Acid-resistant bacillus velezensis DQA21 for producing acetoin and application

A technology of DQA21 and Bacillus, applied in the field of bioengineering, can solve the problems of unmentioned difference, strain ACT yield needs to be further improved, unmentioned strain growth, aroma production, etc., to achieve high ACT yield, fast fermentation speed, increase The effect of flavor substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Isolation and screening of Bacillus velezensis DQA21

[0044] 1) Sample processing

[0045] Weigh 1 g of Daqu, put it into a Erlenmeyer flask filled with 99 mL of sterile water and contain sterile glass beads, oscillate to disperse Daqu evenly, and prepare a sample suspension. The suspension was heated in a water bath at 85°C for 10 minutes to eliminate non-spore-forming bacteria, and then 1 mL of the suspension was added to the enrichment medium for overnight enrichment culture.

[0046] Liquid enrichment medium in g / L: glucose 30g / L, peptone 10g / L, yeast powder 5g / L, sodium chloride 0.5g / L, wine fermented grain extract, pH 6.0, sterilized at 121°C for 20min . Among them, put 10g of fermented grains in a 250mL triangular flask, add 50mL of water, stir well, and soak at room temperature (25°C) for 15min; during the soaking time, stir once every 5min; Make up to 100mL.

[0047] Two) separation and purification

[0048] Use a pipette gun to draw 1mL of the...

Embodiment 2

[0055] Example 2: 16S rDNA identification and physiological and biochemical experiments

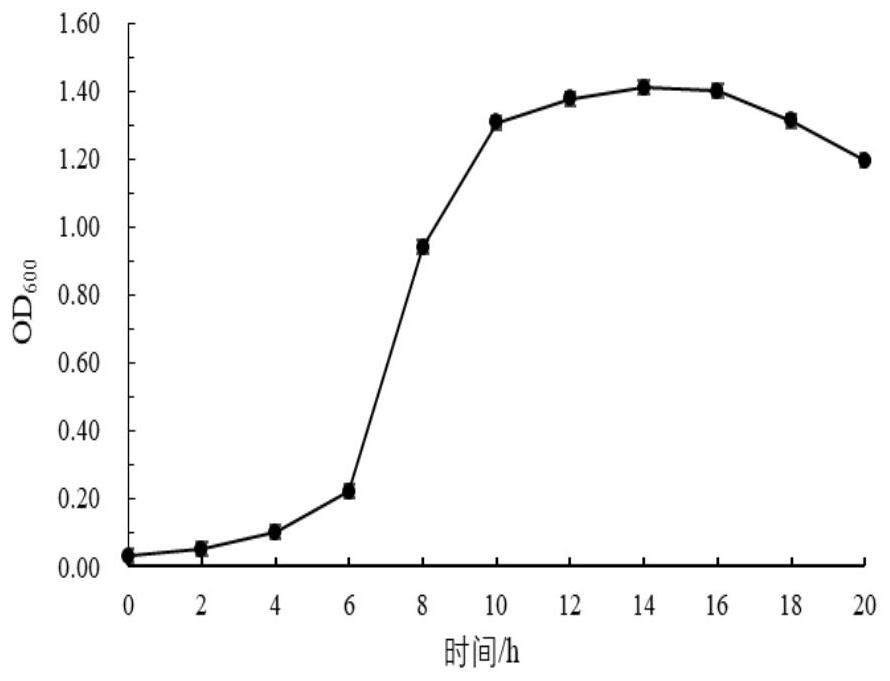

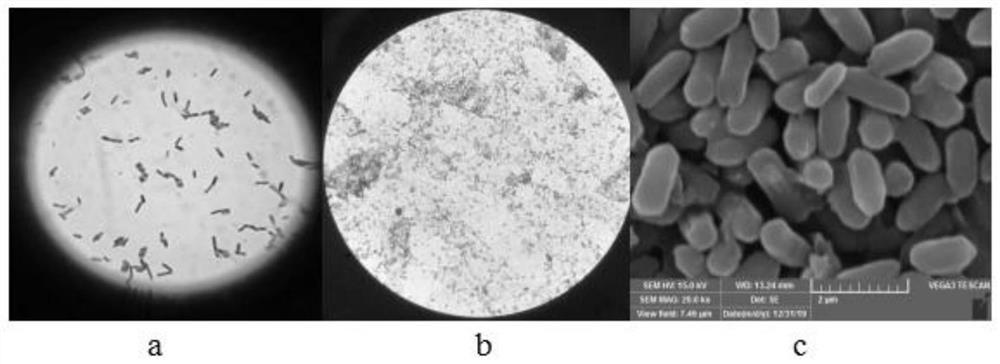

[0056] 1) Identification: First, through physiological and biochemical experiments, it was preliminarily judged to be Gram-positive short bacillus, and then identified by 16SrDNA molecular biology technology to confirm that the strain was Bacillus velezensis and named it Bacillus velezensisDQA21.

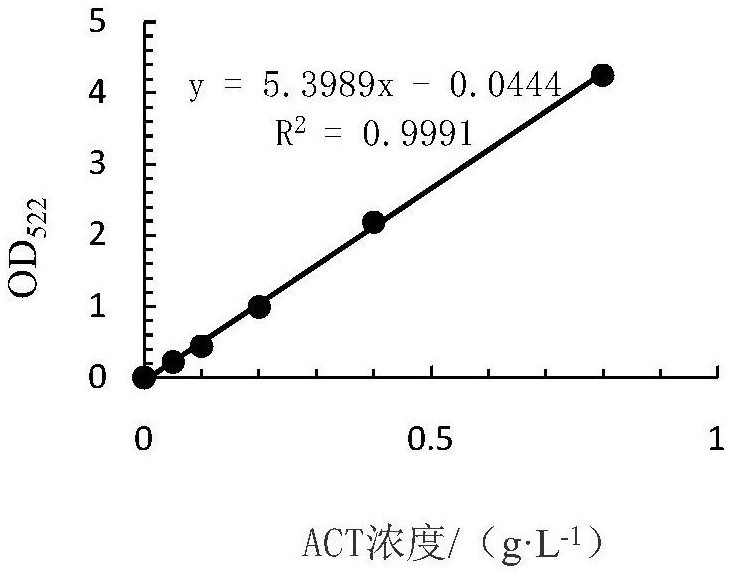

[0057] 2) ACT standard curve drawing

[0058] Concentrations of 0.05, 0.1, 0.2, 0.4, 0.8g / L ACT standard solutions were prepared respectively. Pipette 0.1mL of ACT standard solutions of different concentrations into test tubes, add 4.5mL of creatine mixture, shake and mix well, react in a water bath at 30°C for 30min, and measure the OD value at 522nm. The ACT standard curve was drawn with the ACT concentration as the abscissa and the absorbance value as the ordinate. Such as figure 1 As shown, its regression equation is y=5.3989x-0.0444, and the correlation coefficient R 2 =0.9991, indicat...

Embodiment 3

[0070] Example 3: Optimization of fermentation conditions for high-yield ACT strains

[0071] 1) Single factor test

[0072] The glucose concentrations were selected to be 40, 60, 80, 100, 120g / L, the pHs were 5.0, 5.5, 6.0, 6.5, 7, the temperatures were 31, 34, 37, 40, 43°C, and the inoculum sizes were 3, 5, 7, 9, 11%, the speeds are 120, 150, 180, 210, 240r / min, the filling volume is 30, 40, 50, 60, 70mL / 250mL triangular flask and other 6 factors to do single factor test , 3 parallel experiments for each group.

[0073] Depend on Image 6 a It can be seen that with the increase of glucose concentration in the fermentation medium, the yield of ACT fermented by Bacillus velezensis DQA21 increases significantly. When the glucose concentration reached 80g / L, the ACT output reached 18.372g / L. When the glucose concentration was greater than 100g / L, the ACT production obviously declined, and it can be seen that the higher sugar concentration has an inhibitory effect on the grow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com