Patents

Literature

1111 results about "Polyoxydony" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

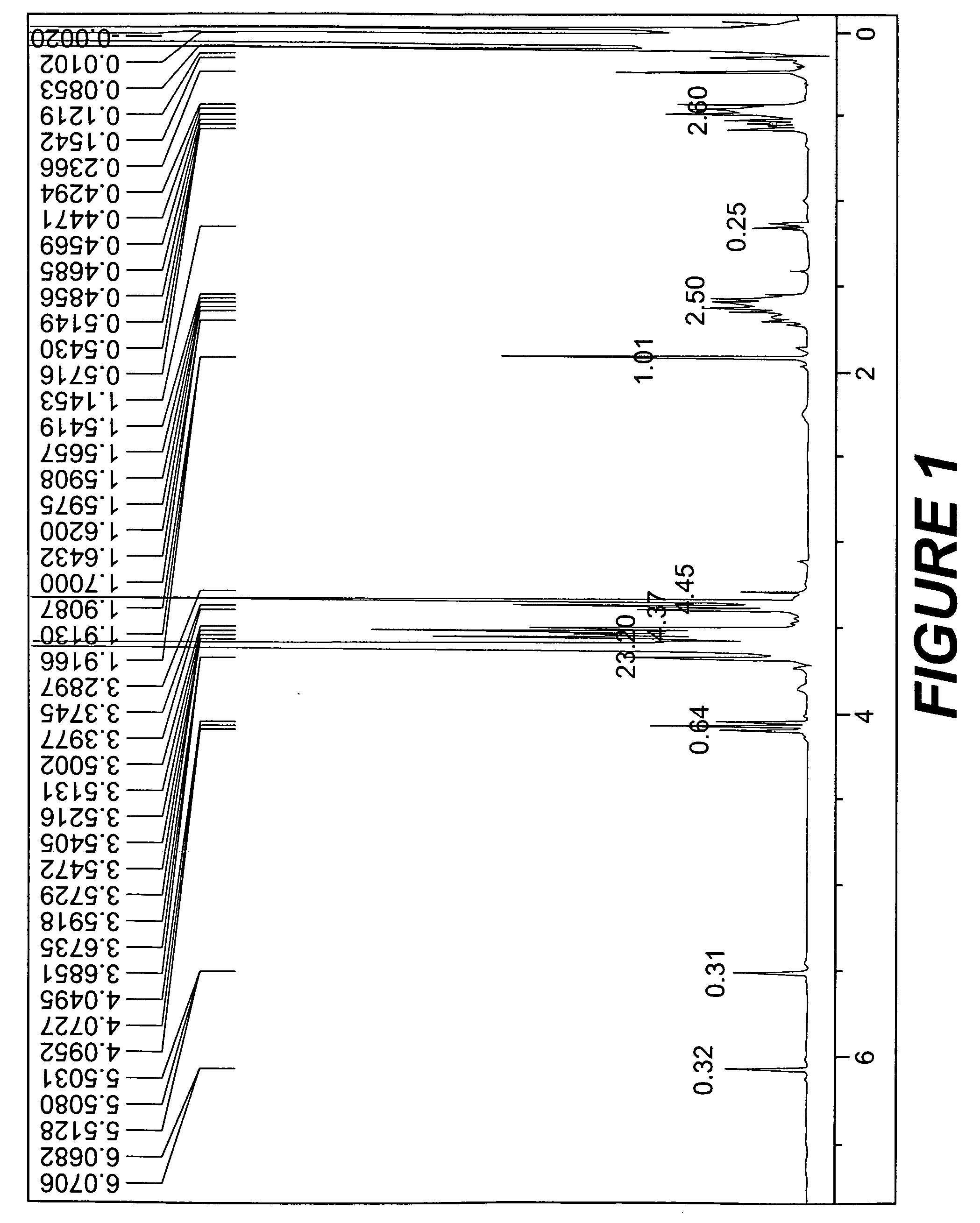

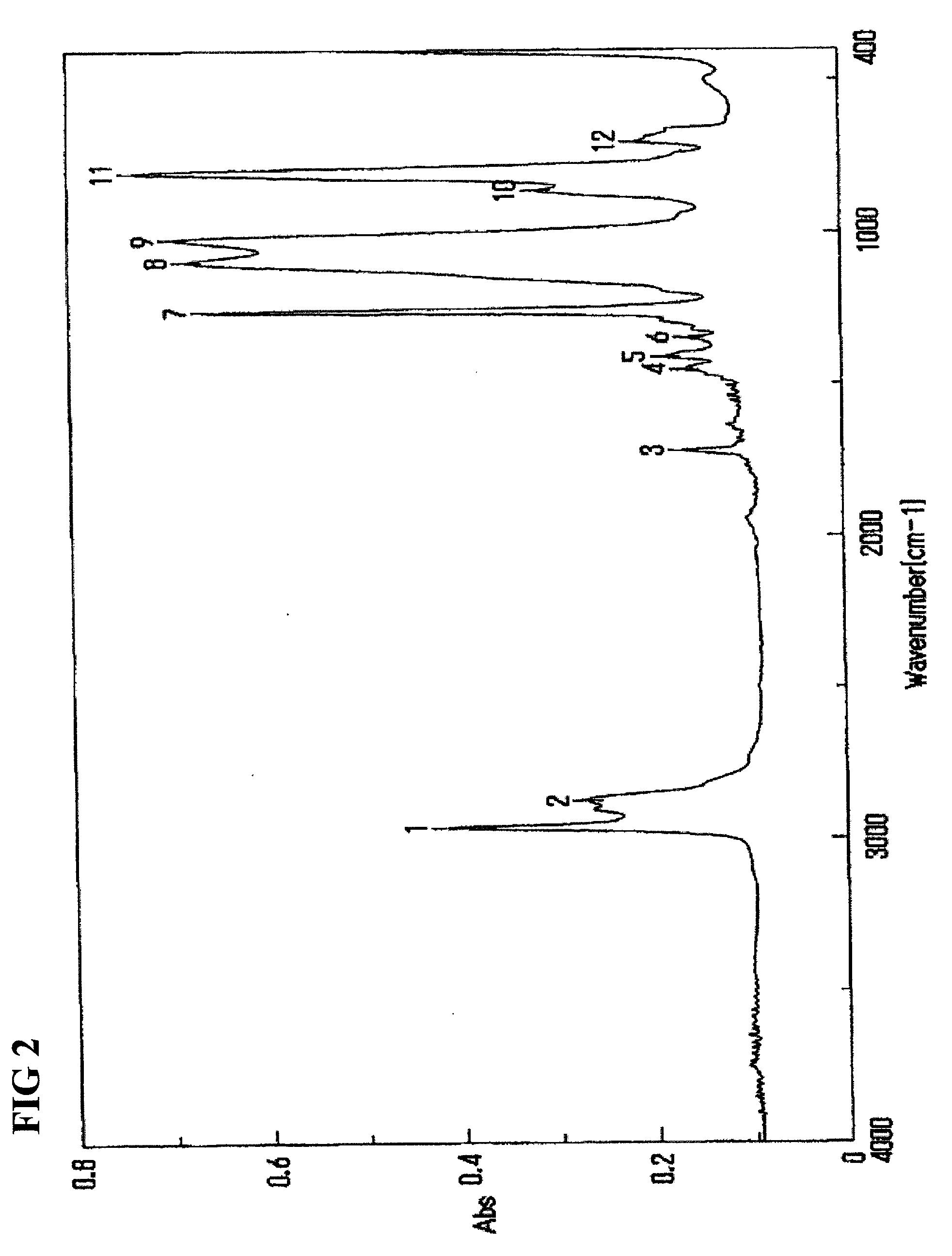

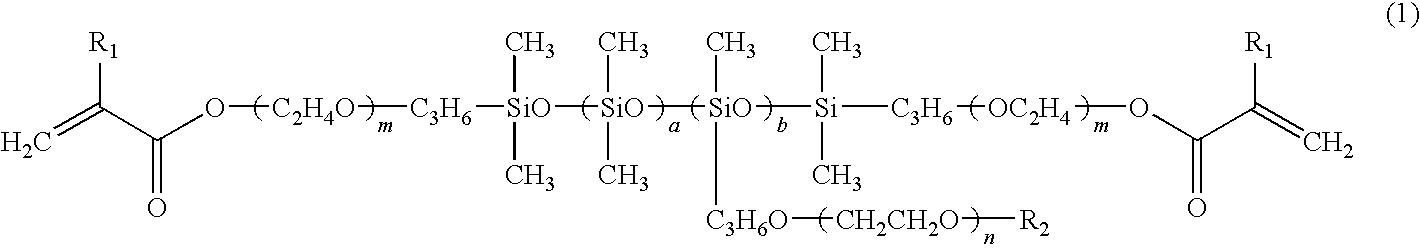

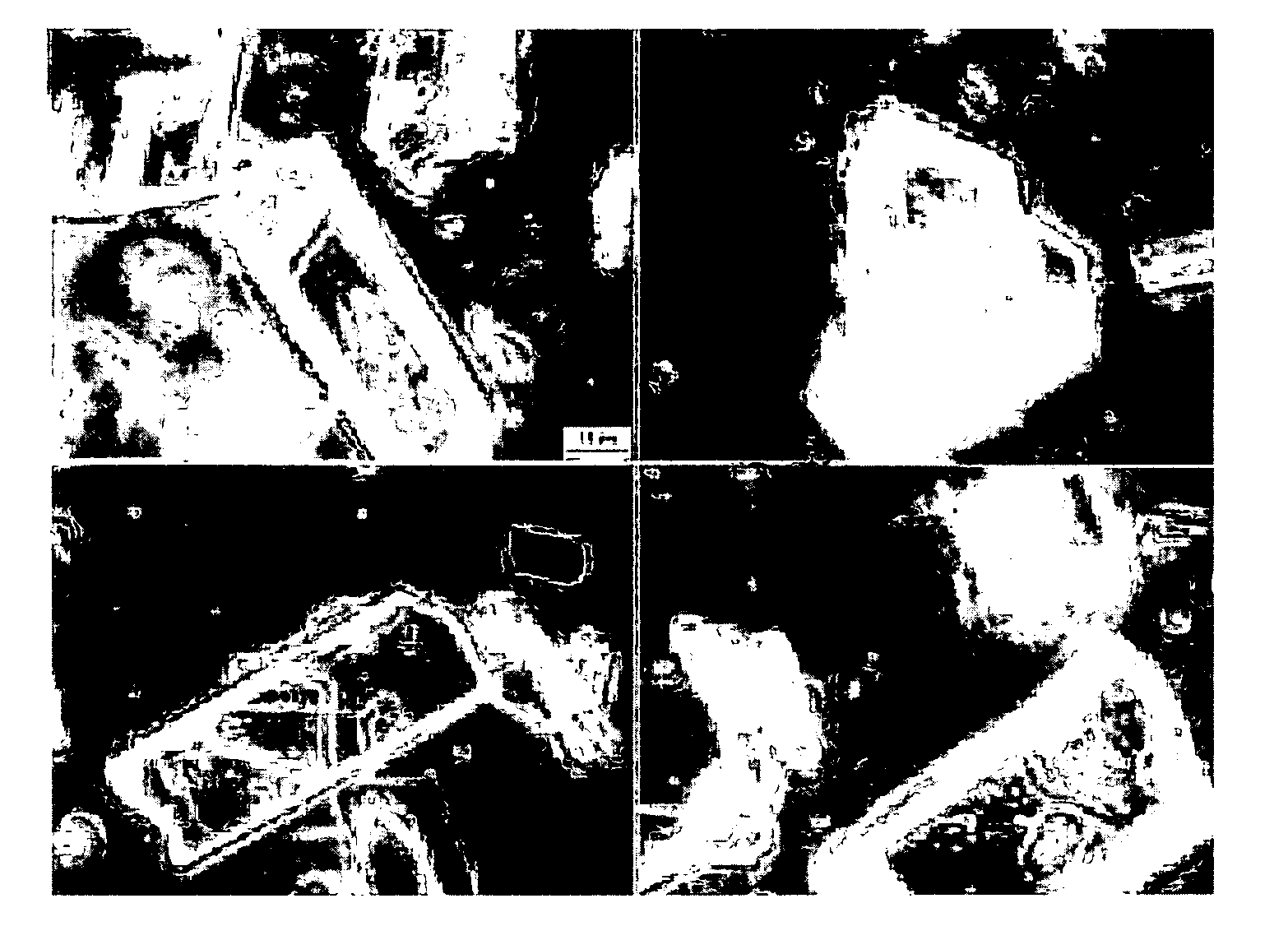

Hydrophilic Polysiloxane Macromonomer, and Production and Use of the same

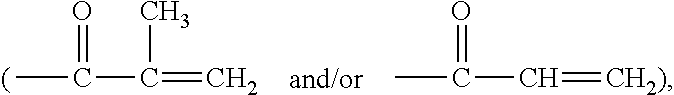

ActiveUS20090234089A1Improve compatibilityHigh oxygen permeabilitySilicon organic compoundsOptical articlesSide chainHydrophile

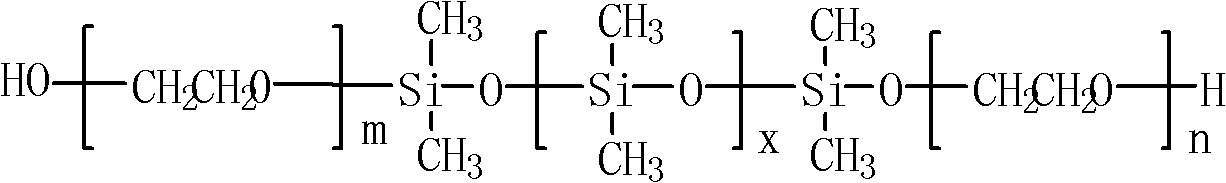

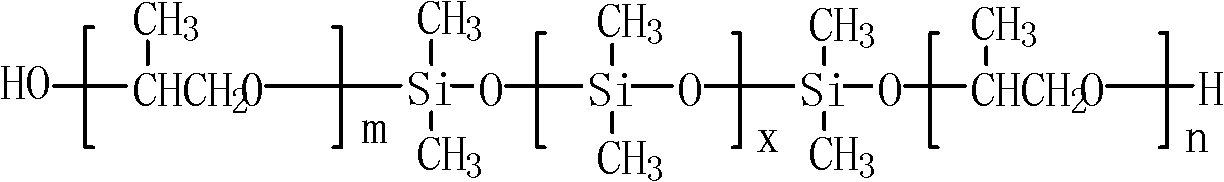

Problem to be Solved To provide an ophthalmic lens, which can be more safely worn, that is, to provide a material, which is transparent and has high oxygen permeability and a high hydrophilic property, and to provide a novel monomer to be a raw material thereof.Solution A hydrophilic polysiloxane macromonomer contains polyoxyethylene as a hydrophilic side chains in a polysiloxane main chain, wherein transparency, oxygen permeability, and hydrophilic properties of the material are controlled by regulating the length of the polysiloxane main chain, the length of the hydrophilic polyoxyethylene side chains, and the number of the side chains.

Owner:COOPERVISION INT LTD

Spontaneous emulsions containing cyclosporine

A pharmaceutical composition contains cyclosporine as the active ingredient. More specifically, the composition is an orally administered pharmaceutical formulation in the form of a spontaneous emulsion comprising cyclosporine, ethanol ethyl oleate and polyoxyethylene glycerol trioleate. A method for preparing an orally administered pharmaceutical composition involves first dissolving cyclosporine in ethanol. Polyoxyethylene glycerol trioleate and an oil component are then added, mixed and diluted in an aqueous media to form a spontaneous emulsion.

Owner:WOCKHARDT EU OPERATIONS SWISS

Injectable compositions of nanoparticulate immunosuppressive compounds

InactiveUS20060210638A1Improve complianceImprove efficacyPowder deliveryBiocideDepressantCompound (substance)

The invention is directed to an injectable nanoparticulate immunosuppressant composition for the formation of a subcutaneous or intramuscular depot. The invention is also directed to an injectable composition of nanoparticulate tacrolimus and / or sirolimus which eliminates the need to use polyoxyl 60 hydrogenated castor oil (HCO-60) and / or polysorbate 80 as a solubilizer. This invention further discloses a method of making an injectable nanoparticulate tacrolimus and / or sirolimus composition and is also directed to methods of treatment using the injectable nanoparticulate formulations comprising tacrolimus, sirolimus, or combination thereof for a subcutaneous or intramuscular depot for the prophylaxis of organ rejection and for the treatment of psoriasis or other immune diseases

Owner:ELAN PHRMA INT LTD

Tris(trimethyl siloxyl)silane vinylic monomers and uses thereof

The invention provides a TRIS-containing vinylic monomer which comprises one sole (meth)acryloyloxy group and a tris(trimethylsiloxy)silyl group covalently linked to the ethylenically-unsaturated group through a polyoxyethylene linker. The present invention is also related to a polymer, an actinically-crosslinkable silicone-containing prepolymer, a silicone hydrogel polymeric material, or a silicone hydrogel contact lens, which comprises monomeric units derived from a TRIS-containing vinylic monomer of the invention. In addition, the invention provides a method for making a TRIS-containing vinylic monomer of the invention.

Owner:SHIN ETSU CHEM IND CO LTD +1

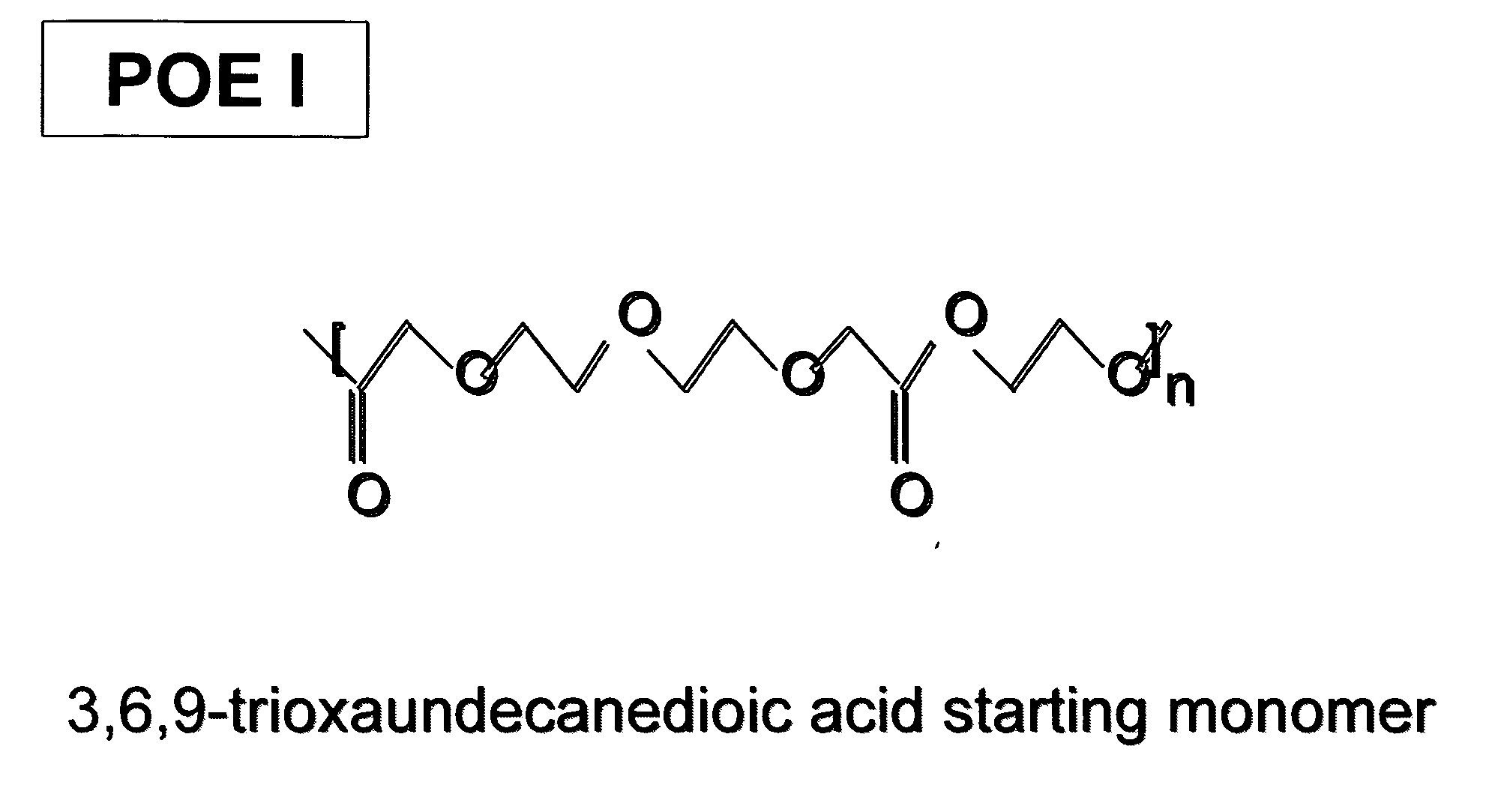

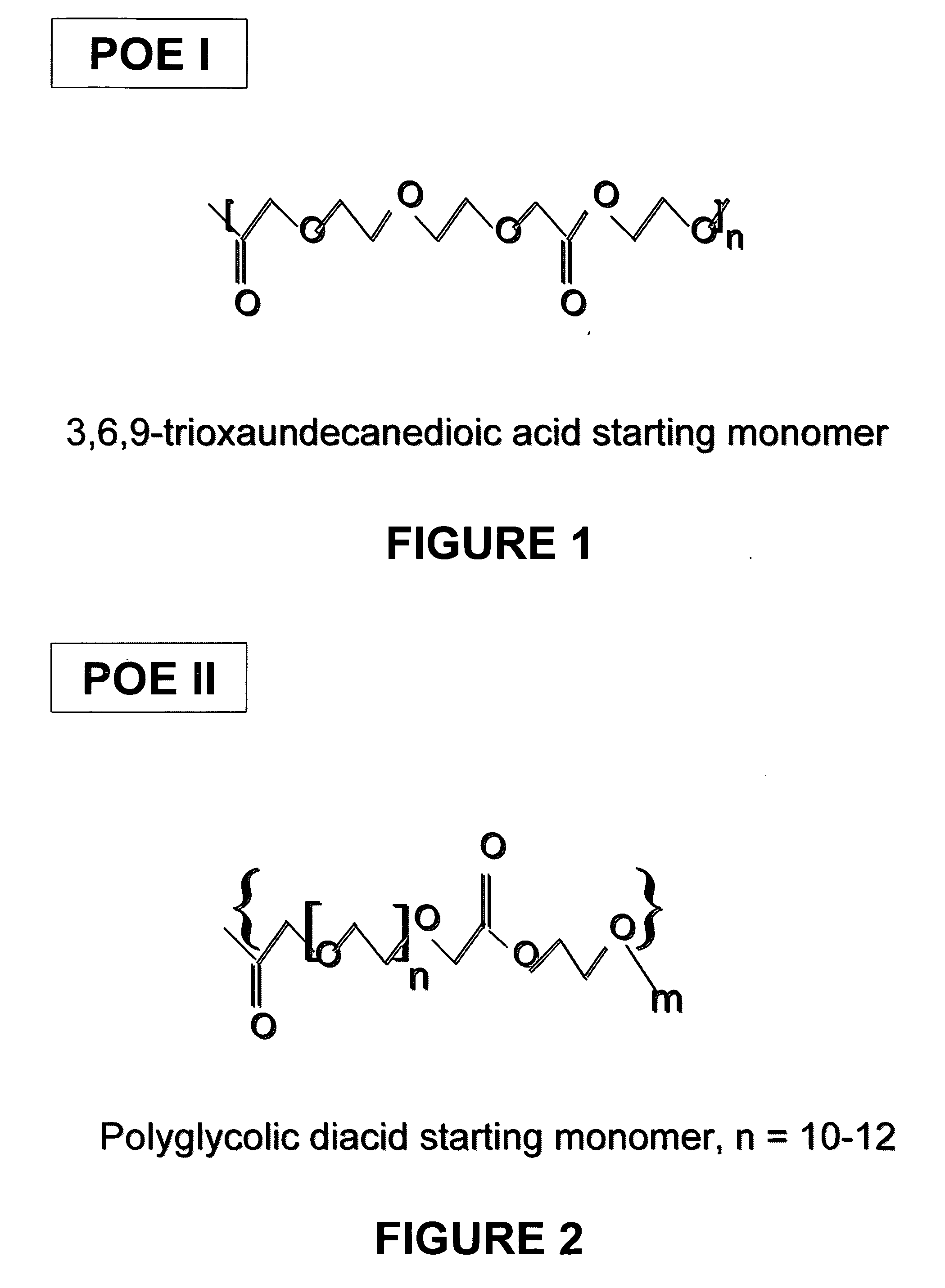

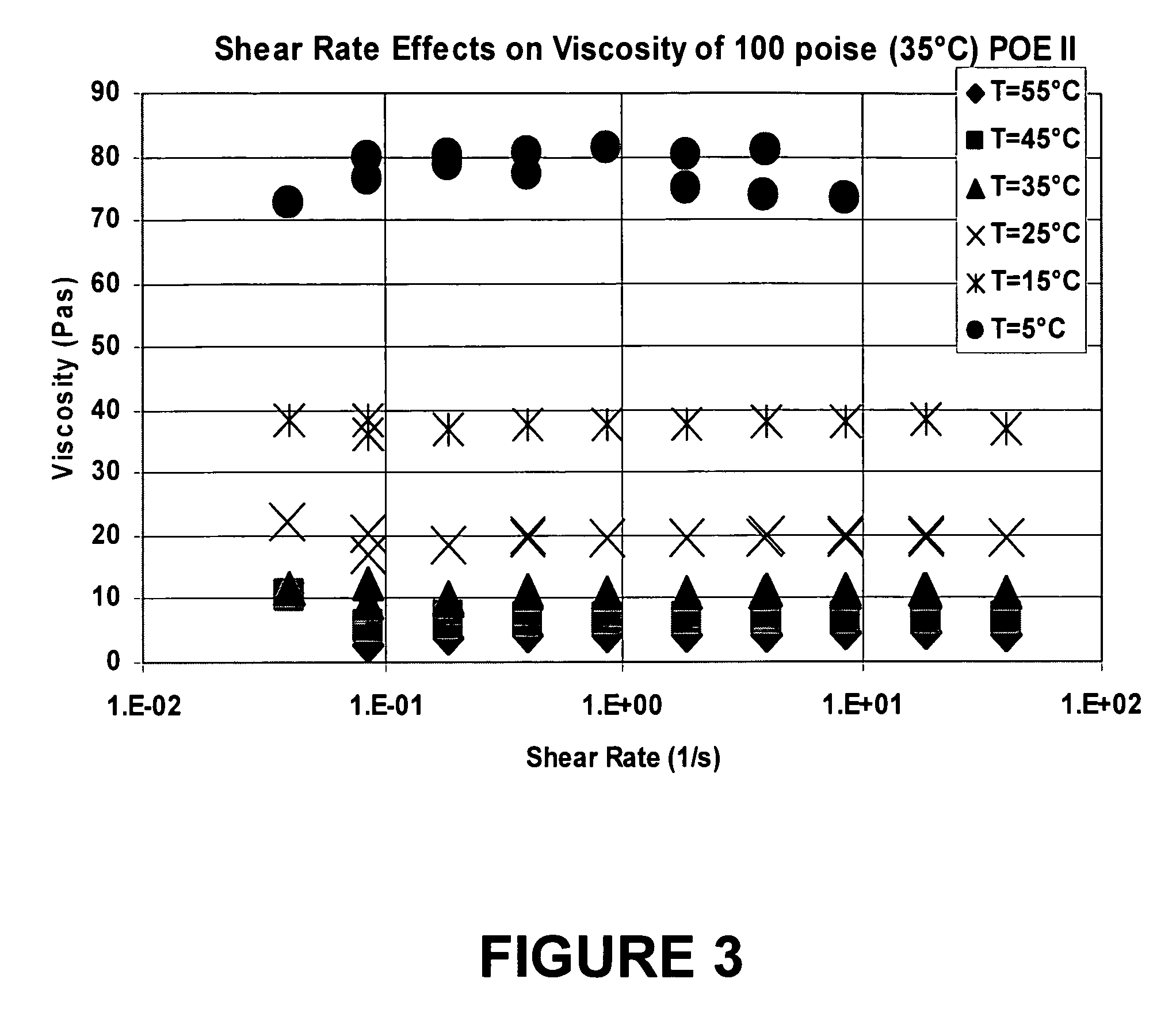

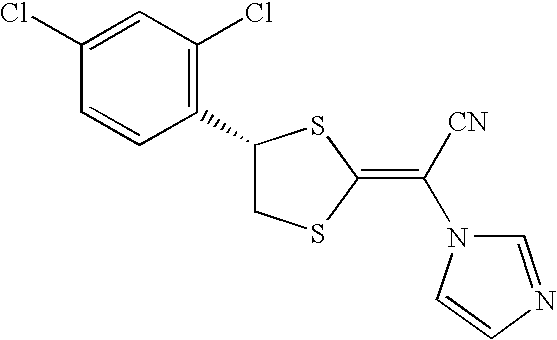

Polyoxaester suspending vehicles for use with implantable delivery systems

ActiveUS20060246138A1LimitMaintain stabilityPowder deliveryOrganic active ingredientsSUSPENDING VEHICLEActive agent

Liquid polyoxaester polymer materials are provided as suspending vehicles suitable for dispensing of pharmaceutically active agents, such as proteins, from delivery devices, for example, pump-driven dosage forms. Polyoxaesters are made from at least one diacid and at least one diol. Through the use of polyoxaesters virtually solvent-free pharmaceutical suspensions can be created.

Owner:INTARCIA THERAPEUTICS INC

Polymer Solid Electrolyte

InactiveUS6162563AEasy to processGood moldabilityHybrid capacitor electrolytesCell electrodesLithium metalBackbone chain

PCT No. PCT / JP97 / 02854 Sec. 371 Date Mar. 11, 1999 Sec. 102(e) Date Mar. 11, 1999 PCT Filed Aug. 19, 1997 PCT Pub. No. WO98 / 07772 PCT Pub. Date Feb. 26, 1998A polymer solid electrolyte obtained by blending (1) a polyether copolymer having a main chain derived form ethylene oxide and an oligooxyethylene side chain, (2) an electrolyte salt compound, and (3) a plasticizer of an aprotic organic solvent or a derivative or metal salt of a polyalkylene glycol having a number-average molecular weight of 200 to 5,000 or a metal salt of the derivative is superior in ionic conductivity and also superior in processability, moldability and mechanical strength to a conventional solid electrolyte. A secondary battery is constructed by using the polymer solid electrolyte in combination with a lithium metal negative electrode and a lithium cobaltate positive electrode.

Owner:OSAKA SODA CO LTD

Low-foaming hydrogen peroxide cleaning solution for organic soils

InactiveUS6686324B2Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesAlkane

A low-foaming cleaning solution and dry particulate formulation which can be diluted with water, deionized water, or mixtures thereof, to form the cleaning solution. The cleaning solution has an alkaline pH, which is preferably from about 8 to about 11.5 and consists essentially of at least one low foaming surfactant in a concentration of from about 0.005% to about 40% w / w of the total solution, at least one active oxygen releasing compound in an amount effective to produce a hydrogen peroxide concentration of from about 0.005% to about 50% w / w of the total solution, at least one builder in a concentration of from about 0.001% to about 50% w / w of the total solution, and at least one diluent selected from the group consisting of water, deionized water, and mixtures thereof. The at least one surfactant is selected from the group consisting of C3-C8 alkane sulfonates, C3-C8 alkyl sulfates, C1-C7 alkyl naphthalene sulfonates, polyoxyethylene / polyoxypropylene block copolymers having a polyoxypropylene molecular weight of from about 1500 to about 8500, of which less than about 30% of the total molecular weight is due to the polyoxyethylene portion, and mixtures thereof. The at least one active oxygen releasing compound is selected from the group consisting of hydrogen peroxide, at least one source of hydrogen peroxide, and mixtures thereof.

Owner:JOHNSONDIVERSEY INC

Organic silicon modified polyurethane resin for synthetic leather and preparation method thereof

The invention designs an organic silicon modified polyurethane resin for synthetic leather and a preparation method thereof, relating to the processing field of synthetic leather. The invention solves the technical problems of poor anti-sticking performance, poor water resistance, poor wear resistance and the like of the existing synthetic leather. The resin provided by the invention is characterized by comprising the following raw materials in mass percent: 2-30% of diisocyanate, 5-40% of polyester or polyether polyol, 0.5-20% of terminal hydroxyl organic silicon, 0-10% of small molecular polyol chain extender, 0-13% of small molecular polyamine chain extender, 0.01-1% of catalyst and the balance of solvent, wherein the terminal hydroxyl organic silicon adopts a polyether-polysiloxane copolymer of which the two ends are hydroxyl groups, and the polyether chain segment is polyoxyethylene or polyoxypropylene. The glossiness and transparency of the polyurethane resin modified by the invention can not be influenced by organic silicon, and simultaneously, the anti-sticking performance, surface smoothness, wear resistance and water resistance of the modified polyurethane resin can be obviously improved.

Owner:ZHEJIANG SUNLIGHT MATERIAL TECH CO LTD

Cleaning solution for cleaning substrate for semiconductor devices and cleaning method using the same

InactiveUS20050020463A1Less cleaningImprove removabilityInorganic/elemental detergent compounding agentsSurface-active detergent compositionsOrganic acidDevice material

A cleaning solution for cleaning a substrate for semiconductor devices and a cleaning method using the said cleaning solution, which comprises at least the following components (A), (B) and (C): (A) an ethyleneoxide-type surfactant containing a hydrocarbon group which may have a substituent group except for phenyl, and a polyoxyethylene group in which a ratio (m / n) of a number (m) of carbon atoms contained in the hydrocarbon group to a number (n) of oxyethylene groups contained in the polyoxyethylene group is in the range of 1 to 1.5, the number (m) of carbon atoms is not less than 9, and the number (n) of oxyethylene groups is not less than 7; (B) water; and (C) alkali or an organic acid. The cleaning solution highly clean the surface of the substrate without occurrence of corrosion by removing fine particles and organic contaminants which are adhered onto the surface of the substrate.

Owner:MITSUBISHI CHEM CORP

Hybrid hydrogel scaffold compositions and methods of use

ActiveUS20130115196A1Reduce usageReduce scarsBiocidePeptide/protein ingredientsHybrid materialMixed materials

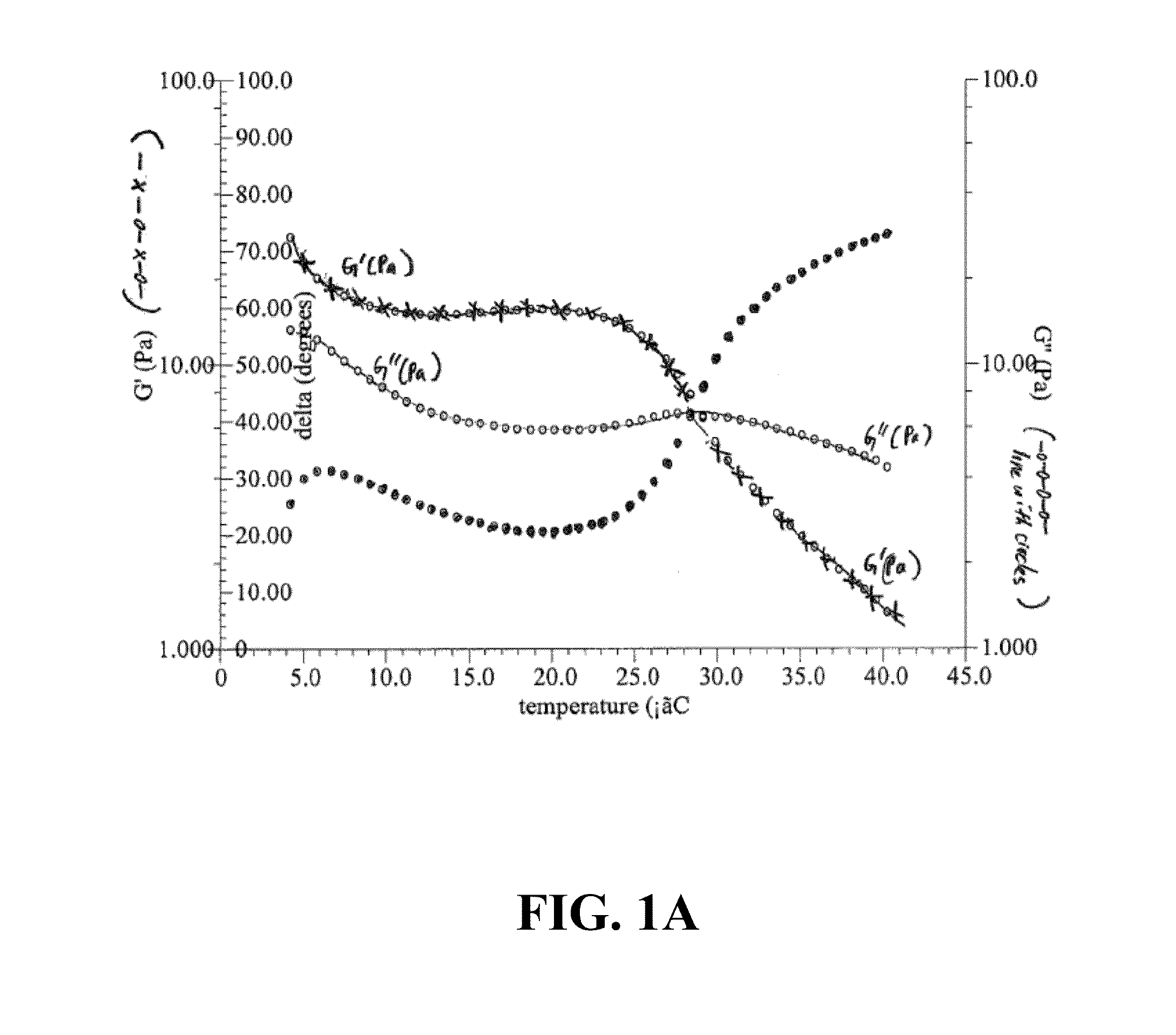

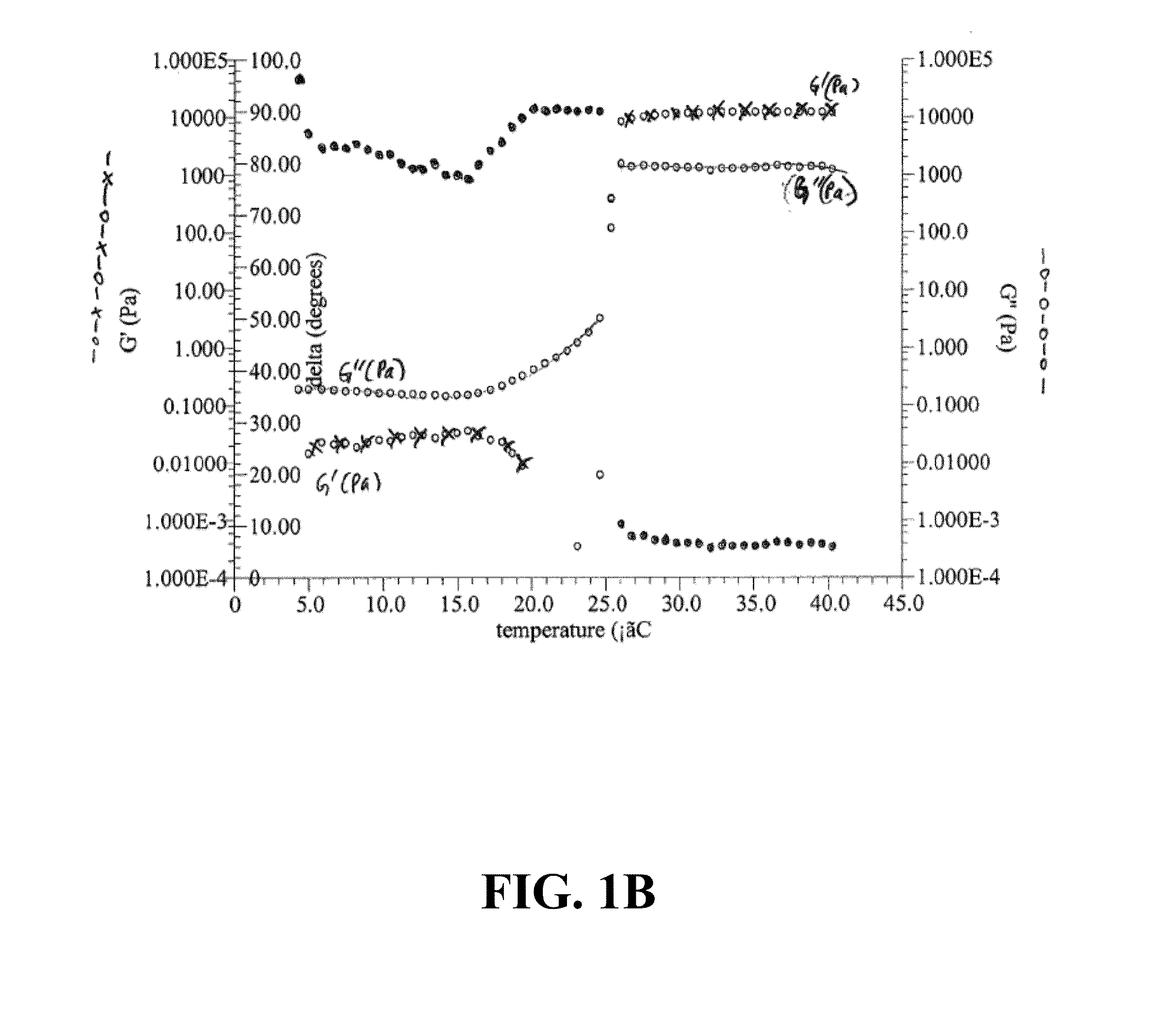

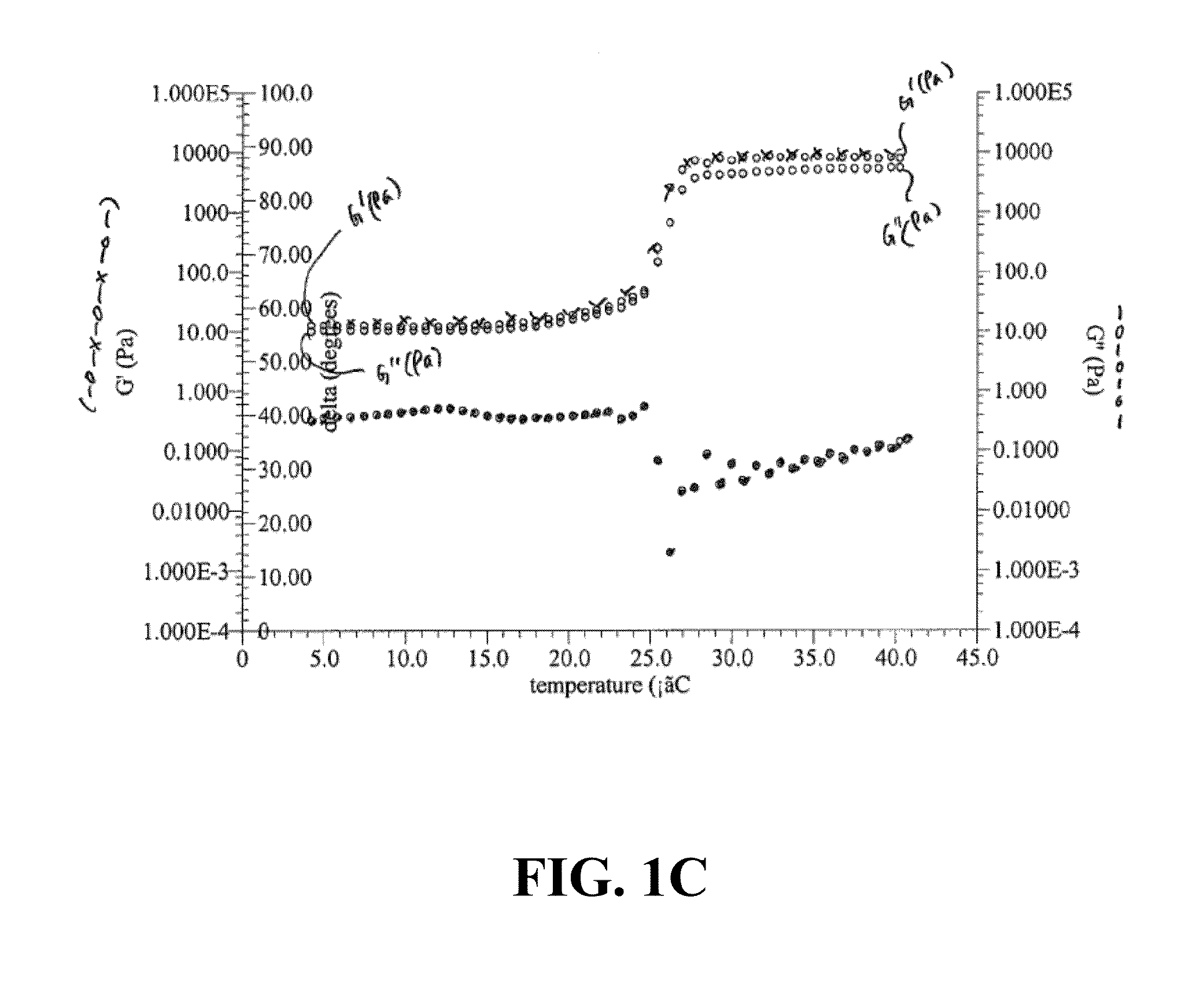

The present invention includes new hybrid hydrogel scaffolds comprised of a polyoxyethylene-polyoxypropylene (block) copolymer (a “poloxamer”) and a self-assembling peptide, which maintain the mechanical and bioactive properties of its individual constituents (as compared to when the individual constituents are scaffolds or hydrogels by themselves). The hydrogels of the invention can include a combination of materials from different origins or with different properties that provides a hybrid material that meets the multiple needs of a scaffold for tissue engineering.

Owner:SAMSUNG DISPLAY CO LTD +1

Ophthalmic composition

ActiveUS20120095097A1Stabilizing vitaminGood effectBiocideSenses disorderOptometryPOLYOXYETHYLENE ETHER

Disclosed is an ophthalmic composition containing (A) not less than 50,000 units / 100 mL of vitamin A, (B) not less than 0.4 W / V % of a polyoxyethylene polyoxypropylene glycol, and (C) trometamol.

Owner:LION CORP

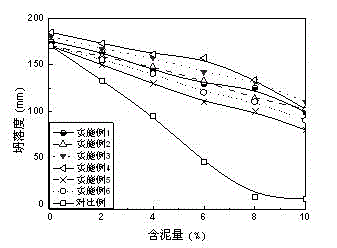

Phosphorous acid concrete super plasticizer with polyethyleneimine structure as well as preparation method and application thereof

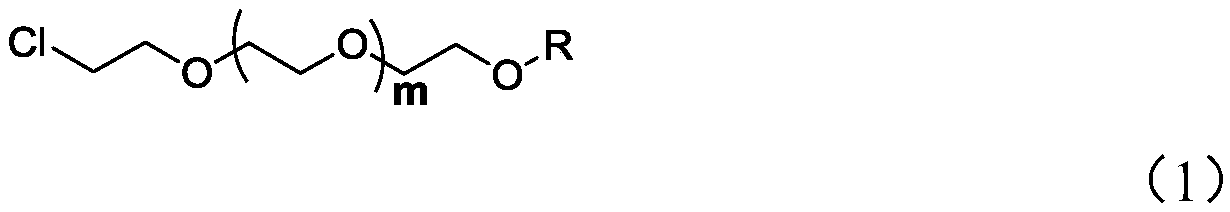

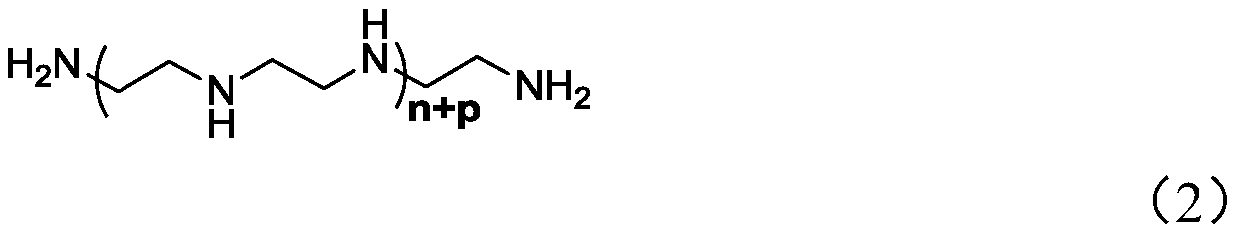

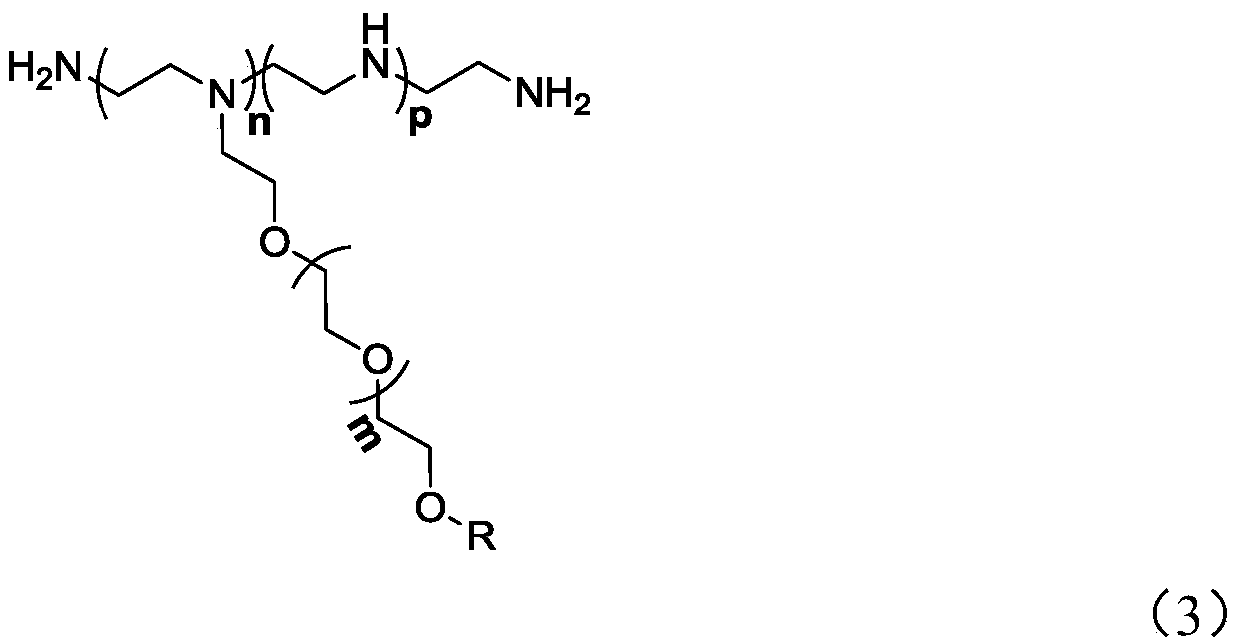

The invention provides a new phosphorous acid concrete super plasticizer with a polyethyleneimine structure as well as a preparation method and an application thereof. The phosphorous acid concrete super plasticizer with a polyethyleneimine structure can effectively improve the concrete fluidity, and the preparation method is simple and effective. The preparation method comprises the following steps: a) making chloro-substituted polyether react with polyethyleneimine so that a part of amino groups H of the polyethyleneimine are substituted to obtain polyethyleneimine with a polyoxyethylene ether branch structure, wherein the molar ratio of the chloro-substituted polyether to the imino groups contained in the polyethyleneimine is 1:(3-8); and b) performing phosphorylation of the remaining amino groups H of the polyethyleneimine with a polyoxyethylene ether branch structure to obtain the phosphorous acid concrete super plasticizer with a polyethyleneimine structure.

Owner:JIANGSU SOBUTE NEW MATERIALS

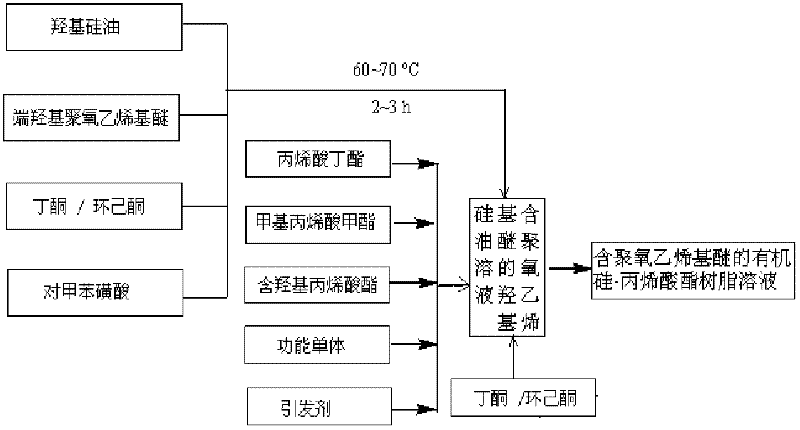

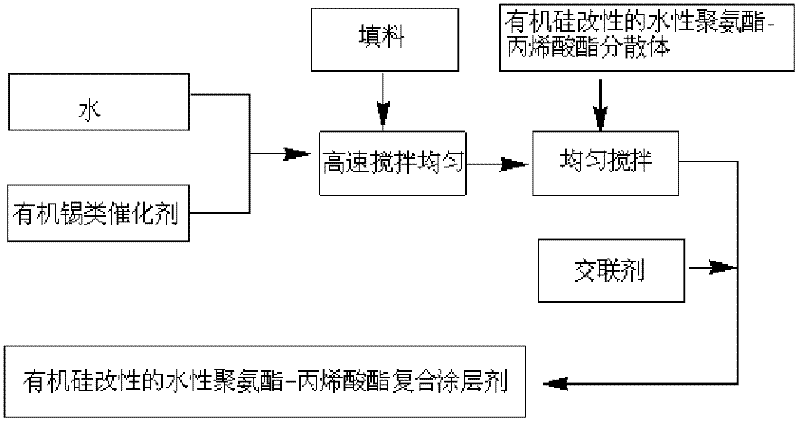

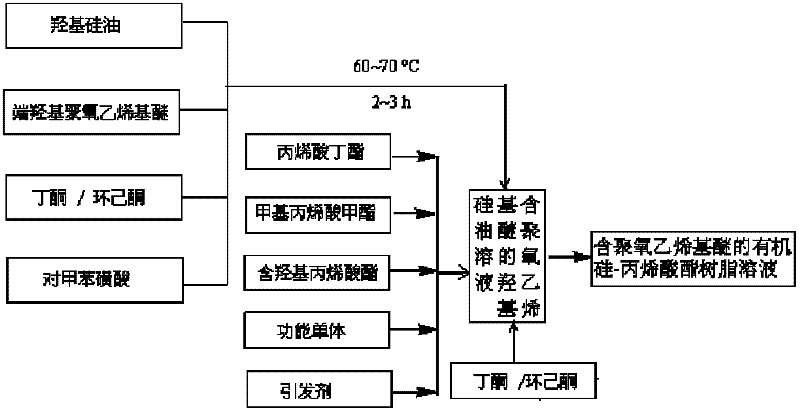

Organosilicon-modified aqueous polyurethane-acrylate composite coating agent and preparation method thereof

InactiveCN102559031AGood compatibilityImprove mechanical propertiesPolyurea/polyurethane coatingsChemical industryVinyl ether

The invention belongs to the technical field of chemical industry, and particularly relates to an organosilicon-modified aqueous polyurethane-acrylate composite coating agent and a preparation method thereof. The method comprises the following steps of: performing hydroxyl condensation reaction by using hydroxyl-terminated silicone oil and polyoxyethylene ether to prepare polyoxyethylene ether-containing hydroxyl silicone oil resin; introducing the polyoxyethylene ether-containing hydroxyl silicone oil resin into isocyanate-terminated polyurethane prepolymer by using a chemical bonding method; preparing organosilicon-modified aqueous polyurethane-acrylate dispersion through a self-emulsification method; and finally preparing the organosilicon-modified aqueous polyurethane-acrylate composite coating agent. According to the method, the problems of poor compatibility among the three components, i. e., organosilicon, polyurethane and acrylate and poor mechanical property of an aqueous composite coating layer of the organosilicon-modified aqueous polyurethane-acrylate composite coating agent are solved well. The preparation method provided by the invention has the advantages of simple process, convenience, high product quality, high input-output ratio and the like. The coating agent has high compatibility and superior mechanical property and is a new-generation environmentally-friendly high-performance chemical product.

Owner:杭州材聚科技有限公司

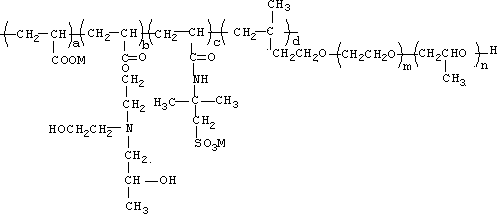

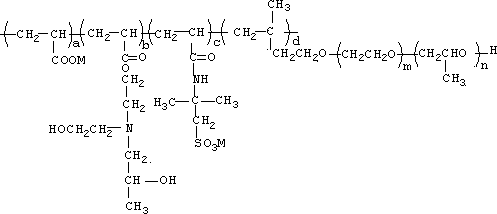

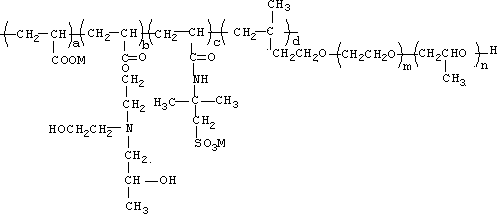

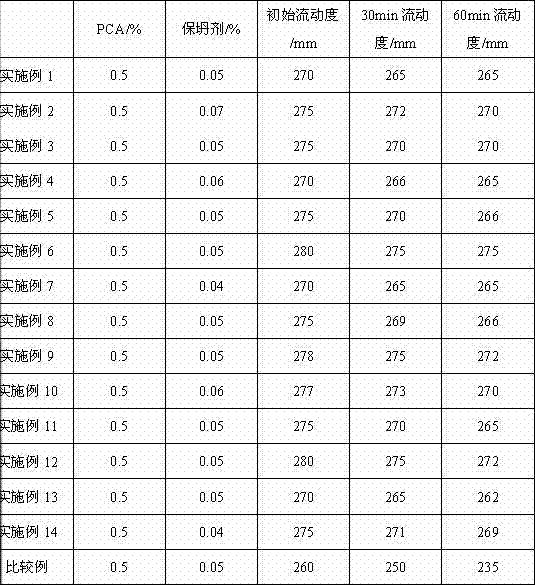

Ethers early strength type polycarboxylate water reducer and preparation method thereof

The invention discloses an ethers early strength type polycarboxylate water reducer and a preparation method thereof. The water reducer regards unsaturated esters, N,N-bis(2-hydroxyethyl)isopropanolamine (DIEPA), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), methyl allyl polyoxyethylene polyoxypropylene ether (TPEG) and the like as main chemical synthesis raw materials, and the main chemical synthesis raw materials are subjected to amidation and copolymerization in certain conditions under the action of a catalyst, an initiator, a chain transfer agent and the like, so that a high-molecular polymer with an amphoteric structure is obtained. The molecular structure of the water reducer comprises hydrophilic hydroxyl, hydrophilic carboxyl, hydrophilic acylamino, hydrophilic sulfonyl, hydrophobic carbon chains and a polyoxyethylene polyoxypropylene ether long-chain structure with certain stereo-hindrance effects, wherein an N containing group can improve early strength of concrete obviously. Therefore, the ethers early strength type polycarboxylate water reducer is applicable to pre-cast concrete components which need improvement of early strength.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Microemulsion

A microemulsion composition containing the following ingredients (A) through (F): (A) a hydrophilic nonionic surfactant having as a hydrophilic group a residue of a sugar, reducing sugar or polyglycerin having a hydrogen atom of at least one hydroxyl group thereof removed; (B) a hydrophilic nonionic surfactant having a polyoxyethylene chain as a hydrophilic group; (C) a water-soluble organic solvent selected from the group consisting of (C1) through (C3) listed below; (C1) a compound having in a molecule thereof two or more oxypropylene groups (PO) and hydroxyl groups (OH), the ratio in number of these two groups (PO / OH) being smaller than 5; (C2) a monohydric alcohol having a carbon number ranging from 2 to 6; and (C3) a dihydric alcohol having a carbon number ranging from 2 to 6; (D) a lipophilic nonionic surfactant; (E) an oily ingredient; and (F) water.

Owner:KAO CORP

Slump loss resistant type gather carboxylate water-reducing agent and preparation method thereof

The invention provides a slump loss resistant type gather carboxylate water-reducing agent, which is a polymer of prenyl polyoxyethylene ether or prenyl polyoxyethylene propenyl ether or methyl allyl polyoxyethylene ether or methallyl polyoxyethylene propenyl ether (a macro-monomer A) and unsaturated carboxylic acid (a micro-monomer B) and an unsaturated carboxylic acid derivative (a micro-monomer C), belonging to the field of concrete admixtures. A synthetic method is as follows: the water-reducing agent is prepared by initiating the macro-monomer A, the micro-monomer B and the micro-monomer C through an oxidative-reductive initiating system by taking water as a solvent at lower temperature, and carrying out copolymerization under the action of a chain transfer agent. The water-reducing agent overcomes the disadvantages of being poor in slump loss resistance, long in setting time and the like of the water-reducing agent synthesized by allyl polyoxyethylene ether and has the advantages of being high in slump loss resistance, good for being suitable to different cements and low in influence on concrete setting time.

Owner:山西山大合盛新材料股份有限公司

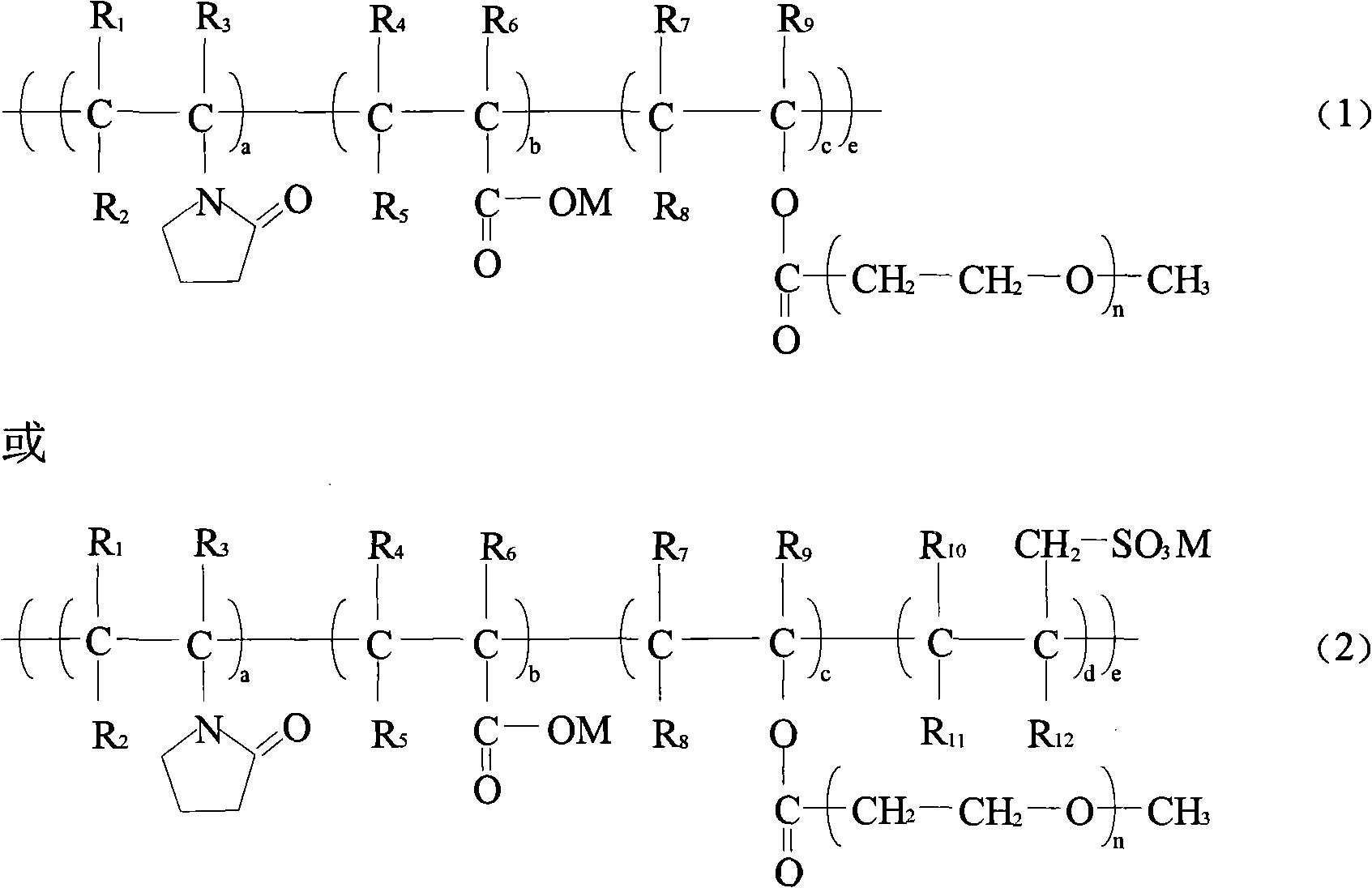

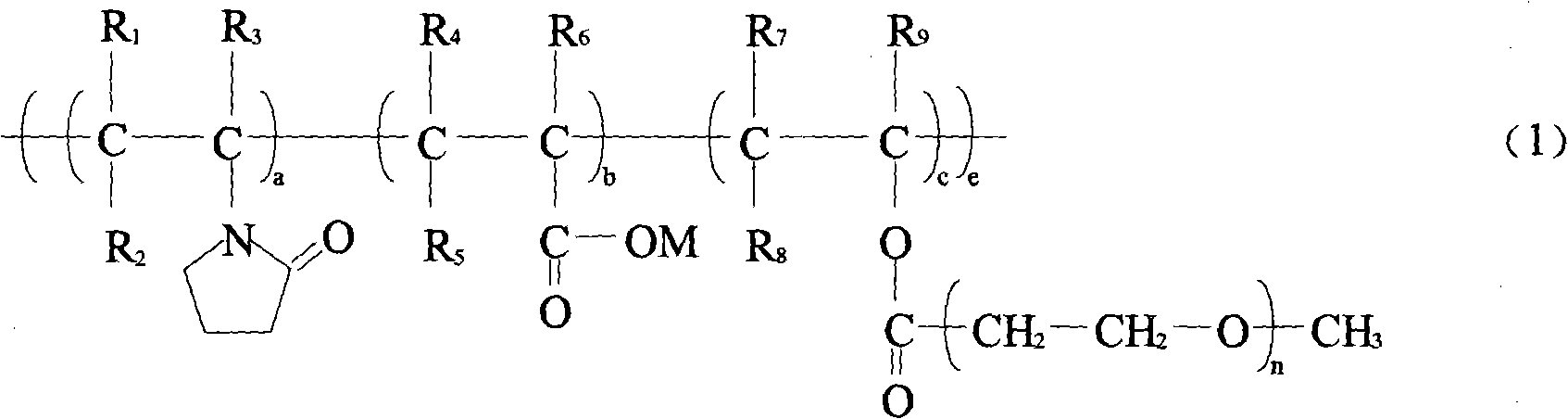

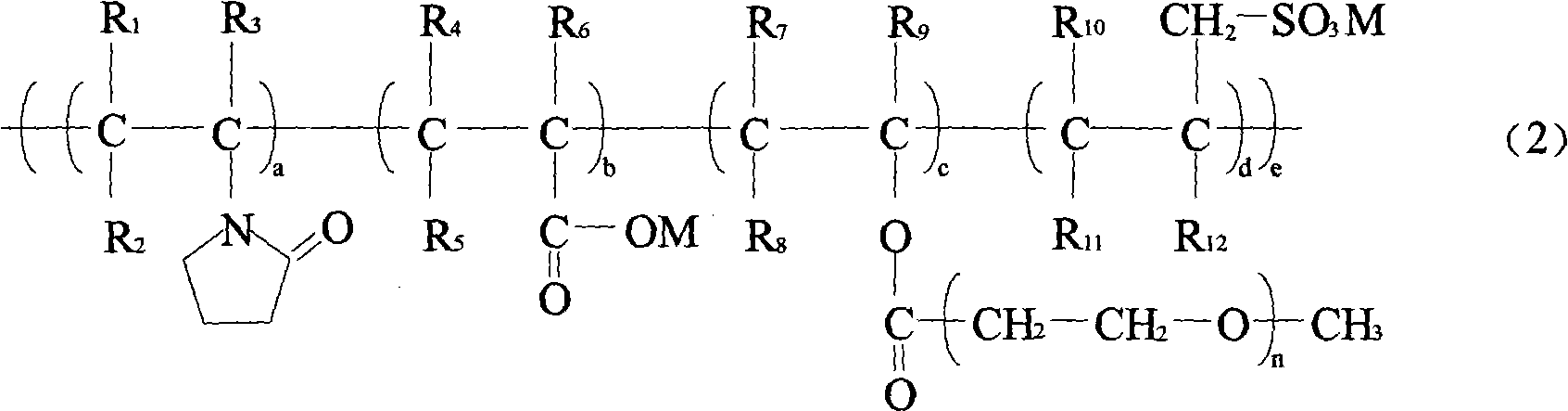

Cement concrete superplasticizer and method for preparing same

The invention discloses a concrete superplasticizer and a preparation method. Based on weight proportion, 1-50% of nitrogen-containing functional monomer a, 5-50% of unsaturated carboxylic acid and the derivative b of the unsaturated carboxylic acid, 15-94% of polyoxyethylene vinyl propionate ester ene single-ether and the derivative c of the polyoxyethylene vinyl propionate ester ene single-ether, as well as 0-50% of allyl sulfonate d are mixed to prepare a mixed monomer solution; the initiator which takes up 0.5-15% of the total weight of the mixed monomer, and the chain transfer agent which takes up 0-15% of the total weight of the mixed monomer are added into the mixed monomer solution so as to prepare the concrete super plasticizer through ternary or quaternary copolymerization. Without going through analysis purification, the invention can directly obtain the product and has simple synthetic process, less equipment investment, simple operation and easily controlled reaction conditions; the obtained product has better compatibility with cement and good adaptability with other additives, and is free from segregation and bleeding phenomena; the product also has good concrete slump retentivity and high water reduction rate.

Owner:SHENZHEN OCEANPOWER NEW MATERIALS TECH

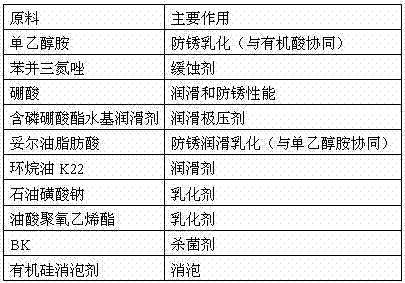

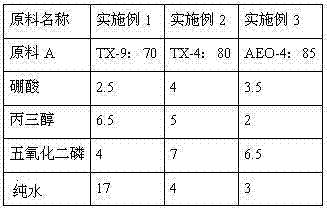

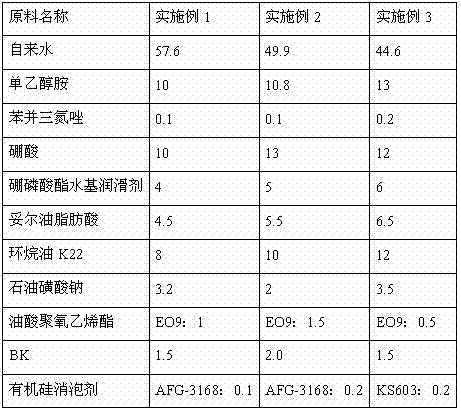

Multi-effect semi-synthetic cutting solution

ActiveCN102899152AReduce dosageHigh lubricating extreme pressure performanceLubricant compositionWater basedPhosphate

The invention discloses a multi-effect semi-synthetic cutting solution. The solution is prepared by uniformly mixing the following raw material components in percentage by total mass of 100%: 10 to 14% of monoethanolamine for industrial use, 0.1 to 0.2% of benzotriazole for industrial use, 10 to 13% of boric acid for industrial use, 4 to 6% of phosphate-borate-containing water-based lubricant, 4 to 7% of tall oil fatty acid for industrial use, 8 to 12% of naphthenic oil K22, 2 to 4% of petroleum sodium sulfonate No.55, 0.5 to 1.5% of oleic acid polyoxyethylene ester for industrial use, 1.5 to 2% of 1,3,5-tri(2-hydroxyethyl)-hexahydrotriazine for industrial use, 0.1 to 0.2% of organic silicon defoamer for industrial use and the balance of water. The solution has high lubrication extreme pressure performance and is biodegradable and environment-friendly.

Owner:无锡纳润特科技有限公司 +1

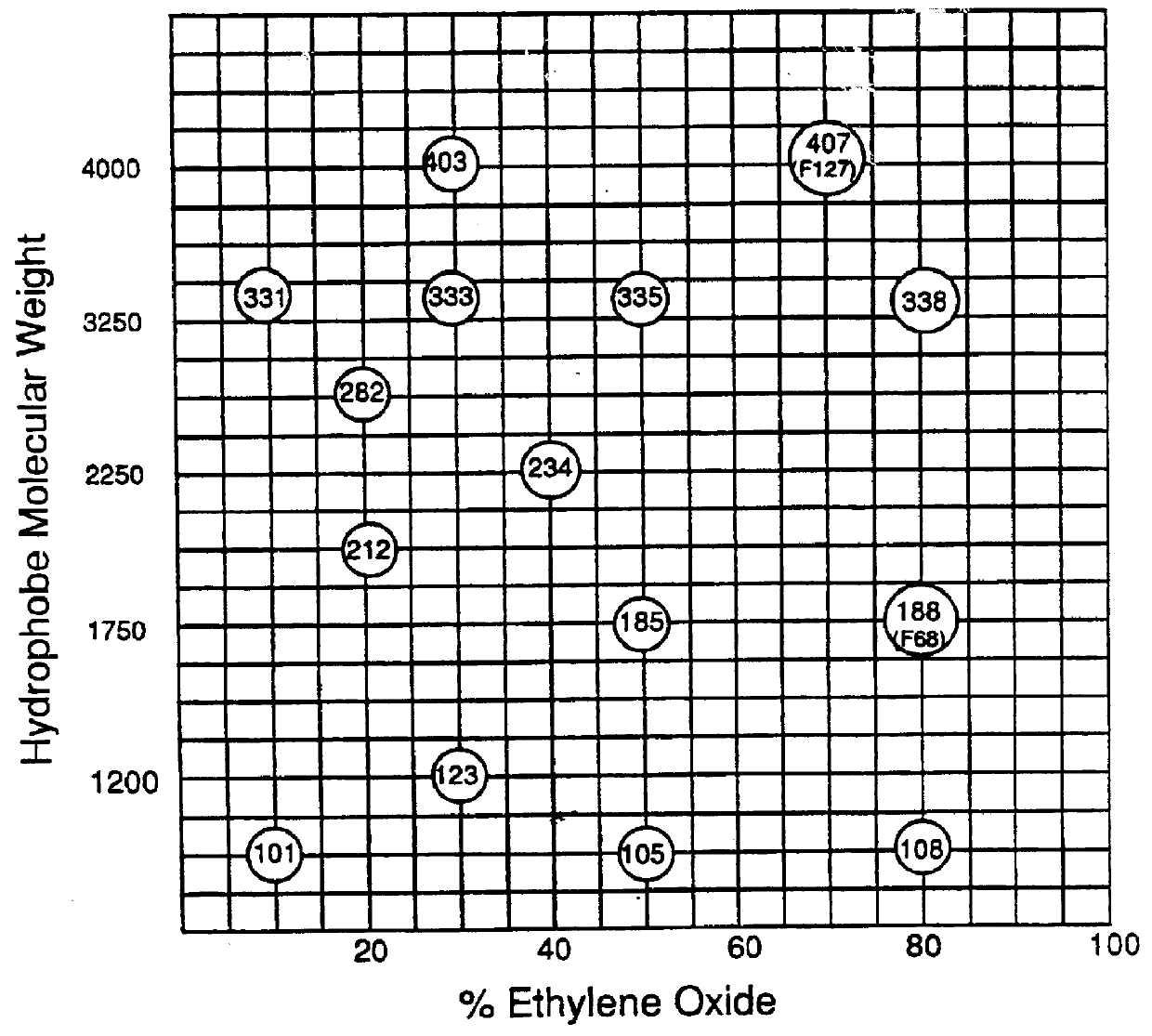

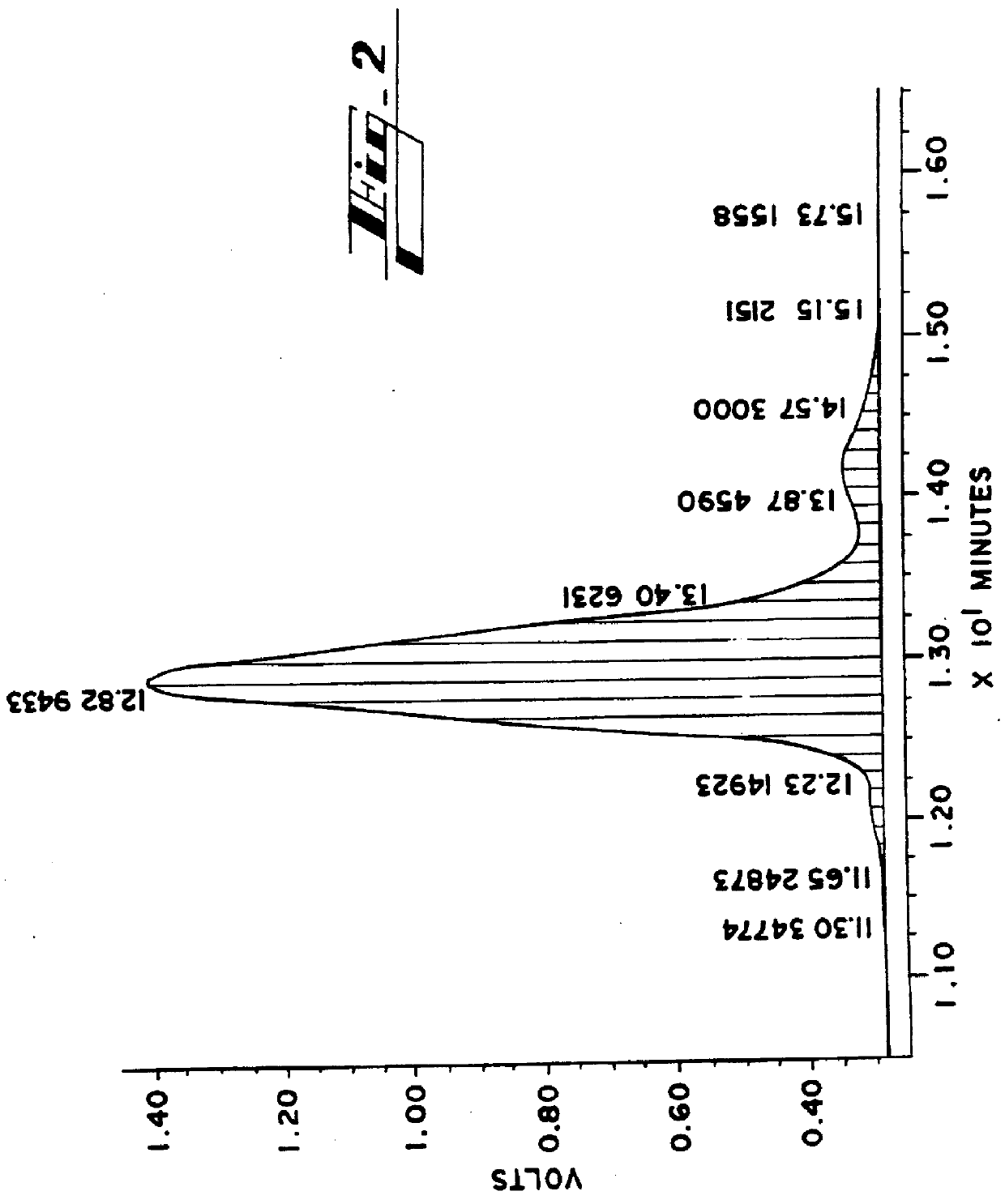

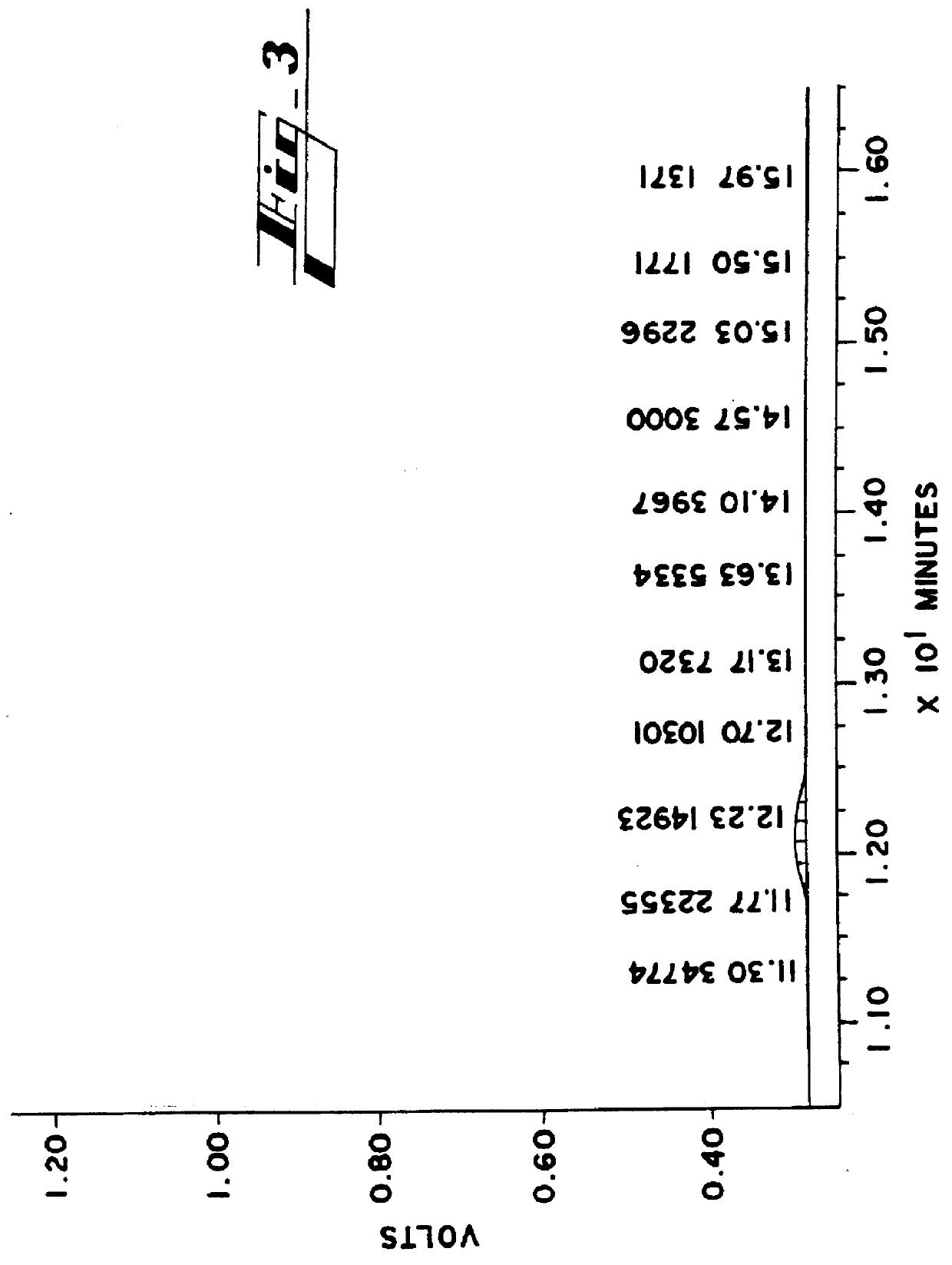

Polyoxypropylene/polyoxyethylene copolymers with improved biological activity

InactiveUSRE36665E1Improve biological activityMore predictableOrganic chemistryPharmaceutical non-active ingredientsDrug biological activityCopolymer

The present invention comprises novel preparations of polyoxypropylene / polyoxyethylene copolymers which retain the therapeutic activity of the commercial preparations, but are substantially free from the undesirable effects which are inherent in the prior art preparations. Because the preparations of polyoxypropylene / polyoxyethylene copolymers which comprise the present invention are a less polydisperse population of molecules than the prior art polyoxypropylene / polyoxyethylene copolymers, the biological activity of the copolymers is better defined and more predictable.

Owner:CYRX CORP

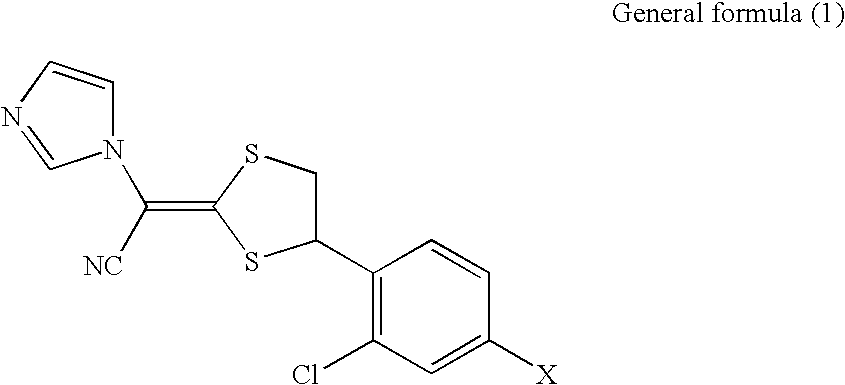

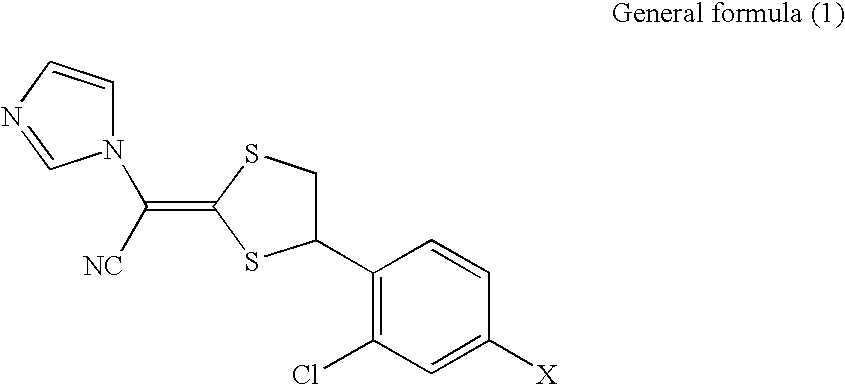

Antifungal composition

Disclosed is a pharmaceutical composition for antifungal use, comprising: 1) one or more compounds selected from compounds represented by the general formula (1) below and physiologically acceptable salts thereof; 2) one or more compounds selected from polypropylene glycol, diesters of dibasic acids, triacetin, 2-ethyl-1,3-hexanediol, lauromacrogol, and polyoxyethylene-polyoxypropylene glycol; and 3) one or more compounds selected from glucono-δ-lactone, propylene glycol, glycerin, and lactic acid. General formula (1) (In the formula, X represents a halogen or hydrogen).wherein X represents a halogen or hydrogen.

Owner:POLA PHARMA +1

Water-soluble thick oil viscosity reducer

InactiveCN101906295ALow viscosityReduce dosageDewatering/demulsification with chemical meansDrilling compositionPolyvinyl alcoholActive agent

The invention discloses a water-soluble thick oil viscosity reducer belonging to the technical field of emulsified viscosity reducers of viscous crude oil. The water-soluble thick oil viscosity reducer is prepared from the following components in parts by weight: 0.01-1.0 part of surface active agent, 0.01-1.0 part of dispersant and 0.01-0.6 part of demulsifier, wherein the surface active agent is a nonionic surface active agent selected from OP-10, TX100, Span80 and Tween80, the dispersant is a water-soluble polymer material selected from polyacrylamide, polyvinyl alcohol, guar gum and cellulose, and the demulsifier is a polyoxyethylene-polyoxypropylene segmented copolymer. The invention has good emulsifying and viscosity-reducing effects, the emulsified crude oil can be automatically demulsified to reach a dehydration rate over 95 percent, and the viscosity reducer has little consumption and low cost by adopting low-price materials.

Owner:SICHUAN HAIDUN PETROLEUM NEW TECH DEV

Polyoxaester suspending vehicles for use with implantable delivery systems

ActiveUS7959938B2LimitMaintain stabilityOrganic active ingredientsPowder deliverySUSPENDING VEHICLEActive agent

Liquid polyoxaester polymer materials are provided as suspending vehicles suitable for dispensing of pharmaceutically active agents, such as proteins, from delivery devices, for example, pump-driven dosage forms. Polyoxaesters are made from at least one diacid and at least one diol. Through the use of polyoxaesters virtually solvent-free pharmaceutical suspensions can be created.

Owner:INTARCIA THERAPEUTICS INC

Spin finish

InactiveUS20050142360A1Easy to processLow fumingFibre typesSynthetic resin layered productsHydrogenHydroxy group

The present spin finish composition comprises at least about 10 percent by weight based on the spin finish composition of components (a) and (b) having the formula R1—(CO)x—O—(CH(R2)—CH2—O)y—(CO)z—R3 wherein each of R1 and R3 is selected from the group consisting of hydrogen or an alkyl group having from one to 22 carbon atoms or an alkylene hydroxy group having from one to 22 carbon atoms, x is zero or one, R2 may vary within component (a) or component (b) and is selected from the group consisting of hydrogen or an alkyl group having from one to four carbon atoms, y is zero, or from one to 25, and z is zero or one, in component (a), x and z are equal to zero and the average molecular weight of component (a) is less than or equal to 1,900 and if R2 varies, component (a) is a random copolymer; and in component (b), at least x or z is equal to one or component (b) is a complex polyoxyethylene glyceride-containing compound having greater than 10 polyoxyethylene units; up to about five percent by weight based on the spin finish composition of component (c) of an ethoxylated silicone; and at least about one percent by weight based on the spin finish composition of component (d) having the formula R4(CH2O(CO)aR5)b wherein R4 is —C— or —COC—; a is 0 or 1; R5 is —H; from —CH3 to —C18H37; or —CH(R6)—CH2O; b is 4 or 6; and R6 is —H or —CH3 or —H and —CH3 in a ratio of 10:90 to 90:10. The present spin finish composition may be used on industrial yarn.

Owner:PERFORMANCE FIBERS

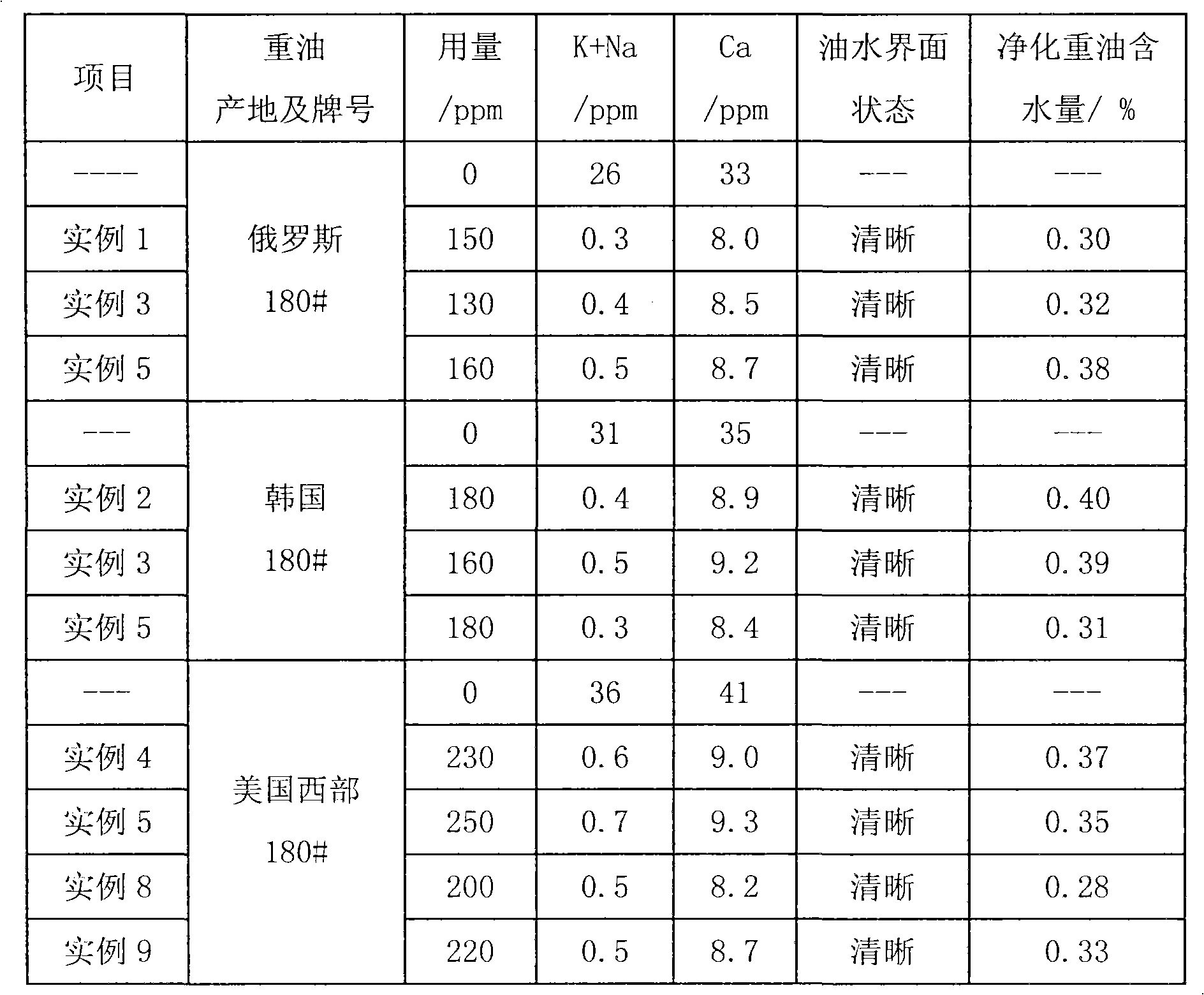

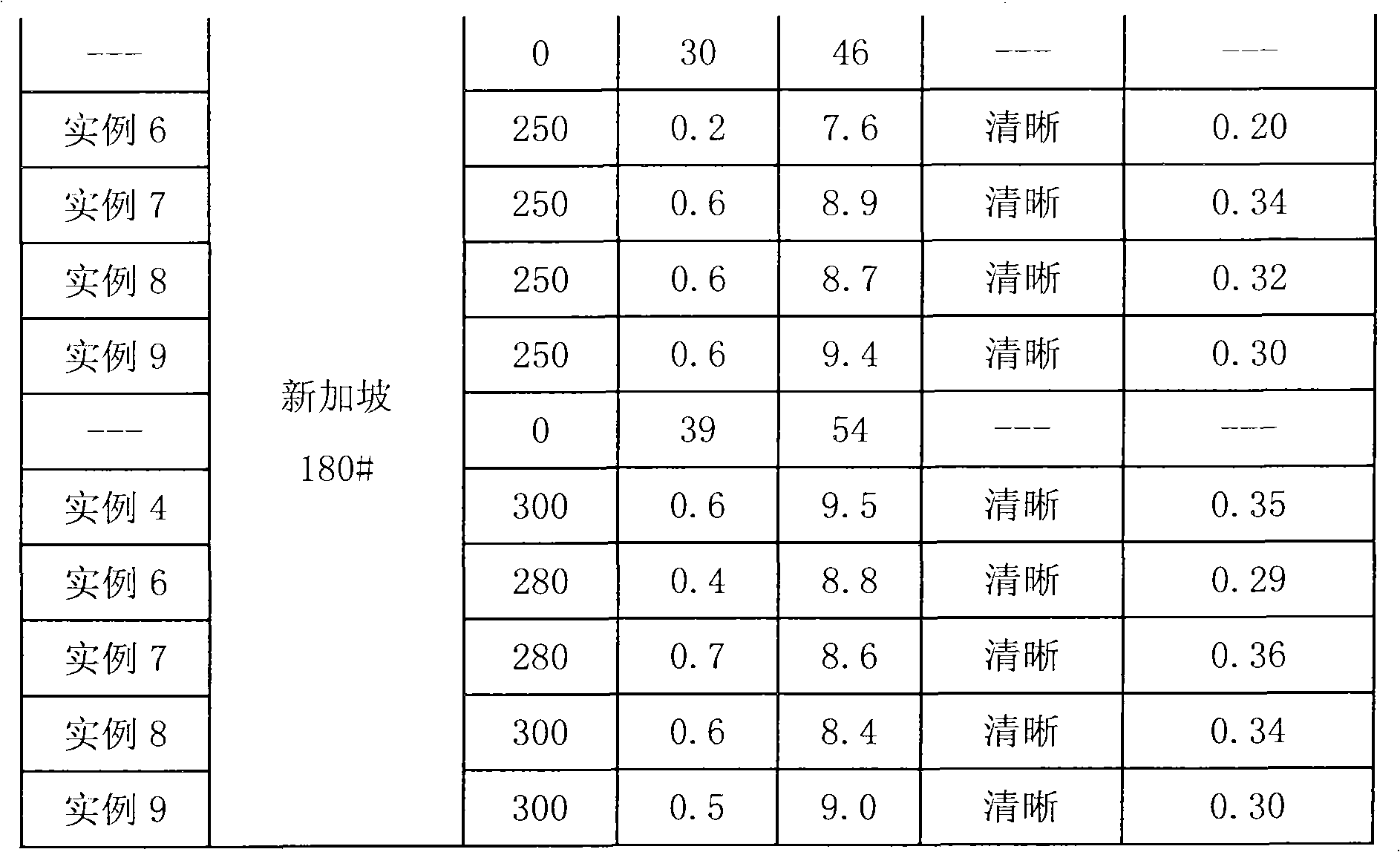

Polyelement composite heavy oil emulsion splitter and preparation method thereof

InactiveCN101831316AReduce dosageGood demulsification effectDewatering/demulsification with chemical meansRefining by water treatmentWater contentSolvent

The invention discloses a polyelement composite heavy oil emulsion splitter and a preparation method thereof. The heavy oil emulsion splitter comprises the following components in percentage by weight: 30-55 percent of polyether, 5-15 percent of surface active agent and 40-60 percent of solvent, wherein the polyether is formed by mixing polyethylene polyamine polyoxyethylene polyoxypropylene ether and fatty alcohol polyoxyethylene polyoxypropylene ether, the surface active agent is polyacrylic acid, and the solvent comprises ethanol and deionized water. The heavy oil emulsion splitter is mainly used for the water scrubbing purification of heavy oil of a gas-turbine power plant and has emulsion splitter dosage of 100-300ppm and good emulsion splitting effect; the K and Na total content of purified heavy oil is less than 1ppm, an oil-water interface is clear, and the water content of the purified heavy oil is less than 0.4 percent and has good broad spectrum activity and lower cost. The polyelement composite heavy oil emulsion splitter can also be used for processing inferior crude oil or crude oil mixed with heavy oil with a larger proportion before catalysis and cracking.

Owner:广州市金汇杰环保科技实业有限公司 +1

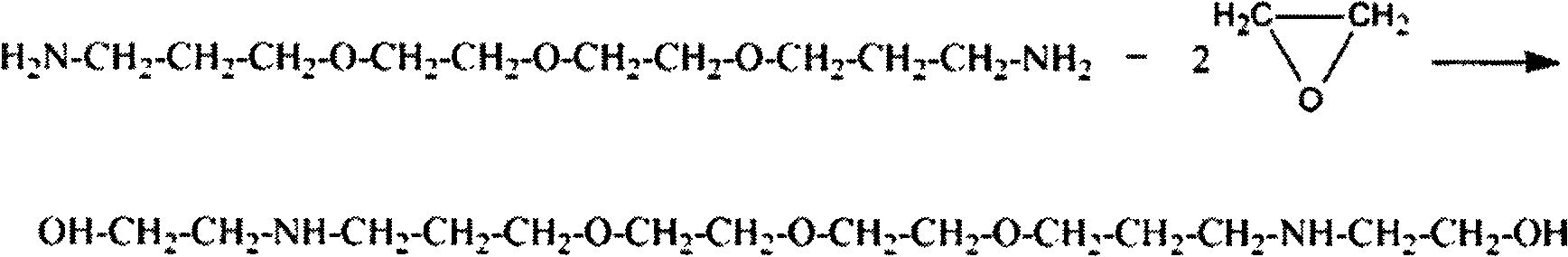

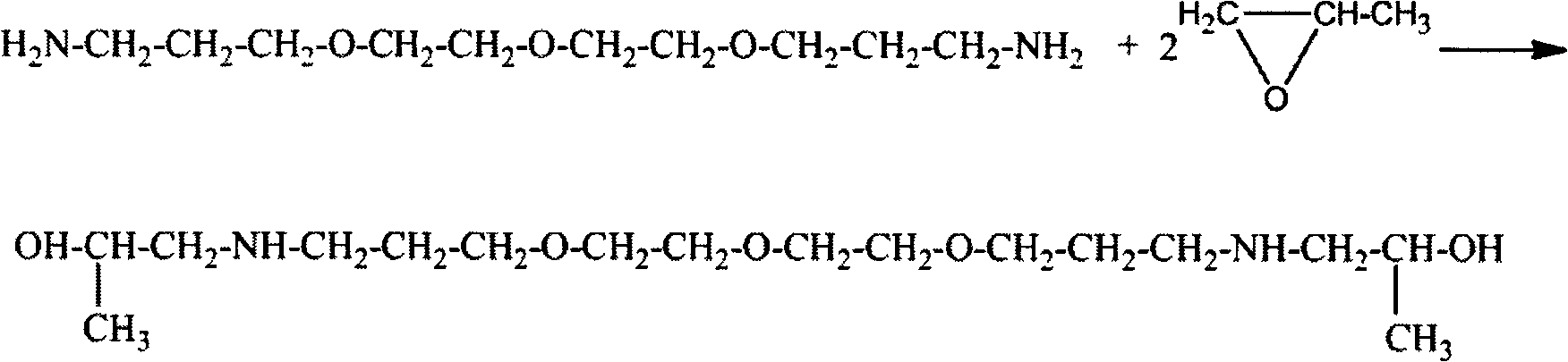

Amine shale stabilizer for drilling fluid

The invention relates to a development for an amine shale stabilizer for a drilling fluid and a preparation method for the same, which is characterized in that the amine shale stabilizer disclosed by the invention is a polymer generated by reacting polyethenoxyamine with epoxide alkane. The polyethenoxyamine is polyoxyethylene diamine or polypropylene diamine or polyoxyethylene propylene diamine, and the molecular weight thereof is less than 1000. The epoxide alkane is one or the mixture composed of two or more of ethylene oxide, propylene epoxide and butylene oxide. During a preparation process, the polyethenoxyamine and the epoxide alkane are poured in a high-temperature and high-pressure reactor according to a molar ratio of 10: 1 to 1: 20, and then reacted at 90-140 DEG C under the function of a catalyst to obtain the amine shale stabilizer for a drilling fluid. The amine shale stabilizer can efficiently prevent shale and clay from being hydrated.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Emulsified asphalt profile control agent

Disclosed is an emulsified asphalt profile control agent. The emulsified asphalt profile control agent is applied to adjustment of injection profiles of water injection wells in the water injection development process of oil fields. The water drive wave and efficiency are improved. The emulsified asphalt profile control agent comprises, by weight, 45-65% of asphalt, 0.3-1.2% of dodecyl diphenyl ether sodium disulfonate, 0.3-1.2% of sodium alcohol ether sulphate, 0.05-0.1% of polyoxyethylene fatty acid, 0.02-0.8% of phenethyl phenyl polyoxypropylated polyoxyethylene ether, 0.3-1.5% of sodium pyrophosphate, 0.02-0.1% of ultra-fine calcium powder, 0.02-0.08% of carboxymethyl cellulose, 0.02-0.08% of anionic polyacrylamide, 0.000004-0.04% of sodium hydroxide and the balance fresh water of which the salinity is less than 1,000mg / L. The emulsified asphalt profile control agent has the advantages that the emulsified asphalt profile control agent can enter deep portions of oil reservoirs effectively, the water plugging rate is more than 90% under the condition that the injection capacity accounts for 1-15% of the reservoir preprocessing radius hole volume, the validity period of the water plugging is more than 2 years and oil flow channels are not damaged.

Owner:PETROCHINA CO LTD

Cleansing composition and cleansing sheet

A cleansing composition according to the present invention comprises (A) an aqueous phase containing 1 to 25% by weight of a water-soluble compound (a), which has a polyoxypropylene structure having 3 or more addition number of propylene oxide but neither an alkyl group having 4 or more carbon atoms nor a polyoxyethylene structure, in the aqueous phase and (B) an oil phase which is liquid at 30° C., wherein the weight ratio (A):(B) of the aqueous phase (A) and the oil phase (B) is 97:3 to 40:60, and water is contained more than 10% by weight in the total composition. Moreover, a cleansing sheet according to the present invention comprises a nonwoven fabric which is made of a fiber having a cellulose content of at least 70% by weight and has a density of about 0.15 to 0.3 g / cm3 impregnated with an oil-in-water emulsion composition comprising (A) an aqueous phase containing 1 to 25% by weight, in the aqueous phase, of a water-soluble compound (a) which has a polyoxypropylene structure having 3 or more addition number of propylene oxide but neither an alkyl group having 4 or more carbon atoms nor a polyoxyethylene structure, (B) an oil phase containing 50% by weight or more of an oil (b) having a boiling point of 160 to 300° C. at 1,013.25 hPa and (C) 0.01 to 1% by weight of an aqueous thickening agent having a hydrophobic part, wherein the weight ratio (A):(B) of the aqueous phase (A) and the oil phase (B) is 97:3 to 40:60.

Owner:KAO CORP

Low-foaming hydrogen peroxide cleaning solution for organic soils

InactiveUS20030078178A1Inorganic/elemental detergent compounding agentsOrganic detergent compounding agentsParticulatesAlkane

A low-foaming cleaning solution and dry particulate formulation which can be diluted with water, deionized water, or mixtures thereof, to form the cleaning solution. The cleaning solution has an alkaline pH, which is preferably from about 8 to about 11.5 and consists essentially of at least one low foaming surfactant in a concentration of from about 0.005% to about 40% w / w of the total solution, at least one active oxygen releasing compound in an amount effective to produce a hydrogen peroxide concentration of from about 0.005% to about 50% w / w of the total solution, at least one builder in a concentration of from about 0.001% to about 50% w / w of the total solution, and at least one diluent selected from the group consisting of water, deionized water, and mixtures thereof. The at least one surfactant is selected from the group consisting of C3-C8 alkane sulfonates, C3-C8 alkyl sulfates, C1-C7 alkyl naphthalene sulfonates, polyoxyethylene / polyoxypropylene block copolymers having a polyoxypropylene molecular weight of from about 1500 to about 8500, of which less than about 30% of the total molecular weight is due to the polyoxyethylene portion, and mixtures thereof. The at least one active oxygen releasing compound is selected from the group consisting of hydrogen peroxide, at least one source of hydrogen peroxide, and mixtures thereof.

Owner:JOHNSONDIVERSEY INC

Polycarboxylate superplasticizer for effectively resisting adverse influence from clay and preparation method of polycarboxylate superplasticizer

A polycarboxylate superplasticizer or effectively resisting adverse influence from clay is obtained by copolymerization of a monomer a, namely alkenyl polyoxyethylene polyoxypropylene amine ether, a monomer b, namely acrylic acid or methacrylic acid and a monomer c, namely acrylamide derivative through free radicals, wherein the mol ratio of the monomer a to the monomer b to the monomer c is (11-17):(65-75):(14-18). The polycarboxylate superplasticizer has the advantages of abundant raw material sources, simple reaction steps, mild conditions and no chloride ions in products. The effective doping amount of the polycarboxylate superplasticizer is 0.2-0.3 percent of the total amount of the cementitious materials and can resist the mud content of aggregate within 8 percent.

Owner:山东建科建筑材料有限公司

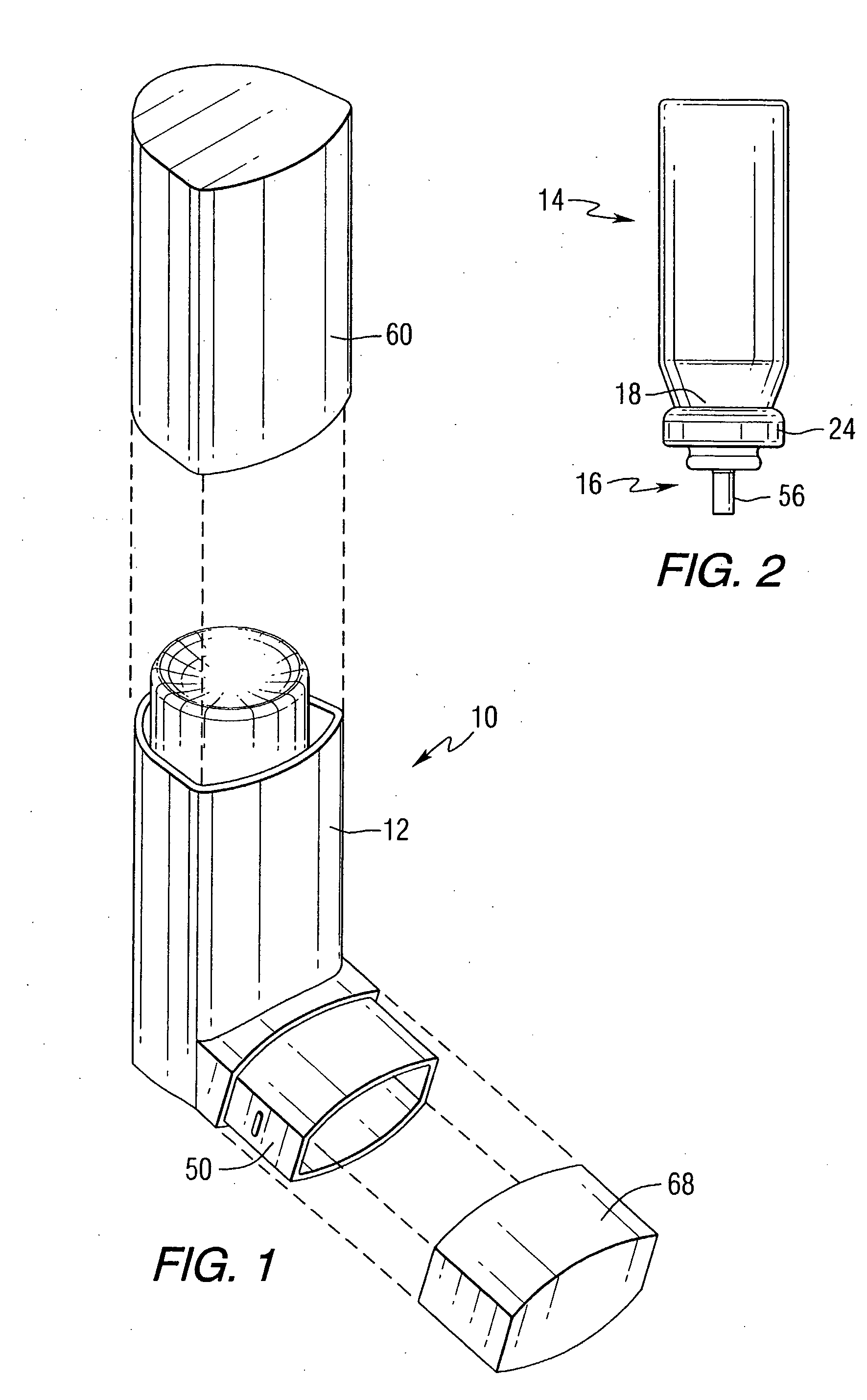

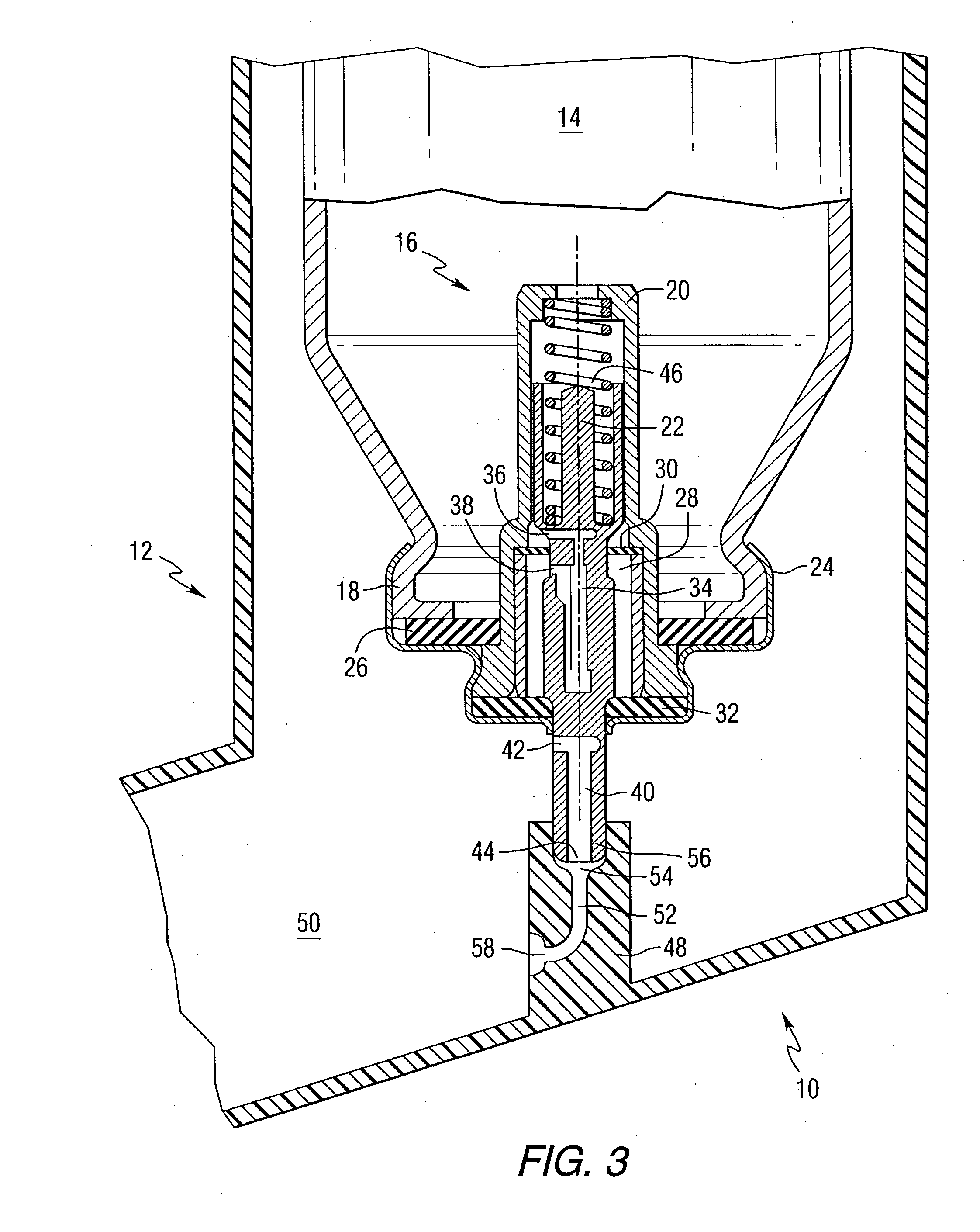

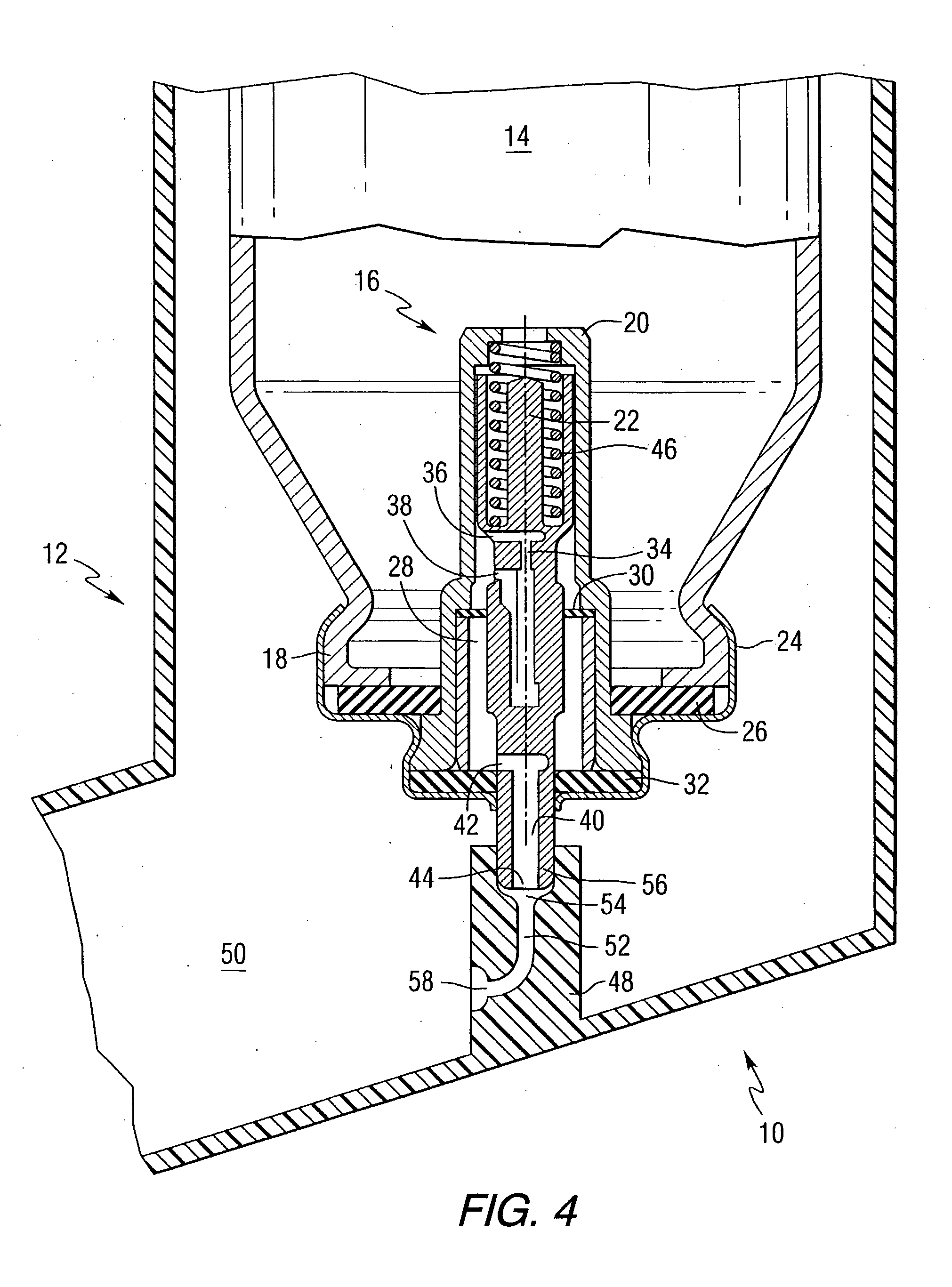

Orally Absorbed Pharmaceutical Formulation and Method of Administration

InactiveUS20090214657A1The process is simple and convenientIncrease glucose levelsPowder deliveryPeptide/protein ingredientsSolventSplit dose

A pharmaceutical formulation for absorption through oral mucosae comprising an effective amount of (a) a pharmaceutical agent in mixed micellar form, (b) at least one micelle-forming compound selected from the group comprising an alkali metal alkyl sulfate and a polyoxyethylene sorbitan monooleate, (c) a block copolymer of polyoxyethylene and polyoxypropylene, (d) at least one additional micelle-forming compound, and (e) a suitable solvent. The invention also provides a metered dose dispenser (aerosol or non-aerosol) containing the present formulation and a method of administering insulin using the metered dose dispenser comprising administering split doses of a formulation containing insulin before and after each meal.

Owner:GENEREX PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com