Patents

Literature

141 results about "Enzyme membrane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A synthetic DNA enzyme inserts into a cell membrane, causing lipids to shuffle between the inner and outer membrane layers. A new synthetic enzyme, crafted from DNA rather than protein, flips lipid molecules within the cell membrane, triggering a signal pathway that could be harnessed to induce cell death in cancer cells.

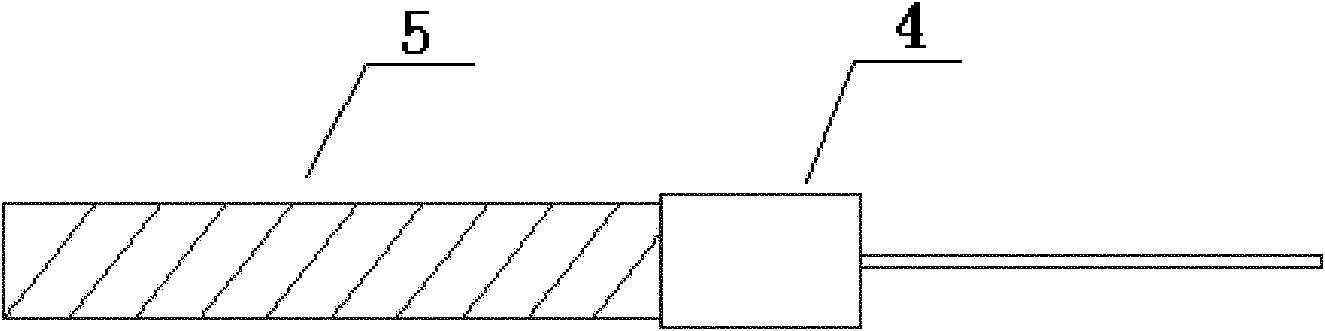

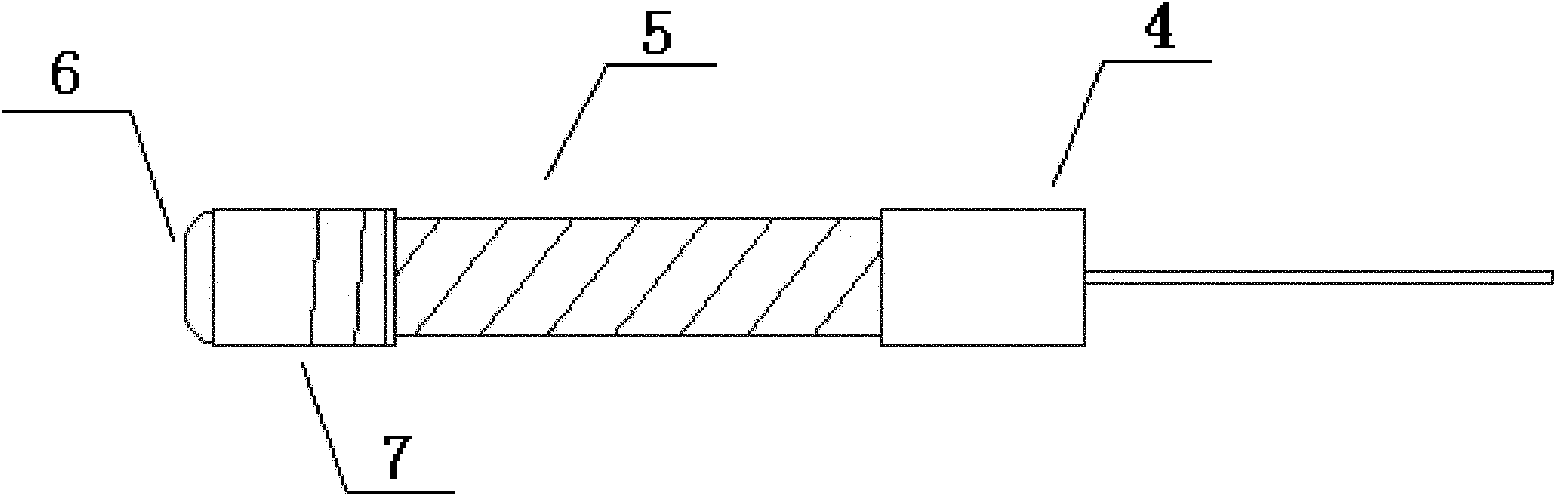

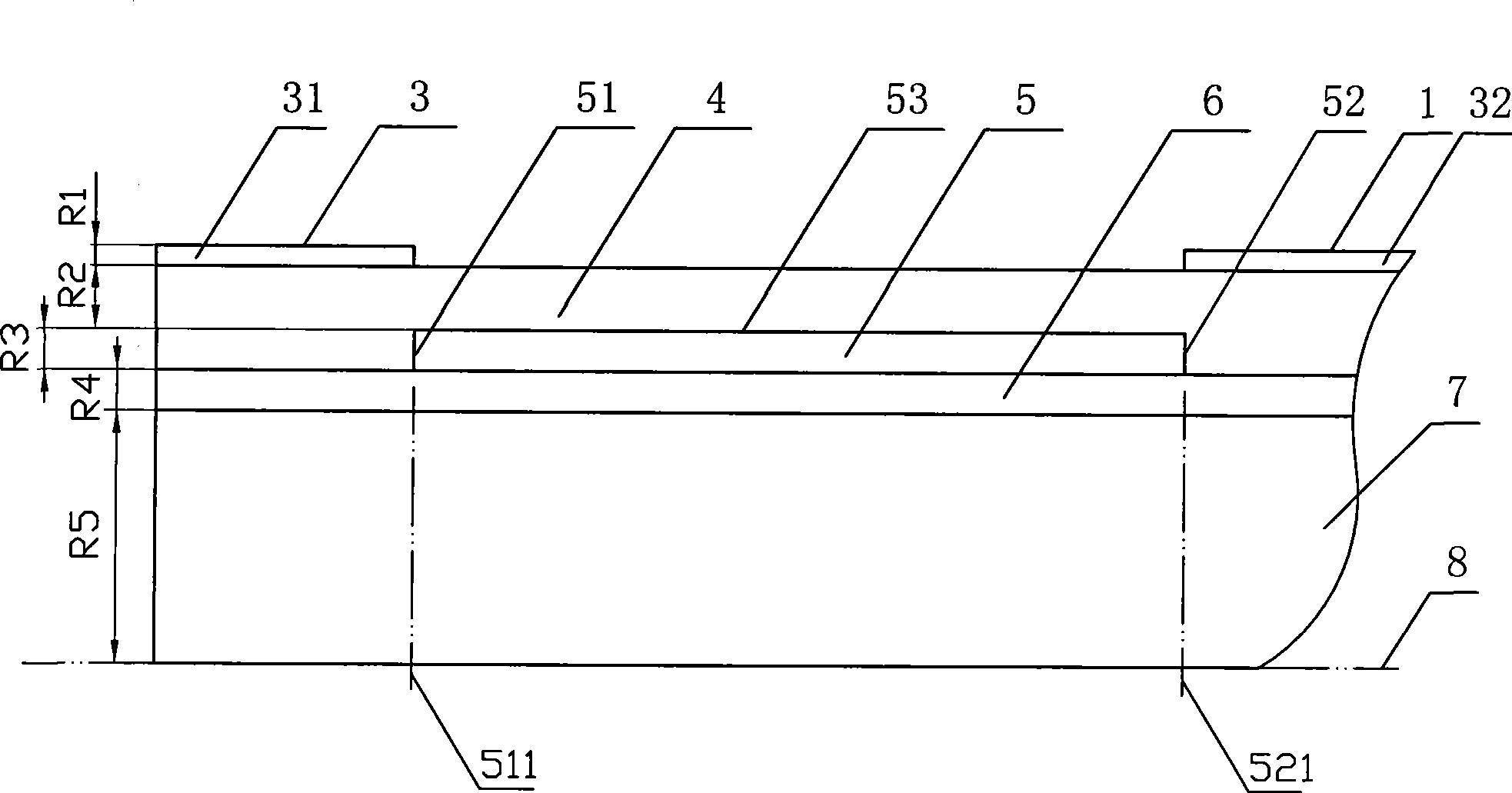

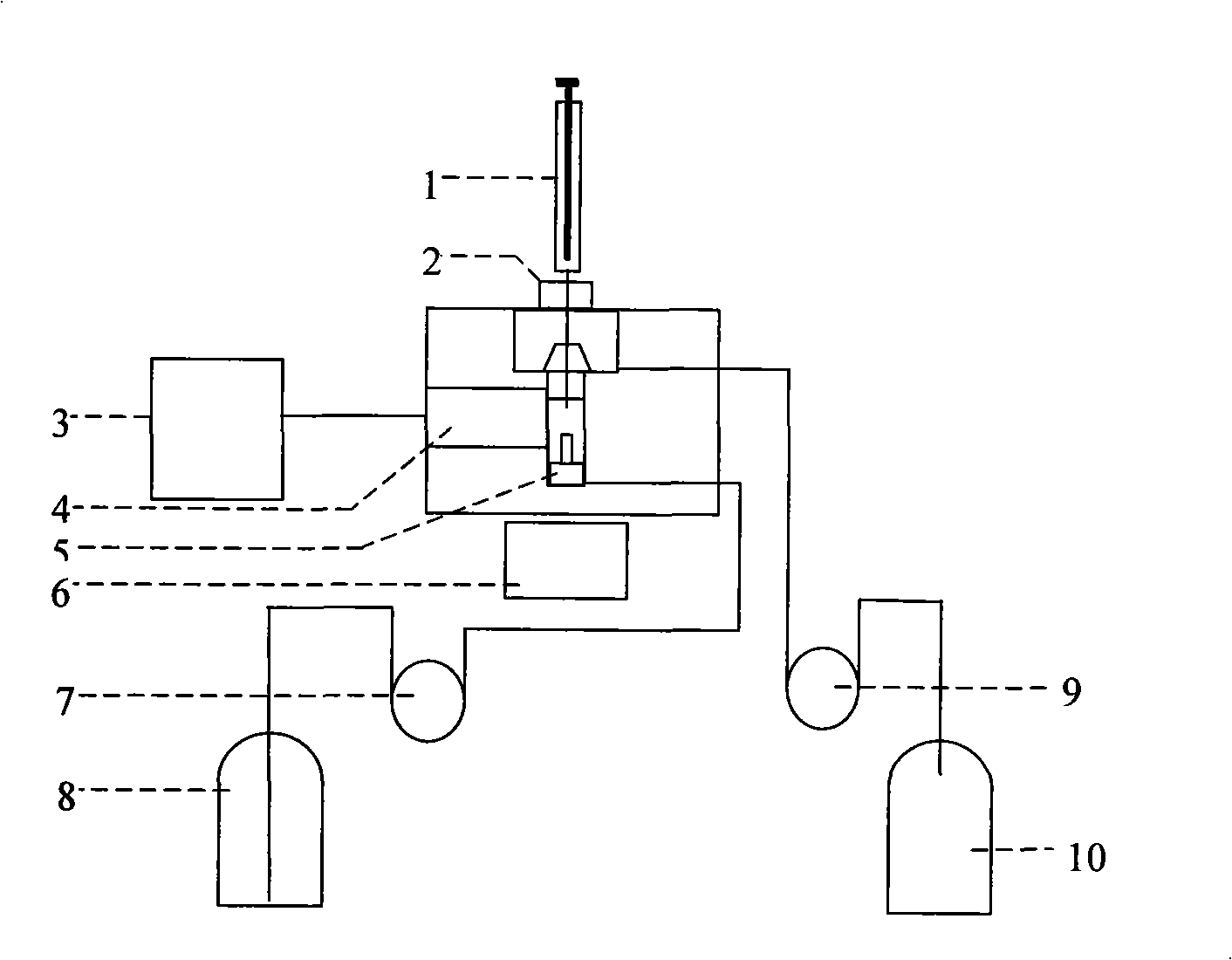

Needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof

ActiveCN101530327AShort response timeStable jobDiagnostic recording/measuringSensorsGlucose sensorsConcentrations glucose

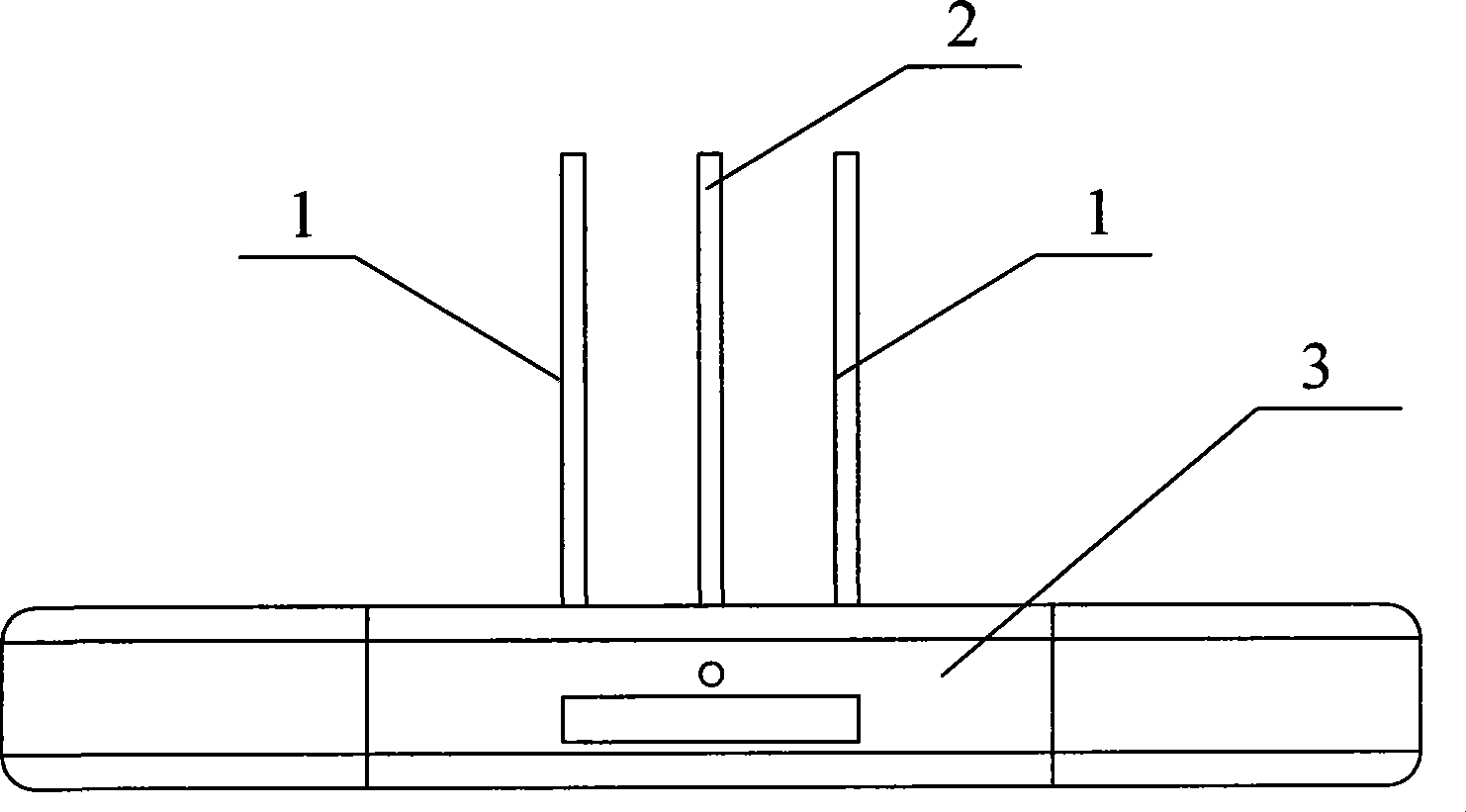

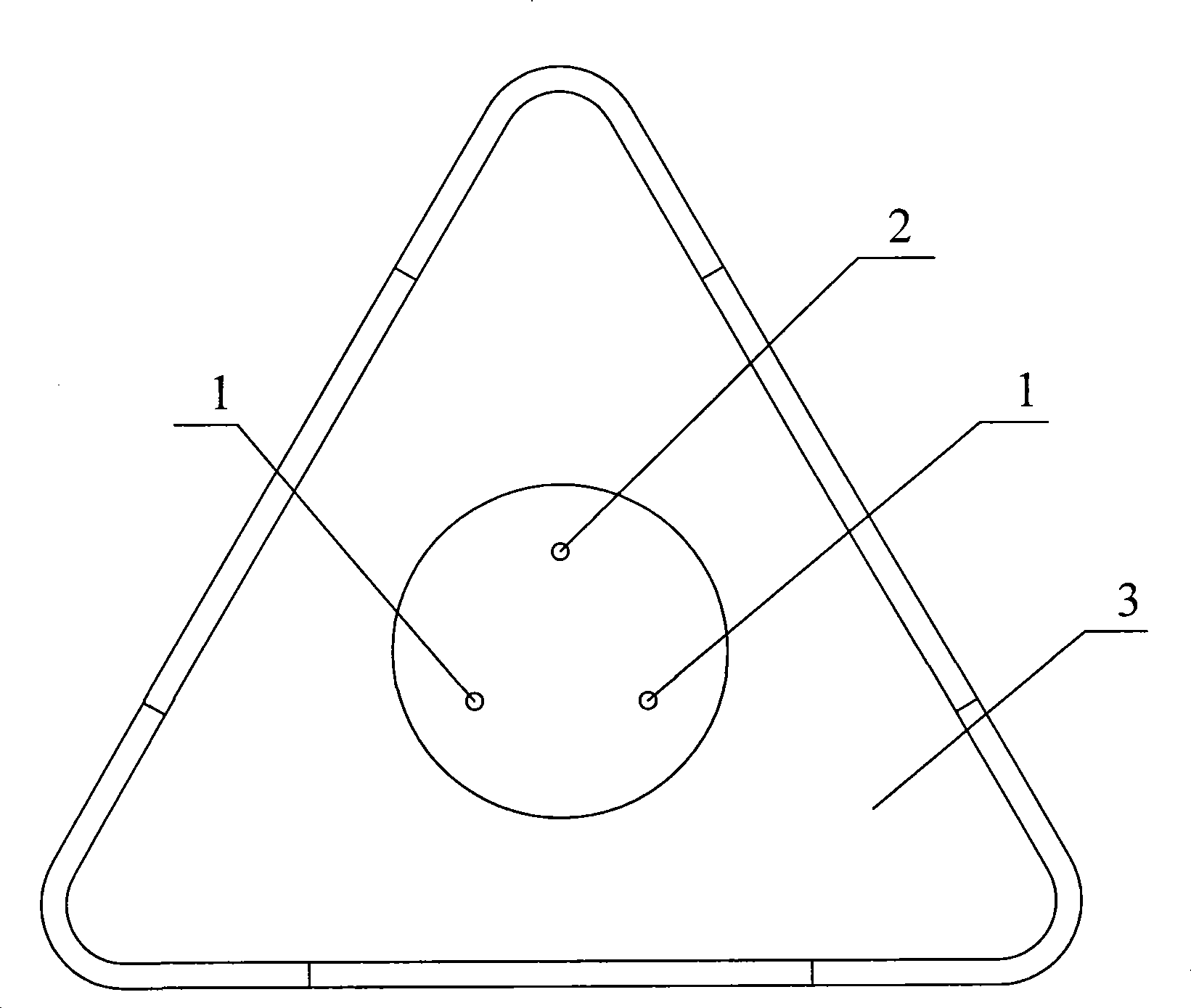

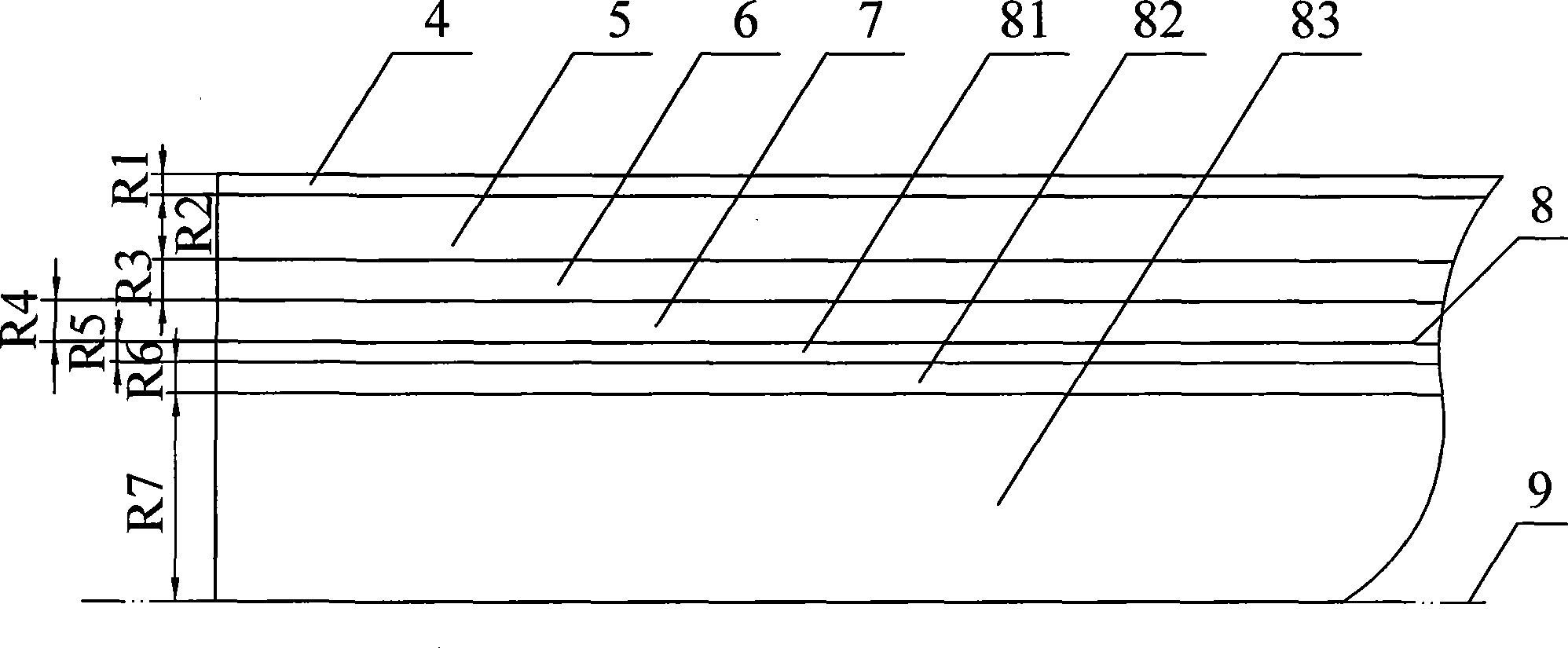

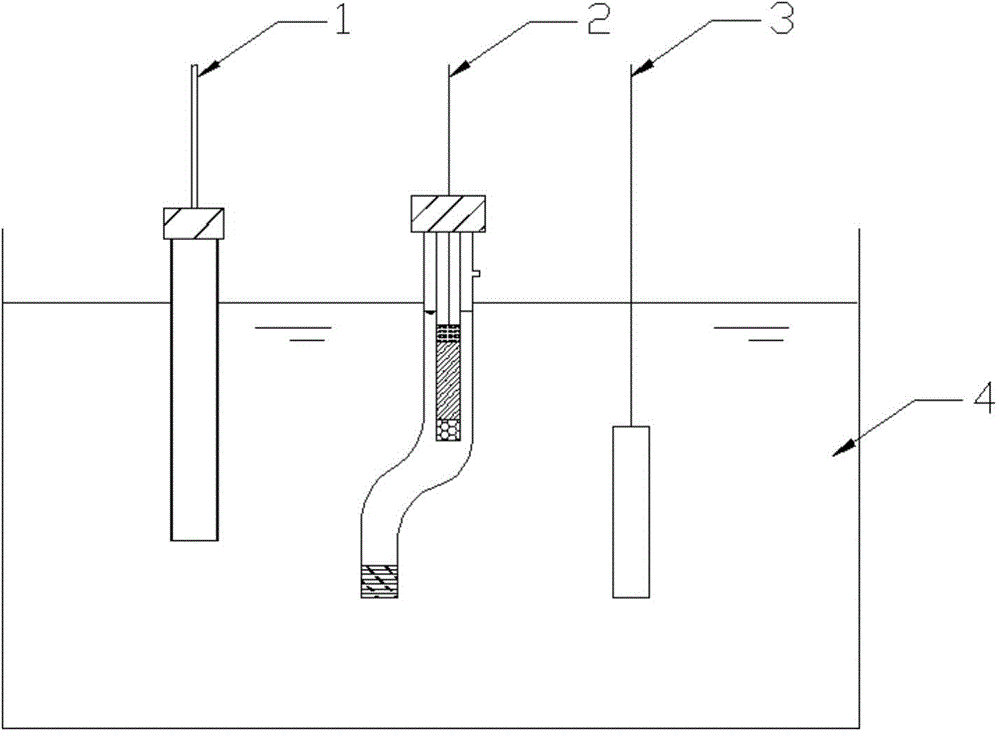

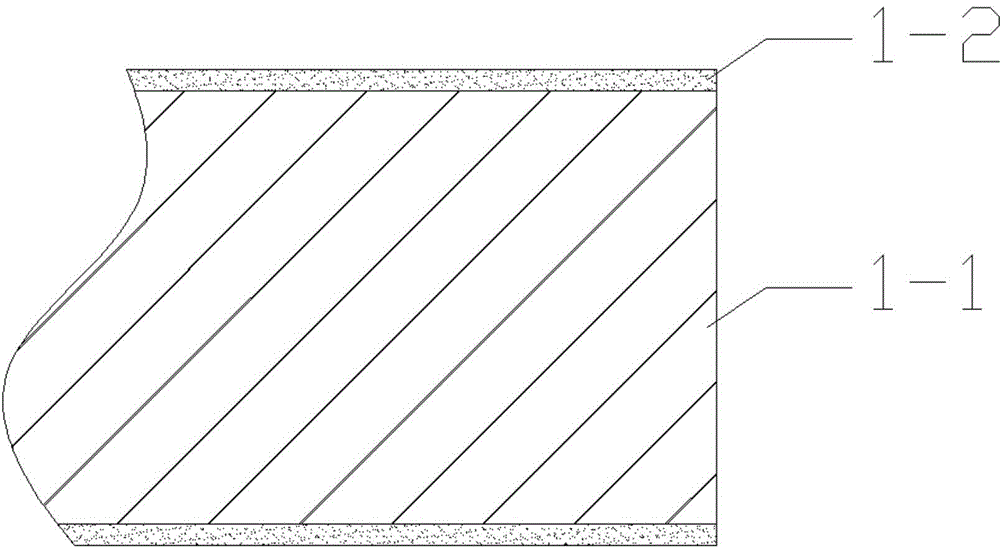

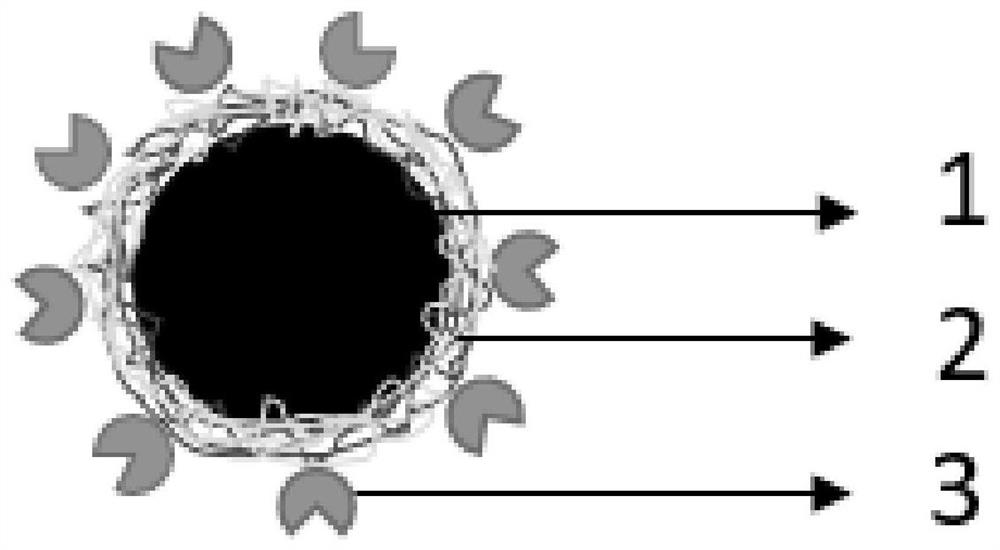

The invention discloses a needle amperometric determination type glucose sensor for subcutaneous tissue real-time monitoring and manufacturing method thereof. The sensor comprises a needle reference electrode (2) and at least one needle working electrode (1) including a conducting layer (8) and an enzyme membrane layer (6), and is characterized in that the working electrode (1) further comprises a polymer material inner membrane layer (7) and a polymer material control diffusion layer (5), and the conducting layer (8), the polymer material inner membrane layer (7), the enzyme membrane layer (6) and the polymer material control diffusion layer (5) are coated in turn from inner to outside. According to the manufacturing method in the invention, the glucose sensor has good stability, high flexibility, wide linear range of output current and glucose concentration, short response time, continuous real-time monitoring, good fastness and stability of enzyme bonding, high flexibility, selectivity and repeatability.

Owner:HUZHOU MEIQI MEDICAL EQUIP CO LTD

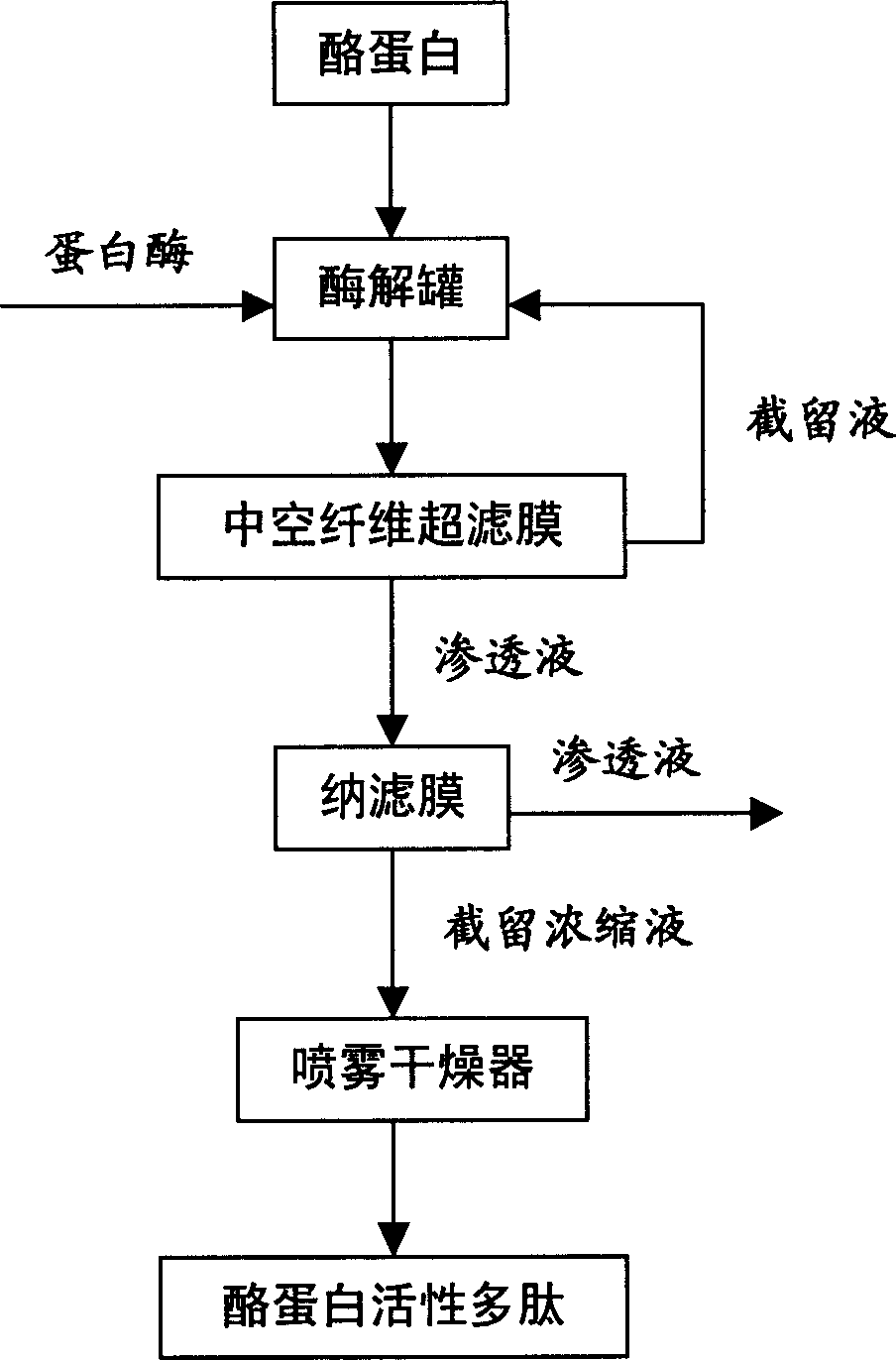

Process of continuous production of casein bioactive peptide by enzymolysis and filtering membrane concentration

The invention relates to a process of continuous production of casein bioactive peptide by enzymolysis and filtering membrane concentration which comprises, using caseinum as raw material and at least one prolease action, obtaining biologically active polypeptides having multiple functions in multi-stage enzyme membrane reactor combined from enzymolysis tank and hyperfiltration, nano filter membrane of dissimilar entrapment molecular weight.

Owner:TIANJIN UNIV

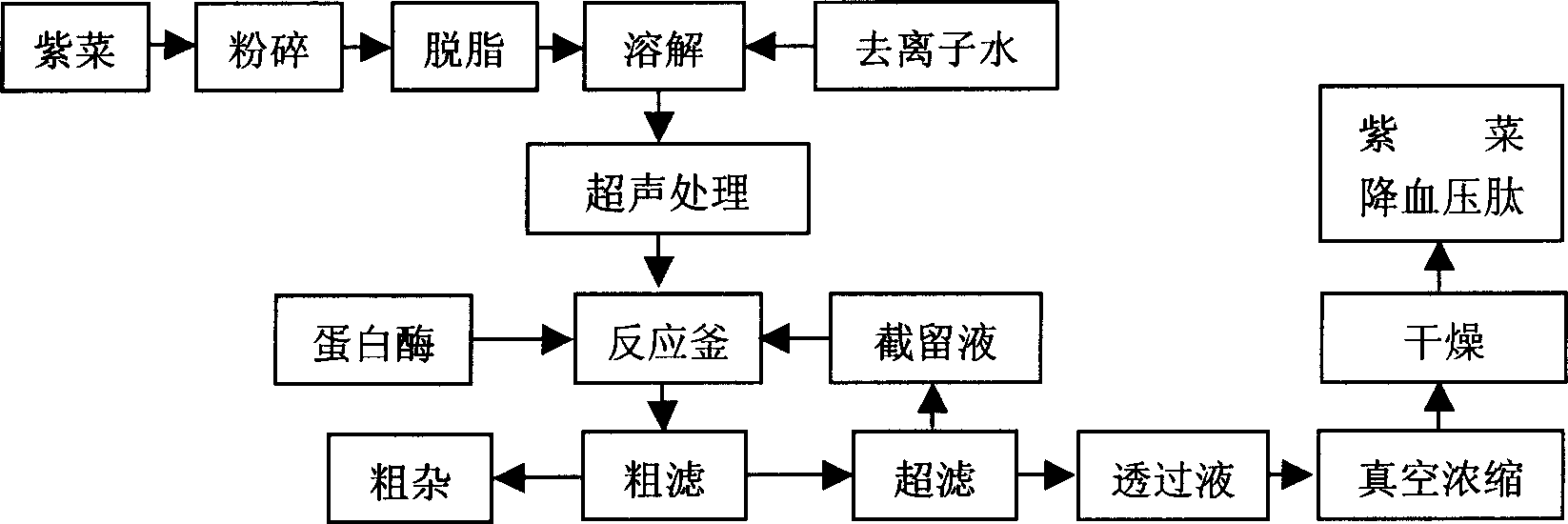

Method for preparing peptide of decrease blood pressure in laver by using enzyme-membrane coupling technique and application thereof

InactiveCN1687444ARapid dissolutionQuick recyclingPeptide/protein ingredientsChemical recyclingEnzyme membraneCoupling

This invention provided a method of using enzyme-membrane coupling technology to prepare laver peptide of lowering blood pressure. It consists of the way: after the process of smashing, the degreasing, the dissolution, supersonic affects, laver solution must be extracted out peptide of lowering blood pressure by the above technology, at last obtain the product by filter, condense, dry course. This invention adapt the above technology, at the period of enzyme decompose process, the supersonic affects was used to filter the production out of the system of separation. It carries out quick reaction of enzyme decompose and circle usage of proteinase, enhances the quality of production, shortens the time of disinfect operation.

Owner:JIANGSU UNIV

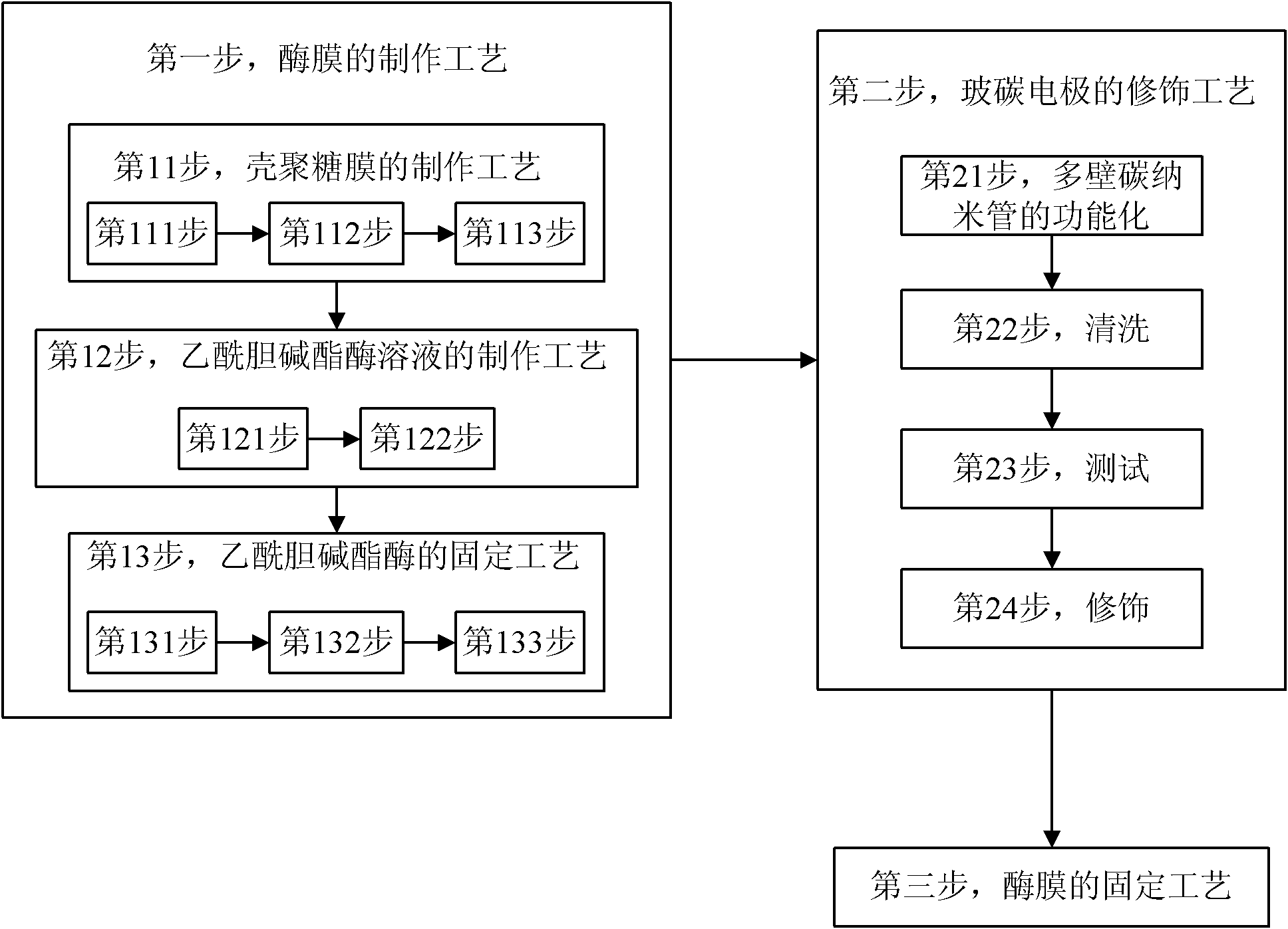

Method for manufacturing electrochemical acetylcholinesterase biological sensor

ActiveCN102103115AHigh precisionAvoid interferenceMaterial electrochemical variablesCholinesteraseAcetylcholinesterase

The invention relates to the technical field of sensors, in particular to an acetylcholinesterase biological sensor. A method for manufacturing an electrochemical acetylcholinesterase biological sensor comprises the following steps of: manufacturing an enzyme membrane; modifying a glassy carbon electrode by using functionalized multi-wall carbon, namely functionalizing a multi-wall carbon nanotube, cleaning, testing and modifying; and fixing the enzyme membrane. Due to the technical scheme, the acetylcholinesterase biological sensor manufactured by the method has the advantages of simple structure, high sensitivity, repeated detection and the like.

Owner:SHANDONG UNIV OF TECH

Method for preparing bio-diesel by immobilized lipase-alcohol perselective membrane bioreactor

InactiveCN101255348AEfficient preparationAvoid cleaningBiofuelsLiquid production bioreactorsFiberHollow fibre

The invention discloses a biological preparation by immobilized lipase-alcohol permeable membrane biological reactor. The process is that lipase is immobilized on surface of alcohol permeable membrane made of hollow fiber by physical absorption, membrane member of immobilized lipase is prepared, then assembled into enzyme-membrane reactor. Oil passes through shell side of membrane member, and low carbon alcohol passes through tube pass of the same, then fatifies them into biological diesel under catalysis of immobilized lipase. Low carbon alcohol selectively permeates hollow fibers to provide low carbon alcohol needed in preparation of biological diesel, so that inhibitory action towards enzyme activity caused by bottom articles is effectively avoided, and biological diesel is efficiently prepared. Moreover, solvent washing and batchwise charging is avoided, which meets the need of green chemistry, and reduces cost, simplify process, realizes continuous production.

Owner:ZHEJIANG UNIV

Hypodermic glucose sensor and making method thereof

ActiveCN101530328AStop lossImprove and optimize performanceDiagnostic recording/measuringSensorsGlucose sensorsEnzyme membrane

The invention discloses a hypodermic glucose sensor, comprising a needle preference electrode (2) and at least one needle working electrode (1), wherein the working electrode (1) comprises a conducting layer (7) and an enzyme membrane layer (5), the working electrode (1) further comprises an inner hydrophobic layer (6), a polymer material control diffusion layer (4) and an outer hydrophobic layer(3), the conducting layer (7), the inner hydrophobic layer (6), the enzyme membrane layer (5), the polymer material control diffusion layer (4) and the outer hydrophobic layer (3) are coated in turn from inside to outside. The invention further discloses a manufacturing method of the hypodermic glucose sensor. According to the technical proposal of the invention, the performance, mutual compatibility and consistency of the actual glucose sensor are improved and optimized.

Owner:德美医疗科技(湖州)有限公司

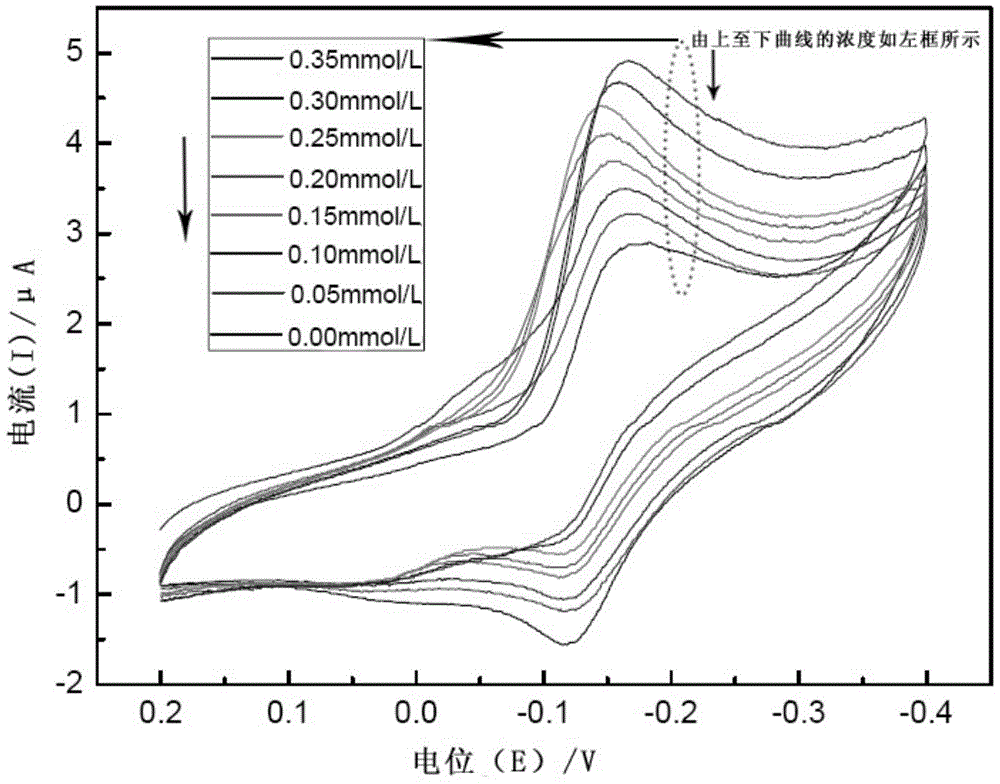

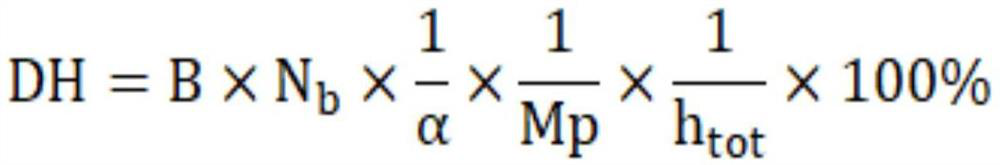

Enzyme biosensor for detecting cholesterol as well as preparation method and application of biosensor

InactiveCN103954660AFacilitates electron transferExcellent electron transfer abilityMaterial electrochemical variablesElectrochemical biosensorEnzyme membrane

The invention belongs to the technical field of electrochemical biosensors and particularly relates to an enzyme biosensor for detecting cholesterol as well as a preparation method and an application of the biosensor. The enzyme biosensor adopts a classical three-electrode system, wherein a specific matter recognizing enzyme membrane is solidified on a working electrode and mainly formed by mixing graphene, thionine, cholesterol oxidase, horse radish peroxidase and chitosan. The preparation method of the enzyme biosensor comprises the following steps: firstly uniformly mixing a thionine solution, a chitosan solution of the graphene, a horse radish peroxidase solution and a cholesterol oxidase solution, dripping onto the processed working electrode, forming the three-electrode system together with a reference electrode and a counter electrode to obtain the enzyme biosensor. The enzyme biosensor disclosed by the invention has the advantages of economical efficiency, simplicity, rapidness, sensitivity and the like, is simple in preparation and can be used for the quantitative determination of the cholesterol.

Owner:SOUTH CHINA UNIV OF TECH

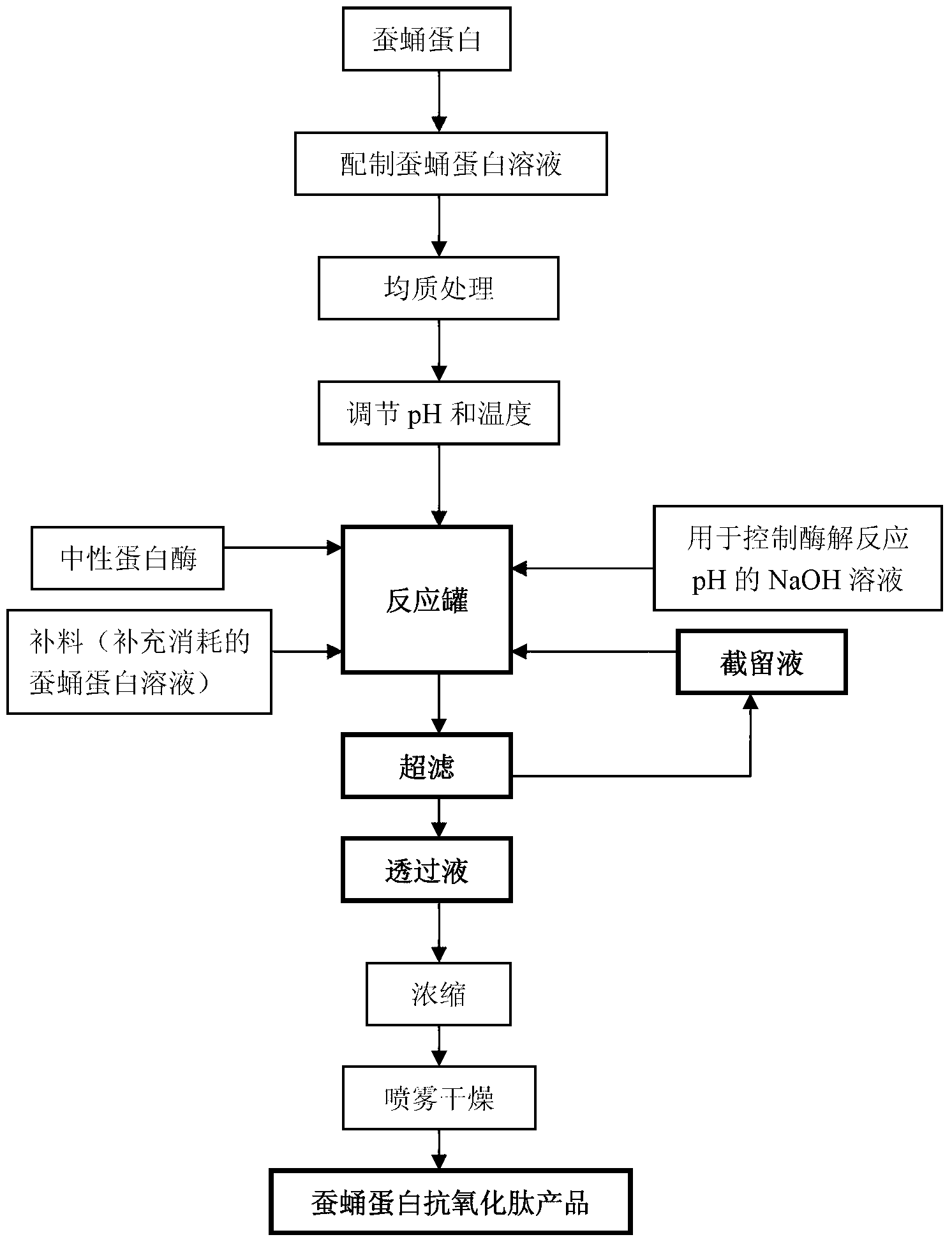

Method for continuously preparing silkworm chrysalis protein antioxidant peptides by using enzyme membrane reactor

ActiveCN103233054ARealize onlineAchieve separationPeptide preparation methodsFermentationDPPHUltrafiltration

The invention relates to a method for continuously preparing silkworm chrysalis protein antioxidant peptides by using an enzyme membrane reactor. The method comprises the following steps of: firstly, preparing silkworm chrysalis protein into a suspension by using distilled water; secondly, homogenizing the suspension by using a homogenizer, and then adding the suspension together with incision enzyme into the enzyme membrane reactor for continuously preparing antioxidant peptides; thirdly, penetrating the enzymolysis product solution through an ultrafiltration membrane to ensure that the silkworm chrysalis protein which is not fully reacted and the incision enzyme are captured and then reflow into a reaction tank for continuous reaction; and finally, collecting the enzymolysis product penetrating fluid penetrating through the ultrafiltration membrane, and concentrating and then carrying out spray drying to obtain a powdered silkworm chrysalis protein antioxidant peptide product. The silkworm chrysalis protein antioxidant peptide prepared by the method is good in activity, the IC50 for clearing DPPH (1,1-Diphenyl-2-picrylhydrazyl radical 2,2-Diphenyl-1-(2,4,6-trinitrophenyl)hydrazyl) free radical is 0.9-1.6mg / mL, the IC50 of the capacity of clearing hydroxy radical is 0.2-0.6mg / mL, and the IC50 of the capacity of chelating Fe<2+> is 1.4-2.7mg / mL.

Owner:JIANGSU UNIV OF SCI & TECH

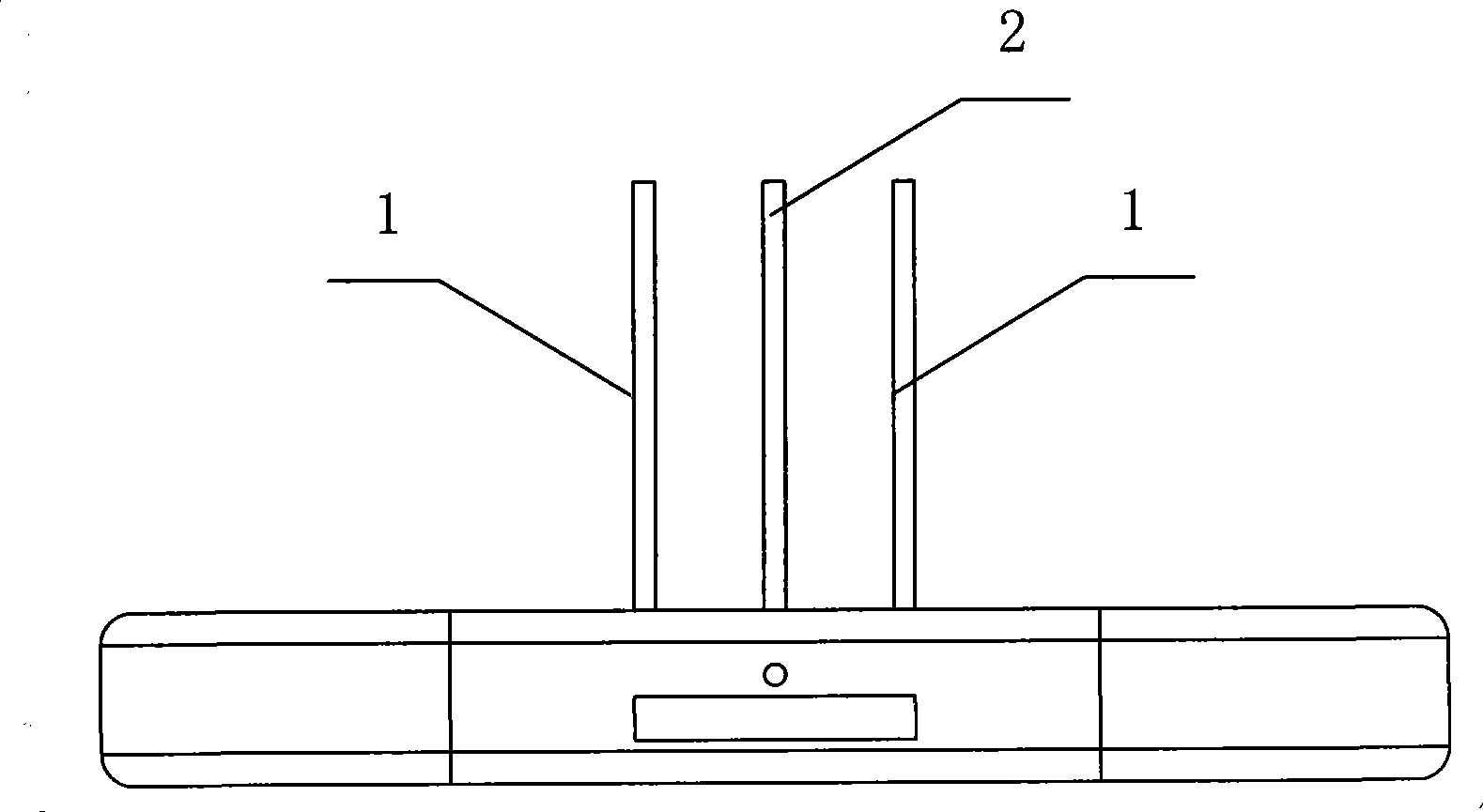

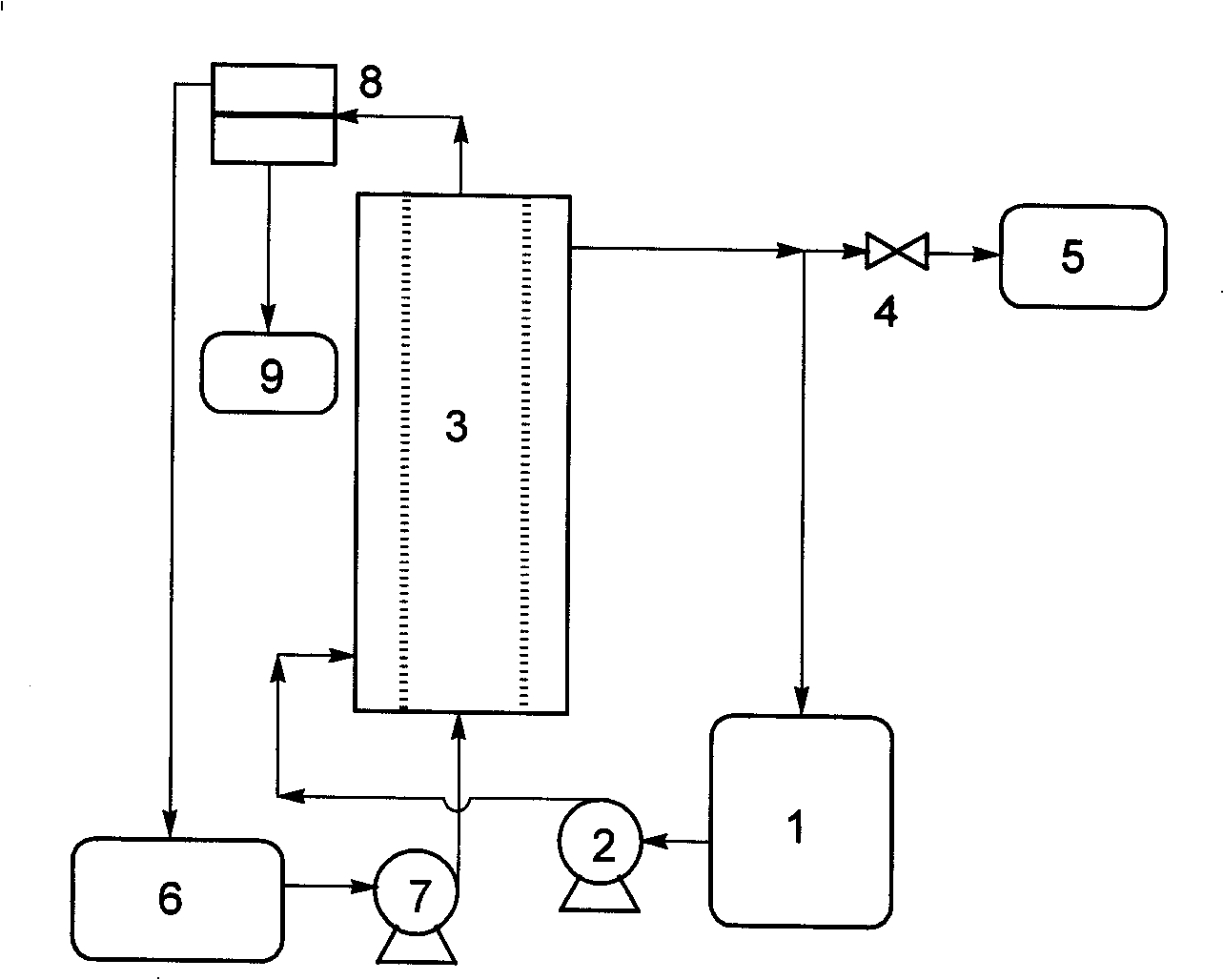

Method for preparing high-activity corn antihypertensive peptide and special device

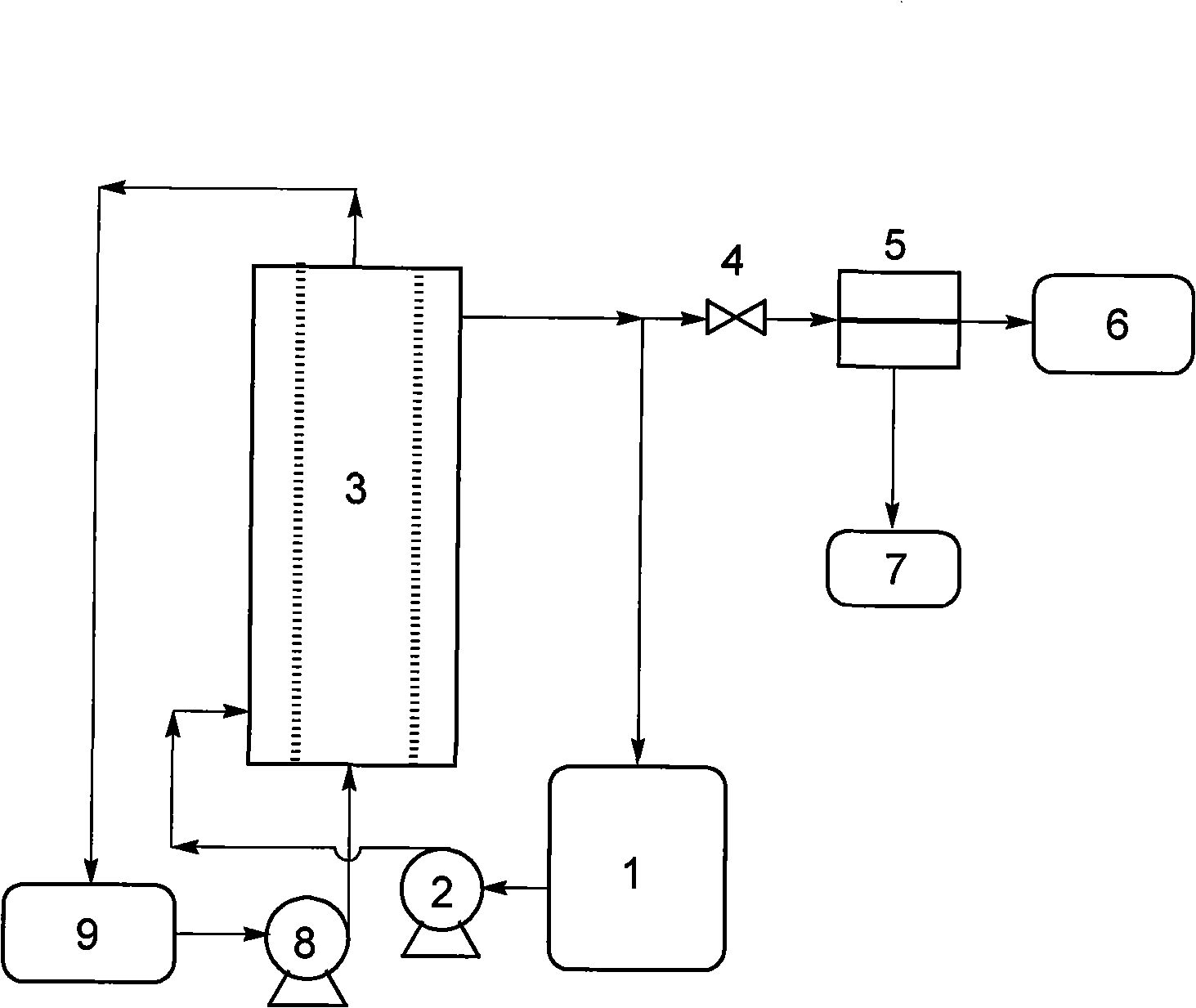

InactiveCN102453741AInhibitory activity maintainedAchieve integrationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpEnzyme membrane

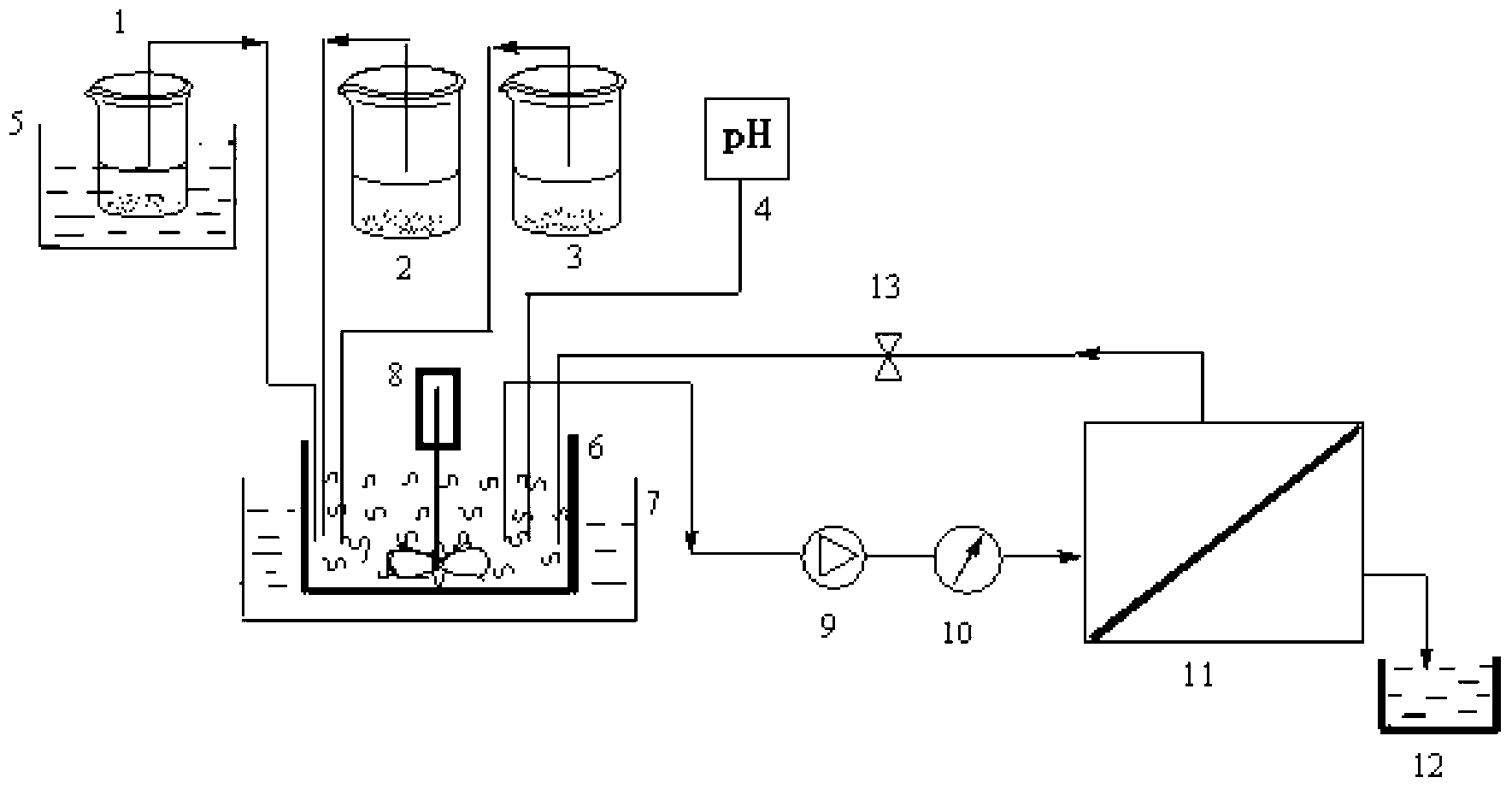

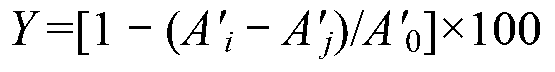

The invention belongs to the technical field of natural product preparation and particularly relates to a method for preparing high-activity corn antihypertensive peptide and a special device. An enzyme membrane reactor comprises a reaction tank, a temperature control system, an automatic pH dripping instrument, a strong force stirrer, a material liquid storage tank, a peristaltic pump, a control valve, a pressure meter, an ultrafiltration membrane assembly, a pipeline heat exchanger, a collection tank, a liquid level controller, a nanofiltration membrane assembly and the like. The process method comprises the following steps that corn gluten meal is subjected to alcohol alkali liquid extraction to obtain concentrated corn protein, the concentrated corn protein is pretreated at high temperature and is then added into a continuous enzyme membrane reactor system, the corn antihypertensive peptide is prepared by adopting the enzyme membrane coupling technology, then, the products are subjected to ultrafiltration grading through the ultrafiltration membrane assembly and then are subjected to desalting through the nanofiltration membrane, and the high-activity corn antihypertensive peptide is obtained. The inhibitory activity of the obtained corn antihypertensive peptide on angiotensin-converting enzyme (ACE) is maintained at a value higher than 86 percent, the protein recovery rate reaches higher than 70 percent, and in addition, the systolic pressure of spontaneously hypertensive rats can be obviously reduced.

Owner:HUAZHONG AGRI UNIV

Method for preparing pinctada martensii antihypertensive peptide by continuous enzyme membrane reaction

InactiveCN101215594ASimple processContinuous operationApparatus sterilizationFermentationAlkaline proteaseEnzyme membrane

The invention relates to a process for preparing japanese pearl oyster antihypertensive peptides, which is characterized in that the japanese pearl oyster antihypertensive peptides are prepared through adopting alkaline protease to hydrolyze japanese pearl oyster flesh and an enzymatic membrane reactor. The process for preparation comprises following steps: disintegrating the japanese pearl oyster flesh to prepare slurry and heating until denaturation, using water to dilute and obtain reaction solution, continuingly adding the reaction solution into the enzymatic membrane reactor, reacting and separating, continuingly penetrating hydrolysis completed liquid through films and flowing out the enzymatic membrane reactor, spraying and drying the hydrolysis completed liquid, and thereby obtaining the product of japanese pearl oyster antihypertensive peptides whose protein hydrolysis yield is 40-70% and IC50 is 0.3-0.6mg / ml. The process for preparation has high product yield and low production cost and is suitable for scale production and the product can reach the requirement of general functional food.

Owner:GUANGXI UNIV

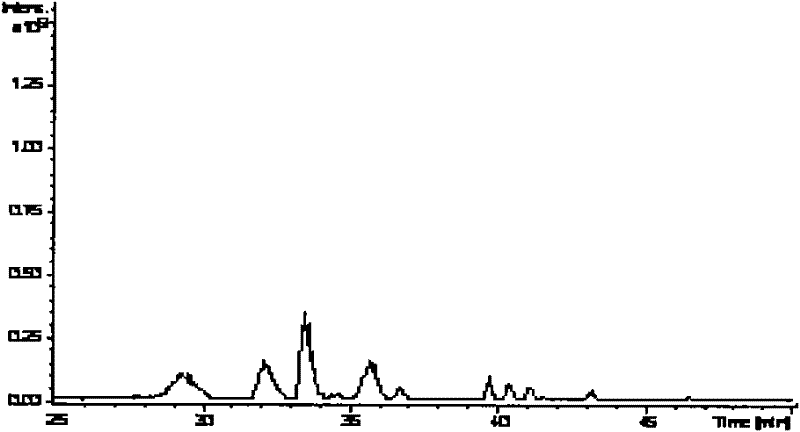

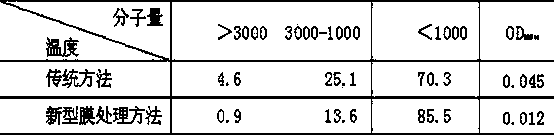

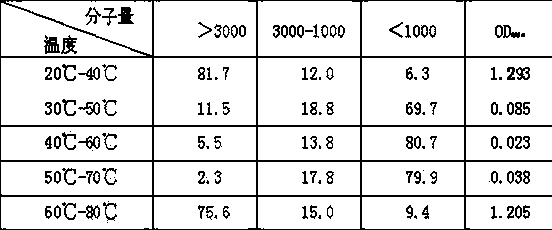

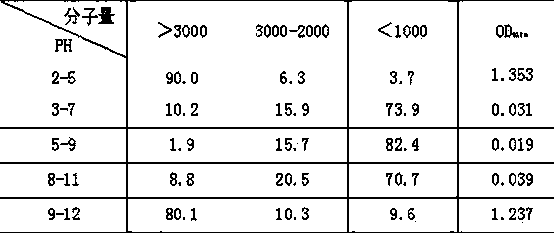

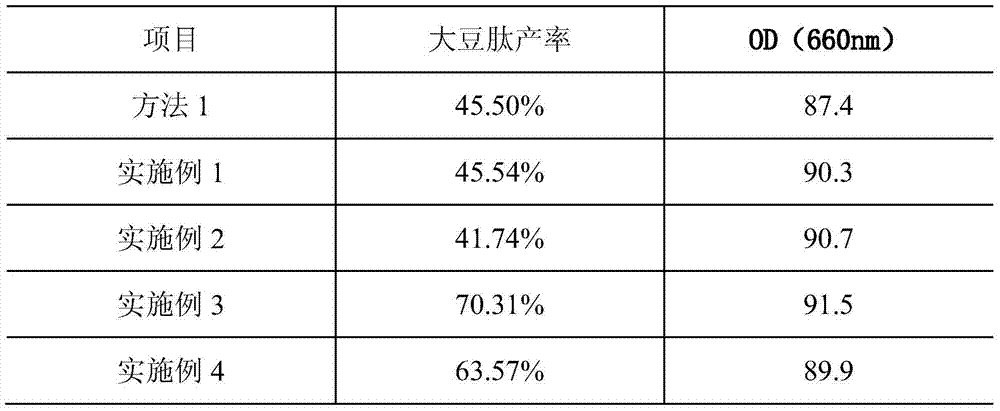

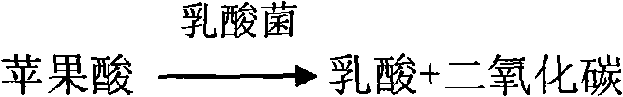

Preparation and efficacy of low molecular weight soybean peptide

The invention belongs to the field of soybean protein deep processing technology, and specifically relates to a method used for extracting soybean peptide via enzyme-membrane method. The method comprises following steps: commercially available soybean isolate protein is taken as a raw material, and is subjected to alkali dissolution, sterilization processing, and enzyme hydrolysis using protease so as to obtain a crude soybean peptide liquid; the crude soybean peptide liquid is processed via novel membrane treatment technology and nanofiltration, and a filtrate containing peptide is obtained via filtration, wherein the molecular weight of most of the peptide is less than 1000D; and the filtrate is subjected to sterilization, and spray drying so as to obtain a soybean peptide powder, wherein more than 80% of the soybean peptide powder is the soybean peptide with the molecular weight less than 1000D, a solution of the soybean peptide powder is clear, and no turbidity is caused by refrigeration of the soybean peptide powder in acid solution. The soybean peptide powder can be used in acid food and various beverages, and possesses excellent flavors and excellent characteristics such as easy absorption.

Owner:NUOLI RUYI ANYANG BIOLOGICAL SCI & TECH

Method for preparing maltose syrup by continuous saccharification of enzyme membrane reactor

InactiveCN102559812AIncrease profitIncrease production capacityFermentationActivated carbonEnzyme membrane

The invention relates to a method for preparing a maltose syrup by continuous saccharification of an enzyme membrane reactor, belonging to the method for preparing the maltose syrup. The method comprises the following steps of: adding starch with high-temperature-resistant alpha-amylase, spraying and liquefying, adopting continuous production process of the enzyme membrane reactor, adding beta-amylase, pullulanase and maltose generation enzyme, saccharifying, performing activated carbon fading and ion exchange, and refining to obtain the maltose syrup with a purity of above 90%. The method has the advantages of high utilization rate of saccharifying enzyme, short enzymolysis reaction cycle, optimized continuous production process as saccharifying process, and capabilities of greatly shortening the production cycle of product by 20-50%, reducing the energy consumption and improving the production efficiency.

Owner:JILIN AGRICULTURAL UNIV

Method for improving yield of soybean peptide with low molecular weight

ActiveCN103695513AHigh molecular weightIncrease the content of peptidesPeptide preparation methodsFermentationEnzymatic hydrolysisEnzyme membrane

The invention discloses a method for improving yield of soybean peptide with low molecular weight, which employs an enzyme-membrane method for carrying out deep processing of isolated soybean protein, and controls yield of reaction by controlling sugar degree of enzymatic hydrolysis liquid, and controls product yield by controlling sugar degree of filtrate and water addition, and controls product transparency by controlling concentrate sugar degree. The invention has the advantages of high peptide content, clear and transparent solution, high yield rate, low soybean peptide molecular weight and easy absorption, and even in acidic solution, the soy peptides do not precipitate, and can be widely applied in the fields such as foodstuff, cosmetic, etc.

Owner:NUOLI RUYI ANYANG BIOLOGICAL SCI & TECH +1

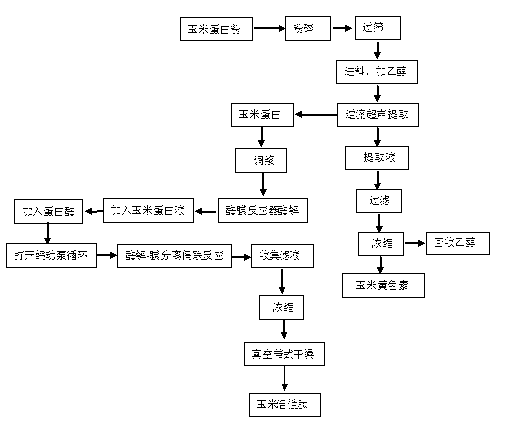

Preparation method of corn oligopeptide

InactiveCN103014108AHigh purityImmunomodulatoryPeptide preparation methodsFermentationEnzyme membraneSolvent

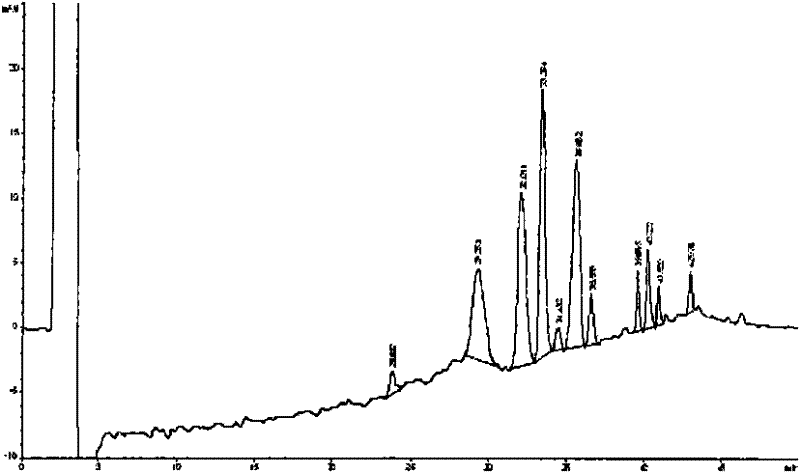

Belonging to the field of biotechnologies, the invention relates to a preparation method of a corn oligopeptide. The method comprises: taking corn protein powder as the raw material, conducting a pretreatment by a continuous countercurrent ultrasonic technology, extracting yellow pigment, carrying out enzymolysis on the well treated raw material by an enzyme membrane reactor, collecting peptide fragments with a proper molecular weight, and performing concentrating and belt vacuum drying, thus obtaining the corn oligopeptide prepared with a lot of physiologically active functions. While preparing the corn oligopeptide, the corn oligopeptide preparation method disclosed in the invention also makes use of the continuous countercurrent ultrasonic extraction technology to extract corn yellow pigment. The process is simple, at the same time, the solvent consumption is reduced to an amount accounting for 40%-50% of that of traditional extraction methods, and the yield is increased by 20%-40%. By using the enzyme membrane reactor to perform enzymolysis on the protein powder, the controllability is good, the prepared corn oligopeptide has a concentrated molecular weight and purity improved by 10%-20%, and has the physiological function activities of hangover alleviating, liver protection, immunoregulation and the like.

Owner:BAOLINGBAO BIOLOGY

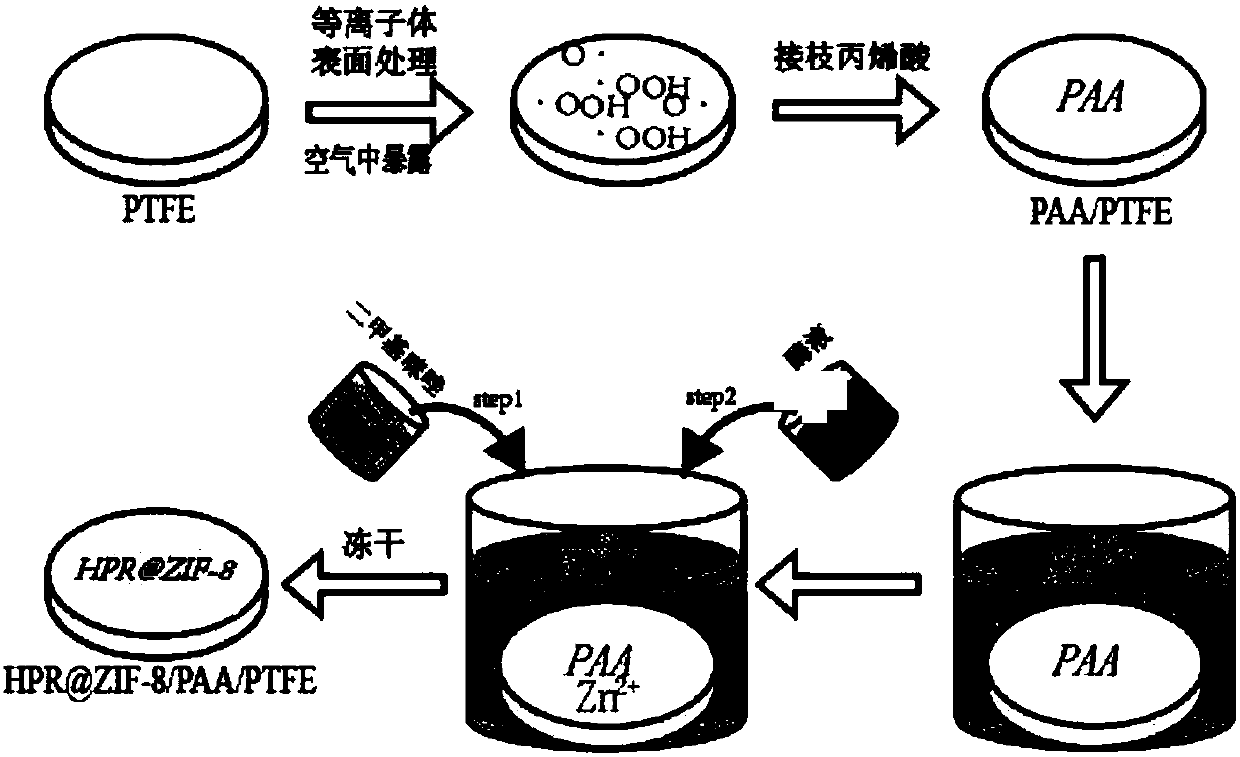

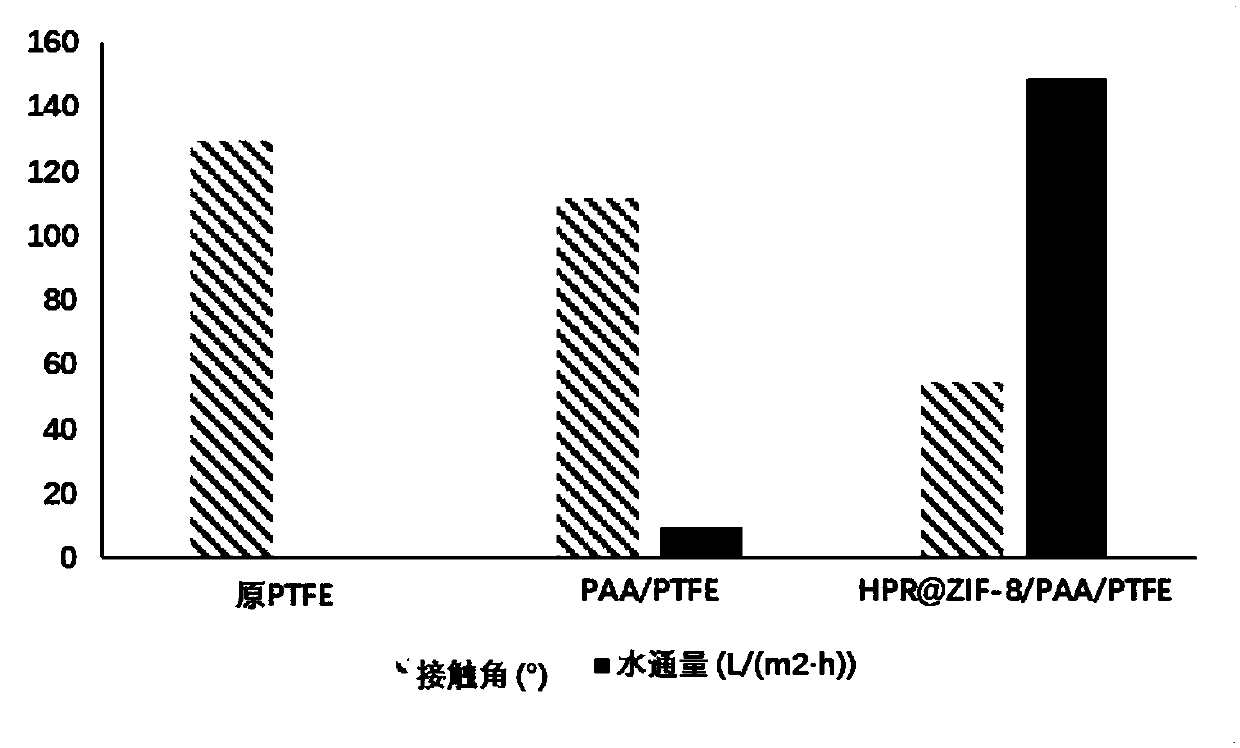

Method for in-situ preparation of nano-enzyme membrane

ActiveCN107723284AImprove hydrophilicityIn situ growthOxidoreductasesOn/in organic carrierEnzyme membranePhotocatalytic degradation

The invention provides a method for in-situ preparation of a nano-enzyme membrane. The method comprises pretreating an original membrane, carrying out grafting polymerization on the membrane surface,carrying out coordination self-assembling and in-situ growth on the nano-enzyme on the membrane surface, immersing the membrane grafted with polyacrylic acid in a MOFs precursor solution for some timeso that metal ions in the precursor solution and the carboxyl group of polyacrylic acid are assembled to the membrane surface through coordination, adding an organic ligand solution and an enzyme liquid into the precursor solution so that the enzyme is wrapped by the MOFs skeleton structure and the in-situ growth of the nano-enzyme on the membrane surface is realized, and carrying out after-treatment on the nano-enzyme membrane so that the nano-enzyme membrane with the nano-enzyme is obtained. The method greatly improves enzyme activity and stability, improves the loading rate of the enzyme on the membrane, reduces the water contact angle of the original membrane, realizes high water flux and provides the polymer membrane with pollution resistance, biocatalysis, photocatalytic degradationof pollutants and other functions.

Owner:深圳市新纳捷科技有限公司

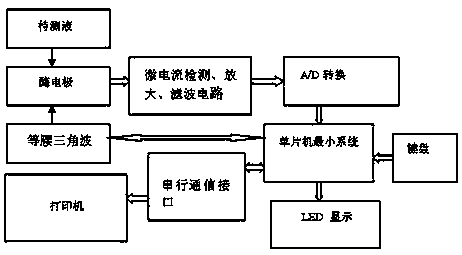

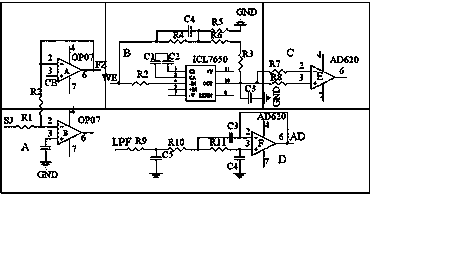

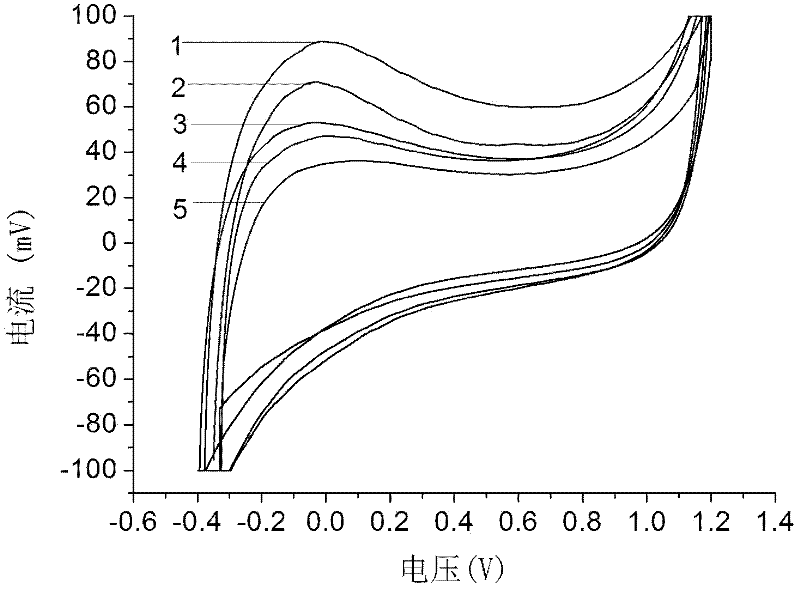

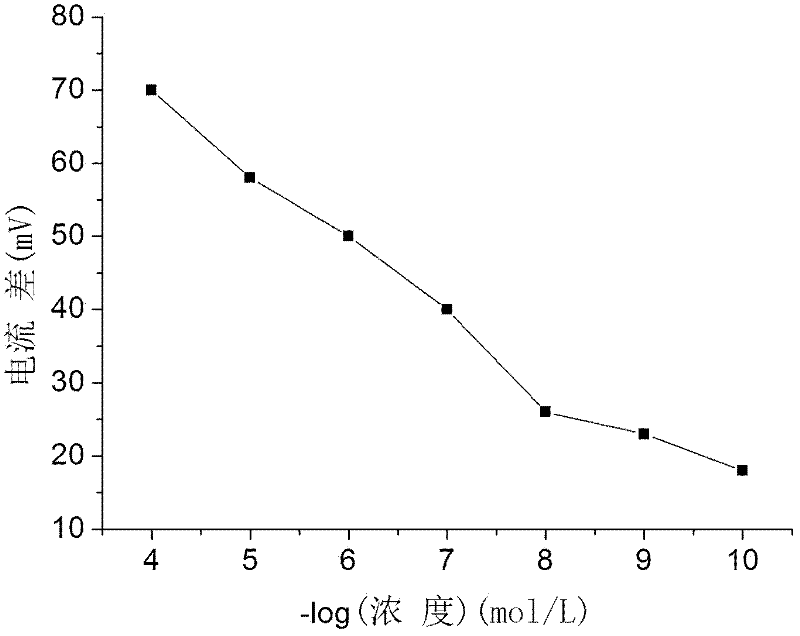

Rapid domestic fruit and vegetable pesticide residue detection instrument

ActiveCN103529114AReduced Power RequirementsMaterial electrochemical variablesEnzyme membranePesticide residue

The invention discloses a rapid domestic fruit and vegetable pesticide residue detection instrument, and relates to the technical field of agriculture product detection. Organophosphorus and carbamate pesticide residues in vegetables and fruits can be detected on site. The instrument consists of a detection panel, a detection instrument body and an enzyme biologic sensor, and further comprises a pocket with a reagent prepared at a certain ratio and an enzyme membrane for fixing acetylcholin esterase. According to the detection principle, on the basis of a cyclic voltammetry method, the concentration of the pesticide is measured by measuring the change of current generated from an electrode which is modified by acetylcholin esterase before and after contacting the pesticide. Weak current signals generated from an enzyme electrode are acquired, amplified and converted through an amplifier, and output to a data processing device, a display and a mini printer are arranged at a data acquisition terminal, whether the pesticide exceeds the standard or not can be displayed, and the result can be printed and output. The instrument is applicable to an occasion for on-site rapid detection on pesticide residues.

Owner:SHANDONG UNIV OF TECH

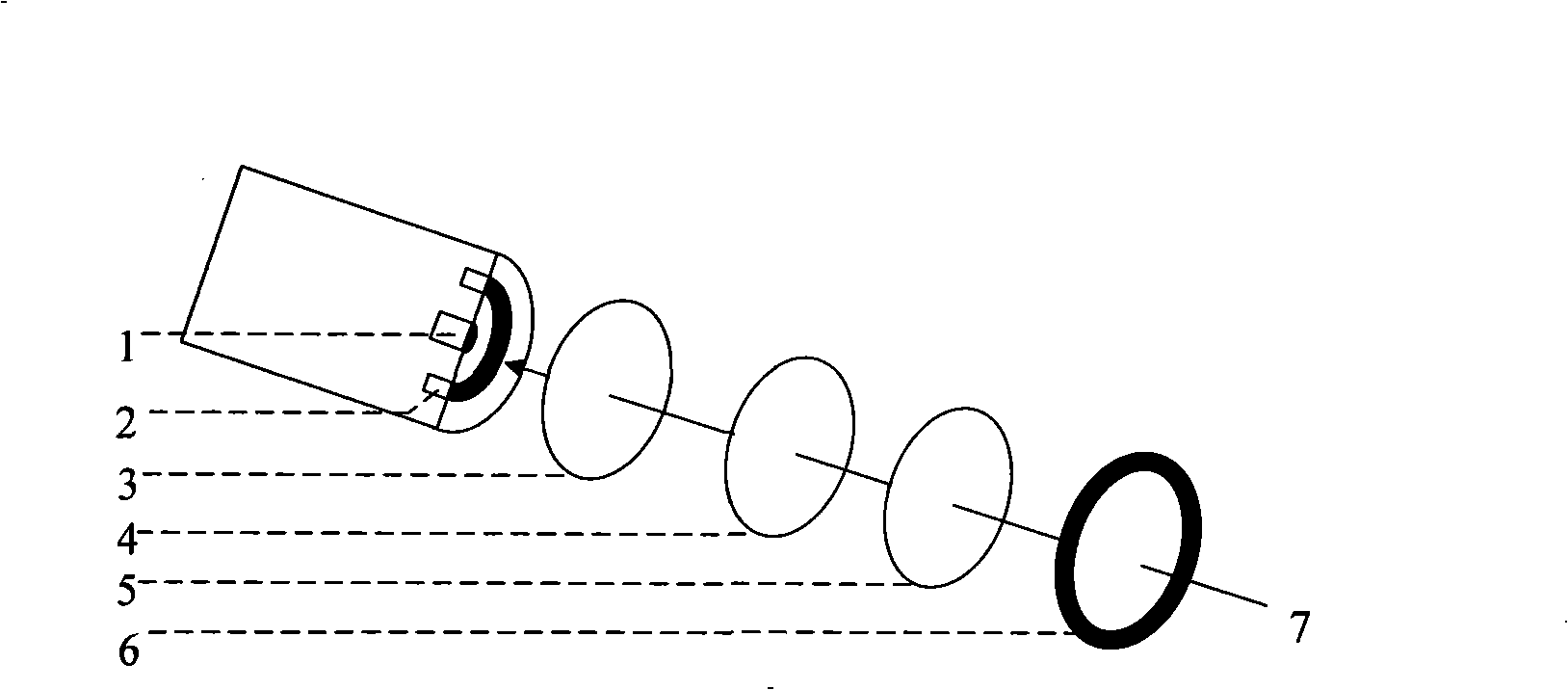

Mediator electrochemical enzyme electrode and method for making same

InactiveCN101285792AEasy to getImprove reaction efficiencyMaterial analysis by electric/magnetic meansAnti jammingEnzyme membrane

The invention discloses a mediator electrochemical enzyme electrode and a method for making the same. Acrylonitrile copolymer with a functionalized mediator is prepared through the coupling reaction of acrylonitrile copolymer and an electric mediator with a reactive group in dimethylformamide. The dimethylformamide is taken as solvent, the functionalized acrylonitrile copolymer is taken as a raw material, an electrochemical electrode is taken as an accepting electrode, a copolymer fiber membrane is prepared on the surface of the electrode through an electrostatic spinning method, then a covalent method is used to fix xidoreductase on a fiber layer on the surface of the electrode to form an activated layer of fibers. In the invention, extremely high specific surface area of the electrostatic spinning fiber, the reaction group on the surface of the electrostatic spinning fiber and the fixed electric mediator ensure that the electrochemical enzyme electrode has higher enzyme-carrying efficiency, high stability and high response strength. The mediator electrochemical enzyme electrode has the advantages of simple preparation process, repeated use, large surface area of an effective enzyme membrane, strong anti-jamming ability and so on, and is suitable for batch production.

Owner:ZHEJIANG UNIV

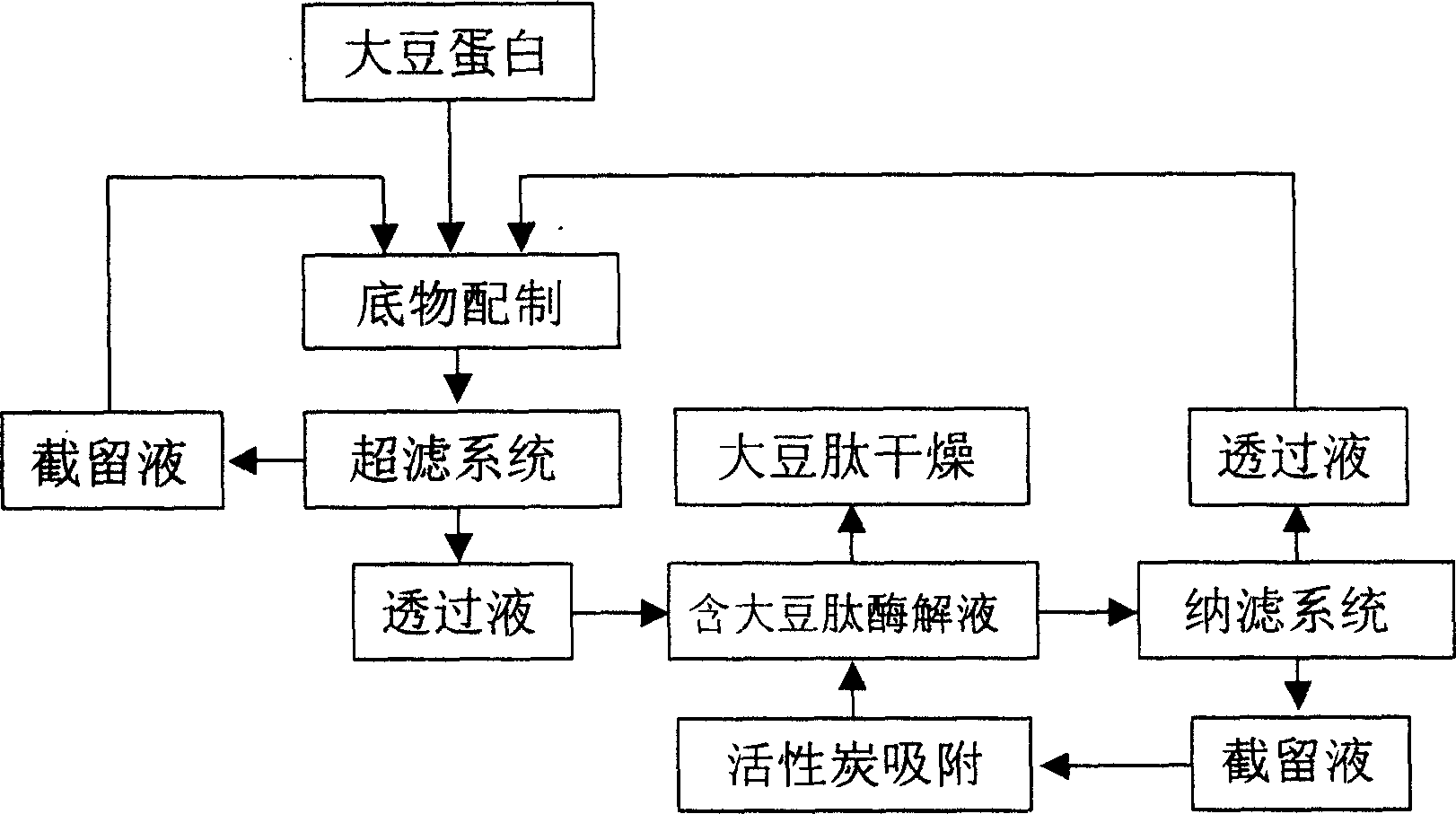

Method for measuring malic acid-lactic acid fermentation quality of wine

InactiveCN101344502AWill not cause churnUndisturbedMaterial analysis by electric/magnetic meansLactate oxidasePhosphate

The invention relates to a lactic fermentation quality measuring method of a wine malic acid, which belongs to the technical field of biosensors. The method adopts the following preparation steps: an L-lactic acid oxidase is solidified and combined with an H2O2 electrode into a biological L-lactalase electrode sensor, a phosphate buffering liquid with the pH of 7.2 and the mole weight of 0.1 millimole per liter <-1> and a standard liquid containing 500 milligram <-1> of the L-lactic acid in each liter are adopted, the instrument automatically displays the base enzyme membrane activity in 20 seconds after 25 microliter of the standard liquid is injected into a reaction pool, a calibrate button is pressed for 500 calibration, and the instrument is automatically cleaned and can be used for sample measurement again.

Owner:BIOLOGY INST OF SHANDONG ACAD OF SCI

Method for preparing peptide of soybean through continuous enzyme membrane reaction of soyabean protein

InactiveCN1563405AComplete enzymatic hydrolysisStable concentrationFermentationActivated carbonUltrafiltration

A method for preparing soybean peptide by soybean protein continuous zyme film reactions is to carry out the bean protein zyme film reaction in super filtration and separation and to carry out activated carbon adsorption and bean peptide concentration. This invention can realize circulation use of zyme and mother liquid and bean peptide decolor, debitter and concentration at the same time.

Owner:GUANGXI UNIV

Ampere type biosensor electrode and method for making same

InactiveCN101285791AEasy to fixEasy to prepareMaterial analysis by electric/magnetic meansFiberPorosity

The invention discloses an ampere type biosensor electrode and a method for making the same. Dimethylformamide is taken as solvent, acrylonitrile copolymer and an electric mediator are taken as raw materials, an electrochemical electrode is taken as an accepting electrode, a composite fiber membrane of the acrylonitrile copolymer and the electric mediator is prepared on the surface of the electrode through electrostatic spinning, then a covalent method is used to fix xidoreductase on the surface of fibers to form an activated layer of the fibers on the surface of the electrode. The activated layer of the fibers has large specific surface area, high porosity rate and a through-hole structure; at the same time, the electric mediator is provided, so the electrode has higher response strength, linear detection range and stability. The mediator electrochemical enzyme electrode has the characteristics of simple preparation process, repeated use, large surface area of an effective enzyme membrane, strong anti-jamming ability and so on, and is suitable for batch production.

Owner:ZHEJIANG UNIV

Ampere enzyme electrode based on electrostatic spinning fiber membrane and method for making same

The invention discloses an amperometric enzyme electrode based on an electrostatic spinning fibrous membrane and a method for preparing the same. The method uses dimethyl formamide as solvent, a platinum electrode, a gold electrode, a glassy carbon electrode or a carbon paste electrode as a receiving electrode and acrylonitrile copolymer as raw materials, and deposits a copolymer fibrous membrane layer on the surface of the electrode through the electrostatic spinning method. The method is as follows: firstly, a monolayer of redoxase is constructed on the surface of fibers through the covalent method; secondly, bifunctional reagent is added into enzyme solution, and enzyme congeries is driven to be covalently fixed on the enzyme membrane on the surface of the electrode. In the amperometric enzyme electrode, due to large specific surface area and high porosity of the fibrous membrane and the unique enzyme immobilization method, the electrochemical enzyme electrode is characterized by large response strength, high stability, wide linear detection range and so on. The method for preparing the enzyme electrode is simple and is suitable for mass production, and the enzyme electrode can be reused and preserved for a long term.

Owner:ZHEJIANG UNIV

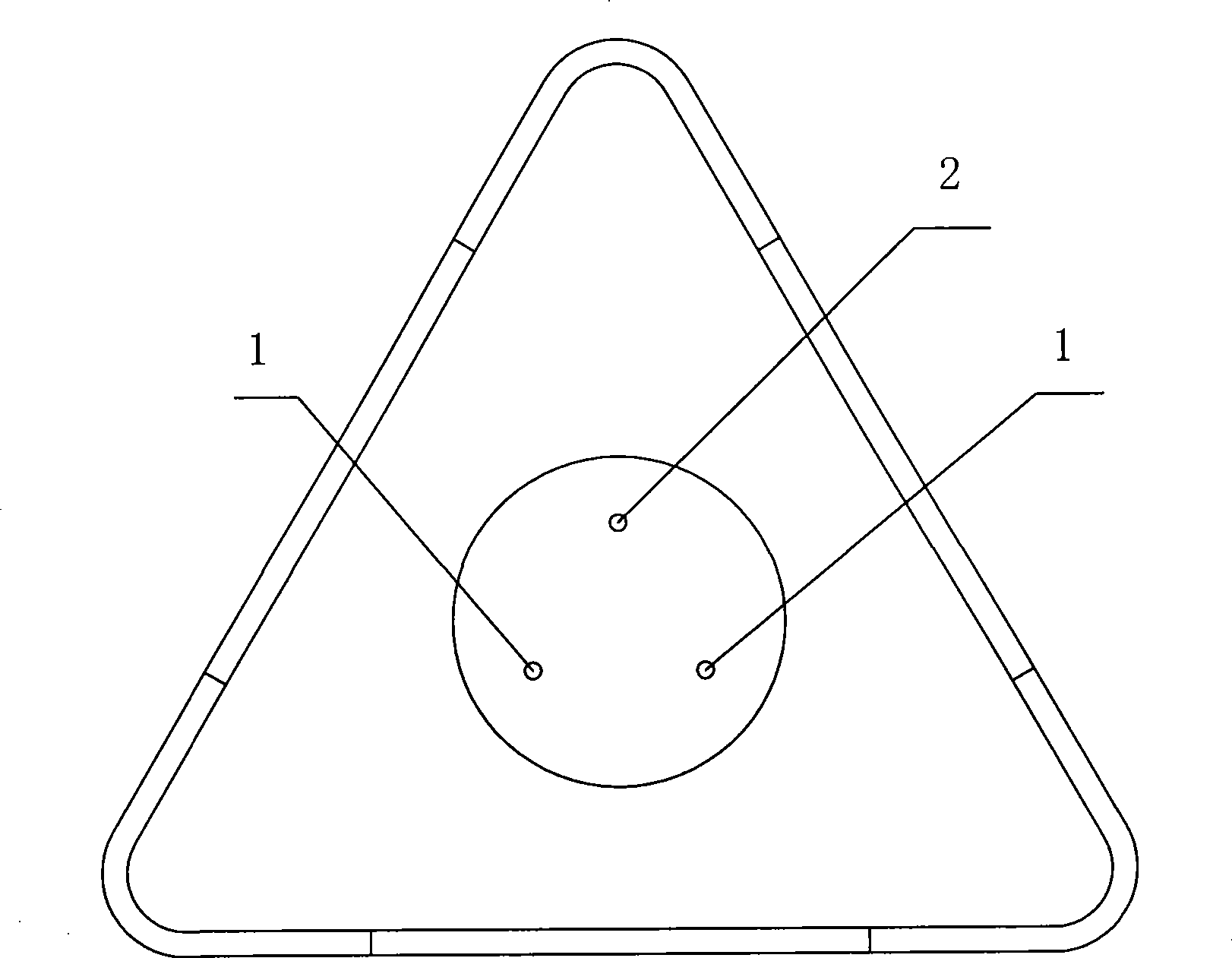

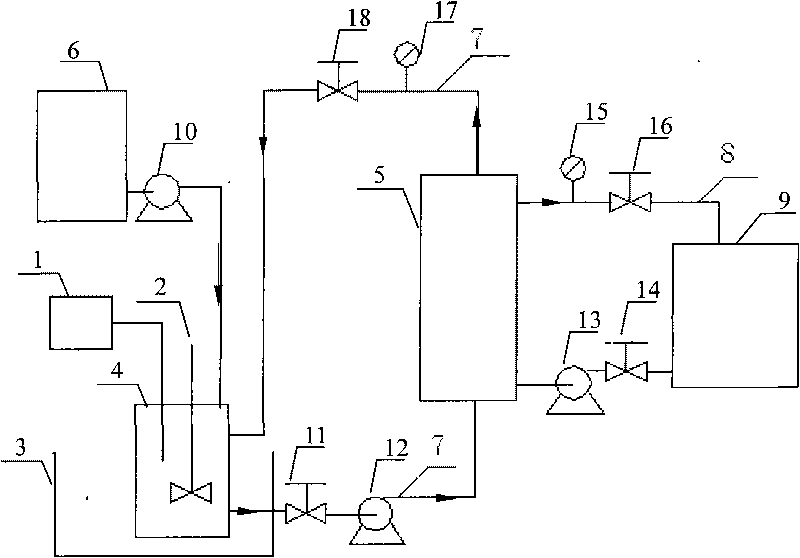

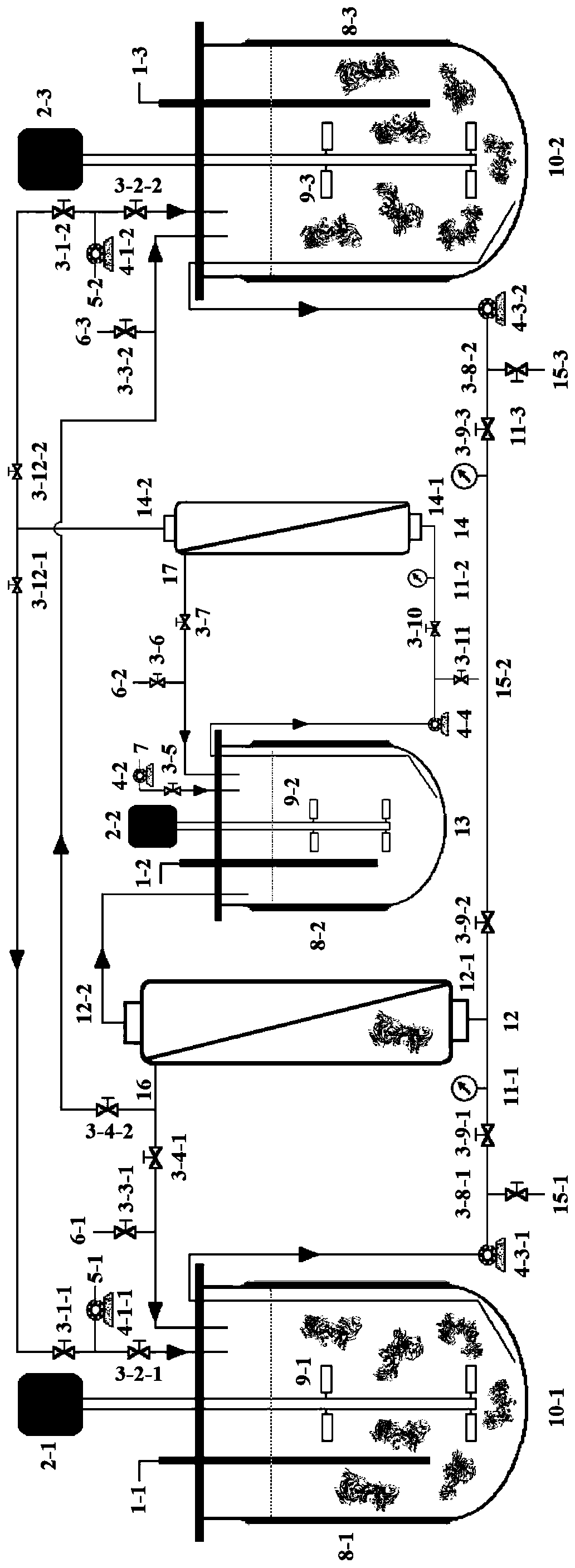

Whey protein antihypertensive peptide prepared by utilizing continuous enzyme membrane reactor and special device thereof

ActiveCN101724555AAchieve recyclingImprove utilization efficiencyApparatus sterilizationAlbumin peptidesPeristaltic pumpEnzyme membrane

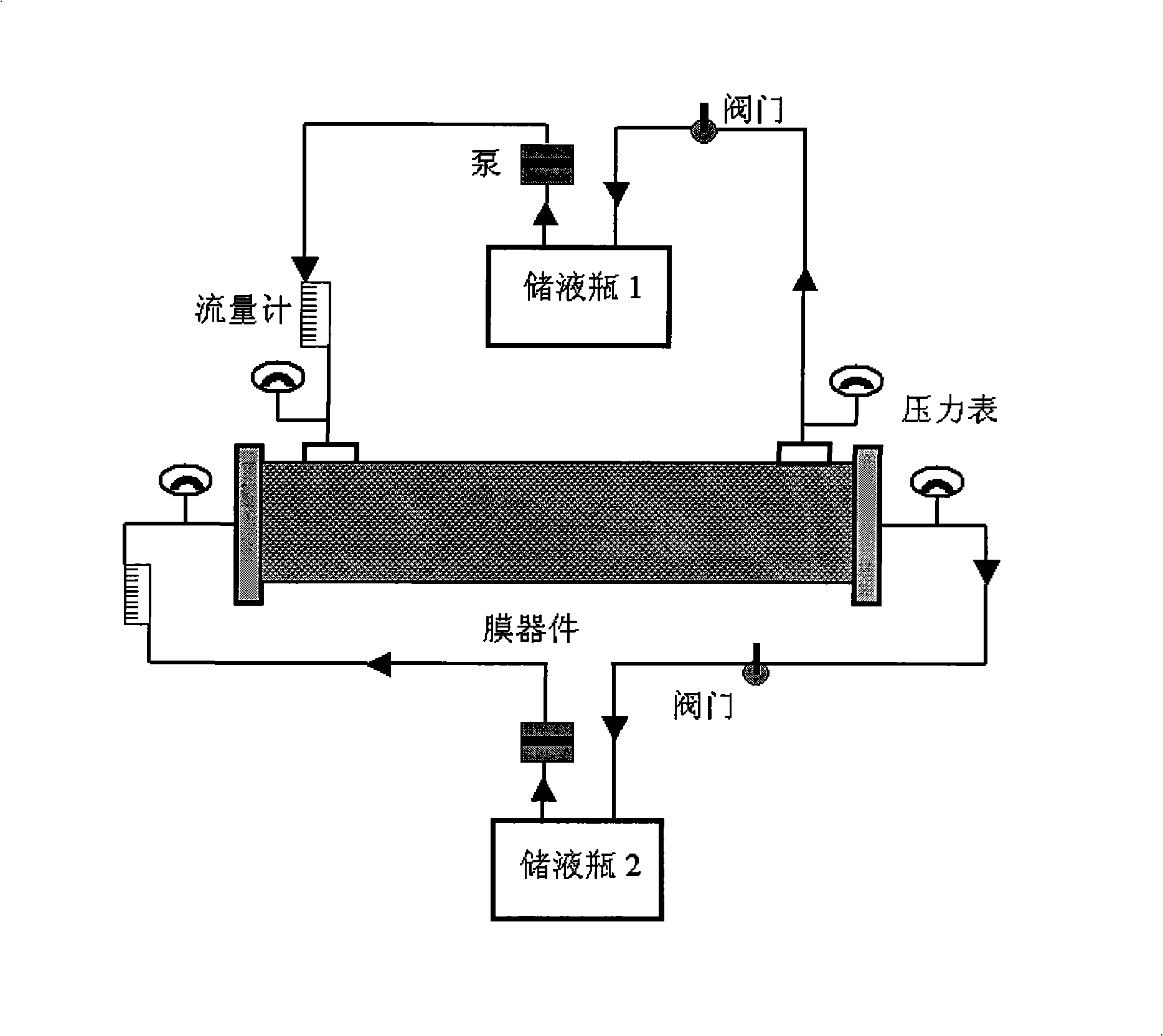

The invention discloses a whey protein antihypertensive peptide prepared by utilizing a continuous enzyme membrane reactor and a special device thereof. The continuous enzyme membrane reactor provided by the invention comprises a reactive tank (4), an ultrafiltration membrane assembly (5), a circulating system (7), a collecting tank (9) and a feed tank (6), wherein the reactive tank (4) is connected with the ultrafiltration membrane assembly (5) through the circulating system (7), the feed tank (6) is connected with the reactive tank (4) through a pipeline, and a peristaltic pump (10) is arranged on the pipeline. After whey protein is preprocessed through dissolution, hydration and the like, the antihypertensive peptide is prepared in the continuous enzyme membrane reactor by adopting thetechnologies of proteolysis and membrane separation and coupling. The enzyme membrane reactor shows excellent stability in the operating process, and the ultrafiltration amount thereof always keeps more than 90 percent after the enzyme membrane reactor continuously works for 12 hours. The protein recovery rate reaches more than 78 percent, and the highest suppression ratio of an ACE can reach 90.11 percent.

Owner:CHINA AGRI UNIV

Grease catalysis separation biphasic enzyme-film bioreactor and its preparation and application

InactiveCN101265448ANot easy to fall offIncrease the areaFibre typesMonocomponent synthetic polymer artificial filamentFiberLipid formation

The invention relates to a grease catalyzing and separating biphasic enzyme-membrane reactor and a method for preparing and using hydrolyzed edible glyceride. The method comprises the steps of filling polyphosphazene superfine fiber complex film into a mould with an inner and an outer cylinders to form a roll membrane device; sequentially injecting activating agent solution and lipase solution into the membrane device, and causing the lipase to be chemically fixed on the surface of the superfine fiber film to obtain an enzyme-membrane reactor; and injecting edible glyceride and phosphate buffer respectively into the inner side and the outer side of the superfine fiber film to conduct hydrolysis reaction on the surface of the superfine fiber surface. The reactor can be used for catalyzing the hydrolysis of the glyceride, and for producing diglyceride or monoglyceride edible oil and extracting functional lipid by treating lard or fish oil. The glyceride hydrolyzate accounts for more than 85%. The grease catalyzing and separating biphasic enzyme-membrane reactor is designed by combining efficient biocatalysis and complex film separation, and has the advantages of repeatable use, realized continuous efficient production, reduced cost, saved resource and good development prospect.

Owner:ZHEJIANG UNIV

Method for preparing biological diesel oil from immobilized lipase-porous membrane biological reactor

InactiveCN101265413AEfficient preparationAvoid cleaningLiquid production bioreactorsLiquid hydrocarbon mixture productionHollow fibreFiber

The invention discloses a method for preparing biodiesel through an immobilized lipase-porous membrane bioreactor. The hollow fiber porous membrane modules of immobilized lipase are assembled into an enzyme-membrane bioreactor, the admixture of grease and lower alcohol passes through the shell pass of the membrane modules, water passes through the tube pass of the membrane modules, after the grease and the lower alcohol are circularly reacted for a period of time under the catalytic action of the immobilized lipase, the grease and the lower alcohol can be transformed into the biodiesel. Because the method of the invention adopts the lipase-porous membrane as the medium between the grease phrase and the water phase, not only the on line byproduct glycerol separating can be performed, but also necessary water can be actively supplied to the immobilized lipase, therefore high enzyme activity and stability can be maintained, and biodiesel can be efficiently prepared, simultaneously solvent cleaning and batch charging are avoided, and the method has the advantages that the technology is simple, the continuous operation can be performed, the cost is lower, and the method meet the green chemical development trend.

Owner:ZHEJIANG UNIV

Method for preparing chitosan oligosaccharides by feed-batch-oxidative pretreatment assistant with enzyme hydrolysis of chitosan oligosaccharides

PendingCN108588150AGood viscosity reductionGood thickening effectFermentationHigh concentrationPretreatment method

The invention discloses a method for preparing chitosan oligosaccharides by feed-batch-oxidative pretreatment assistant with enzyme hydrolysis of chitosan oligosaccharides, and relates to a method forpreparing low-molecular-weight chitosan. The method comprises the steps that degradable solution is obtained through feed-batch-oxidative pretreatment of chitosan oligosaccharides; the hydrogen peroxide is removed; enzymatic hydrolysis and inhibition of side reactions of the chitosan is carried out; and product separation and drying is carried out, and the chitosan oligosaccharides is obtained. In the process oxidative pretreatment, the substrate concentration in a chitosan degradation system is increased the feed-batch method, the initial hydrolysis is achieved, and finally, the chitosan wasfurther hydrolyzed by the enzyme. Compared with the high-concentration hydrolysis of the chitosan, the pretreatment method has simple equipment and high adaptability, can easily be combined with a enzyme membrane reactor, immobilized enzyme and other technologies, and has a great application prospect in the preparation of the chitosan oligosaccharides with narrow molecular weight distribution.

Owner:XIAMEN UNIV

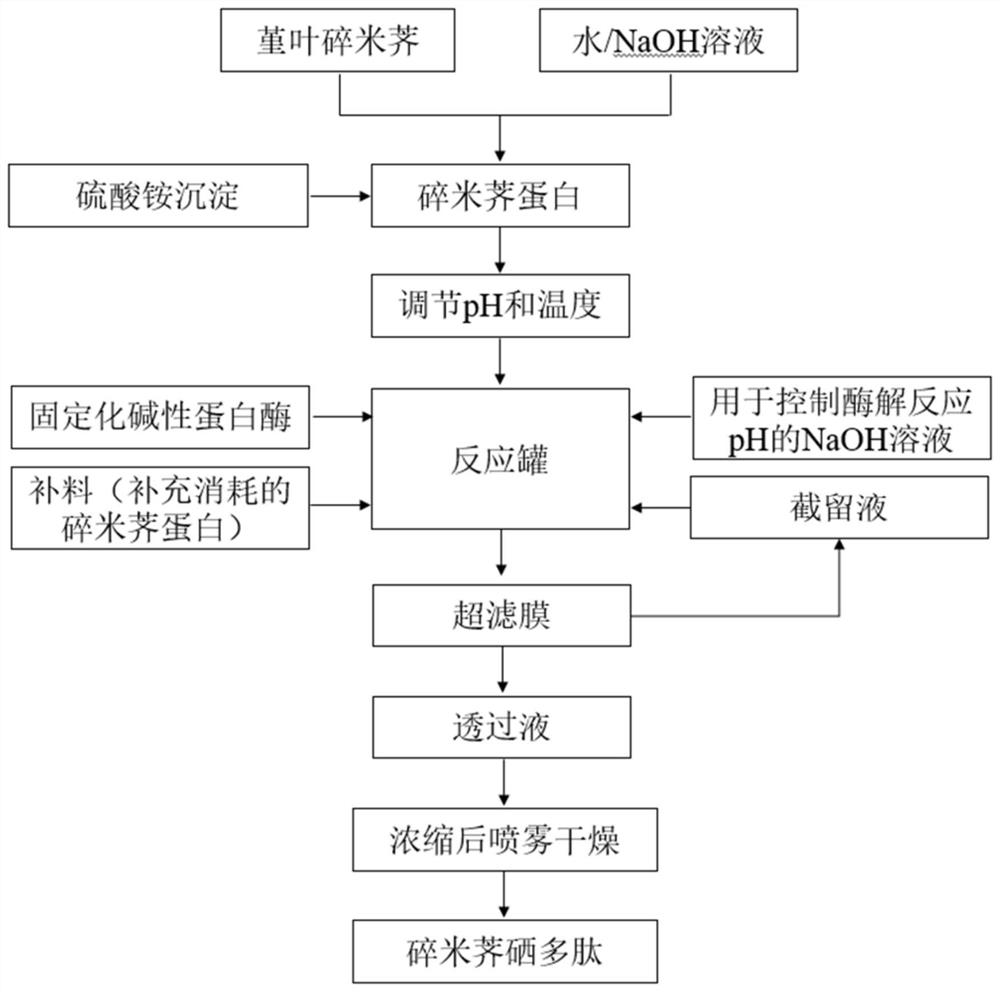

Method for preparing cardamine selenium polypeptide through continuous enzymolysis and cardamine selenium polypeptide

PendingCN112458140AImprove stabilityEasy to useHydrolasesPeptide preparation methodsHydrolysateEnzyme membrane

The invention belongs to the field of peptide preparation, and particularly relates to a method for preparing cardamine selenium polypeptide through continuous enzymolysis and the cardamine selenium polypeptide. The method comprises the following steps of: preparing cardamine protein powder; constructing immobilized enzyme; performing pre-enzymolysis; performing ultrafiltration and material supplementation; concentrating and drying. The method integrates reaction, product separation and enzyme recycling, and can realize continuous operation. According to the method, substrate protein is subjected to continuous enzymolysis through an immobilized enzyme membrane reactor, so that a reaction product can be selectively removed, the product inhibition phenomenon is reduced, and the reaction rateand the substrate conversion rate are increased; through the selectivity of a membrane, the molecular weight of a hydrolysate can be controlled; the molecular weight of the cardamine selenium polypeptide obtained by the method is intensively distributed at 300-3,000Da, and the DH (degree of hydrolysis) can reach about 27 percent and is increased by 8.4 percent compared with the DH value of the conventional intermittent enzymolysis.

Owner:WUHAN POLYTECHNIC UNIVERSITY

Boron-doping diamond film based ascorbic acid oxidase sensor electrode

InactiveCN102590306AExtended service lifeExcellent physical and chemical propertiesMaterial analysis by electric/magnetic meansOvervoltageElectrochemical biosensor

The invention discloses a boron-doping diamond film based ascorbic acid oxidase sensor electrode which is composed of a boron-doping diamond film, an amino monomolecular layer and an enzyme membrane layer. The preparation method of the ascorbic acid oxidase sensor electrode comprises the steps of: firstly, depositing a boron-doping diamond film on a tantalum sheet which is subjected to a surface pre-treatment by utilizing a hot filament CVD (Chemical Vapor Deposition) device; then performing amination modification on the boron-doping diamond film; and finally fixing the ascorbic acid oxidase on the surface of the ammoniated diamond film by adopting a chemical crosslinking way, wherein the electrode can be used on an electrochemical biosensor. The boron-doping diamond film based ascorbic acid oxidase sensor electrode, disclosed by the invention, has the advantages of having the limit of detection of 1*10-11 mol / L, and having high sensitivity, good reproducibility and long service life as the electrode inherits the advantages of corrosion resistance, extremely high oxygen evolution overvoltage, wide electric potential window, high electrochemical stability and the like of the diamond.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

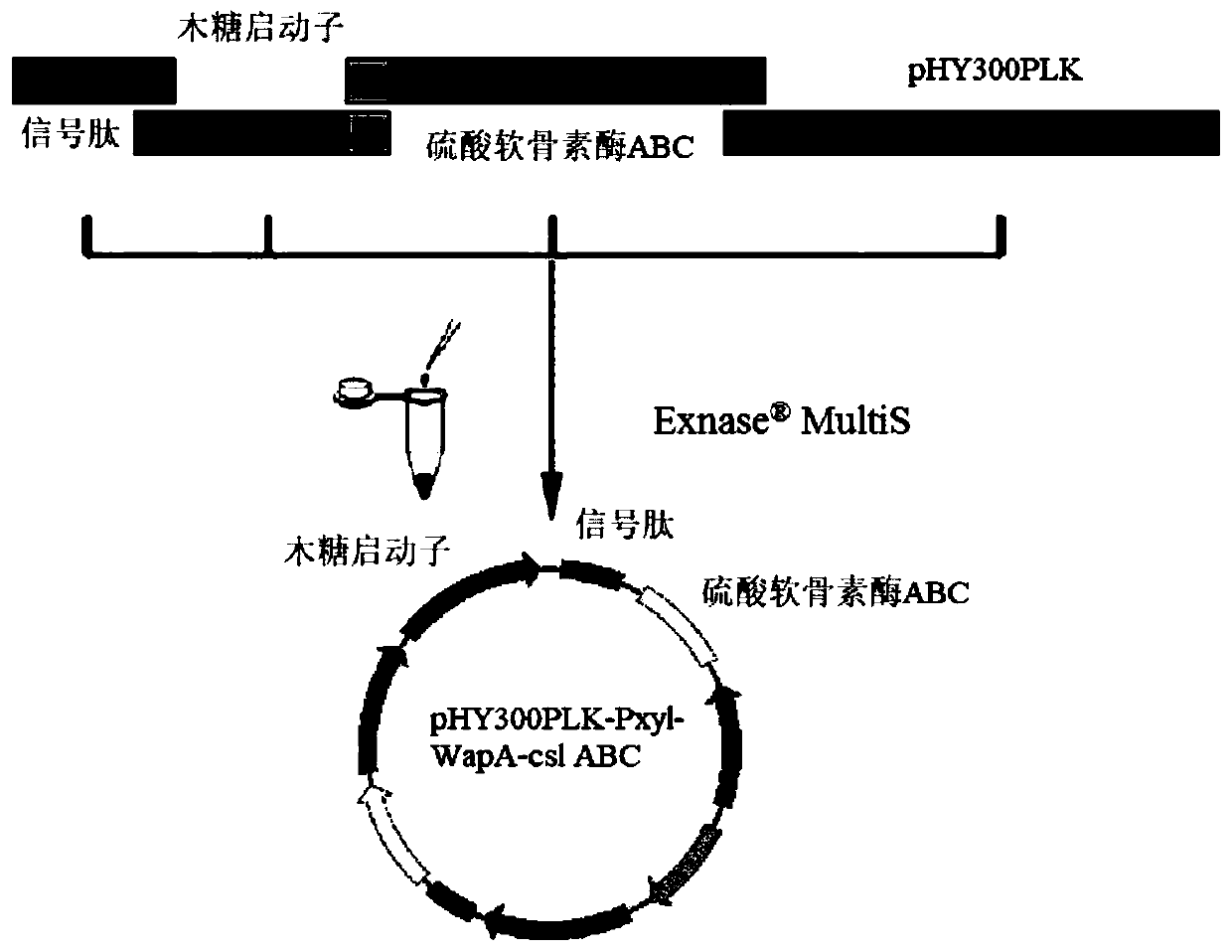

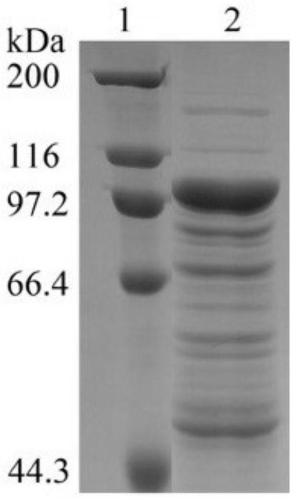

Method for efficiently preparing micromolecular chondroitin sulfate and micromolecular hyaluronic acid by one step

ActiveCN109988739AEasy to operateAvoid immobilizationBacteriaMicroorganism based processesHeterologousEnzyme membrane

The invention discloses a method for efficiently preparing micromolecular chondroitin sulfate and micromolecular hyaluronic acid by one step, and belongs to the technical field of bioengineering. According to the method, chondroitin sulfate ABC lyase derived from proteus vulgaris ATCC33420 is heterologously expressed, a signal peptide wapA is selected, and constitutive xylose promoter Pxyl and pHY300PLK vectors are used, and secreted expression of the chondroitin sulfate ABC lyase in bacillus subtilis is realized through induction by xylose; the micromolecular chondroitin sulfate and the micromolecular hyaluronic acid can be produced efficiently and continuously by a designed chondroitin lyase-enzyme membrane reactor. The method has the advantages that the food-grade bacillus subtilis serves as a host strain, and safety and reliability are realized; effective reference is provided for industrial green production of the micromolecular chondroitin sulfate and the micromolecular hyaluronic acid; energy conservation and emission reduction are realized, and economic and social benefits are remarkable.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Preparation method of fixed enzyme membrane

InactiveCN101781645ACatalytic activity unchangedHigh catalytic activityOn/in organic carrierBacillus licheniformisAlkaline protease

The invention relates to a preparation method of a fixed enzyme membrane. The invention solves the problems of low enzyme protein carrying capacity and low catalytic activity of a fixed enzyme membrane prepared by the traditional method. The method comprises the following steps of: (1) preparing a methyl methacrylate grafted membrane; (2) preparing a methyl methacrylate grafted membrane with absorbed hexanediamine; and (3) soaking and processing the methyl methacrylate grafted membrane with the absorbed hexanediamine into a bacillus licheniformis alkaline protease solution or a transglutaminase solution so as to obtain a fixed enzyme membrane. The fixed enzyme membrane prepared by the invention has good enzyme protein carrying capacity, bacillus licheniformis alkaline protease carrying capacity larger than 35mg / g membrane and transglutaminase carrying capacity larger than 20mg / g membrane. The fixed enzyme membrane prepared by the method has good absorption capability, catalytic activity and thermal stability.

Owner:HARBIN UNIV OF COMMERCE

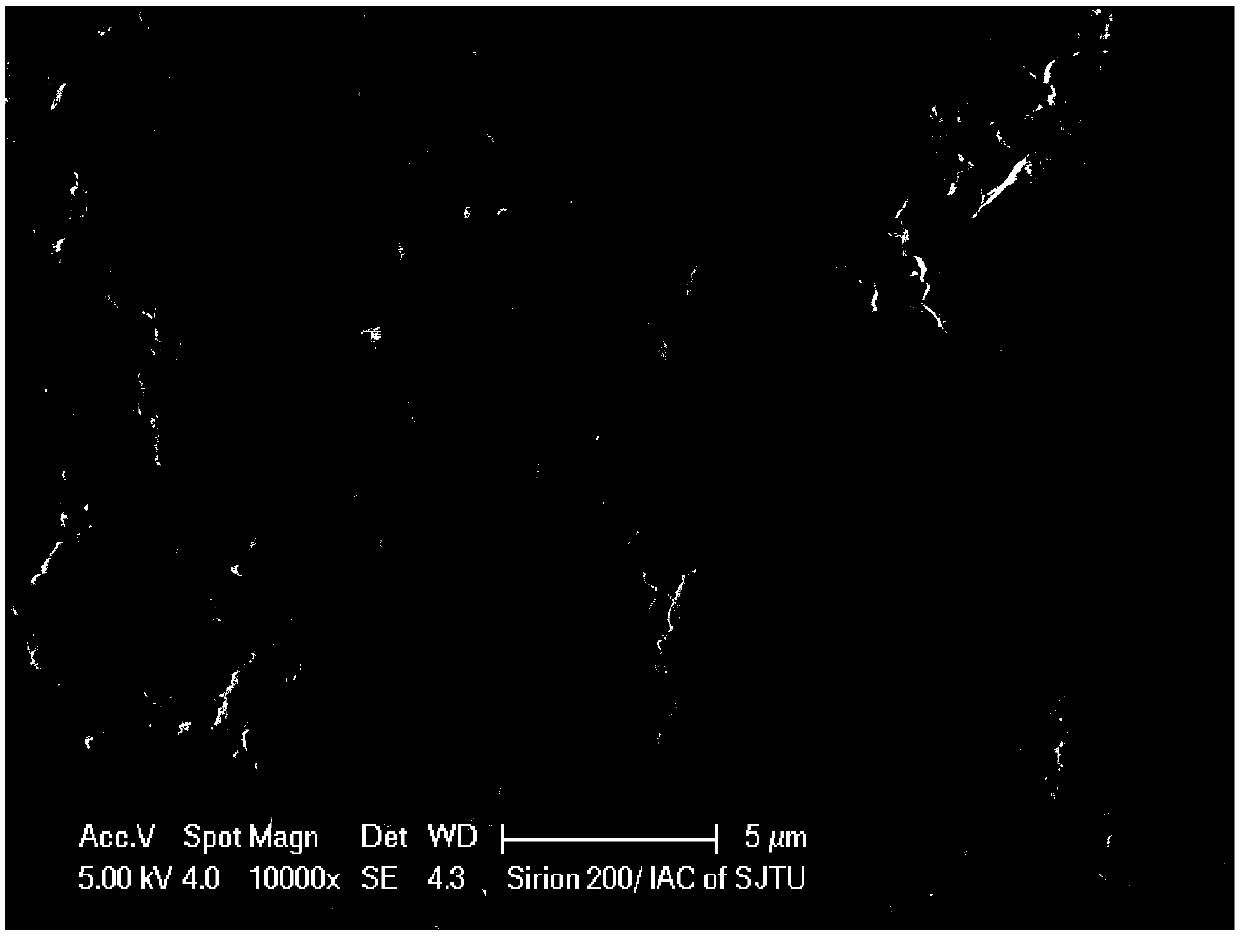

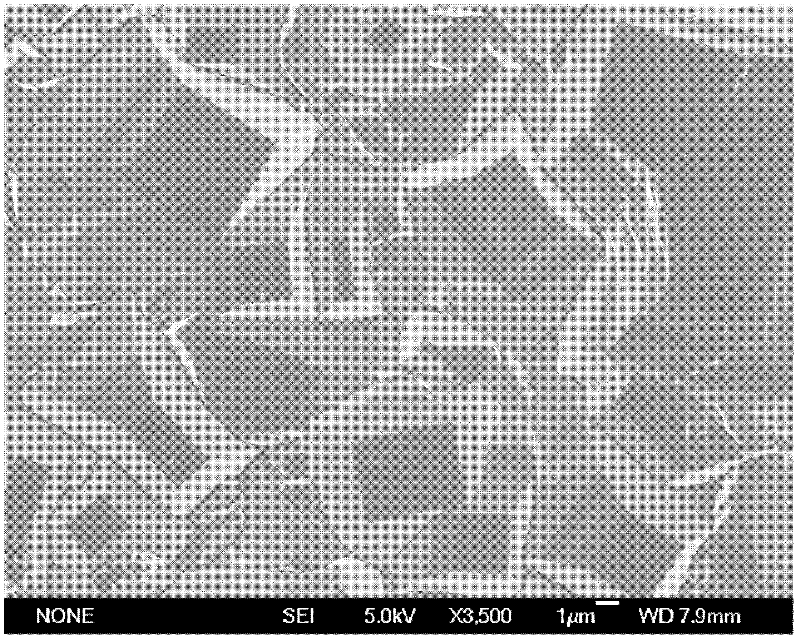

A method for immobilizing phospholipase with cellulose acetate/polypropylene composite membrane

InactiveCN102286453AGood chemical stabilityImprove adsorption capacityOn/in organic carrierPolypropylene compositesComposite film

The invention provides a cellulose acetate / polypropylene composite film prepared by using cellulose acetate and polypropylene film as materials, adopts an adsorption-crosslinking immobilization method, and uses the composite film to immobilize phospholipase. The effects of different immobilization conditions such as adsorption time, enzyme solution concentration, crosslinking agent concentration, crosslinking time and crosslinking temperature on the immobilization efficiency and catalytic effect of phospholipase were studied, and the enzymatic properties of the immobilized enzyme membrane were investigated. discuss. The advantage of using cellulose acetate / polypropylene composite membrane to immobilize phospholipase was further explained by the SEM images of the immobilized enzyme membrane. According to the adsorption characteristics of the composite membrane in the present invention, the immobilized phospholipase improves the activity and stability of the enzyme in the reaction system, regulates and controls the activity and selectivity of the enzyme, thereby facilitating the recovery of the enzyme and the production of the product, and finally obtains The immobilized enzyme activity is 4.6U / cm2.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com