Patents

Literature

118results about How to "High substrate conversion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for fermentation-membrane separation combined production of long-chain dicarboxylic acid

ActiveCN104862348AHigh substrate conversion rateReduce inhibitionMicroorganism based processesFermentationAlkaneCandida viswanathii

The invention discloses a method for fermentation-membrane separation combined production of long-chain dicarboxylic acid and especially relates to a method for high yield production of dodecanedioic acid (DC12). The method comprises introducing a Candida viswanathii culture seed liquid into a liquid fermentation medium mixed solution which contains 5-40% (v / v) of C10-C18 n-alkane and 95-60% (v / v) of saccharic multielement substrate as a growth carbon source and has pH of 5.0-8.5, carrying out culture on the mixed solution under conditions of a temperature of 24-40 DEG C and ventilatory capacity of 0.1-3.0vvm for 42-194h, starting a fermentation-membrane separation combined device, returning the cells separated by the combined device into a fermentation cylinder, feeding the permeate liquid separated by the combined device into an extraction unit, preparing long-chain dicarboxylic acid, simultaneously, supplying a medium into the fermentation cylinder and carrying out fermentation. In n-dodecane transformation production of DC12, the method has an acid yield of 250g / L and an acid production rate of more than 1.6g / h.L, improves microbial density in fermentation, shortens a fermentation period, improves dicarboxylic acid production intensity and returns the unused n-dodecane into the fermentation unit.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

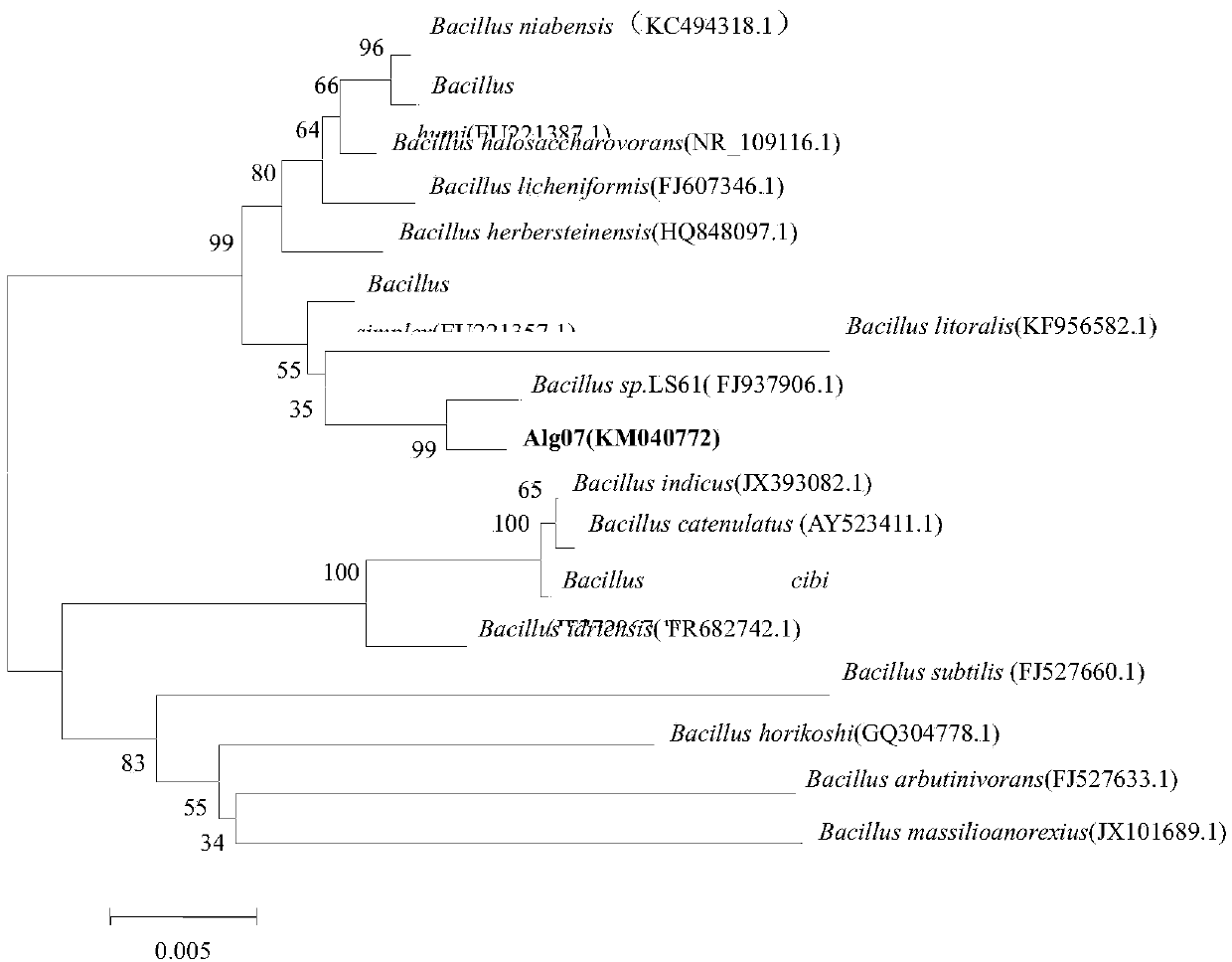

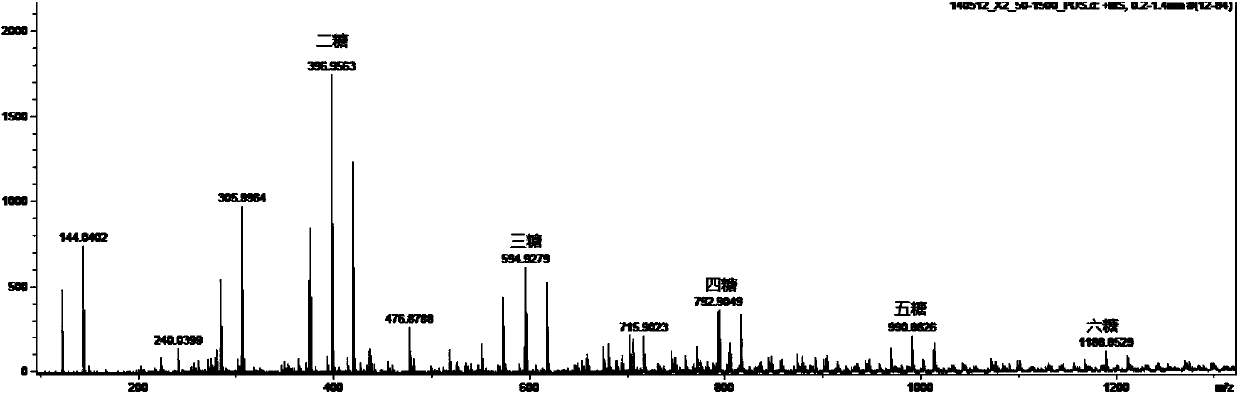

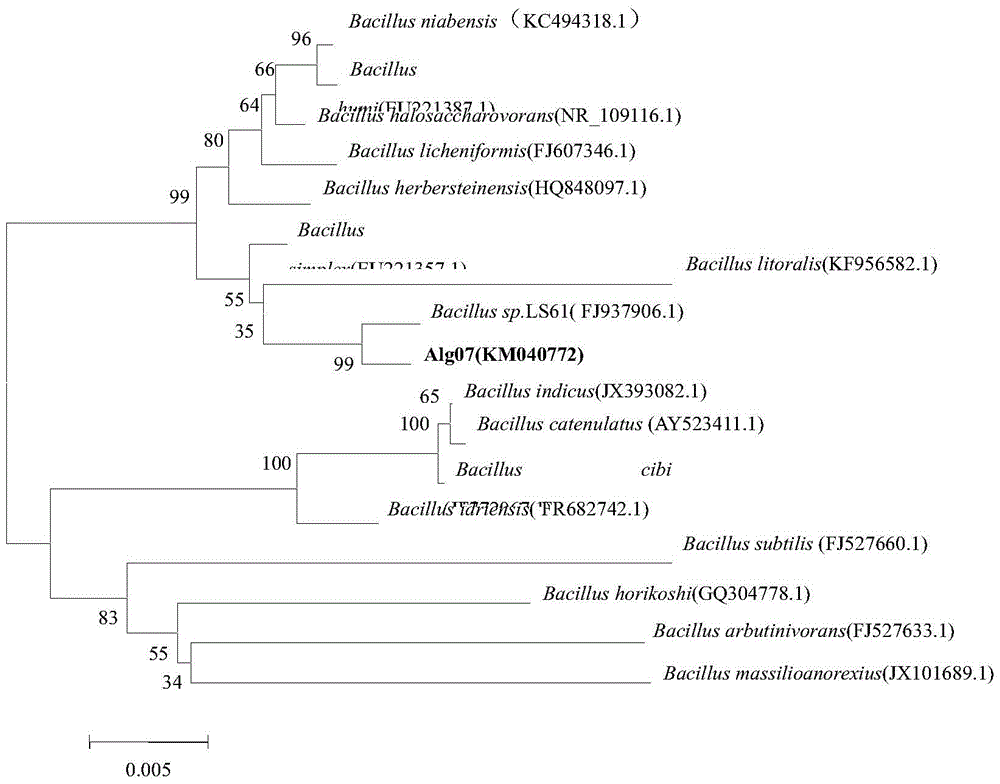

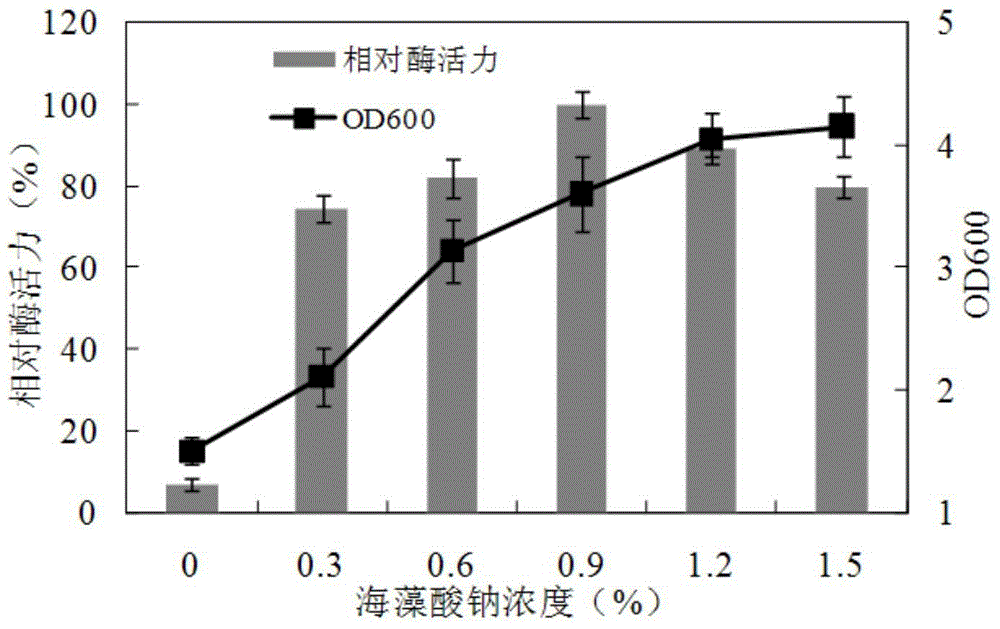

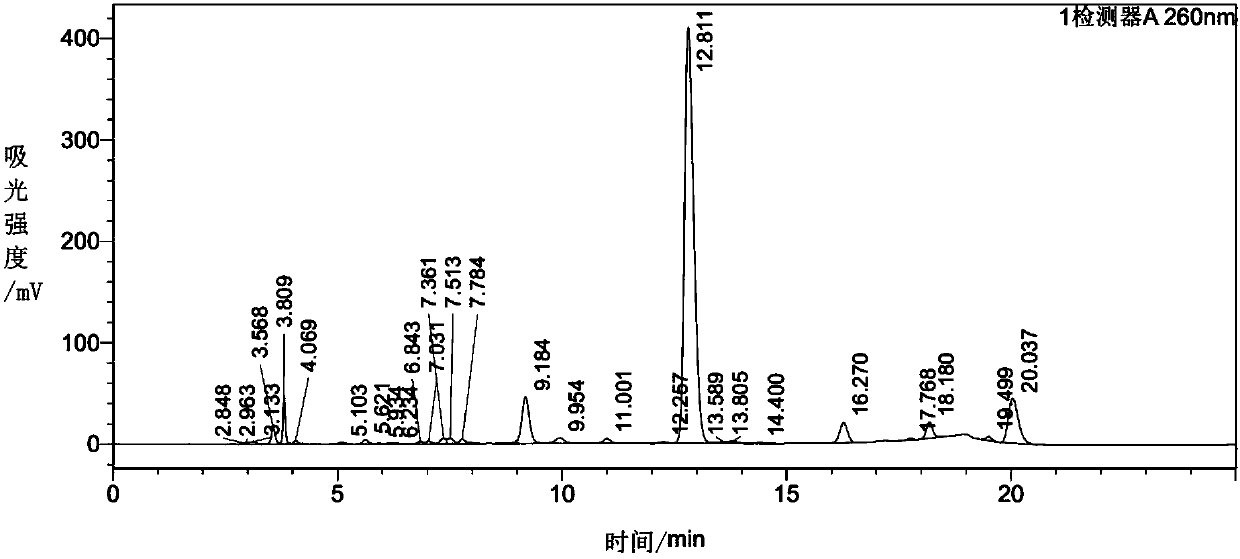

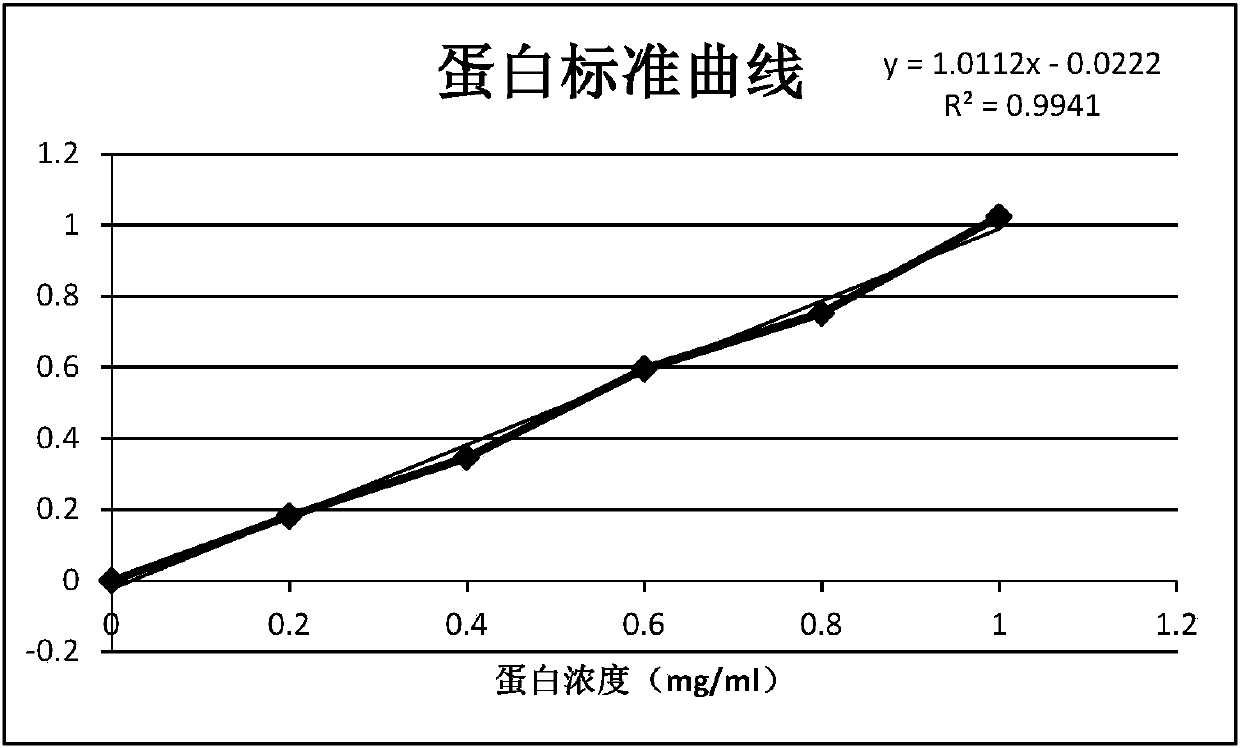

Bacillus sp capable of producing alginate lyase and application thereof

ActiveCN104195080AIncrease enzyme activitySimple nutritional requirementsBacteriaMicroorganism based processesSpecific enzymeAlginate lyase

The invention provides Bacillus sp Alg07 capable of producing an alginate lyase. The preservation number of the Bacillus sp Alg07 is CGMCC No.9391. The Bacillus sp Alg07 provided by the invention has the advantages that requirement on nutrition is low and fermentation time is short; a crude enzyme is easily prepared, and the crude enzyme can be obtained through centrifugation; the alginate lyase produced by the Bacillus sp Alg07 has high enzyme activity, the specific enzyme activity of an unpurified crude enzyme can reach 20000-40000 U / mg (563U / mL); the alginate lyase produced by the Bacillus sp Alg07 has good stability, is not obviously changed in enzyme activity after being preserved at 40 DEG C for 24 hours and is high and stable in enzyme activity at pH of 5.5-8.5; and the produced alginate lyase is capable of degrading sodium alginate to generate alginate-derived oligosaccharide with biological activity.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Method for preparing furfural, polyether polyalcohol, phenolic resin and nanometer silicon dioxide from straw

The invention relates to a comprehensive utilization process of the classification conversion of straw. The process is characterized in that the straw is split selectively and structurally by the combined pretreatment technology in which steam explosion is taken as a core to form hemicellulose-enriched washing liquor, a hybrid-cell-enriched component, a cellulose-enriched component and a lignin component; and steam explosion washing liquor is catalyzed directly to form furfural, the hybrid-cell-enriched component is burned to form nanometer silicon dioxide, the cellulose-enriched component and the lignin component are liquefied respectively to form plant-based polyether polyalcohol, and the lignin component is also used for preparing phenolic resin further. In the method, the furfural is prepared by a two-step method, so the conversion rate is improved; a solid acid catalyst also can be used repeatedly, and the cellulose-enriched component and the lignin component are liquefied respectively, so the conversion rate of a substrate is improved; and the relative molecular weight of the polyether polyalcohol is distributed narrowly, so the polyether polyalcohol can be used for preparing high-quality polyurethane materials. By the method, the problems of low conversion efficiency, secondary pollution and the like during the utilization of the integral plant of the straw are solved, and the high-efficiency cleaning conversion of the straw is realized.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

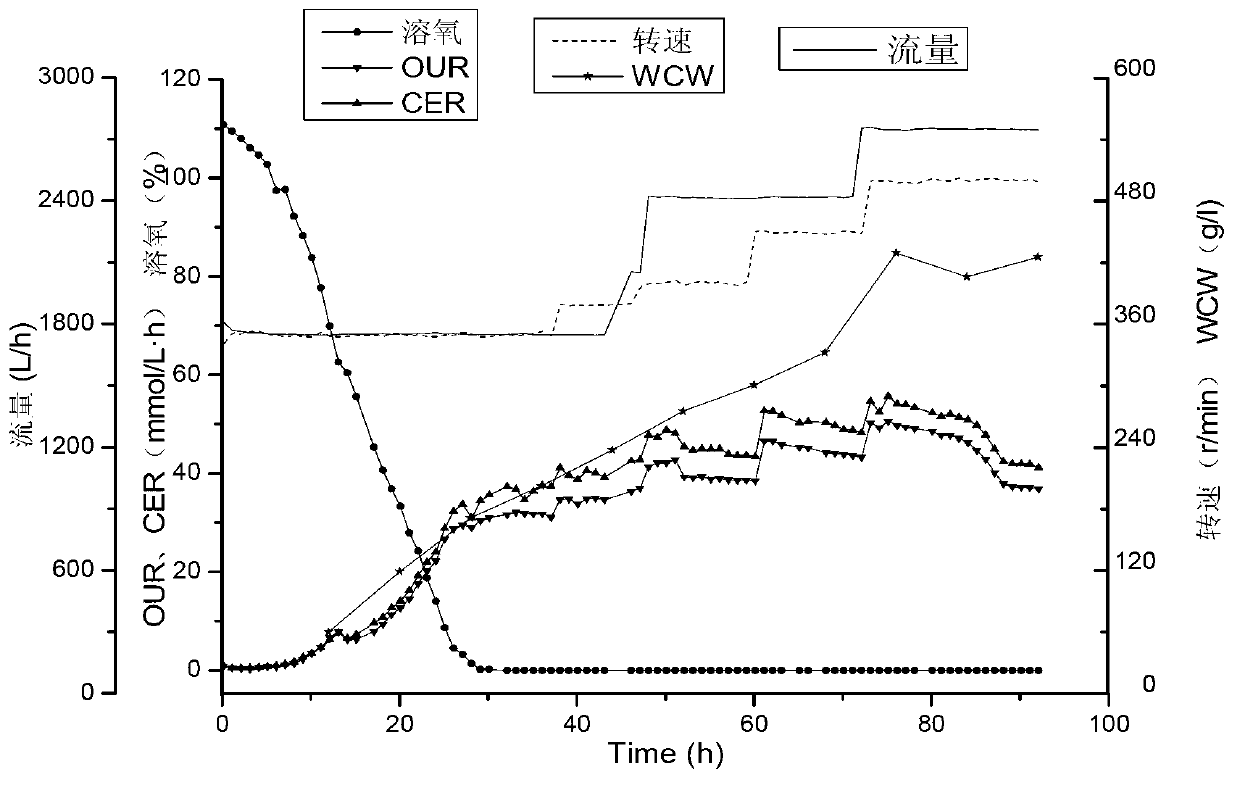

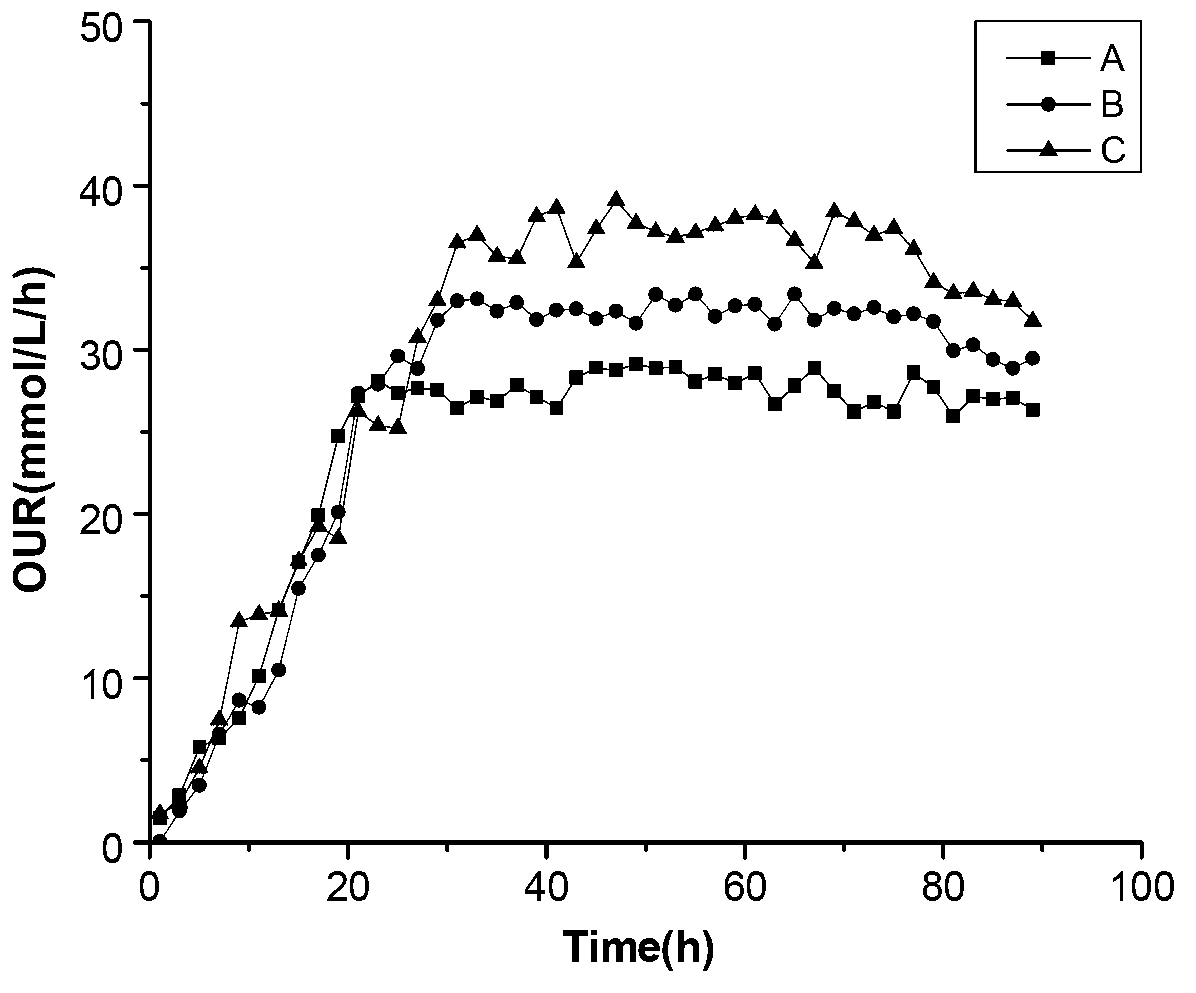

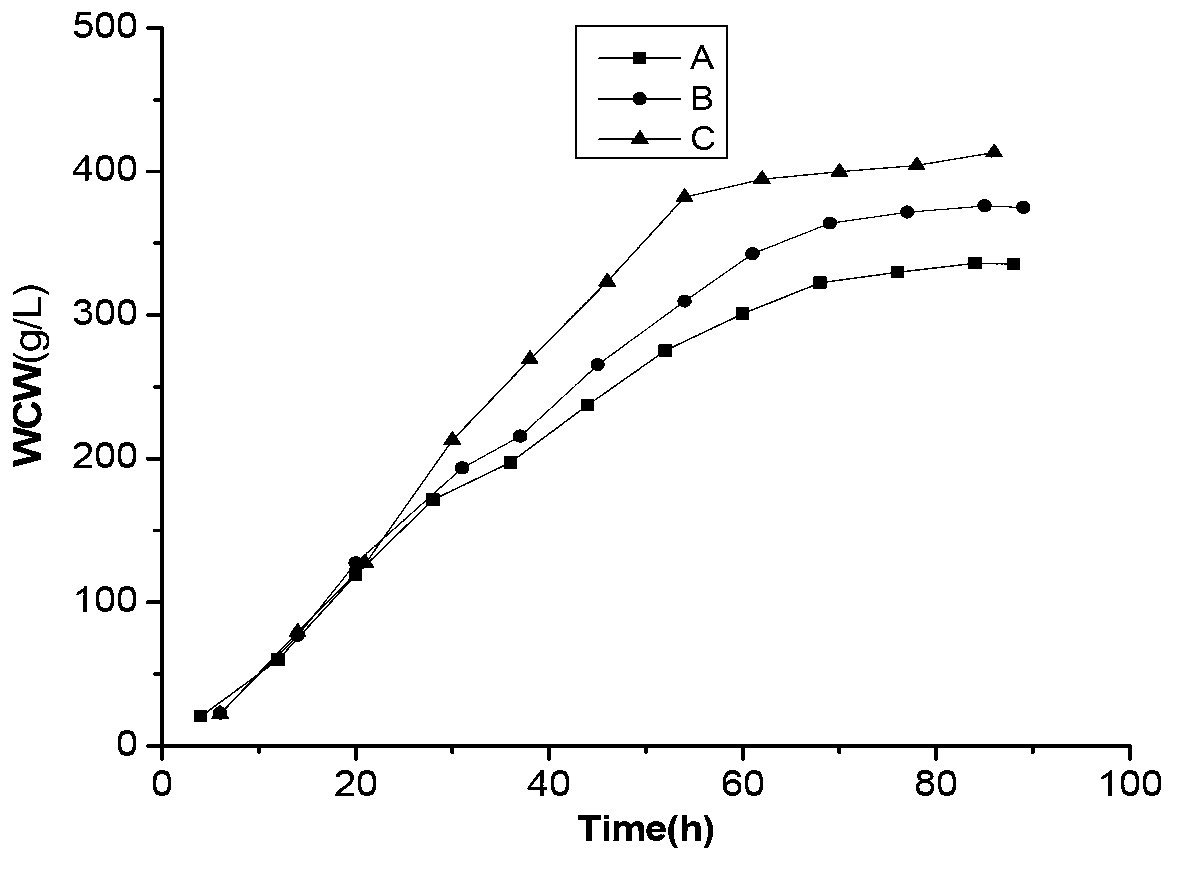

Novel process for fermenting coenzyme Q10 based on online oxygen consumption rate control

ActiveCN102876743AHigh yieldReduce wasteMicroorganism based processesFermentationOperabilityFermentation

The invention provides a novel process for fermenting coenzyme Q10 based on online oxygen consumption rate control. Oxygen consumption rate is controlled at 30-150mmol / L*h during fermentation of coenzyme Q10 strain production, so that growth of thallus and starting and accumulation of coenzyme Q10 synthesis are promoted. Yield of coenzyme Q10 is evidently increased, unit energy consumption is lowered, and production cost is lowered greatly. The novel process is simple to control, high in operability, energy-saving and the like.

Owner:SHANGYU NHU BIOCHEM IND +1

Synthetase gene for T.fusca mycose and method for preparing mycose

This invention relates to a new clone mycose synthesized zyme gene and its expression in the correlated host which zyme gene clone belong to thermobifida turning the malt sager to mycose under normal biochemical reaction, its zyme substrate conversion efficiency increases along with the decreasing of the reaction temperature, taking the malt sager or amylum as the raw material and turn it to alpha 1-mycose alpha-1 by cloned.

Owner:GUANGXI UNIV

Method for producing long-chain binary acid through fermentation separation coupling

ActiveCN104862347AHigh substrate conversion rateReduce inhibitionMicroorganism based processesFermentationTO-18Alkane

The invention discloses a method for producing long-chain binary acid through fermentation separation coupling, in particular to a method of high-yield dodecanedioic acid (DC12). According to the technical scheme, the method includes the steps that candida viswanathii is cultivated into a seed solution which is led into 5-40% (v / v) n-alkane and 60-95% (v / v) liquid fermentation medium mixture, wherein the pH of the n-alkane ranges from 5.0 to 8.5, and 10 to 18 carbon atoms are contained in the n-alkane; a saccharic multielement substrate serves as a growth carbon source of the liquid fermentation medium mixture; mixing liquid is cultivated for 42 h to 194 h under the conditions that the temperature ranges from 24 DEG C to 40 DEG C, and the air passing amount ranges from 0.1 vvm to 3.0 vvm, a centrifugal fermentation separation coupling device or a plate frame filtering fermentation separation coupling device is started, cells passing through the separation coupling device are circulated back to a fermentation cylinder, and clear liquid passing through the separation coupling device enters an extraction link to prepare long-chain binary acid; and meanwhile the fermentation process is continuously carried out on a cultivation medium in a fermentation tank. The method is used for converting n-dodecane so as to produce the DC12, the produced acid reaches 240 g / L, and the acid production rate is larger than 1.5 g / h.L.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Biological sterol transforming process with cyclodextrin and its application

InactiveCN101020919AImprove solubilityPromote biotransformationMicroorganism based processesFermentationSolubilityMicroorganism

The present invention belongs to the field of biological sterol transforming technology, and is especially biological sterol transforming process with cyclodextrin and its derivative and its preparation. In a transforming system, cyclodextrin or its derivative in certain amount is added, or substrate and cyclodextrin or its derivative in certain ratio are made to form inclusion compound, so as to facilitate transformation. The process of the present invention is especially suitable for microbial transformation of hydrophobic compound, and can raise the solubility of reaction substrate in water solution, raise the substrate utilizing rate and reaction rate, release substrate and product inhibition and raise product converting rate. When the substrate concentration is 3-20g / L, the present invention has conversion period shorted to 3-4 days, conversion rate of 50-95 % and high industrial application value.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for producing 2-phenylethanol under biological catalysis

ActiveCN106957878AImprove conversion rateIncrease productionMicroorganism based processesFermentationPhenylalanine dehydrogenaseKetonic acids

The invention relates to the field of bioengineering and biotechnologies, and discloses a method for producing 2-phenylethanol under biological catalysis. The method comprises the following steps: adding wet cells of E.coli / Pdh, E.coli / Kdc and E.coli / ADH undergoing induced expression into a biological catalysis system taking L-phenylalanine as a substrate for performing a catalytic reaction; centrifuging after finishing the reaction; extracting supernatant to obtain the 2-phenylethanol. In the method, the L-phenylalanine is taken as the substrate, and recombinant escherichia coli transformed with a phenylalanine dehydrogenase gene, a 2-keto acid decarboxylase gene and an alcohol dehydrogenase gene is added into a reaction system for performing a biological deamination, decarboxylation and reduction three-step catalytic reaction in order to generate a product, namely, phenylethanol; a coenzyme, namely, NAD (Nicotinamide Adenine Dinucleotide) is added once and can be recycled, excess ketonic acid and hydrogen sources do not need to be added, no unnecessary side products are generated, a high substrate transforming rate is achieved, and the yield of the phenylethanol is increased remarkably.

Owner:BOTON SHANGHAI BIOLOGICAL TECH CO LTD

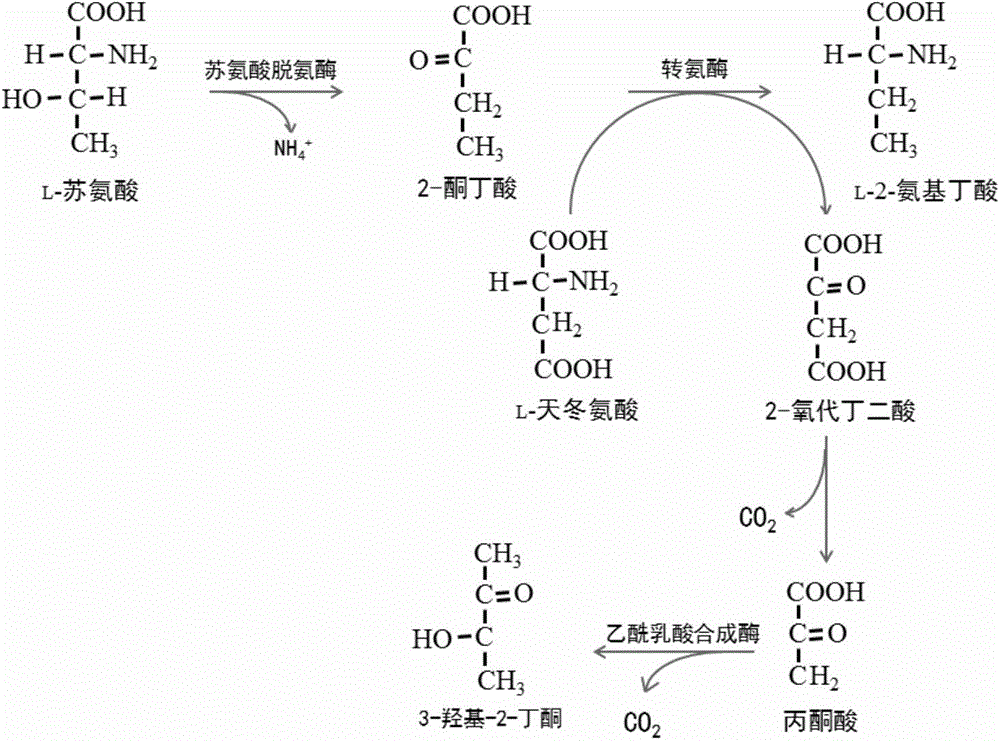

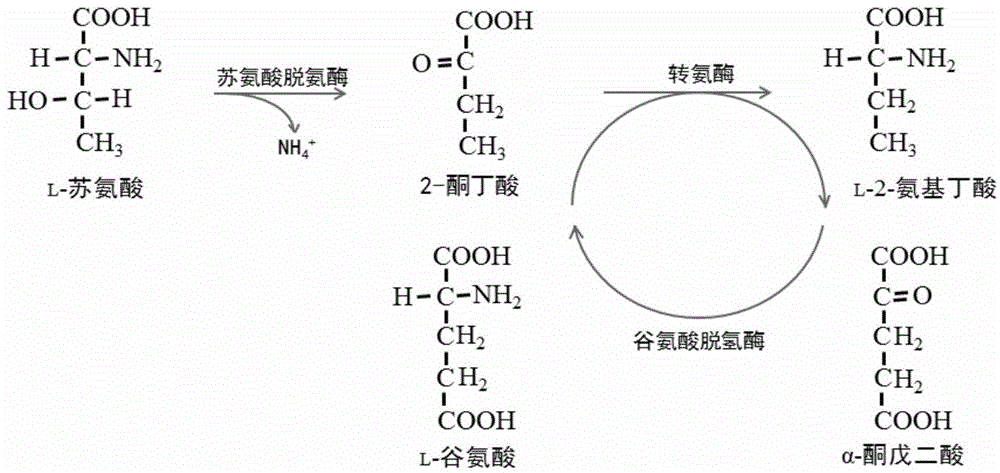

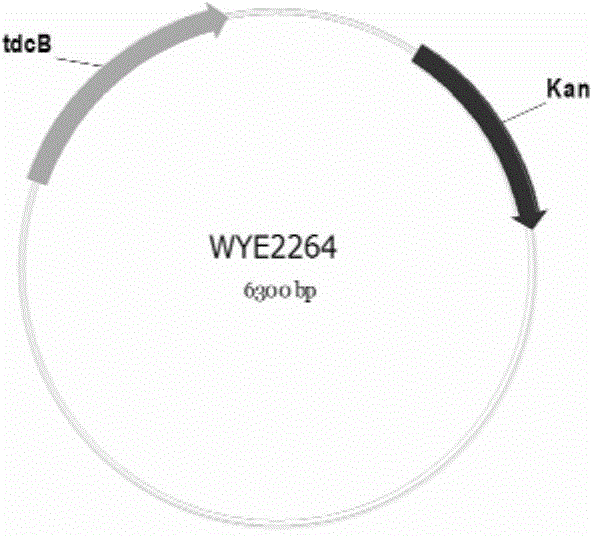

Recombinant strain for producing L-2-aminobutyric acid and preparing method and application thereof

ActiveCN106148259AIncrease productionHigh substrate conversion rateBacteriaMicroorganism based processesL-2-Aminobutyric AcidThreonine

The invention discloses a recombinant strain for producing L-2-aminobutyric acid and a preparing method and application thereof. The recombinant strain is a strain obtained in the mode that threonine dehydratase, transaminase and glutamate dehydrogenase are subjected to overexpression at the same time. Due to the recombinant strain for producing the L-2-aminobutyric acid with threonine serving as a substrate, the yield of the L-2-aminobutyric acid and the substrate conversion ratio are remarkably increased, accumulation of by-products is effectively reduced, and the production technology is simplified.

Owner:INST OF MICROBIOLOGY - CHINESE ACAD OF SCI

Production method for L-cysteine

InactiveCN105274554ANo emissionsSimple production processElectrolysis componentsElectrolytic organic productionAllergic symptomsCompanion animal

The invention discloses a production method for L-cysteine, and the method belongs to the field of production of amino acids. According to the method, L-cystine, diluted hydrochloric acid with the concentration of 20%, active carbon and a sodium hydroxide aqueous solution with the concentration of 10% are employed as raw materials for producing L-cysteine. The method possesses the advantages of being simple in production technology, mild in reaction conditions, high in substrate conversion rate, free of polluted waste discharge, high in product purity, convenient for batch production, and the like. The main purposes of the product comprise: on the medicine aspect, the product is capable of detoxifying, is capable of effectively preventing and treating radioactive damage, and possesses effects of improving inflammation and skin allergic symptoms; on the cosmetics aspect, the product is a natural whitening cosmetic, and can be used to produce hair-waving essence and sunscreen cream; and on the foodstuff aspect, the product can be used as a bread fermentation promoter, an antistaling agent, a nutrition additive of pet / beast food, and the like.

Owner:XINYI HANLING BIO ENG

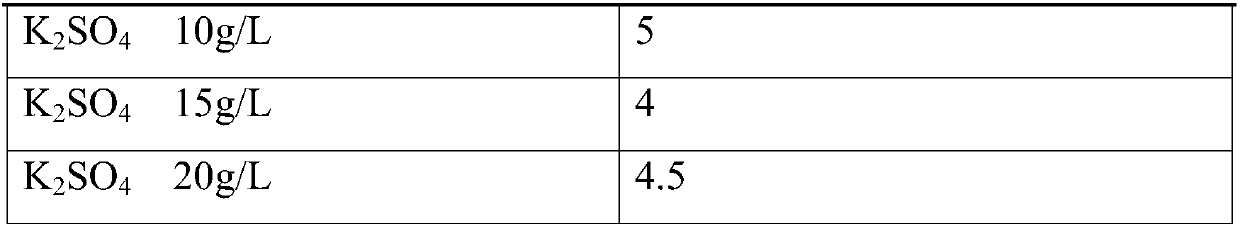

Production method of agricultural gamma-polyglutamic acid

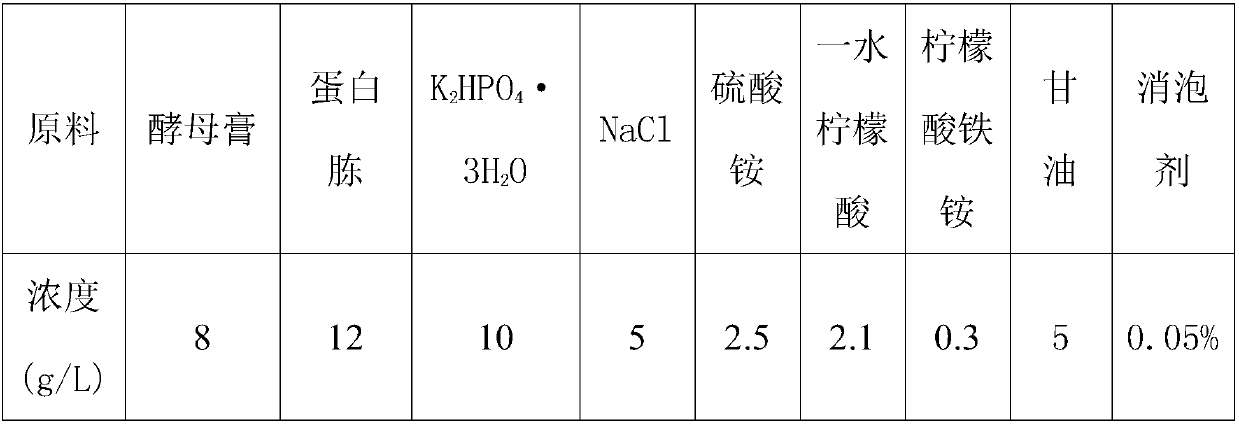

InactiveCN107760732ALow costIncrease productionMicroorganism based processesFermentationAlcoholPotassium

The invention relates to a production method of agricultural gamma-polyglutamic acid, comprising the following steps: strain activation; inoculating original strain of Bacillus licheniformis to a slant culture-medium for culture activation; preparation of a seed solution; inoculating activated seeds to a seed medium to obtain a gamma-polyglutamic acid seed solution; inoculating the seed solution to a fermentation medium for fermentation; and centrifuging to remove thalline after the fermentation, carrying out alcohol precipitation to obtain polyglutamic acid, and drying so as to prepare yellowpowdery agricultural polyglutamic acid. Through a laboratory study on fermentation of agricultural polyglutamic acid, it is found that potassium salts have a great effect of promoting synthesis of agricultural polyglutamic acid. By adding potassium chloride and raising agricultural output, conversion rate of a substrate is raised. The method is convenient to operate. By the method, output is increased, and cost of later polyglutamic acid extraction is reduced in comparison with a production method of cosmetic polyglutamic acid.

Owner:天津北洋百川生物技术有限公司

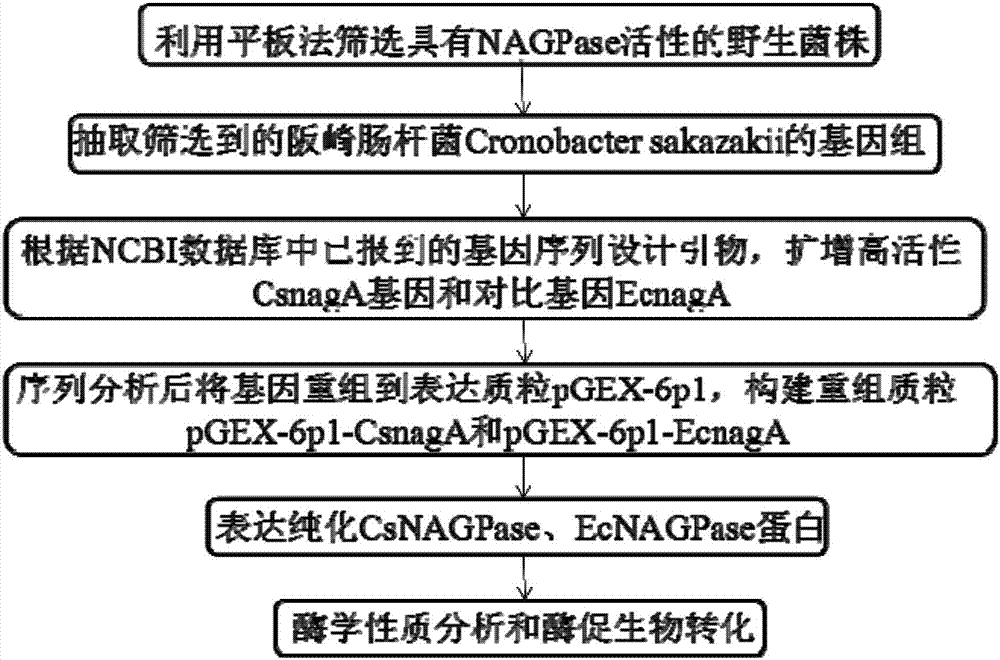

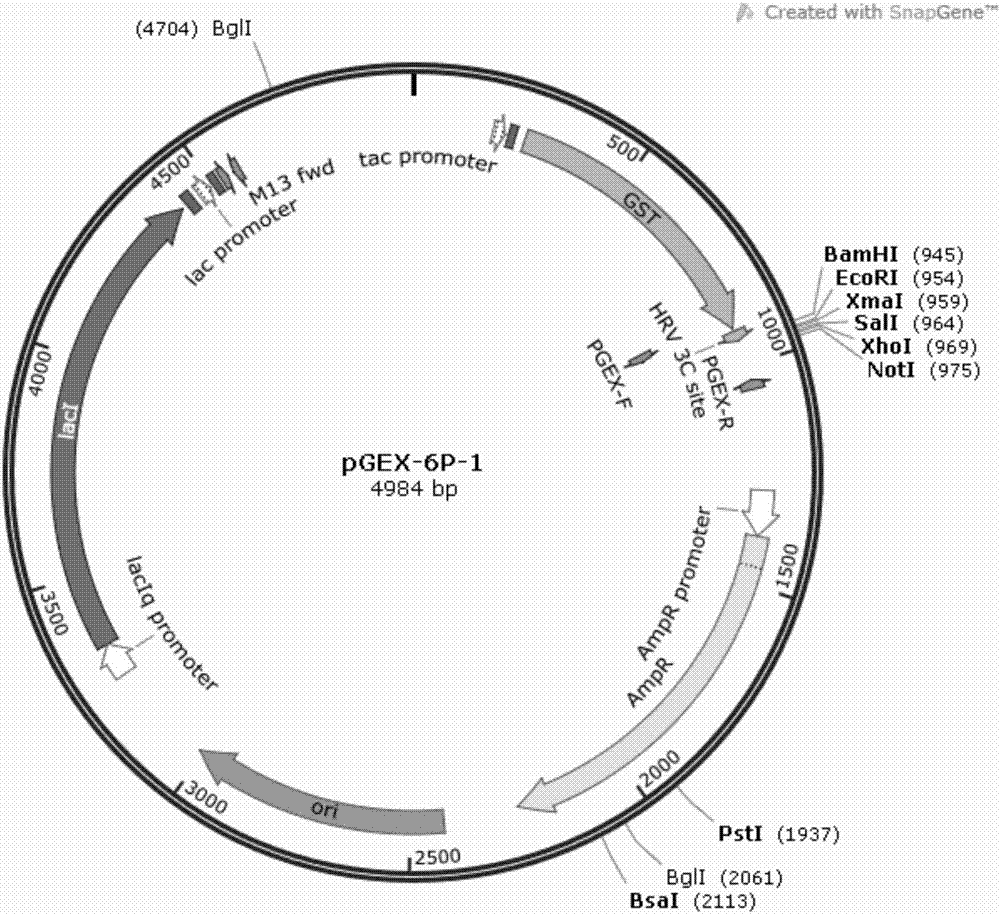

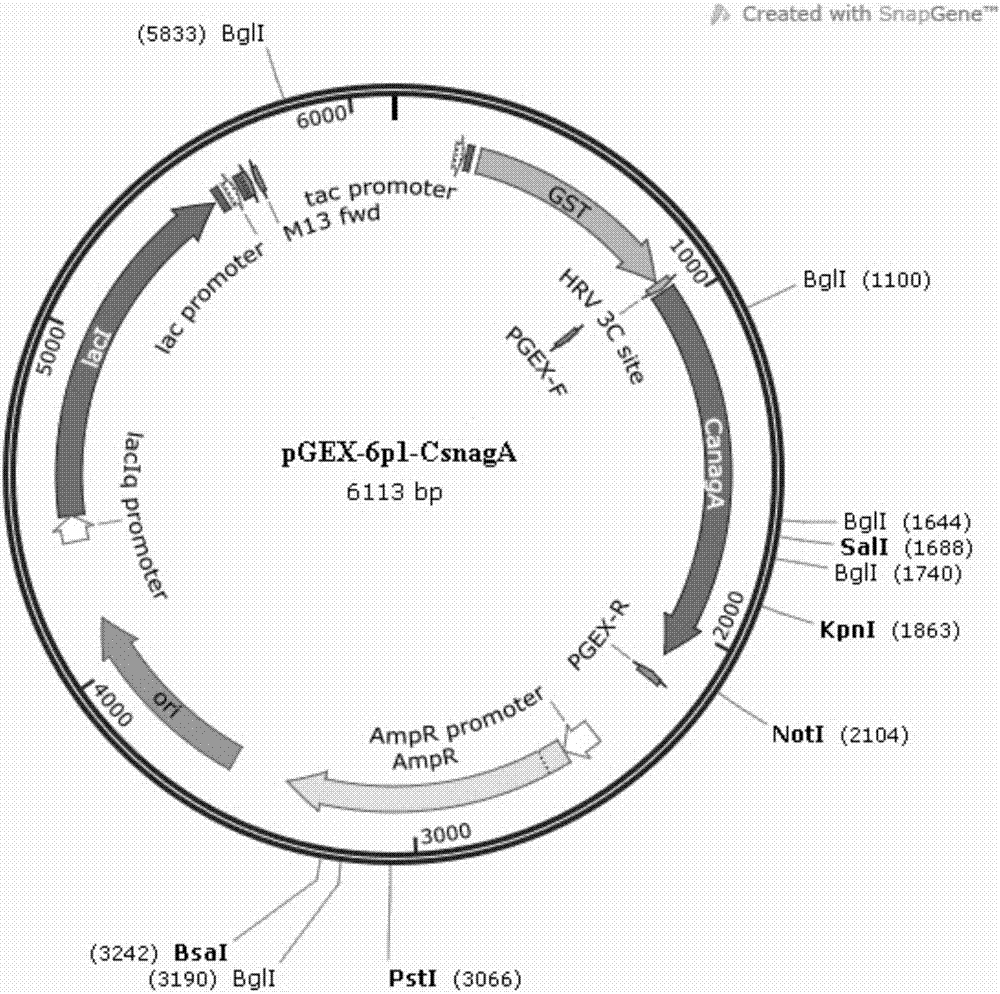

Deacetylase capable of producing high-yield glucosamine and coding gene thereof

InactiveCN107022538AGood enzymatic propertiesImprove thermal stabilityBacteriaHydrolasesProtein proteinGenomic DNA

The invention belongs to the technical field of microorganism gene engineering, and particularly relates to deacetylase capable of producing high-yield glucosamine and a coding gene thereof. The gene CsnagA is separated from the natural strain cronobacter sakazakii 0360. Genomic DNA is separated from cronobacter sakazakii with the preservation number of CCTCC NO:M 2016162. The nucleotide sequence of the gene is shown in SEQ ID NO:1. The sequence of protein coded by the gene is shown in SEQ ID NO:2. By means of genetic recombination, the gene is transferred into escherichia coli to construct genetically engineered bacteria, so as to obtain an efficient glucosamine fermentation production capacity, and glucosamine can be produced with the enzymatic biosynthesis method. Compared with the prior art, the deacetylase has the advantages that the production efficiency is improved, and the production cost is reduced.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

Biological transformation method by utilizing hydrophobic compound of cyclodextrin

InactiveCN101168765AImprove conversion rateIncrease the rate of conversion reactionsMicroorganism based processesFermentationMicroorganismReaction rate

The invention discloses a bioconversion method by using cyclodextrin and the hydrophobic compound of the derivative thereof, belongs to the bioconversion technical field, in particular relates to the bioconversion method by using the cyclodextrin and the hydrophobic compound of the derivative thereof, and provides the bioconversion method by using the cyclodextrin and the hydrophobic compound of the derivative thereof. The method of the invention is particularly suitable for the microbial conversion of hydrophobic compounds, can effectively improve the dissolubility of reaction substrate in aqueous solution, improve the utilization rate and the reaction rate of the substrate, release the inhibition of the substrate and the product to a certain extent, and improve the conversion rate of the product. The invention adopts a conversion system including the cyclodextrin, the special structure of the cyclodextrin ensures the cyclodextrin to have a certain solubilizing power, and strengthens the bioavailability of the substrate.

Owner:TIANJIN UNIV OF SCI & TECH

Method for increasing pulullan output through fed-batch fermentation

InactiveCN104911231AHigh substrate conversion rateAids in synthesisMicroorganism based processesFermentationPullulanAnimal science

The invention relates to a method for increasing pulullan output through fed-batch fermentation, which comprises the following steps: culturing seeds, performing fermentation culture and separating pulullan; continuously feeding a fed-batch solution after fermenting for 24-28 hours, controlling the residual sugar of a broth to maintain at 6-12g / L, supplementing 0.5-2g / L of amino acid solution for once by every two hours, wherein the total fermentation period is 65-67 hours. Aiming at defects of long period and low substrate conversion rate during a process of fermentation of aureobasidium pullulans with a preservation number of No. 7055 to produce pulullan, a proper amount of amino acid is continuously fed during the fermentation process for synthesis of pullulan, substrate conversion rate is increased, operation is convenient, effect is obvious, fermentation period is greatly shortened, and cost of pullulan can be reduced.

Owner:天津北洋百川生物技术有限公司

Bacillus proliferation promoting mineral substance regulator used for fermentation

InactiveCN103695344AHigh product concentration and substrate conversionImprove product effectiveness and stabilityBacteriaMicroorganism based processesDigestive enzymeMicronutrient

The invention discloses a bacillus proliferation promoting mineral substance regulator used for fermentation. The mineral substance regulator has a unique growth promotion function for fermentation culture of bacillus and can not only provide micronutrients required by bacillus proliferation but also increase dissolved oxygen and the like in water by regulating pH of the water and hydrogen bonds between activated water molecule and weakened water molecule clusters in a culture medium and promote growth and propagation of bacillus and improve the activity of digestive enzymes to achieve the aims of obtaining higher product concentration and substrate conversion rate and improving the effectiveness and stability of the product; and therefore the mineral substance regulator has various advantages, is especially suitable for popularization and application in the field and has a very extensive market prospect.

Owner:DALIAN OCEAN UNIV

Surface immobilized yeast fermentation technology

The invention discloses a surface immobilized yeast fermentation technology. According to the surface immobilized yeast fermentation technology, a fiber material is immobilized into a spherical grid,and then yeast is immobilized to a fiber carrier through an adsorption effect. According to the surface immobilized yeast fermentation technology, the defects in the prior art are overcome, the immobilized method is low in input cost, convenient to operate, stable in technique and good in adsorption effect, and has the great protecting and promoting effects on cell activity and growth. Yeast cellswith immobilized media is adopted to ferment to produce ethyl alcohol, it can be effectively ensured that the yeast is efficiently and stably fermented for a long term, and the conversion rate of a substrate can further be increased.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

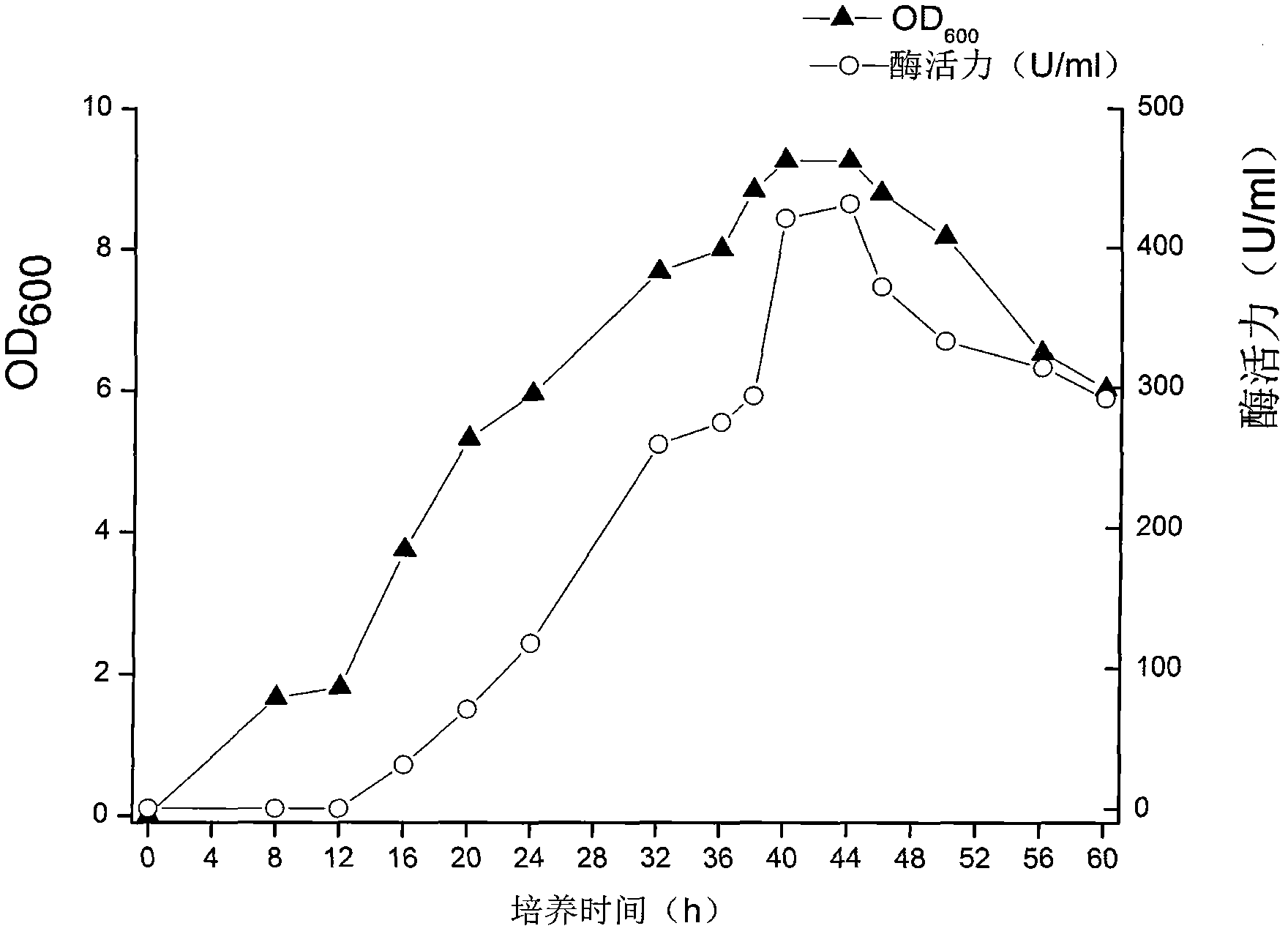

Method for preparing cardamine selenium polypeptide through continuous enzymolysis and cardamine selenium polypeptide

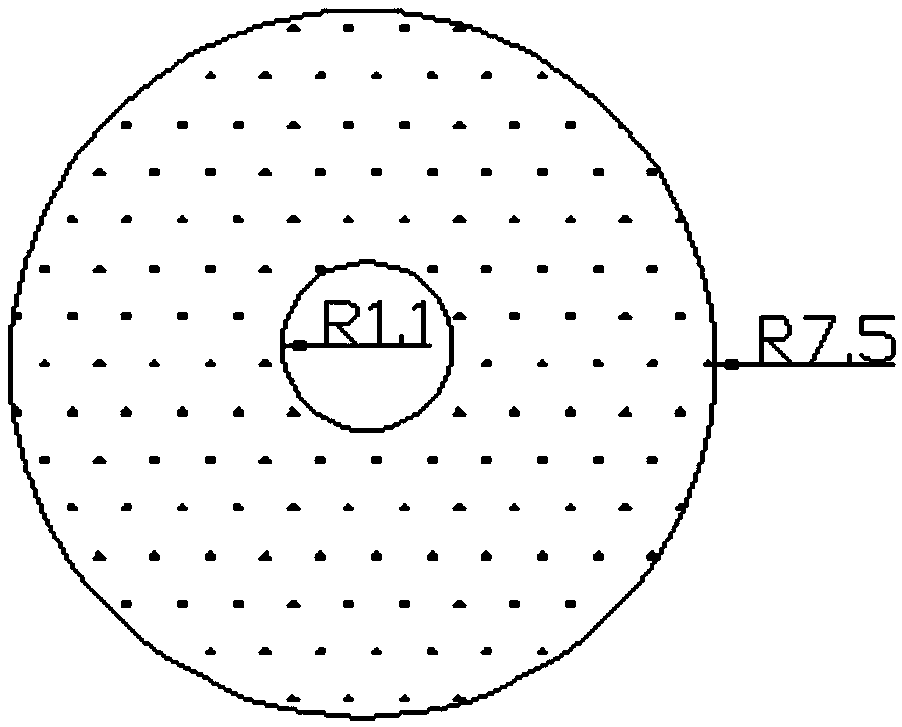

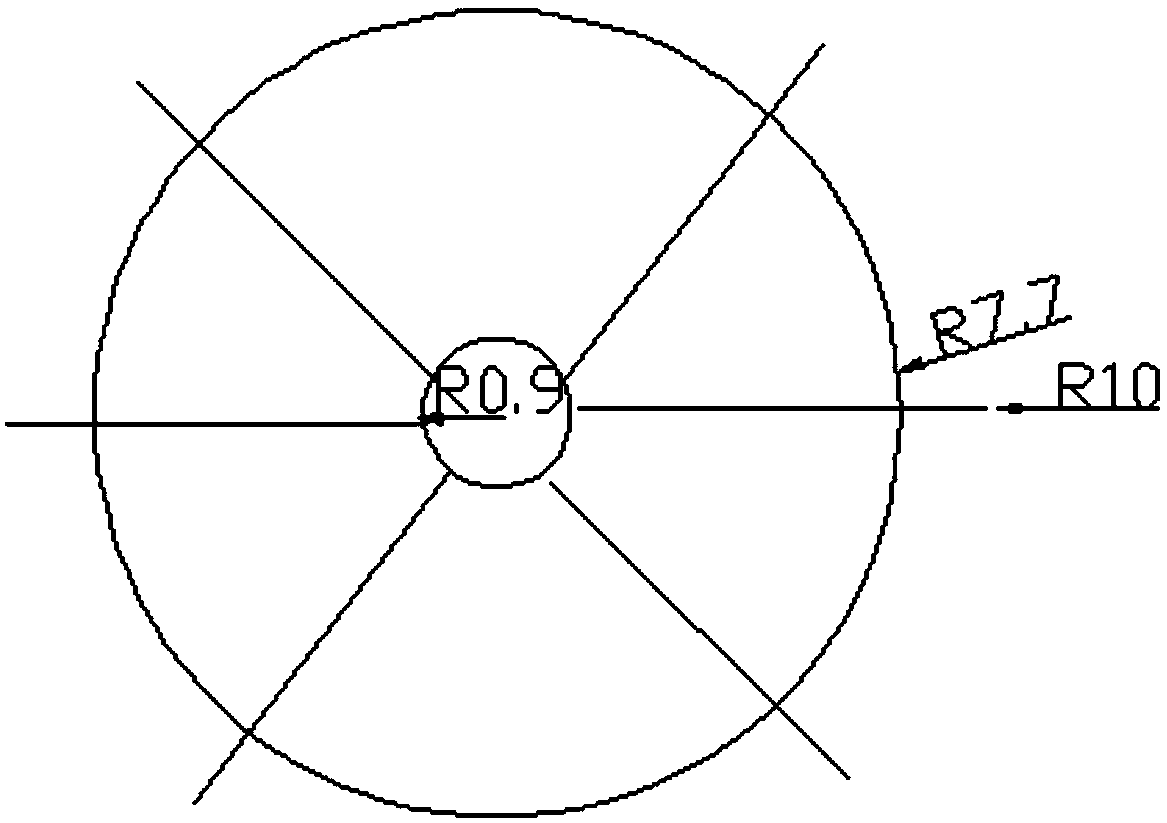

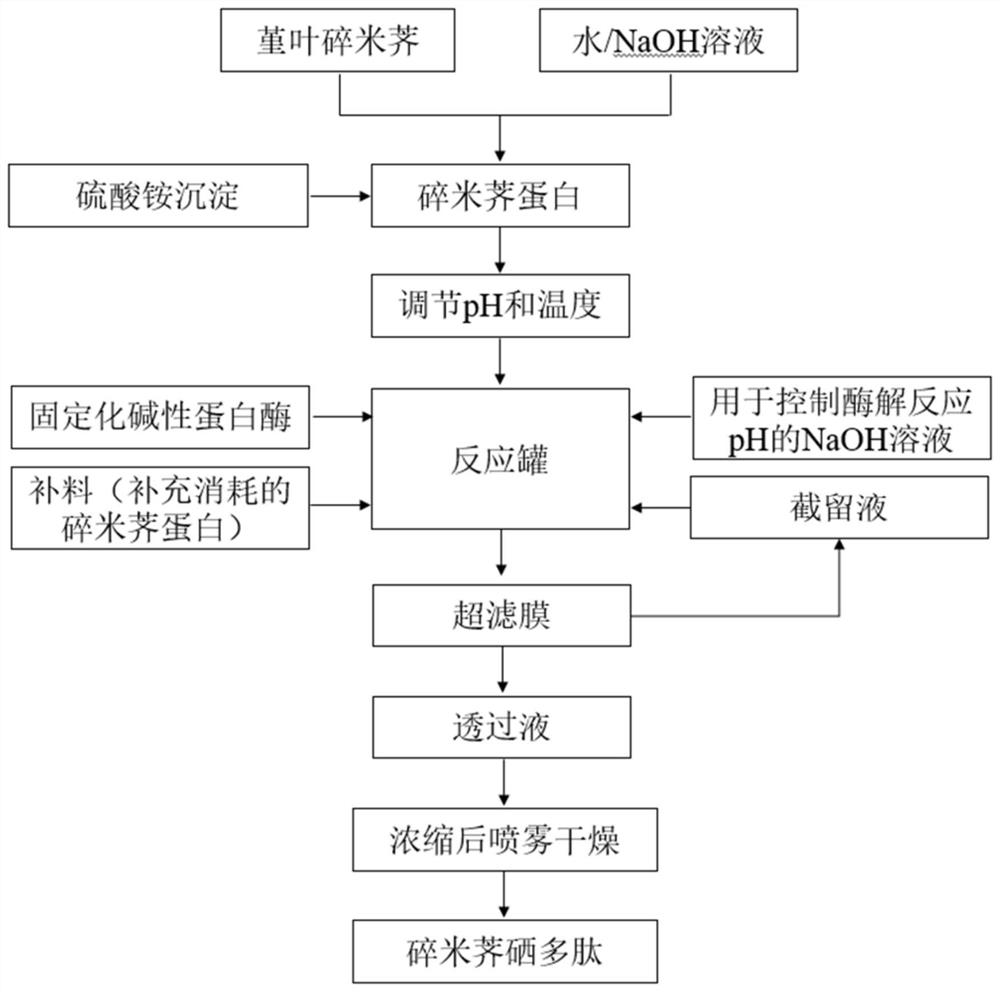

PendingCN112458140AImprove stabilityEasy to useHydrolasesPeptide preparation methodsHydrolysateEnzyme membrane

The invention belongs to the field of peptide preparation, and particularly relates to a method for preparing cardamine selenium polypeptide through continuous enzymolysis and the cardamine selenium polypeptide. The method comprises the following steps of: preparing cardamine protein powder; constructing immobilized enzyme; performing pre-enzymolysis; performing ultrafiltration and material supplementation; concentrating and drying. The method integrates reaction, product separation and enzyme recycling, and can realize continuous operation. According to the method, substrate protein is subjected to continuous enzymolysis through an immobilized enzyme membrane reactor, so that a reaction product can be selectively removed, the product inhibition phenomenon is reduced, and the reaction rateand the substrate conversion rate are increased; through the selectivity of a membrane, the molecular weight of a hydrolysate can be controlled; the molecular weight of the cardamine selenium polypeptide obtained by the method is intensively distributed at 300-3,000Da, and the DH (degree of hydrolysis) can reach about 27 percent and is increased by 8.4 percent compared with the DH value of the conventional intermittent enzymolysis.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Production method for pullulan based on cell metabolism regulation strategies

ActiveCN103805651AImprove permeabilityReduce feedback inhibitionMicroorganism based processesFermentationBiotechnologyPullulan

Owner:SHANDONG FREDA BIOTECH

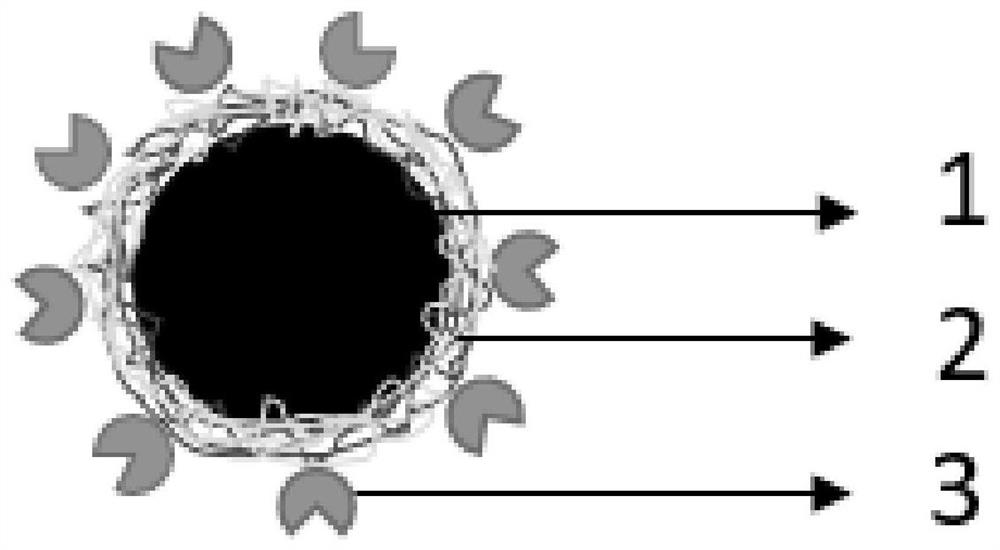

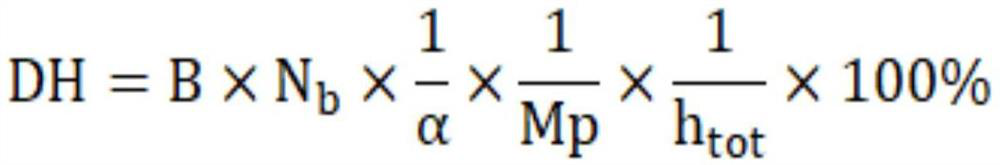

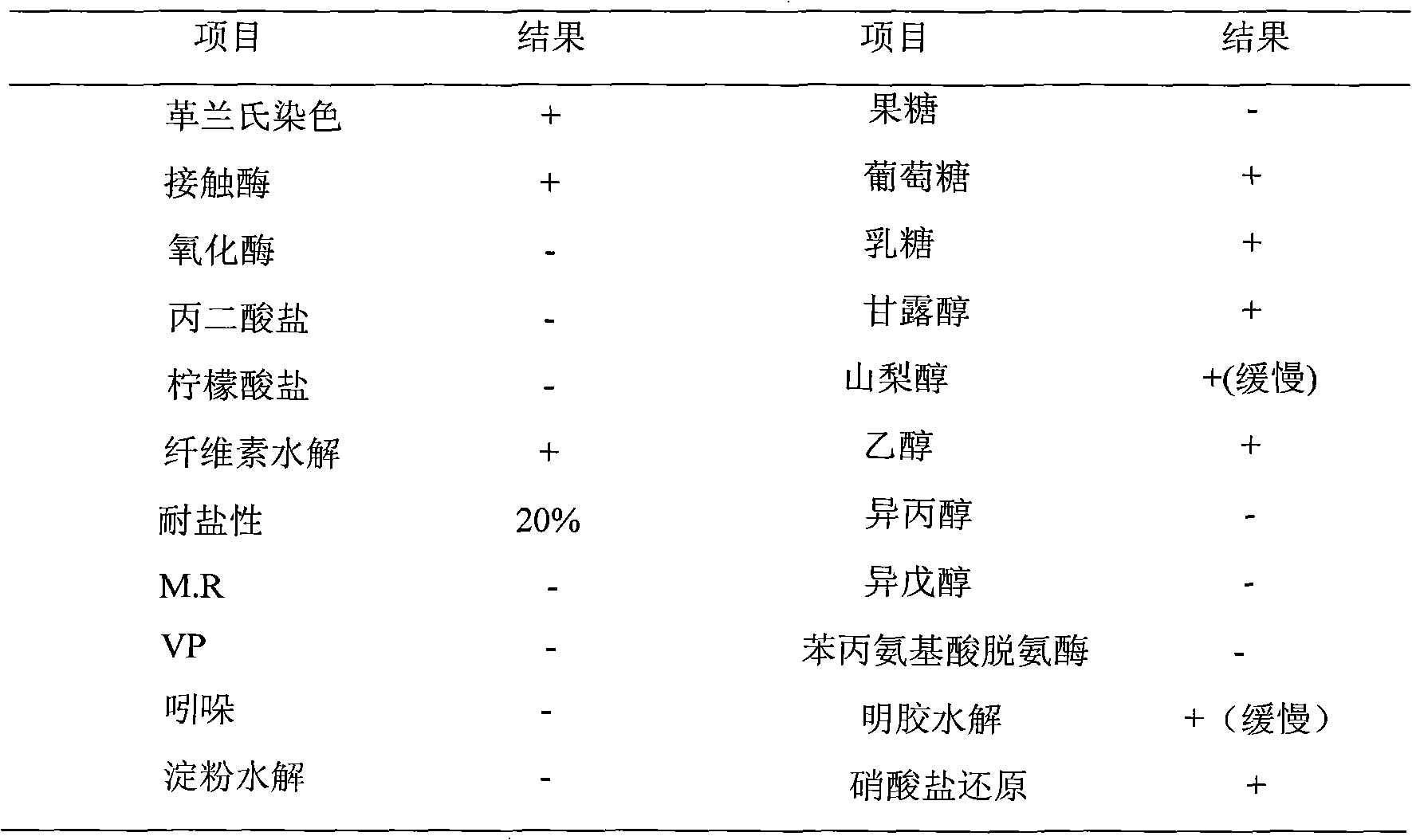

Isoptericola halotolerans capable of highly producing alginate lyase and application method for isoptericola halotolerans

ActiveCN102433274AIncrease vitalityHigh substrate conversion rateBacteriaMicroorganism based processesMicroorganismBiotechnology

The invention belongs to the technical field of biology, and particularly relates to isoptericola halotolerans WX capable of highly producing alginate lyase and an application method for the isoptericola halotolerans WX. The isoptericola halotolerans WX capable of highly producing the alginate lyase is obtained through screening for the first time; and the strain WX is identified as the isoptericola halotolerans according to morphological characteristics and physiological-biochemical characteristics. The strain was collected in China General Microbiological Culture Collection Center on October 12th, 2011, and the collection number of the strain is CGMCC No.5336. The strain can produce the alginate lyase to degrade sodium alginate so as to produce alginate oligosaccharide, and the enzymatic activity can reach 432U / ml. The alginate lyase produced by the strain can efficiently degrade algin so as to produce the alginate oligosaccharide which has multiple bioactivities.

Owner:JIANGNAN UNIV +1

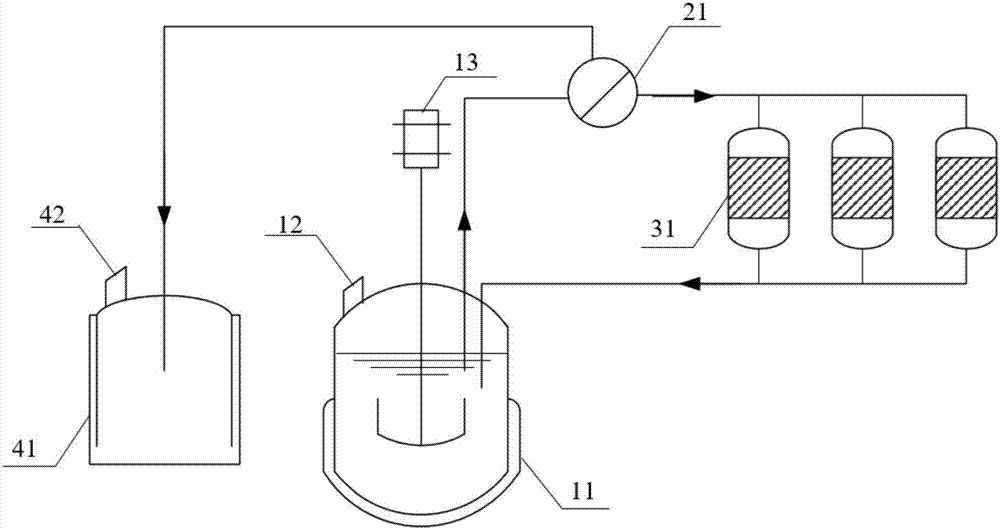

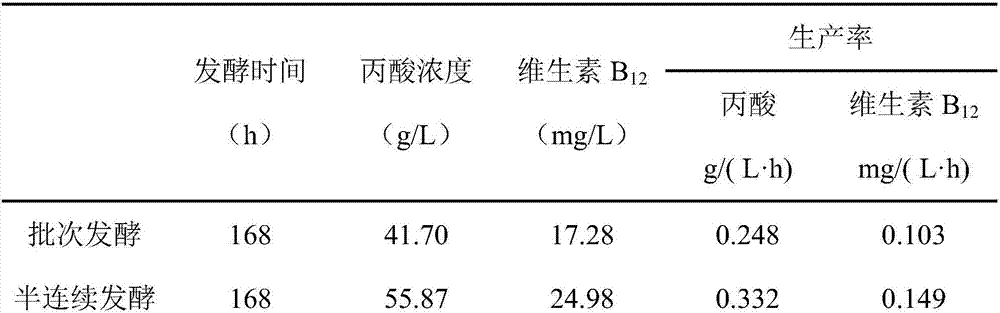

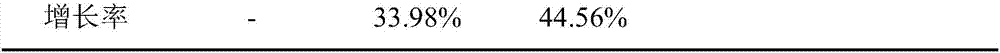

Device and method for producing propionic acid and coproduced vitamin B12 by means of semi-continuous fermentation

ActiveCN106916729AImprove conversion rateRealize joint productionBioreactor/fermenter combinationsBiological substance pretreatmentsRefluxPropanoic acid

The invention provides a device and a method for producing propionic acid and coproduced vitamin B12 by means of semi-continuous fermentation. The device comprises a fermentation unit, a membrane separation unit, a propionic acid separation unit and a vitamin B12 conversion unit, wherein a discharge hole of the fermentation unit is connected with a feeding hole of the propionic acid separation unit and a feeding hole of the vitamin B12 conversion unit by the membrane separation unit; a discharge hole of the propionic acid separation unit is connected with a reflux inlet of the fermentation unit; the membrane separation unit comprises a membrane separation device; the membrane separation device comprises a membrane core; the aperture of the membrane core is 0.1-0.22mu m. The method and the device not only effectively overcomes the feedback inhibition action of the propionic acid for fermentation, but also overcomes the disadvantages that an expanded bed is low in filling efficiency and difficult to enlarge, solves the problem that the addition of DMB has adverse effects on resource utilization of fermentation wastewater, and realizes the cyclic utilization of the fermentation wastewater.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Radioactivity resistant anomalous coccus trehalose synthase gene and trehalose making method

InactiveCN1570098AEnhanced inhibitory effectSignificant progressBacteriaIsomerasesSynechococcusFood industry

The invention relates to gene cloning of wholly new fucose synthetase and its expression in related host. The enzyme gene is cloned from Deinococcus radioduran, which can transform the malt to fucose under normal biochemical conditions. The substrate conversion rate rises while the reaction temperature reduces. The fucose can be used in food industry, sea product cold storage and pharmaceutical activity preserving.

Owner:南宁中诺生物工程有限责任公司

A strain of Bacillus producing alginate lyase and its application

ActiveCN104195080BIncrease enzyme activitySimple nutritional requirementsBacteriaMicroorganism based processesSpecific enzymeCentrifugation

The invention provides Bacillus sp Alg07 capable of producing an alginate lyase. The preservation number of the Bacillus sp Alg07 is CGMCC No.9391. The Bacillus sp Alg07 provided by the invention has the advantages that requirement on nutrition is low and fermentation time is short; a crude enzyme is easily prepared, and the crude enzyme can be obtained through centrifugation; the alginate lyase produced by the Bacillus sp Alg07 has high enzyme activity, the specific enzyme activity of an unpurified crude enzyme can reach 20000-40000 U / mg (563U / mL); the alginate lyase produced by the Bacillus sp Alg07 has good stability, is not obviously changed in enzyme activity after being preserved at 40 DEG C for 24 hours and is high and stable in enzyme activity at pH of 5.5-8.5; and the produced alginate lyase is capable of degrading sodium alginate to generate alginate-derived oligosaccharide with biological activity.

Owner:TIANJIN INST OF IND BIOTECH CHINESE ACADEMY OF SCI

Method for synthesizing NADPH through immobilized enzyme catalysis

ActiveCN107557412ASimple production processShorten the production cycleImmobilised enzymesFermentationDivalent metal ionsEnzyme catalysis

The invention discloses a method for synthesizing NADPH through immobilized enzyme catalysis. The method comprises the following steps: (1) in the presence of divalent metal ions, preparing a first reaction liquid by taking NAD and metaphosphate as substrates, adding immobilized NAD kinase into the first reaction liquid, and performing catalyzing synthesis of NADP; and (2) removing immobilized NADkinase in the first reaction liquid, continuously adding glucose for preparing a second reaction liquid, adding immobilized glucose dehydrogenase into the second reaction liquid, and performing catalyzing synthesis of NADPH. The method disclosed by the invention realizes that NADPH is synthesized through continuous reaction, production technology is simple, production period is short, productioncost is low, and product quality is more stable; besides, the immobilized enzyme catalysis is adopted for preparing NADPH, an immobilized enzyme can be continuously and repeatedly used, the productioncost is further reduced, introduction of protein impurities into a product is avoided, and NADPH can be beneficially produced with high purity and high yield when the immobilized enzyme is applied tothe method.

Owner:山东蓝康药业有限公司

Immobilized yeast continuous fermentation technology

The invention discloses an immobilized yeast continuous fermentation technology. The technology comprises the following steps: a fiber material is fixed in a spherical grid as an immobilization medium, and at the same time, the immobilized medium is filled in 1-5 fermentation cylinders in series connection, and the yeast is fixed on a fiber carrier by adsorption effects and fermented. The immobilized yeast is stably and continuously fermented by switching the fermentation cylinder sequence, in order to maintain activity of the immobilized yeast in the terminal fermentation cylinders. The immobilization method has the advantages of low input cost, convenient operation, stable process, good adsorption effect, and long-lasting and high activity of the immobilized yeast.

Owner:NANJING HIGH TECH UNIV BIOLOGICAL TECH RES INST CO LTD

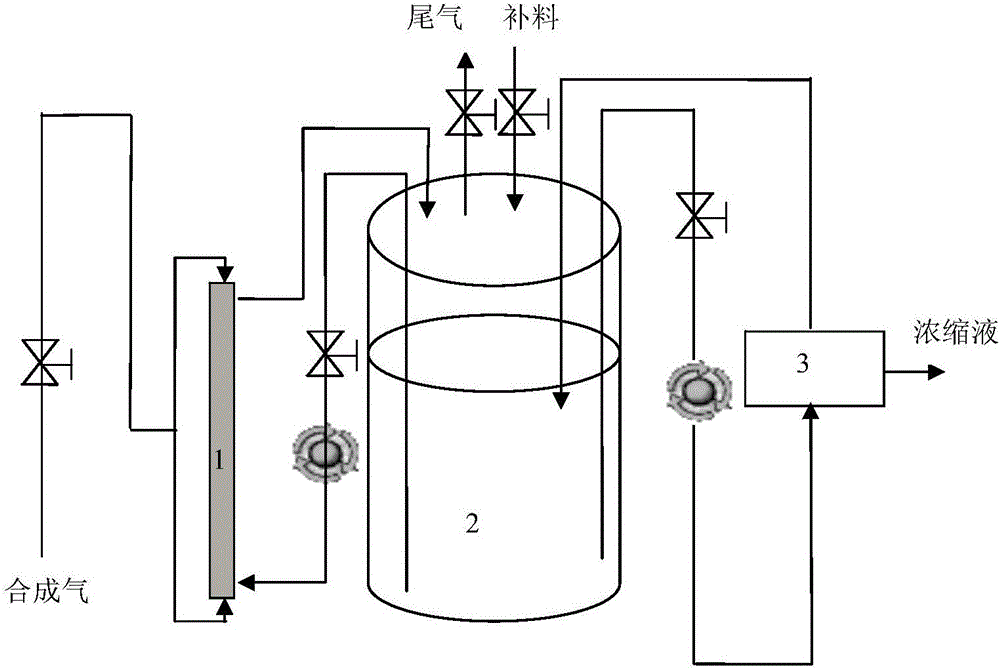

System for fermenting synthesis gas to produce alcohol and processing method thereof

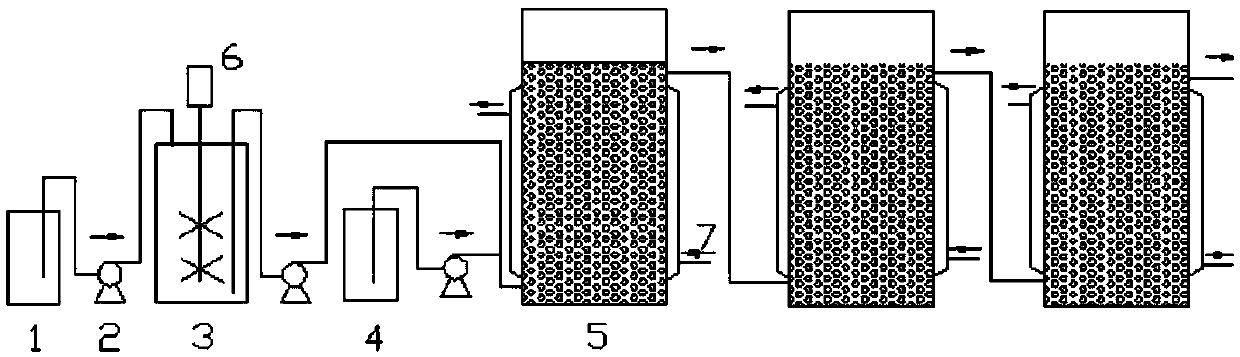

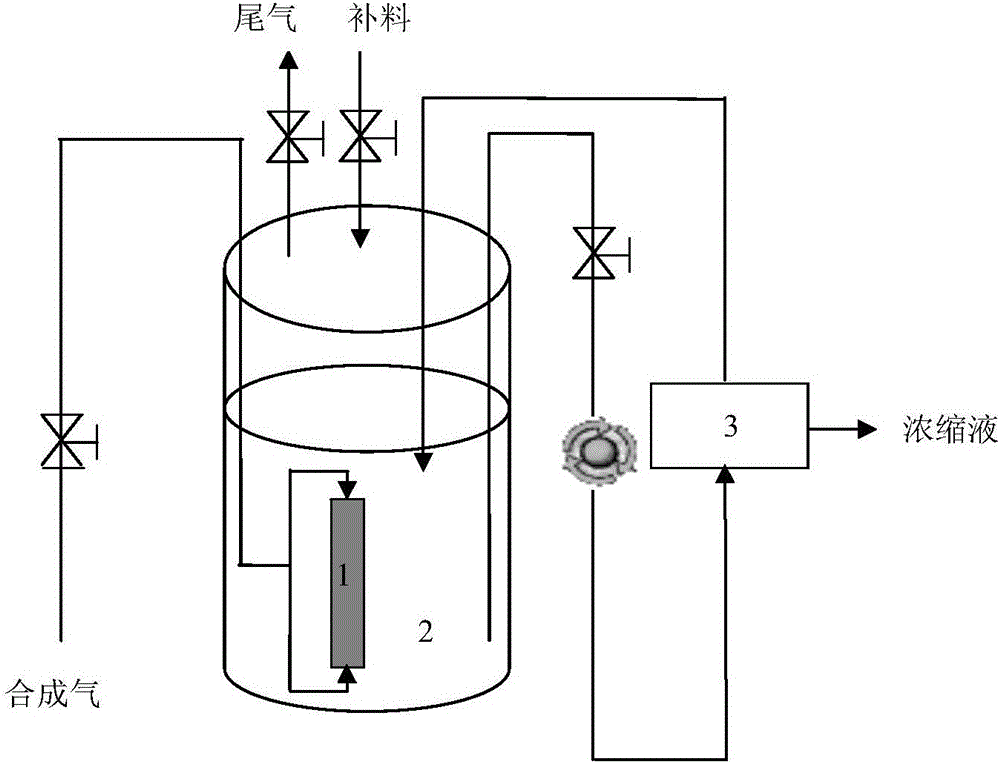

InactiveCN106754259AIncrease membrane areaLower the air supply unitBioreactor/fermenter combinationsBiological substance pretreatmentsAlcoholMembrane technology

The invention provides a system for fermenting synthesis gas to produce alcohol and processing method thereof. The system comprises a bubble-free gas supply membrane component, a bioreactor and a pervaporation membrane component, wherein the bubble-free gas supply membrane component is placed in or out of the bioreactor, the gas inlet of the bubble-free gas supply membrane component is connected with the synthesis gas; a fermentation liquor outlet of the bioreactor is connected with a feed port of the pervaporation membrane component, a trapped liquor outlet of the pervaporation membrane component is connected with a material inlet of the bioreactor. The system and method provided by the invention improve the gas liquor transmission efficiency, the gas utilization efficiency, the microorganism cell concentration and the product concentration in a mixed gas fermentation process by use of the bubble-free gas supply membrane technology in double-end or single-end gas inlet, and in combination with a fermentation technology in fermentation-pervaporation separation coupling; the material consumption of cell culture is lowered, the cell concentration in the fermentation process is improved, the fermentation efficiency and the product concentration are improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

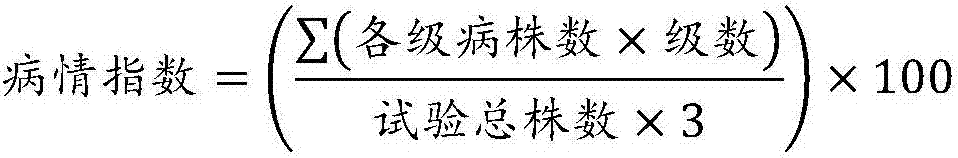

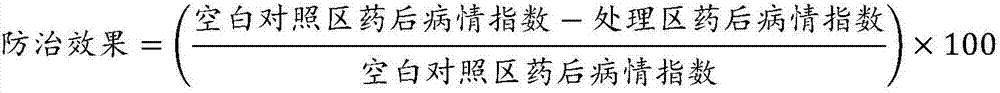

Water soluble sterilization fertilizer with amino acid and preparation method of fertilizer

InactiveCN107235769AImprove the bactericidal effectReduce the possibilityBiocideDead animal preservationInsect pestPlant disease

The invention belongs to the technical field of fertilizer processing, and particularly relates to a water soluble sterilization fertilizer with amino acid and a preparation method of the fertilizer. The water soluble fertilizer with the amino acid takes DL-pyroglutamic acid waste as a raw material, various Chinese herbal medicine components are added and suitably matched, so that the water soluble fertilizer has remarkable sterilization effect, diseases and insect pests are prevented and treated in advance when nutrient requirements of crops in the overall growth process are guaranteed, and the possibility of the diseases and insect pests of plants is remarkably reduced, used pesticides are decreased. The invention further provides a novel recycling pathway of DL-pyroglutamic acid. The produced water soluble fertilizer with the amino acid can be completely dissolved in water and used for the crops liking chlorine, calcium and magnesium fertilizers, has comprehensive nutrient elements and is particularly applicable to tomatoes, cotton, rice, wheat and corn, and the nutrient elements are easily absorbed by the crops.

Owner:峨眉山市龙腾生物科技有限公司

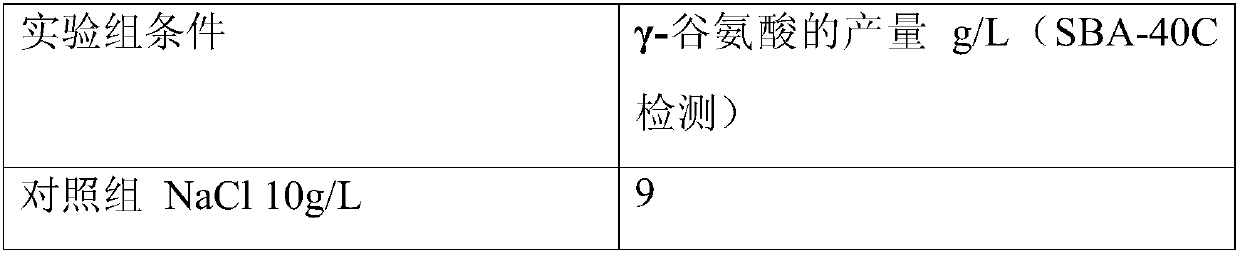

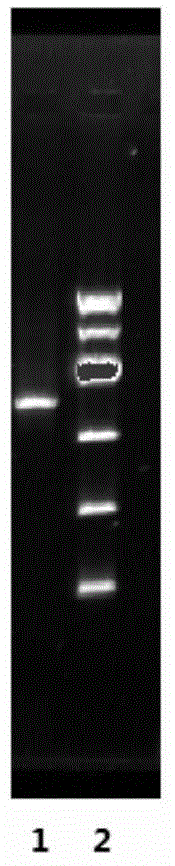

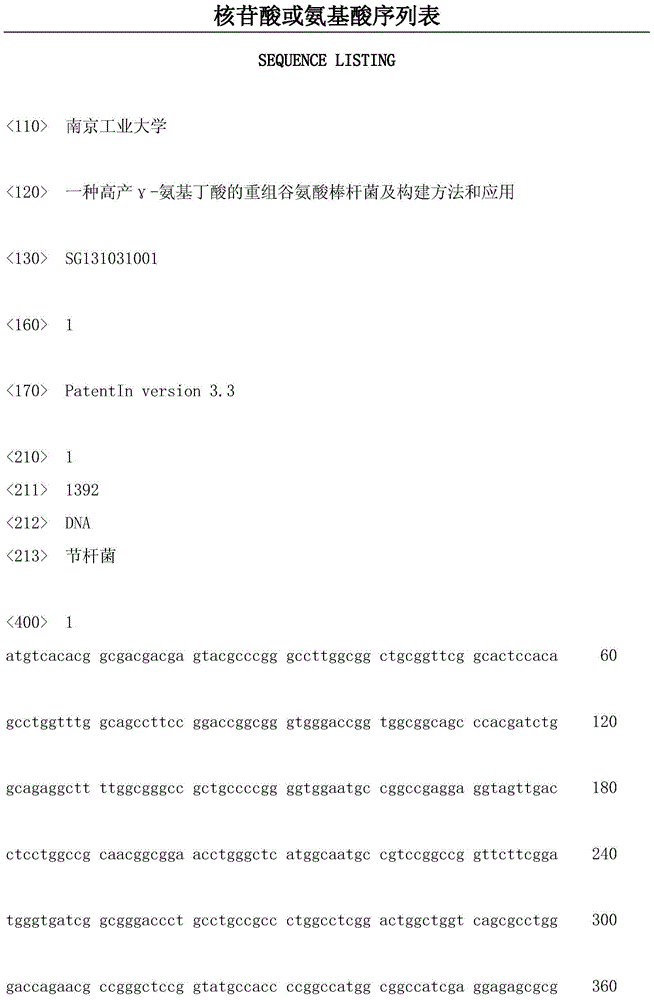

Recombinant corynebacterium glutamicum for high production of gamma-aminobutyric acid as well as construction method and application thereof

ActiveCN103555647AIncrease productionHigh substrate conversion rateBacteriaMicroorganism based processesGlutamate decarboxylaseGamma-Aminobutyric acid

The invention discloses recombinant corynebacterium glutamicum for high production of gamma-aminobutyric acid. The recombinant corynebacterium glutamicum is classified and named as corynebacterium glutamicum NJ-M6 and is collected at the China Center for Type Culture Collection (CCTCC) with the collection number of CCTCC No. M2013486 on October 22, 2013. Corynebacterium glutamicum of a glutamate decarboxylas gene derived from arthrobacterium is guided into the recombinant corynebacterium glutamicum. The invention also discloses a construction method and an application of the recombinant corynebacterium glutamicum. By the method, the concentration of gamma-aminobutyric acid in feed-batch fermentation liquid can reach 36.1g / L, while C. glutamicum CICC10240 basically does not produce gamma-aminobutyric acid under the same culture condition.

Owner:NANJING UNIV OF TECH

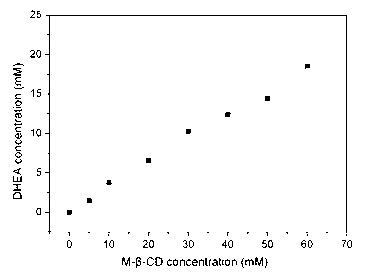

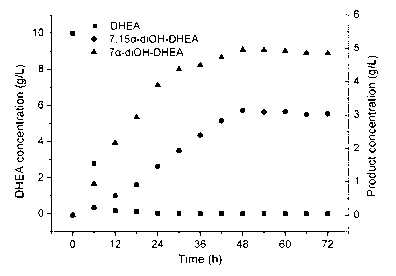

Method for hydroxylating dehydroisoandrosterone by using colletotrichumlini

ActiveCN102703558AHigh feeding concentrationHigh substrate conversion rateMicroorganism based processesFermentationChemistryWater soluble

The invention relates to a method for hydroxylating dehydroisoandrosterone (DHEA) by using colletotrichumlini ST-1. The method for hydroxylating the dehydroisoandrosterone by using the colletotrichumlini ST-1 is characterized in that: in a conversion process, a way of pre-including the DHEA and methyl-beta-cyclodextrin with an equimolar ratio first and then feeding is adopted, so that the water solubility and the conversion efficiency of the DHEA are significantly improved. Under a condition that a substrate feeding amount is 10g / L, the conversion rate is as high as 95% and the total yield of products 7 alpha-OH-dehydroepiandrosterone and 7,15 alpha-OH-dehydroepiandrosterone is 80.94%.

Owner:ZHEJIANG XIANJU JUNYE PHARM CO LTD +1

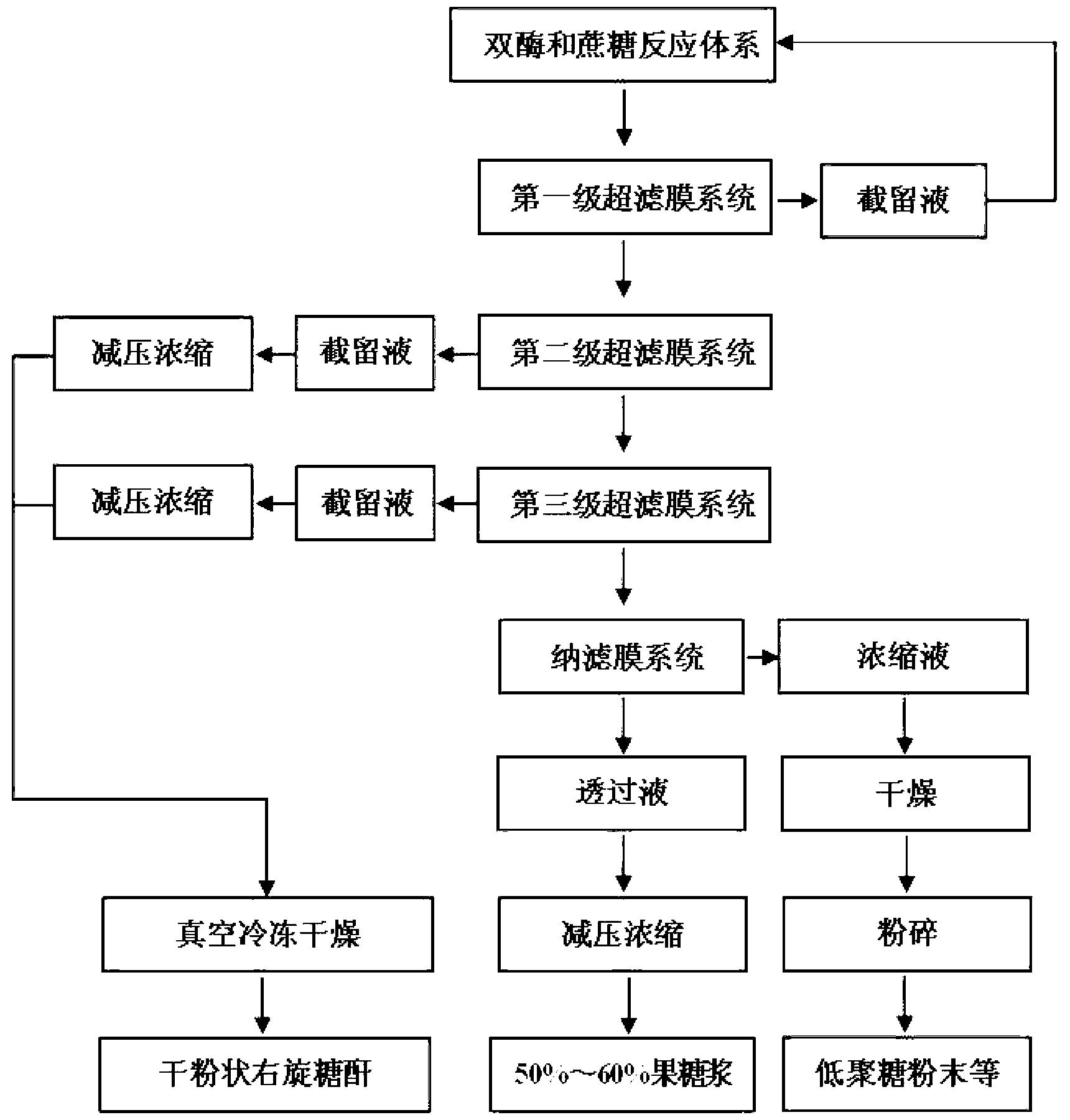

Method for preparing pharmaceutical dextran and levulose by bi-enzyme coupled multistage membrane separation

InactiveCN103266149AHigh substrate conversion rateFacilitate industrial promotion and applicationFructose productionFermentationSucrose solutionNanofiltration

The invention discloses a method for preparing pharmaceutical dextran and levulose by bi-enzyme coupled multistage membrane separation, which comprises the following steps: simultaneously adding dextran sucrase and dextranase into a sucrose solution used as a substrate to form a bi-enzyme / sucrose reaction system; and after the reaction product is separated by a multistage membrane system composed of hyperfiltration membranes and a nanofiltration membranes, directly obtaining the pharmaceutical dextran in the hyperfiltration membrane separation stage, and obtaining the high-purity levulose solution in the last nanofiltration membrane separation stage, wherein the enzymes and macromolecular dextran contained in the trapped solution of the first-stage hyperfiltration membrane return to the bi-enzyme / sucrose reaction system to participate in the reaction again, thereby implementing cyclic utilization of the enzymes. The invention has the advantages of lower cost, environment friendliness, high safety and high efficiency, is simple to operate, implements oriented adjustable production of high-quality pharmaceutical dextran with target molecular weight, and obtains the high-purity high-added-value levulose byproduct.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION CENT FOR ANALYSIS & TEST RES

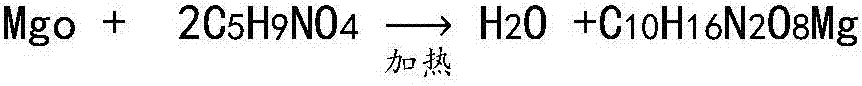

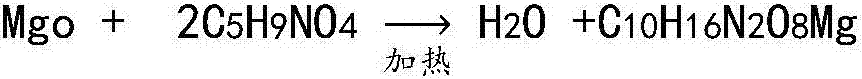

Method for producing amino-acid-containing water-soluble fertilizer

InactiveCN107417368APromote absorptionImprove absorption rateCalcareous fertilisersMagnesium fertilisersHydrolysateNutrient

The invention belongs to the technical field of fertilizer processing and in particular relates to a method for producing an amino-acid-containing water-soluble fertilizer. The method comprises the following steps: carrying out a hydrolysis reaction between DL-pyroglutamic acid and hydrochloric acid so as to produce hydrolysate containing glutamic acid; and adding magnesium oxide and calcium oxide for chelating and filtering, thereby obtaining the amino-acid-containing water-soluble fertilizer. According to the method disclosed by the invention, the amino-acid-containing water-soluble fertilizer is produced by taking the DL-pyroglutamic acid wastes as raw materials, a novel DL-pyroglutamic acid recycling pathway is provided, and the produced amino-acid-containing water-soluble fertilizer is a fertilizer which can be completely dissolved in water. The amino-acid-containing water-soluble fertilizer is comprehensive in nutrient elements and capable of being easily absorbed by crops, has the utilization rate of 90% or higher, can be widely applied to facility agriculture and green agriculture, and has significance on developing high-efficiency water-saving modern agriculture and promoting a water-fertilizer integrated technology.

Owner:峨眉山市龙腾生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com