A water-based metal surface treatment agent based on graphene composite

A technology of metal surface treatment and graphene compounding, applied in coatings, polyurea/polyurethane coatings, anti-corrosion coatings, etc., can solve problems such as failure to fully exert the anti-corrosion effect of single-layer graphene, environmental hazards, and difficulty in uniform dispersion. Achieve excellent water dispersion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

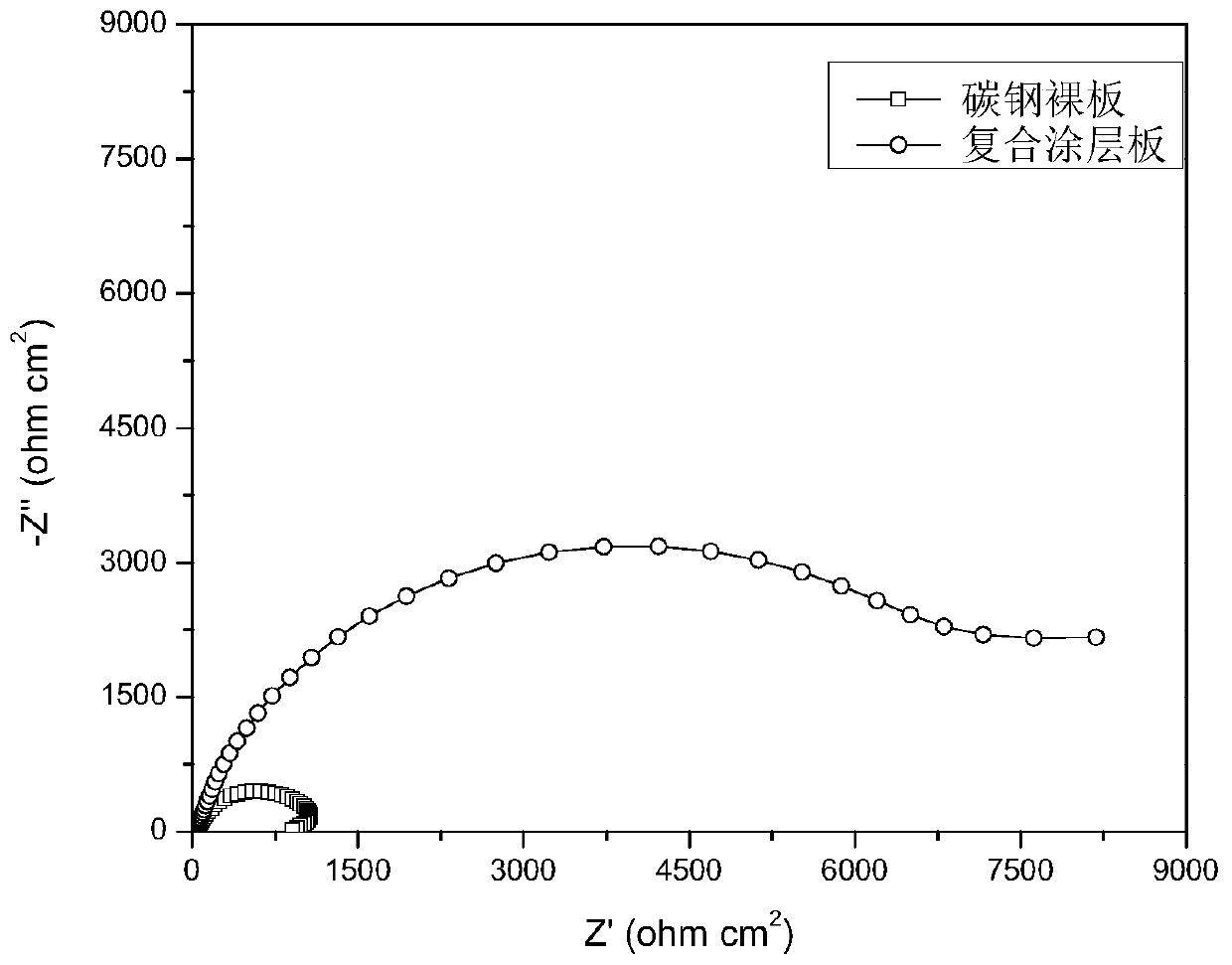

[0031] The mass percent of the water-based metal surface treatment agent is: functionalized graphene, 0.01%; organosiloxane modified resin, 15%; phytic acid, 0.4%; ammonia water, appropriate amount; the balance is deionized water. The pH value of the surface treatment agent is 5.

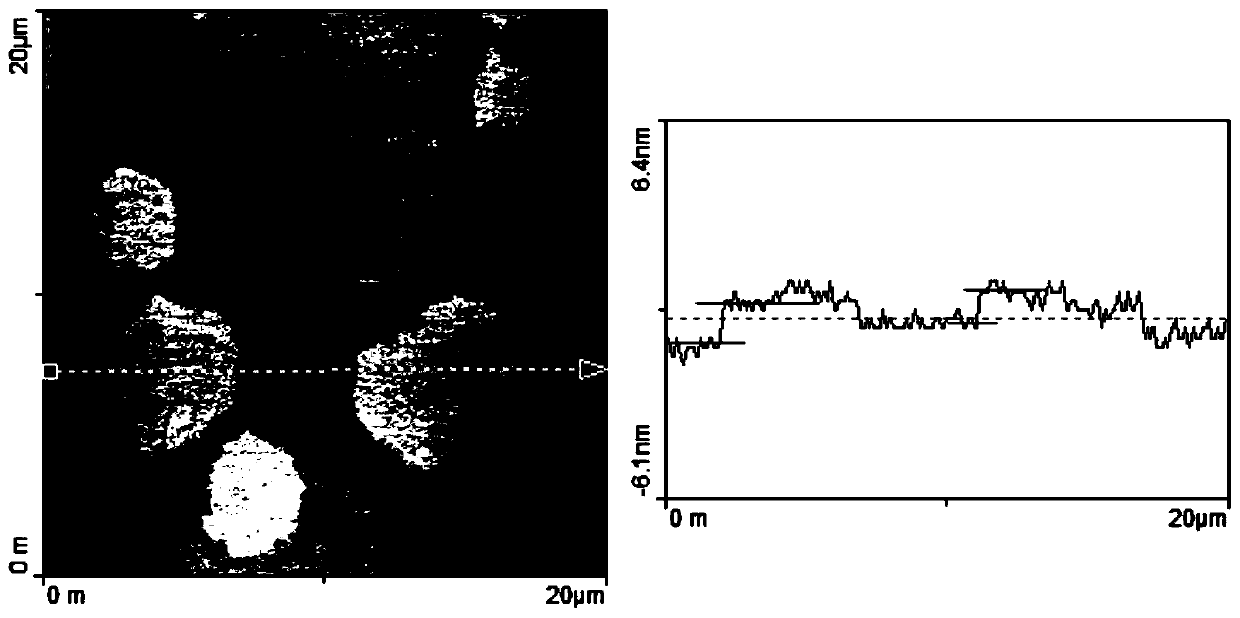

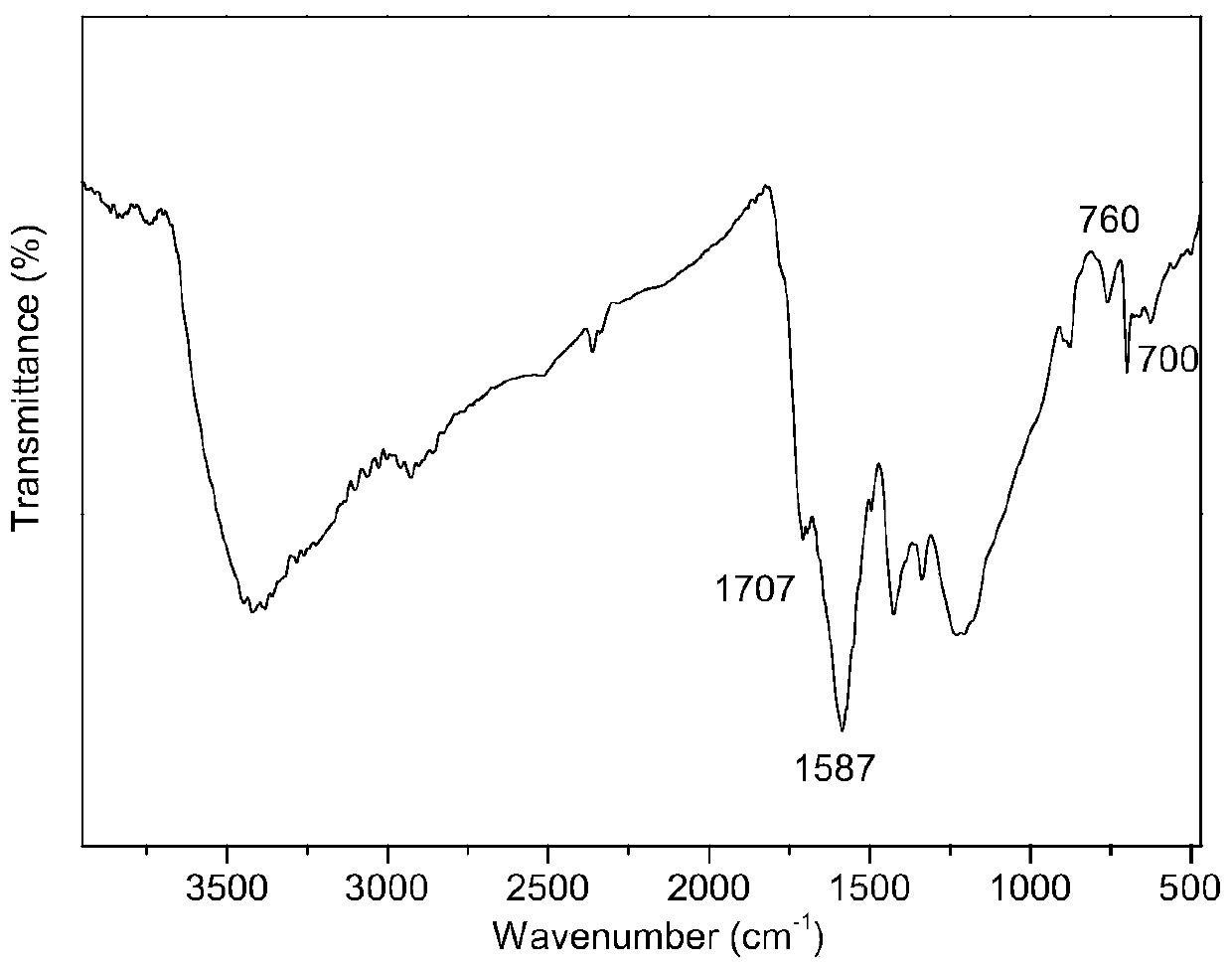

[0032] Disperse 0.25 g of styrene-maleic anhydride copolymer (SMA1000, SARTOMER, USA) in 1 L of aqueous solution, adjust the pH of the solution to 10 with sodium hydroxide, and stir for 4 h at 90 ° C to make the solution transparent , cooled to room temperature and used as an electrolyte, using high-purity graphite rods as cathode and anode, and applying a constant voltage DC power supply of 12V for 16 hours to obtain a black functionalized graphene aqueous dispersion. Adjust the pH value of the graphene aqueous dispersion to about 8 with ammonia water, sonicate in an ultrasonic disperser for 2 hours, and centrifuge in a low-speed centrifuge at 2000 rpm to remove large aggregates to obtain the funct...

Embodiment 2

[0034] The components and mass percentages of the water-based metal surface treatment agent are: functionalized graphene, 0.03%; polyurethane, 25%; sodium metavanadate, 0.1%; acetic acid, appropriate amount; the balance is deionized water. The surface treatment agent has a pH value of 7.

[0035] Disperse 0.2 g of styrene-maleic anhydride copolymer (SMA1000, SARTOMER, USA) in 1 L of aqueous solution, adjust the pH of the solution to 11 with sodium hydroxide, and stir for 4 h at 90 ° C to make the solution transparent , cooled to room temperature and used as an electrolyte, using high-purity graphite rods as cathode and anode, and applying a constant voltage DC power supply of 10V to electrolyze for 20h to obtain a black functionalized graphene aqueous dispersion. Adjust the pH value of the graphene aqueous dispersion to about 8 with ammonia water, sonicate in an ultrasonic disperser for 2 hours, and centrifuge in a low-speed centrifuge at 2000 rpm to remove large aggregates to...

Embodiment 3

[0037] The mass percent of the water-based metal surface treatment agent is: functionalized graphene, 0.08%; acrylate resin, 20%; sodium molybdate, 0.04%; acetic acid, appropriate amount; the balance is deionized water. The pH value of the surface treatment agent is 8.

[0038] Disperse 0.5 g of styrene-maleic anhydride copolymer (SMA2000, SARTOMER, USA) in 1 L of aqueous solution, adjust the pH of the solution to 10 with sodium hydroxide, and stir for 4 h at 90 ° C to make the solution transparent , cooled to room temperature and used as an electrolyte, using high-purity graphite rods as cathode and anode, and applying a constant voltage DC power supply of 15V to electrolyze for 14 hours to obtain a black functionalized graphene aqueous dispersion. Adjust the pH value of the graphene aqueous dispersion to about 8 with ammonia water, sonicate in an ultrasonic disperser for 2 hours, and centrifuge in a low-speed centrifuge at 2000 rpm to remove large aggregates to obtain the fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com