A water-based carbon steel surface treatment agent based on polypyrrole/graphene composite

A surface treatment agent and composite material technology, applied in polyurea/polyurethane coatings, anti-corrosion coatings, coatings, etc., can solve problems such as difficulty in uniform dispersion and failure to fully exert the anti-corrosion effect of single-layer graphene, and achieve an increase in specific surface area , Avoid the decline of water resistance, improve the effect of easy aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

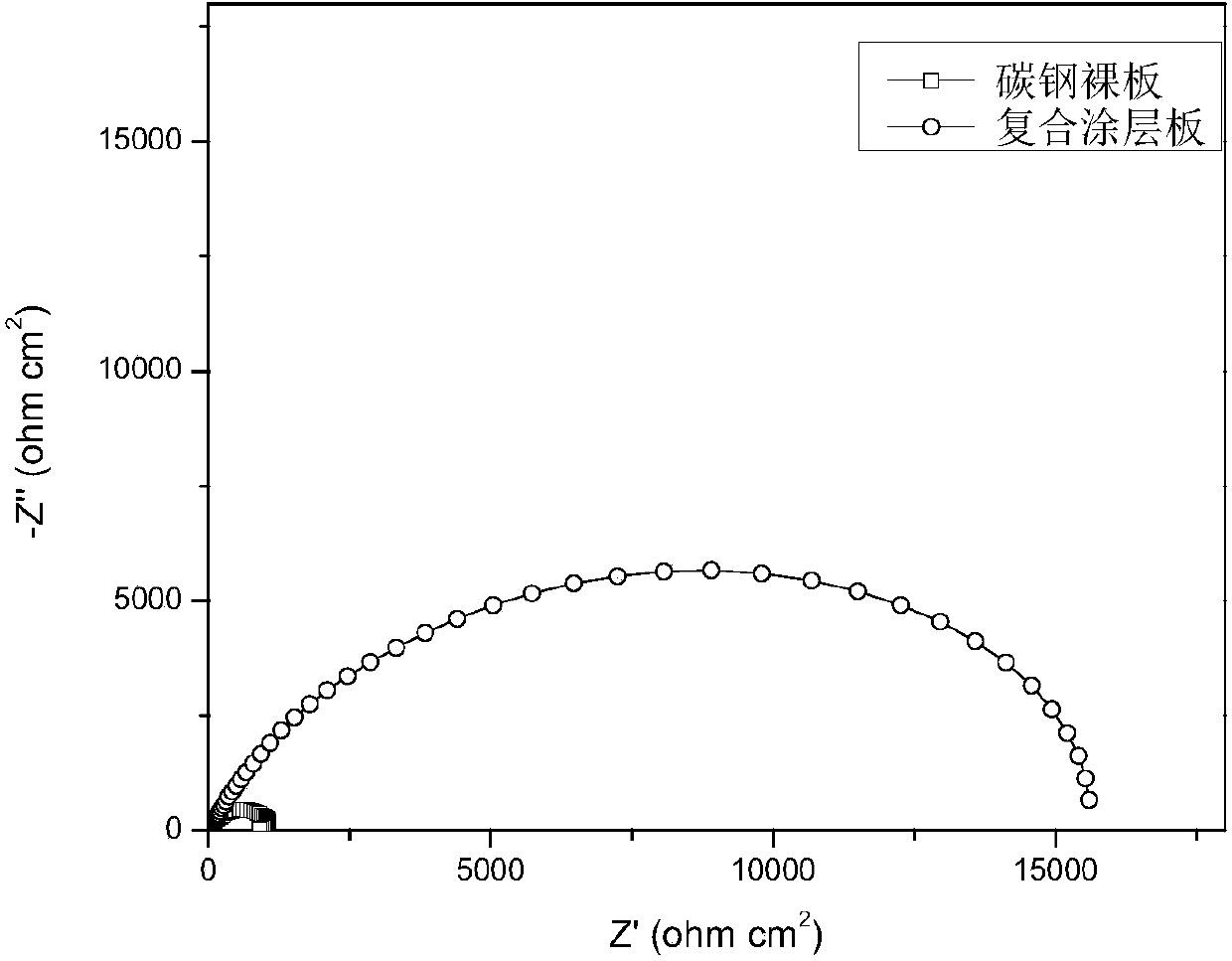

[0033] The mass percent of the water-based carbon steel surface treatment agent is: graphene / polypyrrole composite material, 0.06%; organosiloxane modified resin, 15%; phosphoric acid, 0.2%; ammonia water, appropriate amount; the balance is deionized water. The pH value of the surface treatment agent is 5.

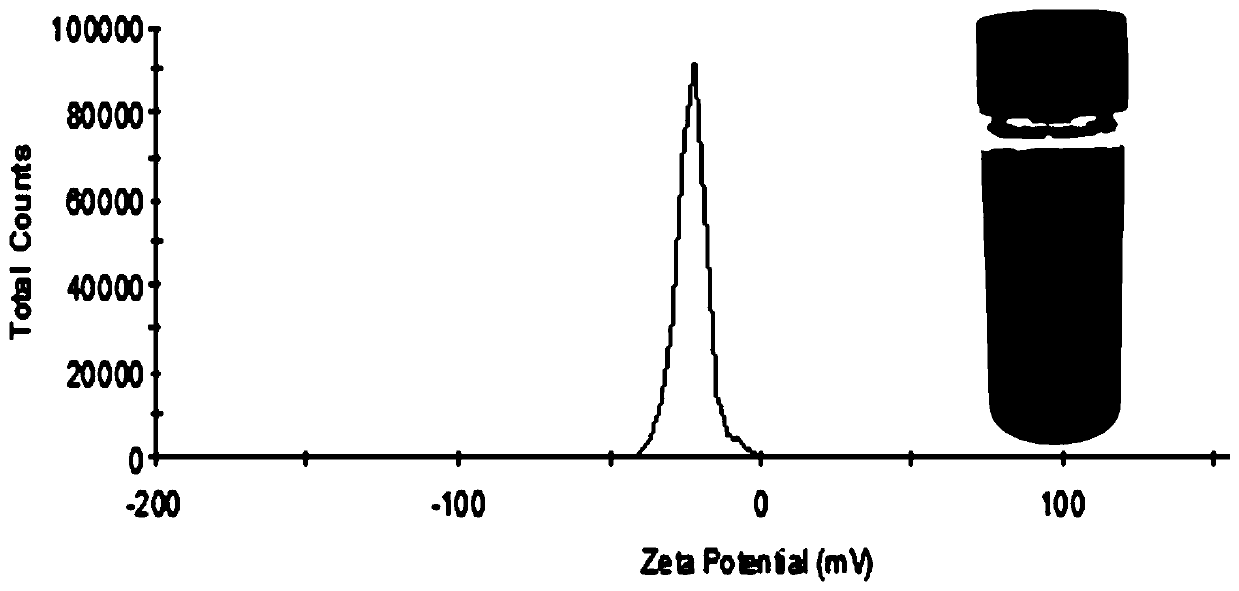

[0034] Pyrrole is added to the styrene-maleic anhydride copolymer functionalized graphene water dispersion, wherein the mass ratio of graphene to pyrrole is 1:1, after stirring for 30min, slowly add the oxidant ammonium persulfate aqueous solution dropwise, wherein the ammonium persulfate The molar ratio with pyrrole is 1:1. After reacting for 24 hours, add acid to flocculate, and obtain the polypyrrole / graphene composite material by high-speed centrifugation, wash with water until the centrifuged supernatant is colorless, and finally ultrasonically disperse the polypyrrole / graphene composite material in In water with a pH of about 9, a stable graphene / polypyrrole composit...

Embodiment 2

[0036] The mass percent of the water-based carbon steel surface treatment agent is: graphene / polypyrrole composite material, 0.10%; polyurethane resin, 25%; sodium metavanadate, 0.4%; acetic acid, appropriate amount; the balance is deionized water. The surface treatment agent has a pH value of 7.

[0037] Pyrrole is added to the styrene-maleic anhydride copolymer functionalized graphene aqueous dispersion, wherein the mass ratio of graphene to pyrrole is 1:5, after stirring for 30min, slowly add the oxidant ammonium persulfate aqueous solution dropwise, wherein the ammonium persulfate The molar ratio with pyrrole is 1:1. After reacting for 24 hours, add acid to flocculate, and obtain the polypyrrole / graphene composite material by high-speed centrifugation, wash with water until the centrifuged supernatant is colorless, and finally ultrasonically disperse the polypyrrole / graphene composite material in In water with a pH of about 9, a stable graphene / polypyrrole composite water ...

Embodiment 3

[0039] The mass percent of the water-based carbon steel surface treatment agent is: graphene / polypyrrole composite material, 0.06%; organosiloxane modified resin, 15%; sodium molybdate, 0.02%; acetic acid, appropriate amount; the balance is deionized water . The pH value of the surface treatment agent is 5.

[0040] Pyrrole is added to the styrene-maleic anhydride copolymer functionalized graphene water dispersion, wherein the mass ratio of graphene to pyrrole is 1:1, after stirring for 30min, slowly add the oxidant ammonium persulfate aqueous solution dropwise, wherein the ammonium persulfate The molar ratio to pyrrole is 1:1. After reacting for 24 hours, add acid for flocculation, high-speed centrifugation to obtain the polypyrrole / graphene composite, wash with water until the centrifuged supernatant is colorless, and finally ultrasonically disperse the polypyrrole / graphene composite in In water with a pH of about 9, a stable graphene / polypyrrole composite water dispersion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com