Urethane resin composition, film and synthetic leather

A urethane and resin composition technology, applied in physical treatment, coating, fiber treatment, etc., can solve the problems of no discovery, hydrolysis resistance and other physical properties inferior to solvent systems, etc., to achieve improved hydrolysis resistance, high resistance to Improved abrasion resistance and excellent hydrolysis resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

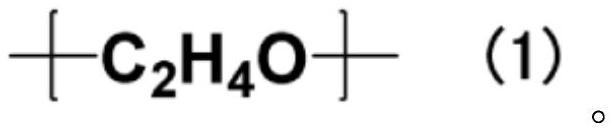

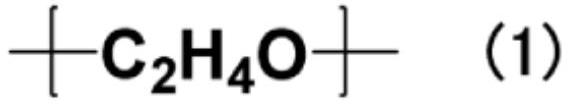

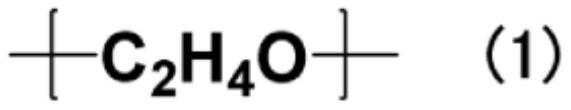

[0074]100 parts by mass of polytetramethylene glycol (number average molecular weight: 2000, hereinafter abbreviated as "PTMG") was placed in a 4-neck flask equipped with a stirrer, a reflux cooling tube, a thermometer and a nitrogen gas introduction tube under a nitrogen gas flow. , a random copolymer of ethylene oxide and propylene oxide (a substance using ethylene glycol as an initiator, the structure represented by formula (1) (hereinafter, referred to as "EO".) and the following formula (2) The molar ratio of the structure shown (hereinafter, abbreviated as "PO".) (hereinafter the same.) [EO / PO] = 50 / 50, number average molecular weight: 1750, hereinafter abbreviated as "EOPO (1)") 35 parts by mass , 3 parts by mass of 2,2-dimethylolpropionic acid (hereinafter referred to as "DMPA".), and 121 parts by mass of methyl ethyl ketone (hereinafter referred to as "MEK"). 36 parts by mass of cyclohexylmethane diisocyanate (hereinafter, abbreviated as "HMDI"), then, 0.1 part by mas...

Embodiment 2

[0080] In a 4-neck flask equipped with a stirrer, a reflux cooling tube, a thermometer, and a nitrogen introduction tube, 100 parts by mass of PTMG, polycarbonate diol (a substance using 1,6-hexanediol as a base material, Number average molecular weight: 2000, hereinafter referred to as "PC") 30 parts by mass, a random copolymer of ethylene oxide and propylene oxide (with ethylene glycol as an initiator, [EO / PO]=75 / 25 , number-average molecular weight: 1400, hereinafter referred to as "EOPO (2)".) 40 parts by mass, 3 parts by mass of DMPA, 149 parts by mass of MEK, after mixing uniformly, 46 parts by mass of HMDI was added, and then, dilauric acid was added 0.1 mass part of butyltin was reacted at 70 degreeC for about 4 hours, and the methyl ethyl ketone solution of the urethane prepolymer which has an isocyanate group was obtained.

[0081] Next, 2.3 parts by mass of triethylamine was added to neutralize the carboxyl groups in the urethane polymer, 522 parts by mass of ion-ex...

Embodiment 3

[0084] In a 4-necked flask equipped with a stirrer, a reflux cooling tube, a thermometer and a nitrogen introduction tube, 100 parts by mass of PTMG, a random copolymer of ethylene oxide and oxolane (with tetrahydrofuran as an initiator) were added under nitrogen flow. The substance of the agent, the molar ratio of EO to the structure represented by the following formula (3) (hereinafter referred to as “TMO”.) [EO / TMO]=50 / 50, number average molecular weight: 1800, hereinafter referred to as “EOTMO ( 1)".) 80 parts by mass, 4 parts by mass of DMPA, 159 parts by mass of MEK, after mixing uniformly, 34 parts by mass of HMDI, 9.4 parts by mass of hexamethylene diisocyanate (hereinafter referred to as "HDI".) were added, and then Next, 0.1 part by mass of dibutyltin dilaurate was added, and the reaction was performed at 70° C. for about 4 hours, thereby obtaining a methyl ethyl ketone solution of a urethane prepolymer having an isocyanate group.

[0085] Next, after adding 3 mass p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com