Parallel-connection type double-sound-wave-vortex viscosity reducing and oil enhancing device

A parallel and eddy current technology, which is applied in the direction of cleaning equipment, wellbore/well parts, earthwork drilling and production, etc., can solve the problems that cannot be applied to low-depth oil wells, large fluctuations, unstable output of oil boosters, etc., and reaches the scope of use wide, long product life, good superiority effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

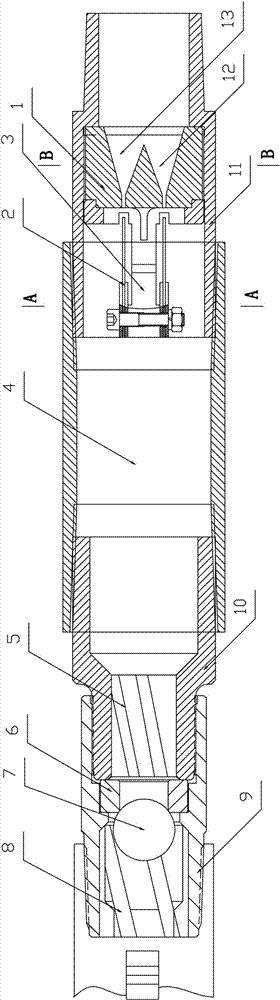

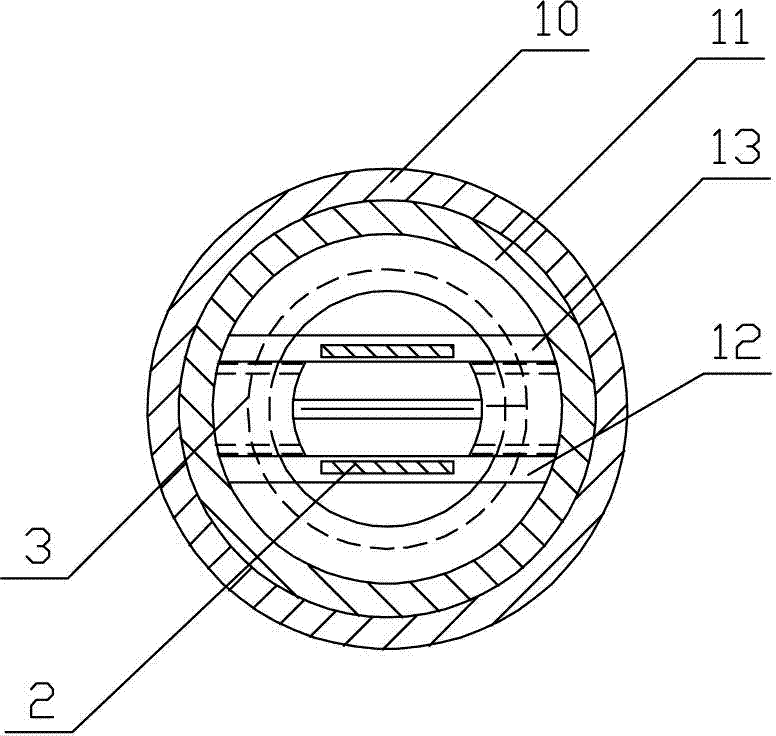

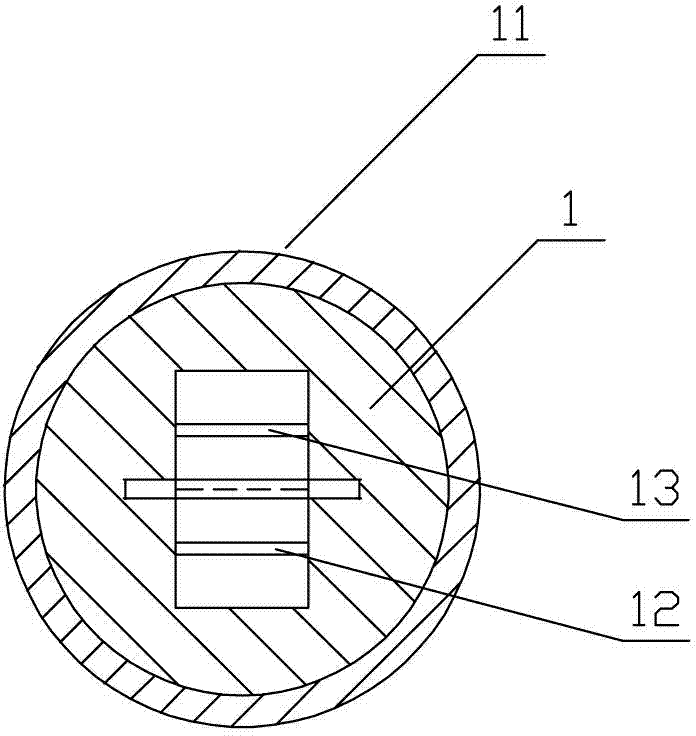

[0034] see figure 1 —3. The present invention consists of two parts, a jet acoustic wave oscillator and a vortex injector, which are formed by a cavitation cabin 4 transition butt joint. The cavitation cabin 4 of the present invention is made of a double-headed internal thread pipe joint, and cavitation The chamber 4 can also be formed by extending the tubular housing 11 of the double-jet ultrasonic oscillator or extending the joint part of the guide section 9 of the vortex guide injector. Wherein: the jet ultrasonic oscillator among the present invention has a steel tubular housing 11, the oil inlet end of housing 11 is shaped on screw thread, makes a plug-shaped jet head 1 and is threadedly connected with housing, has on the jet head 1 Two wedge-shaped through-holes 12, 13; the size of each wedge-shaped through-hole 12, 13 in the jet head 1 is 25mm×28mm, and the size of the small mouth is 25mm×3mm; the small-mouth end is designed as a flat nozzle fuel injection port, The sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com