Liquid crystal epoxy modified water-based alkyd resin and preparation method thereof

A water-based alkyd resin and liquid crystal epoxy technology, used in polyester coatings, coatings, etc., can solve the problems of slow drying speed of paint film, poor water resistance, and acid value paint is easy to thicken, and achieves fast drying speed, Superior water resistance, excellent decorative and protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

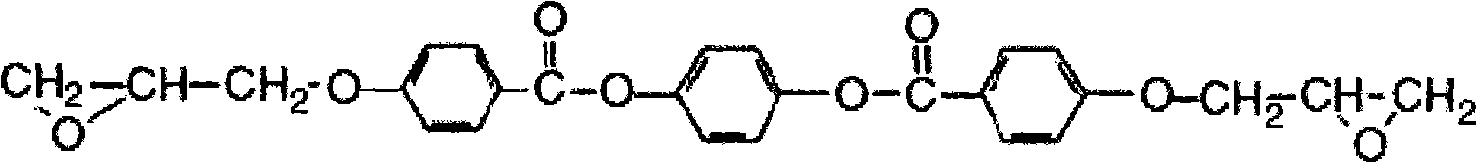

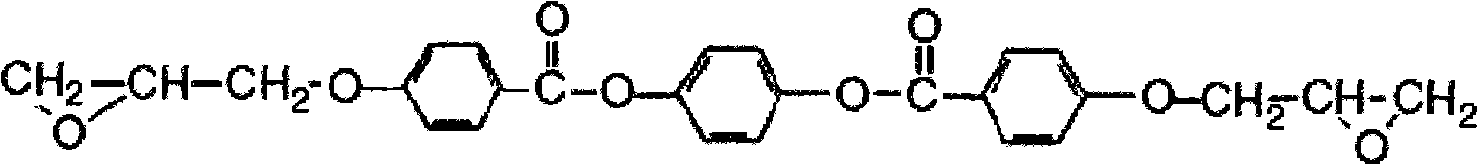

Image

Examples

Embodiment 1

[0025] The present embodiment is made by following raw material proportioning: 19% maleic anhydride linolenic acid, 6% liquid crystal epoxy resin bis 4-glycidyl ether hydroquinone benzoate (p -PEPB), 0.03% catalyst I: tin octoate, 1% organic sulfonate oligomer, 4% 2,4-diethyl-1,5-pentanediol, 11% trimethylolpropane , 24.5% isophthalic acid, 0.07% catalyst II: dibutyltin dilaurate, 5% trimellitic anhydride, 16.93% butyl ether, 13% dibutanol. Maleinized linoleic acid is made from: 88-93% linoleic acid, 7-12% maleic anhydride. Organosulfonate oligomer is composed of: 35% sodium 5-sulfonate isophthalate, 64.92% 2,4-diethyl-1,5-pentanediol and 0.05% Catalyst II: Dilauryl Made of dibutyltin acid.

[0026] Its preparation method comprises the following steps:

[0027] (1) Production of maleic anhydrided linoleic acid: Add the linoleic acid and maleic anhydride of the above formula to a four-necked flask with a stirrer, condenser, and thermometer, and feed CO 2 , heat up to 205±2°...

Embodiment 2

[0037] The present embodiment is 22% maleic anhydride linolenic acid made by the following raw material ratio, 7% liquid crystal epoxy resin bis 4-glycidyl ether hydroquinone benzoate (p- PEPB), 0.03% Catalyst I: Zirconium Octanoate, 2% Organic Sulfonate Oligomer, 8% Neopentyl Glycol, 8% Pentaerythritol, 20% Phthalic Anhydride, 0.07% Catalyst II: Dilauric Acid Butyl tin, 3% trimellitic anhydride, 16.93% butyl ether, 13% dibutanol. Maleinized linoleic acid is made from: 88-93% linoleic acid, 7-12% maleic anhydride. The organosulfonate oligomer is composed of: 35% sodium tartrate, 64.92% neopentyl glycol and 0.05% Catalyst II: dibutyltin dilaurate. Its preparation method is with embodiment 1.

Embodiment 3

[0039] The present embodiment is made by the following raw material ratio: 21% maleic anhydride linolenic acid, 8% liquid crystal epoxy resin bis 4-glycidyl ether hydroquinone benzoate (p -PEPB), 0.03% catalyst I: tin octoate, 2% organic sulfonate oligomer, 5% 1,3-butanediol, 10% trimethylolpropane, 20% maleic anhydride, 0.07% Catalyst II: dibutyltin dilaurate, 4% trimellitic anhydride, 16.93% butyl ether, 13% dibutanol. Maleinized linoleic acid is made from: 88-93% linoleic acid, 7-12% maleic anhydride. The organic sulfonate oligomer is composed of: 35% sodium succinic anhydride sulfonate, 64.92% 1,3-butanediol and 0.05% catalyst II: dibutyltin dilaurate. Its preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com