Preparation method of nanosheet self-assembled C-doped (BiO)2CO3 microsphere visible light catalyst

A technology of self-assembly and nanosheets, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as low crystallinity of bismuth oxycarbonate, unstable structure, and unsatisfactory photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0036] Dissolve 0.46g of sodium carbonate in 75mL of deionized water, add 0.0580g of glucose to it, then add 1.6g of bismuth citrate (the molar ratio of bismuth citrate to sodium carbonate is 0.926:1, the molar ratio of bismuth citrate to glucose Ratio is 12.476:1, bismuth citrate concentration is 0.0536mol / L), after stirring for 30 minutes, the mixed solution obtained is moved into a 100mL autoclave, and reacted at 180°C for 24 hours. After the reaction, the reaction product was taken out, the reaction product was centrifuged, filtered, washed twice with water and washed with ethanol twice, and then dried the obtained solid at 80°C to obtain C-doped (BiO) 2 CO 3 catalyst of light.

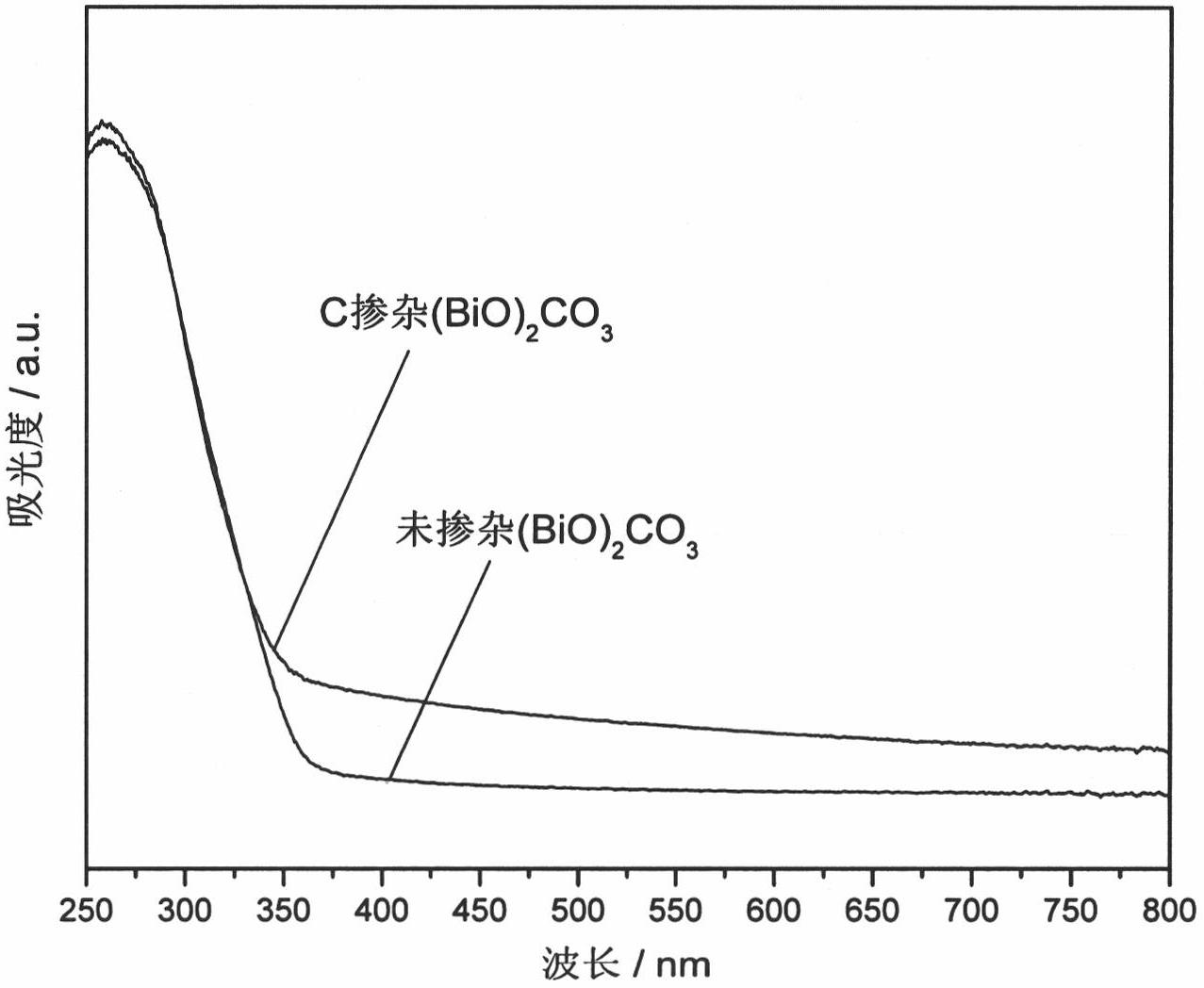

[0037] Doping the resulting C (BiO) 2 CO 3 The photocatalyst was analyzed by UV-vis DRS, the results are as follows figure 1 as shown, figure 1 C-doped (BiO) prepared for Example 1 of the present invention 2 CO 3 The UV-vis DRS spectrum of the photocatalyst, the results show that, with undo...

Embodiment example 2

[0040] Dissolve 0.46g of sodium carbonate in 75mL of deionized water, add 0.1160g of glucose to it, then add 1.6g of bismuth citrate (the molar ratio of bismuth citrate to sodium carbonate is 0.926:1; the molar ratio of bismuth citrate to glucose The ratio is 6.238:1; the bismuth citrate concentration is 0.0536mol / L), after stirring for 30 minutes, the resulting mixed solution was moved into a 100mL autoclave, and reacted at 180°C for 24 hours. After the reaction, the reaction product was taken out, the reaction product was centrifuged, filtered, washed twice with water and washed with ethanol twice, and then dried the obtained solid at 80°C to obtain C-doped (BiO) 2 CO 3 catalyst of light.

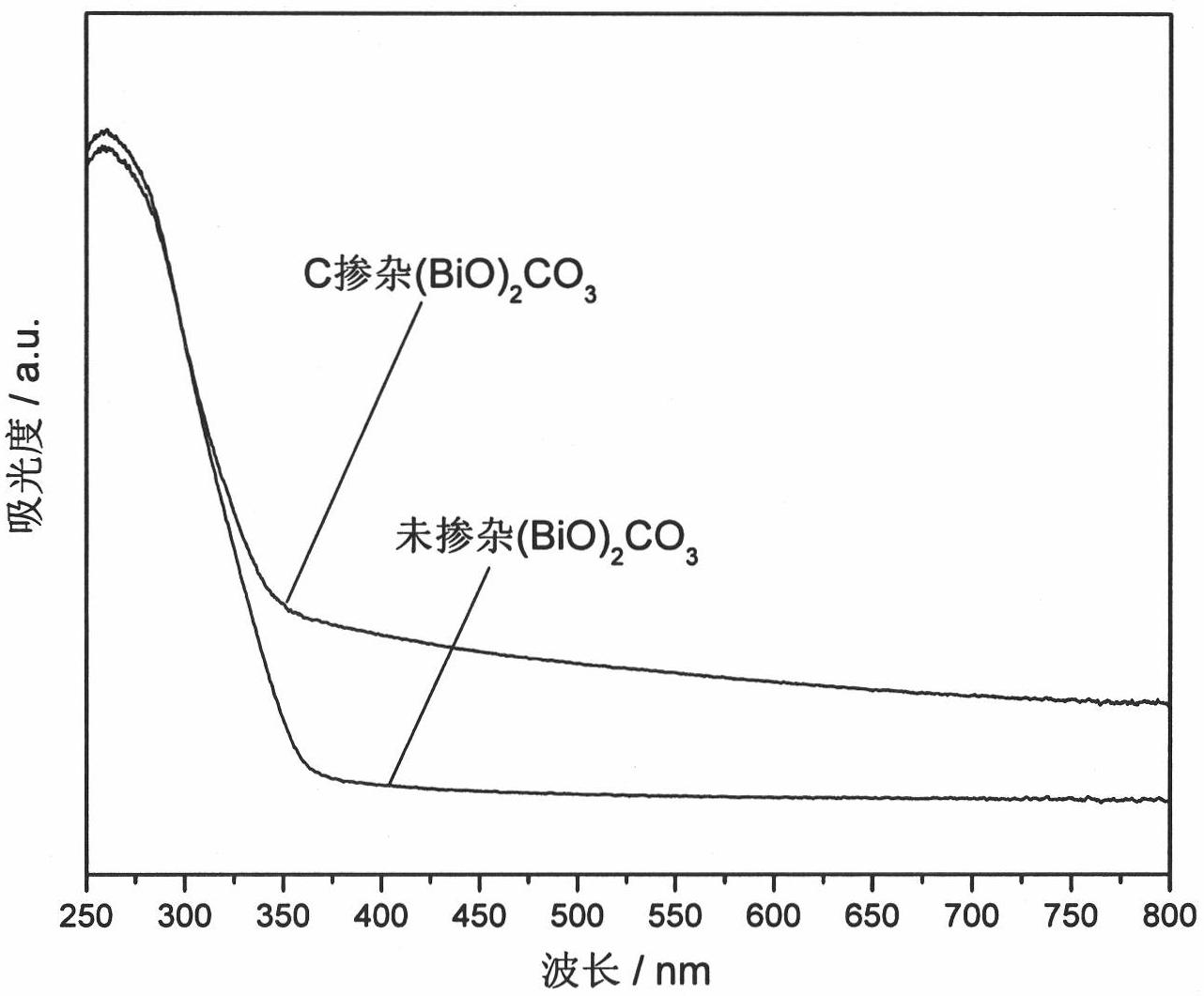

[0041] image 3 For the UV-vis DRS collection of illustrative plates of the photocatalyst that the embodiment of the present invention 2 prepares, the result shows, with undoped (BiO) 2 CO 3 In contrast, due to the effect of C doping, the C doped (BiO) prepared in this example 2 CO ...

Embodiment example 3

[0044] Dissolve 0.46g of sodium carbonate in 75mL of deionized water, add 0.20g of glucose to it, then add 1.6g of bismuth citrate (the molar ratio of bismuth citrate to sodium carbonate is 0.926:1; the molar ratio of bismuth citrate to glucose The ratio is 3.618:1; the bismuth citrate concentration is 0.0536mol / L), after stirring for 30 minutes, the resulting mixed solution was moved into a 100mL autoclave, and reacted at 180°C for 24 hours. After the reaction, the reaction product was taken out, the reaction product was centrifuged, filtered, washed twice with water and washed with ethanol twice, and then dried the obtained solid at 80°C to obtain C-doped (BiO) 2 CO 3 catalyst of light.

[0045] Figure 5 For the UV-vis DRS collection of illustrative plates of the photocatalyst that the embodiment of the present invention 3 prepares, the result shows, with undoped (BiO) 2 CO 3 In contrast, due to the effect of C doping, the C doped (BiO) prepared in this example 2 CO 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com