Patents

Literature

72results about How to "Wide reaction temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

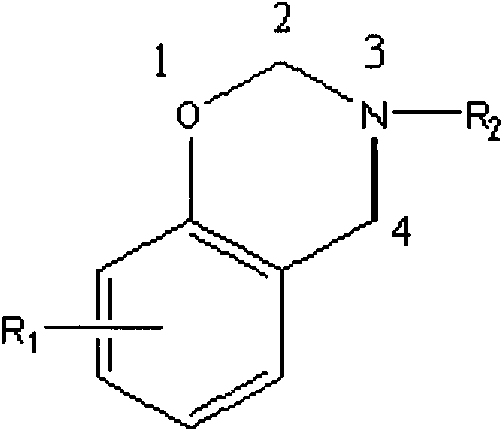

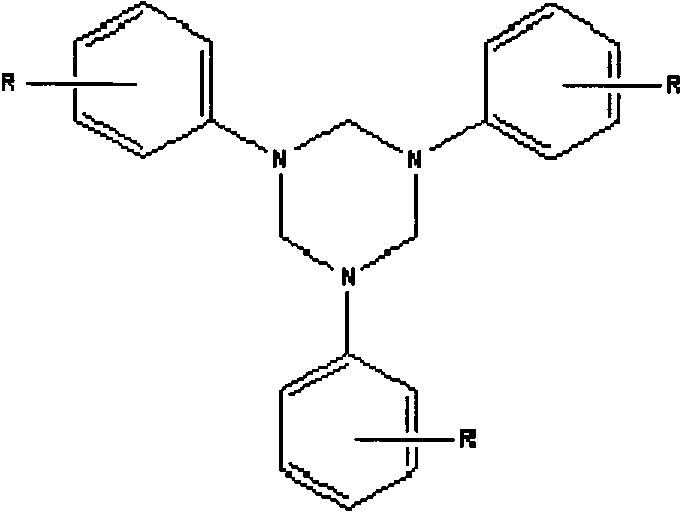

Method for preparing benzoxazine intermediate containing triazine structure

The invention provides a preparation method of triazine structure containing benzoxazine intermediate, which sequentially includes: (1) performing synthetic reaction of aldehyde compound and amine compound at a molar ratio of at least 1:1 which includes adding aldehyde compound and solvent of at least one of clean water, methanol, ethanol, isopropanol, and ethyl acetate into a reactor at the room temperature under the normal pressure to obtain mixed solution with aldehyde mass concentration of no greater than 95%, adding amine compound while stirring, and reacting at 0-100 DEG C under the normal pressure for at least 15 minutes to obtain the reactant liquor; (2) pouring into the cleaning solution, stirring and cleaning, and filtering to collect solid substance, or directly filtering the reactant liquor to collect the solid substance; and (3) drying the solid substance obtained in step (2) at 30-100 DEG C.

Owner:SICHUAN UNIV

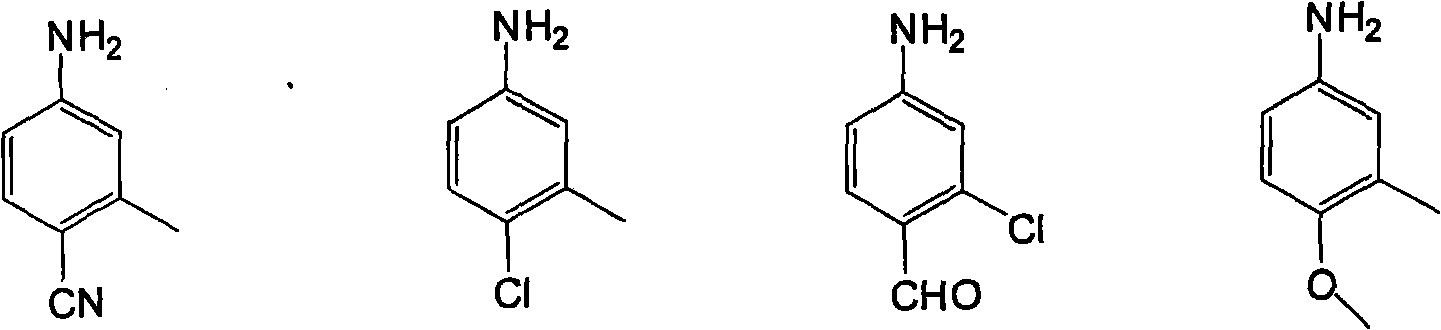

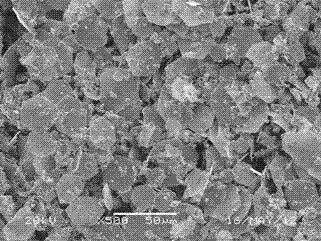

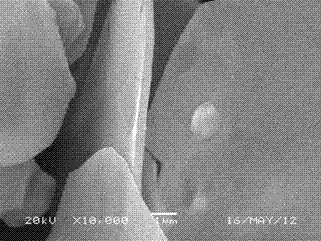

Preparation method for micro-order platy silver powder

The invention discloses a preparation method for a micro-order platy silver powder, which comprises the following steps: preparing 10-180g / L AgNo3 aqueous solution, and regulating the pH value to be 2.0-5.0; (2) preparing 12 / 204g / L ascorbic acid aqueous solution; (3) preparing dilute sulphuric acid or soluble sulfate solution, wherein the mass of sulfate ions is 0.3-1.5 times that of AgNO3; (4) at 10-60 DEG C under stirring state, mixing the dilute sulphuric acid or soluble sulfate solution and the reducing agent ascorbic acid aqueous solution with certain volume into certain volume of silver nitrate solution for reaction for 3-6 minutes, standing for 5-300 minutes and carrying out liquid-solid separation; and (5) rinsing the solid product obtained from the step (4) with deionized water and absolute ethyl alcohol respectively until the pH of the cleaning solution is neutral, and drying at 30-65 DEG C for 1.5-5 hours, thus obtaining the micro-order platy silver powder product. By adopting the preparation method, the micro-order platy silver powder which has a width-to-thickness ratio larger than or equal to 10 and plate diameter of 5-50mum; and the preparation method omits the grinding procedure of the traditional machine, is simple in technique, easy to operate, and low in cost and has no pollution to the environment.

Owner:CENT SOUTH UNIV

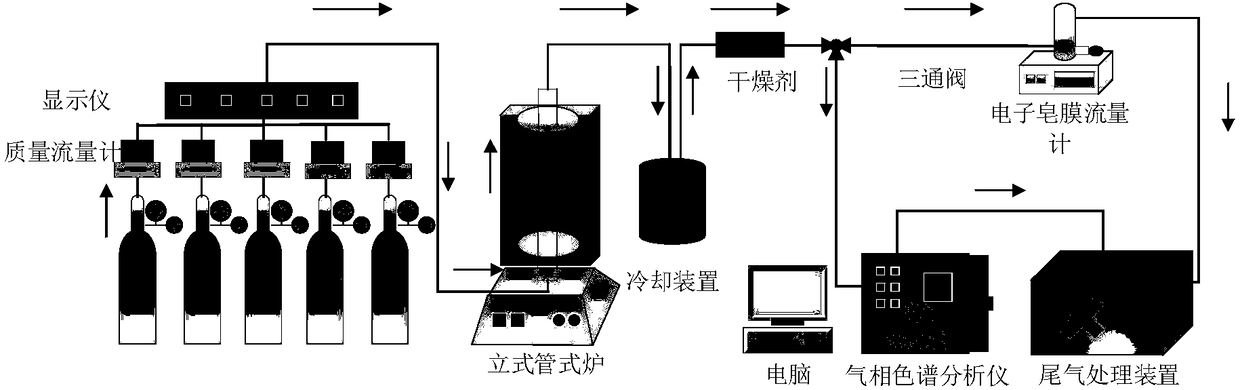

Catalyst for catalyzing methane dry-reforming reaction as well as preparation method and application of catalyst

InactiveCN107282086AImprove stabilityEfficient preparationHydrogenMolecular sieve catalystsSyngasGas phase

The invention belongs to the field of chemical engineering and catalyst preparation and relates to a catalyst for catalyzing a methane dry-reforming reaction as well as a preparation method and an application of the catalyst. The catalyst for catalyzing the methane dry-reforming reaction adopts oxide as a carrier C to carry metals A and B with an impregnation method and a redox replacement method, and a B-A / C catalyst is obtained. The invention further provides the preparation method and the application of the catalyst for catalyzing the methane dry-reforming reaction. The B-A / C catalyst performs reforming catalysis for CH4 and CO2 in a gas phase, and synthesis gas of H2 and CO is produced. The B-A / C catalyst prepared with the impregnation-replacement method shows an obvious effect on catalysis of the methane dry-reforming reaction, the obtained H2 / CO content is higher than 80%, and the yield of hydrocarbon in a follow-up Fischer-Tropsch reaction is increased; the conversion rate of a reactant is increased and the stability of the catalyst is enhanced.

Owner:NANJING UNIV

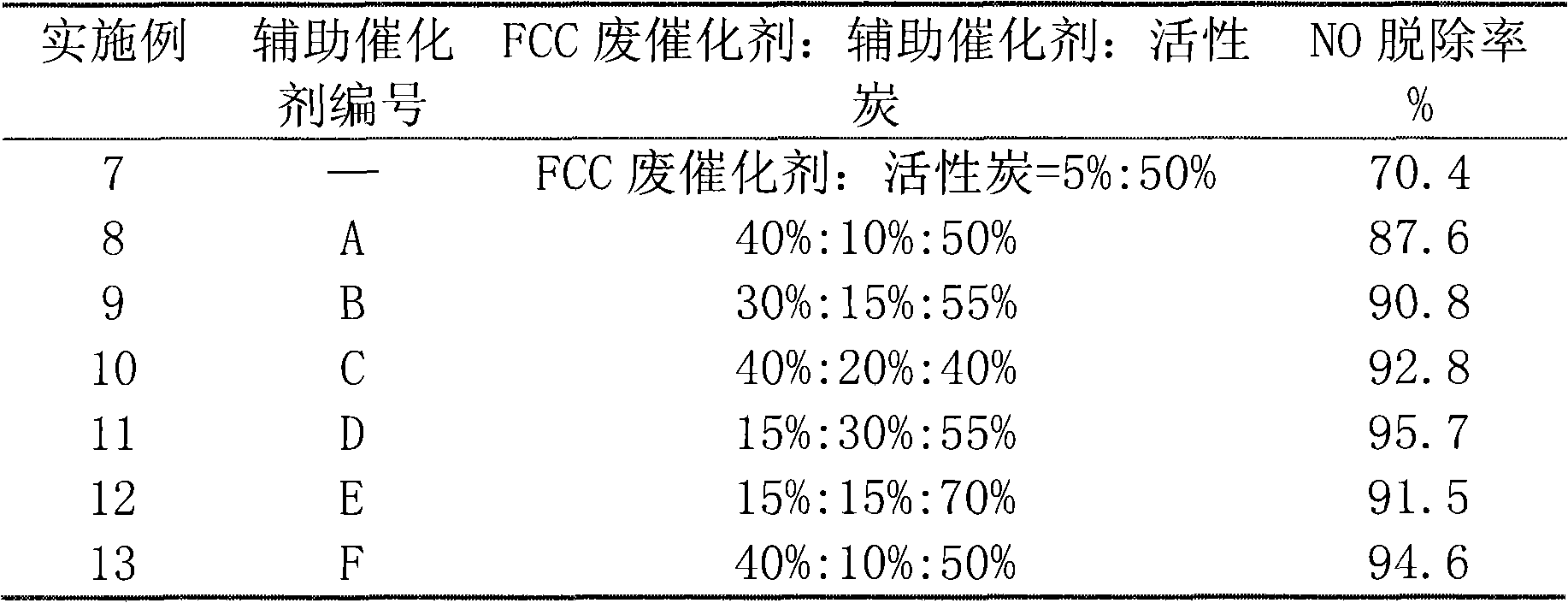

Method for removing NO (nitric oxide) in flue gas

ActiveCN102631838AHigh removal rateWide reaction temperature rangeNitrous oxide captureDispersed particle separationActivated carbonFlue gas

The invention discloses a method for removing NO (nitric oxide) in flue gas. Gas containing the NO flows through a reactor with the reaction temperature ranging from 400 DEG C to 800 DEG C at airspeed of 1000-10000h-1, from 10 to 40% of main catalyst, from 5 to 30% of auxiliary catalysts and from 30 to 70% of activated carbon are filled in the reactor by total weight of catalyst, and shortcomings that NO removal rate is low and a removal process is complex in the prior art are overcome.

Owner:CHINA PETROLEUM & CHEM CORP +1

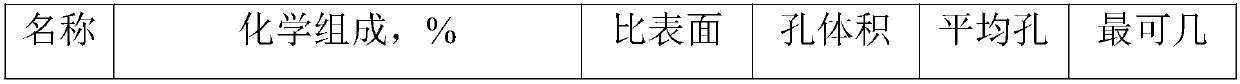

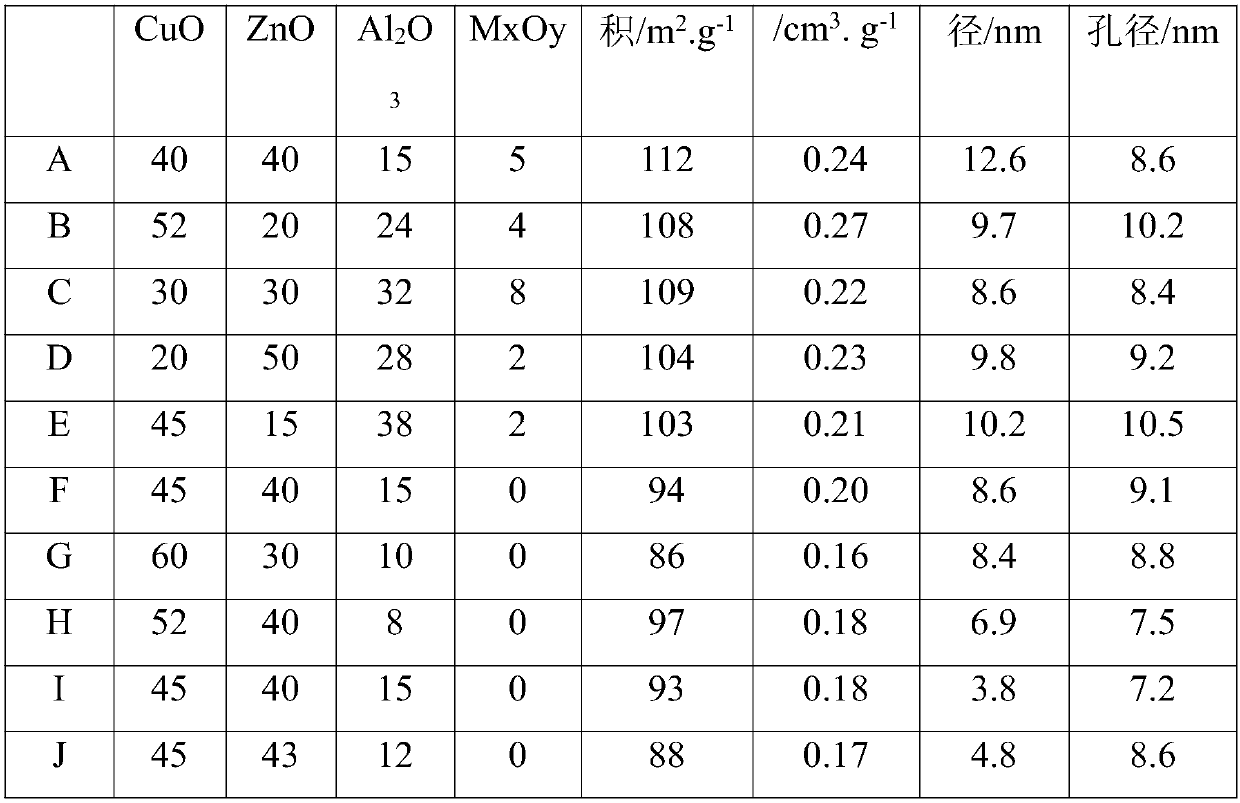

Highly-effectively copper-based catalyst for decomposing methanol to produce hydrogen

ActiveCN107824190ALarge specific surface areaHigh catalytic activityHydrogenHeterogenous catalyst chemical elementsAlkaline earth metalHydrogen

The invention discloses a highly-effective copper-based catalyst for decomposing methanol to produce hydrogen. The highly-effective copper-based catalyst is a mixture of, based on the weight, 10-60% of CuO, 10-60% of ZnO, 5-50% of Al2O3 and 1-10% of MxOY, wherein alkaline-earth metal M is selected from one of Mg, Ca, Ce and Sr. An adopted preparation method comprises the following steps: (1) modifying alumina carriers by adding the alkaline-earth metal to prepare Al-M modified carriers; (2) adding low-molecular alcohol into mother liquid of the modified carriers, then adding active-metal saltsolution and an alkaline precipitation agent to carry out precipitating reaction, carrying out solid-liquid separation, washing, drying and roasting after the reaction is ended to prepare the catalyst. The highly-effectively copper-based catalyst prepared by the preparation method not only is high in catalytic activity, wide in reaction temperature area and good in low-temperature activity, but also is good in selectivity, fewer in side product and long in service life.

Owner:SHANDONG QILU KELI CHEMICAL RESEARCH INSTITUTE CO LTD

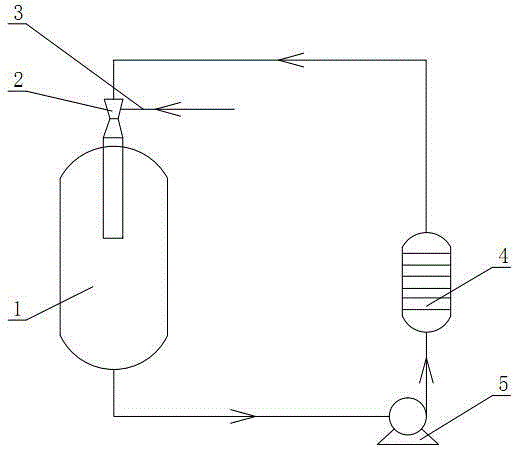

Method for preparing 2-chloro-5-chloromethylthiazole by jet loop reactor

ActiveCN105254583AImprove mixing efficiencyReduce manufacturing costOrganic chemistryOrganic solventBiochemical engineering

The invention discloses a method for preparing 2-chloro-5-chloromethylthiazole by a jet loop reactor, and relates to the technical field of synthesis of the 2-chloro-5-chloromethylthiazole. The jet loop reactor comprises an ejector, wherein the ejector is arranged at the upper part of the reaction kettle; a lower outlet of the reaction kettle is communicated with an inlet of a circulating pump; an outlet of the circulating pump is communicated with the inlet of a heat exchanger; the outlet of the heat exchanger is communicated with the top inlet of the ejector; an air inlet pipe is arranged on the side surface of the ejector; 1-isothiocyano-2-chlorine-2-propylene is dissolved into an inert organic solvent to prepare a liquid-phase material; the liquid-phase material is added to the reaction kettle, and enters from the top inlet of the ejector after passing through the circulating pump and the heat exchanger; chlorine enters the ejector through the air inlet pipe and is mixed with the liquid-phase material; the mixed material passes through the reaction kettle, the circulating pump and the heat exchanger and then returns to the top inlet of the ejector; circular reaction is carried out until the chlorine is introduced; a 2-chloro-5-chloromethylthiazole product is obtained after post-treatment. The method disclosed by the invention is high in yield, few in solid wastes and high in production efficiency; the reaction temperature is easy to control.

Owner:河北德瑞化工有限公司

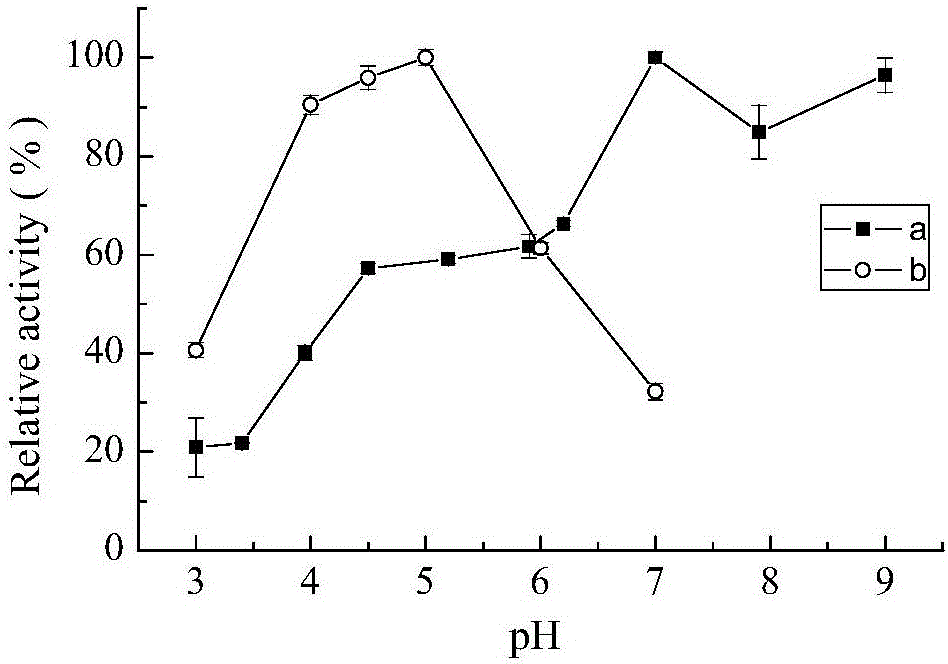

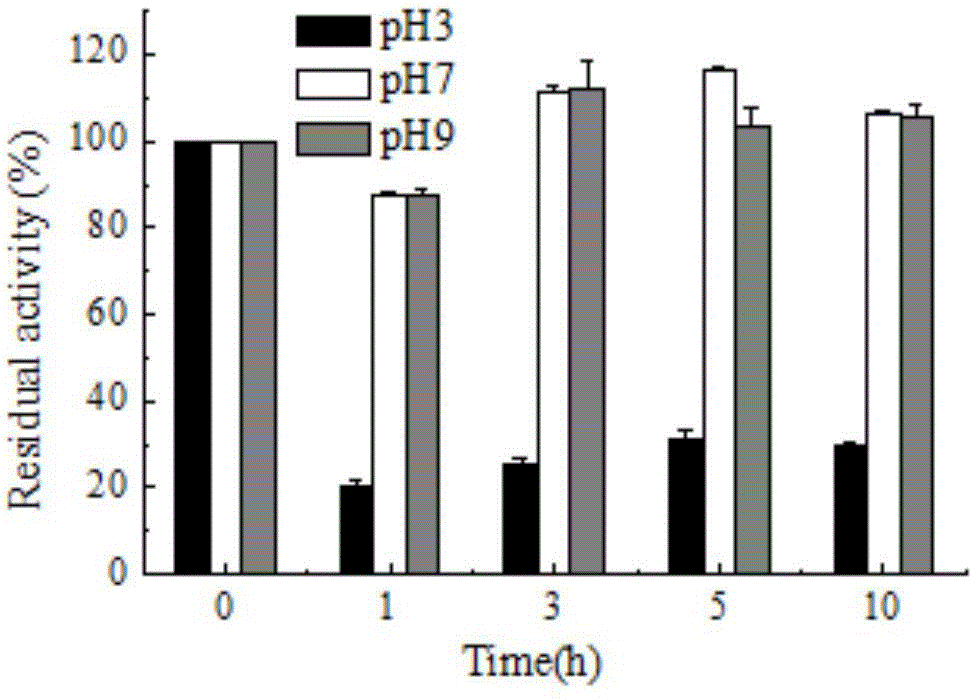

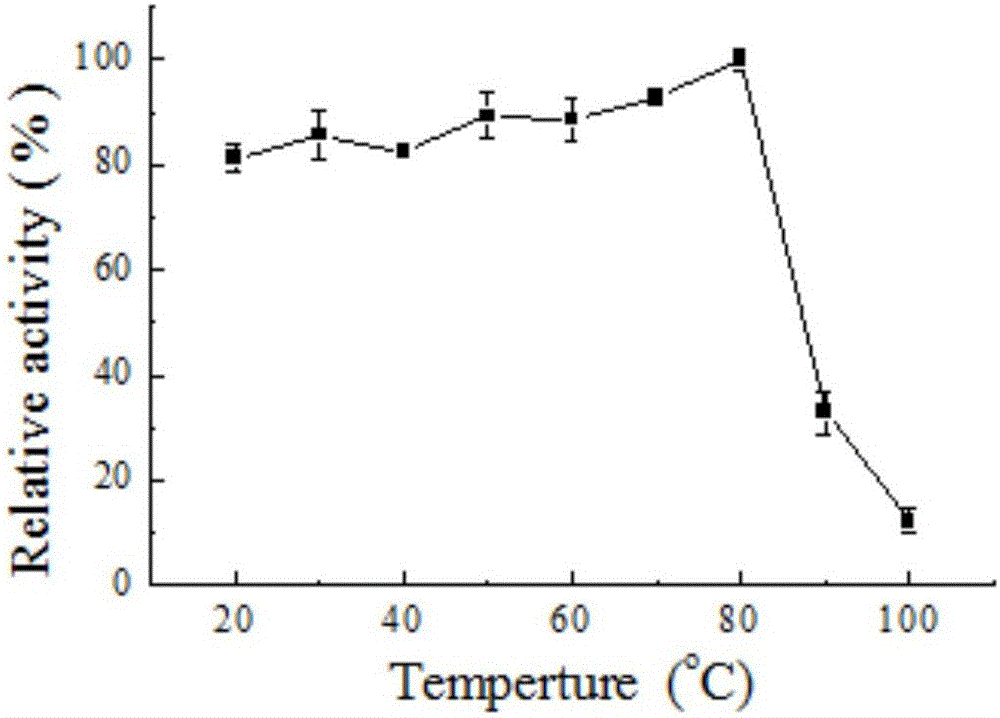

Laccase from Bacillus licheniformis LS04 and use thereof

InactiveCN102154148AHigh activityImprove thermal stabilityBacteriaMicroorganism based processesBacillus licheniformisHigh concentration

The invention discloses preparation, a catalytic property and use in dye decolorizing of spore laccase from Bacillus licheniformis LS04 (CGMCC No.4263). The invention also relates to a nucleotide sequence coding the spore laccase. The invention also relates to a nucleotide sequence for coding the spore laccase. In the invention, Bacillus licheniformis LS04 ferments at 37 DEG C for 5 days on a solid sporulation culture medium, spores are washed off by deionized water, and pore suspension with laccase activity can be obtained by series measures such as lysozyme treatment. The spore laccase has high catalytic activity under alkaline and high-temperature conditions, can maintain high enzyme activity in high-concentration organic solvent and salt solution, has good decolorizing effect on synthesized dyes of different structures under action of an amboceptor and can be used for treating industrial dye waste water.

Owner:NORTHEAST FORESTRY UNIVERSITY

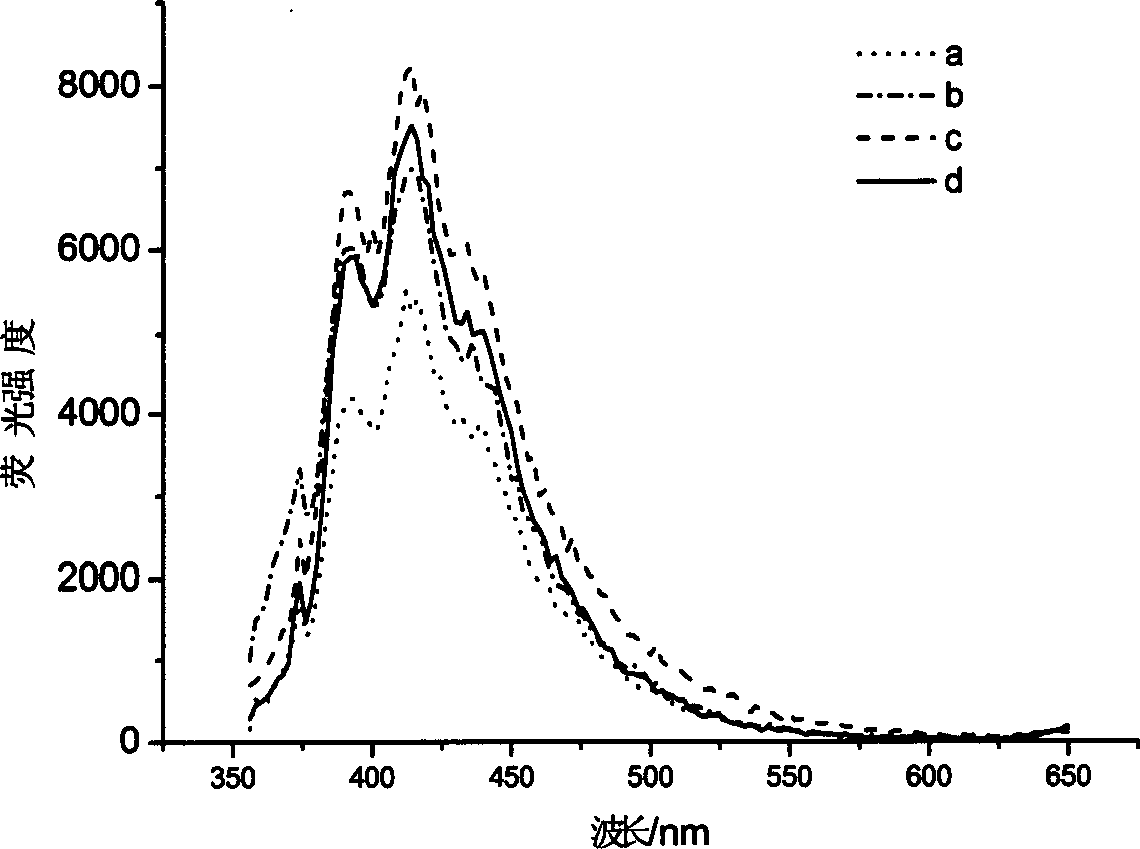

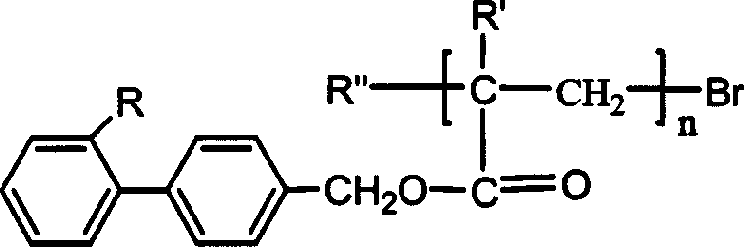

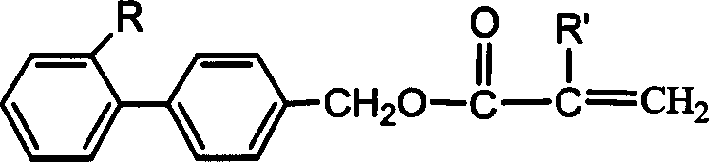

Acrylic ester and methyl acrylic ester kind side chain type luminous polymer and its synthesis

ActiveCN1786106APromote aggregationThe polymerization method is easy to synthesizeLuminescent compositionsMethacrylatePolymer science

The present invention discloses an acrylate and methylacrylate side chain type luminescent polymer. It is characterized by that on the side chain of polymer the diphenyl group is contained. Said invention also provides the method adopted for synthesizing said polymer and monomer synthesized in the reaction process. Said invention can utilize an atomic transfer free radical polymerization method to synthesize a new side-chain type luminescent polymer.

Owner:上海种亿化学技术有限公司

Method for preparing 1,2,3,4-tetrachloro-hexafluoro butane

InactiveCN101851145AImprove conversion rateHigh selectivityPreparation by hydrogen halide split-offSurface treatment compositionsKetoneDichloroethane

The invention discloses a method for preparing 1,2,3,4-tetrachloro-hexafluoro butane. In the presence of an oxygen-containing organic compound catalyst, 1-iodine-1,2,2-trifluoro-1,2-dichloroethane and zinc particles react to prepare 1,2,3,4-tetrachloro-hexafluoro butane, wherein the oxygen-containing organic compound catalyst is one or a combination of more of alcohol, ketone, ester, ether and amide; the added quantity of the oxygen-containing organic compound catalyst accounts for 5 to 50 weight percent of that of the 1-iodine-1,2,2-trifluoro-1,2-dichloroethane; the particle size of the zinc particles is of between 3 and 6 mm; and the added quantity of the zinc particles accounts for 10 to 50 weight percent of that of the 1-iodine-1,2,2-trifluoro-1,2-dichloroethane. The invention also provides a method for preparing hexachlorobutadiene from the 1,2,3,4-tetrachloro-hexafluoro butane. The hexachlorobutadiene can be used as a polymer monomer, an etching gas or the like.

Owner:SINOCHEM LANTIAN +1

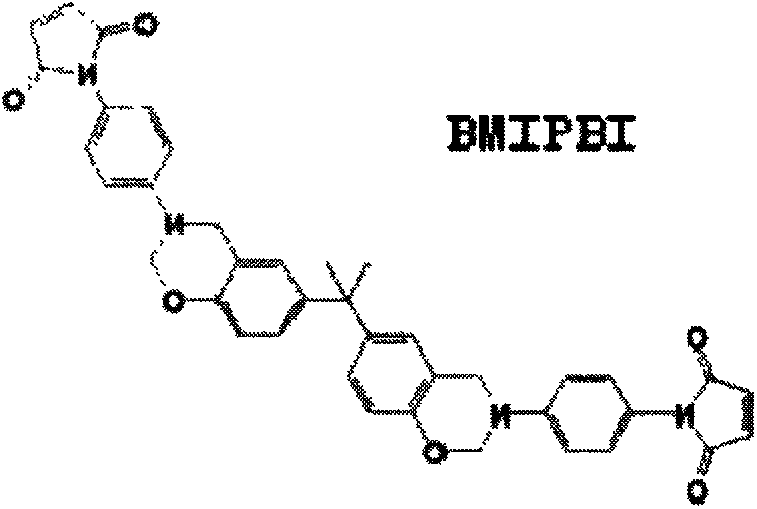

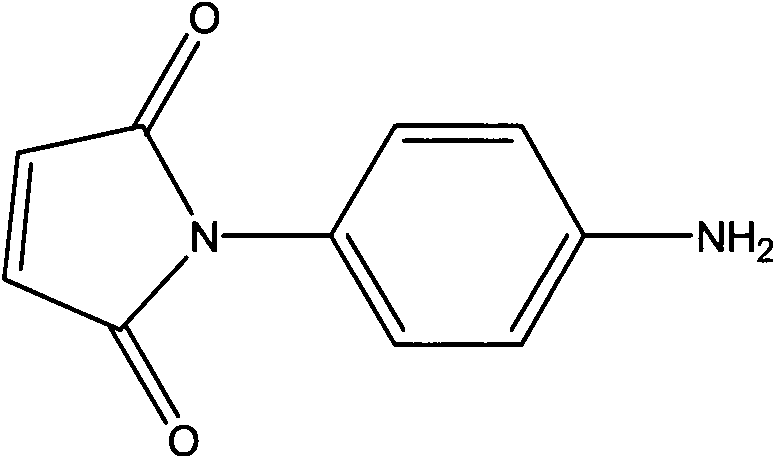

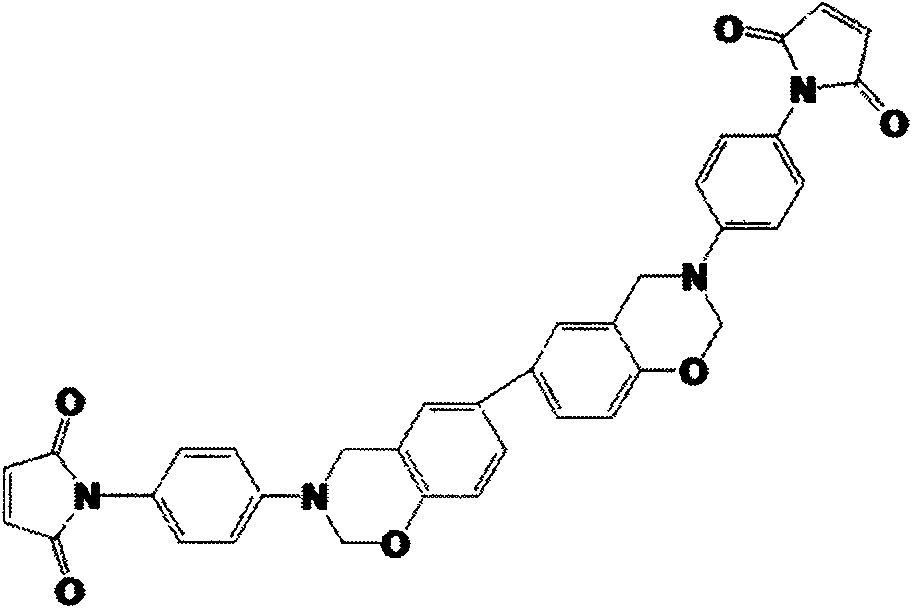

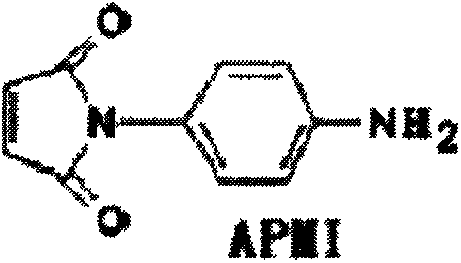

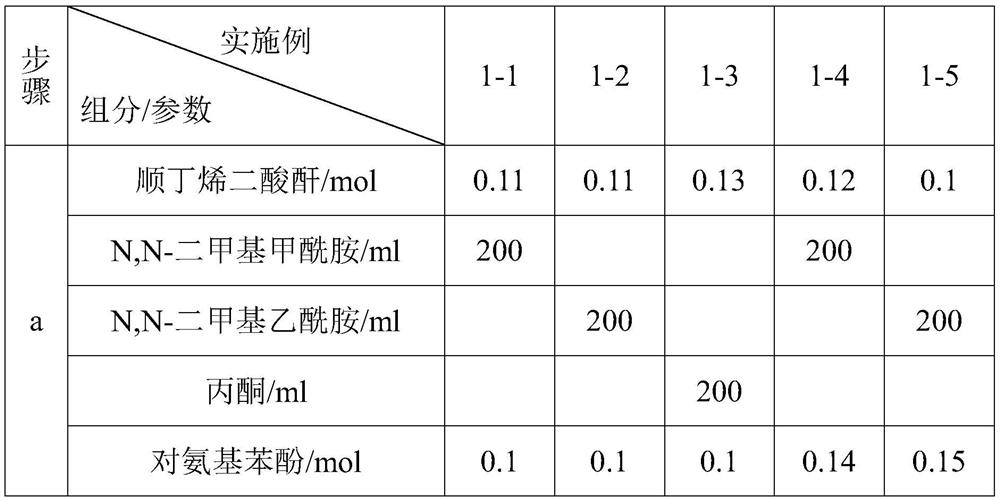

Preparation method of benzoxazine containing maleimide bisphenol A-type structure

The invention discloses a preparation method of a benzoxazine intermediate containing a maleimide bisphenol A-type structure. The preparation method comprises the steps: (1) adding an aldehyde compound and a solvent into a reaction vessel to uniformly mix at room temperature and normal pressure, then, adding an amine compound into the vessel under stirring, and reacting at the temperature of 0-100 DEG C and normal pressure for at least 10h; (2) pouring the reaction solution into a cleaning solution to clean, filtering and collecting a solid substance, and drying at the temperature of 30-100 DEG C; (3) sequentially adding the obtained solid substance, the aldehyde compound and bisphenol A into a reaction vessel to uniformly mix, heating to 160 DEG C, and reacting for at least 7h under stirring to obtain a brown solid product; (4) dissolving the brown solid product by using a proper amount of ethyl acetate, extracting, collecting an ethyl acetate solution, and then, washing the solution to be neutral by using a 6% sodium bicarbonate solution and tap water; (5) drying the obtained ethyl acetate extracting solution by using anhydrous MgSO4, filtering, and rotatably evaporating the solution at the temperature of 45 DEG C to obtain the yellow solid target product.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE

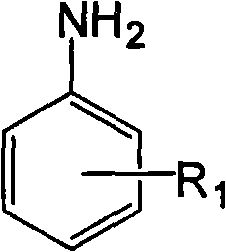

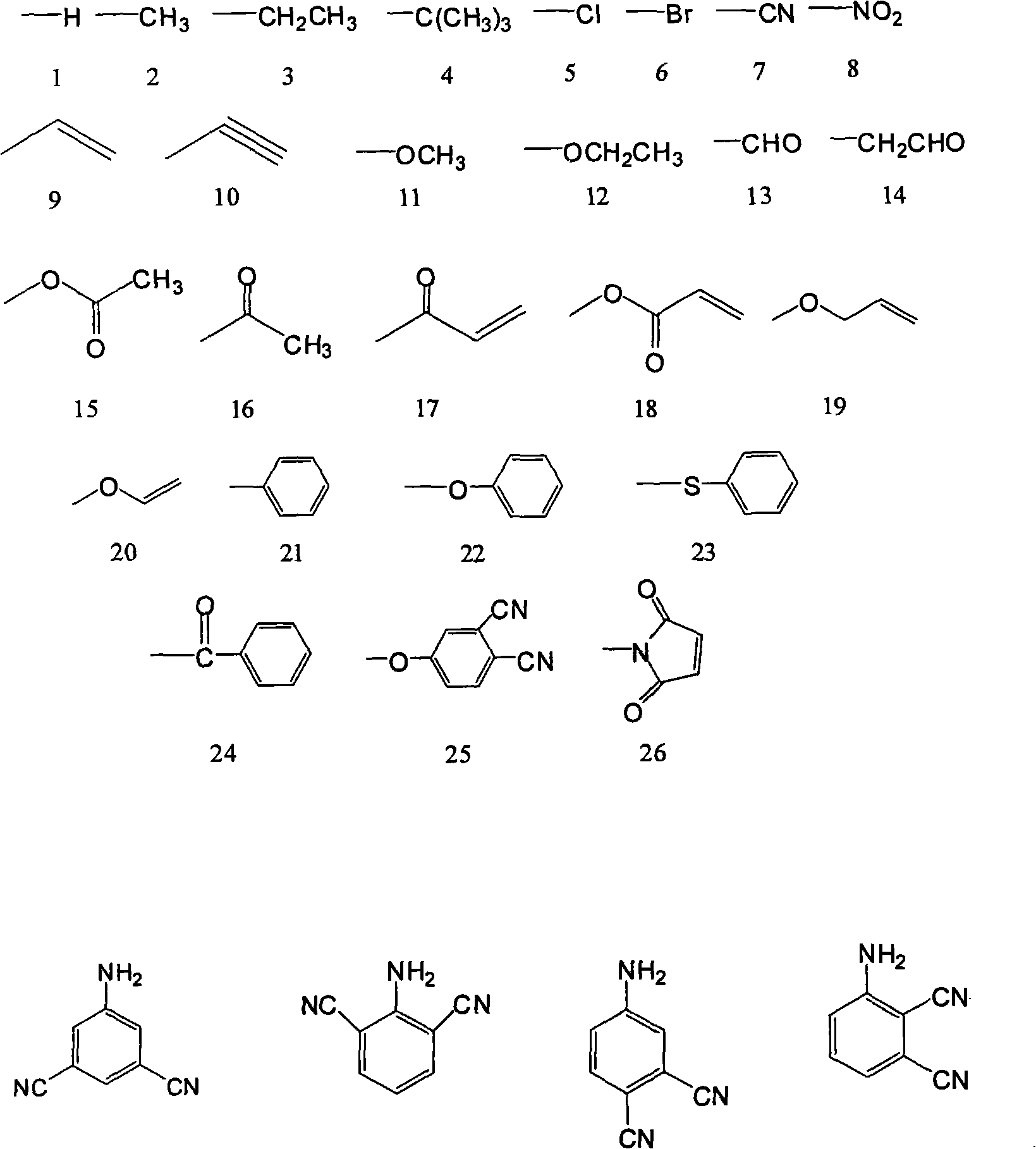

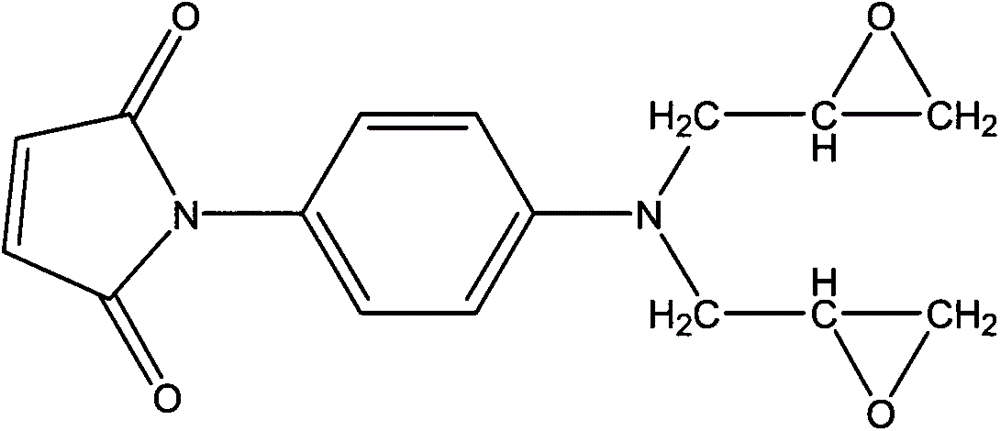

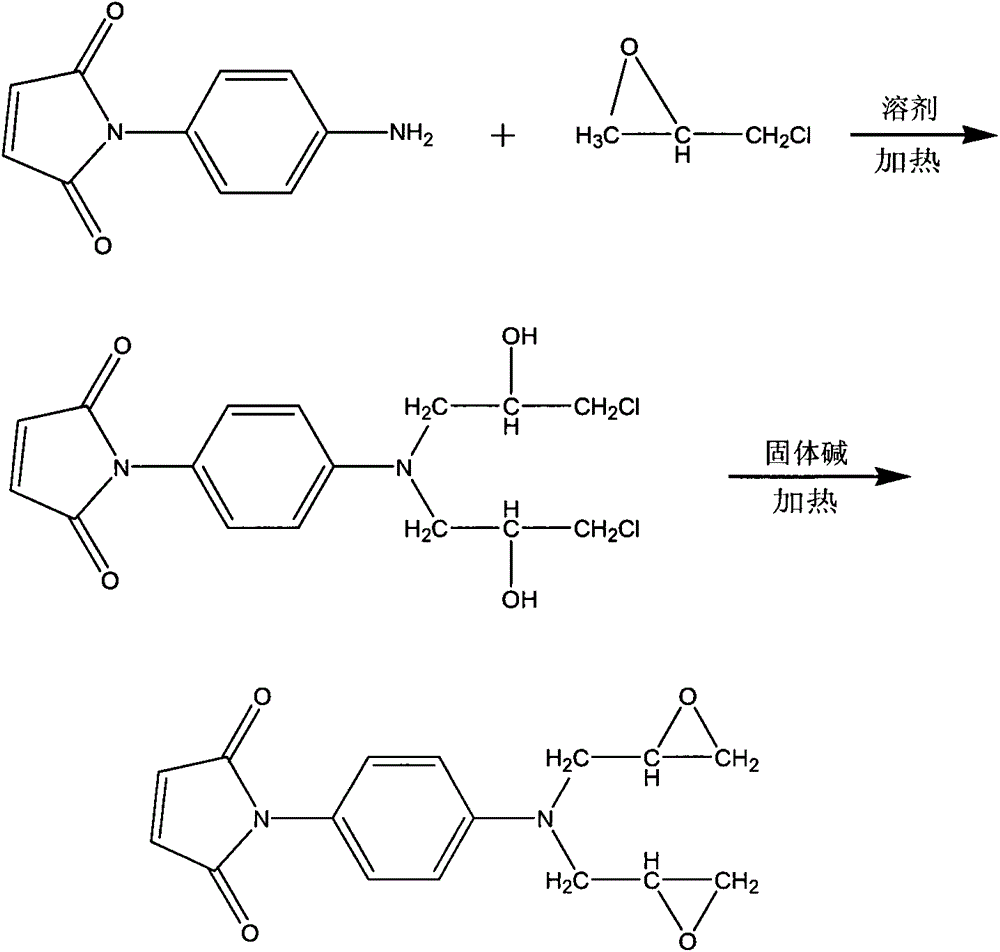

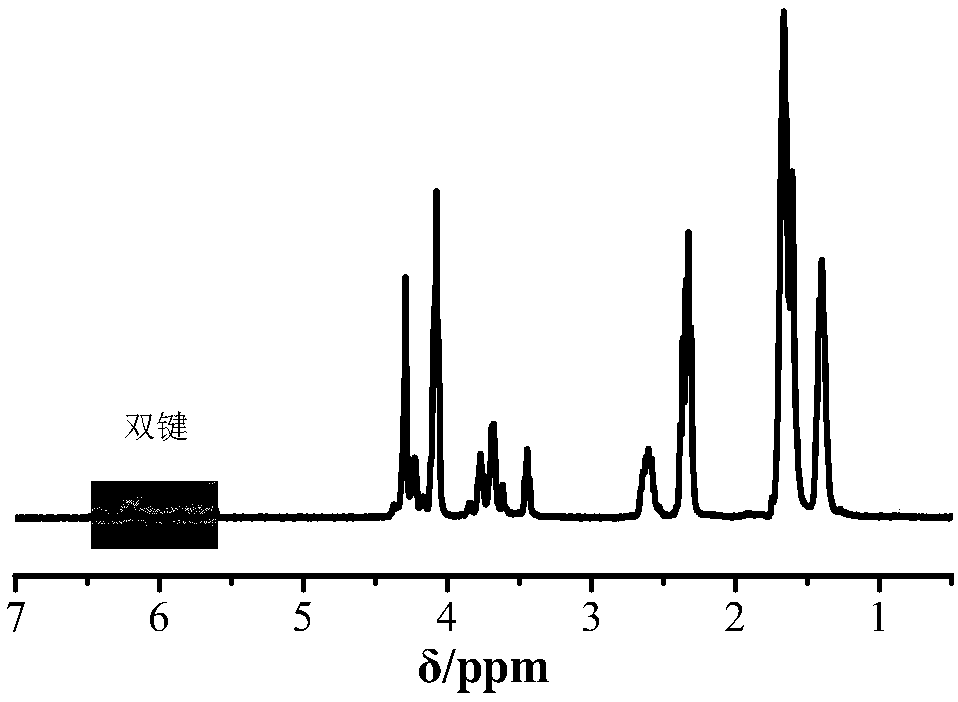

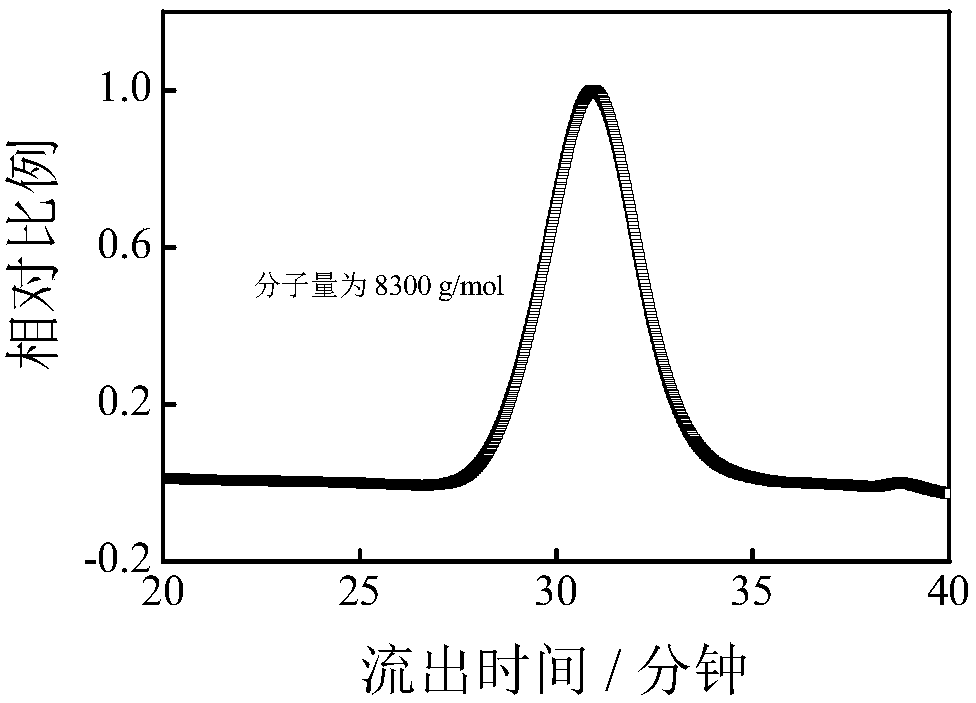

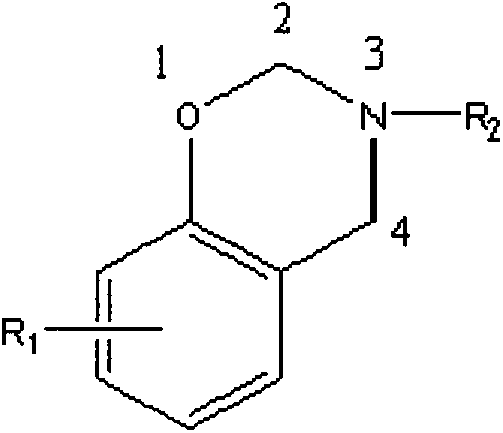

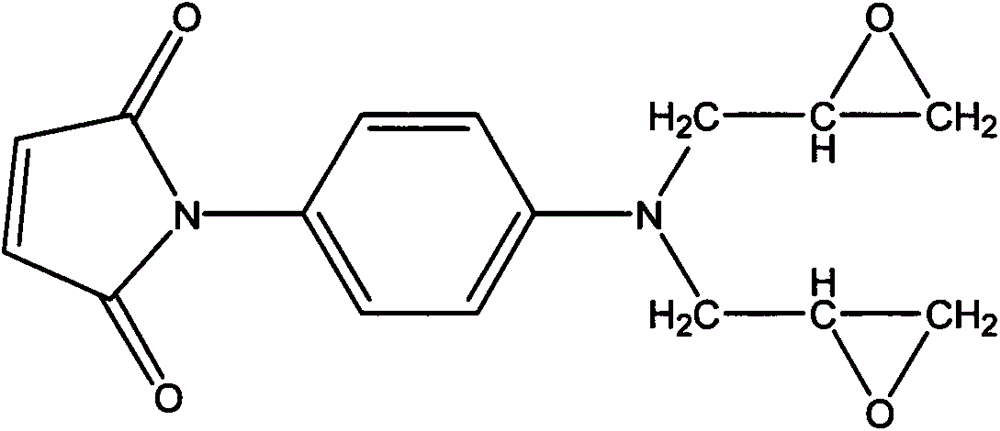

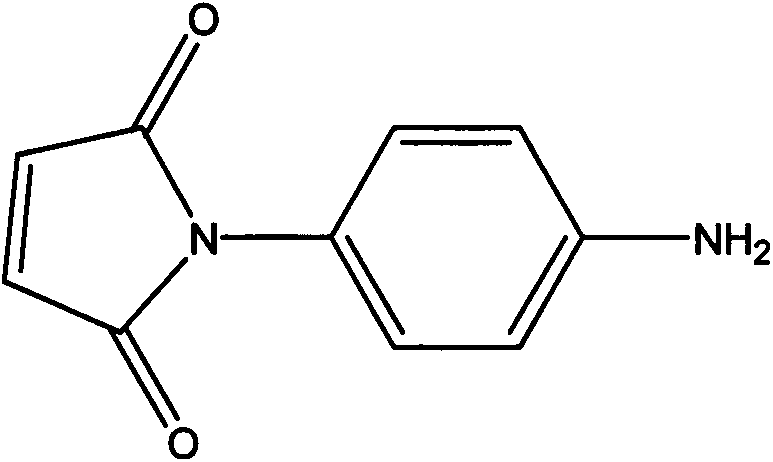

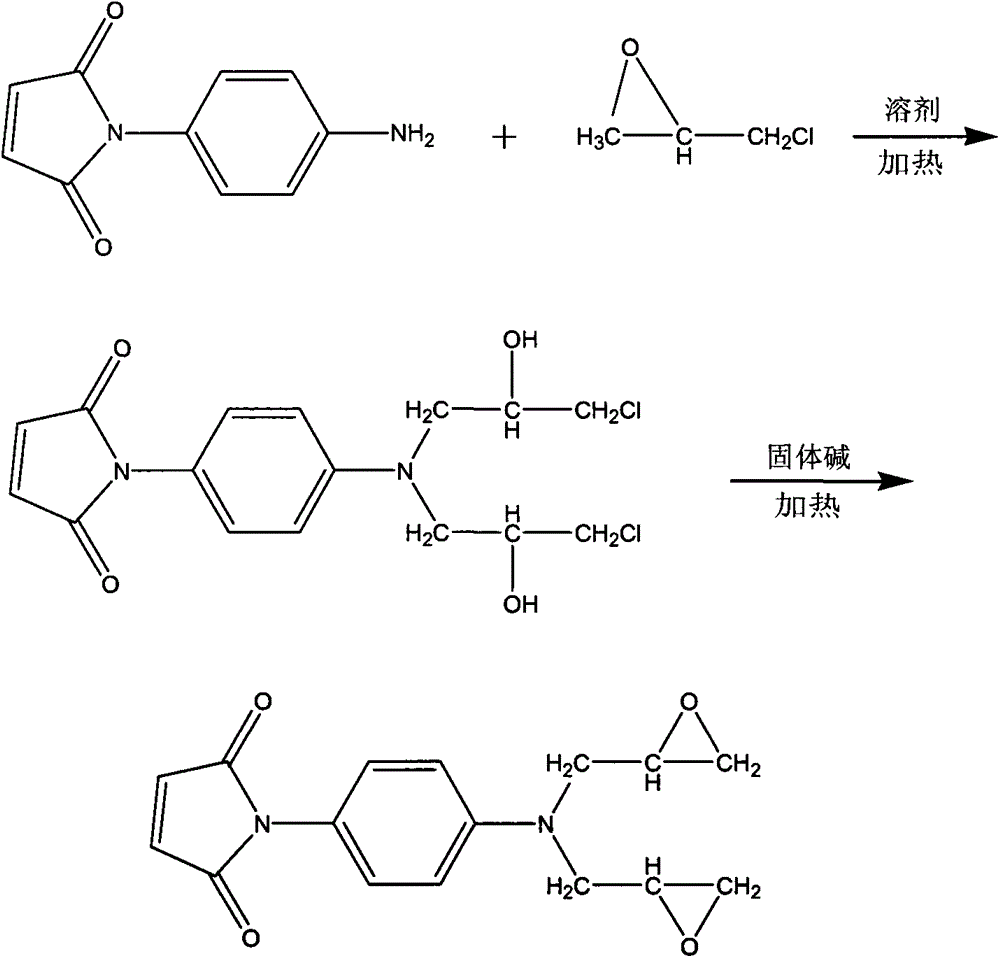

Method for preparing maleimide-containing epoxy resin curing agent

The invention belongs to the field of epoxy resin curing agents, and in particular relates to a method for preparing a maleimide-containing epoxy resin curing agent. The method for preparing the maleimide-containing epoxy resin curing agent is simple and environment-friendly in process, wide in reaction temperature range, gentle in reaction condition and beneficial to industrial production. The method comprises the following process steps in sequence: (1) dissolving an amine compound and a phase transferring catalyst into a proper amount of organic solvent; under the protection of nitrogen, heating to 65 DEG C, then dropwise adding epoxy chloropropane; and after epoxy chloropropane is completely dropwise added, cooling to 55 DEG C, reacting for 2-8 hours; (2) cooling the reaction system to 30-40 DEG C, adding solid alkali, heating to 50 DEG C, and implementing ring-closure reaction for 1-6 hours; (3) cooling to the room temperature after the reaction is finished, performing suction filtration, extracting the filtrate by using a proper amount of ethyl acetate, washing with deionized water for many times, and implementing rotary evaporation at 45 DEG C so as to remove ethyl acetate, thereby obtaining a target product, namely maleimide-containing epoxy resin curing agent.

Owner:CHENGDU NORMAL UNIV

Synthesis method of copolyester

The invention belongs to the field of synthesis of copolyester, and particularly relates to a synthesis method of the copolyester. The synthesis method comprises the step of catalyzing copolymerization reaction of two monomers such as a hydroxyl acrylate-containing monomer and a cyclic monomer through small organic molecules to obtain the degradable copolyester with a brand-new structure. The hydroxyl acrylate-containing monomer comprises hydroxyethyl acrylate and hydroxyethyl methylacrylate as well as a derivative thereof; the cyclic monomer comprises an epoxy monomer and a lactone monomer. The epoxy monomer comprises ethylene oxide, epoxypropane, allyl glycidyl ether and the like; the lactone monomer comprises butyrolactone, caprolactone, lactide and the like. A polymerization mode for hydroxyl acrylate in the method is carried out in a proton transfer manner instead of conventional vinyl addition, thereby obtaining polyester with a special structure. Raw materials used in the methodare readily available and are economical and environmentally friendly; reaction conditions are mild, and the reaction rate is high; different functional groups can be introduced into the polyester, so that the application range is expanded; the method has an extremely good application prospect.

Owner:CHANGZHOU UNIV

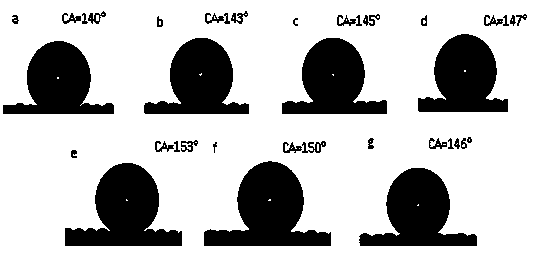

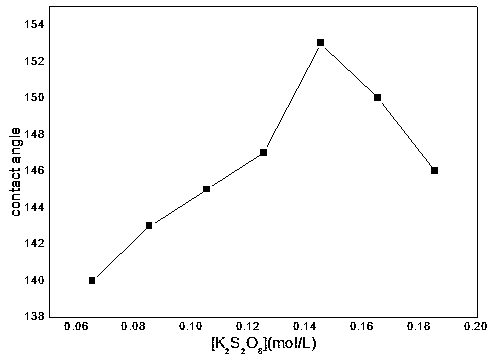

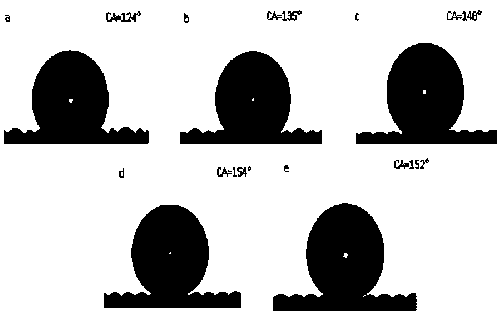

Preparation method for improving metal hydrophobicity based on vapor deposition method

InactiveCN109207979ANo change in appearanceImprove surface hydrophobicityVacuum evaporation coatingSputtering coatingElectricityHexamethyldisilane

The invention discloses a preparation method for improving metal hydrophobicity based on a vapor deposition method. The method comprises the steps that 1, the surface oxidation control method is utilized for generating an oxidation metal film on the metal surface; and 2, hexamethyldisilane modifies oxidation metal through the vapor deposition method. By using the manufacturing method of super-hydrophobic metal, surface hydrophobicity of the metal is improved correspondingly, the hexamethyldisilane is cheap and low in toxicity compared with chlorine and fluorine containing reagent, and is friendly to environment, thus the metal does not corrode easily in the humid environment, or does not frost or freeze easily at the low temperature, thus heat conduction to the metal is avoided, the influence on electricity conducting performance is avoided, the stability of metal products and devices is improved directly and substantially, and the property of people and social safety are guaranteed.

Owner:XUCHANG UNIV

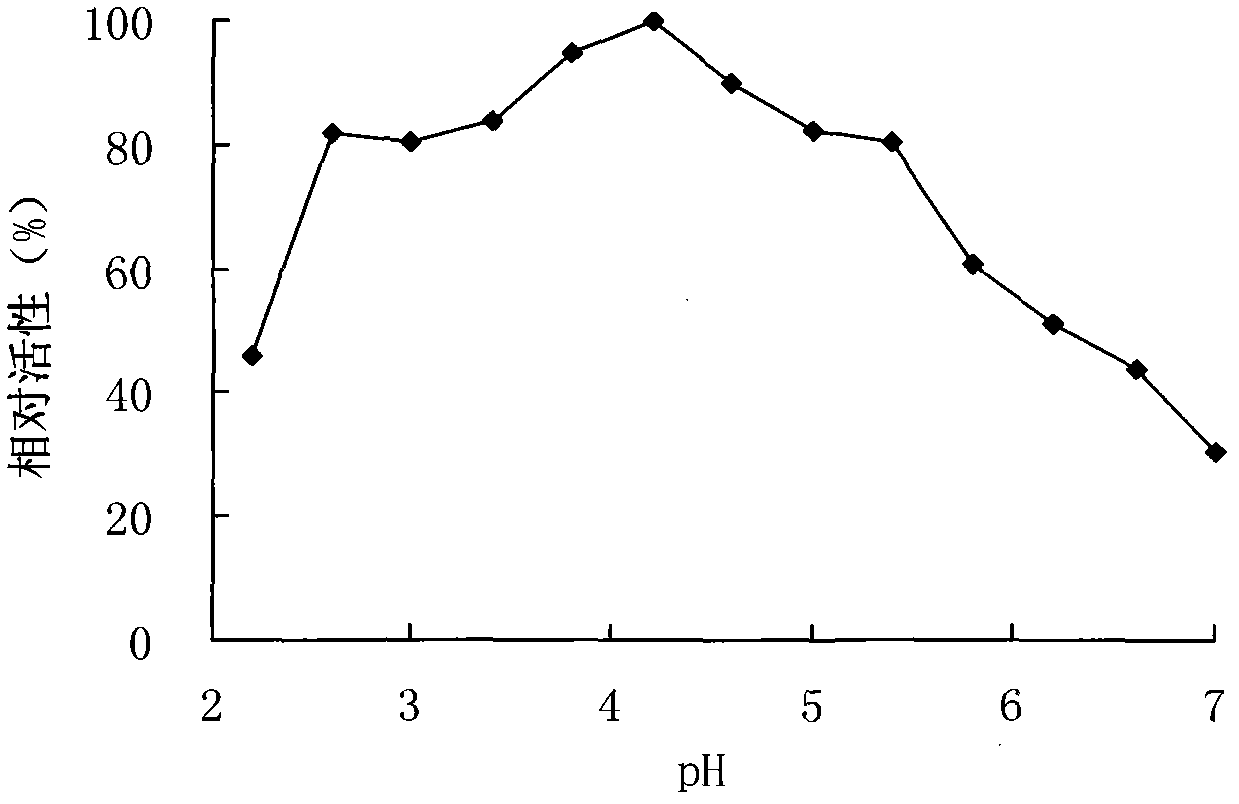

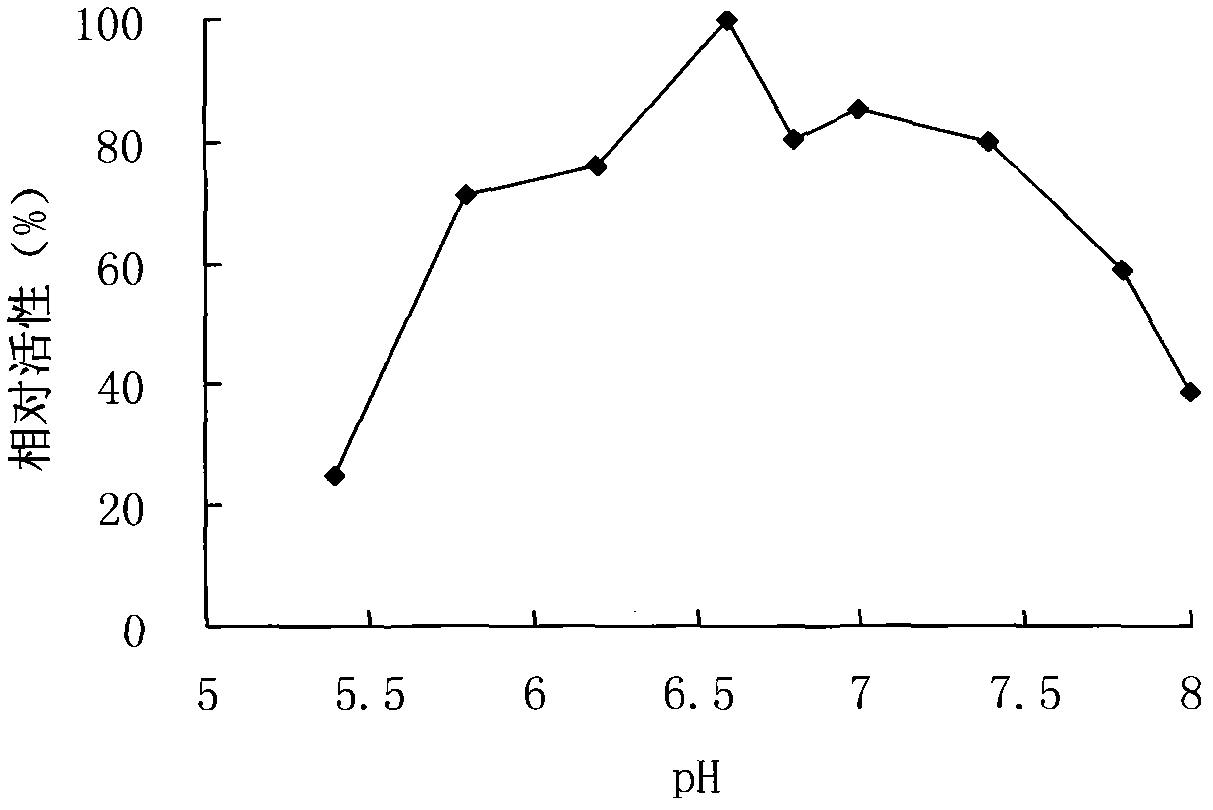

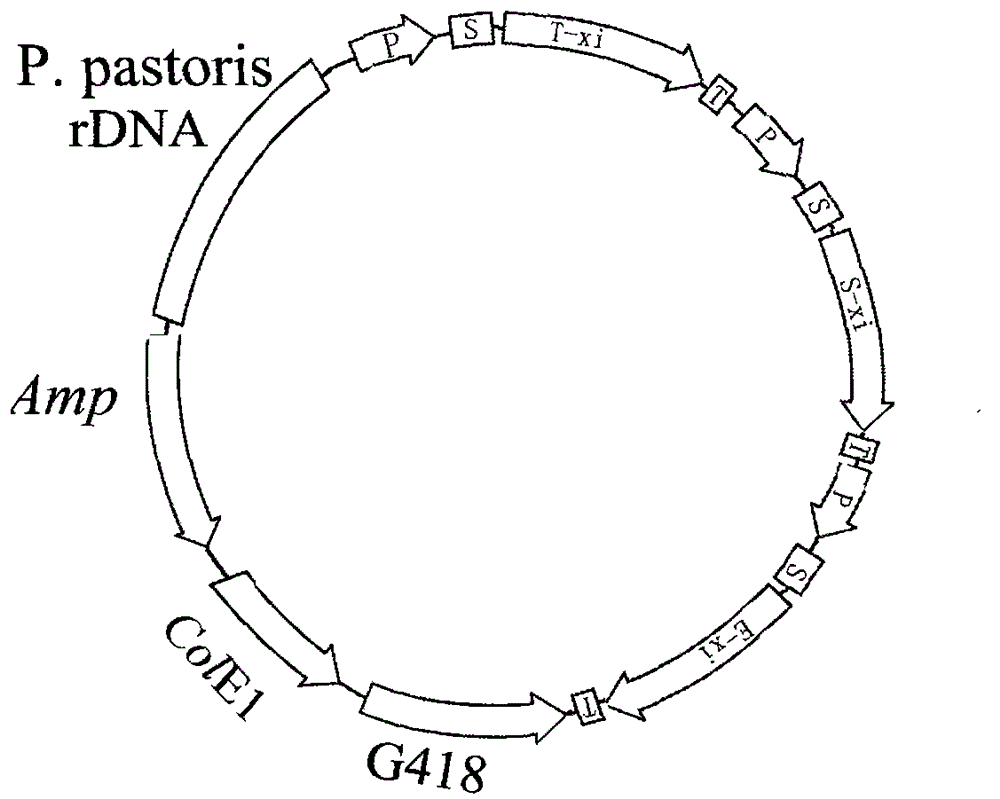

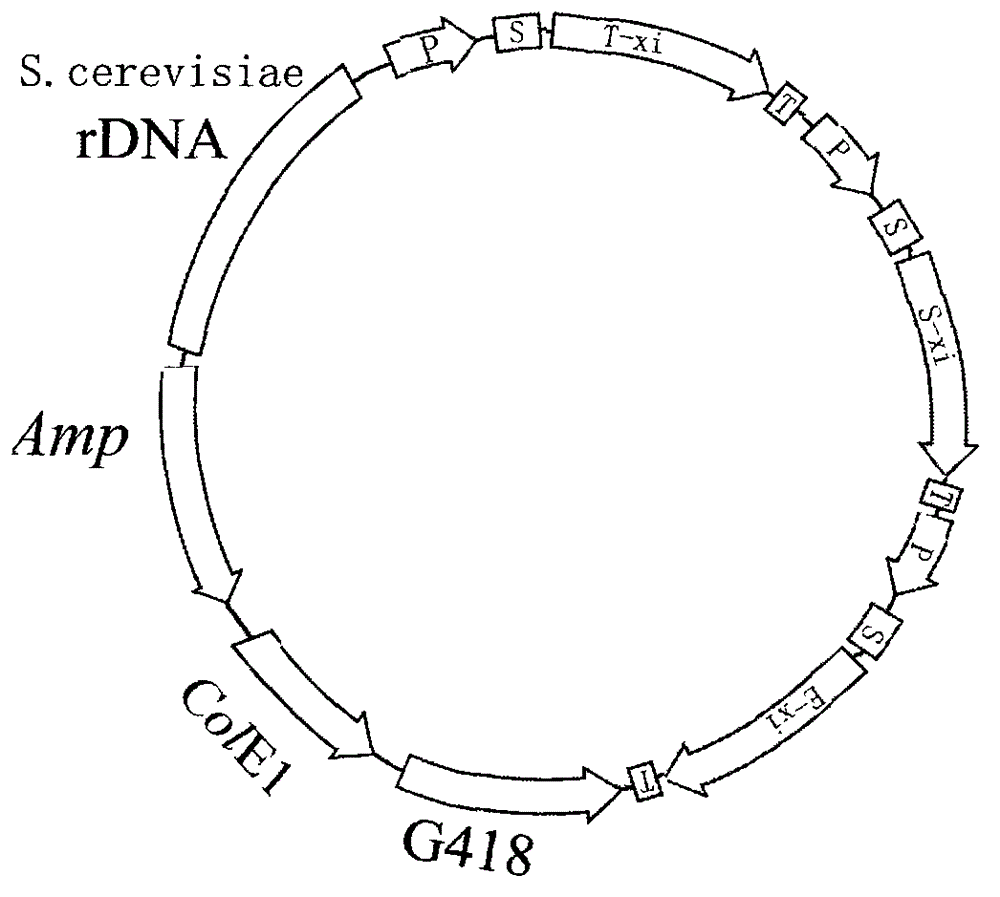

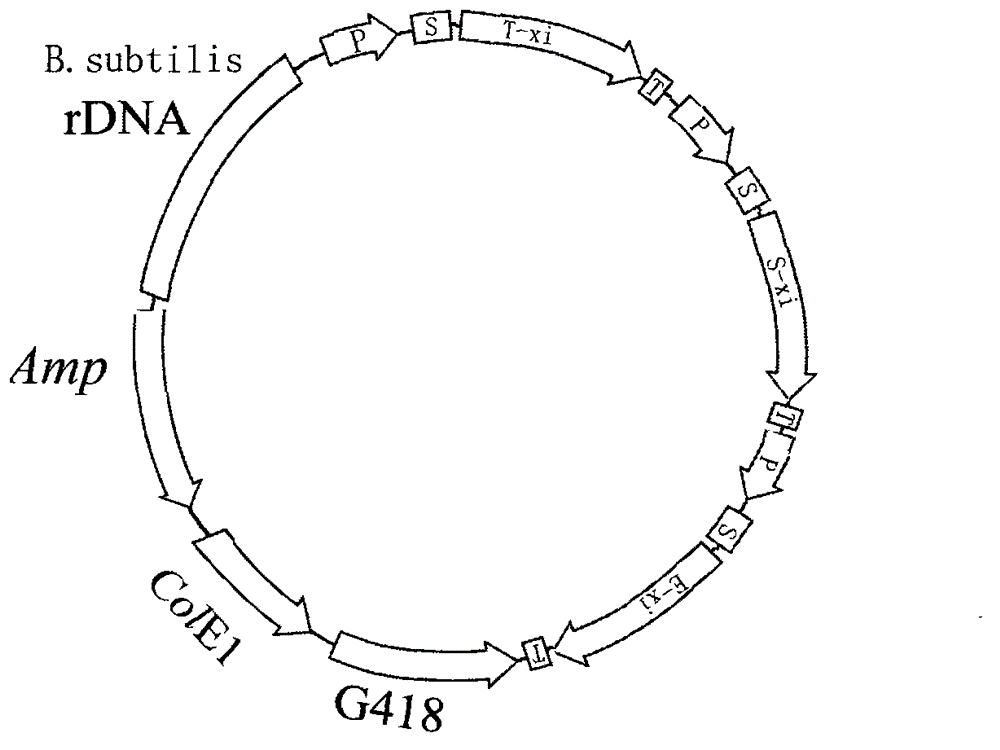

Xylose isomerase producing method

InactiveCN102747063AWide reaction temperature rangeWide reaction pH rangeMicroorganism based processesIsomerasesEscherichia coliGenus Thermus

The invention discloses a xylose isomerase producing method and belongs to the technical field of biology. The xylose isomerase producing method includes: firstly, cloning xylose isomerase genes of thermus, streptomyces and escherichia coli; secondly, constructing a pichia pastoris expression vector, a saccharomyces cerevisiae expression vector and a bacillus subtilis expression vector which include three xylose isomerase gene expression cassettes, and transforming the vectors to corresponding host bacteria respectively; thirdly, respectively screening recombinants of over-expression xylose isomerases as engineering bacteria; and finally, fermenting the pichia pastoris engineering bacteria, the saccharomyces cerevisiae engineering bacteria and the bacillus subtilis engineering bacteria to produce a recombinant mixed xylose isomerase. Different from a traditional single-gene-coded xylose isomerase, the recombinant mixed xylose isomerase is wide in suitable reaction temperature and pH (potential of hydrogen) range and suitable for various purposes, and yield of the xylose isomerase expressed by the engineering bacteria including the polygene expression cassettes is obviously higher than that of the xylose isomerase expressed by engineering bacteria including single genes, so that production cost is reduced.

Owner:INST OF TROPICAL BIOSCI & BIOTECH CHINESE ACADEMY OF TROPICAL AGRI SCI

Preparation method for maleimide-containing biphenol type benzoxazine

A preparation method for a benzoxazine intermediate adopting a maleimide-containing biphenol type structure comprises the following steps: (1) synthetic reaction 1: firstly, adding an aldehyde compound and a solvent into a reaction vessel at the indoor temperature and under normal pressure to be uniformly mixed, then adding an amine compound into the vessel while stirring, reacting for at least 10 hours under the normal pressure and at the temperature of 0-100 DEG C, after the reaction is completed, pouring the reaction liquid into a washing liquid to be washed, filtering and collecting a solid substance, and drying the solid substance at the temperature of 30-100 DEG C, so as to obtain an intermediate containing a triazine structure; (2) synthetic reaction 2: sequentially adding the obtained solid substance (triazine) as well as the aldehyde compound, biphenol, and 1, 4-dioxane intt the reaction vessel to be uniformly mixed, heating up to the temperature of 110 DEG C and carrying out a backflow reaction for 30 hours to obtain a reaction liquid containing earthy yellow precipitation, pouring the reaction liquid into deionized water, fully stirring, precipitating, leaching, washing for multiple times by using the deionized water and ethyl alcohol, and then drying in a dryer, so as to obtain the earthy yellow powder solid target product.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE

Method for preparing 3,4-dichloroaniline by using o-dichlorobenzene through nitration and hydrogenation

InactiveCN109651157ASimple processComplete conversion of raw materialsOrganic compound preparationAmino compound preparationChemistryPalladium on carbon

The invention discloses a method for preparing 3,4-dichloroaniline by using o-dichlorobenzene through nitration and hydrogenation, the method comprises the following steps: materials of o-dichloroaniline, sulfuric acid, recycled acid, and nitric acid in a ratio of 2.34: 1.6: 1.1: 1.3 are added into a nitration kettle for nitration reaction so as to obtain a 3,4-dichloronitrobenzene and 2,3-dichloronitrobenzene mixed solution; the mixed solution enters a main rectifying tower to be subjected to reduced pressure rectification and crystallization separation to obtain more than 99.5% of 3, 4-dichloronitrobenzene and 2,3-dichloronitrobenzene; and 3, 4-dichloronitrobenzene, a palladium-carbon catalyst and ethanol are added into a hydrogenation kettle, hydrogen is introduced while stirring, desolventizing is performed after the reaction is ended, and reduced pressure rectification is performed to obtain a finished product of 3,4-dichloroaniline with the purity of more than 99.5%. The method is simple in process and wide in temperature and pressure range and is easy to control, so that the environment is protected, the cost is saved, and the yield is improved.

Owner:HULUDAO TIANQI SHENGYE CHEM

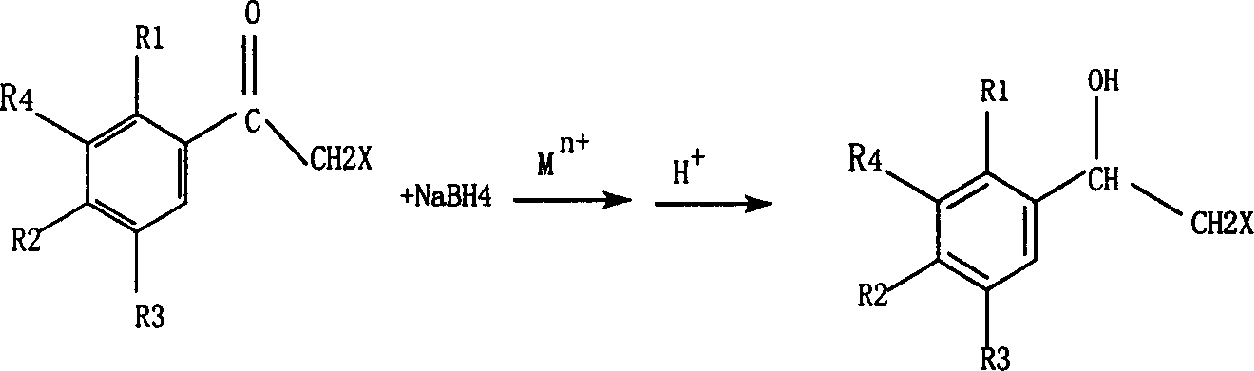

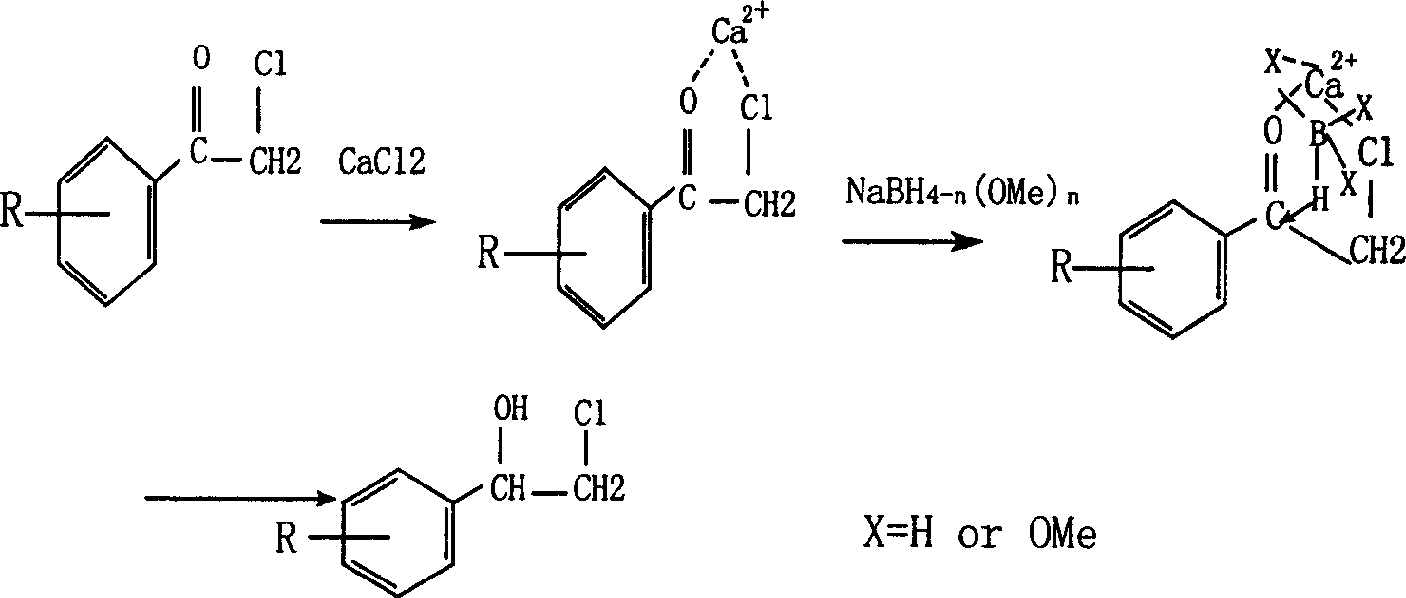

Process for preparing beta-halogen-alpha-phenyl ethyl alcohol compounds

InactiveCN1587243AHigh yieldHigh purityOrganic compound preparationHydroxy compound preparationPotassium borohydrideLanthanide

The present invention discloses the preparation process of beta-halogeno-alpha-phenyl ethyl alcohol compound. With sodium or potassium borohydride as reductant and in the presence of metal ion of Ca, Mg, Sr, Mn, Ln, Zn or Cu in the stoichiometric value or greater than the stoichiometric value, alpha-halogeno-acetophenone compound is reduced into beta-halogeno-alpha-phenyl ethyl alcohol compound in methanol or ethanol medium. Owing to that the metal ion and alpha-halogeno-acetophenone compound form stable compound, the halogen atom in the alpha-position is not substituted or reduced to raise the reaction selectivity greatly. The reaction has wide temperature range, may be performed at normal temperature in high selectivity and yield.

Owner:ZHEJIANG UNIV

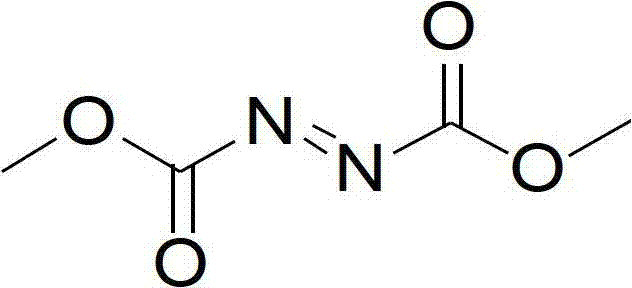

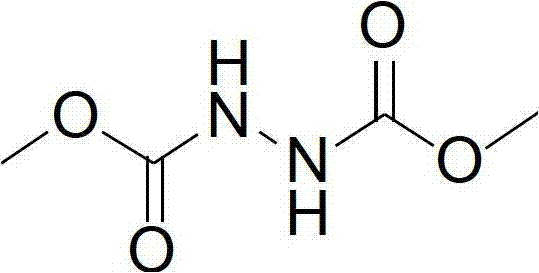

Synthesis method for dimethyl azodicarboxylate and intermediate thereof

ActiveCN102898327ANo pollution in the processIn line with the concept of modern green chemistryHydrazide preparationSodium methoxideSynthesis methods

The invention discloses a synthesis method for dimethyl azodicarboxylate; and the synthesis method comprises the following steps of: (1) heating dimethyl carbonate and methyl hydrazinocarboxylate for 1-6 h under an effect of sodium methoxide; adjusting pH value of a solution to 3-8; separating out white crystals; and recrystallizing the white crystals so as to obtain hydrogenated dimethyl azodicarboxylate; (2) adding the hydrogenated dimethyl azodicarboxylate at (-15)-(45) DEG C; with bromine, hydrobromic acid or sodium bromide and potassium bromide as a catalyst, dripping excessive hydrogen peroxide to an acidic solution to react for 1-10 h; extracting a reaction liquid; and distilling the reaction liquid to remove an organic solvent, so as to obtain flavescent dimethyl azodicarboxylate. The invention further provides the intermediate hydrogenated dimethyl azodicarboxylate and a synthesis method therefore. As the dimethyl carbonate is used as a raw material, the synthesis method for the dimethyl azodicarboxylate, disclosed by the invention, has the advantages of cleanness, environment friendliness, no pollution, recyclable raw materials, better economic efficiency, simplicity in operation, wide reaction temperature range, stability in reaction, low energy consumption and high yield and is beneficial for industrial production.

Owner:SHANDONG NORMAL UNIV

Preparation method for composite terminated waterborne epoxy resin curing agent

The invention discloses a preparation method for a benzoxazine intermediate containing a maleimide biphenyl diphenol structure. The preparation method comprises the following steps: (1) producing a synthesis reaction 1, namely adding an aldehyde compound and a solvent into a reaction container and mixing uniformly under the normal pressure at a normal temperature, adding an amine compound into the container while stirring, and reacting for at least 10 hours at 0-100 DEG C under the normal pressure; after reacting, pouring reaction liquor into washing liquor for washing, filtering, collecting solid matters, and drying at 30-100 DEG C to obtain an intermediate containing a triazine structure; (2) producing a synthesis reaction 2, namely adding the solid matters (triazine), the aldehyde compound, biphenyl diphenol and 1,4-dioxane into the reaction container in sequence, mixing uniformly, heating to 110 DEG C, performing reflux reaction for 30 hours to obtain reaction liquor containing earthy yellow deposits, pouring the obtained reaction liquor into de-ionized water, fully stirring, depositing, performing suction filtration, washing with the de-ionized water and ethanol for multiple times, and drying in a drying oven to obtain an earthy yellow powdery solid target product.

Owner:SICHUAN VOCATIONAL & TECHN COLLEGE

Catalyst for preparing dimethyl ether by dehydration of methanol and preparation method thereof

InactiveCN101444747AHigh activityHigh selectivityMolecular sieve catalystsEther preparation by compound dehydrationMolecular sievePhosphoric acid

The invention discloses a catalyst for preparing dimethyl ether by dehydration of methanol and a preparation method thereof. The catalyst consists of 30-80% (weight at butt) of molecular sieve and 70-20% (weight at butt) of caking agent, wherein, the molecular sieve is nano-ZSM-23 molecular sieve, and the caking agent is at least one of silicon dioxide and aluminium phosphate. The preparation method comprises the steps: the nano-ZSM-23 molecular sieve, the caking agent and the water are mixed and kneaded for molding, and then the catalyst is prepared by drying and calcination. The catalyst has the advantages of high activity and selectivity, good stability, wide reaction temperature range, short production flow and low cost; and the catalyst is also beneficial to industrial production and application.

Owner:EAST CHINA NORMAL UNIV

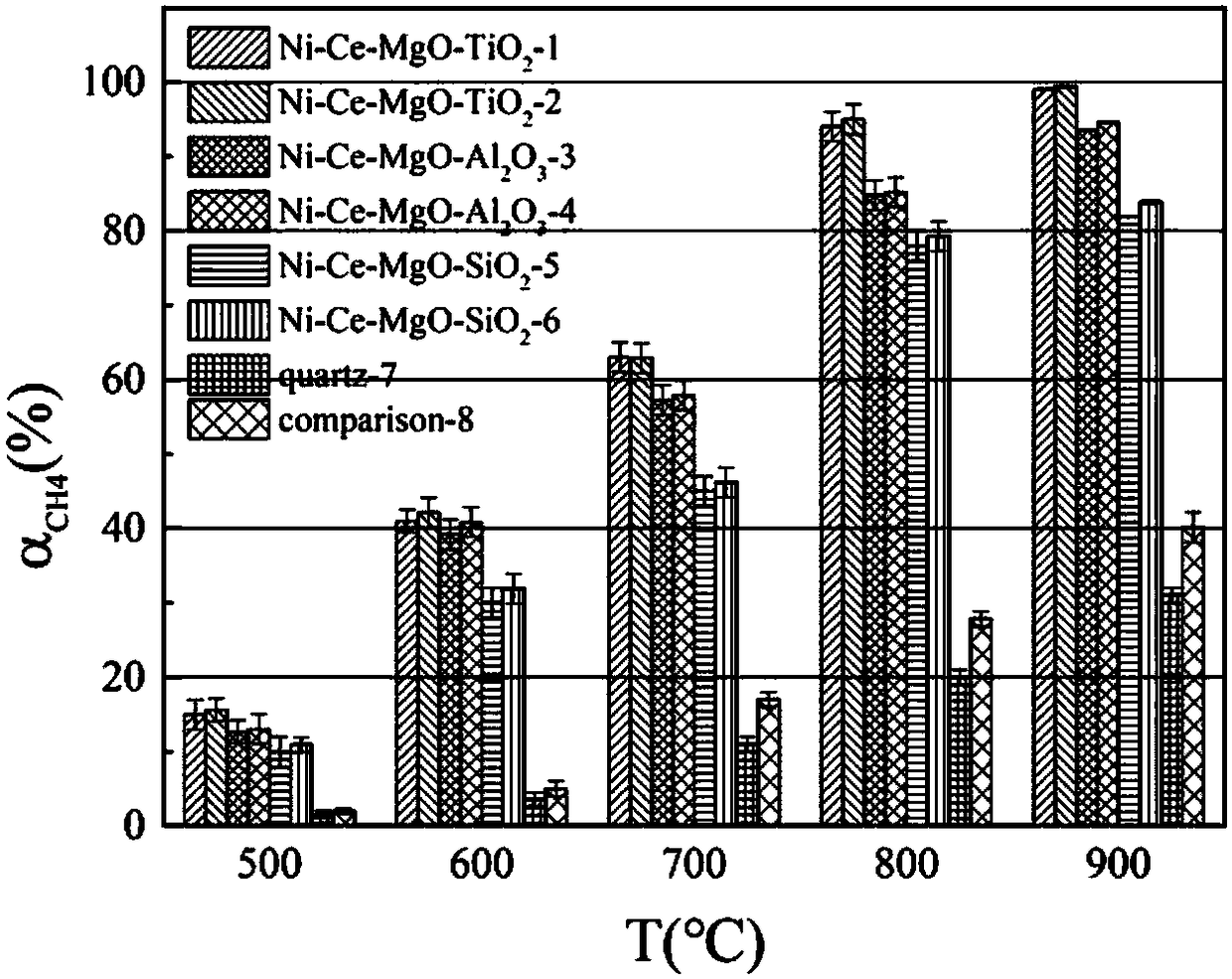

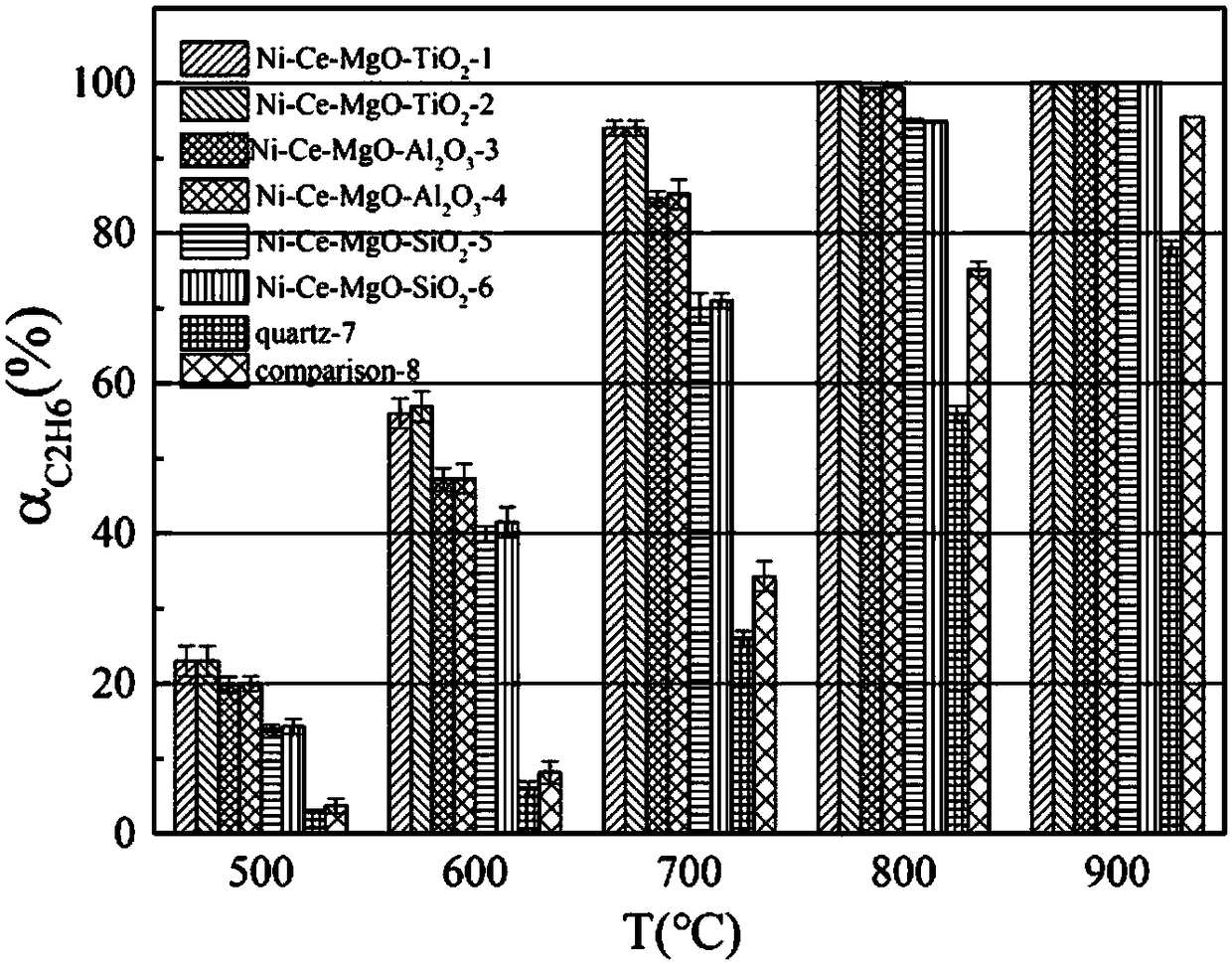

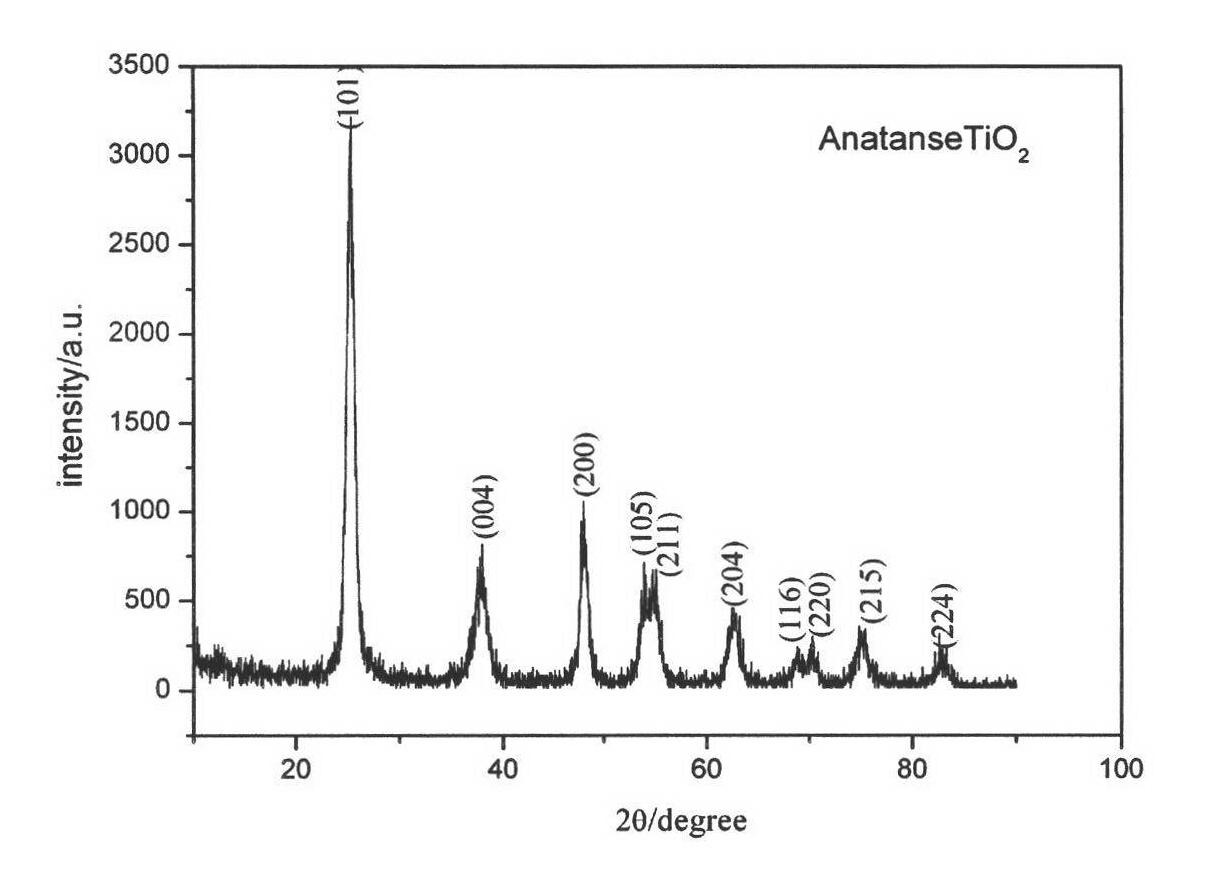

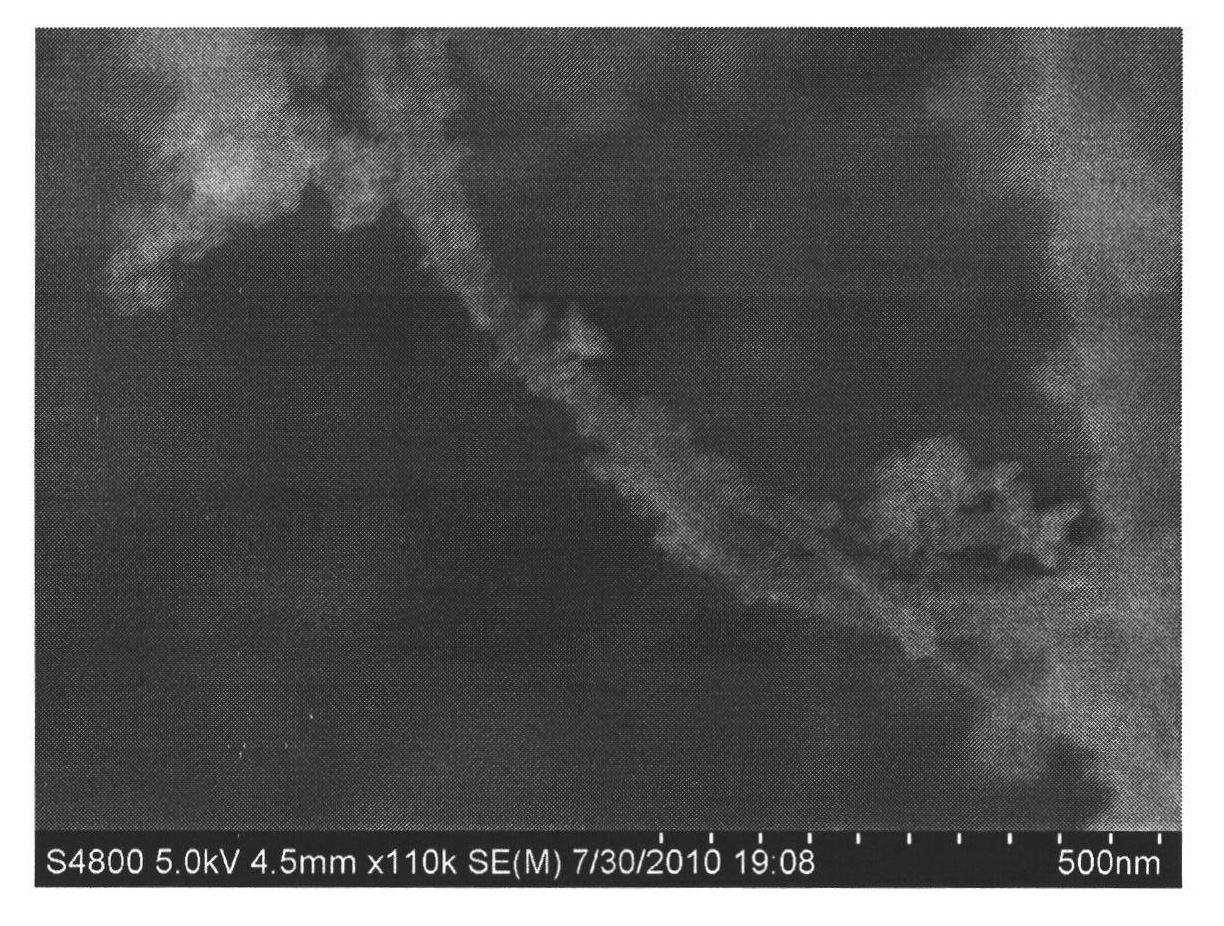

Catalyst applicable to synthesis-gas preparation by catalytic reforming of shale gas and carbon dioxide and preparation method thereof

ActiveCN108144621ALarge specific surface areaImprove dispersionHydrogenGaseous fuelsShale gasGreenhouse gas

The invention discloses a catalyst applicable to synthesis-gas preparation by catalytic reforming of shale gas and carbon dioxide and a preparation method thereof. The catalyst is prepared from the following components in percent by mass: 5%-10% of main active component (nickle), 3%-5% of secondary active component (cerium), 20%-30% of anti-carbon-deposition magnesium oxide and carrier, wherein the mass ratio of the nickle to the cerium is (1-3):1, and the carrier is one or more of titanium oxide, aluminium oxide or silicon oxide. The catalyst disclosed by the invention has the advantages of low reaction temperature, high catalytic activity, good anti-carbon-deposition and good stability, and is applicable to industrial application of fixed beds or fluidized beds. The catalyst has the beneficial effects that in the catalytic reforming application of the shale gas and CO2, the pressure is normal pressure, the reaction temperature is 500-900 DEG C, not only can effective and clean utilization of shale-gas resources be realized, but also two types of greenhouse gases can be treated simultaneously, the greenhouse effect is relieved, and the product has proper H2 / CO ratio and can be directly applicable to other fields of Fischer-Tropsch synthesis and the like, so that the industrial application prospect is wide.

Owner:NANJING UNIV OF SCI & TECH

Vanadium manganese composite catalyst for removing nitrogen oxide in incineration gas and preparation method thereof

InactiveCN101972649ALarge specific surface areaHigh reactivityDispersed particle separationCatalyst activation/preparationManganeseCarbon nanotube

The invention discloses a vanadium manganese composite catalyst for removing nitrogen oxide in incineration gas, which is characterized in that a carbon nano tube and titanium dioxide are taken as composite carriers, and an MnOx and V2O5 composite component is taken as an active ingredient; the atomic ratio of V to Mn of the active components in the catalyst is equal to 1-5; the vanadium manganese composite catalyst comprises the following components by mass percent: 1-20% of active component and 5-10% of carbon nano tube and the balance titanium dioxide. The catalyst can be prepared by a solvothermal method, a sol-gel method and a coprecipitation method; in the catalyst, CNTs and TiO2 are taken as carriers at the same time, thus greatly increasing the specific surface area of the catalyst, and lowering the reaction temperature; and in the catalyst, the mixture of the MOx and V2O5 is taken as an active component, so that the catalyst has wider reaction temperature range, the catalyzing efficiency is gradually increased along with the rising of the temperature, and the rate of removal of NOX can reach 97% at the temperature of 250 DEG C. The catalyst can be widely used for removing the nitrogen oxides discharged by coal fired power plant, waste incineration, metallurgical industries and vehicle exhaust and the like.

Owner:浙江德纳希环保科技股份有限公司

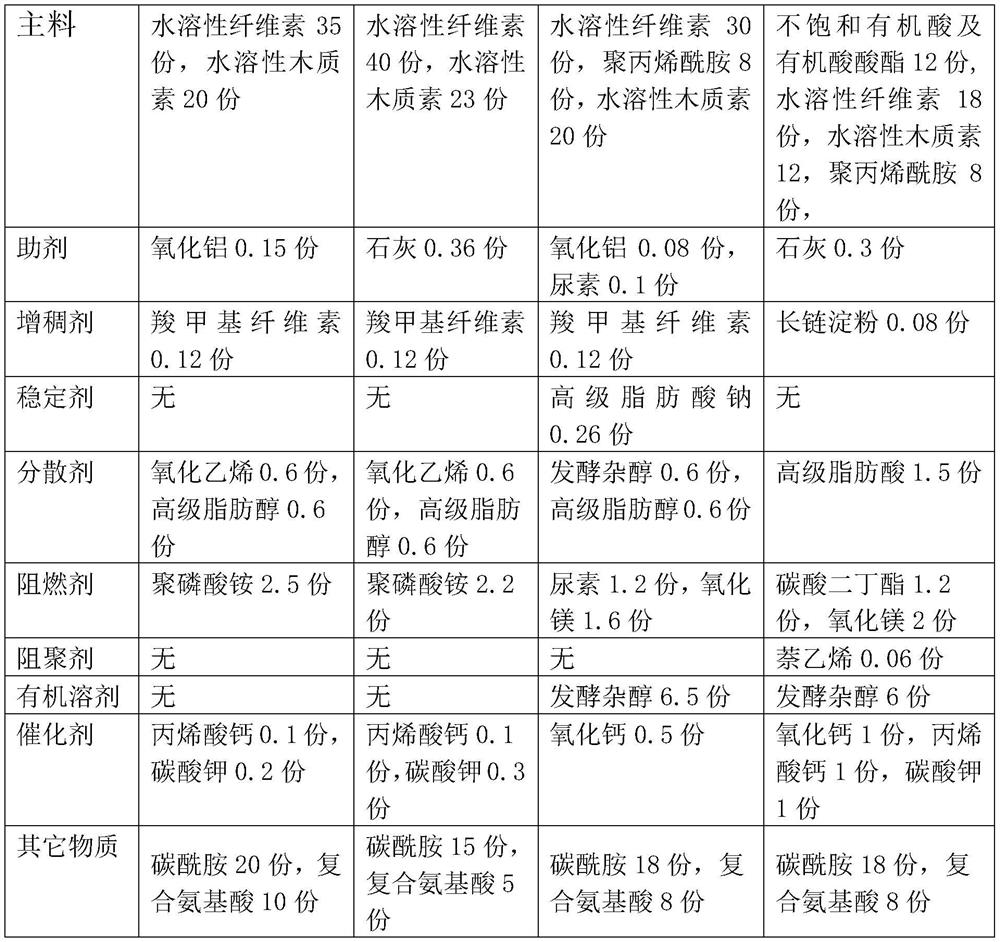

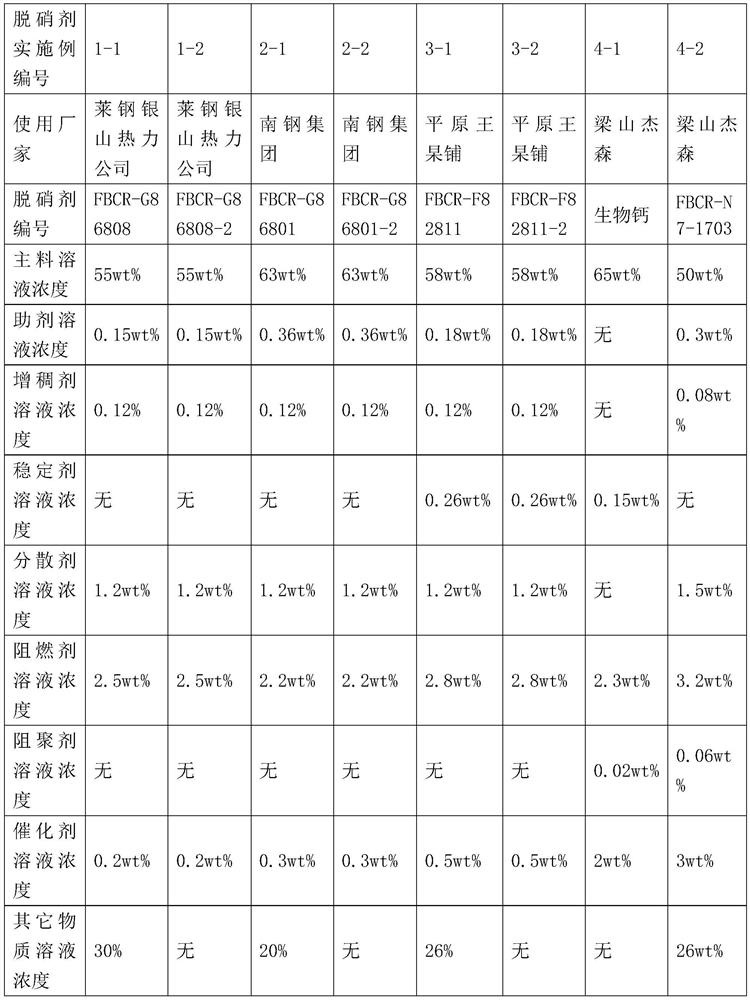

Composite fiber denitration agent and preparation method thereof

The invention discloses a composite fiber denitration agent and a preparation method thereof, wherein the composite fiber denitration agent comprises the following components in parts by weight: a main material, 0.1-0.5 part of an auxiliary agent, 0.1-0.2 part of a thickening agent, 1-2 parts of a dispersant, 2-5 parts of a flame retardant and 0.2-1 part of a catalyst, and the main material contains 30-70 parts of polymer organic fiber. The preparation method of the composite fiber denitration agent is used for preparing the composite fiber denitration agent. The high-molecular organic fiber is used as the main raw material of the denitration agent, in the production and denitration process, no harm is generated to the environment, the high-molecular organic fiber is easy to dissolve and does not need to be emulsified, and the production cost is low. The denitration efficiency is high, and the adaptive temperature range is large.

Owner:山东省昔利环境科技有限公司

A kind of preparation method of nylon salt

ActiveCN105777553BReduce yellowingWide reaction temperature rangeOrganic chemistryReaction temperatureRoom temperature

The invention provides a preparation method of a nylon salt. The method comprises the following steps: 1, providing a saturated nylon salt solution; 2, adding a diamine and a diacid to the solution provided in step 1 to precipitate a nylon salt solid from the solution; and 3, carrying out solid-liquid separation on the product obtained in step 2 to obtain the nylon salt solid. The preparation method of the nylon salt has the following advantages: the reaction temperature range of a reaction system is wide, and especially the reaction can be carried out at room temperature, so reaction conditions are mild; and high temperature heating is avoided, so energy consumption is reduced, and byproduct impurities generated in high temperature reactions are reduced, thereby the nylon yellowing phenomenon in the subsequent polymerization process of the nylon salt is mitigated.

Owner:CATHAY R&D CENT CO LTD +2

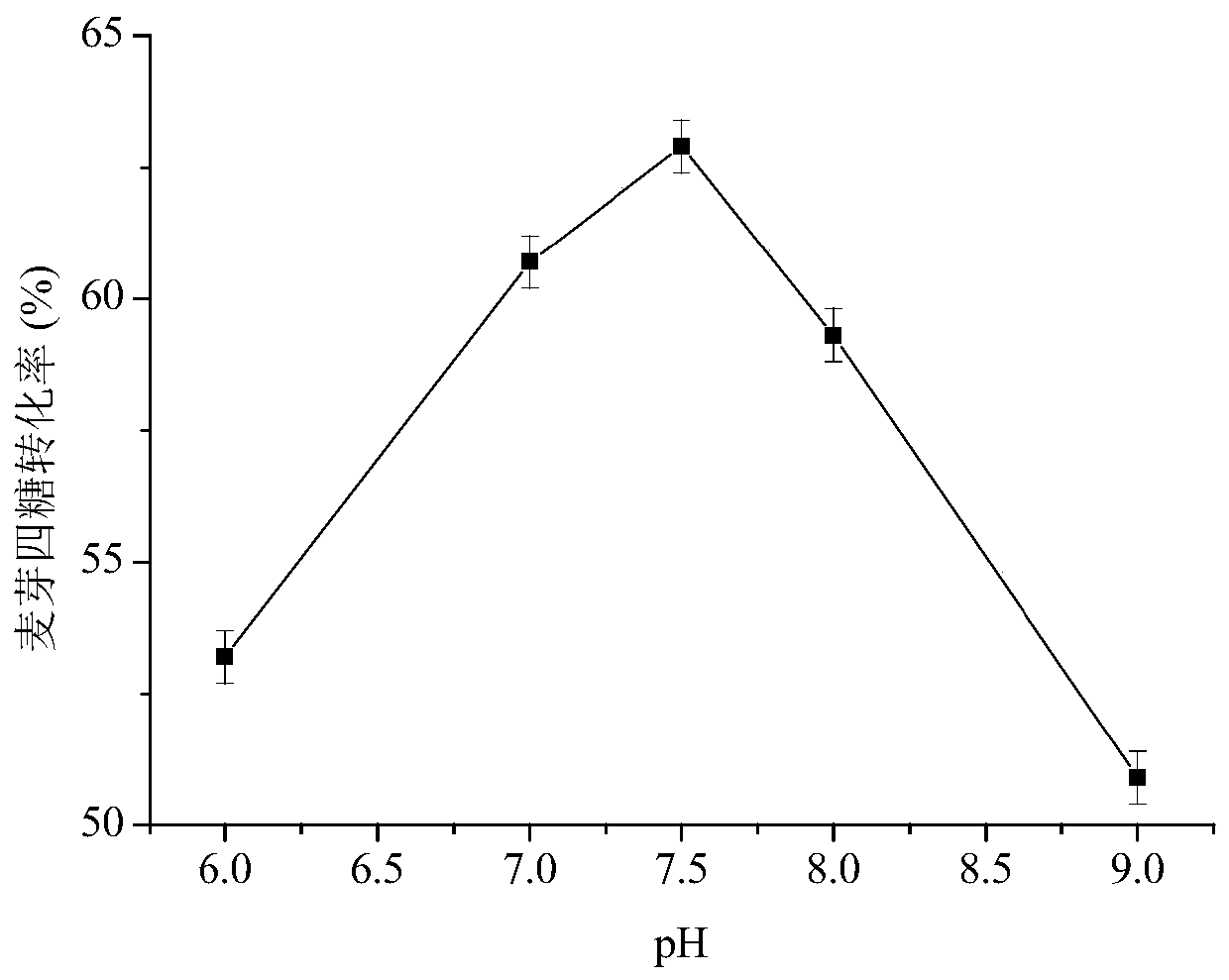

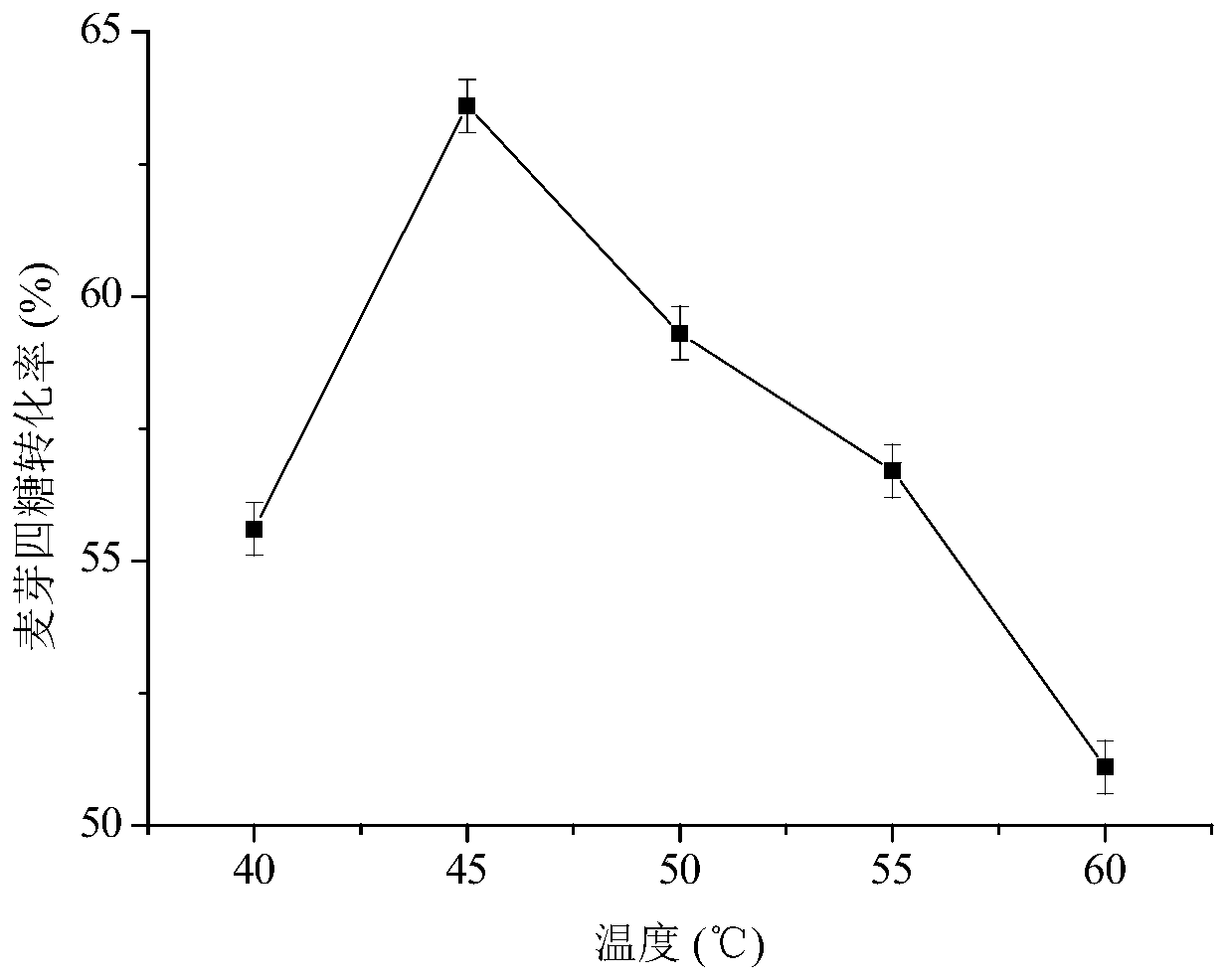

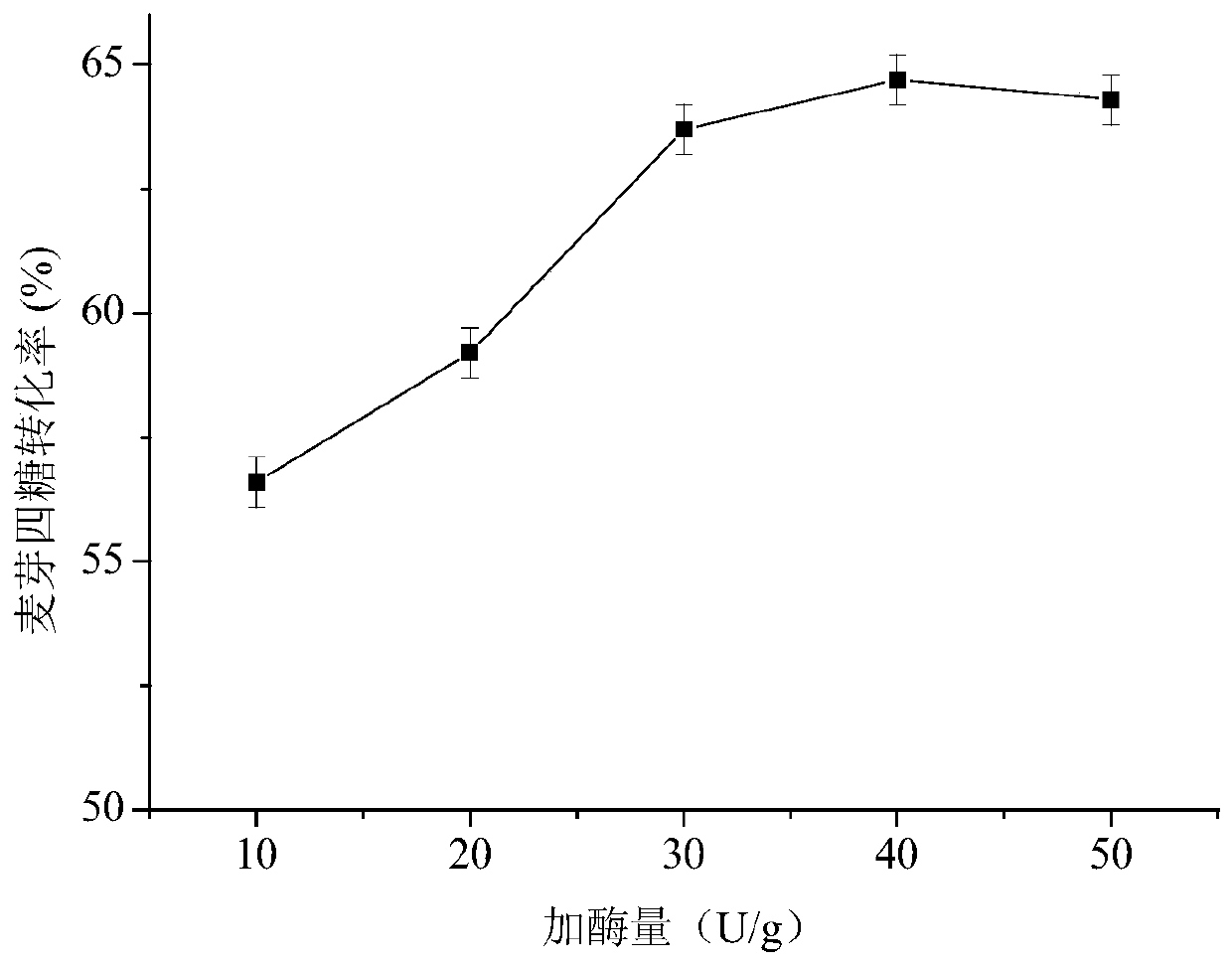

A kind of thermophilic bacillus producing maltotetraose amylase and application thereof

ActiveCN110144312BWide reaction temperature rangeReduce energy consumptionBacteriaDigestive systemAmylaseFermentation broth

The invention discloses a thermophilic bacillus and an application thereof, belonging to the technical field of fermentation engineering. The invention obtains a strain of thermophilic bacillus expressing maltotetraose amylase, uses maltodextrin as a substrate, and uses strain fermentation liquid as a catalyst to synthesize maltotetraose. In the present invention, the maltodextrin with a final concentration of 20g / 100mL is used as the substrate, the amount of maltotetraose amylase fermentation liquid added is 40U / g maltodextrin, and the enzyme reaction is carried out at pH 7.5 and temperature 45°C for 18 hours. The conversion rate of maltotetraose can reach 65.7%.

Owner:JIANGNAN UNIV

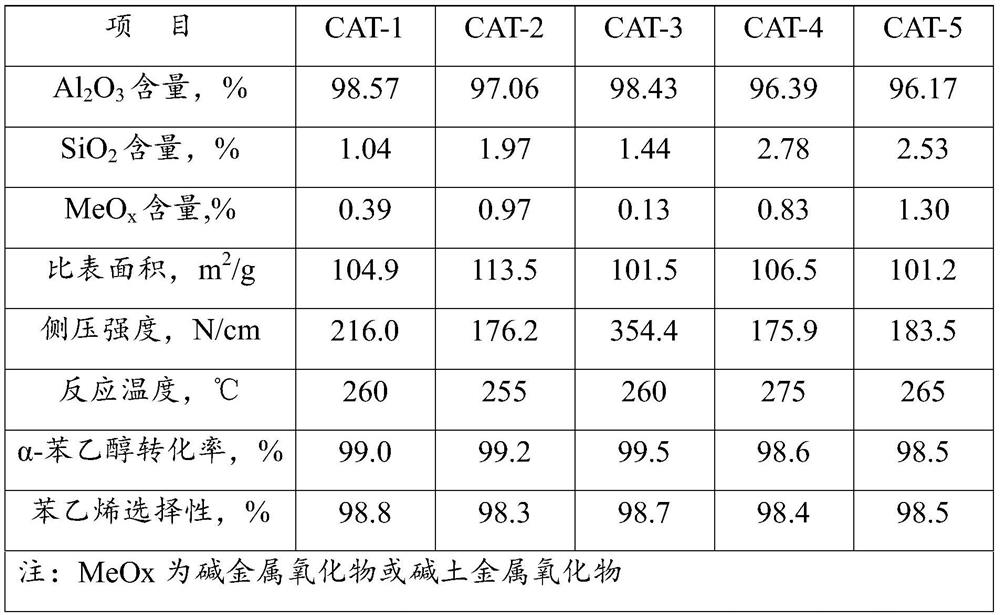

Alpha-phenethyl alcohol dehydration catalyst and preparation method thereof

PendingCN112452319AHigh catalytic activityWide reaction temperature rangeCatalystsHydrocarbon preparation catalystsPtru catalystAdhesive

The invention belongs to the technical field of industrial catalysts, and particularly relates to an alpha-phenylethanol dehydration catalyst and a preparation method thereof, the alpha-phenylethanoldehydration catalyst is prepared by taking an alumina precursor as a raw material, adding a modifying aid, an adhesive, an extrusion aid and a hardener, and then carrying out extrusion molding, reinforced hardening, drying, activation and other processes. The catalyst is simple in preparation process, high in mechanical strength in a water-containing reaction system, free of pulverization after long-term use, suitable for alpha-phenylethanol dehydration and other reactions, high in selectivity and good in activity stability.

Owner:SHANDONG QILU HUAXIN HIGH TECH

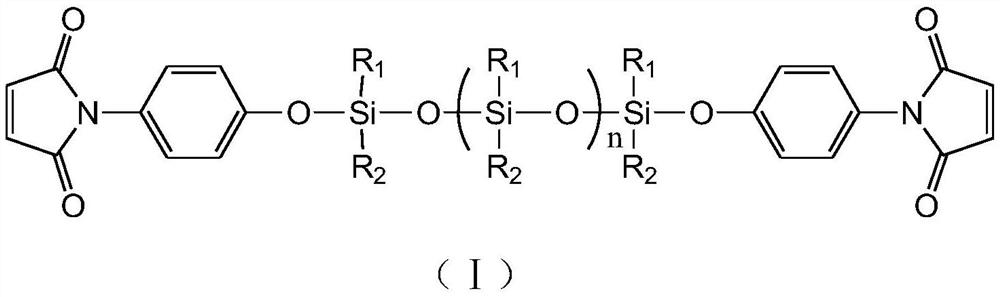

High-heat-resistance single-component adhesive and preparation method thereof

PendingCN113736401AWide reaction temperature rangeExothermic stableNon-macromolecular adhesive additivesEpoxynovolac adhesivesImidePolymer science

The invention discloses a high-heat-resistance single-component adhesive and a preparation method thereof. The high-heat-resistance single-component adhesive is characterized by being prepared by mixing the following components in parts by weight: 5 to 30 parts of toughening modified bismaleimide resin, 15 to 55 parts of epoxy resin, 0.1 to 5 parts of epoxy active diluent, 3 to 18 parts of a latent curing agent, 0.01 to 0.5 part of a defoaming agent, 0.01 to 0.5 part of a wetting dispersant, 0.1 to 5 parts of a catalyst and 5 to 60 parts of an inorganic filler. The preparation method comprises the following steps: preparing bismaleimide resin, carrying out toughening modification treatment, adding the toughening modified bismaleimide resin and other raw materials into a vacuum planetary mixer, and carrying out mixing. The high-heat-resistance single-component adhesive disclosed by the invention has the characteristics of gentle heat release in a curing process, high heat resistance of a cured product, high toughness, low thermal expansion coefficient, good high and low temperature impact resistance and the like, and is suitable for bonding and sealing of electronic and electric appliance elements and metal and nonmetal devices with heat resistance and environment temperature requirements.

Owner:艾蒙特成都新材料科技有限公司

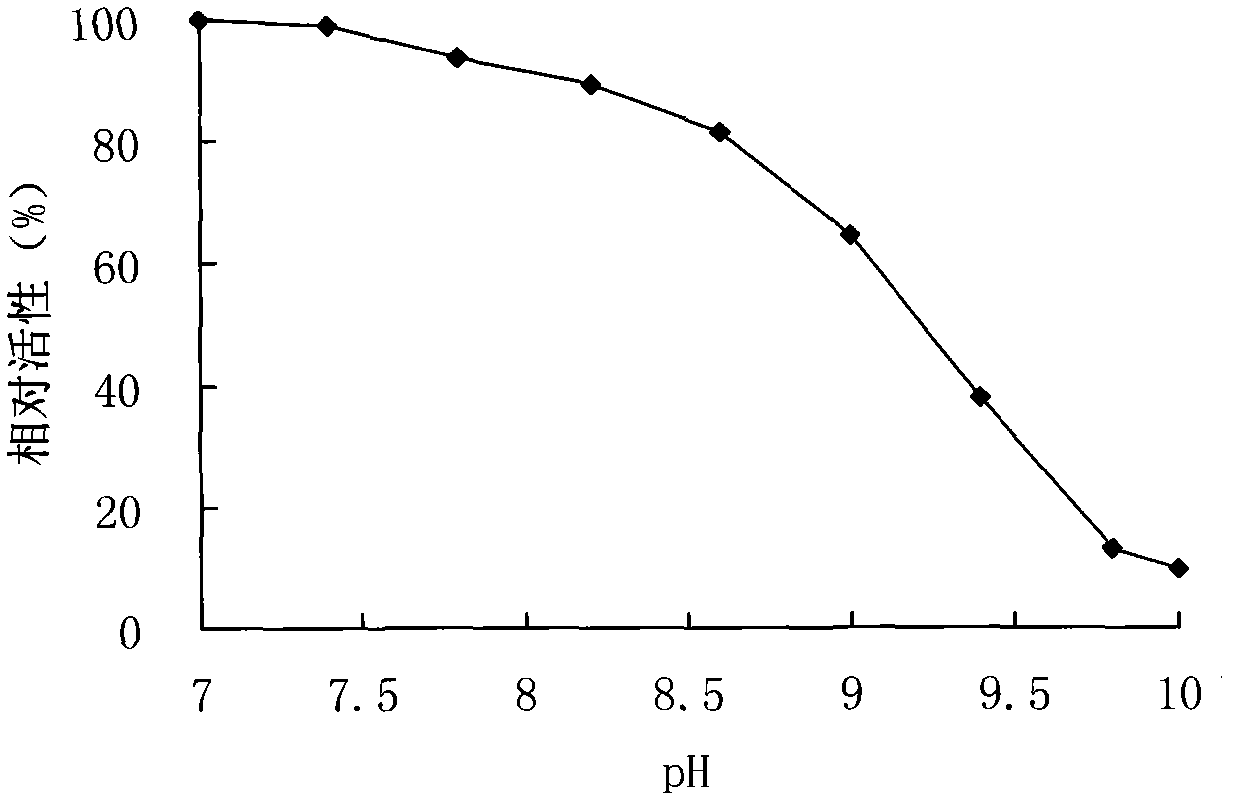

Bacillus subtilis cjp3 for producing CotA laccase as well as CotA laccase and application thereof

PendingCN106754519AMature and easy to operateIncrease enzyme activityBacteriaMicroorganism based processesBiotechnologyChemical structure

The invention discloses a bacillus subtilis cjp3 for producing CotA laccase as well as CotA laccase and application thereof. The CotA laccase producing bacterium is named as Bacillus subtilis, collected in China Center for Type Culture Collection with number CCTCC No: M 2016408 on July 21, 2016 in Wuhan University of China. The DNA sequence of the CotA laccase is shown as SEQ ID NO. 2, and the amino acid sequence is shown as SEQ ID NO. 1. The operation on the CotA laccase is mature and convenient, the obtained laccase has high activity, and the prepared CotA laccase has a wide pH and temperature catalysis range, high stability under alkali and high-temperature conditions in the presence of high salt and high-concentration organic solvents, and stronger practicability than fungal laccase. Under the participation of an acetosyringone mediator, the CotA laccase can be used for effectively decolorizing synthetic dyes of different chemical structures, still keeps a good decolorizing effect under the alkali condition, and has a good application prospect on treatment of industrial dye wastewater.

Owner:NANJING FORESTRY UNIV

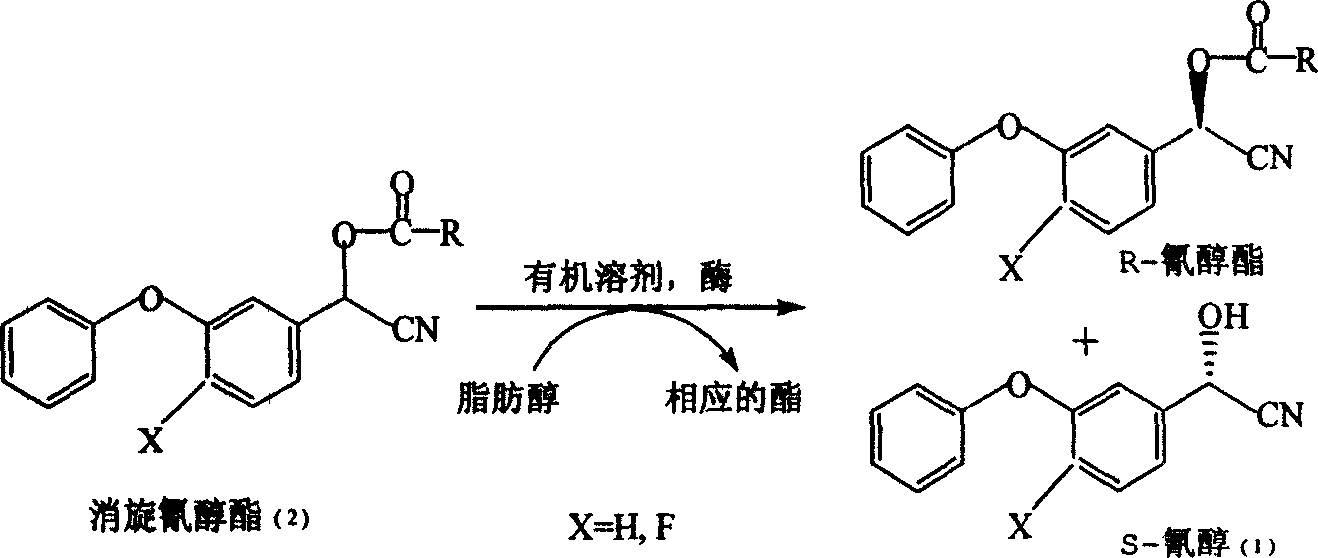

Preparation method for resolving optical active cyan alcohol by enzyme process

The invention publishes a kind preparation methods to aplit optical activity cyan alcohol by enzyme method. The approach follows this. 1, dissolve recemism cyan alcohol in organic solvent and then add aliphatic alcohol. The mol ratio of cyan alcohol ester and aliphatic alcohol is 0.1-1:20 and mix them fully. 2, book the alcoholysis reaction of cyan alcohol ester under the condition of enzyme catalysis in reaction system and then keep the reaction as well as agitating in temperature of 0-70 degree. The ratio of cyan alcohol ester and enzymatic is 0.001-100mol every cyan ester to 1 kilogram enzymatic. 3, filter the reaction fluid and recycle enzymatic to get S-cyan alcohol with capability of high optically active. The invention has many advantages, such as, reactive selection is good, conversion is high and the S-cyan alcohol optical purity is high and its application temperature is wide.

Owner:ZHEJIANG UNIV

Lower carbon number hydrocarbons building-up reaction method

ActiveCN1307133CWide reaction temperature rangeImprove stabilityHydrocarbonsHydrocarbon preparationCarbon numberReaction temperature

The invention discloses a superposition reaction method for lower carbon number olefin, which comprises: on reaction condition as 50~180Deg, 0.5~3.0MPa pressure and 0.5~6.0h-1 feeding weight air speed, contacting the superposition reaction material with a sulfonated composite material catalyst; wherein, the composite material comprises inorganic oxide with element selected from one or more of IIIB group, IVB group, VB group, VIB group, VIIB group, VIII group, IB group, IIB group, IIIA group, IVA group, and VA group; and organic resin polymerized by styrene monomer and divinylbenzene. This method has more wide reaction temperature and longer stable running time.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com