Resin composition for cation electrodeposition paint with excellent inner permeability, containing aromatic sulfonic acid and urethane functional rheology modifier

A cationic electrodeposition and resin composition technology, which is applied in polyurea/polyurethane coatings, electrophoretic coatings, epoxy resin coatings, etc., can solve the problems of water resistance and rust resistance reduction, insufficient flexibility, and deterioration of appearance. Achieve excellent flexibility, reduce production costs, and improve edge rust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

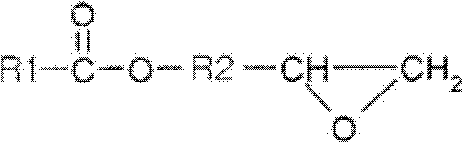

[0091] In the preparation of the curing agent resin of the present invention, the blocked polyisocyanate that can react with the modified polyol compound can be freely selected from conventional blocked polyisocyanates known to be useful in cationic electrodeposition resin compositions. Without limitation, the blocked polyisocyanate is preferably a reaction product of an aliphatic or aromatic diisocyanate and a hydroxyl-containing acrylate compound or alcohol compound.

[0092] Aliphatic or aromatic diisocyanates are preferably selected from 2,4-toluene diisocyanate, 2,6-toluene diisocyanate, diphenylmethane-4,4'-diisocyanate and tetramethylene and hexamethylene diisocyanate , more preferably selected from 2,4-toluene diisocyanate, 2,6-toluene diisocyanate, diphenylmethane-4,4'-diisocyanate and tetramethylene and hexamethylene diisocyanate. The hydroxyl group-containing acrylate compound is preferably 2-hydroxyethyl methacrylate. The alcohol compound is preferably selected fr...

preparation Embodiment 1

[0117] As the aromatic sulfonic acid compound contained in the electrodeposition resin composition of the present invention, a xylenesulfonic acid compound was prepared by the method explained below according to the composition of Table 1 below.

[0118] [Table 1] Preparation of xylenesulfonic acid compound

[0119] raw material

[0120] Into a 3-neck 2L flask equipped with a thermometer, a cooler and a mechanical stirrer, sulfuric acid (A) and xylene (B) as shown in Table 1 were added and heated to 110° C., then maintained for 2 hours. Sulfuric acid (C) was slowly added thereto and maintained at 125°C for 2 hours. At 125°C, 23.2 g of a portion including water (D) was removed from the reactor, and then the reactor was cooled to 90°C. Distilled water (E) was added thereto for 1 hour, and the reactor was cooled to below 60°C to terminate the reaction. The reaction was carried out with care as the reaction mixture tended to boil over during the reaction. The product ...

preparation Embodiment 2

[0122] For the electrodeposition resin composition of the present invention, a rheology control agent having a carbamate functional group was prepared by the method explained below according to the composition of Table 2 below.

[0123] [Table 2] Preparation of rheology control agent

[0124] raw material

[0125] In a 3-neck 2L flask equipped with a thermometer, a cooler and a mechanical stirrer, YD-128 (A) and ethoxylated bisphenol-A (B) shown in Table 2 were added and heated to 140° C., then Xylene (C) and benzyldimethylamine (D) were added thereto and maintained at 140° C. for 4 hours. After cooling the reactor to 120°C, the portion including water (E) was removed from the reactor under reduced pressure, and the reactor was further cooled to 100°C. Methoxypropanol (F) was then added and the reactor was further cooled to 80°C. The premixed diisocyanate (G) and dimethylethanolamine (H) were slowly added dropwise at 80°C for 1 hour, then maintained at 80°C for 1 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com