface of the osteotomy. Progressively larger tapered osteotomes (22) are used until an osteotomy (42) of predetermined size is achieved.

Owner:HUWAIS IP HLDG

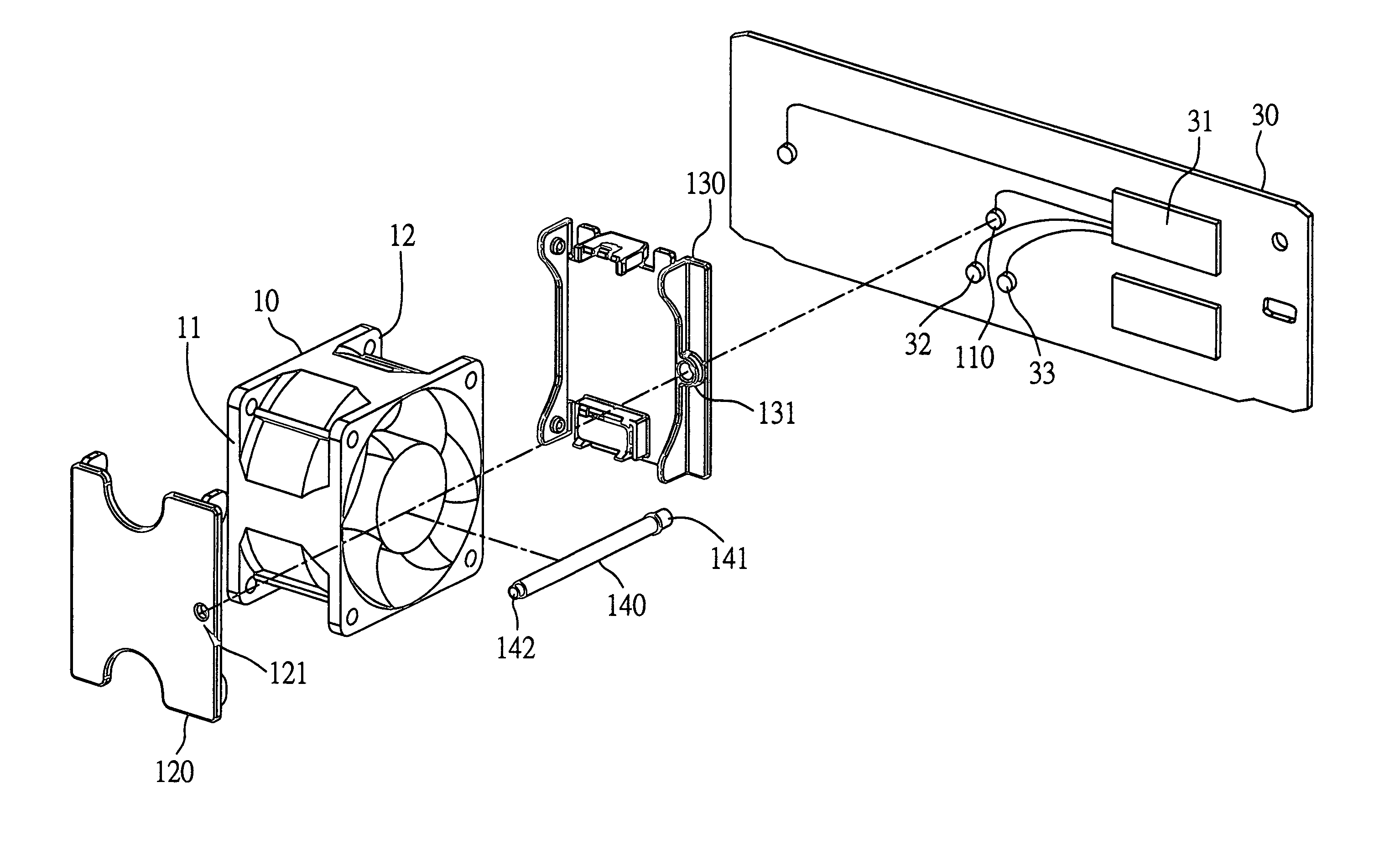

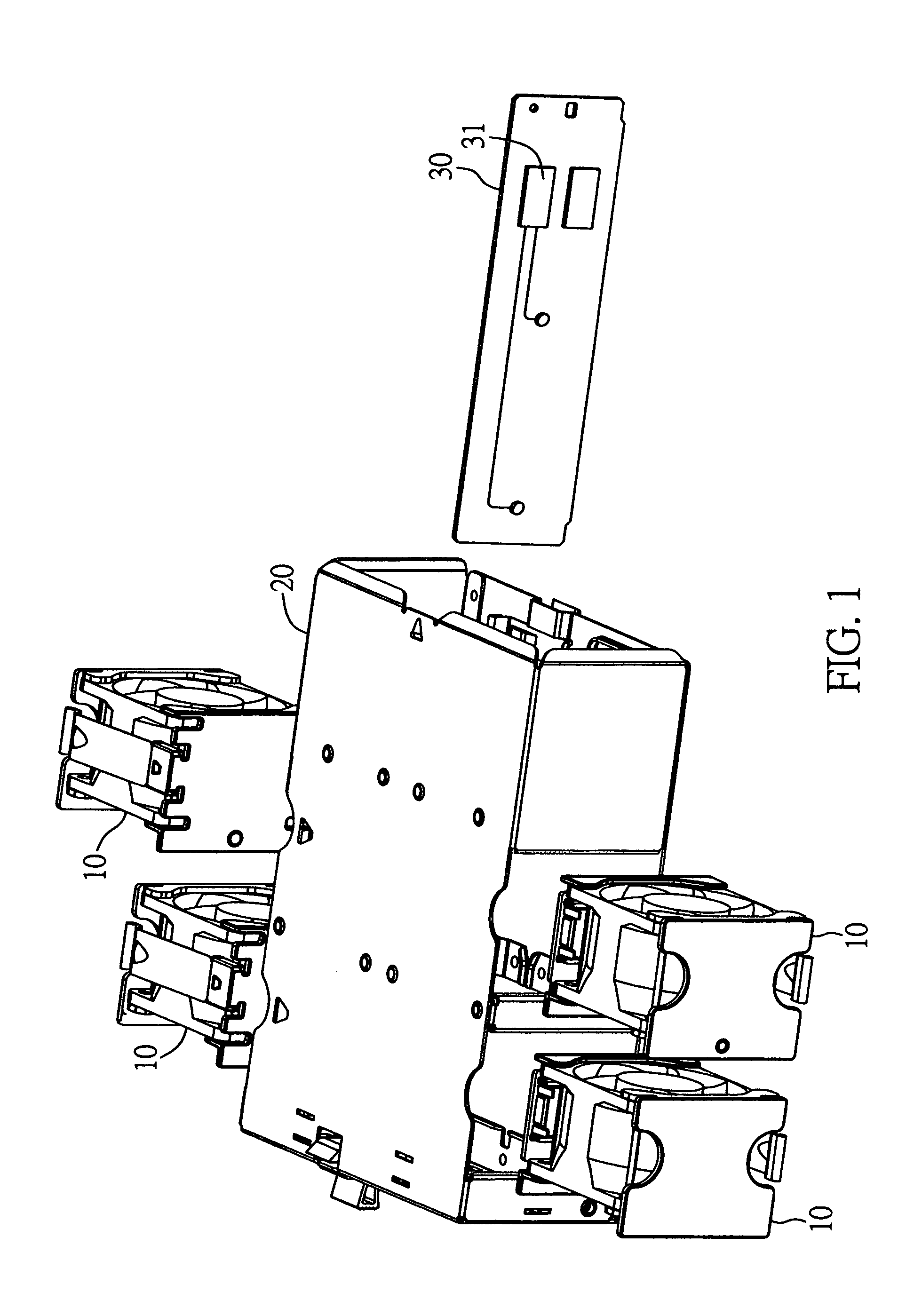

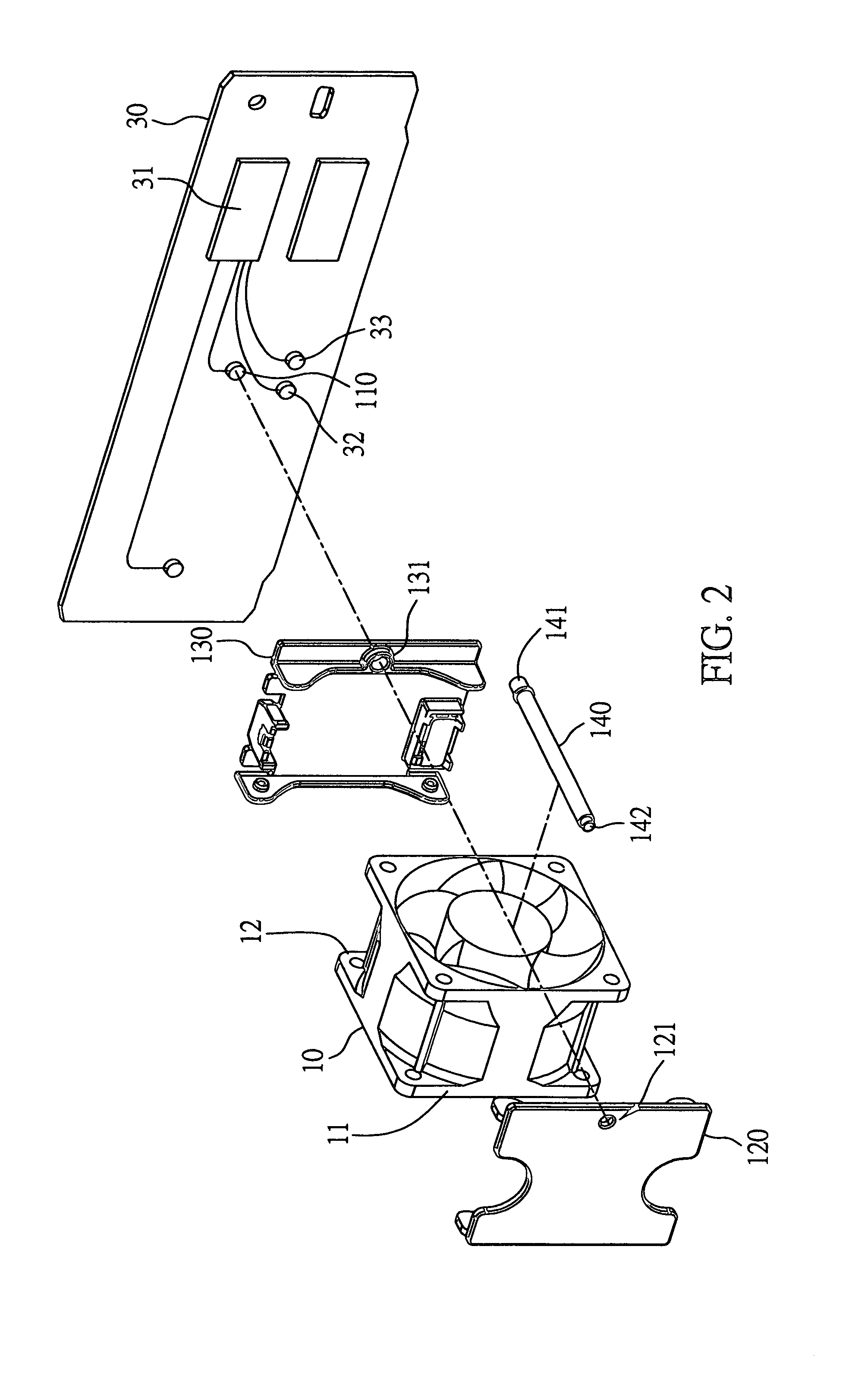

Modularized electronic device operating status display architecture

InactiveUS7040815B2Improve productivitySimple structureCoupling light guidesCooling/ventilation/heating modificationsProduction rateElectronic systems

A modularized electronic device operating status display architecture is proposed, which is designed for use with a modularized electronic device mounted on the inside of a chassis of an electronic system, and which is capable of detecting whether the modularized electronic device operates normally during operation to thereby display its operating status as light signals on the outside of the chassis to allow assembly personnel or user to learn the operating status by visually checking the externally-displayed light signals. The proposed modularized electronic device operating status display architecture is more advantageous to use in that it allows the assembly to be less complex in structure and more increased in productivity. Furthermore, it allows no removal and reconnection of electrical wires during the replacement of a faulted modularized device. This feature allows both assembly and maintenance of the modularized fan unit to be more convenient and efficient than prior art.

Owner:INVENTEC CORP

Low-temperature selective catalytic reduction NOx catalyst based on nanometer activated carbon microspheres and preparation method thereof

InactiveCN103127956AImprove sulfur resistanceEfficient use ofOrganic-compounds/hydrides/coordination-complexes catalystsDispersed particle separationCelsius DegreeMicrosphere

The invention discloses a low-temperature selective catalytic reduction NOx catalyst based on nanometer activated carbon microspheres and a preparation method of the low-temperature selective catalytic reduction NOx catalyst based on the nanometer activated carbon microspheres. The preparation method comprises the following steps of dissolving saccharides, titanium compounds, alkali metal salts and transition metal salts in water according to a molar concentration ratio of 1: 0.01-4:0.5-3:0.01-1 to obtain mixed solution, and adjusting the pH value of the mixed solution into 1-3; and atomizing the mixed solution into aerosol in an ultrasonic way, then inputting N2 or Ar as carrier gas into a tube furnace, conducting calcinations in 300-900 celsius degrees, and obtaining the low-temperature selective catalytic reduction NOx catalyst based on the nanometer activated carbon microspheres. According to the low-temperature selective catalytic reduction NOx catalyst, operation temperature of selective catalytic reduction (SCR) is lowered, and in the SCR technology, a high NO removal rate can be reached below 150 celsius degrees when NH3 is as catalyst. Moreover, when SO2 is contained in a system, higher catalytic efficiency is still kept, and poisoning of SO2 to the system has recoverability.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

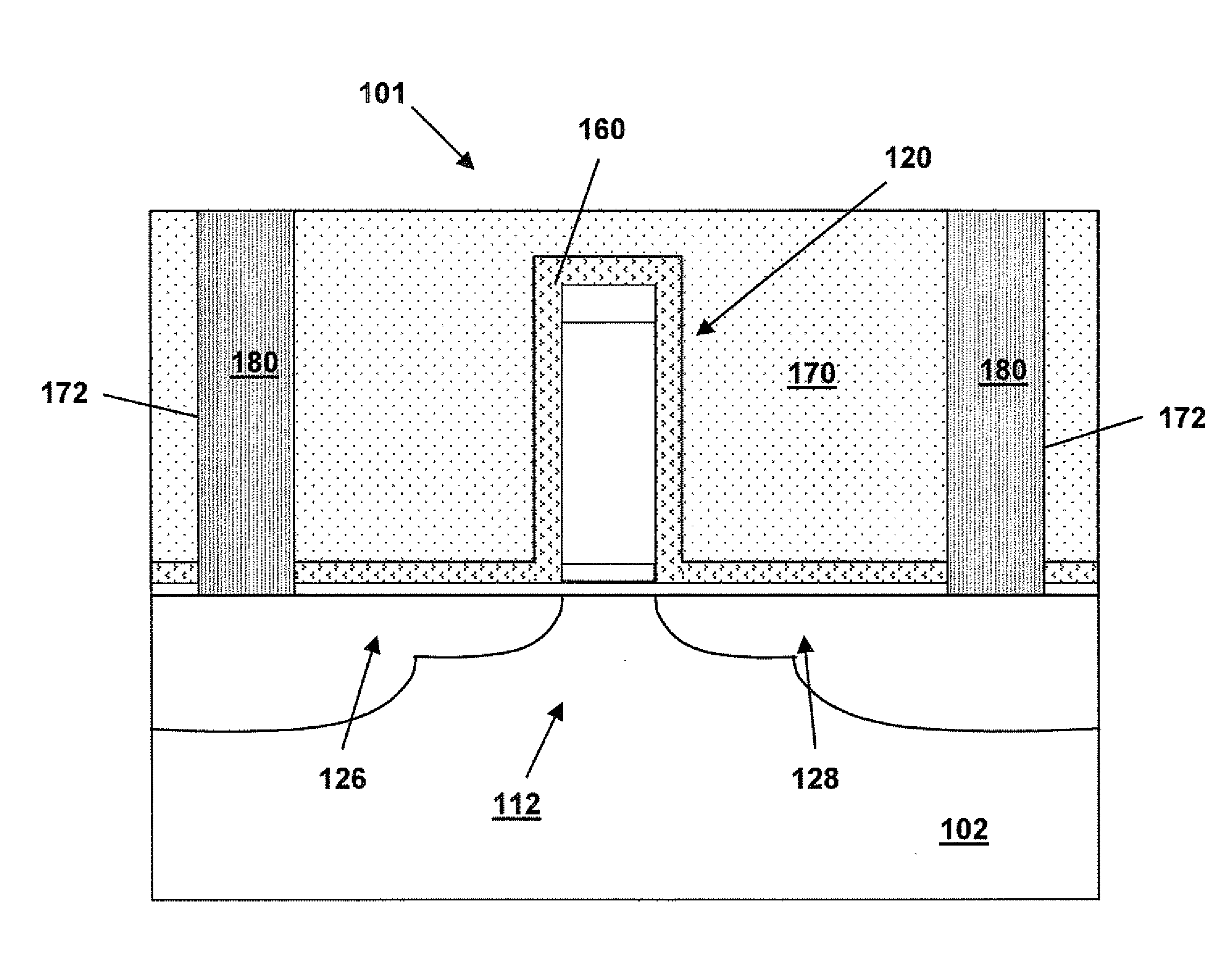

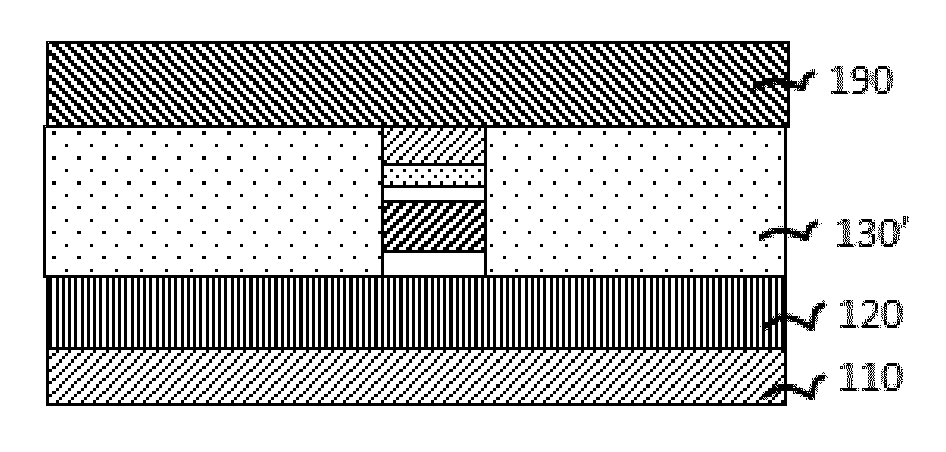

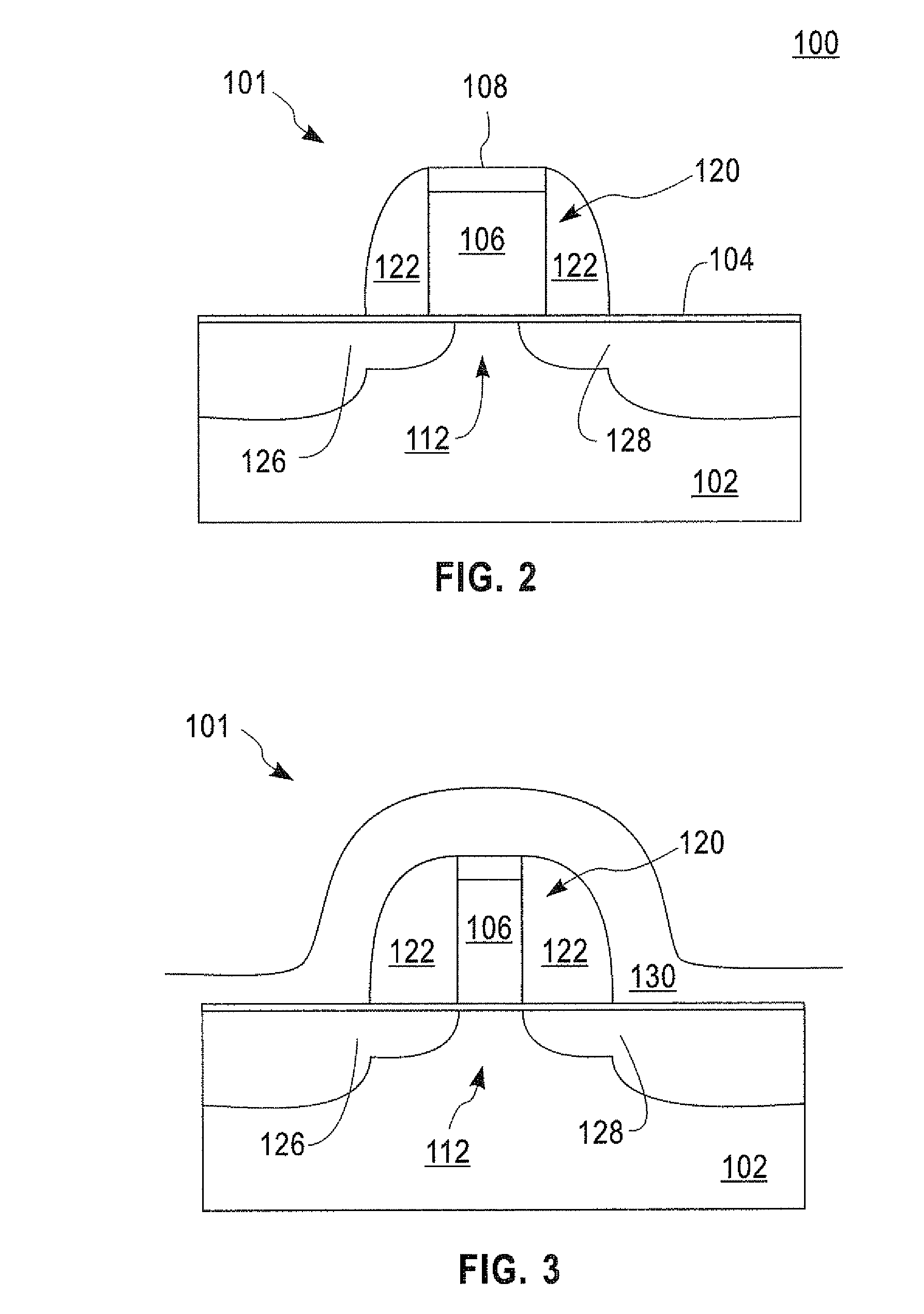

Dielectric spacer removal

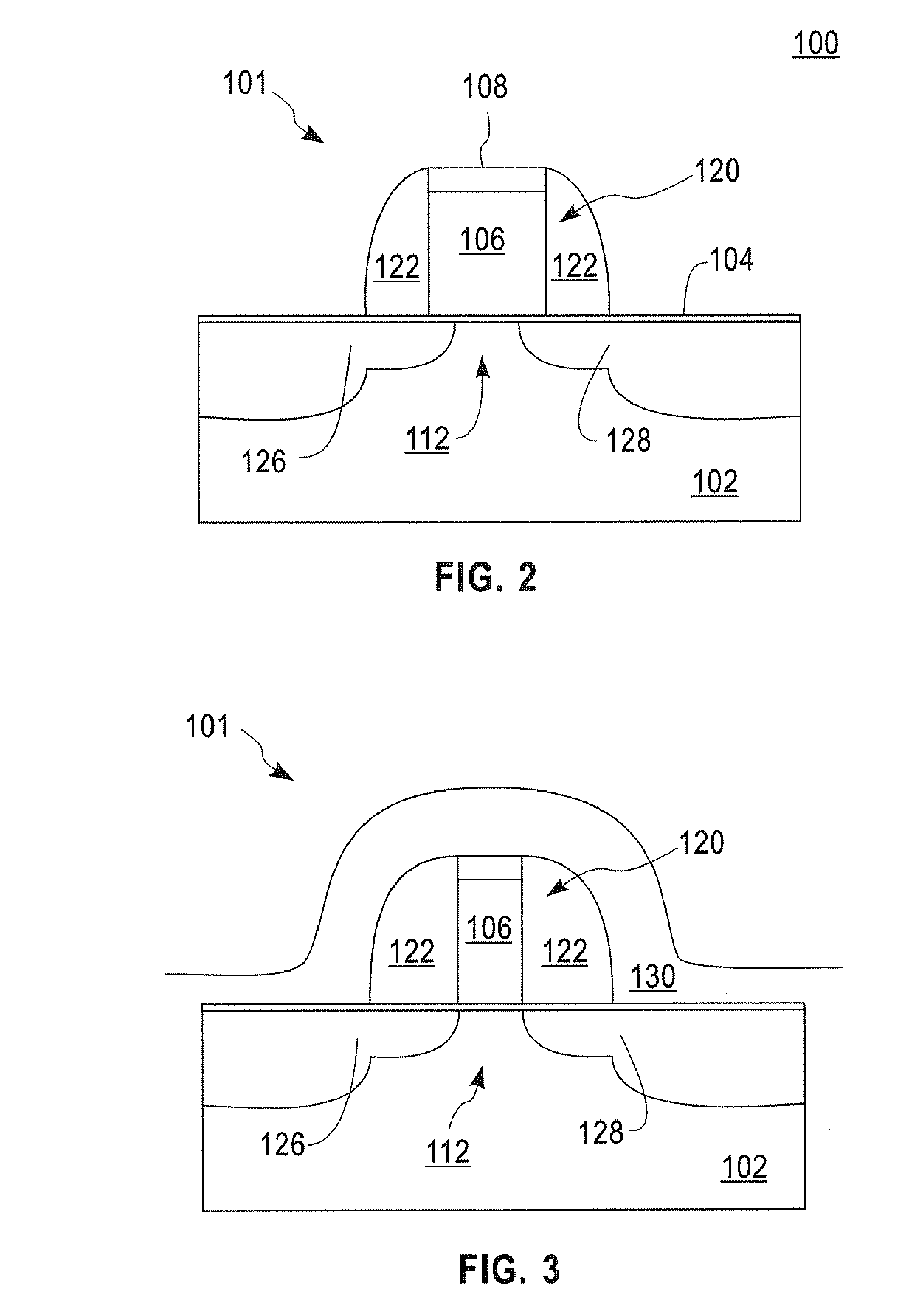

InactiveUS20090065817A1Reduce the likelihood of failureFacilitates different applicationTransistorSemiconductor/solid-state device manufacturingCMOSBiCMOS

The present invention relates to semiconductor devices, and more particularly to a process and structure for removing a dielectric spacer selective to a surface of a semiconductor substrate with substantially no removal of the semiconductor substrate. The method of the present invention can be integrated into a conventional CMOS processing scheme or into a conventional BiCMOS processing scheme. The method includes forming a field effect transistor on a semiconductor substrate, the FET comprising a dielectric spacer and the gate structure, the dielectric spacer located adjacent a sidewall of the gate structure and over a source / drain region in the semiconductor substrate; depositing a first nitride layer over the FET; and removing the nitride layer and the dielectric spacer selective to the semiconductor substrate with substantially no removal of the semiconductor substrate.

Owner:GLOBALFOUNDRIES INC

Preparation method for lignite semi-coke-based denitration agent used for low-temperature catalytic oxidation

InactiveCN106311245AWide variety of sourcesLow priceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsActive componentReaction temperature

The invention discloses a preparation method for a lignite semi-coke-based denitration agent used for low-temperature catalytic oxidation. The method prepares lignite semi-coke through high-temperature carbonization; then the lignite semi-coke is used as a carrier, and an alkaline substance and metal oxide are loaded as active components for modification; and ultrasonic equal impregnation is carried out to prepare the modified lignite semi-coke-based catalyst. The catalyst allows the conversion rate of NO to NO2 under catalytic oxidation to reach 87% at a reaction temperature of 100 DEG G; the catalyst has low catalytic activity and can be used for removing NO from a low-temperature emission source of aerobic waste gas; the method has the advantages of simple process, convenient operation, low operation cost, no need for high temperature and no use of an oxidant; and the catalyst prepared by the using the method has a high NO removal rate.

Owner:YUNNAN MINZU UNIV

Self-assembled surfactant structures

Stabilized surfactant-based membranes and methods of manufacture thereof. Membranes comprising a stabilized surfactant mesostructure on a porous support may be used for various separations, including reverse osmosis and forward osmosis. The membranes are stabilized after evaporation of solvents; in some embodiments no removal of the surfactant is required. The surfactant solution may or may not comprise a hydrophilic compound such as an acid or base. The surface of the porous support is preferably modified prior to formation of the stabilized surfactant mesostructure. The membrane is sufficiently stable to be utilized in commercial separations devices such as spiral wound modules.

Owner:ZNANO LLC

Liquid pressure pattern-transferring ink, a liquid pressure pattern-transferring film, a liquid pressure pattern-transferred article and a method of transferring a print pattern on an objective body under a liquid pressure

InactiveUS20010003611A1Inhibit deteriorationExcellent stateDecorative surface effectsPattern printingWeather resistanceColor printing

A pattern-transferring film having a print pattern provided on an upper surface thereof is floated on a liquid surface within a transferring bath and an objective body is immersed into a liquid within the transferring bath together with the pattern transferring film under a liquid pressure so as to transfer the print pattern onto the objective body. The print pattern is obtained by being printed by using an optional printing ink or inks of blue, yellow, red black and white inks or an ink or inks prepared by blending the printing inks. The liquid pressure pattern-transferring ink or inks comprise at least a resin ingredient and a color pigment. The resin ingredient of each of the color inks is composed of a fluoropolymer resin and the color pigment of each of the color inks is an inorganic pigment. In this manner, with liquid pressure pattern-transferring ink comprising the resin ingredient of the fluoropolymer resin and the inorganic pigment in spite of its color, all the color printing inks have a weather resistance of 5000 hours or more determined by a JIS based sunshine weather meter. Thus, there occurs no removal of the transferred pattern out of the objective body which tends to be caused by a deterioration of the resin ingredient, if otherwise and the color of the transferred pattern neither changes nor fades, which enables the article to have its life span maintained for a longer period.

Owner:TAICA

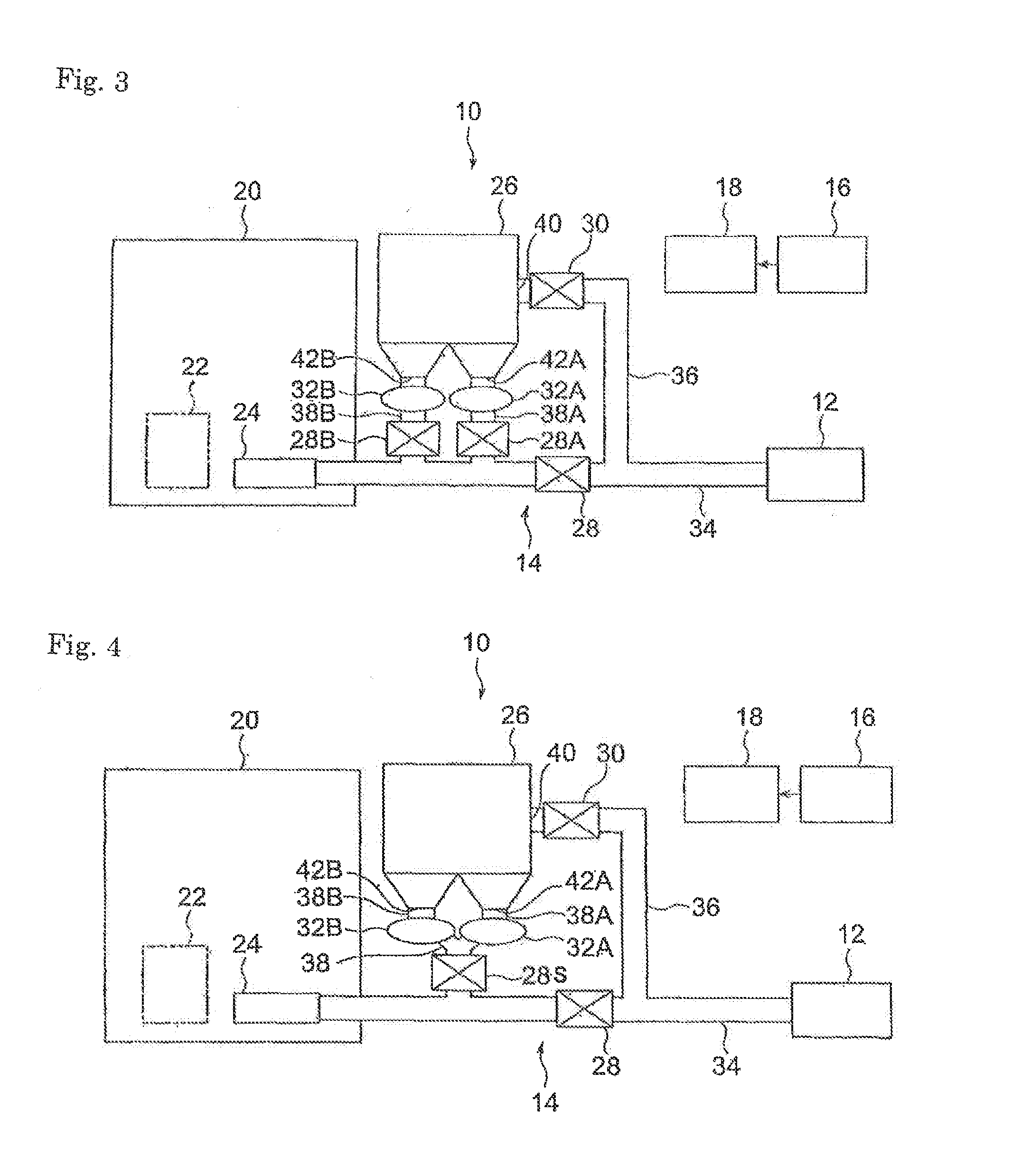

Method for shot-peening and a shot-peening machine

The cost for shot-peening is intended to be reduced. The method for shot-peening of the present invention comprises a first step for processing a work by shot-peening by projecting shots onto the work, and a second step for processing the work by shot-peening by projecting the shots onto the work at a speed for projecting the shots that is slower than the speed in the first step, wherein the second step uses the same shot-peening machine and same shots that have been used in the first step. By this method, an intended distribution of compressive residual stresses is obtained by the processes in the first and second steps and the surface roughness of the work is decreased by the process in the second step wherein the shots are projected at the speed that is slower than that in the first step. Further, no removal or supply of the shots and no re-setting of the conditions for the process that are related to the removal and supply of the shots are required. Multiple shot-peening machines do not need to be installed. Thus the cost for shot-peening is reduced.

Owner:SINTOKOGIO LTD

Full Displacement Pile Tip and Method for Use

ActiveUS20150233075A1Increases size and numberSteelDrill bitsBulkheads/pilesNo removalOperating cost

The device is a Full Displacement Pile Tip (FDPT) with a sacrificial drill bit that is connected to a steel pipe, where the tip comprises at least four flanges or fish tails at the cutting edge extending from a conical, dome-like bottom, and integrally connected to the cutting teeth along the tip's axial shaft. The purpose of the FDPT is allow a steel pier to be screwed into the ground to serve as a foundation for a structure. This is a single operation where the FDPT and pipe remain in the ground. There is no removal of FDPT, minimal pouring of concrete, and there is minimal soil spoilage. A smaller drilling rig can be employed to save operating costs.

Owner:MAGGIO MICHAEL

Catalyst capable of removing N2O, NO and NO2 simultaneously and preparation method

InactiveCN106423184AWide temperature windowImprove denitrification effectNitrous oxide captureHeterogenous catalyst chemical elementsWater vaporOxygen inhibition

The invention relates to the field of industrial catalysis and environmental governance, in particular to a catalyst capable of removing N2O, NO and NO2 simultaneously and a preparation method of the catalyst. After tail gas containing N2O, NO and NO2 is subjected to the action of the catalyst, on one hand, N2O gas is decomposed directly, on the other hand, NO gas and NO2 gas are subjected to an SCR (selective catalytic reduction) denitration reaction, and simultaneous removal of N2O, NO and NO2 is realized. The plate catalyst capable of removing N2O, NO and NO2 simultaneously is prepared from V2O5 and a Co-based composite metal oxide as active components, TiO2 as a supporter and one or two of WO3 and MoO3 as a metal additive through mixing, rolling coating, pleating, drying and roasting. The N2O decomposing efficiency of the catalyst in the temperature range of 300-450 DEG C can reach 80% or higher, the NO removal rate and the NO2 removal rate can reach 85% or higher, and the catalyst has excellent oxygen inhibition resistance and water vapor poisoning resistance.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

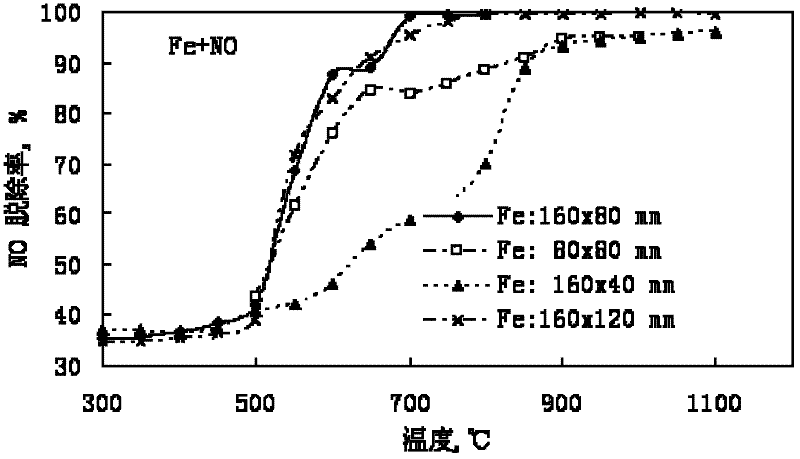

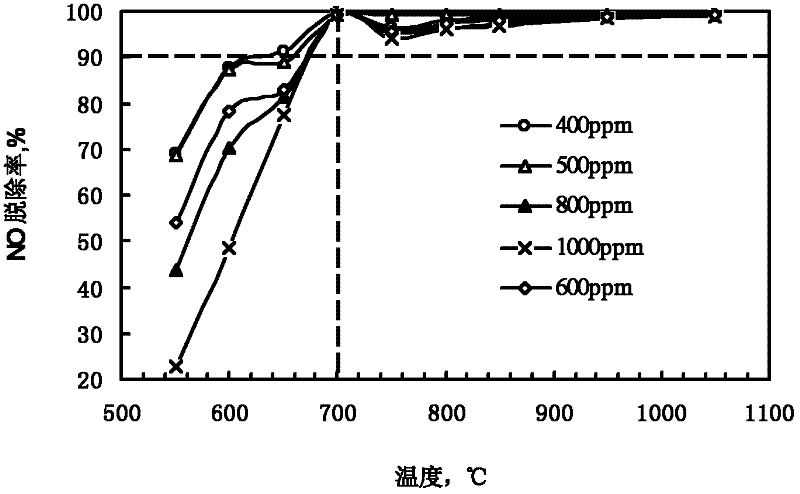

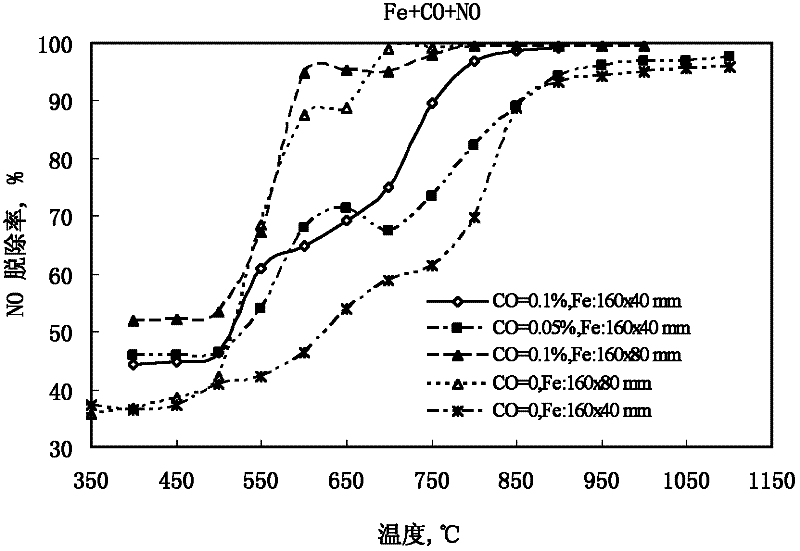

Method for reducing NO by using iron catalyst

InactiveCN102240505AImprove removal efficiencyGuaranteed not to be oxidizedDispersed particle separationNo removalPollution

The invention relates to a method for reducing NO by using an iron catalyst, comprising the following step of: enabling the gas NO generated in a coal burning process to be in contact with metallic iron at a temperature of 500-1100 DEG C. The invention has the advantages of simpleness, low cost and high efficiency without secondary pollution and can achieve the NO removal efficiency more than 95 percent at more than 750 DEG C.

Owner:DONGHUA UNIV

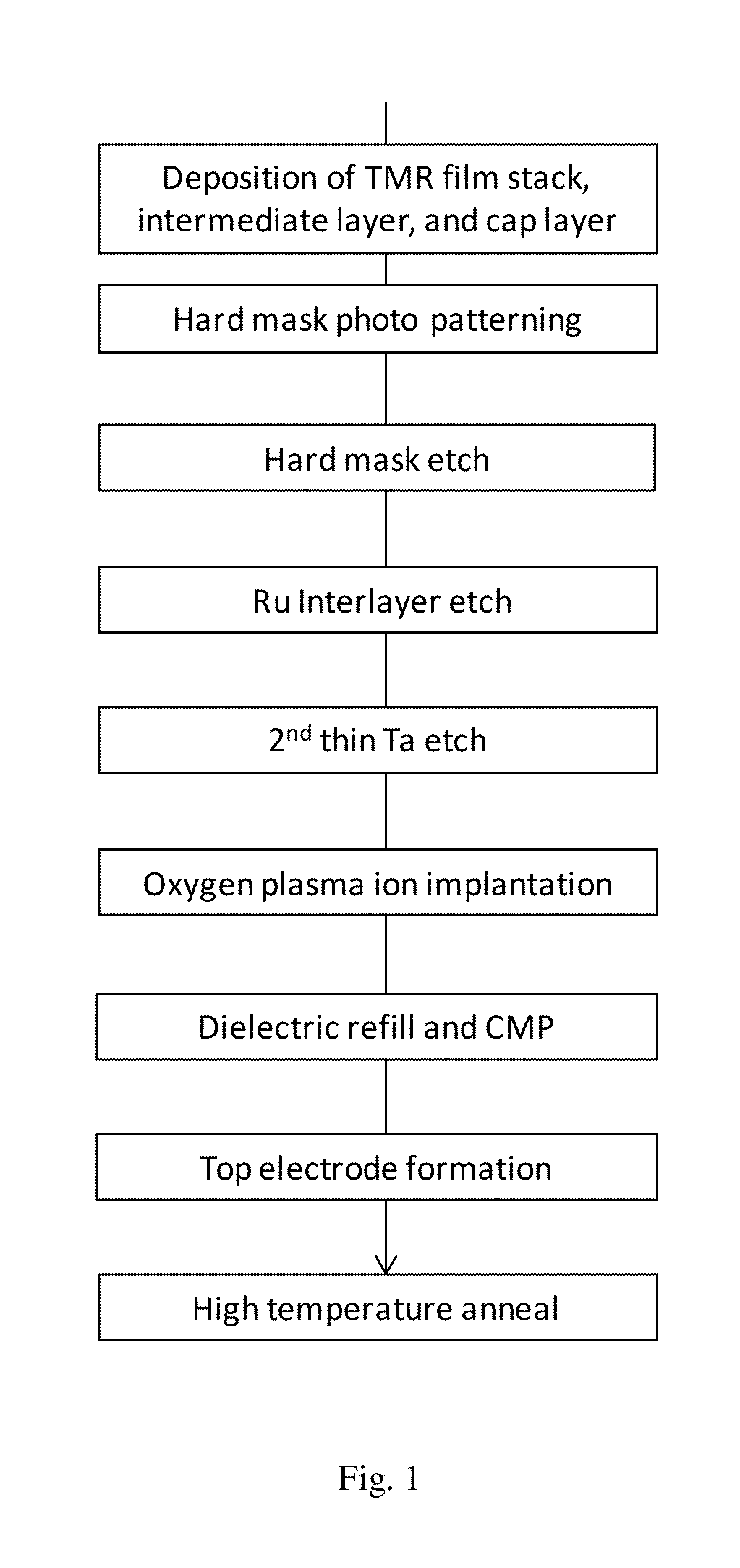

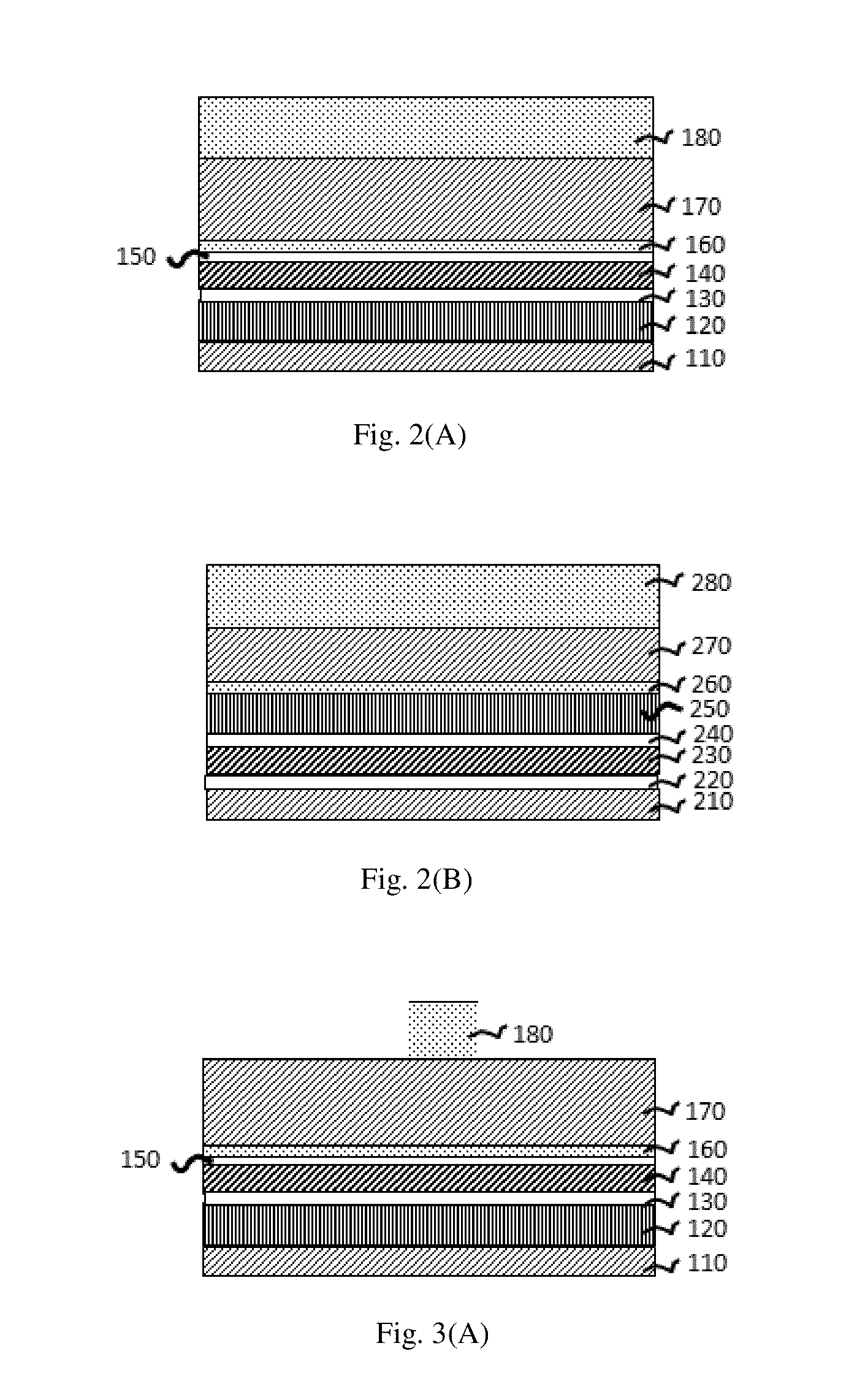

Hybrid method of patterning MTJ stack

InactiveUS9006849B2Magnetic-field-controlled resistorsSemiconductor/solid-state device manufacturingEtchingOxygen plasma

This invention comprises a method to make small MTJ element using hybrid etching and oxygen plasma immersion ion implantation. The method has no removal of the magnetic free layer (or memory layer) and hence prevents any possible physical damage near the free layer edges. After photolithography patterning, alternative Ta, Ru, Ta etchings are performed before it stops on an MgO intermediate layer above the free layer. Then an oxygen plasma immersion ion implantation is performed to completely oxidize the exposed portion of the free layer, leaving the hard mask covered portion unchanged which define the lateral width of the MTJ element.

Owner:GUO YIMIN

Quaternary composite oxide low-temperature SCR (selective catalytic reduction) catalyst and preparation method thereof

InactiveCN106166487AImprove composite propertiesGood dispersionHeterogenous catalyst chemical elementsDispersed particle separationNo removalComposite oxide

The invention discloses a quaternary composite oxide low-temperature SCR (selective catalytic reduction) catalyst and a preparation method thereof. According to the catalyst, TiO2-ZrO2 serves as a carrier, and a manganese-cerium oxide is loaded on the carrier. The mole ratio of Ti to Zr to Mn to Ce in the catalyst is 1: 1: (0.005-1): (0.005-1). The obtained catalyst has the advantages that SCR operation temperature is reduced, high NO removal rate can be reached at the temperature of 80-180 DEG C when NH3 serves as a reducing agent in the SCR process, high catalytic efficiency can be kept when a system contains SO2 and H2O, and the system harmed by the SO2 can be restored.

Owner:GUODIAN ENVIRONMENTAL PROTECTION RES INST CO LTD

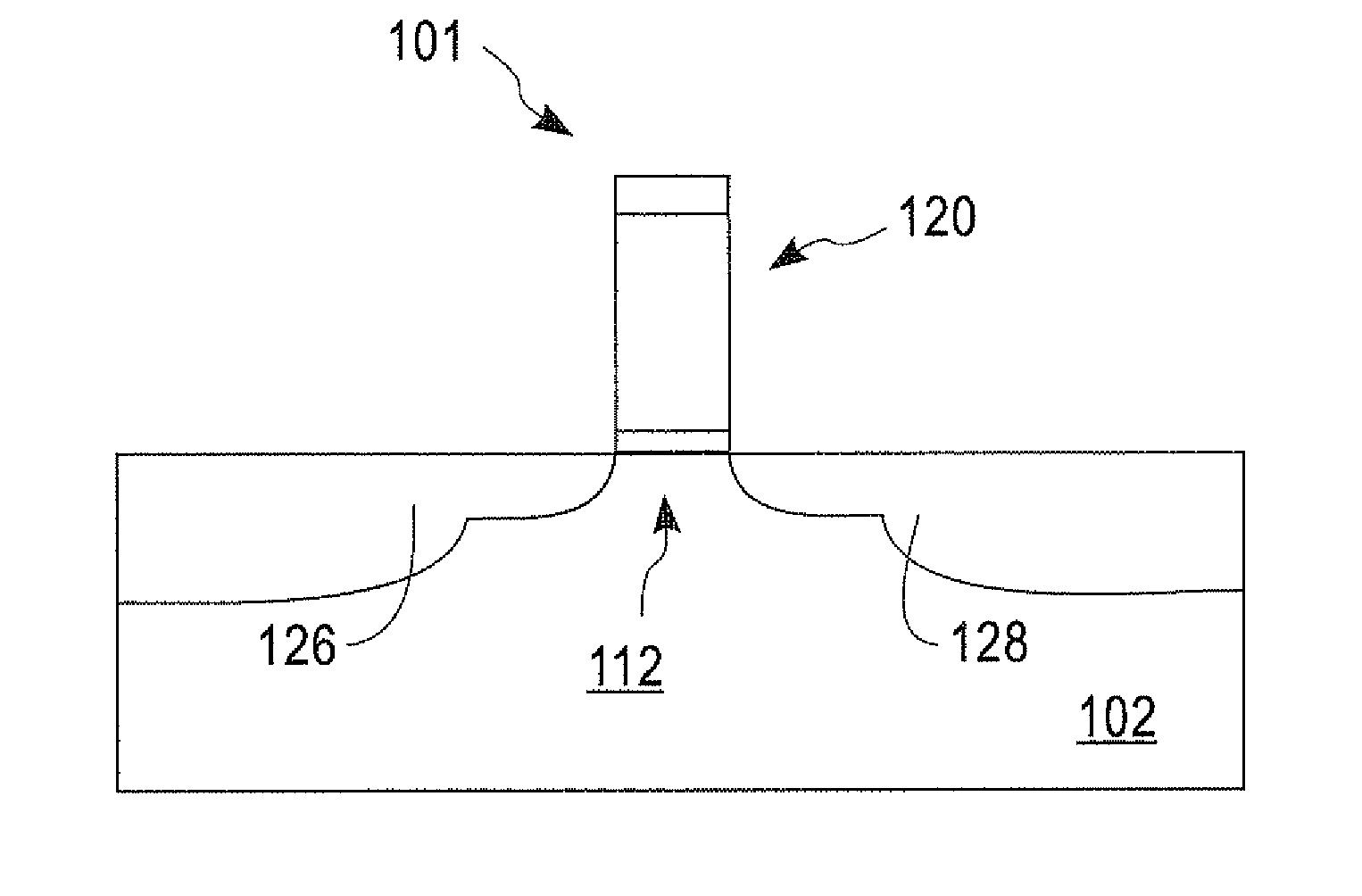

Dielectric spacer removal

InactiveUS7919379B2Reduce the likelihood of failureFacilitates different applicationTransistorSemiconductor/solid-state device manufacturingCMOSEngineering

The present invention relates to semiconductor devices, and more particularly to a process and structure for removing a dielectric spacer selective to a surface of a semiconductor substrate with substantially no removal of the semiconductor substrate. The method of the present invention can be integrated into a conventional CMOS processing scheme or into a conventional BiCMOS processing scheme. The method includes forming a field effect transistor on a semiconductor substrate, the FET comprising a dielectric spacer and the gate structure, the dielectric spacer located adjacent a sidewall of the gate structure and over a source / drain region in the semiconductor substrate; depositing a first nitride layer over the FET; and removing the nitride layer and the dielectric spacer selective to the semiconductor substrate with substantially no removal of the semiconductor substrate.

Owner:GLOBALFOUNDRIES INC

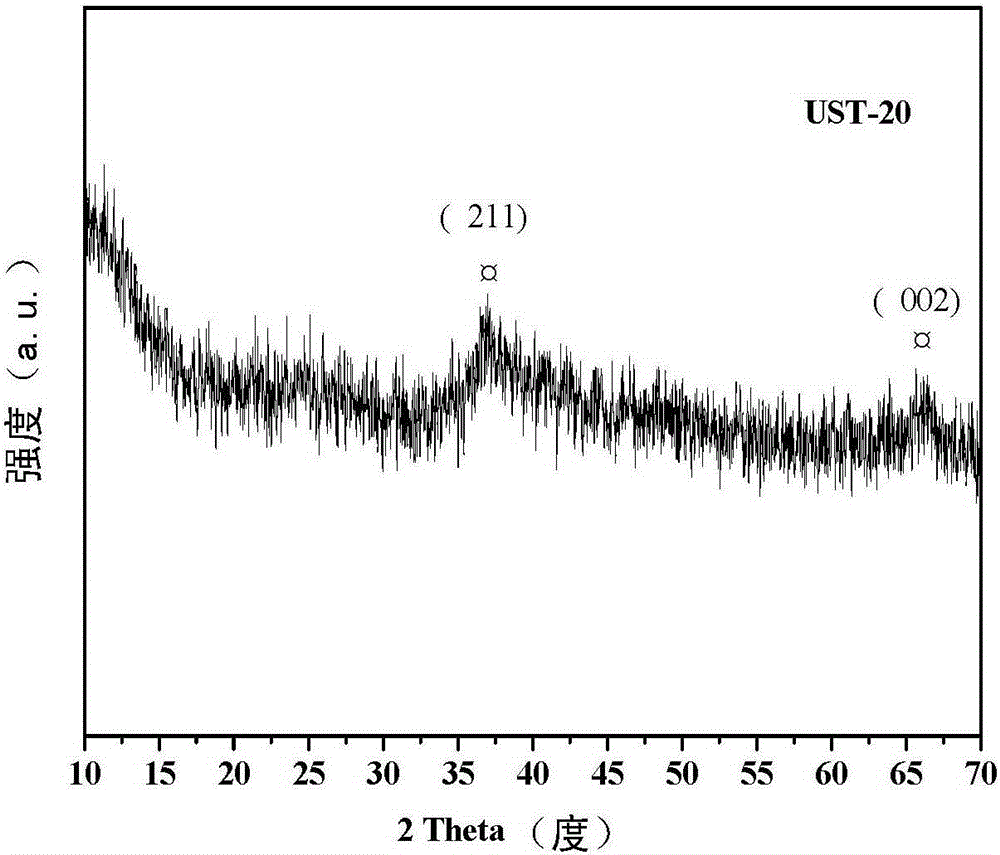

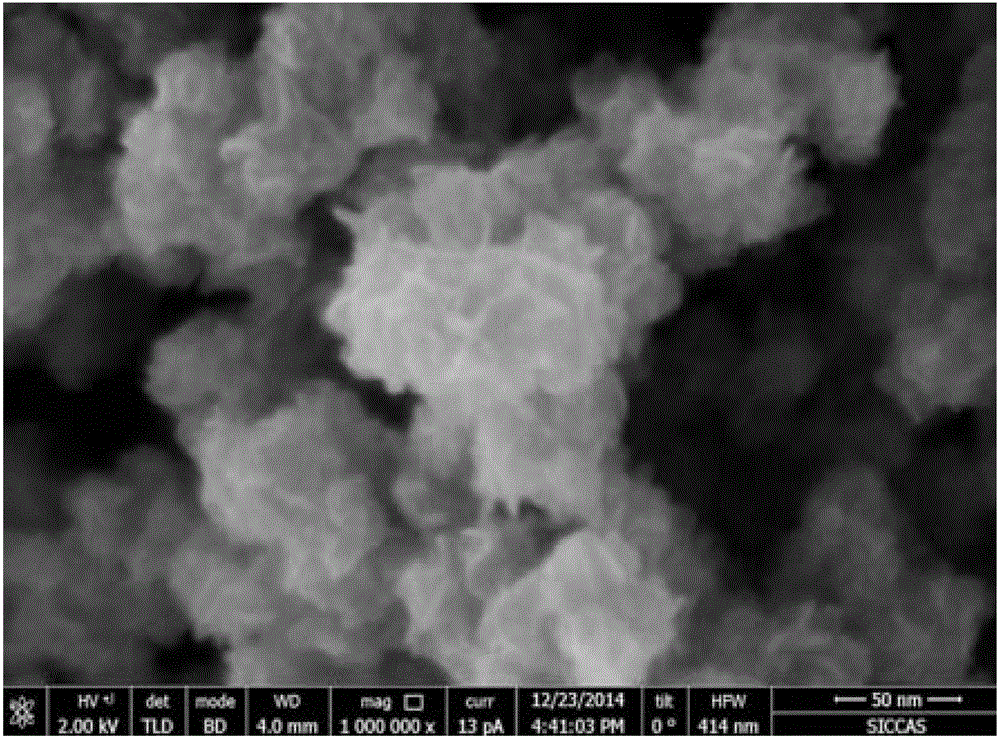

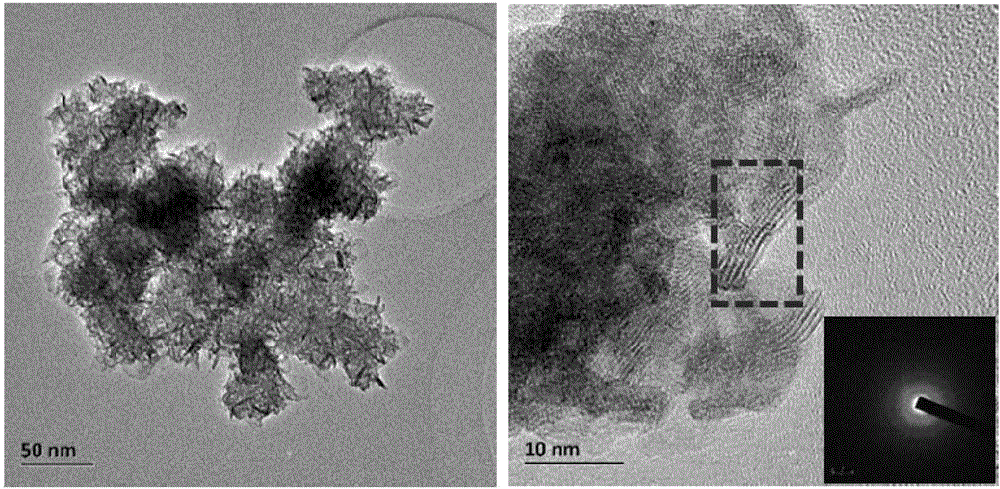

Method for preparing manganese dioxide catalyst for normal-temperature low-concentration NO catalytic purification with ultrasonic assisted alcohol-water solution method

InactiveCN105327697ALow costImprove removal effectDispersed particle separationCatalyst activation/preparationNano catalystAlcohol

The invention relates to a method for preparing a manganese dioxide catalyst for normal-temperature low-concentration NO catalytic purification with an ultrasonic assisted alcohol-water solution method. According to the method, a mixed solution formed through mixing of a potassium permanganate solution and alcohol is subjected to ultrasonic treatment for 10-60 min, solid-liquid separation is performed, acquired solids are dried, and the nano-manganese dioxide catalyst is prepared. According to the method, the ultrasonic assisted alcohol-water solution oxidation-reduction method is adopted to prepare the nano-manganese dioxide catalyst, the alcohol is taken as a raw material, and the cost is low; the oxidation-reduction method is adopted, and the operation is simple and convenient; by means of the ultrasonic treatment, not only is the NO removal performance remarkably improved, but also the preparation time is greatly shortened; the catalyst prepared with the method has excellent catalytic performance, and 100% NO removal rate can be kept for longer than 5 h under the fixed test condition.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

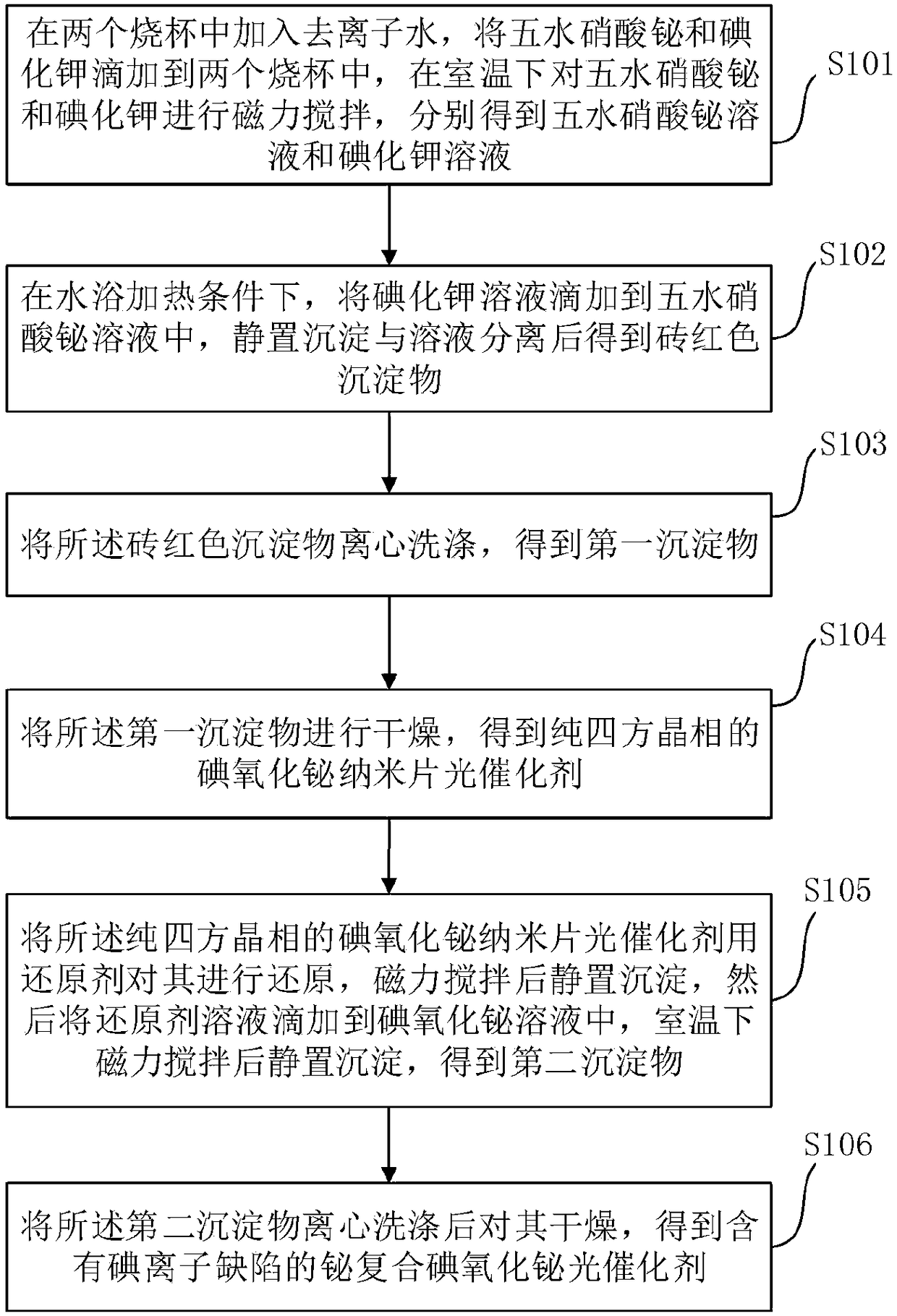

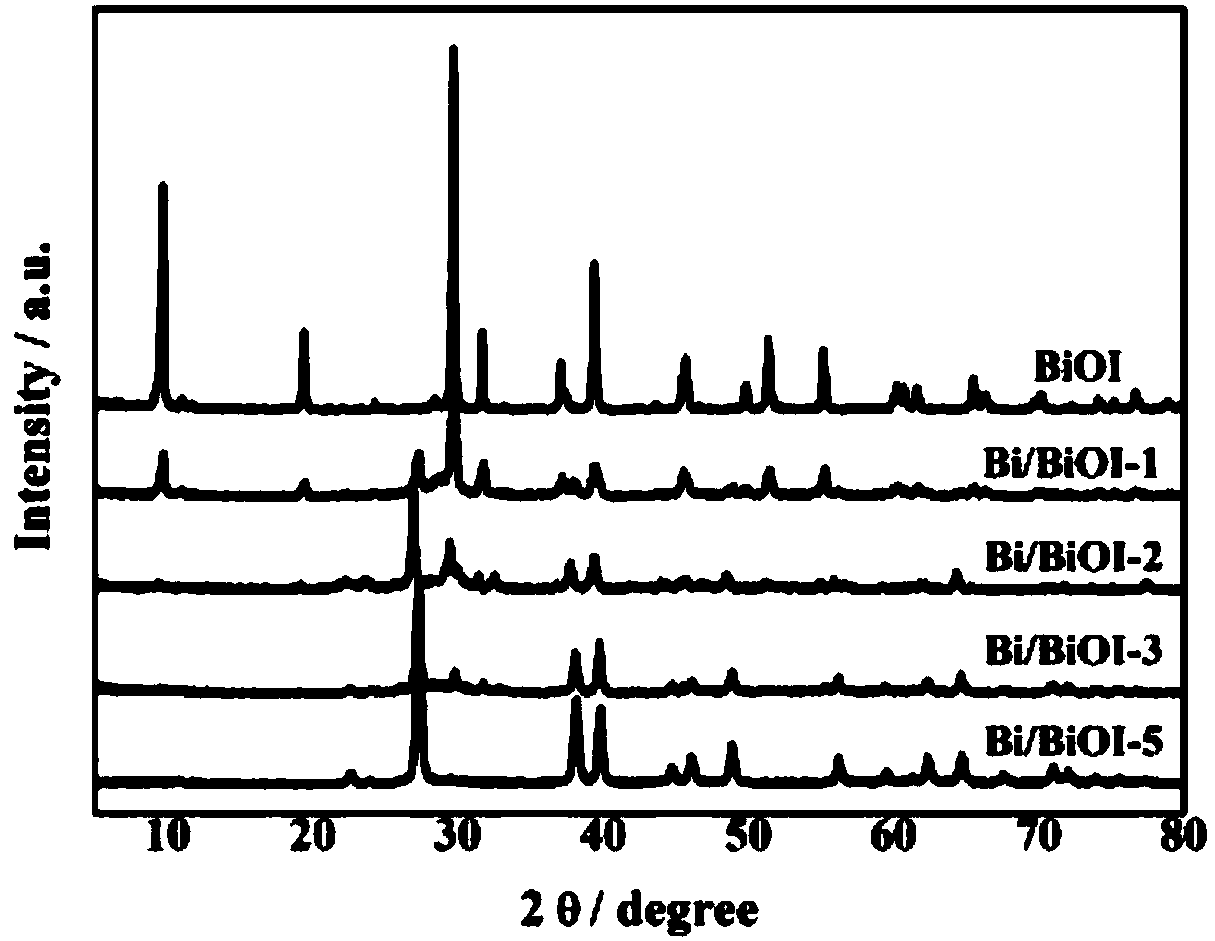

Bismuth compounded bismuth oxyiodide photocatalyst containing iodide ionic defects and preparation method of bismuth compounded bismuth oxyiodide photocatalyst

InactiveCN108435216AAltering the excitation transport pathPromote migration and transformationDispersed particle separationCatalyst activation/preparationElectron holeValence band

The invention discloses a bismuth compounded bismuth oxyiodide photocatalyst containing iodide ionic defects and a preparation method of the bismuth compounded bismuth oxyiodide photocatalyst. The bismuth compounded bismuth oxyiodide photocatalyst containing the iodide ionic defects is prepared through precipitation, centrifugal washing, magnetic stirring and other steps. According to the bismuthcompounded bismuth oxyiodide photocatalyst containing the iodide ionic defects and prepared with the method, a plurality of defect intermediate levels are formed between a valence band and a conduction band of the photocatalyst by constructing the iodide ionic defects, excitation and transmission paths of photo-induced electrons are changed, migration and transformation of photo-generated chargesare promoted, and recombination of photo-induced electron-hole pairs is inhibited. Visible light response range is enlarged, visible light utilization rate is increased, and finally, the NO removal rate of the prepared bismuth compounded bismuth oxyiodide photocatalyst containing the iodide ionic defects is increased. Besides, economic cost for producing the bismuth compounded bismuth oxyiodide photocatalyst containing the iodide ionic defects and prepared with the method is low.

Owner:CHONGQING TECH & BUSINESS UNIV

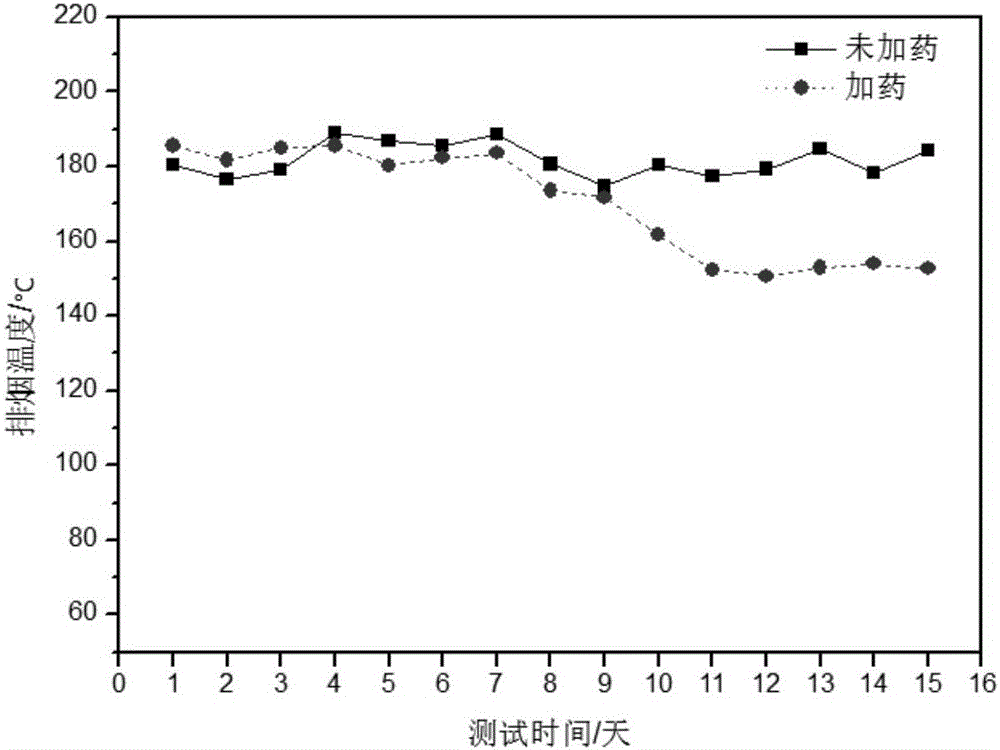

Synergistic-denitration type liquid boiler clinker removal agent and preparation method and application thereof

ActiveCN105670733ALarge specific surface areaAvoid stickingSolid fuelsFuel additivesCerium nitrateCopper nitrate

The invention discloses a synergistic-denitration type liquid boiler clinker removal agent and a preparation method and application thereof and belongs to the field of clean combustion of coal.The clinker removal agent is prepared from, by weight, 5-20% of magnesium acetate, 1-5% of copper nitrate, 1-5% of nickel nitrate, 2-10% of ammonium nitrate, 3-10% of boric acid, 0.5-2% of cerium nitrate and the balance water.The clinker removal agent is atomized and added into a boiler through jetting, magnesium acetate is decomposed to generate MgO and alkyl (CHi) at the high temperature, the fuel intermediate CHi has reduction action for NO, the content of NO in flue gas can be reduced, the synertistic effect is achieved for denitration, generated nanoscale MgO pores are high in specific surface area, the clinker removal agent can serve as a catalytic carrier of a denitration reaction and also can react with a low-melting-point compound in a clinker layer to raise the clinker melting point so that clinker can be loosened and be crispy, the clinker removal agent is small in consumption and can obviously reduce the boiler coking phenomenon, and meanwhile the good synergistic NO removal effect is achieved.

Owner:山东默锐环境产业股份有限公司

Mixed solution for simultaneously desulfurizing and denitrating and application method thereof

InactiveCN101653691ARealize desulfurization and denitrificationFair priceDispersed particle separationAir quality improvementChemical compositionFlue gas

The invention belongs to the technical field of environmental protection, and relates to the technology of simultaneously removing sulphur dioxide and oxynitride in flue gas of a boiler, in particularto a mixed solution for simultaneously desulfurizing and denitrating and an application method thereof. The mixed solution is characterized in that: the mixed solution is prepared from the followingchemical compositions: 0 to 30 mass percent of sodium carbonate solution and 0 to 30 mass percent of sodium chlorite solution. The mixed solution is nontoxic and harmless, is moderate in price, has aSO2 removal rate of 80 to 90 percent and a NO removal rate over 60 percent, and can be produced in batches on a large scale.

Owner:NANKAI UNIV +1

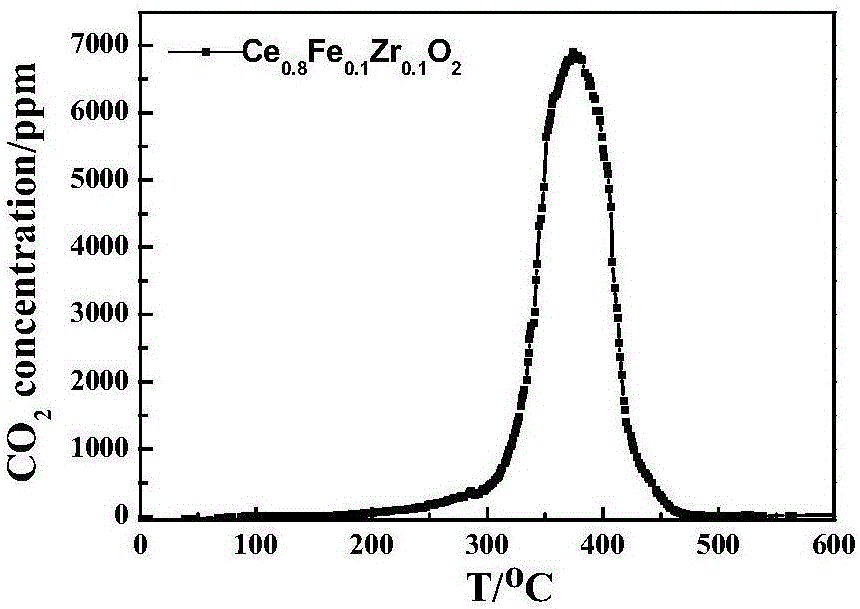

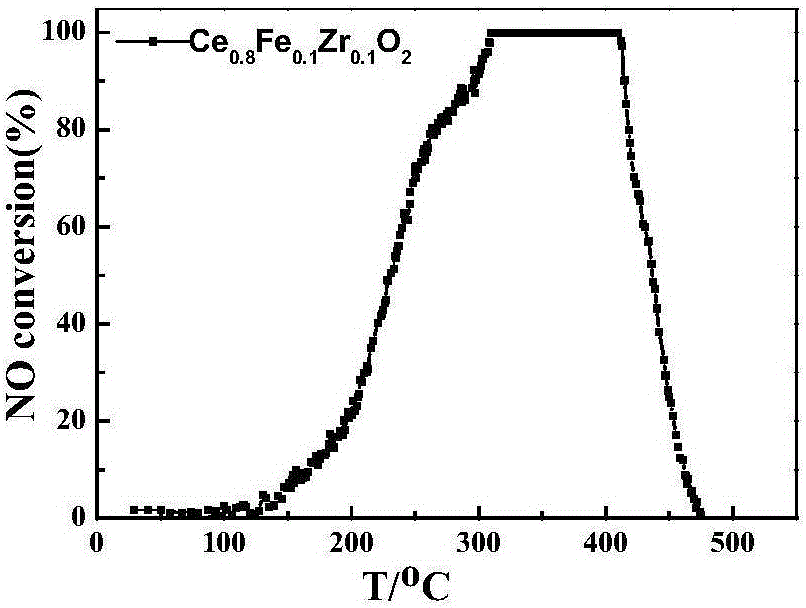

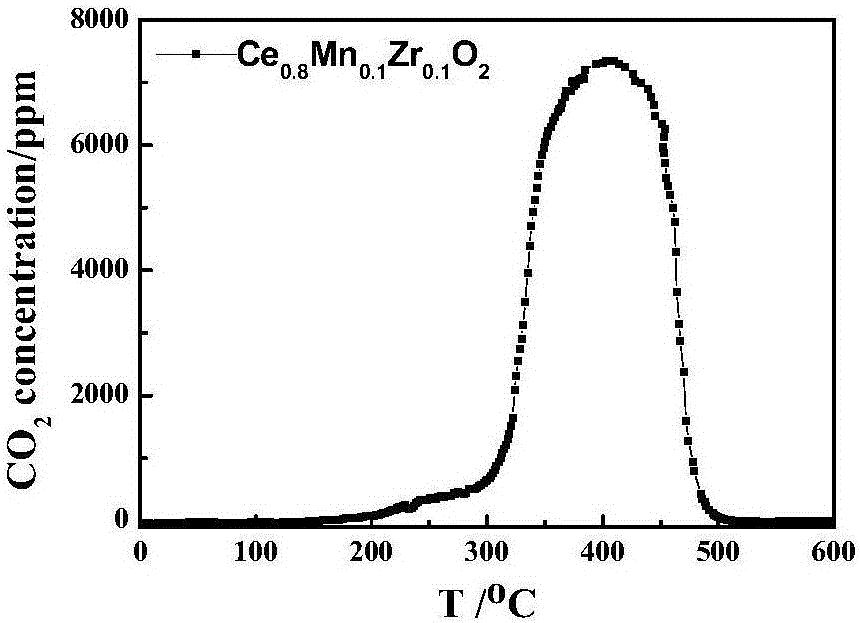

Macroporous Ce-Zr based composite metal oxide catalyst, preparation method, and application thereof

InactiveCN106582665AHigh activityFacilitated DiffusionHeterogenous catalyst chemical elementsDispersed particle separationCeriumCobalt

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com