Method for preparing chitosan oligosaccharides by feed-batch-oxidative pretreatment assistant with enzyme hydrolysis of chitosan oligosaccharides

A fed-batch and pretreatment technology, applied in fermentation and other directions, can solve the problems of low production efficiency, low substrate concentration, high viscosity, etc., and achieve the effects of less chemical reagents, mild reaction conditions, and high product safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Disperse 3g of chitosan uniformly in 96mL of water, add 1mL of glacial acetic acid, stir to dissolve at room temperature, then add 4mL of 30% hydrogen peroxide, stir at 60℃ for 5min, and quickly add 1mL of glacial acetic acid and 3g of chitosan to control the total pretreatment For 1h, add 0.2g catalase to remove hydrogen peroxide, adjust the pH with concentrated ammonia, add 5g cellulase, and react at 55℃ for 12h. The obtained degradation solution is adjusted with ammonia to adjust the pH to 7, using 10kDa ultra The enzyme is removed from the filter membrane, and the filtrate is vacuum freeze-dried to obtain a pale yellow chito-oligosaccharide product, in which the yield of the chito-oligosaccharide that can be dissolved in 75% ethanol reaches 90%. For product identification by thin layer chromatography, see figure 1 (a), S is the standard product, and 1 to 4 are the same samples. Repeat 4 times. The 7 points of the standard from top to bottom are GlcN: Glucosamine; (G...

Embodiment 2

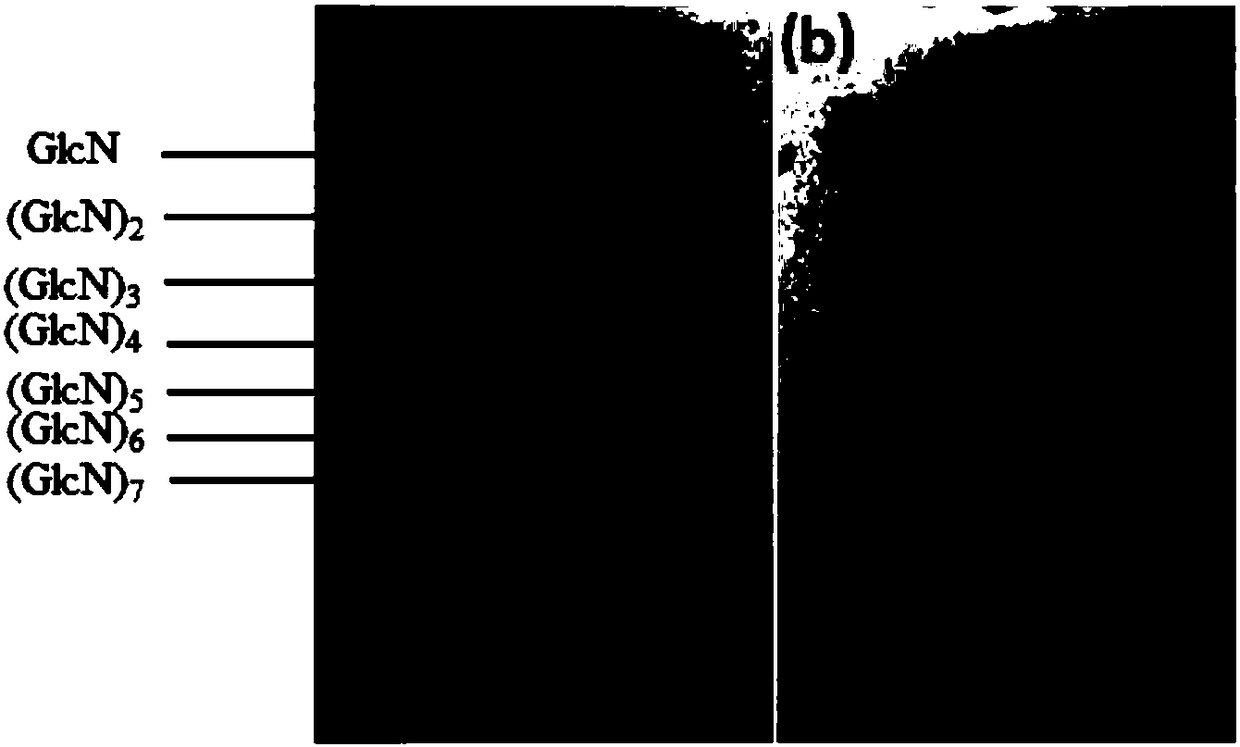

[0024] According to Example 1, 1 mL of glacial acetic acid and 3 g of chitosan were added at the 5th and 15th min of pretreatment, the total pretreatment time was controlled for 0.5h, 0.2g of catalase was added to remove hydrogen peroxide, and the pH was adjusted with concentrated ammonia. Add 5g of cellulase and react in a shaker at 55°C for 6 hours. The product can be dissolved at pH 7-14. Continue to react for 12 hours. The obtained degradation solution is adjusted to pH 7 with ammonia, and the enzyme is removed by a 10kDa ultrafiltration membrane. The filtrate is vacuum freeze-dried to obtain a light yellow chito-oligosaccharide product, in which the yield of chito-oligosaccharide that can be dissolved in 75% ethanol reaches 70%. For product identification by thin layer chromatography, see figure 1 (b). S is the standard product; 5-8 are the same samples repeated 4 times. The 7 points of the standard from top to bottom are GlcN: Glucosamine; (GlcN) 2 :Chitobiose; (GlcN) 3...

Embodiment 3

[0026] According to Example 2, add 1.2g NaHSO during enzymolysis 3 After 12 hours of enzymatic hydrolysis, almost pure white chitooligosaccharides were obtained. Among them, the yield of chitooligosaccharides that can be dissolved in 75% ethanol reached 48%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com