Lower carbon number hydrocarbons building-up reaction method

A superposition reaction, low-carbon olefin technology, applied in the directions of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of low use temperature, swelling, affecting the service life, etc., and achieve good stability, The effect of wide reaction temperature range and long operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

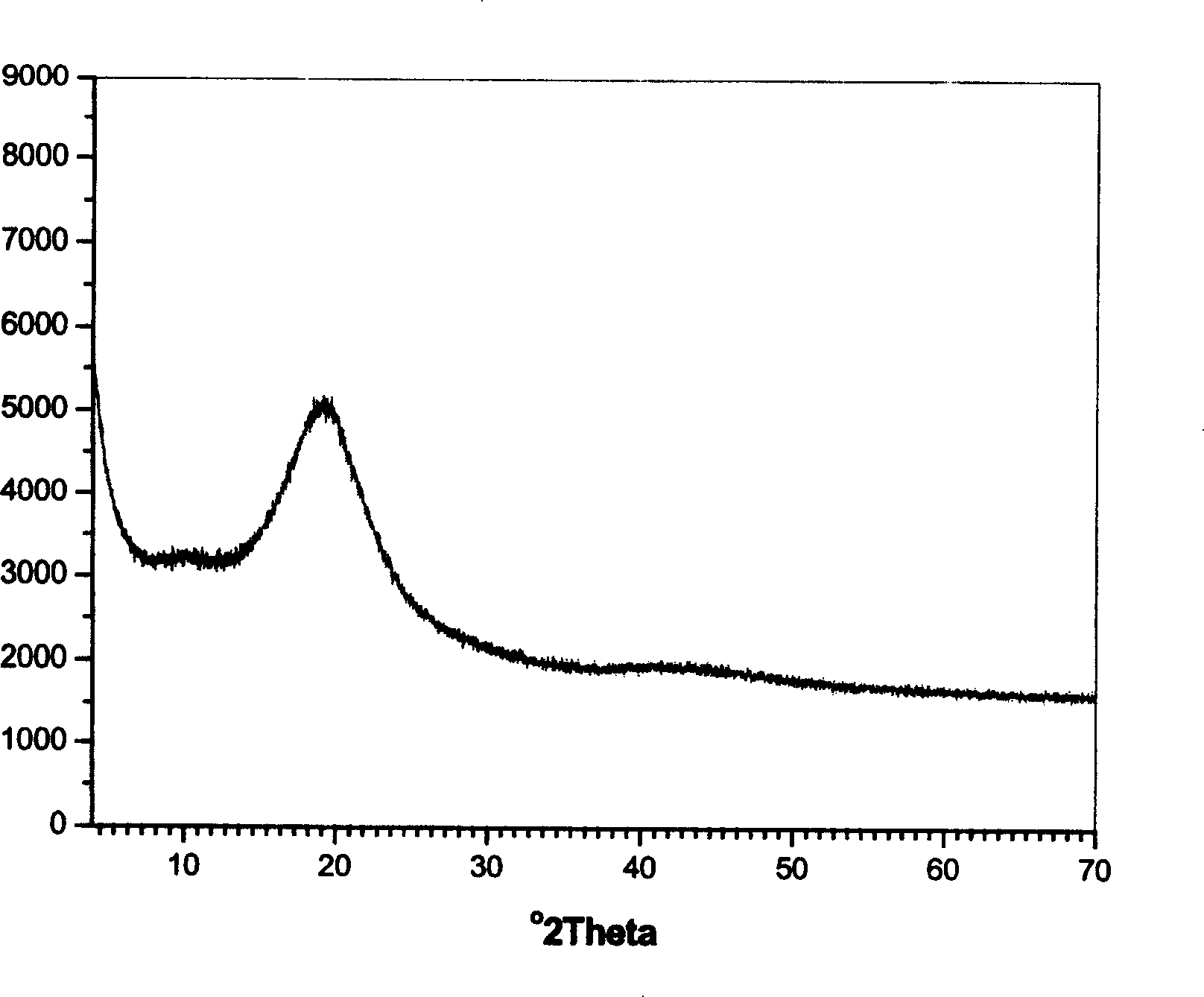

Image

Examples

Embodiment 1

[0027] Install a stirring blade in the middle port of the three-necked glass bottle, and install a thermometer and a condenser tube in the other two ports. 3gTiCl 4 and 3g of gelatin were dissolved in 100g of water; the monomer phase was composed of 10g of styrene and 1g of divinylbenzene, adding initiator benzoyl peroxide 0.03g and porogen isooctane 5g and stirring until completely mixed; After the bulk phase was stirred at 1000r / min for 2 hours, the temperature began to rise. First, the polymerization temperature was raised to 60°C. After 3 hours of reaction, the temperature was gradually raised to 90°C. The heating process lasted for 10 hours. The formed particles were washed several times with hot deionized water and dried at 80°C.

[0028] Sulfonate with 100% concentrated sulfuric acid, carry out sulfonation in a three-necked flask at 90°C for 10 hours, gradually wash with water until the eluate is neutral, and obtain the finished product. Dry at 80°C for use.

[0029]...

Embodiment 2

[0035] Install a stirring blade in the middle port of the three-necked glass bottle, and install a thermometer and a condenser tube in the other two ports. Dissolve 26g of ammonium metavanadate and 3g of gelatin in 100g of water; the monomer phase consists of 10g of styrene and 4g of divinylbenzene, add 0.03g of initiator benzoyl peroxide and 5g of porogen isooctane and stir until completely mixed ; Stir the water phase and the monomer phase at 1000r / min for 3 hours, then start to heat up, first raise the polymerization temperature to 60°C, react for 3 hours, then gradually raise the temperature to 90°C, and the heating process lasts for 10 hours. The formed particles were washed several times with hot deionized water and dried at 80°C.

[0036] Sulfonate with 100% concentrated sulfuric acid, carry out sulfonation in a three-necked flask at 90°C for 10 hours, gradually wash with water until the eluate is neutral, and obtain the finished product. Dry at 80°C for use.

[0037]...

Embodiment 3

[0043] Install a stirring blade in the middle port of the three-necked glass bottle, and install a thermometer and a condenser tube in the other two ports. Dissolve 10g of mixed rare earth chloride salts (rare earth content greater than 99%, produced by Shanghai Pharmaceutical Group Shanghai Reagent Co., Ltd.) and 3g of gelatin in 100g of water; the monomer phase consists of 10g of styrene and 8g of divinylbenzene, and add 0.01g of benzoyl peroxide Acyl and 5 g isooctane were stirred until completely mixed. Stir the water phase and the monomer phase at 1000r / min for 3 hours, then start to raise the temperature. First, raise the polymerization temperature to 60°C. After 3 hours of reaction, gradually raise the temperature to 90°C. The heating process lasts for 10 hours. The formed particles were washed several times with hot deionized water, and dried at 80° C. for 10 hours.

[0044] The sulfonation was carried out with 100% concentrated sulfuric acid, and the sulfonation was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

| thermal stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com