Preparation and efficacy of low molecular weight soybean peptide

A low molecular weight, soybean peptide technology, applied in the direction of fermentation, can solve the problems of difficult to fully absorb, not concentrated, and the soybean peptide solution is not clear and transparent, and achieves the effect of good taste and easy absorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

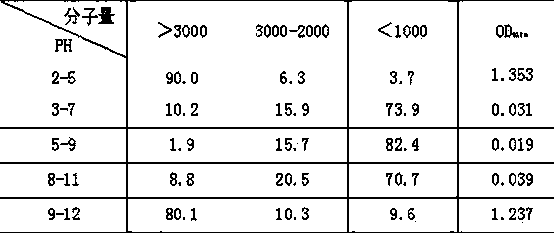

[0018] Example 1: Using soybean protein isolate as raw material, adding alkaline or neutral protease, under fixed temperature conditions, choosing different pH to obtain the molecular weight distribution of soybean peptides and the clarity of the solution, we use the clarity of the solution according to the OD610nm value Size is evaluated.

[0019]

[0020]

Embodiment 2

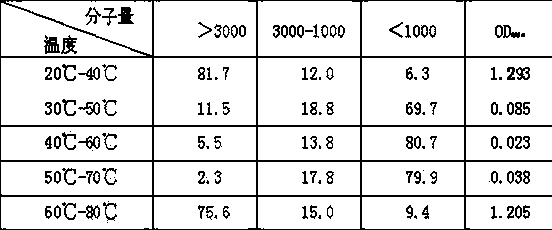

[0021] Example 2: Using soybean protein isolate as raw material, adding alkaline or neutral protease, under fixed temperature conditions, the molecular weight distribution of soybean peptide and the clarity of the solution obtained by selecting different temperatures.

[0022]

[0023]

Embodiment 3

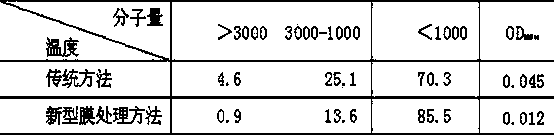

[0024] Example 3: Using soybean protein isolate as raw material, adding alkaline or neutral protease, enzymatically hydrolyzing for 1h-8h at a temperature of 40-70°C and pH5-9, passing through a membrane with a pore size of 0.1μm-0.45μm, The collected filtrate is the soybean peptide mixture we need; the peptide molecular weight and filtrate clarity obtained by comparing the traditional separation method with the membrane filtration method of the present invention are as follows:

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com