A kind of thermophilic bacillus producing maltotetraose amylase and application thereof

A technology of thermophilic bacillus and maltotetraose, applied in the field of microorganisms, to achieve the effects of wide reaction temperature range, extended shelf life, and improved overall texture parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The screening of embodiment 1 bacterial strain

[0043] The soil will be collected from different places in different regions (garbage dumps, starch factories, vegetable markets, food factories, grain processing factories, hotels, etc.), take 2g of soil samples and mix them with 9mL of sterile water, add glass beads and shake well After standing still for a while, take 5mL of supernatant and add it to LB medium, shake and culture at 25°C-37°C, 200r / min for 2-3d. Take 10mL of the culture solution and add it to another fresh LB medium to continue the shaking culture. After repeating this operation twice, spread it on the LB solid plate and culture it upside down at 25°C-37°C for 2-3d. A single colony can be observed and screened A strain that grows well.

[0044] A single colony was selected and inoculated into a high-throughput shallow-well plate filled with LB seed medium, and cultured overnight at 37°C with shaking at 200r / min. Then, according to the inoculum amount ...

Embodiment 2

[0051] The preparation of embodiment 2 maltotetraose

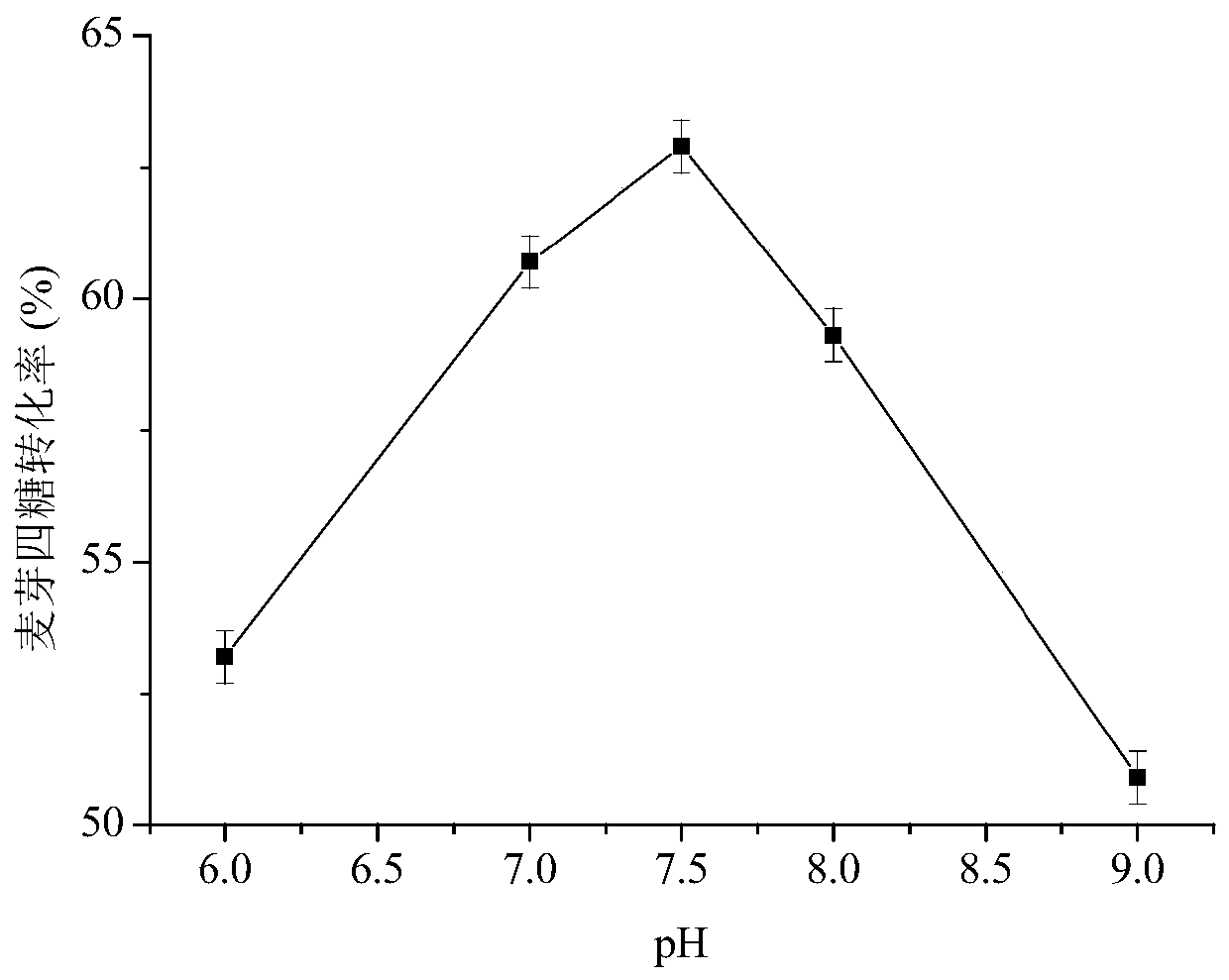

[0052] With 50mmol / L, pH 6.0, 7.0, 7.5, 8.0, 9.0 Na 2 HPO 4 -The final concentration of citric acid buffer preparation is 15% (W / V) maltodextrin, the addition amount of maltotetraose amylase fermentation broth is 30U / g maltodextrin, and the common maltodextrin of 5U / g is added Lulanase, 45°C constant temperature water bath shaker, 150rpm, reacted for 12h. The enzyme conversion product was detected by HPLC.

[0053] The results showed that the enzyme-catalyzed maltotetraose changed significantly with the increase of pH. When the pH was 7.5, the yield of maltotetraose reached 62.9%. Excessive pH will reduce the yield of maltotetraose (see figure 1 ).

Embodiment 3

[0054] The preparation of embodiment 3 maltotetraose

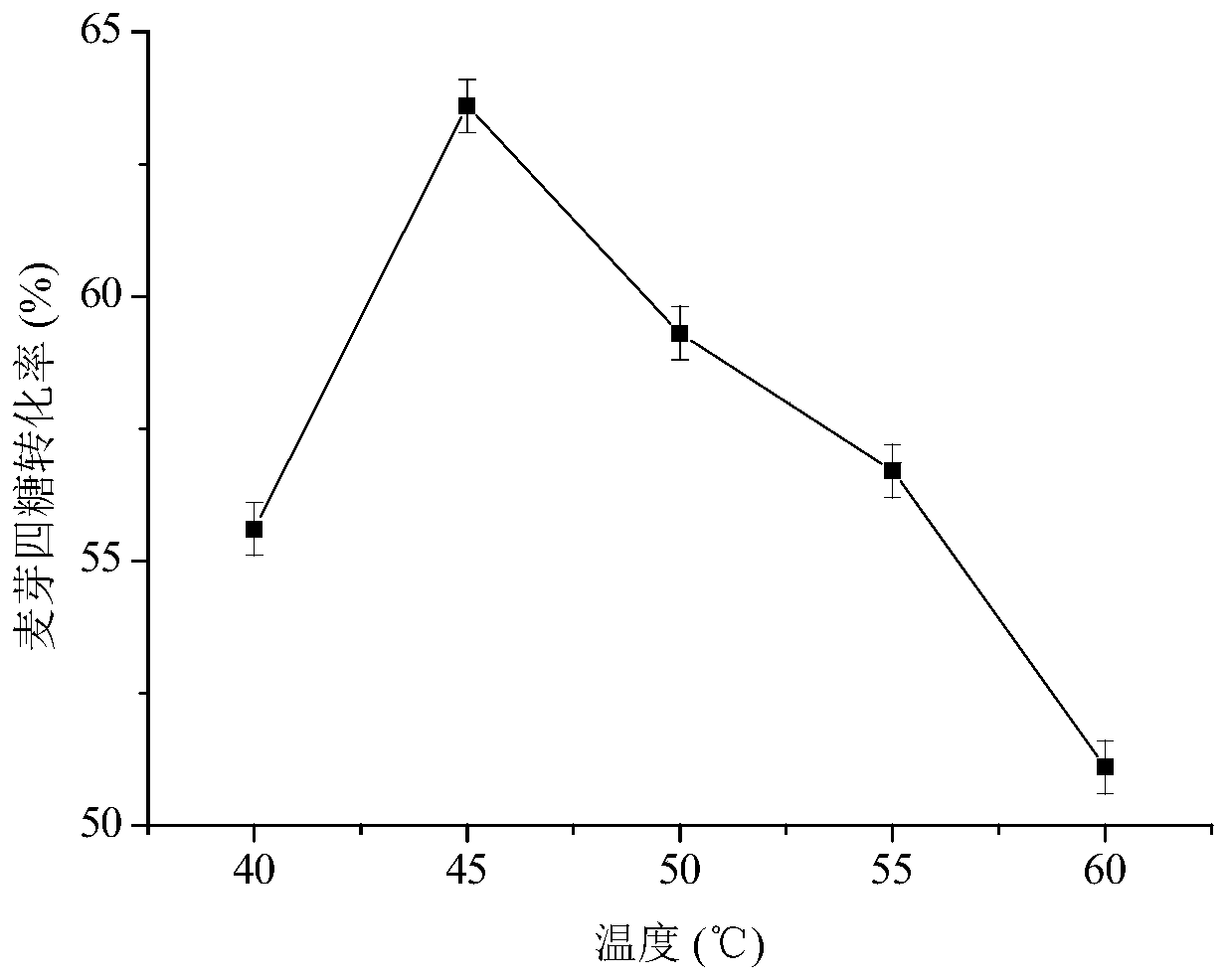

[0055] Use 50mmol / L, pH 7.5 Na 2 HPO 4 -The final concentration of citric acid buffer preparation is 15% (W / V) maltodextrin, the addition amount of maltotetraose amylase fermentation broth is 30U / g maltodextrin, and the common maltodextrin of 5U / g is added For Lulanase, the temperature was 40, 45, 50, 55, 60°C, constant temperature water bath shaker, 150rpm, and reacted for 12h. The enzyme conversion product was detected by HPLC.

[0056] The results showed that the temperature had a great influence on the yield of maltotetraose. When the temperature was 45℃, the yield of maltotetraose reached 63.2%. Continue to increase temperature after this, the yield of maltotetraose begins to decline (see figure 2 ). When the reaction temperature is about 45°C, the higher temperature can prevent the reaction system containing a large amount of sugar from being affected by bacterial contamination, improve the enzyme conversion ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com