Composite lignin-base viscosity breaker for drilling fluid and preparation method thereof

A lignin-based, drilling fluid technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of complex production process, poor viscosity reduction effect, secondary pollution, etc. The effect of easy availability of raw materials and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

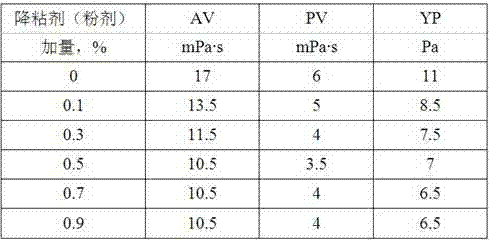

Embodiment 1

[0047] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0048] Pulping black liquor (mixture of wheat straw, Achnatherum splendens, and eucalyptus pulping black liquor, the mass ratio is 3:2:2, and the solid content is 58%): 440 kg

[0049] Concentrated sulfuric acid (98%): 10.3 kg

[0050] Hydrogen peroxide (30%): 6.0 kg

[0051] Formaldehyde (37%): 22.4 kg

[0052] Sodium sulfite: 41.1 kg

[0053] 7 water ferrous sulfate: 35.2 kg

[0054] Potassium permanganate: 7.3 kg

[0055] Concentrated hydrochloric acid (36%-40%): 73.4 kg

[0056] Tributyl phosphate: 0.1 kg

[0057] Sodium tripolyphosphate: 5.9 kg

[0058] Water: 358.2

[0059] 2. Preparation process steps and parameters:

[0060] (1) Sulfonation reaction: first add 440 kg of pulping black liquor with a solid content of 45% to the reactor, and mix 10.3 kg of concentrated sulfuric acid with a content of 98% and 41.1 kg of water to form a sulfuric acid solution with a cont...

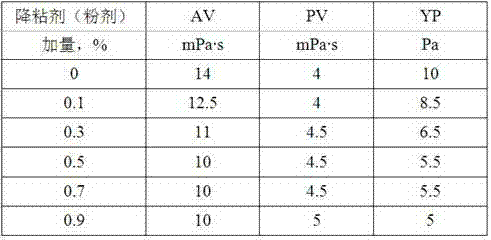

Embodiment 2

[0064] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0065] Pulping black liquor (straw, birch, masson pine kraft black liquor mixture, mass ratio 3:2:1, solid content 58%): 360 kg

[0066] Concentrated sulfuric acid (98%): 13.2 kg

[0067] Hydrogen peroxide (30%): 12 kg

[0068] Formaldehyde (37%): 26.4 kg

[0069] Sodium bisulfite: 38.4 kg

[0070] 4 water ferrous chloride: 36 kg

[0071] Potassium permanganate: 9.6 kg

[0072] Concentrated hydrochloric acid (36%-40%): 102 kg

[0073] TSA-672 high-efficiency silicone foam suppressor: 1.4 kg

[0074] Sodium phosphate: 7.2 kg

[0075] Water: 393.7

[0076] 2. Preparation process steps and parameters:

[0077] (1) Sulfonation reaction: first add 360 kg of pulping black liquor with a solid content of 58% into the reactor, and mix 13.2 kg of concentrated sulfuric acid with a content of 98% and 52.8 kg of water to form a sulfuric acid solution with a content of 19.6% Then add i...

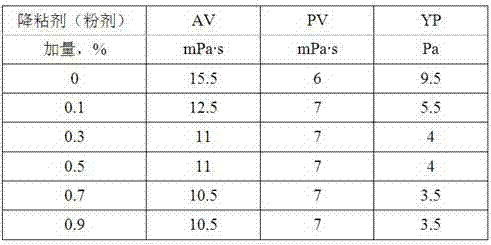

Embodiment 3

[0081] 1. The raw material components used in this embodiment are as follows (unit: kilogram):

[0082] Pulping black liquor (mixture of bamboo, bagasse, and awn stem pulping black liquor, the mass ratio is 7:2:1, and the solid content is 60%): 283 kg

[0083] Concentrated sulfuric acid (98%): 4.7 kg

[0084] Hydrogen peroxide (30%): 14.5 kg

[0085] Formaldehyde (37%): 24.9 kg

[0086] Sodium metabisulfite: 54.8 kg

[0087] Ferrous salt: (mixture of ferrous sulfate 7 hydrates / ferrous chloride 4 hydrates, mass ratio 1:1) 37.8 kg

[0088] Manganese dioxide: 3.8 kg

[0089] Concentrated hydrochloric acid (36%-40%): 96.4 kg

[0090] SPG-303 paper pulping special defoamer: 1.9 kg

[0091] Sodium hexametaphosphate: 47.3 kg

[0092] Water: 431 kg

[0093] 2. Preparation process steps and parameters:

[0094] (1) Sulfonation reaction: first add 283 kg of pulping black liquor with a solid content of 60% into the reactor, and then mix 5 kg of concentrated sulfuric acid with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com