Method for preparing cardamine selenium polypeptide through continuous enzymolysis and cardamine selenium polypeptide

A technology of broken rice and enzymatic hydrolysis is applied in the field of continuous enzymatic hydrolysis to prepare broken rice selenium polypeptide and broken rice selenium polypeptide, which can solve the problems of non-reusable enzymes, high production cost, low production efficiency, etc. stability and reusability, improve stability, and achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

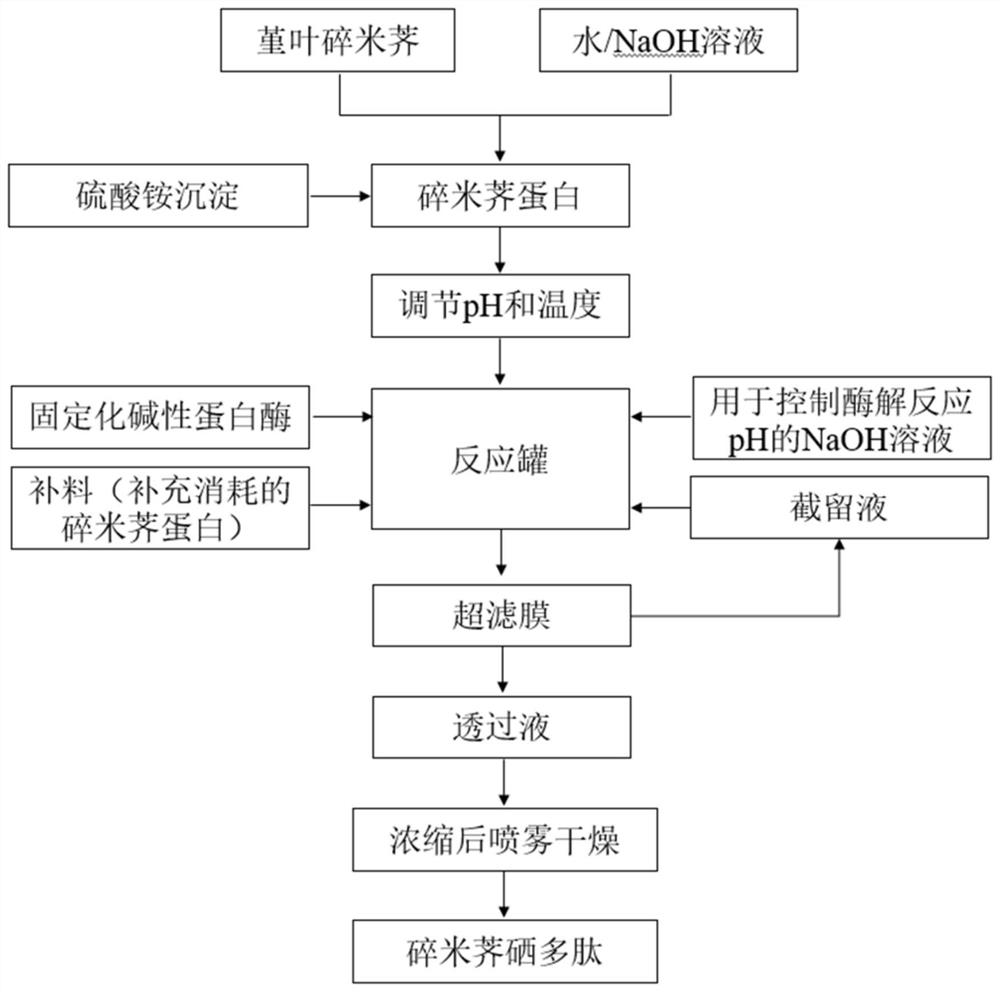

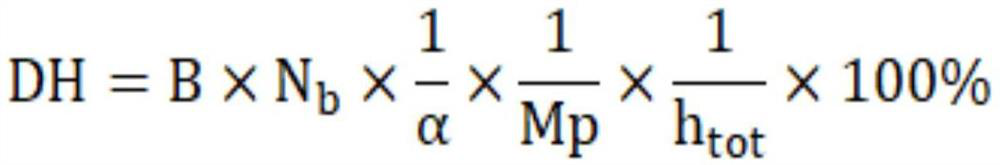

[0059] This example provides a method for continuous enzymatic hydrolysis to prepare selenopolypeptides from the broken rice chestnut, see figure 1 Process flow chart, the steps are as follows:

[0060] (1) Preparation of broken rice chestnut protein: use a high-speed multifunctional grinder to crush the dried rice chestnut, pass through an 80-mesh sieve, and use deionized water and 0.1mol / L NaOH solution successively according to the mass ratio of material to liquid: 1g: 40mL Extracted separately for 8 hours, combined the extracts to obtain the protein liquid of broken rice chestnut, added ammonium sulfate to the protein liquid of broken rice chestnut to a saturation of 60%, redissolved the precipitate after centrifugation with deionized water, and carried out in a 3500Da dialysis bag After dialysis, the dialysate was freeze-dried to obtain the broken orina protein powder.

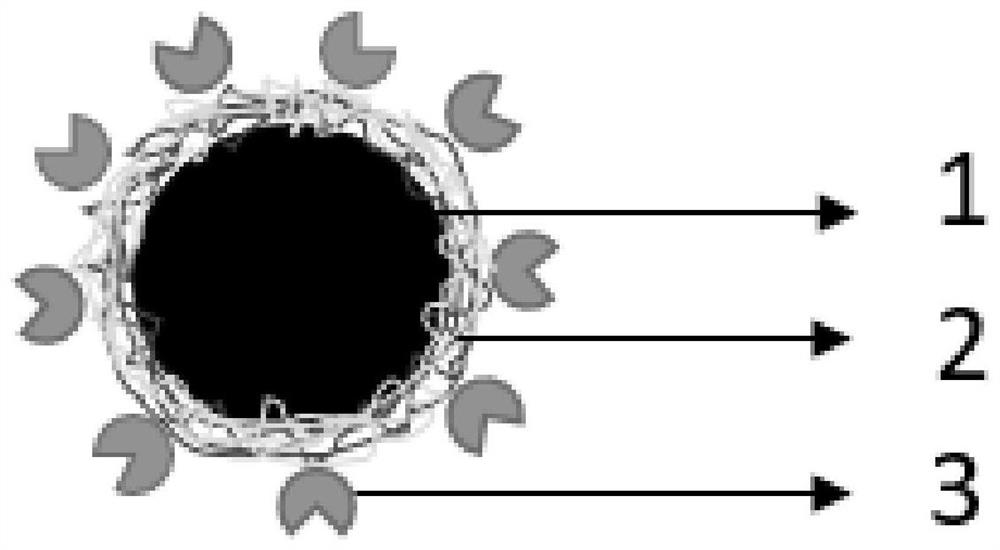

[0061] (2) Construction of immobilized enzyme: Dissolve tannic acid in 10mM Tris-HCl buffer solution ...

Embodiment 2

[0066] The difference with embodiment 1 is:

[0067] In step (2), place the above-mentioned substrate with a fixed coating in an alkaline protease solution of 1 g / L at room temperature and stir at 150 rpm / min for 12 h, then rinse with deionized water;

[0068] In step (3), the pH value is adjusted to 9 with NaOH solution.

Embodiment 3

[0070] The difference with embodiment 1 is:

[0071] In step (2), the above-mentioned matrix with fixed coating is placed in the alkaline protease solution of 1g / L (pH=9.010Mm boric acid buffer solution)

[0072] In step (3), the temperature is heated to 40°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com