Preparation method for maleimide-containing biphenol type benzoxazine

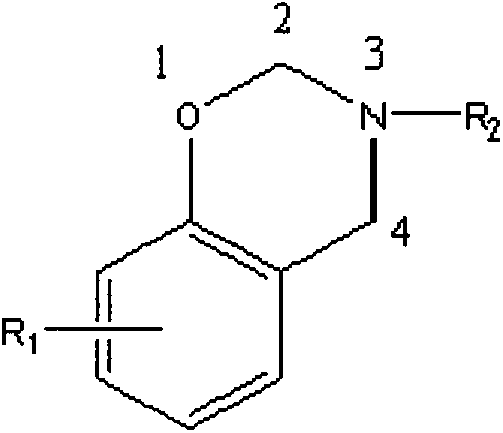

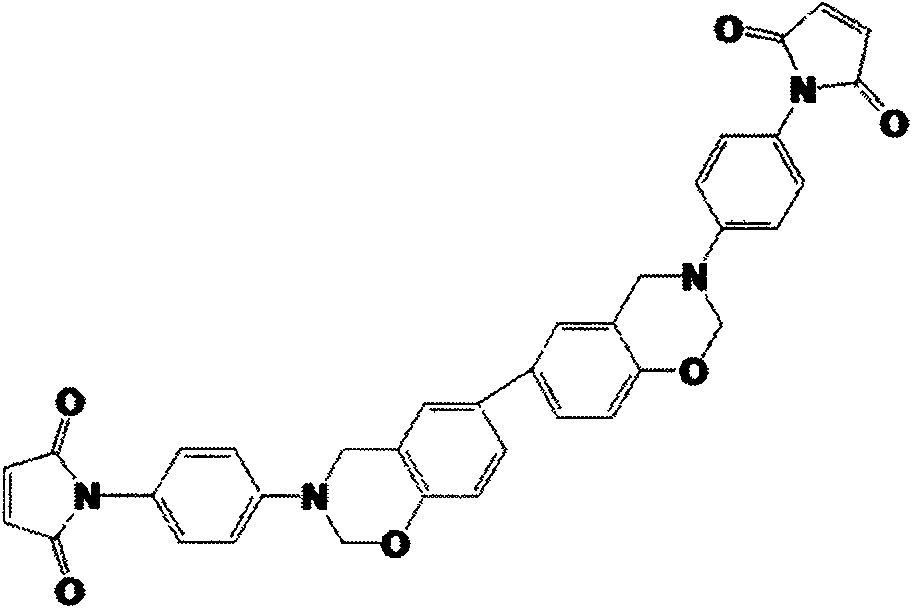

A technology of maleimide biphenol type and benzoxazine, which is applied in the field of preparation of benzoxazine intermediates and can solve the problem of maleimide biphenol type benzoxazine that has not yet been seen. Intermediates and their resin synthesis and curing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] In this embodiment, the preparation method of the benzoxazine intermediate containing maleimide biphenyl diphenol type structure, its process steps are as follows:

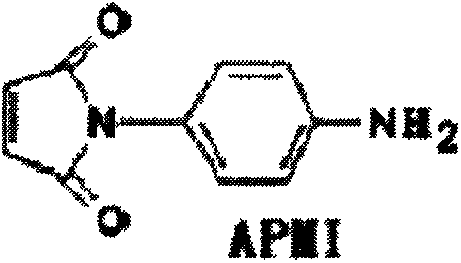

[0029] (1) Synthesis reaction 1

[0030] Add 14g of formaldehyde aqueous solution, 17g of APMI, 800mL of ethyl acetate, and 100mL of water into a 1000mL round-bottomed flask in sequence, and react at room temperature for about 10h, then pour the reaction solution into a beaker filled with 1000mL of water to precipitate, vacuum filter, Washed with tap water, put into an oven and dried at 60° C. for 4 hours to obtain TMIPT as light yellow solid powder with a yield of about 96%.

[0031] (2) Synthesis reaction 2

[0032] Add 3.0g of paraformaldehyde, 19.5g of TMIPT, 12.0g of biphenol, and 1000mL of 1,4-dioxane into a 1500mL round-bottomed flask in turn, raise the temperature to 110°C and reflux for 27h to obtain a khaki-yellow precipitate. The reaction solution, the obtained reaction solution is poured into ...

Embodiment 2

[0034] In this embodiment, the preparation method of the benzoxazine intermediate containing maleimide biphenyl diphenol type structure, its process steps are as follows:

[0035] (1) Synthesis reaction 1

[0036] Add 21g of formaldehyde aqueous solution, 25.5g of APMI, 1200mL of ethyl acetate, and 150mL of water into a 1500mL round-bottomed flask in sequence, and react at room temperature for about 13h, then pour the reaction solution into a beaker filled with 2000mL of water to precipitate, vacuum pump filtered, washed with tap water, and dried in an oven at 60° C. for 6 h to obtain TMIPT as a light yellow solid powder with a yield of about 92%.

[0037] (2) Synthesis reaction 2

[0038] Add 4.5g of paraformaldehyde, 29.5g of TMIPT, 18.0g of biphenol, and 1200mL of 1,4-dioxane into a 1500mL round-bottomed flask in turn, raise the temperature to 110°C and reflux for 30h to obtain a khaki-yellow precipitate. The reaction solution, the resulting reaction solution was poured i...

Embodiment 3

[0040] In this embodiment, the preparation method of the benzoxazine intermediate containing maleimide biphenyl diphenol type structure, its process steps are as follows:

[0041] (1) Synthesis reaction 1

[0042] Add 22.4g of formaldehyde aqueous solution, 27.2g of APMI, 1280mL of ethyl acetate, and 160mL of water into a 1500mL round-bottomed flask in sequence, and react at room temperature for about 14 hours, then pour the reaction solution into a beaker filled with 1500mL of water to precipitate, vacuum Suction filtration, washing with tap water, drying in an oven at 60° C. for 4 hours to obtain TMIPT as light yellow solid powder with a yield of about 94%.

[0043] (2) Synthesis reaction 2

[0044] Add 4.8g of paraformaldehyde, 31.2g of TMIPT, 19.2g of biphenol, and 1300mL of 1,4-dioxane into a 1500mL round-bottomed flask in turn, raise the temperature to 110°C and reflux for 32h to obtain a khaki-yellow precipitate. The reaction solution, the resulting reaction solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com