Patents

Literature

130results about How to "No flocculation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

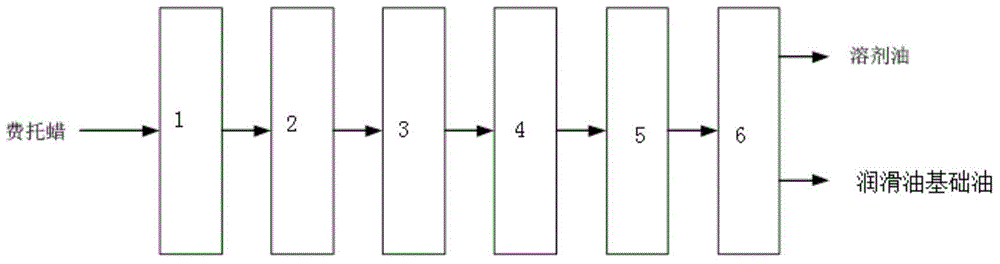

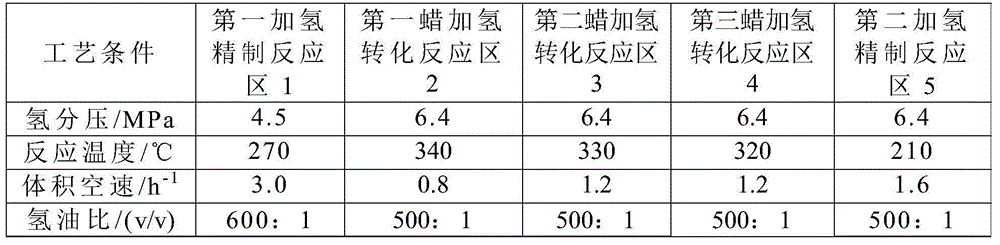

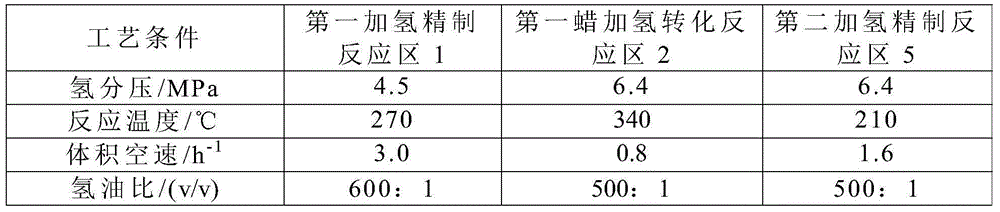

Method of treating Fischer-Tropsch wax, lubricant base oil and preparation method of same

ActiveCN105586083AHigh yieldNo flocculationTreatment with hydrotreatment processesLubricant compositionMolecular sieveWax

The invention discloses a method of treating Fischer-Tropsch wax, including the following steps: 1) successively contacting the Fischer-Tropsch wax with a hydrofining catalyst A, a hydroisomerization catalyst and a hydrofining catalyst B to obtain oil converted and generated from wax. A carrier of the hydroisomerization catalyst includes a molecular sieve. In the flowing direction of the Fischer-Tropsch wax, the hydroisomerization catalyst comprises a hydroisomerization catalyst A and a hydroisomerization catalyst B, wherein the pore diameter of the molecular sieve in the hydroisomerization catalyst B is larger than that in the hydroisomerization catalyst A. The invention also discloses a method of preparing lubricant base oil through the method of treating the Fischer-Tropsch wax and the lubricant base oil prepared through the method. The lubricant base oil is free of flocculation and is high in yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing the red pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415665AProlong hydrolysis timeReduce manufacturing costPigmenting treatmentAmmonium sulfateFertilizer

A process for preparing iron oxide red pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining heptahydrated ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

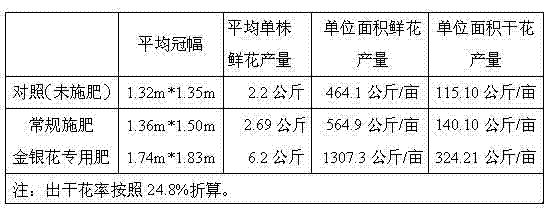

Selenium-enriched foliar fertilizer special for honeysuckle flower and preparation method thereof

InactiveCN102391050AHigh nutrient contentImprove absorption and utilizationFertilizer mixturesBrassicaAcetic acid

Owner:SHANDONG LUFENG HONEYSUCKLE PROMOTION

Novel modified emulsifying olefin concrete curing agent

The invention relates to a novel modified emulsified paraffin concrete curing agent. Aiming at overcoming the defects that the existing concrete curing agent cannot reach the industrial standard on building material in terms of the water retention property and is unfavorable for environmental protection, the price is high and the decoration at later stage is also affected, the following technical proposal is provided: the curing agent is mixed with the following materials and water: 10-20% of vinyl acetate-ethene high molecular polymer emulsion, 0-5% of silicone resin modified acrylic polymer emulsion, 50-75% of paraffin emulsion, 0.1-0.5% of colloidal dispersing agent of the emulsified paraffin for stabilizing the emulsion state and 0.05-0.02% of special defoamer for emulsion. The invention has the beneficial effects that: the chemical curing method which is adopted for retaining water is an innovation for the traditional curing method; compared with the prior art, the method is labor-saving, time-saving and water-saving and is convenient to operate, can improve the film formation ability and the sealing ability of the emulsified paraffin emulsion, and can improve the bonding and absorbing capacity of the emulsified paraffin emulsion on the concrete surface, which leads the effective water retention rate of the coating film to reach more than 90%.

Owner:LIAONING BUILDING SCI RES INST

Method for producing the yellow pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415666AHigh recovery rateAchieve the purpose of separationPigmenting treatmentFerric oxide yellowTitanium oxide

A process for preparing iron oxide yield pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Method for preparing lutein water-soluble dry powder

ActiveCN101177540AMultiple smallImprove solubilityNatural dyesFood preparationSolubilityFluidized bed drying

The invention discloses a preparation method of food-grade lutein water-soluble dry powder. The content of the all-trans isomer of the active ingredient in the product obtained by the existing method is low, and the structure is amorphous, which affects the coloring effect or bioavailability of the product. The steps of the present invention are as follows: after mixing lutein crystals with a low-boiling, volatile organic solvent with high solubility to lutein crystals, heating and dissolving to obtain an oil phase; mixing denatured starch with water, heating and dissolving, and cooling to obtain an aqueous phase ; The oil phase is slowly added to the water phase under stirring to obtain an emulsified mixed solution; the emulsified mixed solution is uniformed through a high-pressure homogenizer, so that the particle size of the emulsion reaches the nanometer level; the organic matter in the emulsion system is removed by conventional separation methods Solvent; use spray drying method or spray-starch fluidized bed drying method to remove water in the emulsion to obtain dry powder. The invention greatly increases the all-trans content of the active ingredients in the final product, is all amorphous, and has good coloring and nutritional strengthening effects.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

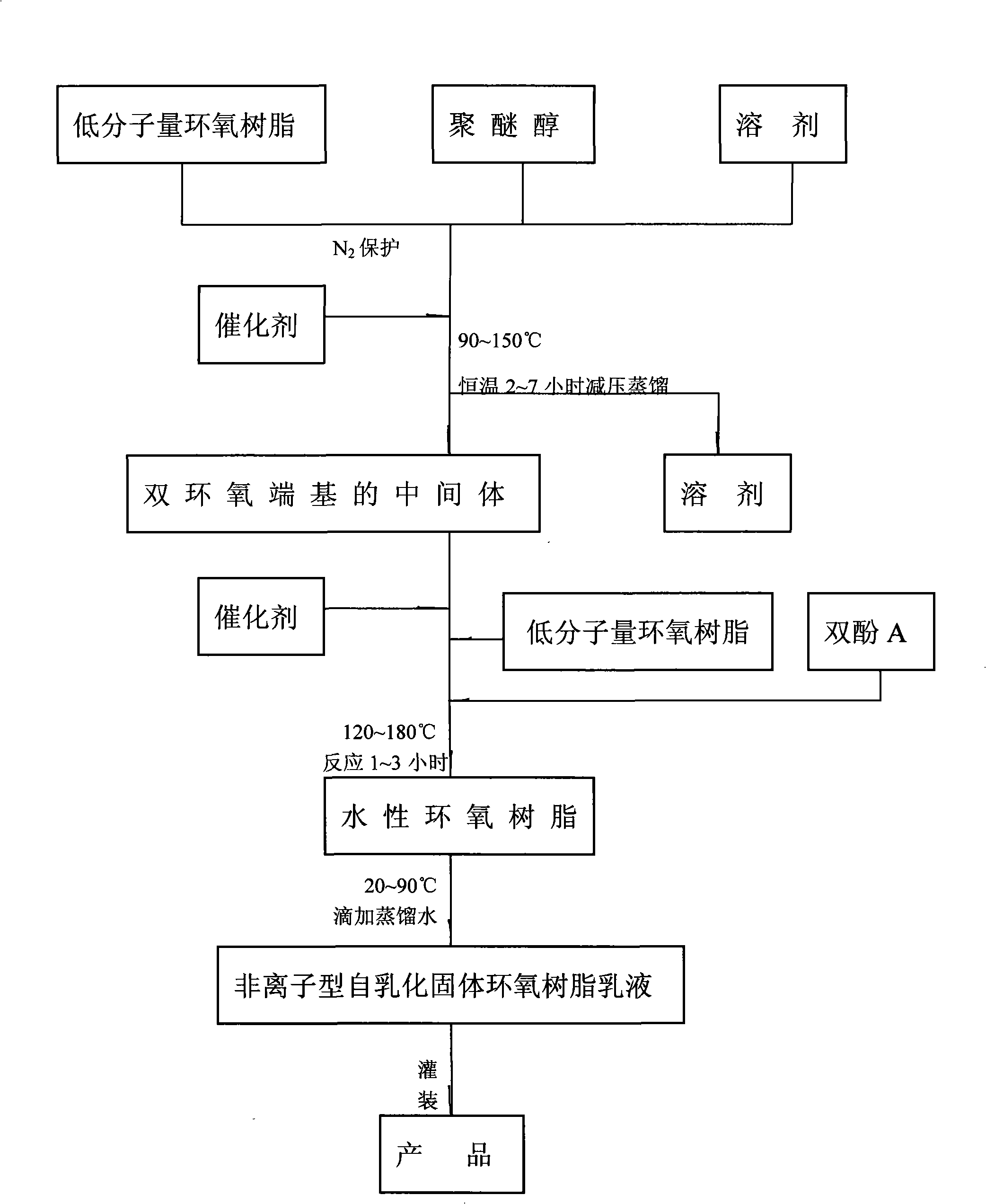

Non-ionic self-emulsification solid epoxy resin and preparation method for emulsion thereof

The invention relates to a non-ionic self-emulsifying solid epoxy resin and a preparation method of the emulsion of the resin, belonging to the coating material chemical manufacturing industry. The preparation method adopts a 'two-step method' principle during preparation: step one: under the protection of nitrogen, the reaction of 5 to 25 percent of low-molecular weight epoxy resin, 40 to 70 percent of polyether alcohol, 1 to 10 percent of solvent and 0.01 to 0.1 percent of catalyst is carried out at 90 to 150 DEG C, and then a constant temperature is kept for 2 to 7 hours before intermediate is obtained through the vacuum distillation of the solvent; step two: 10 to 25 percent of intermediate, 40 to 70 percent of low-molecular weight epoxy resin, 5 to 25 percent of bisphenol A and 0.02 to 0.1 percent of catalyst are heated up to 120 to 180 DEG C, and then a constant temperature is kept for 1 to 3 hours before non-ionic self-emulsifying solid epoxy resin with medium molecular weight and high molecular weight is obtained; and finally, at the temperature of 20 to 90 DEG C, distilled water is dripped in to dilute the solution to a degree with solid content ranging between 30 and 80 percent of through violent stirring, thereby obtaining non-ionic self-emulsifying solid epoxy resin emulsion. The preparation method has convenient operation, stable manufacturing technique, energy conservation and moderate preparation process. Moreover, the water-based epoxy emulsion is exquisite and has uniform particle diameter and high product quality.

Owner:中山大桥化工集团有限公司

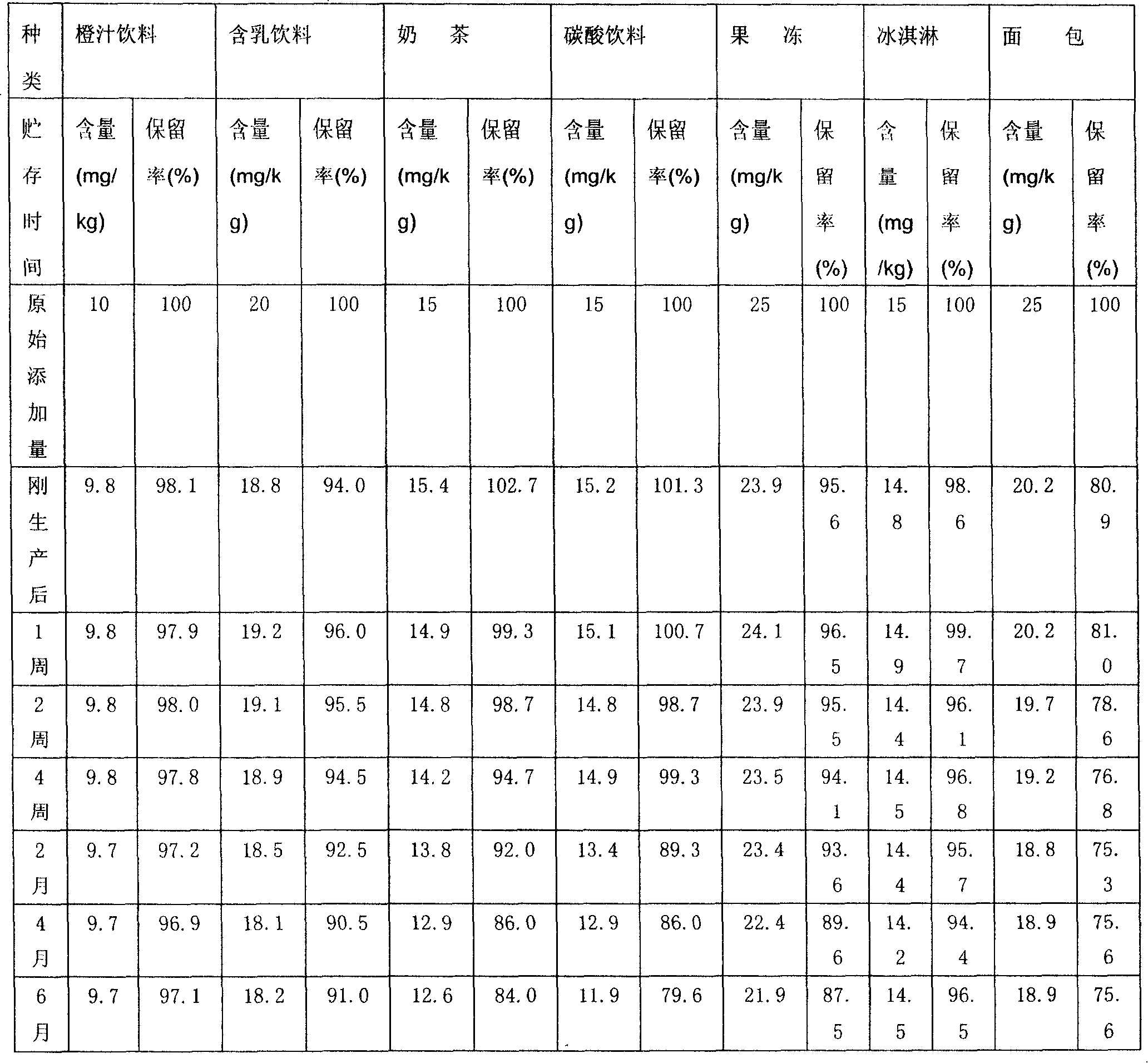

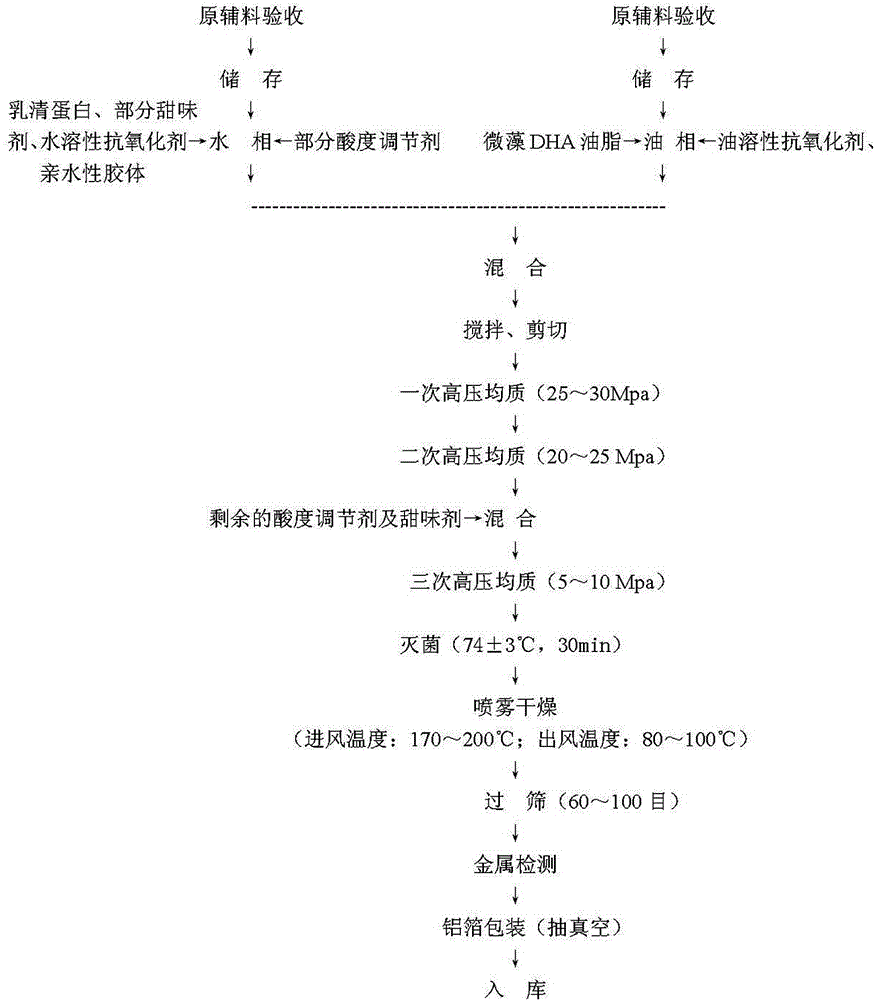

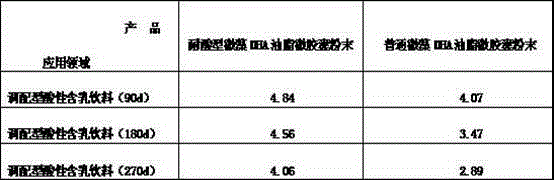

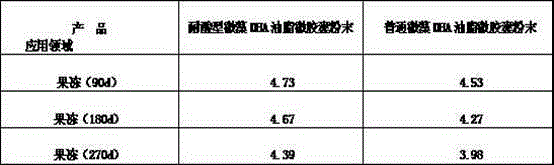

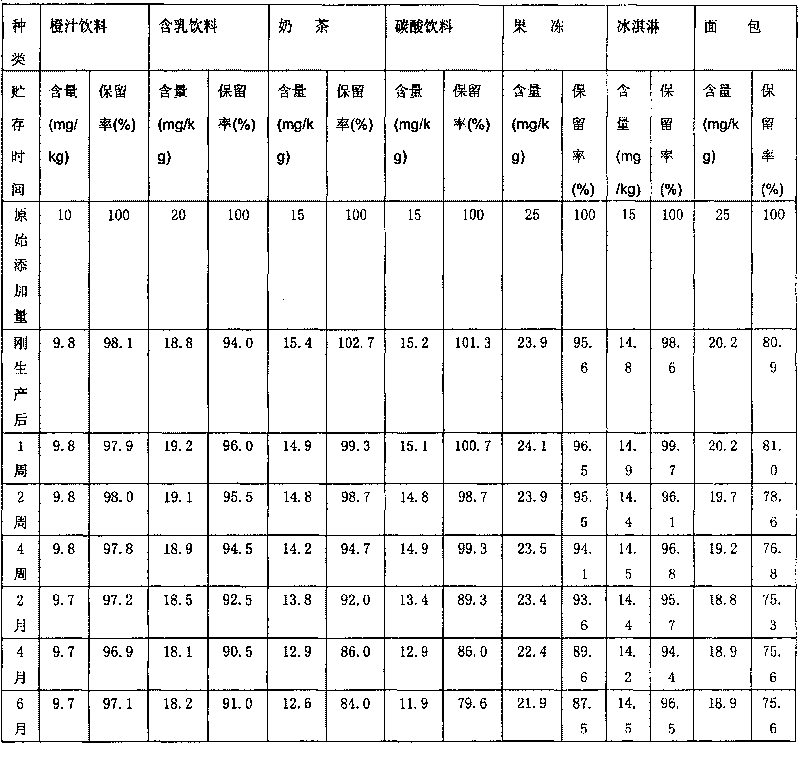

Acid-proof type microalgae DHA oil microcapsule powder and preparation method thereof

ActiveCN104432059AImprove stabilityNo flocculationSugar food ingredientsFood shapingBiotechnologyAcid water

The invention relates to an acid-proof type microalgae DHA oil microcapsule powder and a preparation method thereof. The acid-proof type microalgae DHA oil microcapsule powder is prepared from 12.6%-30.3% of core materials and 69.7%-87.4% of wall materials, concretely comprising the following active ingredients in percentage by weight: 12.5%-30.0% of microalgae DHA oil, 0.1%-0.3% of antioxidant, 25.0%-50.0% of whey protein, 3.0%-8.0% of food emulsifier, 20.0%-54.4% of sweetener, 4.40%-8.0% of hydrophilic colloid, and 0.60%-1.20% of acidity regulator. The prepared acid-proof type microalgae DHA oil microcapsule powder has good acid-proof property, and can be applied in a food system of an acid water system with pH of more than or equal to 3.5, the oxidization speed of microalgae DHA can be effectively reduced and delayed, the activity of the microalgae DHA can be maintained, the stability of microalgae DHA in acid water system food can be enhanced, and the shelf life of the acid water system food with microalgae DHA can be prolonged.

Owner:RUNKE BIOENG FUJIAN

Method for preparing lutein water-soluble dry powder

ActiveCN101177540BMultiple smallImprove solubilityNatural dyesFood preparationSolubilityFluidized bed drying

The invention discloses a preparation method of a food grade phylloxanthin water-soluble dry powder. The content of the all-trans isomer of the active ingredient of the product obtained by means of the prior method is low with an amorphous structure, so that the coloring effect or bioavailability of the product is affected. The procedures of the invention are as follows: when a phylloxanthin crystal is mixed with a low boiling point and volatile organic solvent which has a big solubility to the phylloxanthin crystal, and then the mixer is heated and dissolved so as to get an oil phase; a modified starch is mixed with water, and the mixer is warmed up and dissolved, then is cooled so as to get a water phase; the oil phase is slowly added into the water phase after mixed around, so that an emulsive mixed liquor is gotten; the emulsive mixed liquor is uniform through a high-pressure uniform machine, thereby the latex grain diameter can reach the nanometer level; the organic solvent in thelatex system can be removed by a conventional separation method; the normal water in the latex can be removed to get the dry powder by a spray drying process or spray starch fluidized bed drying process. The invention can greatly improve the all-trans content of the active ingredient of the termination product in amorphous form, thereby the invention has the advantages of good coloring and nutrition strengthening effects.

Owner:ZHE JIANG MEDICINE CO LTD XINCHANG PHARMA FAB

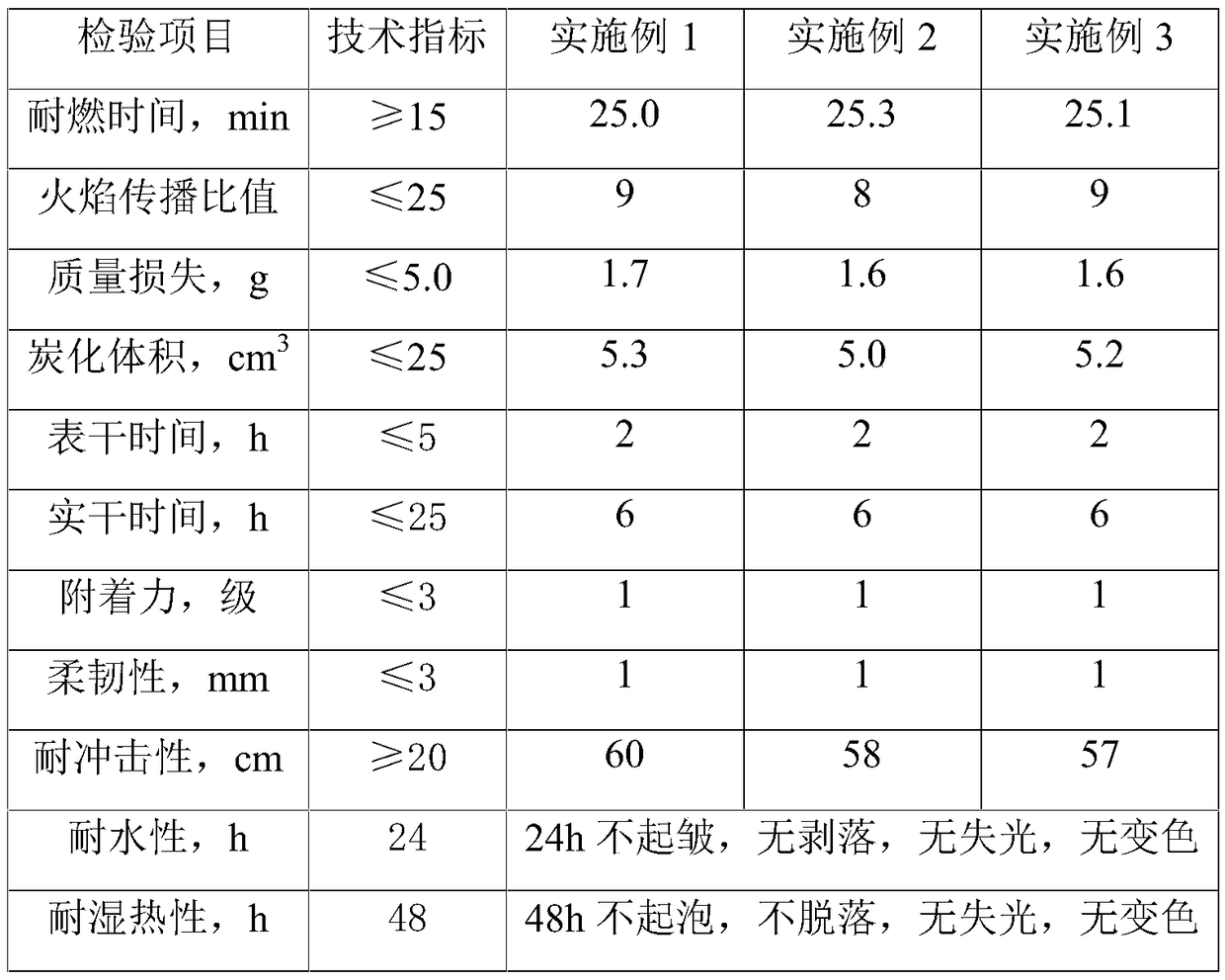

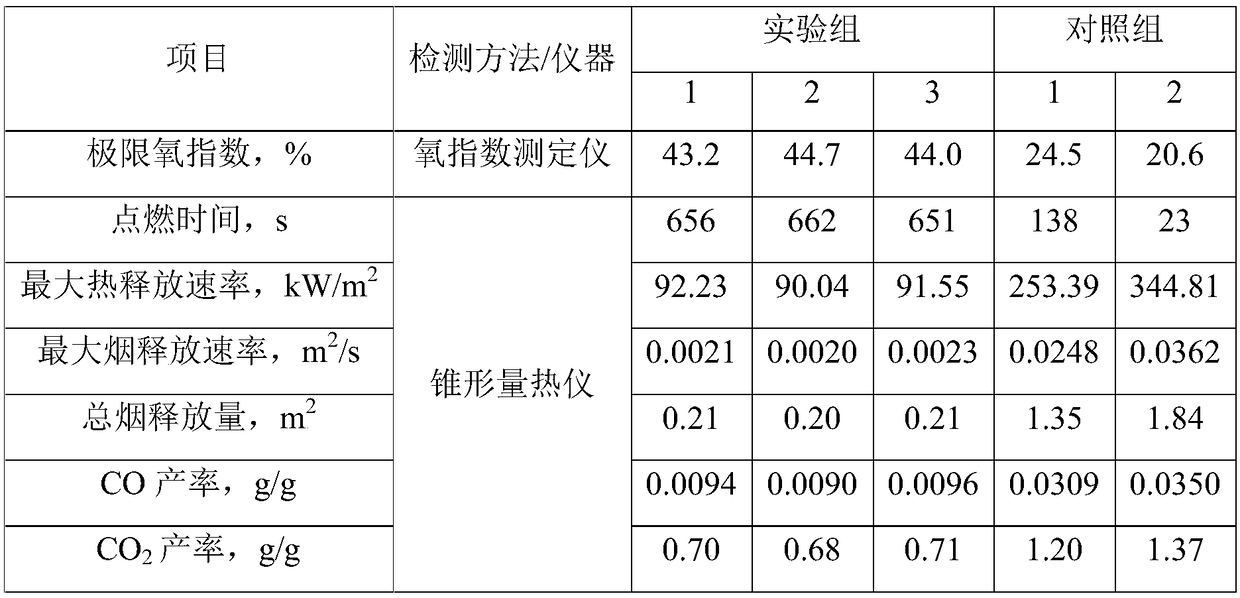

Expansive waterborne fireproof and flame-retardant coating for wood material and preparation method of expansive waterborne fireproof and flame-retardant coating

The invention relates to an expansive waterborne fireproof and flame-retardant coating for a wood material and a preparation method of the expansive waterborne fireproof and flame-retardant coating. The coating comprises water and the following components in parts by weight: 200 parts of melamine-modified urea resin emulsion, 110-120 parts of ethylene-vinyl acetate copolymer emulsion, 20-24 partsof boric acid, 36-38 parts of ammonium polyphosphate, 20-24 parts of guanylurea phosphate, 36-40 parts of pentaerythritol, 30-34 parts of melamine, 1.0-1.4 parts of sulfonated carbon, 3.6-4.0 parts ofzinc borate, 2.0-2.4 parts of ammonium octamolybdate, 16-20 parts of coating auxiliaries and 0-44 parts of pigment and filler. When heated, the expansive waterborne fireproof and flame-retardant coating is capable of greatly retarding the combustion of the wood material so as to prevent fire spreading; and the expansive waterborne fireproof and flame-retardant coating has good smoke inhibiting property and is capable of delaying the smoke generation time, reducing the release amount of smoke and the generation of poisonous gases and providing more safety time and space for escape and rescue of personnel under the condition of a fire hazard.

Owner:湘诚新材料科技有限公司

Oral liquor of anti-fatigue and intensifying immunity and preparing method

InactiveCN101069723AQuality improvementFunctional balanceAnthropod material medical ingredientsSolution deliveryCrataegus FruitDioscorea polystachya

The present invention relates to an oral liquor for resisting fatigue and raising immunity of human body and its preparation process. Said oral liquor is made up by using 10 Chinese medicinal materials of epimedium, astragalus root, Chinese yam, eucommia bark, lyceum berry, crataegus fruit, Chinese angelica root, poria, rubus berry and spiny jujube kernel through a certain preparation process. Said invention also provides the concrete steps of its preparation process.

Owner:SHANGHAI YUSHENGTANG TECH

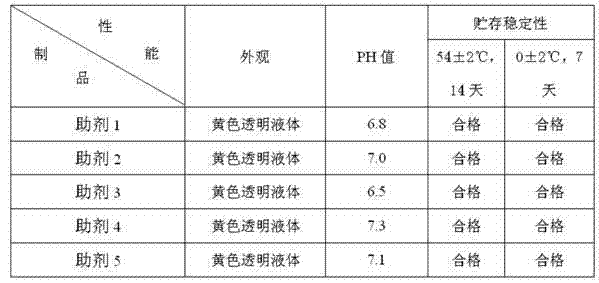

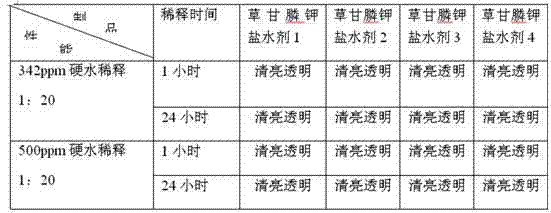

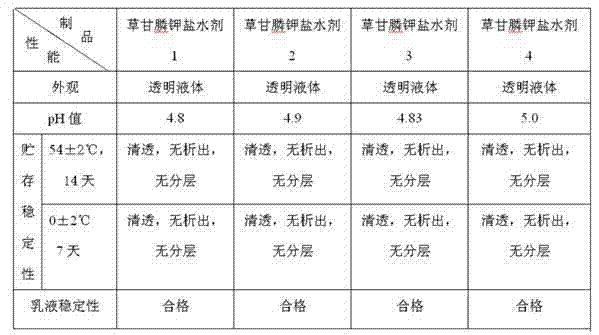

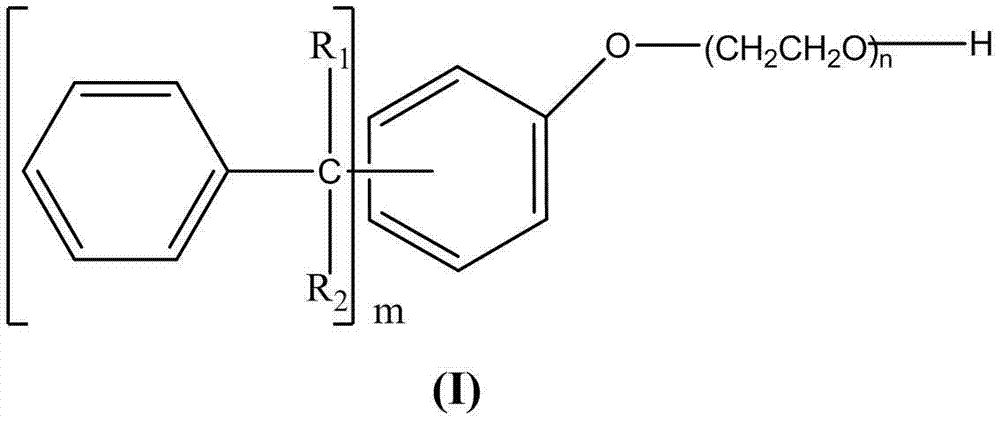

Special adjuvant of glyphosate potassium salt aqueous solution and salt aqueous solution using same

The invention relates to a special adjuvant of glyphosate potassium salt aqueous solution. The special adjuvant comprises (by weight percentage) alkyl polyglycoside (APG) 10-80, fatty alcohol polyoxyethylene ether 0-20, betaine 0-40, tallow amine polyoxyethylene ether 0-20, and the balance of water. The contents of fatty alcohol polyoxyethylene ether, betaine and tallow amine polyoxyethylene ether are not simultaneously zero. The adjuvant adopts environment friendly surfactant such as APG and betaine, is safe, green and bio-degradable, and reduces environment pollution of pesticide. When the adjuvant is used for the glyphosate potassium salt aqueous solution, the adjuvant has good synergic effect to product. With the adoption of the adjuvant, the glyphosate potassium salt aqueous solution has the advantages of simple process, low cost, good hard water resistance, good compatibility with other pesticides, and no layering or condensation phenomenon.

Owner:南京太化化工有限公司

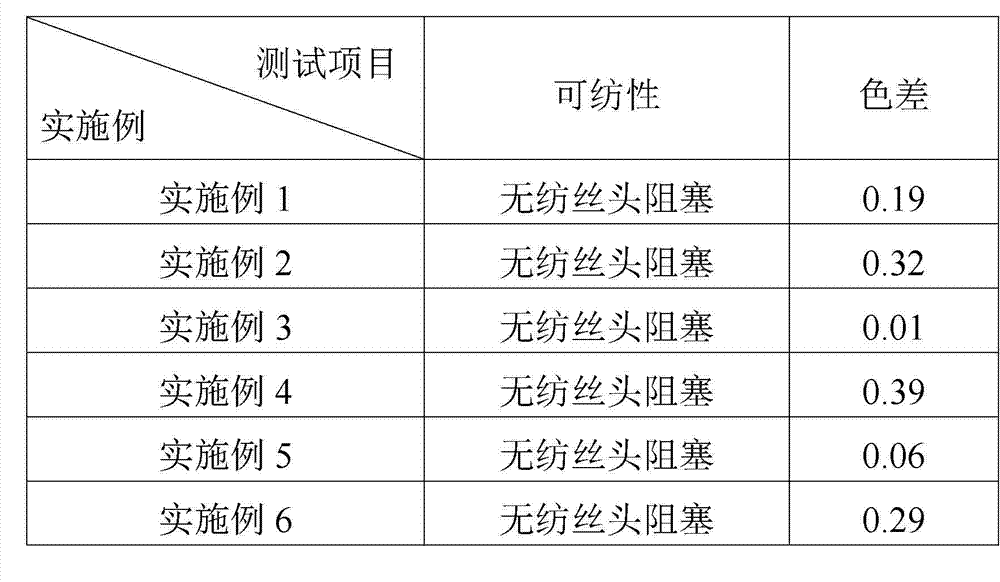

Glycol-based pigment dispersoid for dacron stock solution coloring and preparation method of dispersoid

ActiveCN103031755ASmall particle sizeNarrow particle size distributionDyeing processFlocculationThermal stability

The invention discloses a glycol-based pigment dispersoid for dacron stock solution coloring, and a preparation method of the dispersoid. The glycol-based pigment dispersoid comprises a pigment, a wetting agent, a dispersing agent and glycol, wherein the mass percentage of the pigment accounts for 10-40% of total mass percentage of the glycol-based pigment dispersoid; the mass ratio of the wetting agent to the pigment is (0.03-0.1):1; the mass ratio of the dispersing agent to the pigment is (0.05-0.2):1; and the balance is complemented by glycol. In the presence of the special structures, namely the wetting agent and the dispersing agent, the prepared glycol-based pigment dispersoid has the characteristics of small particle size and narrow particle size distribution range, and has thermostability, temperature stability and higher stability in terephthalic acid and derivatives of terephthalic acid; precipitation, flocculation, and the like do not exist within 12h at 250-280 DEG C; the glycol-based pigment dispersoid serves as a dacron resin colorant and is free from coloring power and brightness reduction and spinning nozzle blocking due to increase of pigment particles in a spinning process; and the glycol-based pigment dispersoid is suitable for the dacron stock solution coloring.

Owner:SUZHOU SUNMUN TECH CO LTD

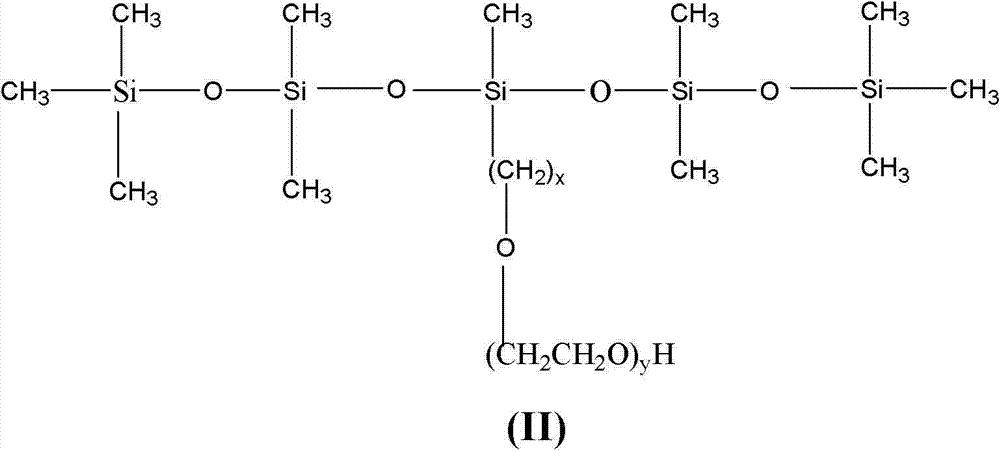

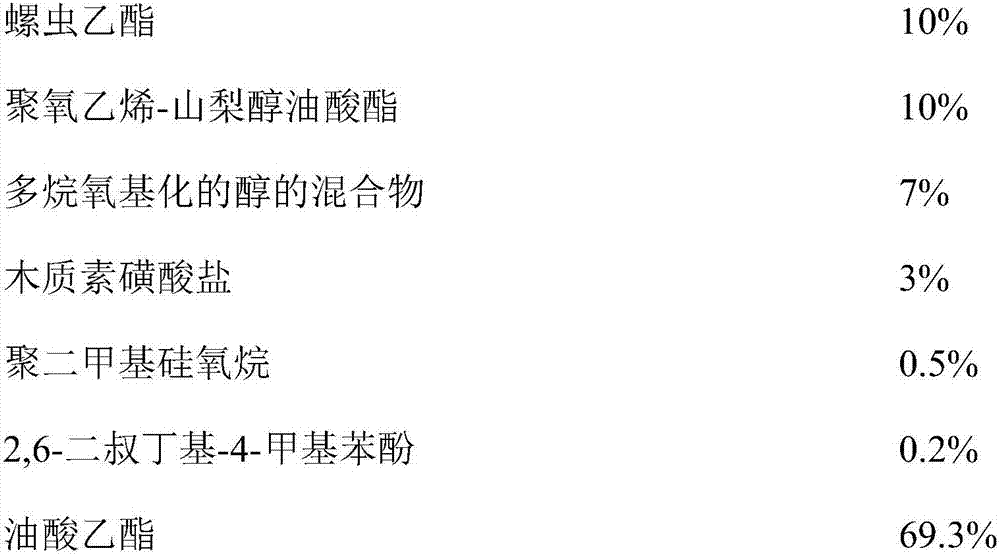

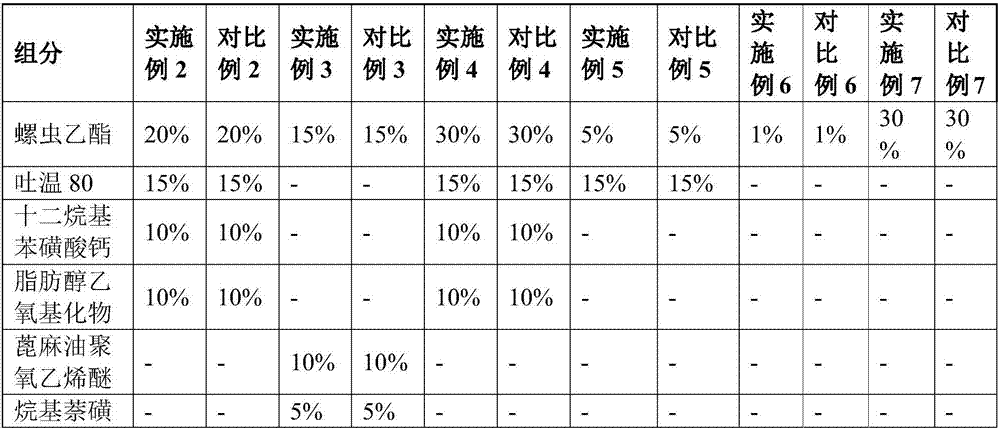

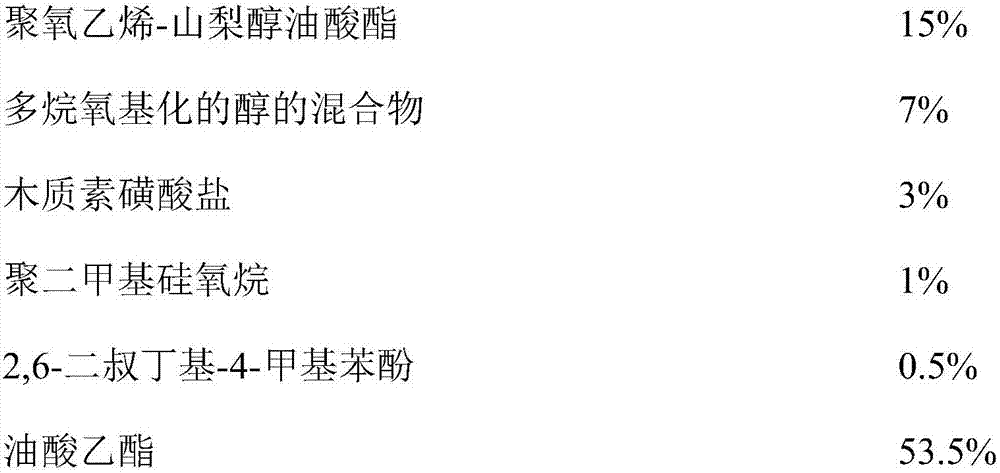

Oil-based suspending agent and preparation method and purpose thereof

PendingCN107484767AExcellent long-term storage stabilityControl particle size growthBiocideAnimal repellantsActive matterSuspending Agents

The invention discloses an oil-based suspending agent and a preparation method and a purpose thereof. The oil-based suspending agent comprises the following components: a component A of at least a solid spirotetramat active matter under room temperature; a component B of at least one fatty acid ester having a general formula of R1-COO-R2 and / or R1-COO-R2-OOC-R1; a component C of at least a nonionic surfactant and / or at least an anionic surfactant; and a component D of any one or at least two additives selected from an emulsifier, an antifoaming agent, an antiseptic, an anti-oxidant, a colouring agent or an inertia filling material. The oil-based suspending agent can effectively control the particle size increase problem of spirotetramat during a storage process, greatly inhibits the particle size increase of spirotetramat suspension particles, and increases the spirotetramat activity, compared with a conventional preparation, the higher activity is obtained, and the usage amount of spirotetramat is reduced.

Owner:JIANGSU ROTAM CHEM

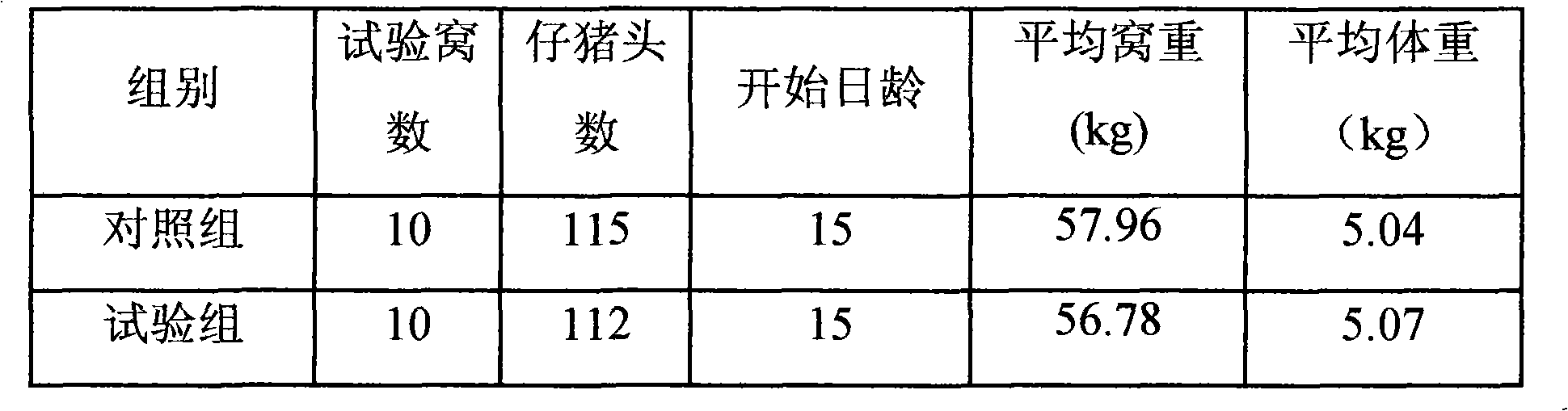

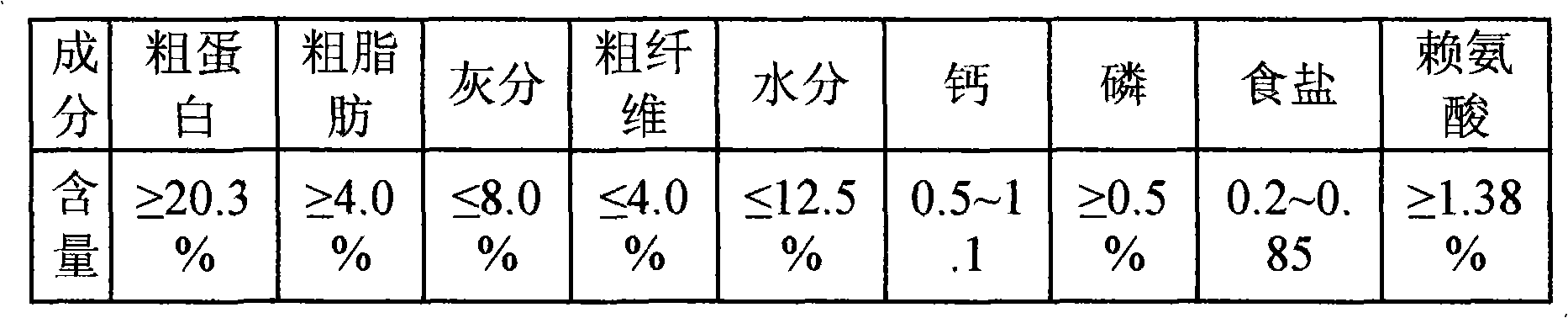

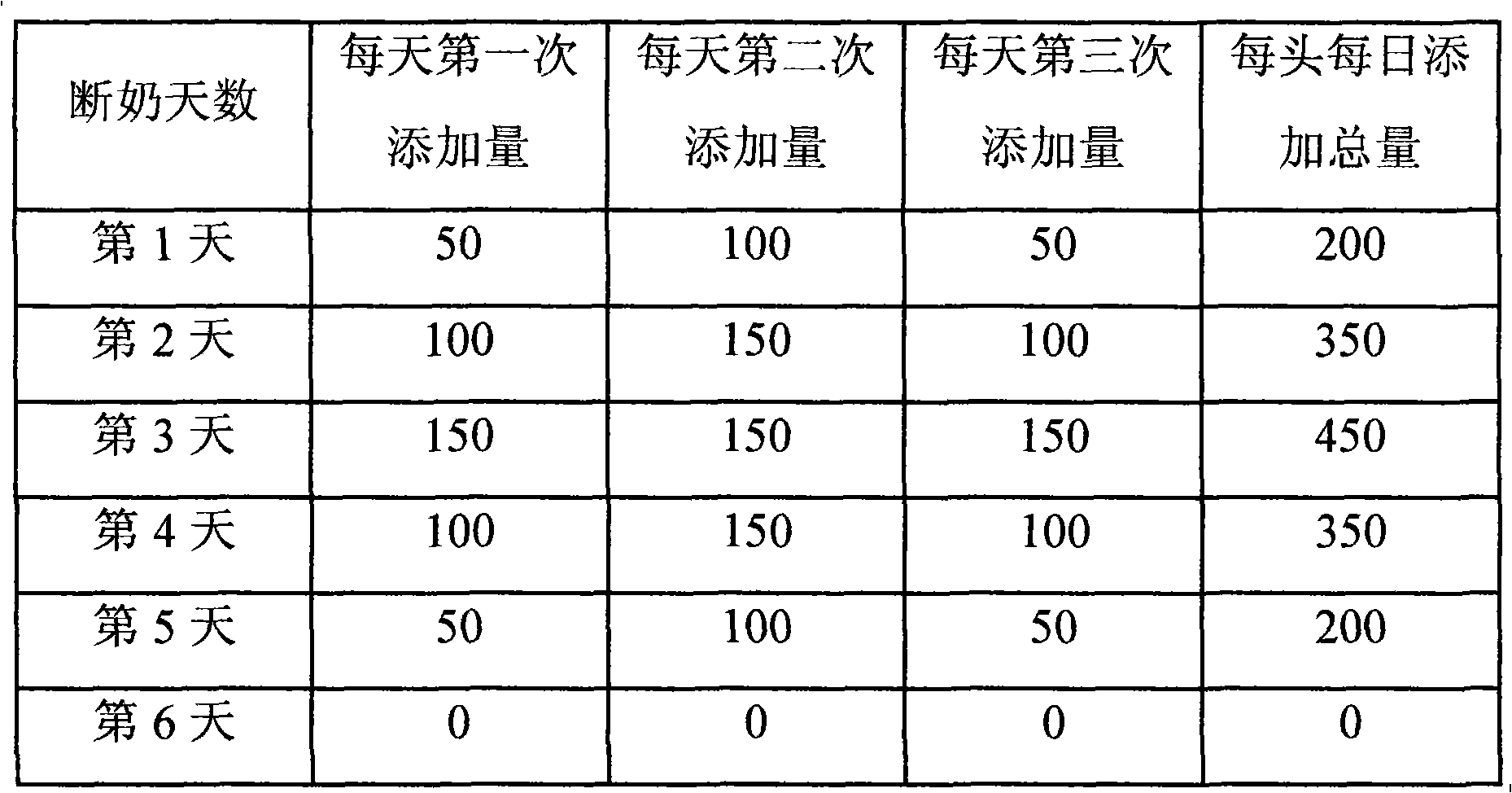

Semisolid piglet feed and preparation method thereof

InactiveCN102461744AIncrease daily food intakePromote absorptionAnimal feeding stuffWeaningAdditive ingredient

The invention discloses a semisolid piglet feed and a preparation method thereof. The semisolid piglet feed comprises, by weight, 5-15% of a milk substitute material, 0.5-0.7% of jelly powder, 0.2-0.25% of a jelly stabilizer, 0.5% of sodium citrate, 0.15-0.20% of citric acid, 0.05% of potassium sorbate, and the balance of water. According to the present invention, the semisolid piglet feed can provides nutritive materials (such as milk protein, lactose, and the like) similar to the breast milk components for the piglet after weaning, wherein the nutritive materials are easily digested by the piglet, such that the poor appetite and other syndromes due to piglet weaning can be solved, the eating amount of the piglet can be increased, and the piglet can absorb the water timely so as to meet the requirements of the water during the piglet growth and development process.

Owner:ANYOU BIOTECH GRP

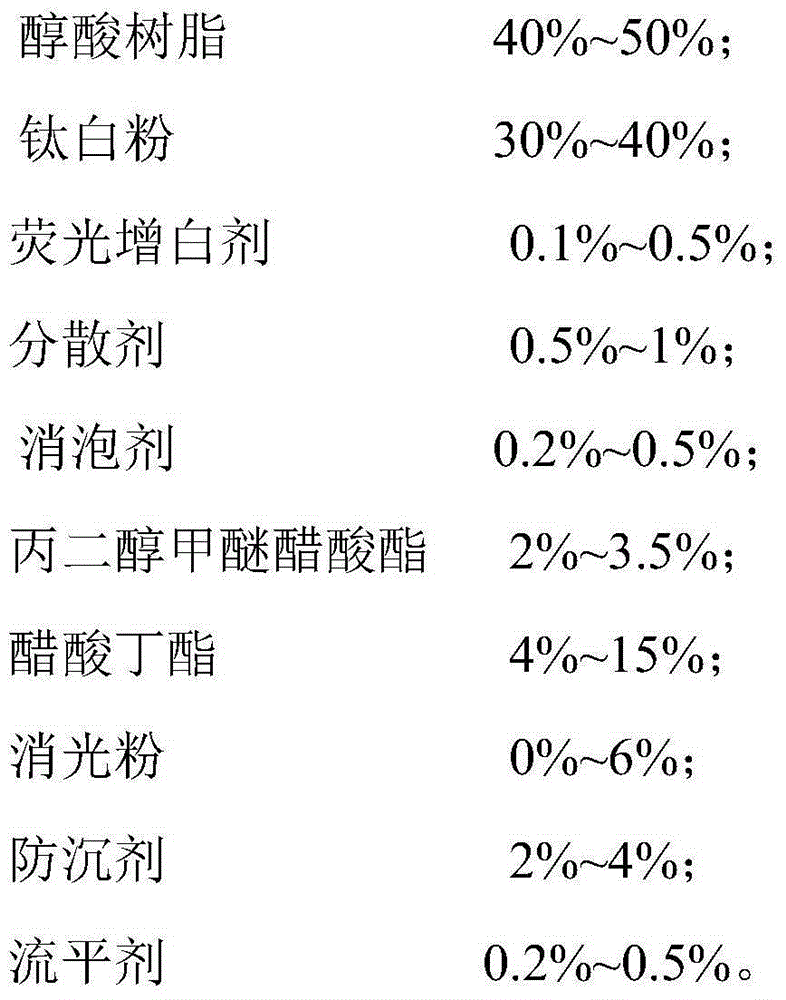

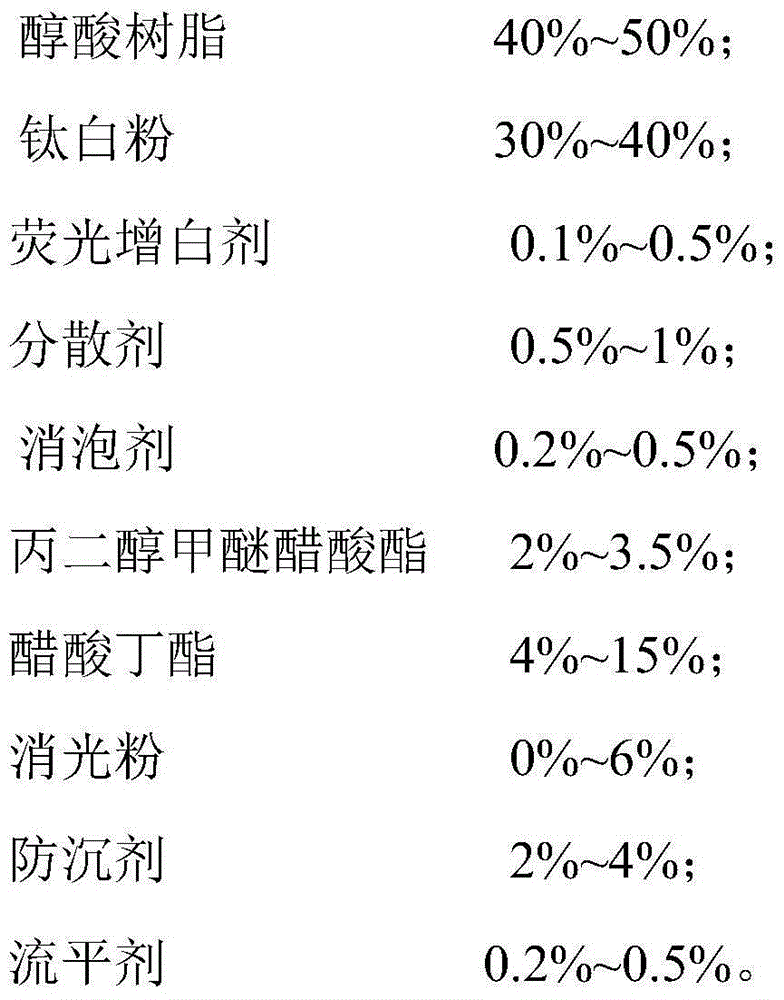

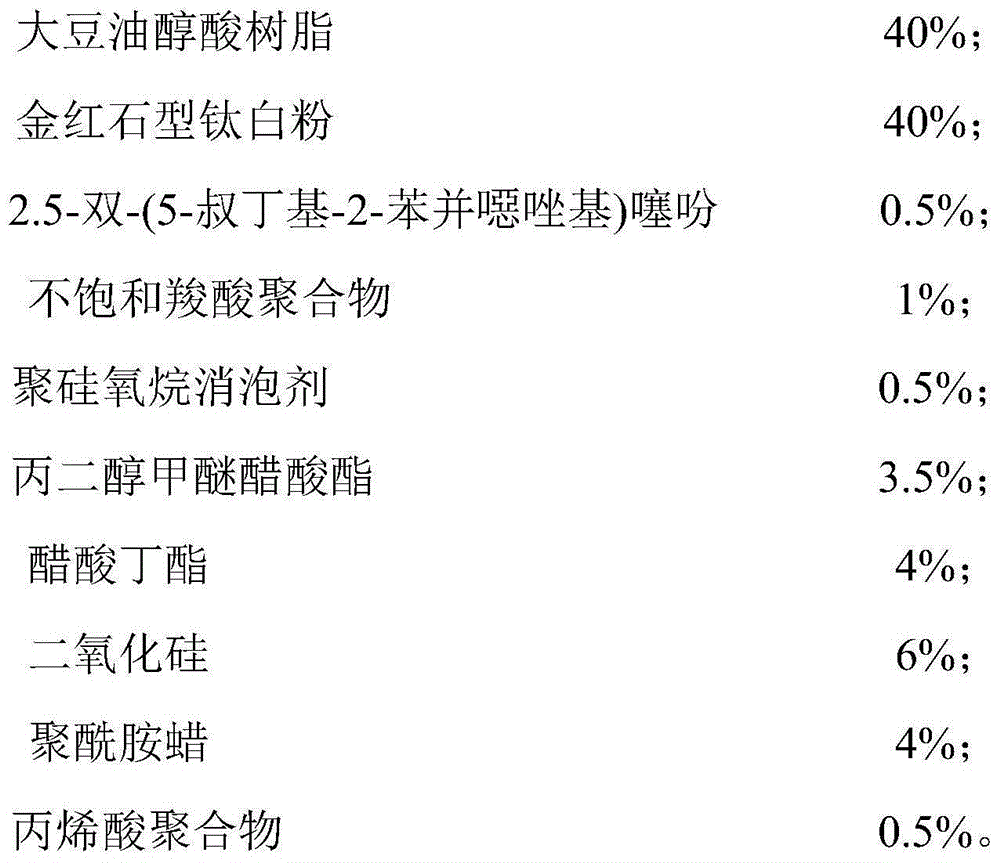

Polyurethane white paint as well as preparation method and application thereof

The invention relates to the technical field of coatings, and particularly discloses a polyurethane white paint as well as a preparation method and application thereof. The polyurethane white paint comprises the following formula components in percentage by weight: 40-50% of alcohol acid resin, 30-40% of titanium dioxide, 0.1-0.5% of a fluorescent brightening agent, 0.5-1% of a dispersing agent, 0.2-0.5% of an antifoaming agent, 2-3.5% of propylene glycol methyl ether acetate, 4-15% of butyl acetate, 0-6% of a matting agent, 2-4% of an anti-settling agent, and 0.2-0.5% of a flatting agent. According to the polyurethane white paint, rutile type titanium dioxide and fluorescent whitening powder are added, mixed and ground, so that the effect of obviously whitening can be achieved, and the polyurethane white paint has favorable covering power and weather resistance. What's more, according to the preparation method, the titanium dioxide and the fluorescent brightening agent are controlled to be ground into titanium dioxide pulp together, so that the whitening effect of the coating is ensured to be achieved.

Owner:中华制漆(新丰)有限公司

Peanut nutrition milk and preparation method thereof

InactiveCN101176487AAvoid preprocessingAvoid cumbersome processes such as extractionMilk preparationFood preparationBiotechnologySucrose

The invention relates to a peanut nutritional milk and the preparation method, belonging to the technical field of food drink processing. The ingredients and the weight percentage of the invention are as follows: the protein 2.0 to 4.0 percent, sucrose 5.0 to 8.0 percent, emulsification stabilizing agent 0.15 to 0.25 percent, and remainder is the water. Compared with the prior art, the invention has the advantages that: (1) using the peanut butter protein directly to avoid the complicated crafts of pretreatment of peanut kernel, the protein extraction and other crafts, thus the production equipment disposition is simplified. (2) the nutritional milk prepared according to the invention has a protein content as high as 2.0 to 4.0 percent. (3) the nutritional milk presents cream color and has the unique fragrance and the taste of peanut and milk, taste is pure without burnt taste. During the guarantee of six months, the milk presents the uniform shape of the emulsion without lamination, flocculation phenomena and obvious deposit layer. Only by slightly shaking, the deposit can restore to the original condition.

Owner:广州合诚实业有限公司

Boiling-resistant aqueous composite ink and preparation method thereof

InactiveCN102532997AGood resolubilityExcellent retort resistanceInksPolymer sciencePigment dispersion

The invention discloses boiling-resistant aqueous composite ink and a preparation method thereof. The boiling-resistant aqueous composite ink mainly comprises raw materials including aqueous polyurethane resin, a pigment and water, and a surface wetting agent, a wetting dispersing agent and a defoaming agent are additionally added. The preparation method of the boiling-resistant aqueous composite ink comprises the following steps of: firstly, adding partial aqueous polyurethane resin into a stirring reaction kettle; secondly, slowly adding the surface wetting agent, the wetting dispersing agent and partial defoaming agent, and adding the pigment after stirring and dispersing; thirdly, stirring and dispersing at high speed, and grinding after dispersing; fourthly, adding the residual aqueous polyurethane resin and defoaming agent and stirring and dispersing, and adding the water until the required viscosity is obtained through regulation; and at last, stirring, dispersing, filtering and packaging. The boiling-resistant aqueous composite ink, provided by the invention, is prepared by taking the high-performance aqueous polyurethane resin as a connecting material, and has the advantages of good pigment dispersibility, wide use range, lower film forming temperature, better mechanical property of formed film, more uniform particle size distribution and the like, and can be used for soft retort packages.

Owner:ZHENGZHOU LETONG NEW MATERIAL TECH

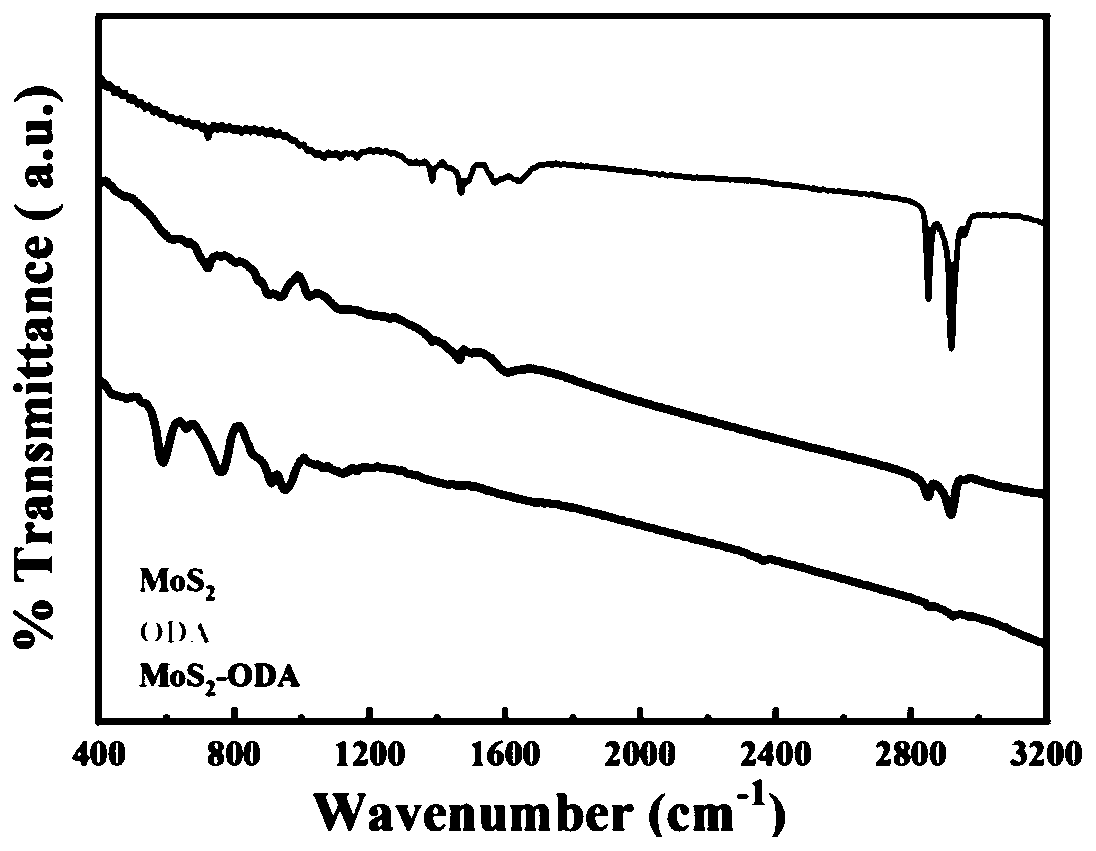

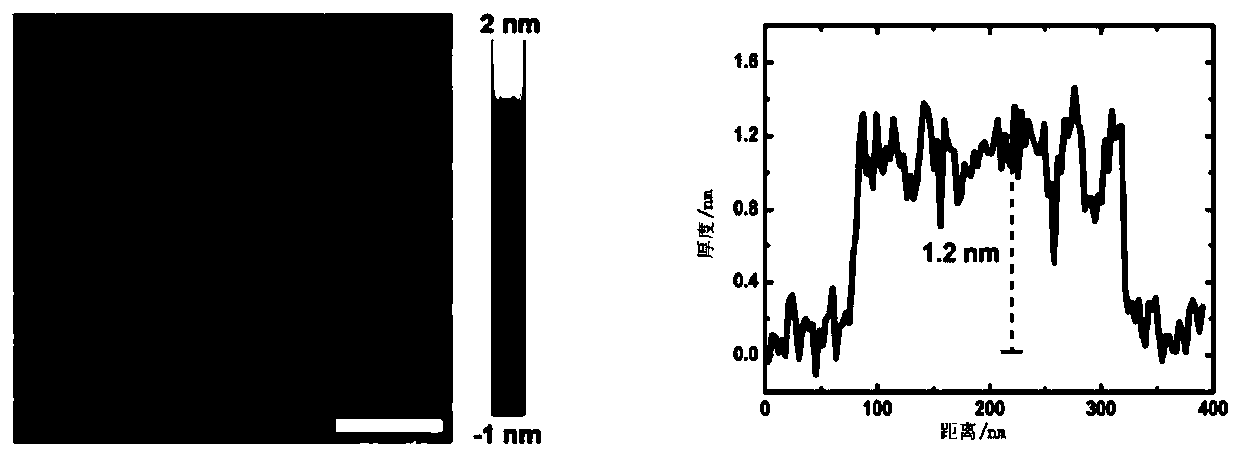

Method for preparing drag reducer from modified MoS2

ActiveCN110452677ALarge specific surface areaImprove propertiesDrilling compositionFlocculationRoom temperature

The invention discloses a method for preparing a drag reducer from modified MoS2, and relates to the technical field of petroleum development. The method comprises the following steps: (1) preparationof the modified MoS2; (2) preparation of a modified MoS2 suspension; (3) preparation of a polymer; and (4) preparation of the drag reducer. The drag reducer prepared in the invention has a good thermal stability, so the product can be stored at room temperature for 30 d without flocculation and sedimentation; the product has good water-soluble dissolving ability, so the product can be fully dissolved in different water solutions, can be still uniformly dispersed after being subjected to gel breaking at a high temperature of 130 DEG C, and breaks through the technical problem of poor thermal stability of the drag reducer due to too high temperature; and the product has the advantages of low concentration and high efficiency, so the order of magnitude of the concentration of the drag reducer is reduced.

Owner:河南郸城顺兴石油助剂有限公司 +1

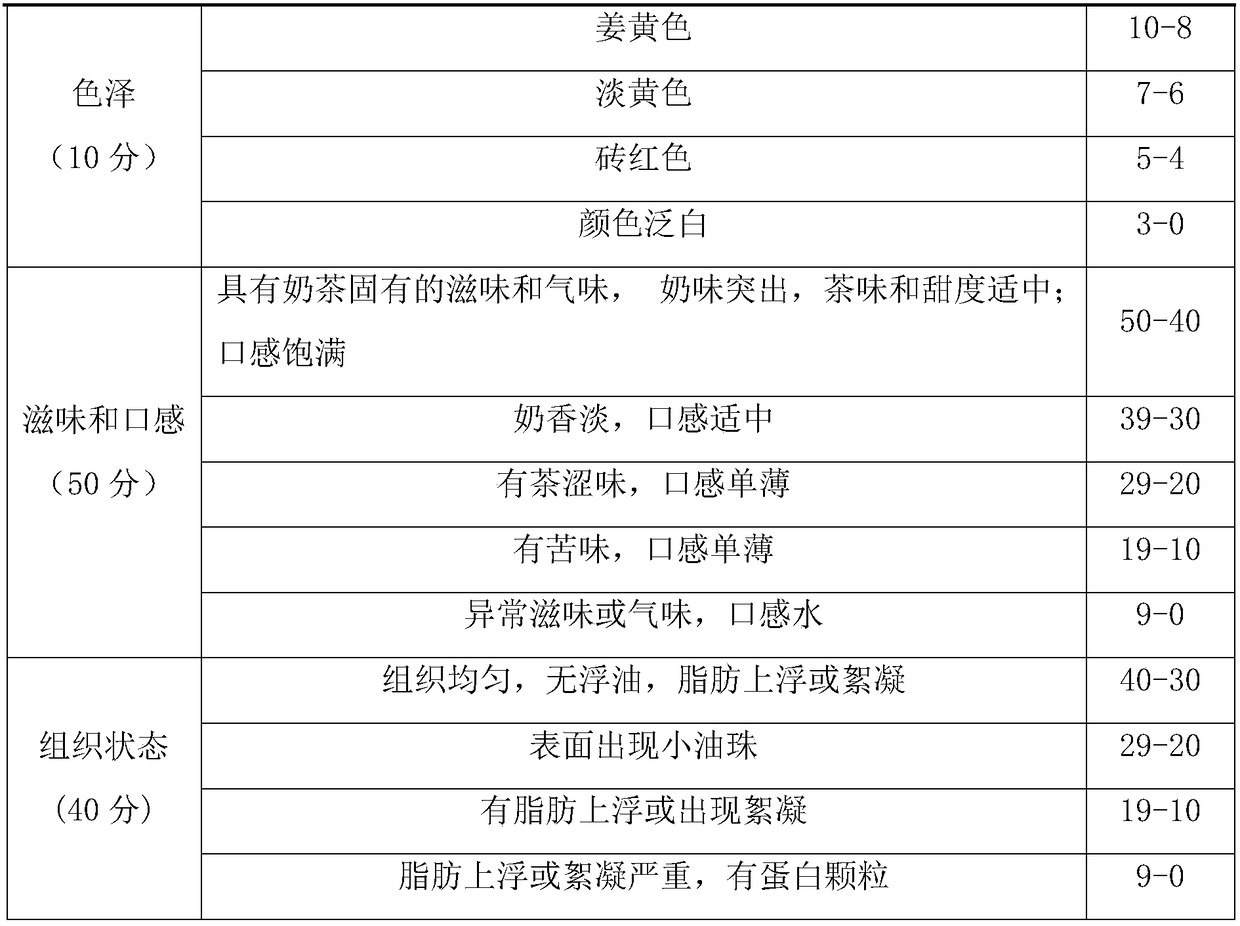

Modified milk for milky tea, preparation method and application thereof

ActiveCN109169910AEasy to useLow costMilk preparationPre-extraction tea treatmentFlocculationCow milking

The invention belongs to the technical field of deep processing of dairy products and especially relates to modified milk for milky tea, a preparation method of the milky tea and an application thereof. The preparation method of the modified milk mainly comprises the following main steps: mixing 60-80% of concentrated cow milk or restored concentrated milk and 2-5% of single cream and then preheating to 50-70 DEG C; adding an emulgator, a stabilizer and buffer salt, dissolving and supplementing with water till the volume is 100%; uniformly stirring, thereby acquiring a mixture containing 5.0-8.0% of fat and 3.0-5.0% of protein; homogenizing at 12-20MPa; sterilizing under the conditions of 132-142 DEG C and 3-5s UHT; and sterilely filling, thereby acquiring the modified milk. The concentrated cow milk is acquired by concentrating raw milk and skim milk for 1.5-2 times. Optimally, RO membrane concentration is adopted for concentrating. When the modified milk is used for preparing the milky tea, the modified milk is directly mixed with tea soup; the preparation is simple and convenient; the prepared milky tea has abundant tastes, strong milk fragrance, high stability and no layering or flocculation phenomenon.

Owner:宁夏塞尚乳业有限公司

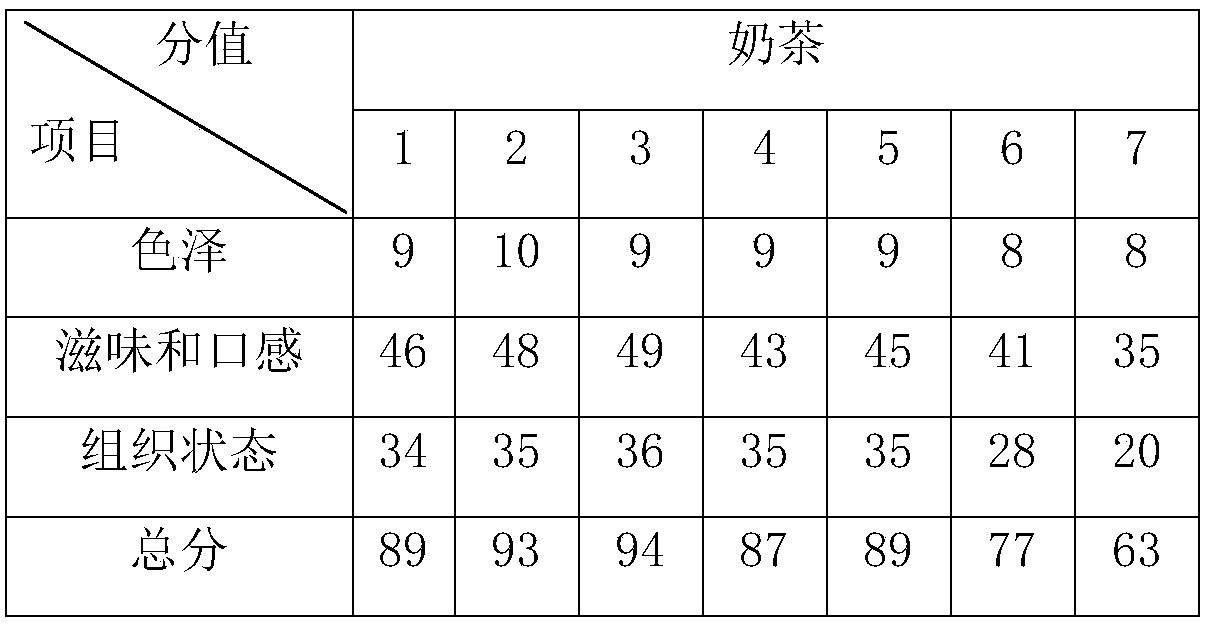

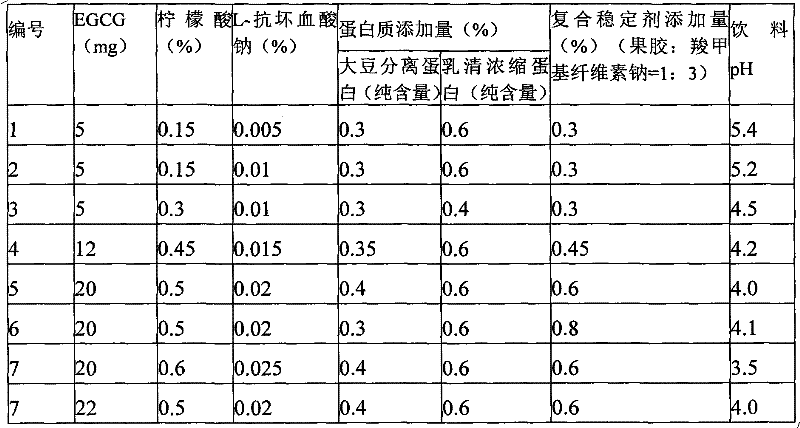

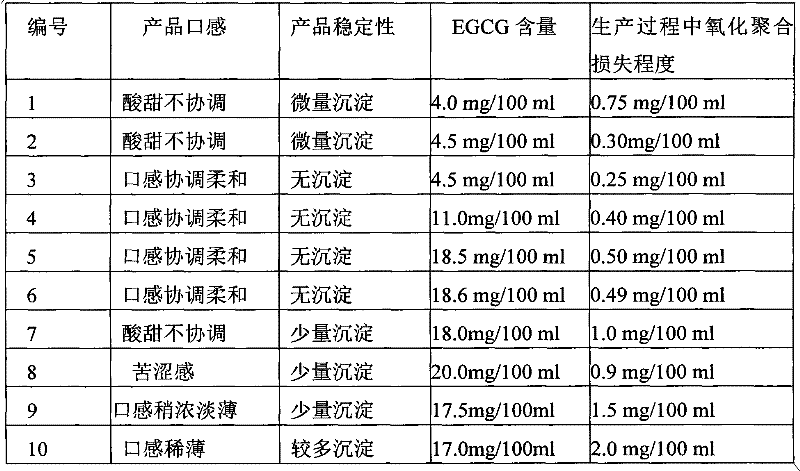

EGCG (Epigallocatechin Gallate)-added compound protein acidic beverage and preparation method thereof

The invention relates to the field of beverage processing, in particular to EGCG (Epigallocatechin Gallate)-added compound protein acidic beverage and a preparation method thereof. According to the EGCG-added compound protein acidic beverage provided by the invention, the EGCG-added compound protein acidic beverage contains 0.7-1.0 part of protein, 0.3-0.6 part of stabilizer, 5*10<-3> to 20*10<-3> part of EGCG, 0.3-0.5 part of citric acid and 0.01-0.02 part of sodium L-ascorbate, based on 100 parts by weight of raw materials. According to the EGCG-added compound protein acidic beverage and the preparation method of the EGCG-added compound protein acidic beverage, the acidity is adjusted by adding the citric acid into the beverage, so that the pH value of the beverage can be in the range of 4.0 to 4.5, the EGCG can be stably present at the acidity, and soybean protein isolate and whey protein concentrate which are simultaneously added can also be stably present without flocculation; and bee honey, polydextrose and oligosaccharides are further added into the beverage, so that the EGCG-added compound protein acidic beverage has the advantages of comprehensive regulation and improvement on human metabolic function, excellent mouth feel and healthcare function.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

High efficiency foliage fertilizer special for flowers and preparation method thereof

InactiveCN105906409ALarge bladeLeaf color dark greenSuperphosphatesMagnesium fertilisersTriple superphosphateRoot system

Belonging to the technical field of fertilizers special for flowers, the invention in particular relates to a high efficiency foliage fertilizer special for flowers and a preparation method thereof. The high efficiency foliage fertilizer special is composed of potassium sulfate, urea, triple superphosphate, ferric sulfate, magnesium sulfate, copper sulfate, manganese sulfate, zinc sulfate, ammonium molybdate, chitosan, an emulsifier, polyaspartic acid, and brassinolide ingredients. The foliar fertilizer special for flowers has high total nutrient content, can rapidly improve the nutrition required by flower growth to promote upgrading of flower color and petal quality and expansion of floral leaf thickness and flower discs, also avoids fertilizer's entry into soil to be fixed and transformed, can prolong the life of functional leaves, promote metabolism of the root system, and achieve the advantages of increasing fertilizer utilization rate, improving crop yield and quality and the like.

Owner:HUNAN UNIV OF SCI & ENG

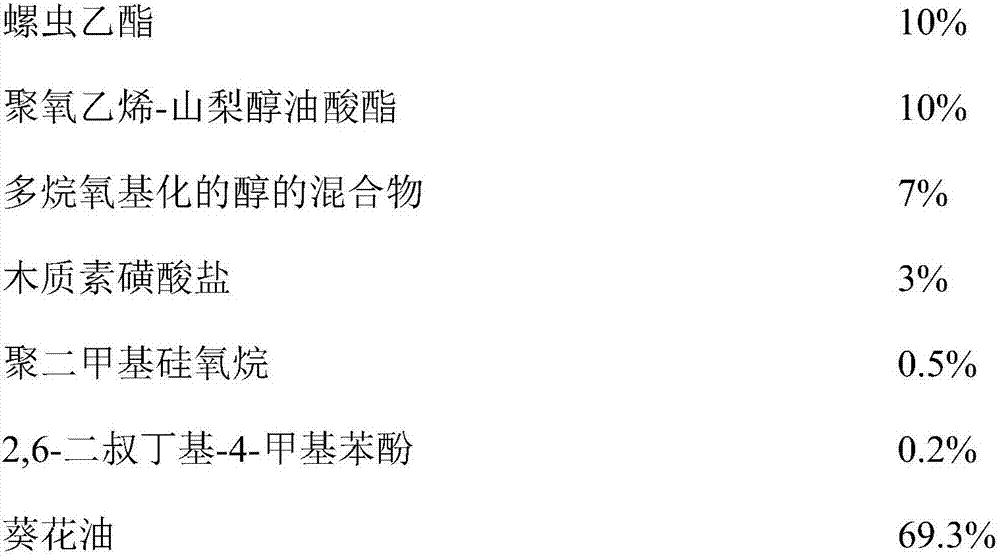

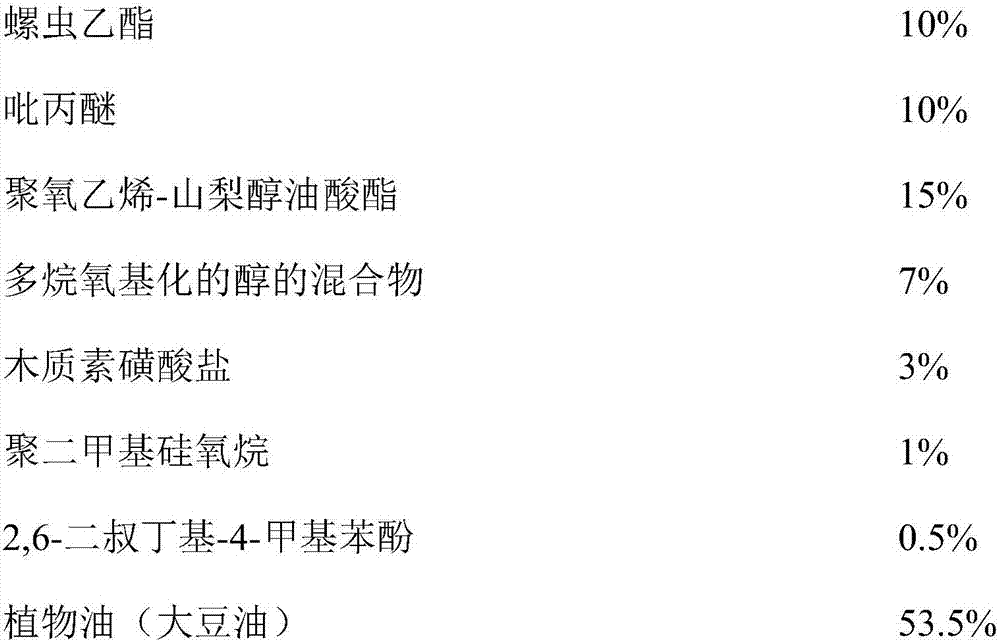

Oil-based concentrated solution, preparation method and application thereof

PendingCN107439569AControl particle size growth issuesSmall particle sizeBiocideAnimal repellantsAntioxidantSpirotetramat

The invention discloses an oil-based concentrated solution, a preparation method and application thereof. The oil-based concentrated solution comprises the following components: (a) at least one active spirotetramat matter which is solid under room temperature, (b) at least one active pyriproxyfen matter which is solid under room temperature, (c) at least one aliphatic ester with the formula R1-COO-R2 and / or R1-COO-R2-OOC-R1, (d) at least one nonionic surfactant and / or at least one anionic surfactant and (e) one or at least two additives randomly selected from an emulgator, a de-foaming agent, a preservative, an antioxidant, a colorant or inertial filling material, wherein pyriproxyfen is dissolved in the component c under molecular state and spirotetramat is suspended in the component c under particle state. The oil-based concentrated solution prepared according to the invention is capable of effectively controlling the problem of grain size increasing of spirotetramat in a storage process, promoting the preparation stability, enhancing the compounding effect and enhancing the bioavailability.

Owner:JIANGSU ROTAM CHEM

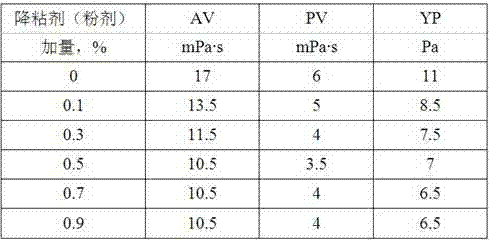

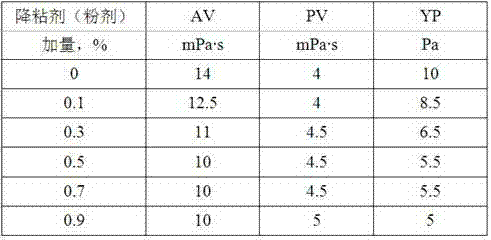

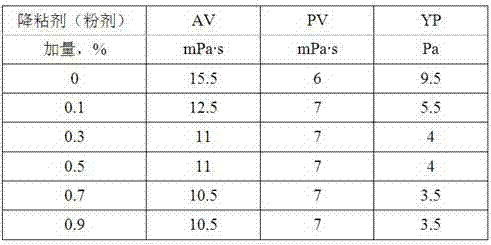

Composite lignin-base viscosity breaker for drilling fluid and preparation method thereof

ActiveCN102888212AStrong temperature resistanceGood synergyDrilling compositionLignosulfonatesEnvironmental geology

The invention discloses a composite lignin-base viscosity breaker for a drilling fluid and a preparation method thereof. The preparation method comprises the following steps: (1) carrying out sulfonation reaction to obtain lignosulfonate; (2) preparing ferrimanganic salt; and (3) preparing ferrimanganic lignosulfonate. In the composite lignin-base viscosity breaker for a drilling fluid, the water-insoluble substance content is at most 0.5%, the calcium sulfate content is at most 1.0%, the iron content is 3-5%, the complexation degree is at least 75%, and the relative molecular weight Mn is 5000-20000. The method has the advantage of low production cost; and the prepared viscosity breaker can display favorable viscosity breaking effect of the inorganic viscosity breaker, and also has favorable temperature resistance and salt resistance of the lignin viscosity breaker, thereby having favorable synergistic action. The preparation technique is simple and does not generate secondary pollution.

Owner:FUZHOU UNIVERSITY

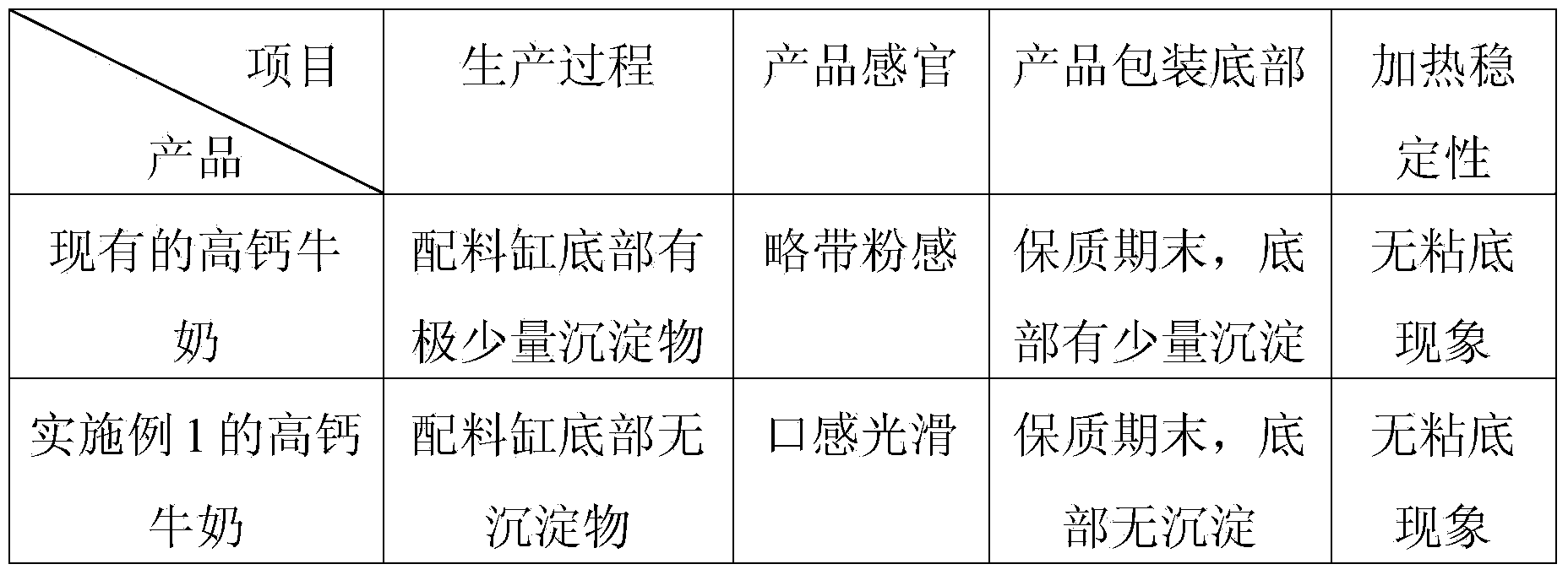

High-calcium milk as well as raw material composition and preparation method thereof

The invention discloses high-calcium milk as well as a raw material composition and a preparation method thereof. The preparation method comprises the following steps of (1) dissolving an annion calcic compound, emulsifying salt and an emulsifier into drinking water so as to obtain a reaction liquid, wherein the temperature of the reaction liquid is 40-55 DEG C; (2) raising the temperature of the milk to be 40-55 DEG C, uniformly adding the reaction liquid prepared in the step (1) into the milk, and stirring for 5-15 minutes; (3) evaporating the moisture, wherein the mass of the moisture is equal to the amount of the drinking water in the step (1); and (4) homogenizing, sterilizing and cooling so as to obtain the high-calcium milk. The high-calcium milk disclosed by the invention is good in stability, free of protein flocculation and free of protein scaling phenomenon after being produced and boiled.

Owner:BRIGHT DAIRY & FOOD

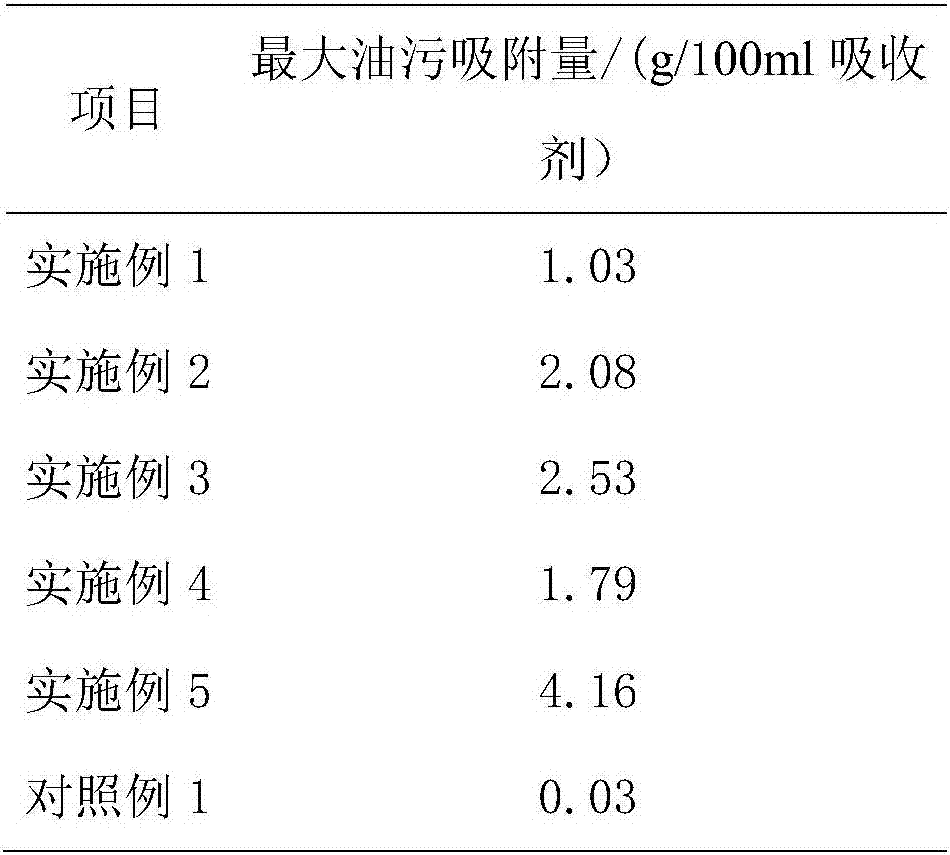

Kitchen fume purifying and dissolution-promoting agent and preparation method thereof

InactiveCN107243226AShorten the dissolution timeEasy to removeGas treatmentDispersed particle separationSolubilityDissolution

The invention belongs to the field of kitchen oil fume absorbents, and in particular relates to a kitchen oil fume purification promoter and a preparation method thereof. sodium nitrate, 1-10% fatty alcohol ethoxylate sulfate, 1-10% nonylphenol ethoxylate-10, 1-5% isopropanol, 1-5% triethanolamine, 1 -5% sodium silicate, 1-5% sodium citrate, the balance is water, and the sum of the weight percentages of each component is 100%. The advantages of the present invention are: the solubilizer for kitchen oil fume purification can increase the ability of water to absorb oil mist in oil fume, greatly improve the solubility of smoke in water, and speed up the speed of water to absorb oil mist, with high oil fume removal efficiency and moderate pH value , non-corrosive to equipment, water can be recycled, the consumption of solubilizer is extremely small, and each component in the formula is basically biodegradable, and has good environmental affinity.

Owner:WUHAN INSTITUTE OF TECHNOLOGY +1

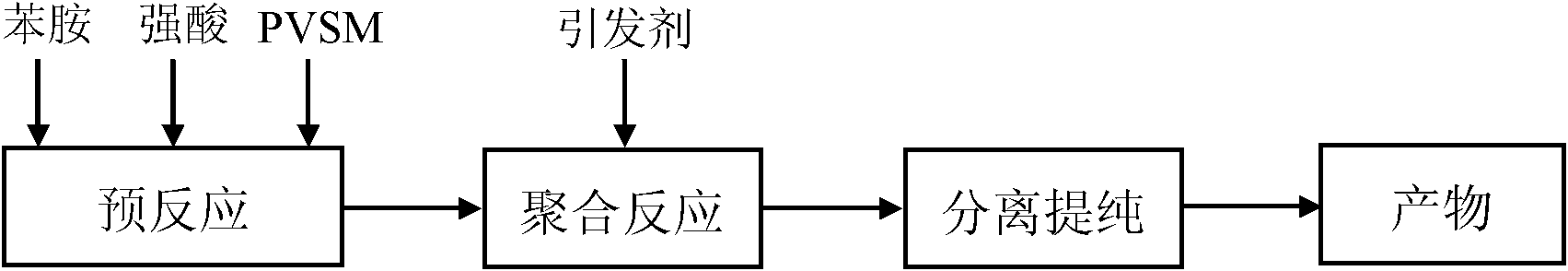

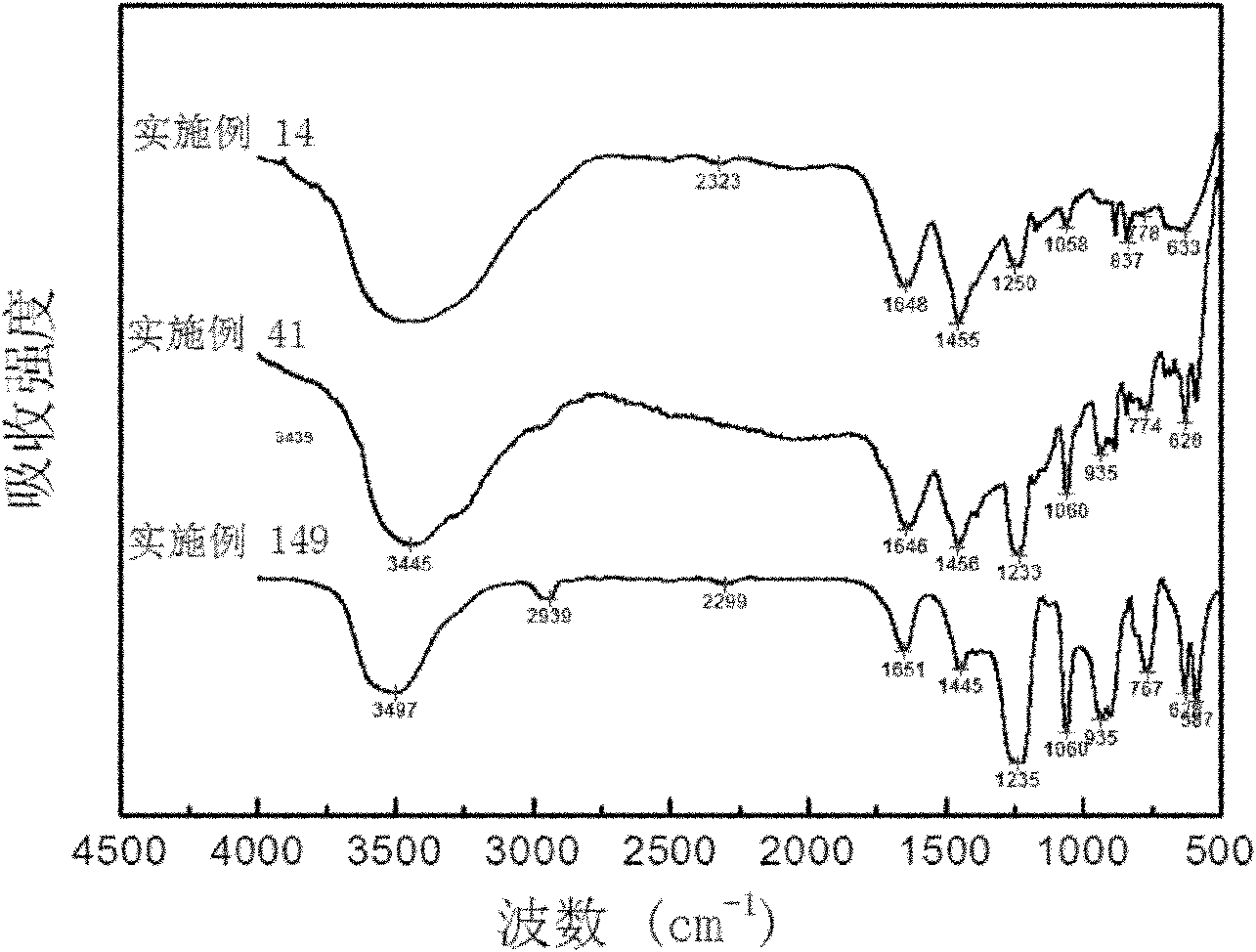

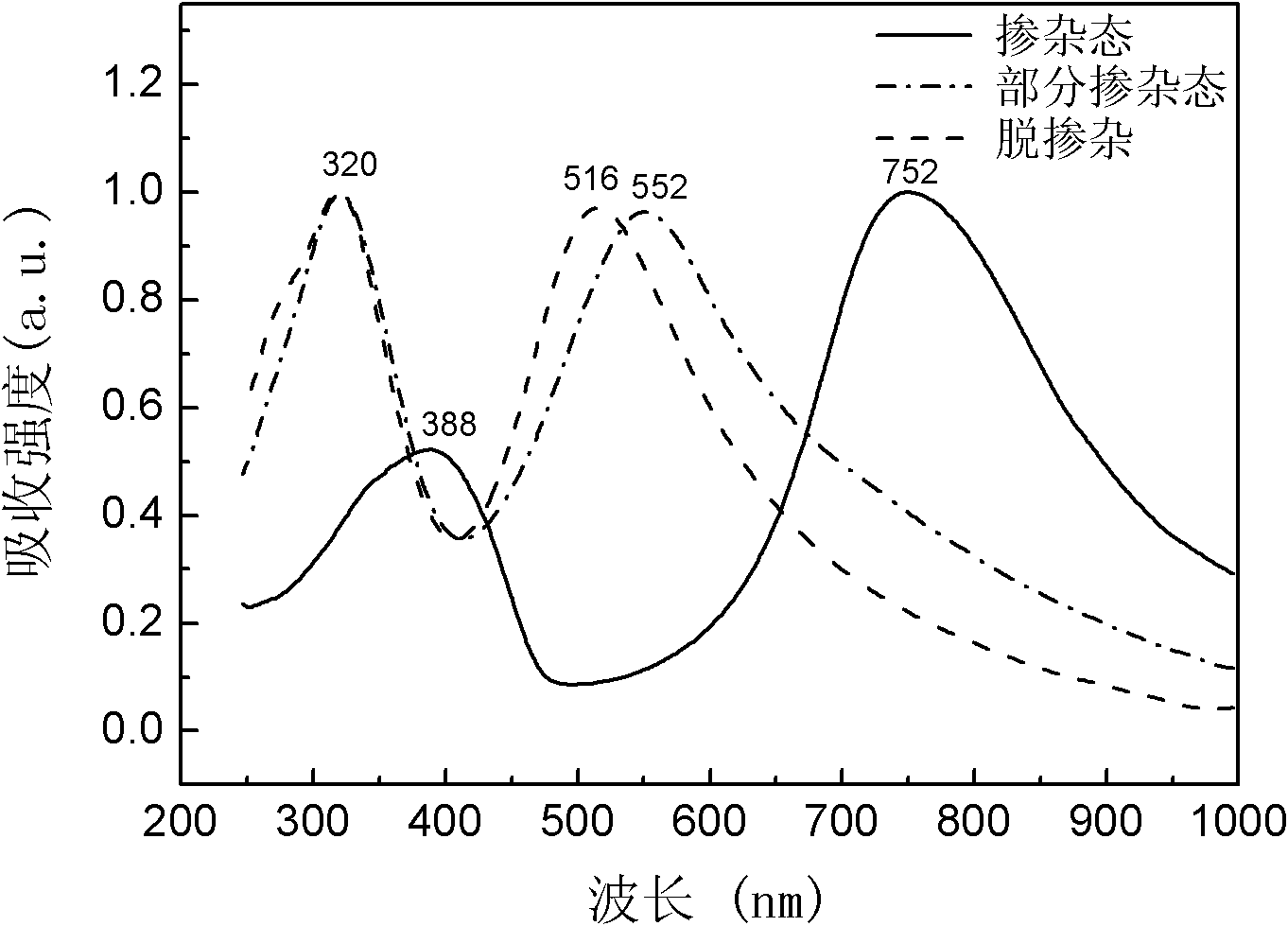

Preparation method of water-soluble self-doped polyaniline (PANI) electrochromic material

InactiveCN102030984AImprove conductivitySensitive to potential changesTenebresent compositionsSolubilitySulfonate

The invention discloses a preparation method of a water-soluble self-doped polyaniline (PANI) electrochromic material, which is used for solving the problems of the PANI synthesized by a solution doping method such as low binding degree, low doping efficiency, complicated aftertreatment procedures, more reaction by-products, poor product stability and the like. The technical scheme is as follows: firstly pre-reacting polyvinyl alcohol sulfonate with aniline; carrying out oxidative polymerization on the aniline by use of an initiator to obtain water-soluble doped PANI; and separating and purifying the obtained PANI / polyvinyl alcohol sulfonate electrochromic material, and finally preserving the product in aqueous solution for later use. The preparation method has the advantages of simple process, high yield and less environmental pollution, and is easy for industrial production; and the obtained product has the advantages of good water solubility, heat stability, solid conductivity and electrochromic performance.

Owner:NAT UNIV OF DEFENSE TECH

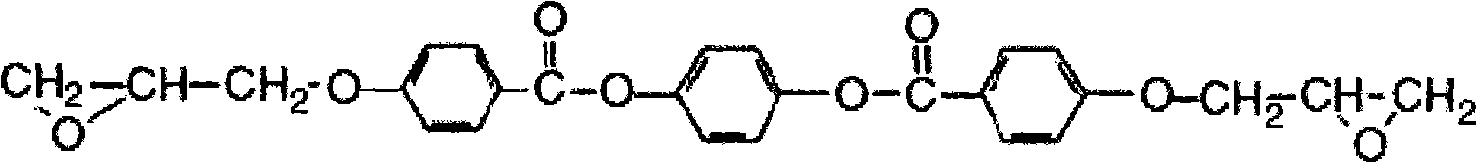

Liquid crystal epoxy modified water-based alkyd resin and preparation method thereof

InactiveCN102311543AExcellent water dispersion stabilityImprove drynessPolyester coatingsWater basedEpoxy

The invention discloses a liquid crystal epoxy modified water-based alkyd resin and a preparation method thereof and belongs to the field of macromolecule synthetic water-based alkyd resin. The invention overcomes the defects of environment pollution, damage to the human body health, resource waste, inflammability, explosion and the like of the conventional solvent borne paint. A method for preparing water-based alkyd resin by the combination of a salifying method and a hydrophilic group introducing method is adopted. Linolenic acid is firstly maleated, then liquid crystal epoxy and organic sulfonate oligomer are introduced, trimethylolpropane and neopentyl glycol are optimally combined, the salifying method and the hydrophilic group introducing method are combined, an esterification catalyst is added, and the production process is safe and simple. The resin is dispersed in water after being neutralized by amine, and the water dispersibility and pigment wetting dispersibility of the resin are improved. The liquid crystal epoxy modified water-based alkyd resin is brown transparent liquid with the viscosity higher than or equal to 25 seconds, non-volatile matter accounts for 68 + / - 2%, and the acid value is 22-32mgKOH / g.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD +1

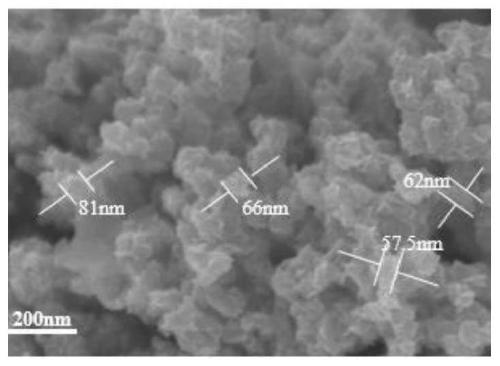

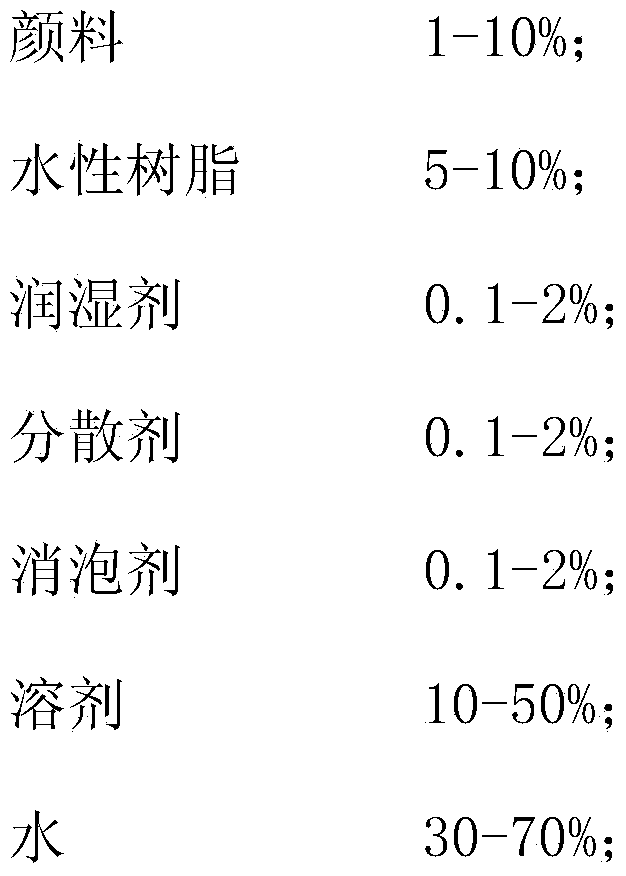

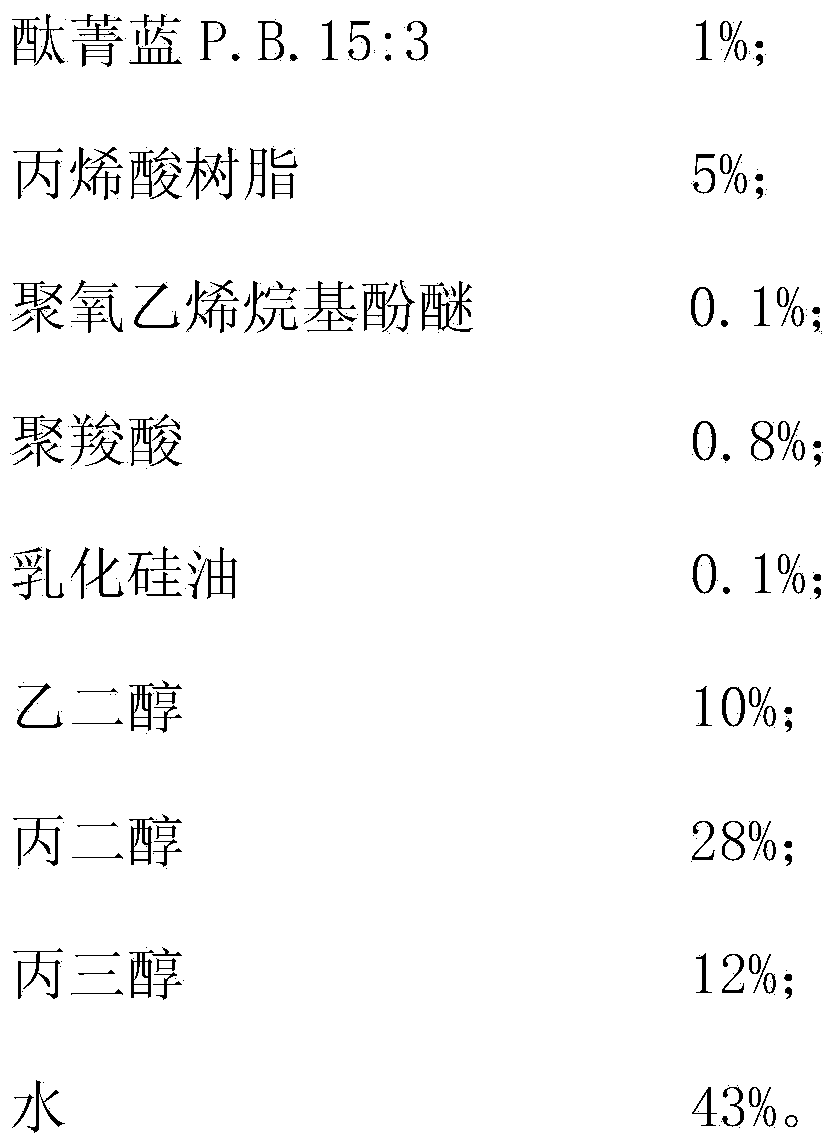

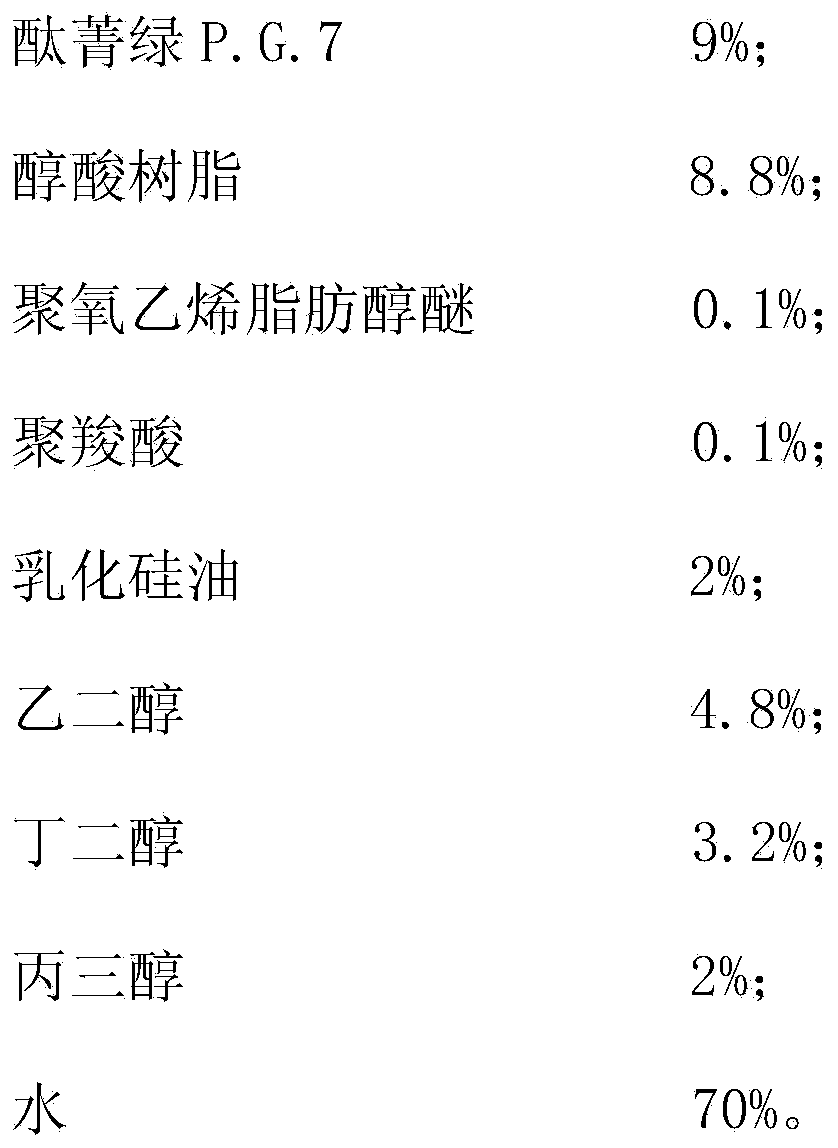

Superfine water-based pigment ink and manufacturing method thereof

The invention relates to superfine water-based pigment ink and a manufacturing method thereof. The superfine water-based pigment ink is suitable for high-requirement pens for writing and printers and comprises the following components in weight percent: 1% to 10% of pigment, 5% to 10% of water-based resin, 0.1% to 2% of wetting agent, 0.1% to 2% of dispersant, 0.1% to 2% of foam killer, 10% to 50% of resolvent and 30% to 70% of water, wherein as different kinds of pigment can be used, the particle diameter of the pigment ranges from 40 nm to 80 nm. The manufacturing technique comprises the steps of shearing and dispersing, high-pressure collision, multi-stage sanding and ink compounding. The ink provided by the invention flows out smoothly and is high in storage stability; a manufactured writing pen can be still used normally after being transported at high temperature for a long time.

Owner:SHANGHAI NNW NEW MATERIALS TECH

Spray-assistant drip irrigation bolt head cleaning-type concentrated fertilizer and preparation method thereof

InactiveCN1907921AImprove solubilityGuarantee unimpededAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphoric acidDrip irrigation

This invention relates to a concentrated fertilizer in aid of sprinkler irrigation bolt head cleaning, belonging to the chemical fertilizer field. The fertilizer includes (from each 1000 parts) solid short chain ammonium low polyphosphate (3 C05G 1 / 00 C05B 7 / 00 C05B 17 / 00 C05C 5 / 00 0 4 1 2006 / 8 / 11 1907921 2007 / 2 / 7 100361940 2008 / 1 / 16 2008 / 1 / 16 2008 / 1 / 16 Heze Exploitation Region Caozhou Chemurgy Co., Ltd. Shandong 274000 Wang Lianxiang Yan Chuansheng Li Jinfeng Zhang Xuefeng Wu Cuiping wang ruyin 37105 The Patent Agency of Jinan City No.187 Jinshi Road, the City of Jinan, Shandong Province 250014

Owner:菏泽开发区曹州农用化学有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com