Patents

Literature

296 results about "Bacillus ramosus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti-disease, growth promotion and drought-resistant functional plant endogenous bacillus velezensis and application thereof

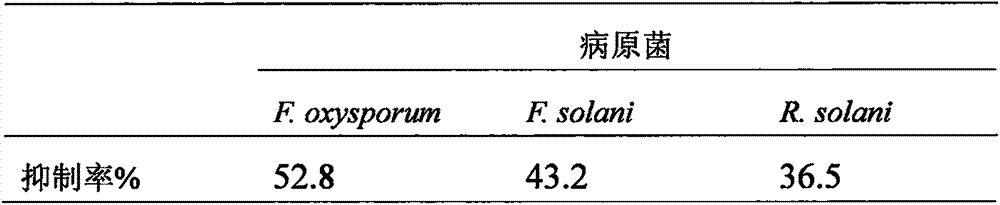

The invention relates to plant endogenous bacillus velezensis which is capable of preventing and treating plant diseases and insects and has functions of growth promotion and drought resistance, and application thereof. The preservation number of the Bacillus velezensis E6 provided by the invention in the China General Microbiological Culture Collection Center is CGMCC No. 9665. The strain is separated from a plant root, is rapid to grow, can be rapidly and greatly colonized at plant roots and has ecological niche advantages; the strain E6 not only has an efficient prevention and treatment function on plant soil-borne fungal diseases and is capable of promoting growth of plant root systems and improving drought resistance of plants, but also is capable of damaging formation of pathogenic bacterium bacterial biofilms, is free of drug resistance of bacteria, has relatively good advantages when being compared with other fungicides, is simple in nutrition requirement and low in productioncost, and has good application prospects.

Owner:河北伊诺生化有限公司

Long chain recombinant human bone morphogenesis protein-2 and its preparation method and uses

ActiveCN1951964AIncreased affinity binding sitesEasy to useBacteriaBone-inducing factorEscherichia coliNucleotide

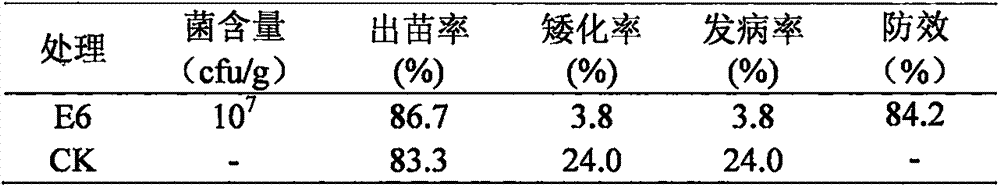

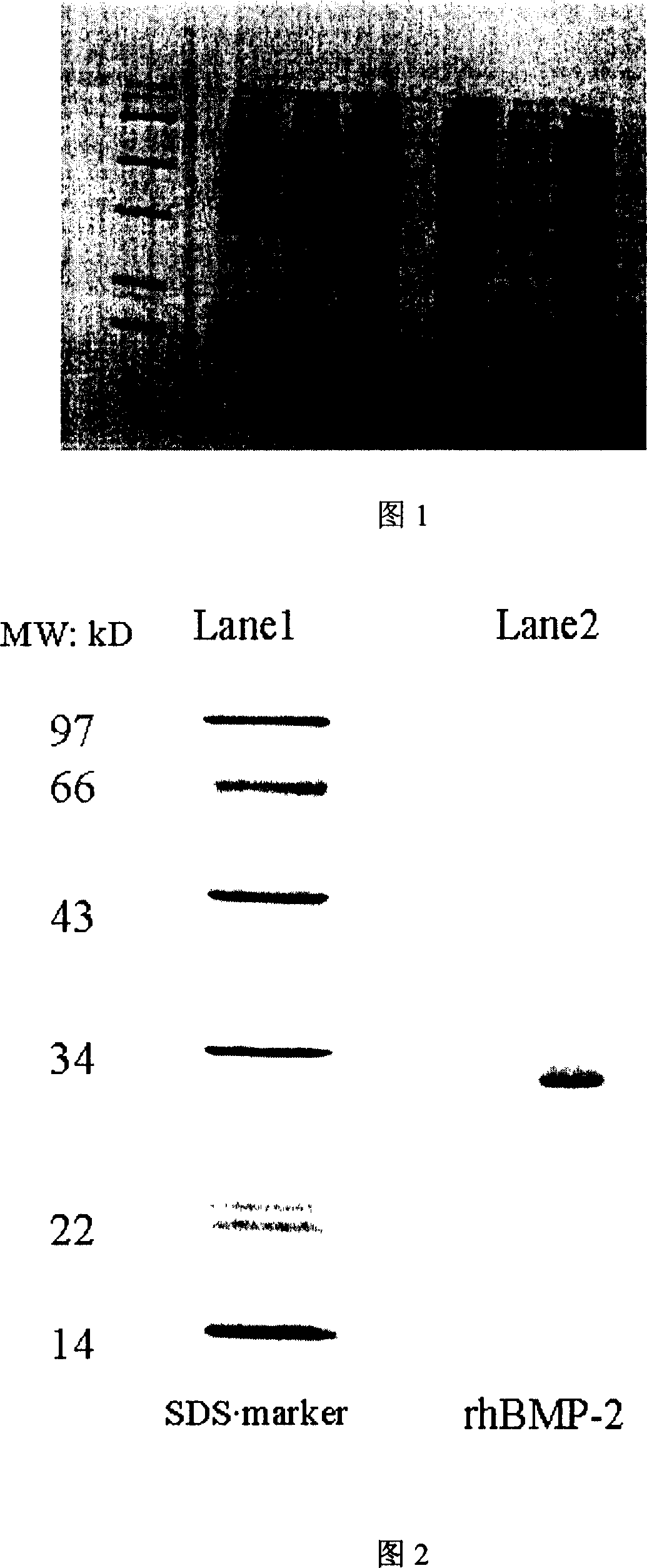

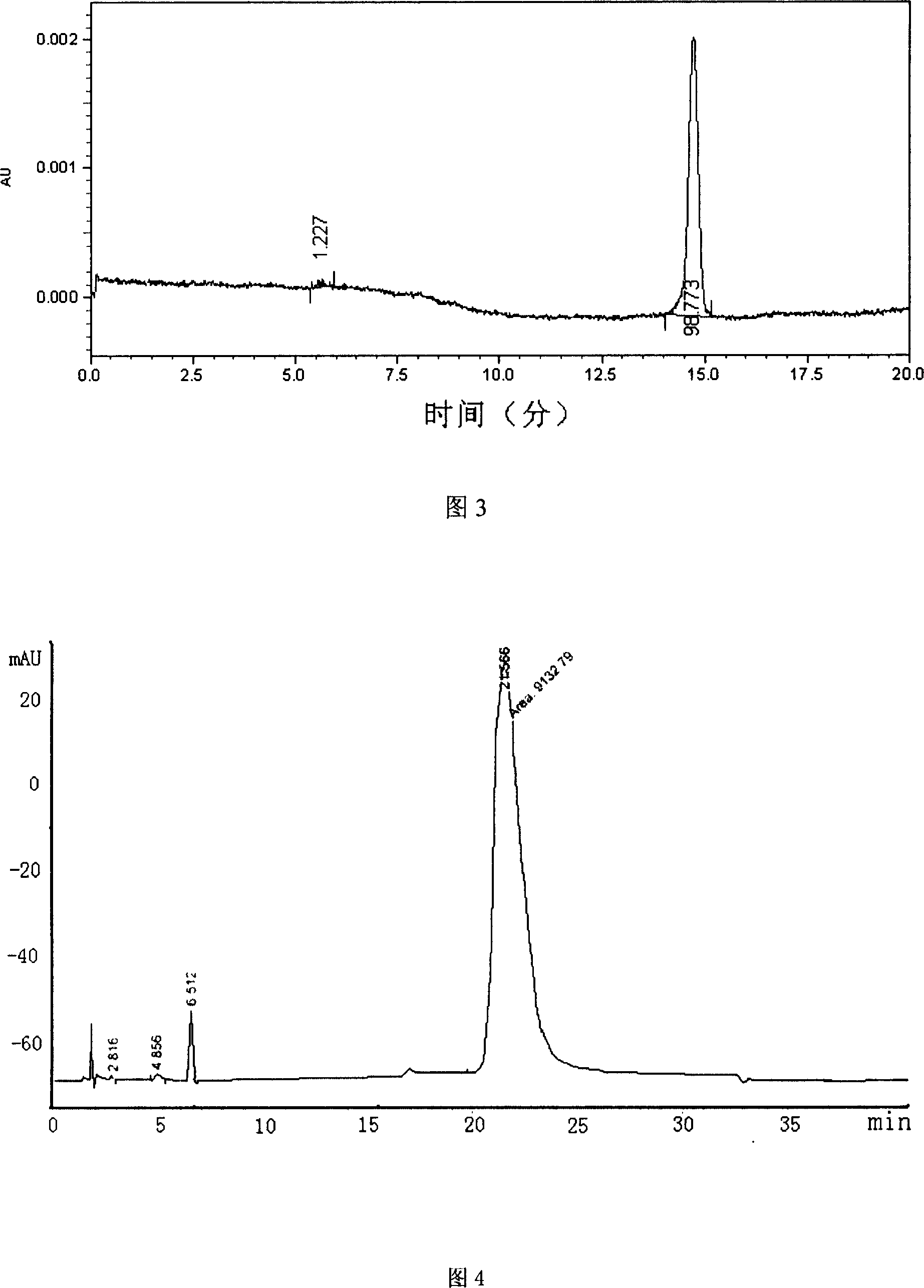

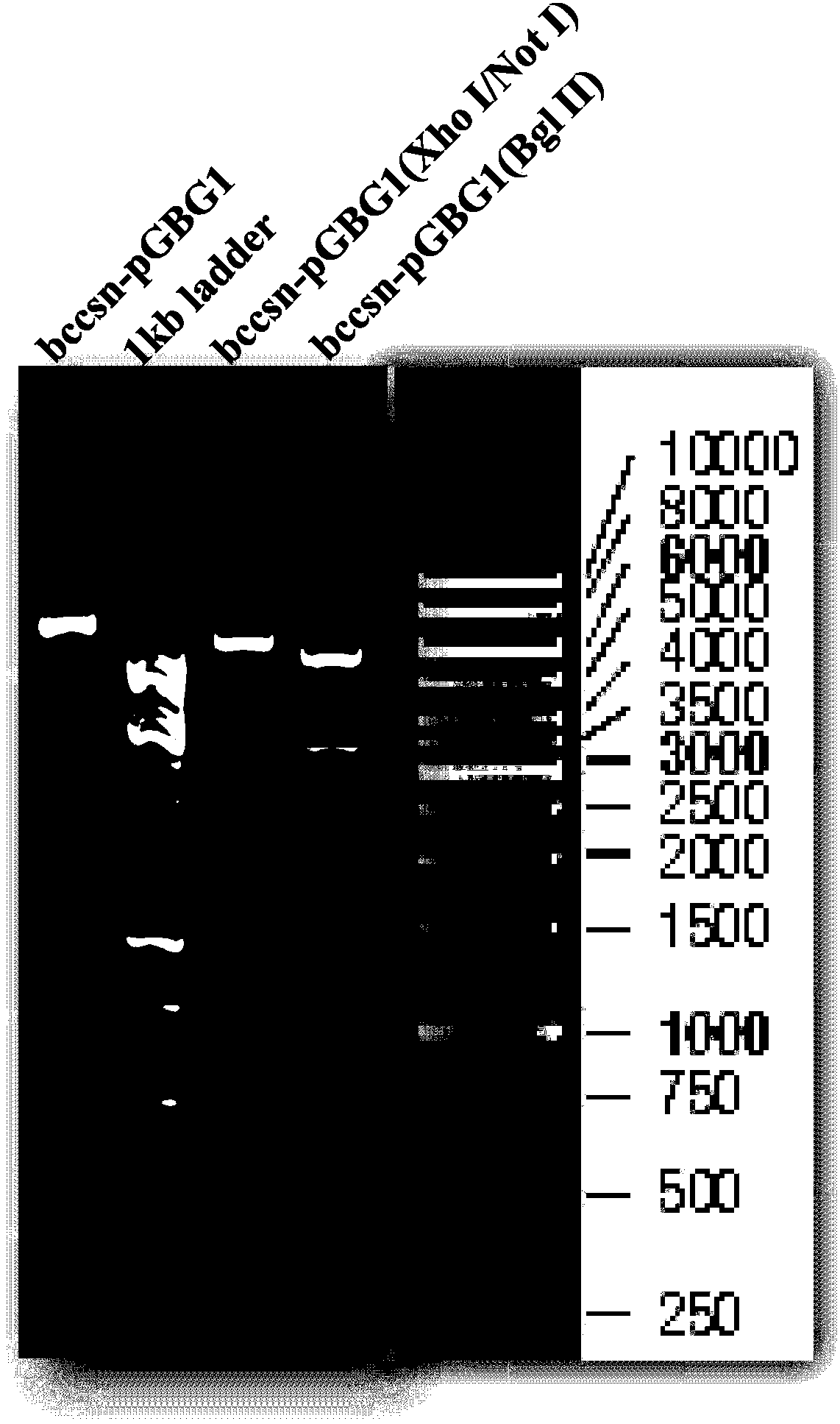

The invention discloses a long-chain recombination human bone pattern generating protein-2 and preparing method and application, which is characterized by the following: utilizing gene project technique to grow the protein in the expressing system of escherichia coli and bacillus subtilis; adopting human bone sarcoma cell mRNA to do reverse transcription to obtain the cDNA as form; augmenting nucleotide sequence of entire 114 amino acids naturally from carboxyl end; adding a segment of nucleotide in front of the first codon of primer 5' end; increasing a segment of polypeptide at N end corresponding to amino acid sequence; obtaining long-chain rhBMP-2 gene with molecular weight at 30KD and purity over 95%.

Owner:SHANGHAI REBONE BIOMATERIALS

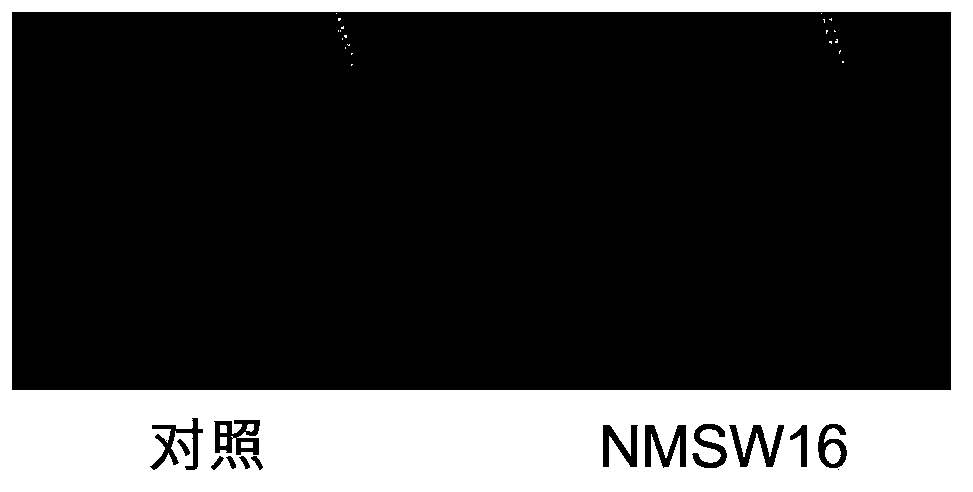

Novel compound microbial agent and applications thereof

InactiveCN102816726AImprove aggregate structureThe effect of increasing production is obviousBacteriaMicroorganism based processesBiotechnologyBacillus licheniformis

The invention discloses a novel compound microbial agent and relates to the technical field of agriculture microbes. 10 parts to 20 parts of bacillus subtilis, 20 parts to 30 parts of bacillus mucilaginosus and 50 parts to 70 pats of bacillus licheniformis serve as raw materials; and 5 parts to 15 parts of sodium humate, 30 parts to 50 parts of bran, 30 parts to 50 parts of rice bran and 5 parts to 15 parts of seaweed serve as raw materials for culture media. A preparation method of the novel compound microbial agent includes mixing and smashing the bacillus and maintaining the moisture to be in 30% to obtain the novel compound microbial agent. Bacterial manure prepared by mixing the novel compound microbial agent with nitrogen, phosphorus and potassium according to an appropriate ratio can effectively improve the granular structure of the soil and has a stimulation effect on the growth of crops, and the yield-increasing effect is apparent.

Owner:临沂中磷生物科技有限公司

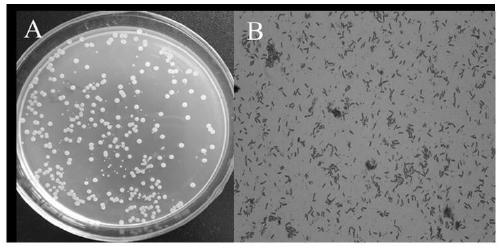

Bacillus cereus and application thereof

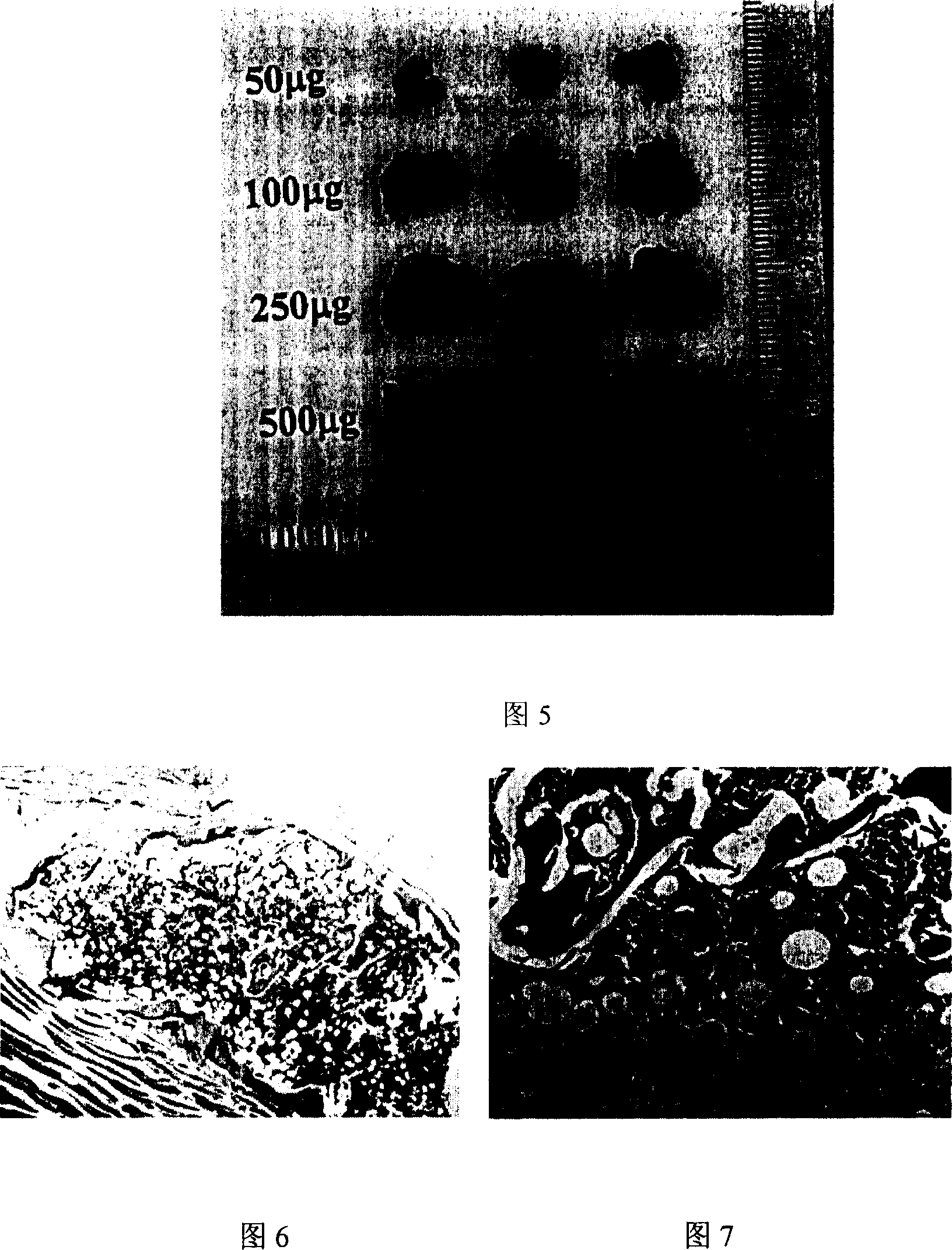

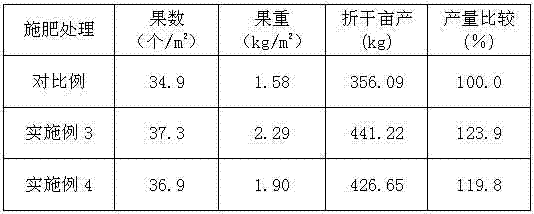

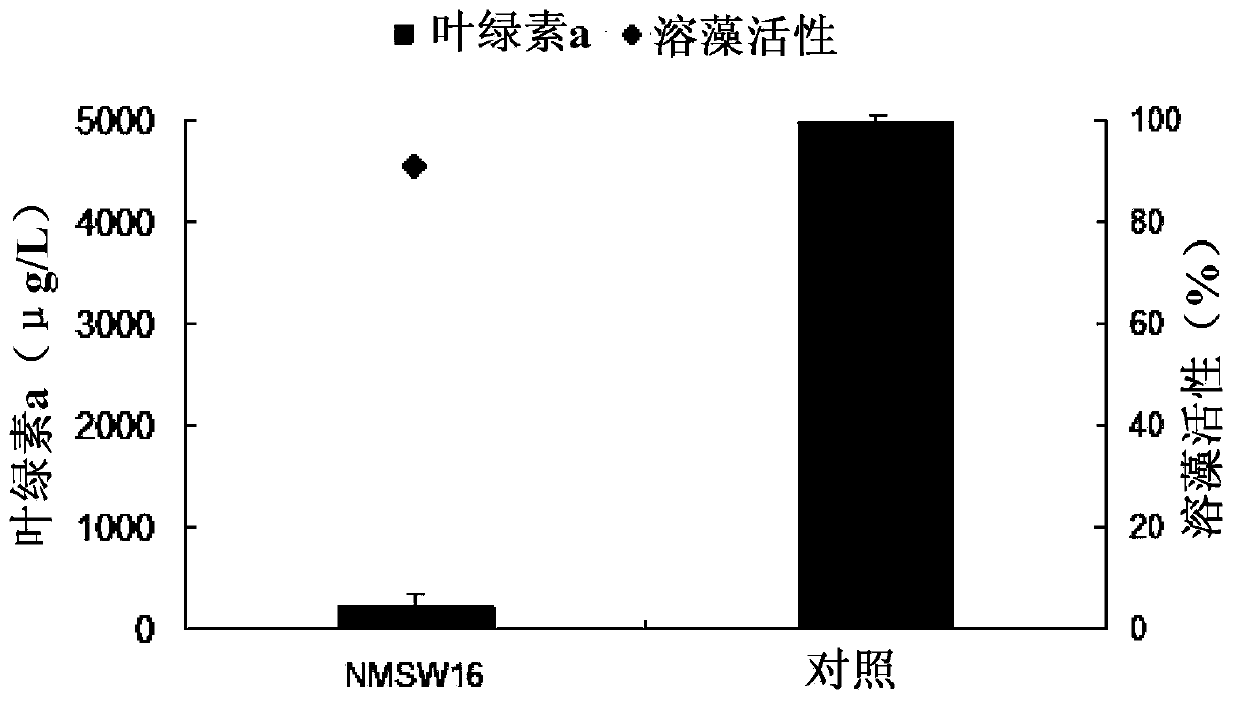

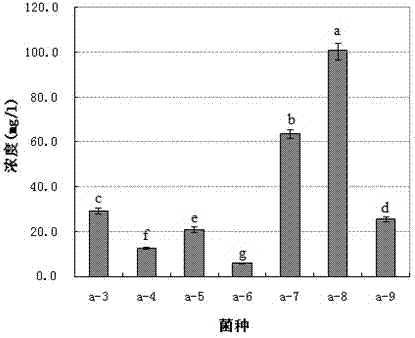

ActiveCN103421717AEnhanced inhibitory effectImprove hydrophilicityBacteriaMicroorganism based processesEutrophicationMicrobiology

The invention discloses bacillus cereus and application thereof. The bacillus cereus has a very strong algal inhibiting effect, and particularly has a very strong inhibiting effect on microcystis aeruginosa, and the algal inhibition rate after a seven-day process is more than 90%. The bacillus cereus NMSW16 is simple in culture and fermentation, can be cultured in a large scale, can generate fermentation liquor through fermenting, and can be used for governing water bloom and restoring water eutrophication.

Owner:无锡亚克生物科技有限公司

Bacillus subtilis BC-198, and selenium-rich microbial inoculum and application thereof

ActiveCN102888376APromote absorptionEfficient use ofBiocidePlant growth regulatorsAzotobacter chroococcumAgricultural science

The invention relates to Bacillus subtilis BC-198, and a selenium-rich microbial inoculum and application thereof. The collection number of the Bacillus subtilis BC-198 is CCTCC No.M2012321. The invention also provides a composite microbial inoculum of which the effective ingredients are the Bacillus subtilis BC-198 and Azotobacter chroococcum AS1.212. The preparation method of the selenium-rich microbial inoculum provided by the invention can utilize the existing universal fermentation plant, is simple to operate and has the advantage of low manufacturing cost; the prepared product has multiple functions of nitrogen fixation, growth promotion, fungus disease control and the like for crops; and after being applied to the crops, the selenium-rich microbial inoculum can increase the yield, improve the quality of the agricultural product, and enhance the selenium content in the agricultural product by more than 20 times, so that the agricultural product reaches the selenium-rich product quality standard.

Owner:HUBEI HENO BIOLOGICAL ENG CO LTD +2

Fresh-keeping method for prolonging preservation duration of strawberries

InactiveCN103431027AConvenient sourceBreed fastFruit and vegetables preservationBiotechnologyFragaria

The invention belongs to the field of food preservation, and particularly relates to a fresh-keeping method for prolonging preservation duration of strawberries. The method comprises the following steps: selecting materials, preparing strawberry extracts, preparing a mixed chitosan solution, preparing fresh-keeping liquid, and soaking and air drying strawberries. The main components of the fresh-keeping liquid are supernate extracted from the strawberries and chitosan, raw materials of the supernate and the chitosan can be obtained conveniently, and particularly the supernate of the strawberries can be directly extracted from the bought strawberries, and is not required to be separately bought. According to the method, bacillus subtilis is added into the fresh-keeping liquid, so that growth and reproduction of mycete and botrytis cinerea can be effectively inhibited. Active substances, such as subtilin and gramicidin are produced during the growth of bacillus subtilis cells, and have obvious inhibition effects on the mycete and botrytis cinerea; in addition, the bacillus subtilis quickly consumes oxygen in the environment, and produces organic acids, such as lactic acid, so that the PH value of the environment is reduced, the growth of the mycete and botrytis cinerea is indirectly inhibited, and the storage duration is greatly prolonged.

Owner:HENAN UNIV OF SCI & TECH

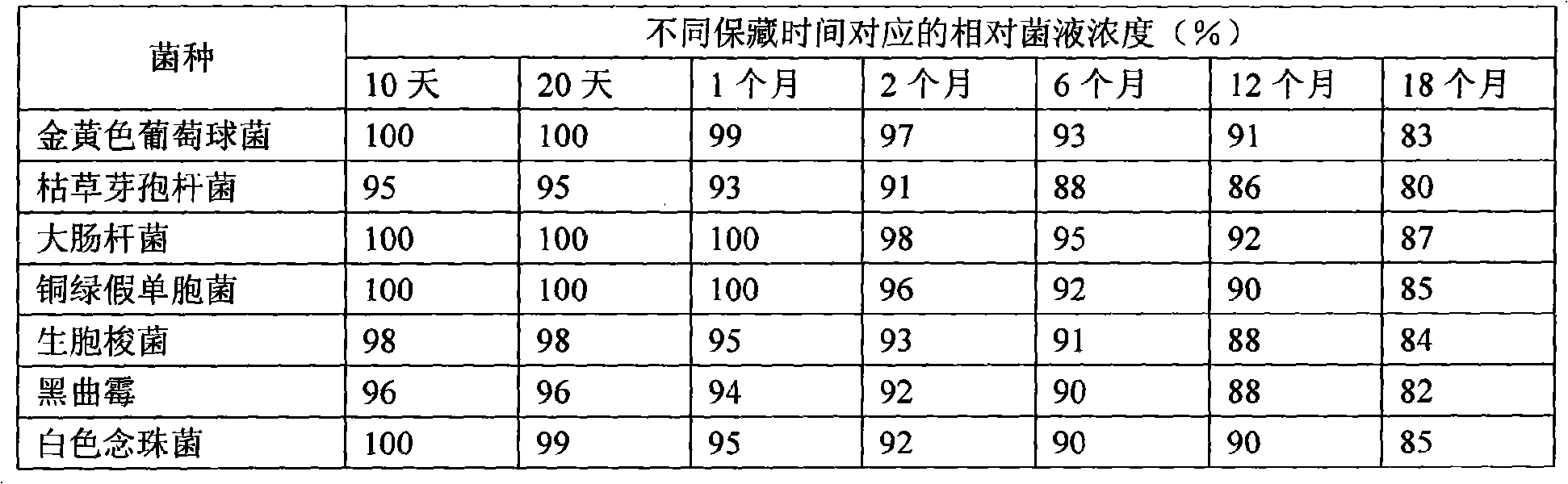

Culture collection process

InactiveCN101307293ALong storage timeStable concentrationMicroorganism based processesMicroorganism preservationRefrigerated temperatureAspergillus niger

The invention provides a spawn preservation method adopting semisolid low-temperature air-tight culture. A spawn is inoculated in an aseptic semisolid culture medium which is vertically stored at an ambient temperature of between 6 and 8 DEG C after aseptic liquid paraffin is added into the culture medium. The spawn is staphylococcus aureus, escherichia coli, pseudomonas aeruginosa, bacillus subtilis, clostridium orogenes, aspergillus niger or candida albicans. The specific process is as follows: preparing the semisolid culture medium, carrying out sub-package and sterilization, and then culturing for 2 to 3 days, inoculating the spawn into the semisolid culture medium in a mode of stab inoculation after asepsis is ensured, with the number of stab inoculation points parallel with the plane of the culture medium being no less than 3; pouring the aseptic liquid paraffin with a height of 1 to 2 cm into the culture medium which is sealed by a sealing film and is stored in a refrigerator at a temperature of between 6 and 8 DEG C. The method can not only prolong the spawn preservation time but also keep a relatively stable spawn concentration, thereby saving much cost for production and test, reducing the treatment and discharge of rejected material after spawn use, and reducing environmental hazard.

Owner:药大制药有限公司

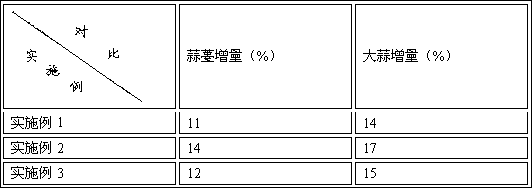

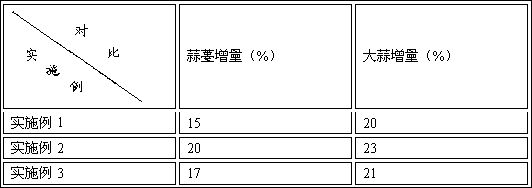

Special composite microbial fertilizer for garlic and preparation method thereof

InactiveCN103274841AReduce dosageEasy to fixBio-organic fraction processingOrganic fertiliser preparationBiotechnologyAllium sativum

The invention discloses a special composite microbial fertilizer for garlic and a preparation method thereof. The special composite microbial fertilizer for garlic comprises components in percentage by weight as follows: 8%-12% of potassium chloride, 0.2%-1.0% of manganese sulfate, 1%-3% of zinc sulfate, 20%-25% of grass carbon, 5%-15% of chicken manure, 4%-6% of wastes in a chicken slaughter house, 16%-18% of stalk ends, 10%-12% of aginomoto slag, 18%-20% of bean pulp powder, 0.3%-0.5% of bacillus amyloliquefaciens, 0.2%-0.4% of bacillus subtilis, 0.4%-0.6% of bacillus mucilaginosus, 0.8%-1% of bacillus stearothermophilus, 0.2%-0.4% of bacillus laevolacticus, 0.9%-1.1% of aspergillus oryzae, 0.5%-0.7% of hemicellulose and 1.2%-1.4% of a straw leavening agent, and the sum of all components is 100%. According to the special composite microbial fertilizer for garlic and the preparation method thereof, production increase range of young garlic shoots and garlic is larger, and the quality is improved remarkably.

Owner:SUZHOU RENCHENG BIO SCI & TECH

Bacillus cereus for activating soil nutrient and application of bacillus cereus

ActiveCN103173380AImprove micro-ecological environmentConducive to sustainable useAgriculture tools and machinesBacteriaNucleotideBacillus cereus

The invention discloses a bacillus cereus for activating soil nutrient and application of the bacillus cereus. The bacillus cereus is preserved in the China General Microbiological Culture Collection Center (CGMCC) on May 21, 2012 with preservation number of CGMCC No. 6127, and the 16SrDNA nucleotide sequence is shown by SEQ ID No: 1. According to the bacillus cereus, the soil nutrient can be obviously activated, the effectiveness of phosphorus and nitrogen in soil can be improved, the composition of a soil microbial community can be improved, the diversity and the evenness of the soil microbial community can be improved, the metabolic activity of the soil microbe can be improved and the like, the soil fertility can be improved, the crop growth can be promoted, the bacillus cereus is good for the agricultural sustainable development and utilization, and the bacillus cereus is wide in application prospect in the production practice.

Owner:广东润华环保产业有限公司

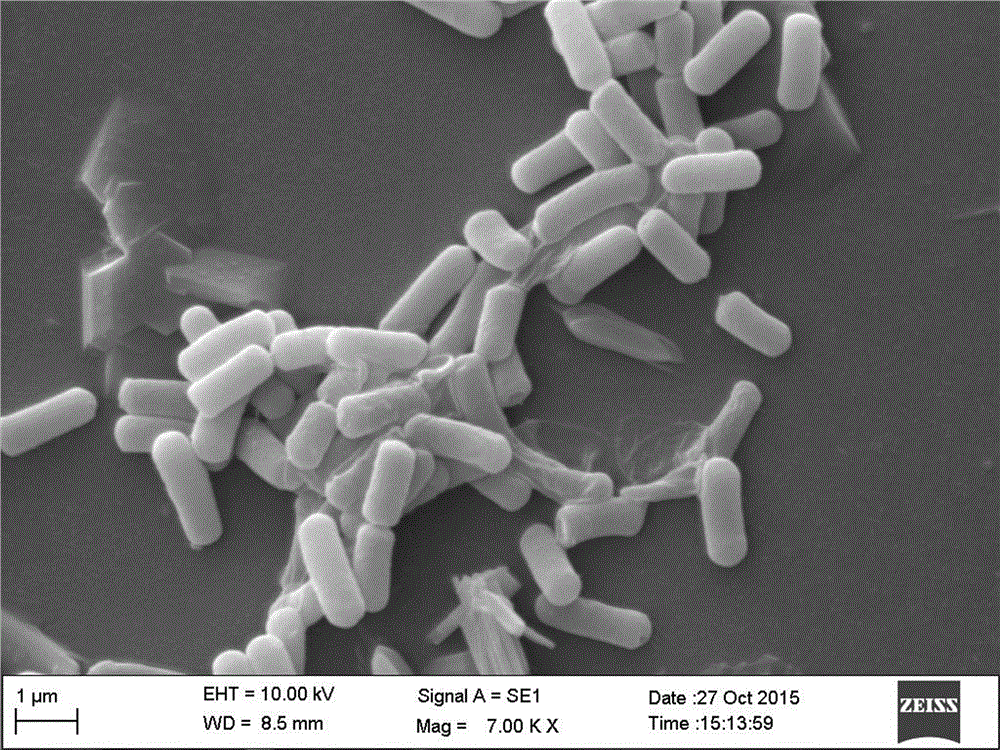

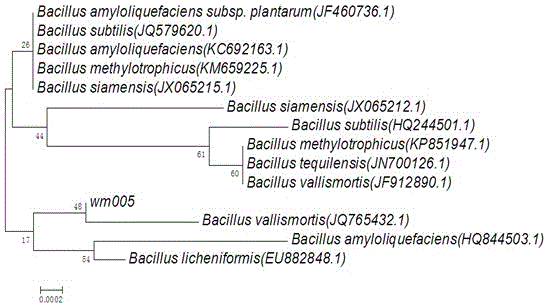

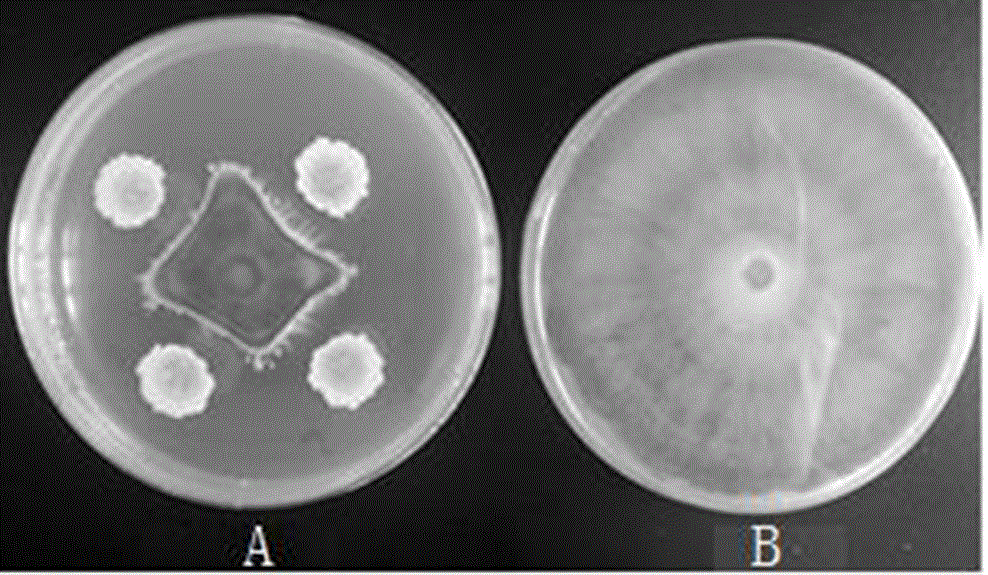

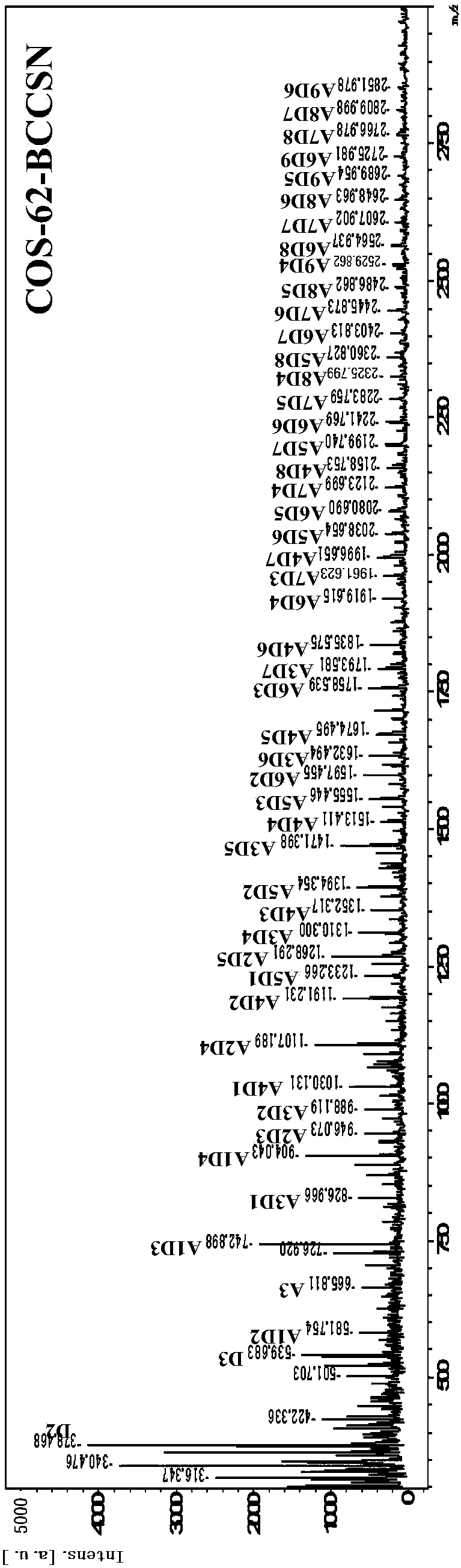

Bacillus vallismortis and application thereof

ActiveCN105802882AStrong antagonistic effectStable colonizationBiocideBacteriaIrrigationFusarium wilt

The invention provides bacillus vallismortis WM005 with the preservation number being CCTCC NO: M2016020. The bacillus vallismortis can be stably planted in watermelon plants, thereby effectively preventing the occurrence of the fusarium wilt of watermelons. During use, a bacillus vallismortis liquid with the bacillus vallismortis content being 1, 010 cfu / mL can be prepared from the bacillus vallismortis for root irrigation of watermelon seedlings in fields, so that the purpose of preventing the fusarium wilt of the watermelons is achieved. The bacillus vallismortis agent is high in control effect, convenient to use and suitable for being applied and popularized in a large scale.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Bacillus circulans chitoanase as well as preparation method and application thereof

ActiveCN107586768AEnsure safetyImprove efficiencyMicroorganism based processesEnzymesPichia pastorisNeutral proteinase

The invention discloses bacillus circulans chitoanase as well as a preparation method and application thereof. According to the preference of pichia pastoris codons, a chitoanase coding gene sequencein bacillus circulans is obtained by utilizing a whole gene synthesis method; an optimized nucleic acid sequence is shown as SEQ ID NO. 2. Furthermore, efficient secreting expression is carried out onan optimized chitoanase coding gene by utilizing a pichia pastoris expression system to obtain the bacillus circulans chitoanase; an amino acid sequence of the bacillus circulans chitoanase is shownas SEQ ID NO. 1. The chitoanase disclosed by the invention has relatively high hydrolysis activity on a chitosan substrate and a crude enzyme solution produced by shake-flask fermentation has a hydrolysis capability of degrading 5g of chitosan by utilizing 1mL of the crude enzyme solution (with the protein content of about 0.77mg); when the chitosan with the same amount is degraded, about 150mg ofneutral proteinase obtained from bacillus subtilis is needed; the efficiency is theoretically improved by about 200 times; the bacillus circulans chitoanase has a very good industrial application prospect.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

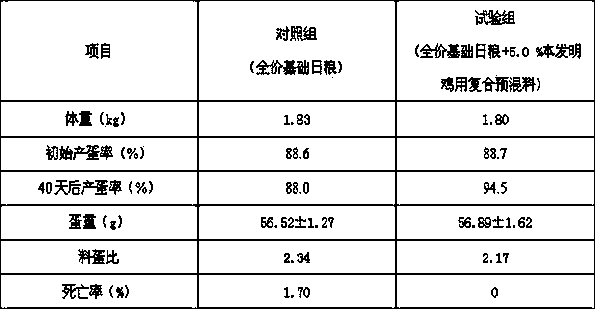

Compound premix for chicken

ActiveCN103892054AIncrease egg productionReduce the risk of infectionAnimal feeding stuffAccessory food factorsBiotechnologyVitamin C

The invention belongs to the technical field of poultry cultivation and particularly relates to a compound premix for chicken. The compound premix for the chicken is composed of following components in parts by weight: 0.1-0.3 part of a zanthoxylum bungeanum maxim extract, 5-8 parts of acanthopanax senticosus, 12-13 parts of ampelopsis grossedentata, 3-5 parts of yeast powder, 10-12 parts of astragalus membranaceus, 15-18 parts of malts, 35-40 parts of bamboo vinegar, 0.02-0.05 part of vitamin C, 0.5-0.8 part of DL-methionine, 0.2-0.4 part of bacillus and 1 part of a vitamin premix in a mixing manner. The compound premix for the chicken has the advantages of natural components, capability of effectively improving the immunity and the disease resistance of the chicken and the like, and the formula is reasonable.

Owner:HUIZHOU XINGTAI MODERN AGRI

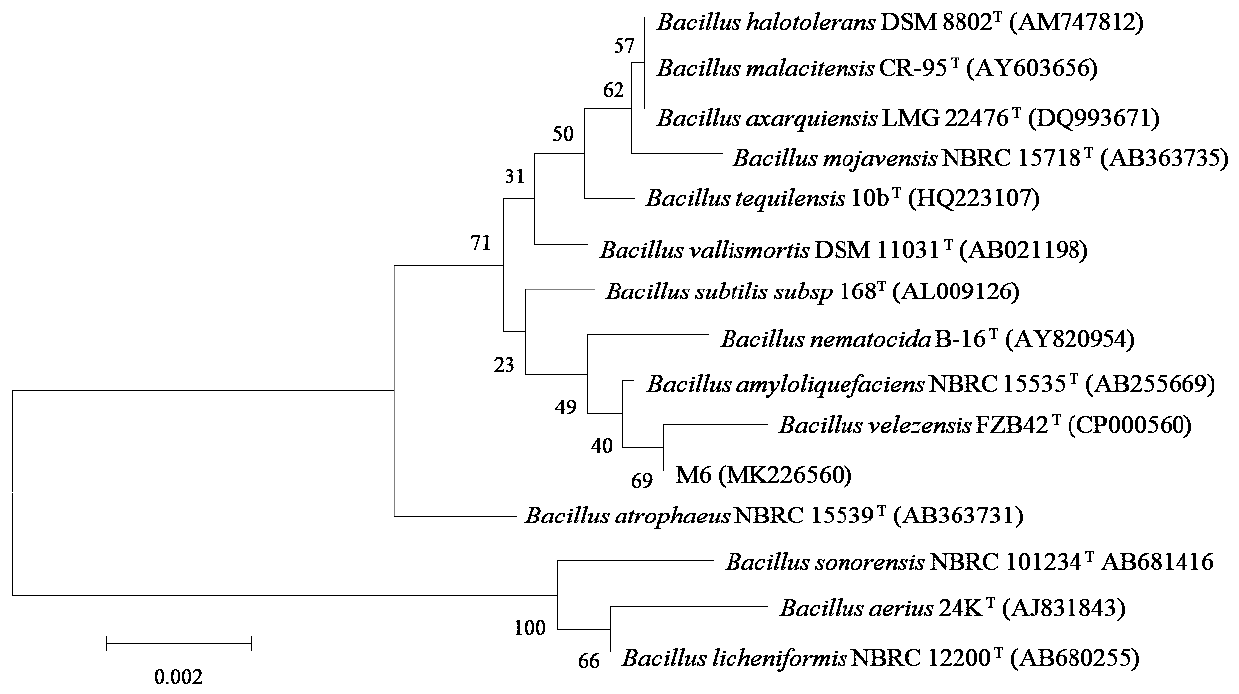

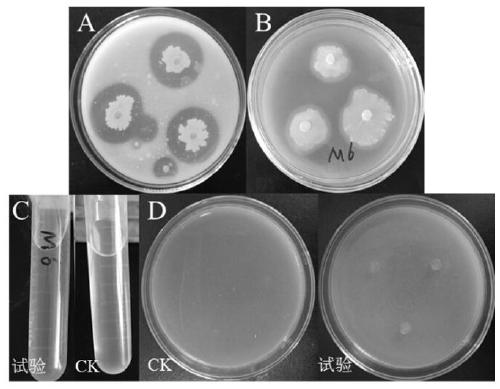

Bacillus velezensis and application thereof in wheat sheath blight control and growth promotion

ActiveCN109554317AEnhanced inhibitory effectEfficient use ofPlant growth regulatorsBiocideGrowth promotingSheath blight

The invention relates to bacillus velezensis and an application thereof in wheat sheath blight control and growth promotion. The strain is bacillus velezensis M6, is preserved in China General Microbiological Culture Collection Center, has the preservation number of CGMCC No.15628 and can produce indoleacetic acid (IAA), siderophore and other growth-promoting substances; at the same time, the strain also has a significant effect of dissolving organic phosphorus; in addition, the strain has a good control effect on wheat sheath blight caused by rhizoctonia solani.

Owner:MICROBIOLOGY INST OF SHAANXI

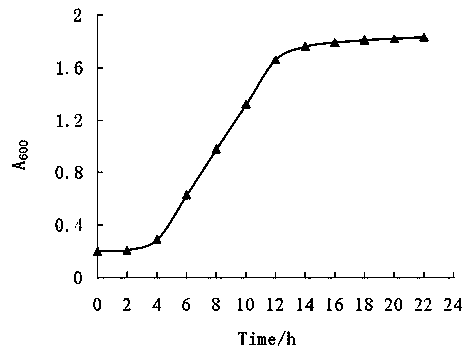

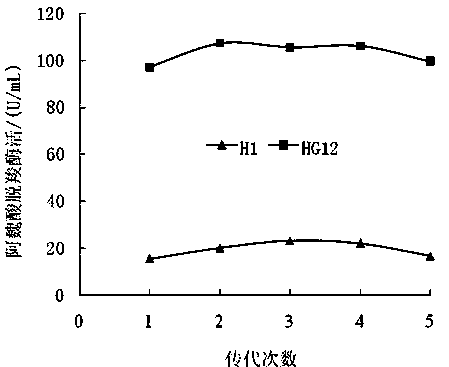

Bacillus circulans and application for same in preparation for ferulic acid decarboxylase

InactiveCN103451133AHigh deacidase activitySimple production processBacteriaMicroorganism based processesYeastUV-Mutagenesis

The invention belongs to the technical field of bioengineering, and particularly discloses bacillus circulans and an application of the same in preparation for ferulic acid decarboxylase. The bacillus circulans is characterized in that a bacillus circulans HG12 strain is obtained by separating from a high-temperature yeast for brewing Maotai-flavour liquor in the white wine plants of China, and screening by virtue of ultraviolet mutation, as well as has the characteristics of being fast in growth and propagation speeds, capable of producing the ferulic acid decarboxylase under the induction of ferulic acid, stable in performance of producing the ferulic acid decarboxylase, and high in enzymatic activity. According to the bacillus circulans and the application disclosed by the invention, continuous and large-scale production for the ferulic acid decarboxylase can be realized, and industrialized production for the ferulic acid decarboxylase is facilitated; moreover, the enzyme is simple and convenient in production process, short in production cycle, and low in cost.

Owner:QILU UNIV OF TECH

Multifunctional probiotic

The invention discloses a multifunctional probiotic, and belongs to the technical field of the preparation of probiotic preparation. The probiotic contains the following components active substances: Lactobacillus casei, Bacillus licheniformis, Bacillus subtilis, Bacillus cereus, Saccharomyces cerevisiae and Pseudomonas stutzeri. The multifunctional probiotic composition provided by the invention can be prepared into a solution for preparation of beneficial bacteria forage, can be used for deodorization of animal dung, prevention and treatment of enteritis and diarrhea of animals, and has wide range of application.

Owner:HEBEI AGRICULTURAL UNIV.

Bacillus subtilis with effect of efficiently dissolving phosphorus and application of bacillus subtilis

InactiveCN103773709AStrong Phosphorus SolubilizationBacteriaMicroorganism based processesBiotechnologyPlant growth

The invention relates to a bacillus subtilis with the effect of efficiently dissolving phosphorus. The bacillus subtilis is preserved in the China General Microbiological Culture Collection Center and has the preservation NO. of CGMCCNo. 8241. The bacillus subtilis has the relatively high effect of dissolving the phosphorus, cannot pollute environment, and is ecological and safe. The efficient bacillus subtilis can be used independently, or used together with other organic and inorganic nutritional ingredients required by plants to be prepared into biological compound fertilizer, and which has the effects of increasing yield and improving quality.

Owner:HEBEI AGRICULTURAL UNIV.

Composting microbial inoculant

The invention discloses a composting microbial inoculant. The composting microbial inoculant is prepared from aspergillus fumigatus, saccharomyces cerevisiae, bacillus subtilis and bacillus cereus. The composting microbial inoculant is prepared by uniformly mixing an inoculant with ingredients, inoculating a mixture into a composting material according to the inoculation proportion of 0.3 to 0.5 percent, uniformly mixing, controlling the fermentation temperature at 55 to 65 DEG C and finishing fermenting in seven days. By inoculating high temperature composting microorganisms in the process ofstraw / livestock and poultry manure composting (aerobic fermentation), the heating of a compost body can be promoted, the degradation and humification of lignocellulose are promoted, and crop straws,manures and the like can be quickly decomposed; straw compost also achieves complete composting, so that the aims of shortening the composting cycle and improving the composting quality are achieved;the composting microbial inoculant is a good innovative scheme and has a good marketing prospect.

Owner:广东高龙环保科技有限公司

Compound fungicide and continuous fermentation method of compound microorganisms adopted

ActiveCN104371960ASave cost of oxygen removalReduced Pollution ChancesBacteriaMicroorganism based processesBiotechnologyBacillus licheniformis

The invention discloses a continuous fermentation method of compound microorganisms. The continuous fermentation method comprises the following steps: 1) respectively preparing a bacillus subtilis liquid, a bacillus licheniformis liquid and a clostridium butyricum liquid; 2) adding a basic fermentation liquid into a fermentation tank; 3) controlling the temperature of the basic fermentation liquid at 36-38 DEG C, controlling the pressure of the tank at 0.01MPa, firstly, inputting the bacillus subtilis liquid to cultivate, then, inputting the bacillus licheniformis liquid for continuous fermentation and cultivation and finally inputting the clostridium butyricum liquid to stand for anaerobic fermentation and cultivation; and 4) centrifugally concentrating the obtained fermentation liquid which is filtered in the step 3) to 28-32% of the original liquid in volume; and then spraying and drying to obtain a compound probiotic preparation. The method disclosed by the invention can be used for overcoming the defects that the number of sterilization and feeding in a single fermentation process of microorganisms are great, the fermentation procedure is simplified and meanwhile, the viable count is increased and the number of contaminating microorganisms is decreased by virtue of neutralizing synergistic effects of different microorganisms by continuous fermentation, so that the effect of microorganisms is improved.

Owner:ZHEJIANG HUIJIA BIOTECH +1

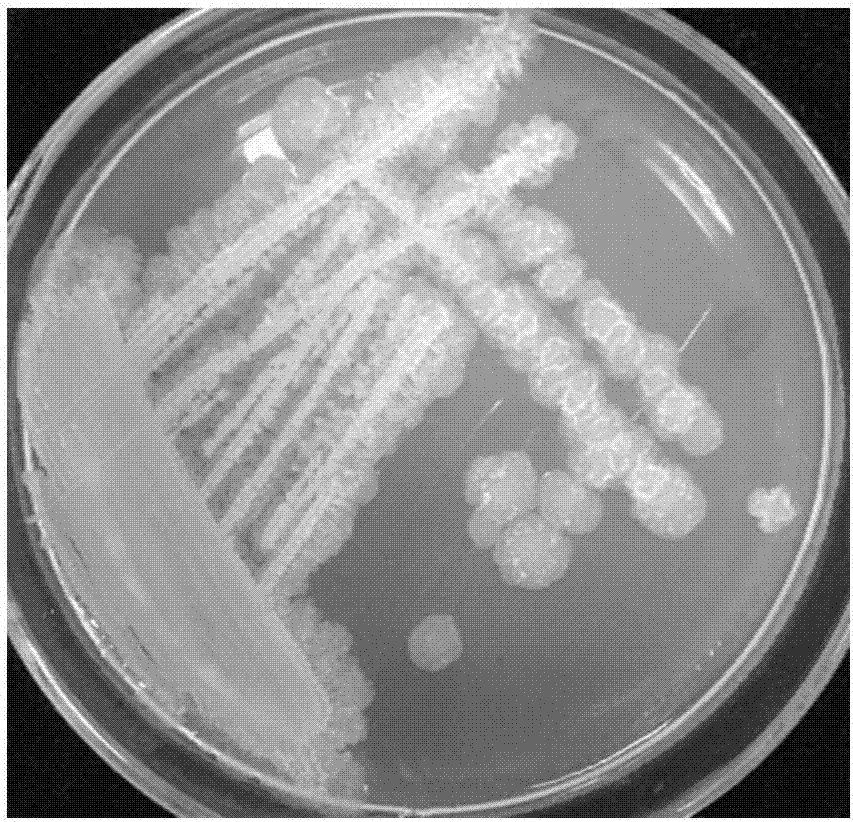

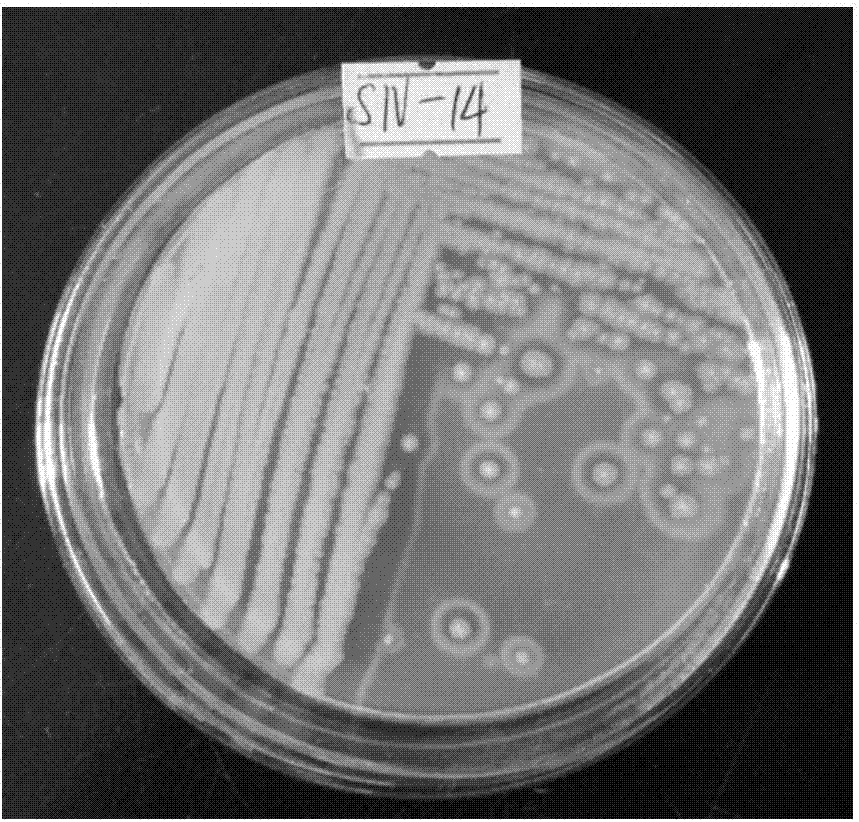

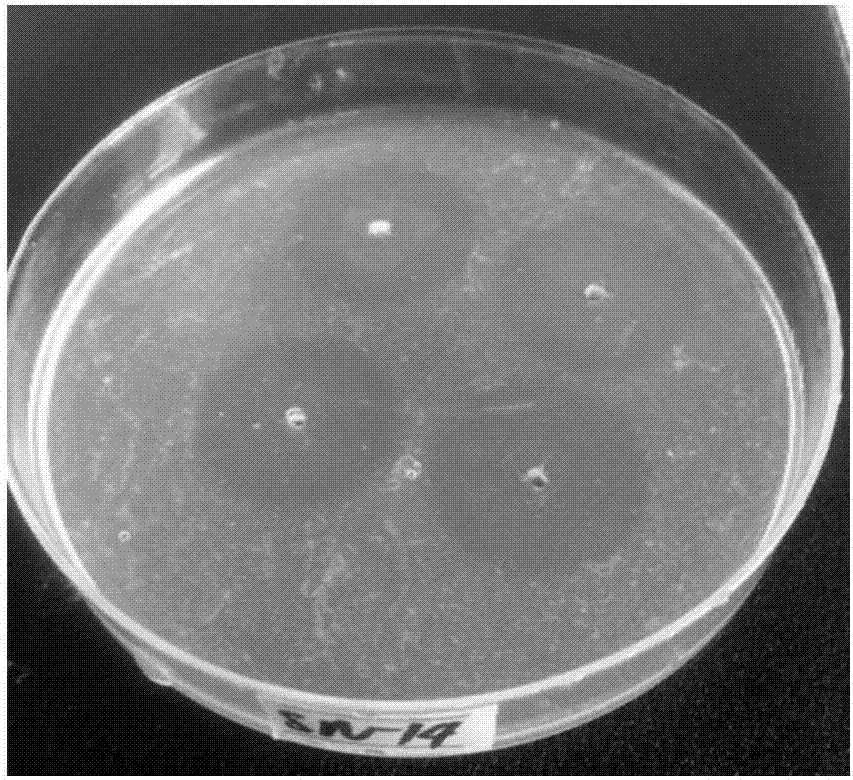

Nattokinase-producing bacillus velezensis strain and application thereof

ActiveCN107129944AImprove securityGreat tasteBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention discloses a nattokinase-producing bacillus velezensis strain which is characterized in that the strain is bacillus velezensis SN-14. Compared with the prior art, the strain disclosed by the invention has the advantages that (1) the bacillus velezensis SN-14 in the invention comes from local fermented soya beans in Guizhou, and the safety of the strain is high; (2) natto products obtained from the bacillus velezensis SN-14 in the invention have excellent taste; and (3) the bacillus velezensis SN-14 disclosed by the invention has high nattokinase-producing activity and is a primary condition for researching and developing nattokinase products. Therefore, the bacillus subtilis has excellent application prospects for improving the food taste, improving the fermentation activity and enriching effects of natto health care products.

Owner:GUIZHOU UNIV

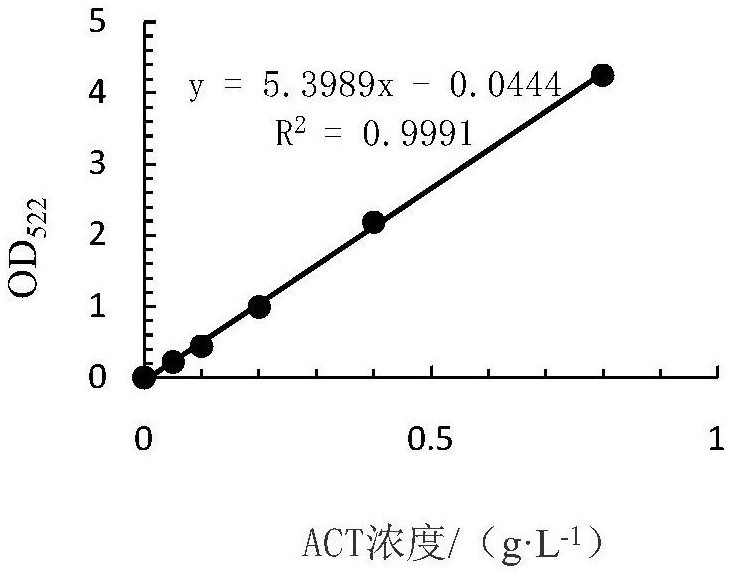

Acid-resistant bacillus velezensis DQA21 for producing acetoin and application

ActiveCN112251379AAcid resistantConducive to metabolic engineeringBacteriaMicroorganism based processesBiotechnologyConcentrations glucose

The invention discloses acid-resistant bacillus velezensis DQA21 for producing acetoin and application. The acid-resistant bacillus velezensis DQA21 was preserved in the China Center for Type CultureCollection (CCTCC) with the preservation number being CCTCC NO:M 2020360 on July 27, 2020. The fermentation conditions of the strain are optimized, and the optimal fermentation conditions are as follows: the glucose concentration is 80 g / L, the pH is 5.46, the temperature is 37.31 DEG C, the liquid loading amount is 49.17 mL, the inoculation amount is 5%, and the rotating speed is 210 r / min. Underthe conditions, the average yield of the acetoin fermented by a strain shake flask is 25.60 g / L, and is improved by 39.36% compared with the yield of 18.37 g / L of the strain before optimization. Thestrain has the advantages of high acetoin yield, high fermentation speed and the like, can be used for producing baijiu, and can be used for increasing the content of the acetoin in the baijiu, improving the mouthfeel and flavor and enhancing the quality of the baijiu.

Owner:WULIANGYE +1

Bacillus siamensis and application thereof in acetoin-rich table vinegar

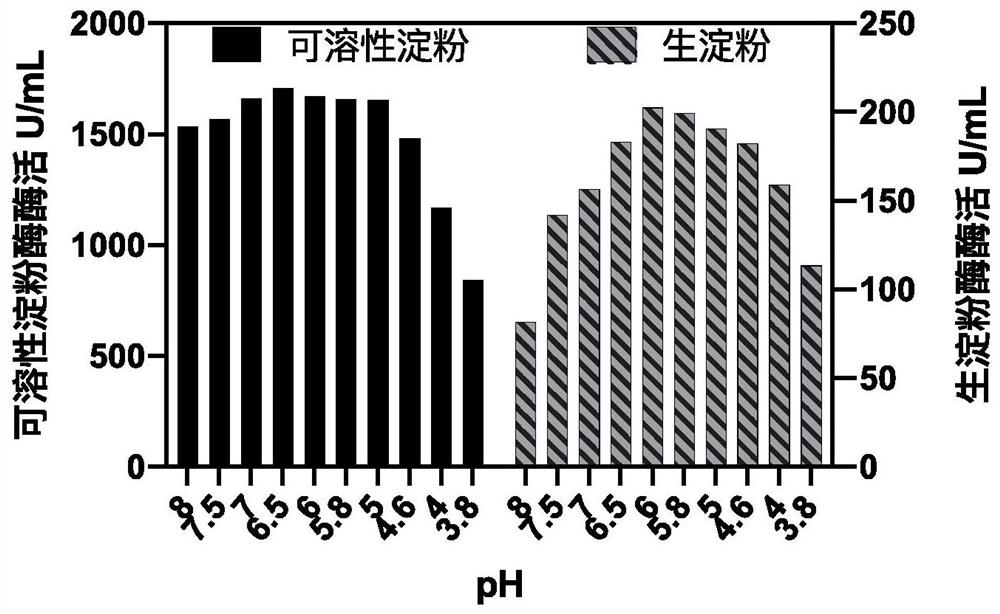

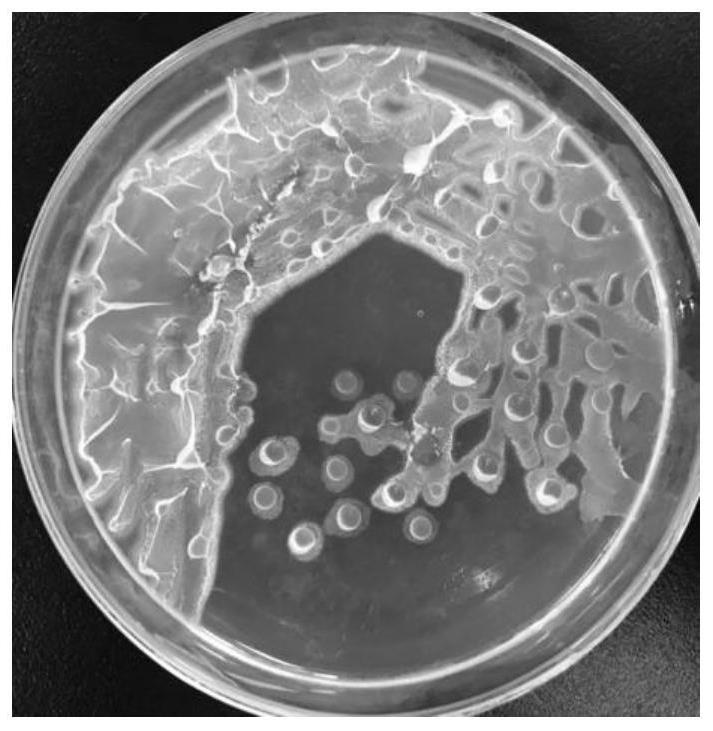

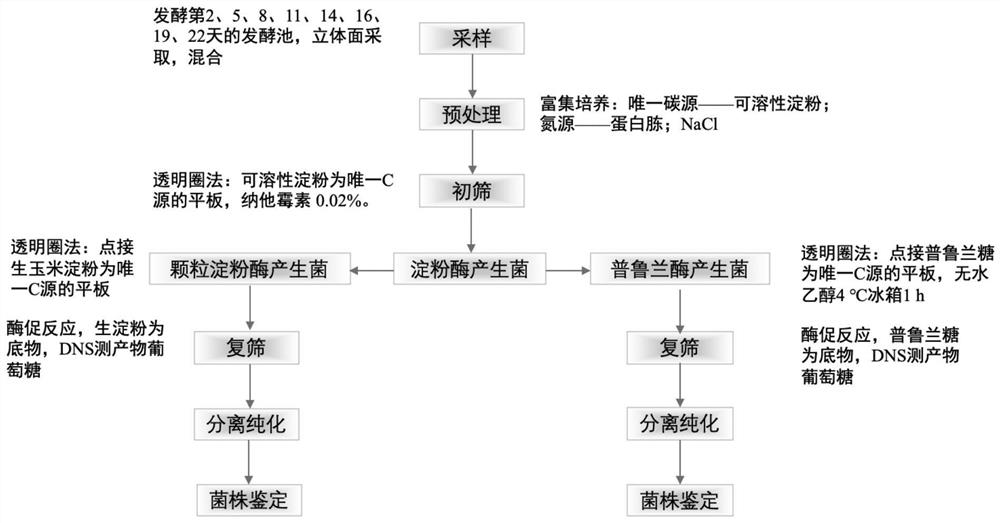

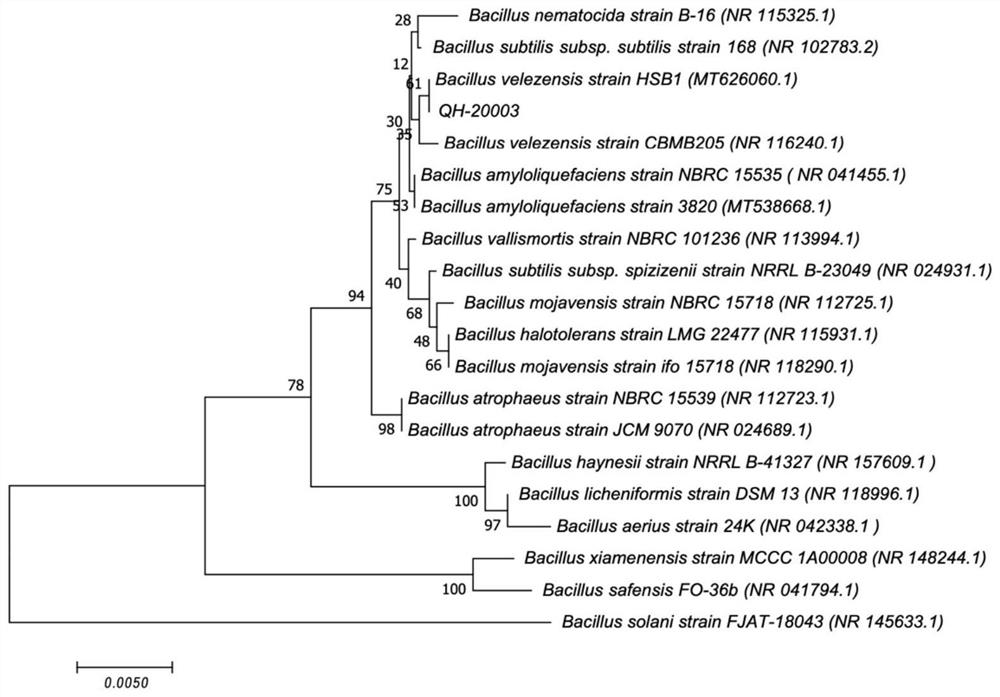

ActiveCN112795519AIncrease profitIncreased acetoin contentBacteriaMicroorganism based processesBiotechnologyAmylase

The invention discloses bacillus siamensis and application thereof in acetoin-rich table vinegar, bacillus siamensis QH-20009 can grow and metabolize under an acidic condition and produce amylase, granular amylase, pullulanase and protease at the same time, is applied to the field of food, and can remarkably improve the starch utilization rate and the nonvolatile acid content of a table vinegar brewing raw material, so that the yield of the vinegar is increased, and the production cost is reduced. The problem that the raw material utilization rate is not high in the vinegar brewing process can be solved, full utilization of grains is guaranteed, the amino acid content in the vinegar is increased, carbohydrates can be metabolized to produce acetoin, the acetoin content in the brewed vinegar can be increased, the flavor of the brewed vinegar can be improved, and the vinegar product quality can be improved.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Bacillus velezensis and application thereof in vinegar brewing

The invention discloses bacillus velezensis and application thereof in vinegar brewing. The strain is bacillus velezensis QH-20003, which has been deposited in the China General Microbiological Culture Collection Center at Institute of Microbiology, Chinese Academy of Sciences, No. 3, Beichen West Road, Chaoyang District, Beijing, on January 13, 2021 with a deposit number of CGMCC No.21613. The bacillus velezensis is applied to cellar vinegar brewing, can grow, metabolize and produce enzymes under an acidic condition, has a capability of producing high-activity acid-resistant granular amylase, pullulanase and protease, can improve utilization rate of raw materials, provides a new enzyme source and a beneficial microbial fermentation strain for the vinegar brewing industry, thereby improving quality of a vinegar product and improving flavor of the vinegar.

Owner:QIANHE CONDIMENT & FOOD CO LTD

Preparation method and application of Bacillus subtilis A16

InactiveCN103289914ALow costSimple manufacturing processBacteriaMicroorganism based processesWeight gainingAnimal science

The invention provides a preparation method of Bacillus subtilis A16, and application of the Bacillus subtilis A16 and its metabolic products in livestock, poultry and aquaculture. The Bacillus subtilis A16 is mainly used as a feed additive for livestock, poultry and aquaculture, such as the feed additive of chickens, ducks, pigs, cattle, sheep, fish and the like. The Bacillus subtilis A16 can significantly improve the feed intake of piglets, promote the efficiency of feed utilization, and increase the growth speed and daily weight gain of piglets so as to substantially improve the production performance of pigs. The Bacillus subtilis A16 also can replace part of antibiotics, and has good application prospects.

Owner:GUANGZHOU GLAM BIOTECH

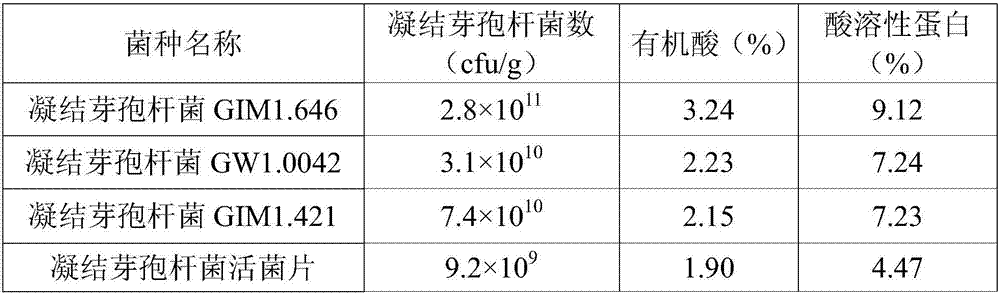

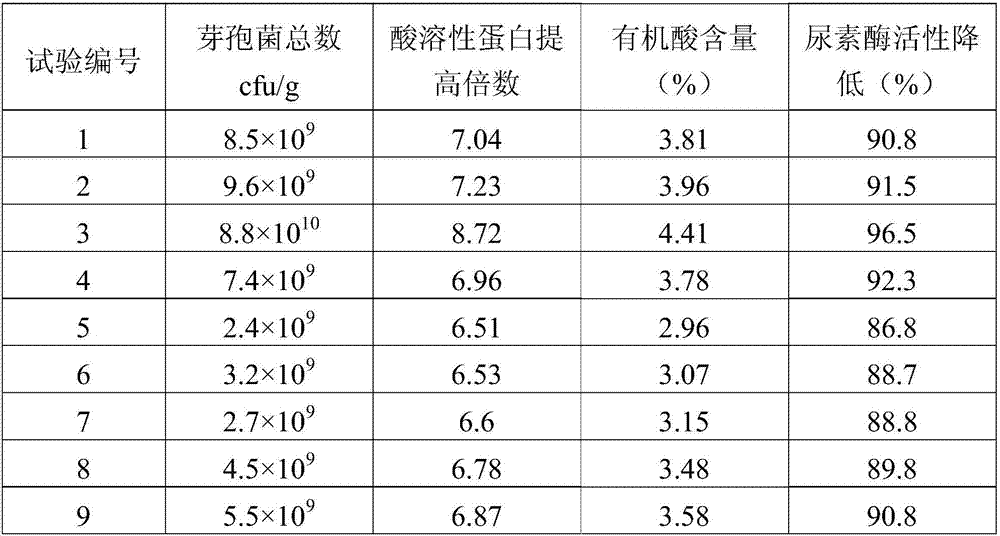

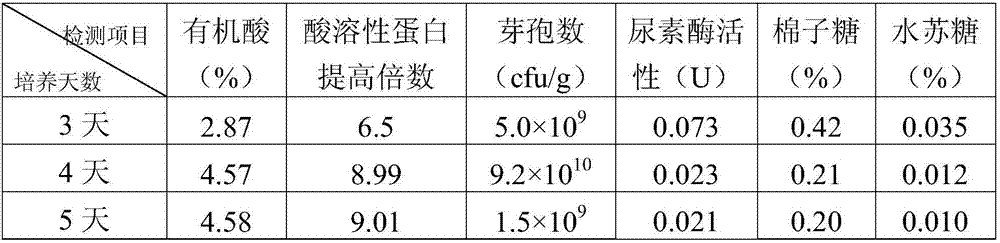

Method for producing efficient protein feed by feed enzymes cooperated with bacillus coagulans

ActiveCN106974063ARegulates Gut HealthAdjustable healthFood processingAnimal feeding stuffBiotechnologyAcid dissolution

The invention discloses a method for producing efficient protein feed by feed enzymes cooperated with bacillus coagulans, and belongs to the field of biotechnology fermentation. The bacterium enzymes are used for treating bean meal in a cooperated way; the sterilization treatment on the bean meal is not needed; the facultative anaerobic and anaerobic fermentation are performed in the whole process; the energy consumption is low; the dry substance loss is low. The technical flow process operation is simple and convenient; the method is suitable for direct production and feeding in a culture plant and is also suitable for scaled production in a feed plant; in addition, the raw material cost is low; the method is suitable for industrial production. The fermented bean meal has high acid fragrance; the palatability is high; the pH is 3.2 to 4.5; the organic acid content is 2.8% or above; the acid dissolution protein is improved by 6.5 times or above through being compared with that before the fermentation; the soluble protein with the relative molecular weight within 500 is 60% or above; the urease activity is lower than 0.073U / g; the cotton seed sugar content is lower than 0.42 percent; the stachyose is lower than 0.035 percent; the spore number of the bacillus coagulans is 2.0*10<9>cfu / g or above.

Owner:南宁精成生物科技有限公司

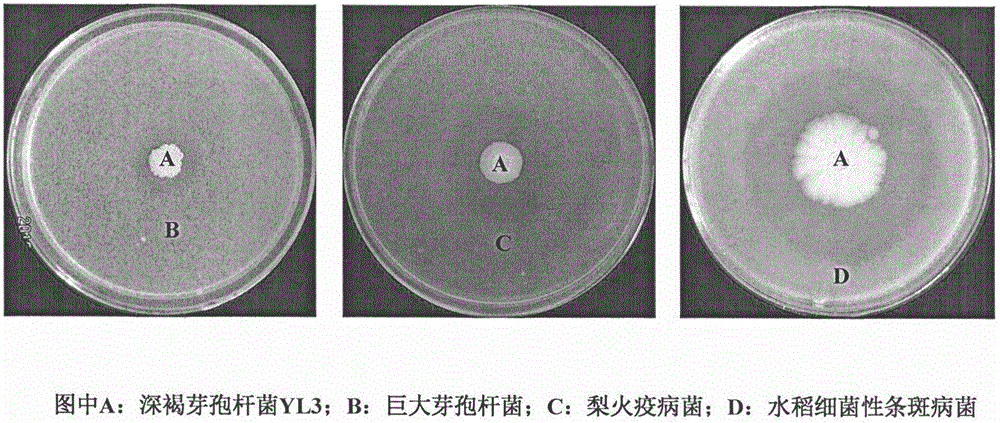

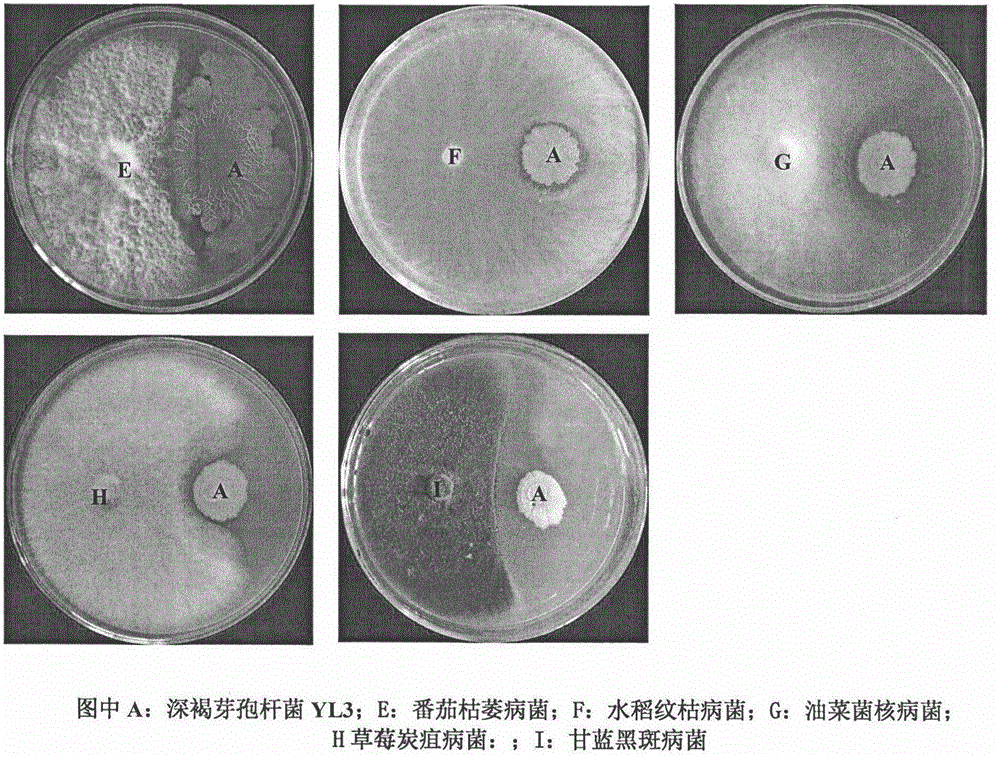

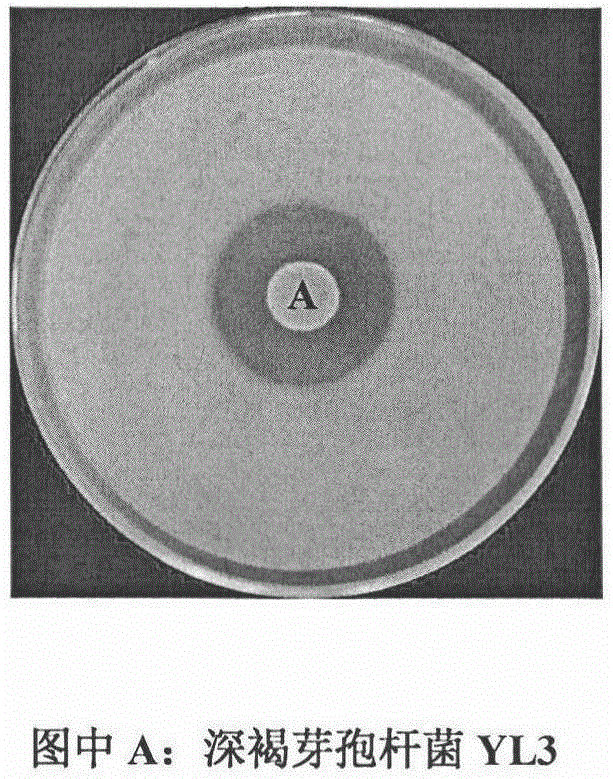

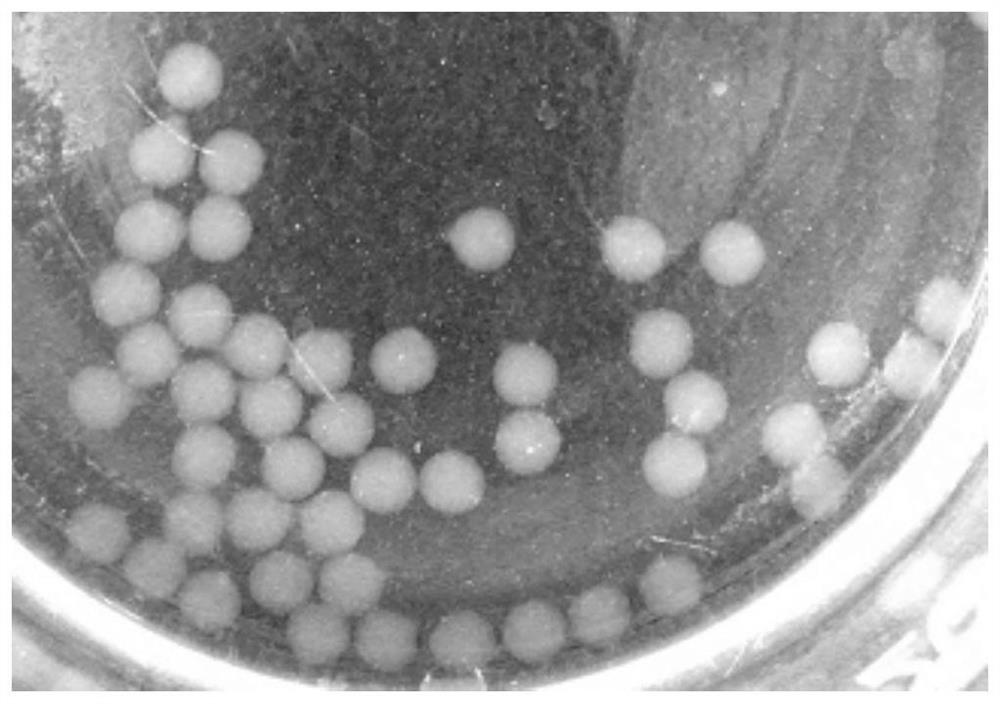

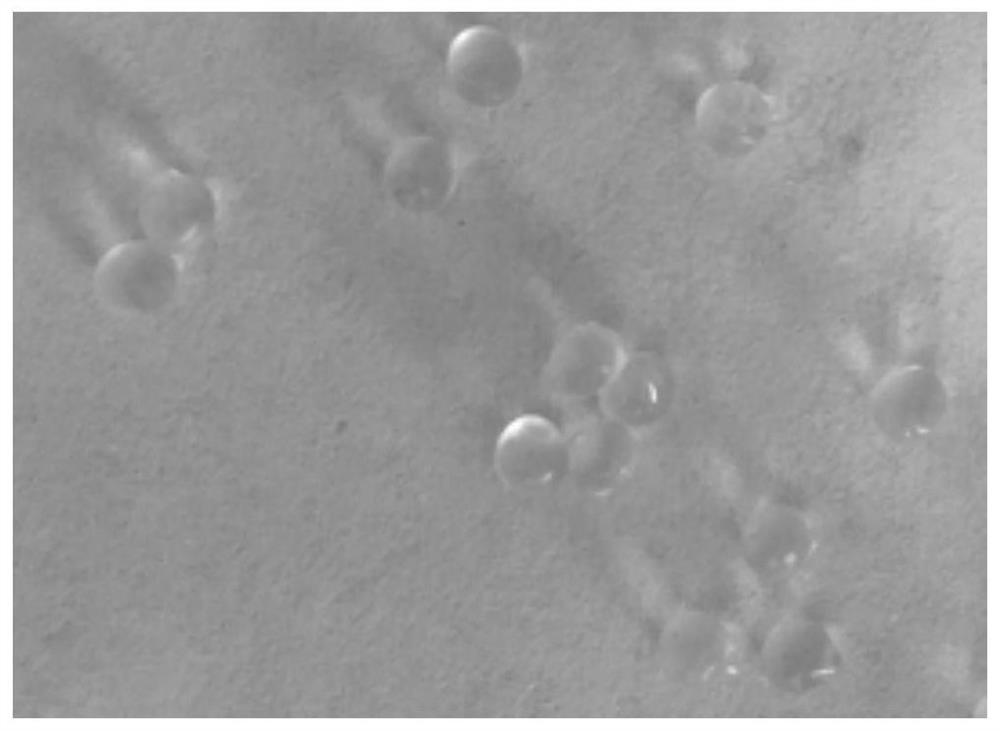

Bacillus atrophaeus YL3 and application thereof

ActiveCN105410031AReduce usageResidue reductionBiocideMicroorganism based processesSheath blightPlant disease

The invention relates to antibiological inoculant. The effective active component of the antibiological inoculant is bacillus atrophaeus YL3. The antibiological inoculant is characterized in that the antibiological inoculant is an aqueous solution and is prepared from, by weight, 89.5-99.8% of bacillus atrophaeus YL3, 0.1-10% of sodium dodecyl sulfate and 0.1-0.5% of potassium sorbate. During application, the aqueous solution is used for preventing and treating strawberry anthracnose and strawberry powdery mildew when sprayed on leaf surfaces and used for preventing and treating various types of crop wilt and the like when irrigated to roots. The antibiological inoculant has the advantages that by introducing bacillus atrophaeus YL3 which is safe to humans and livestock and has a good effect on preventing and treating diseases of strawberries and various plants, and the antibiological inoculant can prevent and treat plant diseases through biological agents; the dosage of chemical agents is reduced; meanwhile, the biological environment is improved, and the amount of chemical agents left in agricultural products is decreased.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Bacillus tequilensis, microcapsule microbial agent and preparation method

PendingCN112680379AStrong stress resistancePromoting effect is goodPlant growth regulatorsBiocideBiotechnologyPlant roots

Owner:SHENZHEN BATIAN ECOTYPIC ENG +1

Process for treating desulfurization wastewater of power plant

ActiveCN104528949AEfficient removalPromote degradationWater contaminantsWaste water treatment from gaseous effluentsBacillus cereusPseudomonas fluorescens

The invention belongs to the field of wastewater treatment and specifically disclosesrocess for treating desulfurization wastewater of a power plant. The process comprises the steps of preparing a biological preparation and treating the wastewater, wherein thiobacillus denitrificans, bacillus cereus, baumanii, rhodococcus and pseudomonas fluorescens are used. The process disclosed by the invention is suitable for treating the desulfurization wastewater of the power plant and can be used for effectively removing sulfur-containing compounds and industrial COD.

Owner:YANCHENG LANFENG ENVIRONMENTAL ENG TECH

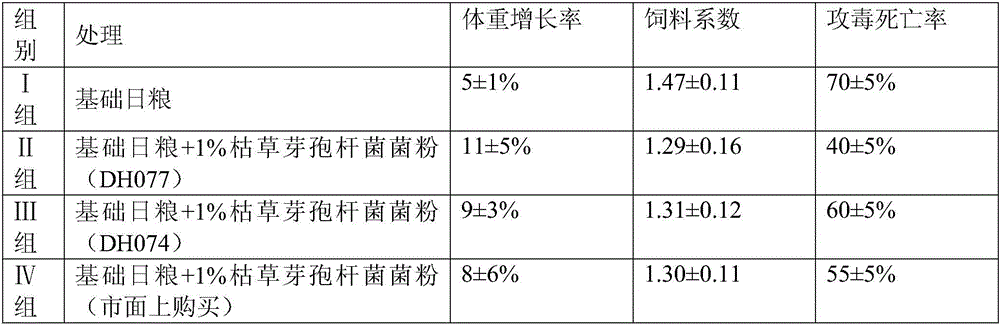

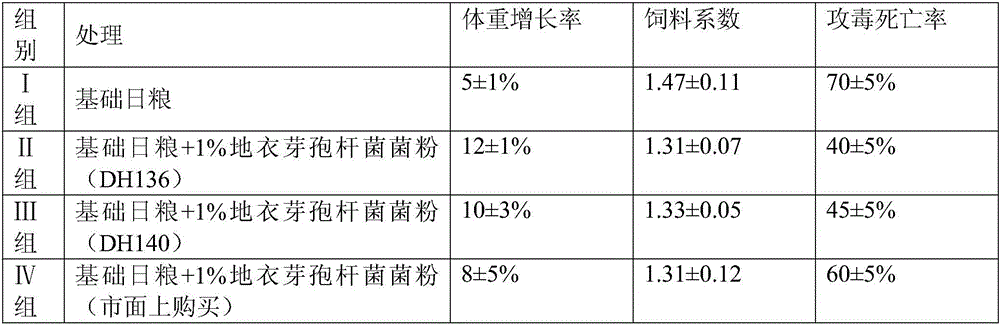

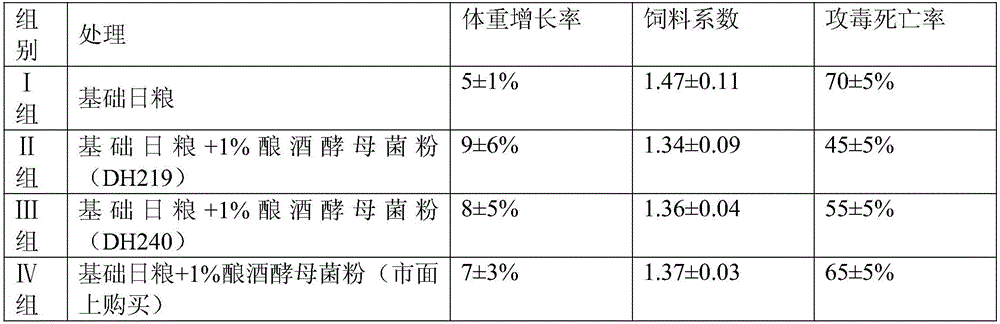

Micro-ecological preparation applied to culture of turbots

ActiveCN106721523AReduce feed factorIncrease growth rateFungiBacteriaBiotechnologyBacillus licheniformis

The invention relates to the field of feed additives, and discloses a micro-ecological preparation applied to culture of turbots. The micro-ecological preparation comprises bacillus subtilis, bacillus licheniformis, saccharomyces cerevisiae or lactobacillus acidophilus. The micro-ecological preparation is applied to increase of the growth rate of turbots, reduction of feed coefficients of turbots, and increase of the culture survival rate of turbots. The complex micro-ecological preparation can be separately used after being prepared into veterinary drugs and feed additives, and can also be directly fed after being mixed with culture feed of turbots, thus being obvious in application effects, and having good economic and social benefits.

Owner:青岛家宝生物科技有限公司 +1

Microbial agent and applications thereof

ActiveCN110622996APromote plant growthImprove qualityPlant growth regulatorsBiocideChemistryHydroxycitric acid

The invention provides a microbial agent and applications thereof, and relates to the technical field of biological agents. The microbial agent comprises citric acid fermentation tail liquid, peptone,yeast powder, bacillus alcaligenes and water; wherein the volume ratio of the citric acid fermentation tail liquid to the bacillus alcaligenes to the water to the peptone to the yeast powder is (15-25)mL: (2-3) mL:(975-985) mL:(8-12) g: (4-6) g; the content of organic matters in the citric acid fermentation tail liquid is 150-250g / L. The microbial agent provided by the invention not only has a remarkable effect of improving saline-alkali soil, but also can promote crop growth, increase crop yield and improve fruit quality.

Owner:JIANGSU GUOXIN UNION ENERGY CO LTD +1

Bacillus velezensis and use thereof in preventing and treating diseases of bergamot pears

ActiveCN112322560AImprove protectionGood treatment effectBiocideBacteriaBiotechnologyDickeya fangzhongdai

The present invention discloses bacillus velezensis and use thereof in preventing and treating diseases of bergamot pears and belongs to the technical field of biological prevention and treatment of plant diseases. A gjfn2 strain which is screened frombacteria of fruit and vegetable enzyme fermentation broth has a remarkable antibacterial effect on valsa mali var. pyri, erwinia amylovora and dickeya fangzhongdai, is identified as bacillus velezensis and preserved in China General Microbiological Culture Collection Center (CGMCC) on November 18, 2020 and has the preservation number of CGMCC No.21203. A bacillus velezensis gjfn2 fermentation broth and active metabolites in the fermentation broth have broad-spectrum resistance to the valsa mali var. pyri, erwinia amylovora and dickeya fangzhongdai, and have outstanding advantages of haivng high selectivity, being not prone to generating drug resistance, safe, efficient, environmentally friendly and the like, and having great potential inthe biological prevention and treatment of diseases of pear trees.

Owner:XINJIANG AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com