Alpha-phenethyl alcohol dehydration catalyst and preparation method thereof

The technology of dehydration catalyst and phenethyl alcohol is applied in the directions of catalysts, carbon compound catalysts, chemical instruments and methods, etc. It can solve the problems affecting the long-term operation of the device, the catalyst is easy to deposit carbon, the catalyst is pulverized, and the like, and the preparation method is simple and feasible. The effect of good activity stability and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

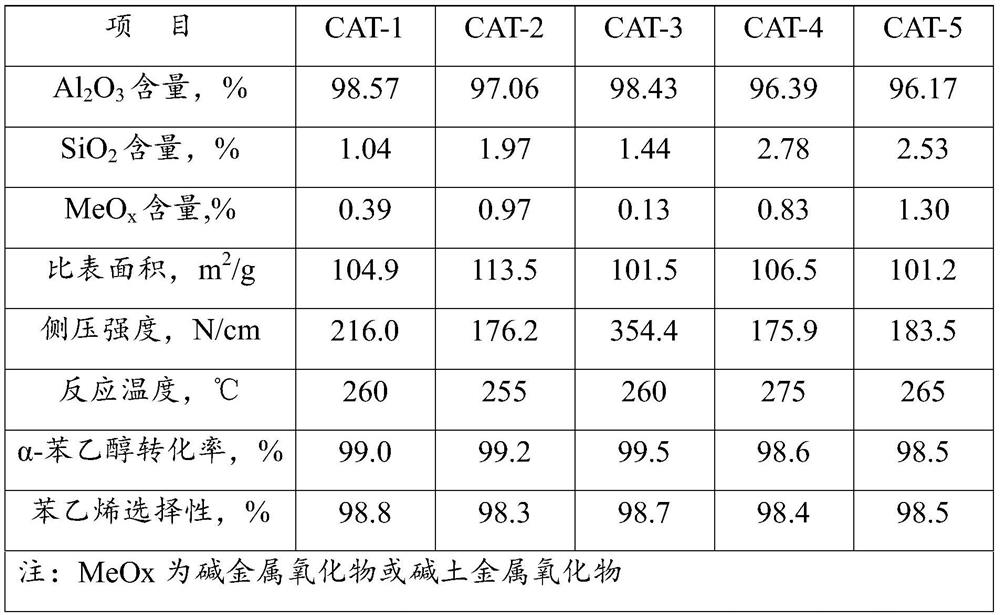

Embodiment 1

[0028] An α-phenylethanol dehydration catalyst is prepared according to the following preparation method: Weigh 123g of pseudo-boehmite by carbonization method, add 0.5g of sodium carbonate, 3g of turnip powder, and 2g of kaolin, mix well, add Al2O3 with a content of 20% 40g of aluminum sol, stirring and kneading evenly; choose a five-leaf clover orifice plate with an outer diameter of 5.0mm, extrude five-leaf clover strips, and then use a shaping machine to shape the particles to keep the particle length between 3 and 8mm.

[0029] After shaping, the particles were hardened at 45°C for 24 hours, then transferred to an oven, dried at 120°C for 4 hours, and then calcined at 950°C for 4 hours in a high-temperature furnace to obtain the catalyst, code number CAT-1.

Embodiment 2

[0031] An α-phenylethanol dehydration catalyst is prepared according to the following preparation method: Weigh 130 g of pseudo-boehmite of aluminum alcohol method, add 1.8 g of sodium bicarbonate, 2 g of scallop powder, and 3 g of white clay, mix evenly, and add a concentration of 3% 35g of aqueous nitric acid solution, stirring and kneading evenly; select a four-leaf clover orifice plate with a diameter of 3.2mm×4.0mm to extrude four-leaf clover strips, and then use a shaping machine to shape the particles to keep the particle length between 3 and 8mm.

[0032] After shaping, the particles were hardened at 60°C for 24 hours, then transferred to an oven, dried at 120°C for 4 hours, and then calcined at 1050°C for 4 hours in a high-temperature furnace to obtain the catalyst, code number CAT-2.

Embodiment 3

[0034] An α-phenylethanol dehydration catalyst is prepared according to the following preparation method: Weigh 110 g of double hydrolysis pseudo-boehmite, add 1.6 g of sodium bicarbonate, 3 g of methyl cellulose, and 2.5 g of clay, and mix uniformly; add Al2O3 38g of aluminum sol with a content of 10% was stirred and kneaded evenly; a clover orifice plate with a diameter of 4.0mm was selected to extrude clover strips, and then a shaping machine was used for shaping to keep the particle length between 3 and 8mm.

[0035] After shaping, the particles were hardened at 45°C for 24 hours, then transferred to an oven, dried at 120°C for 4 hours, and then calcined at 1000°C for 4 hours in a high-temperature furnace to obtain a catalyst, numbered CAT-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com