Phosphorous acid concrete super plasticizer with polyethyleneimine structure as well as preparation method and application thereof

A technology of polyethyleneimine and superplasticizer, which is applied in the field of concrete admixtures, can solve the problems of prolonged setting delay, setting delay, and high cost of water-reducing agent preparation, and achieve improved fluidity, good working performance, and simple preparation method effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

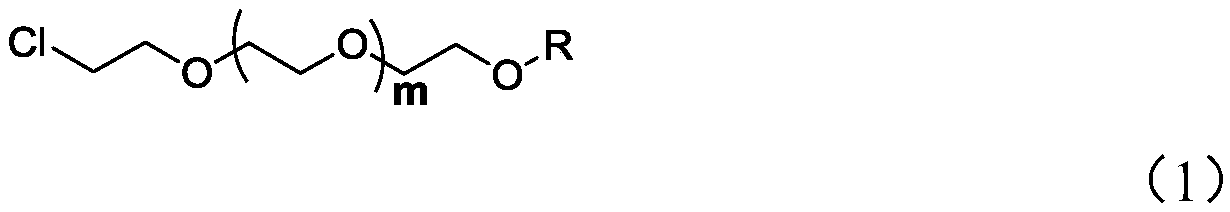

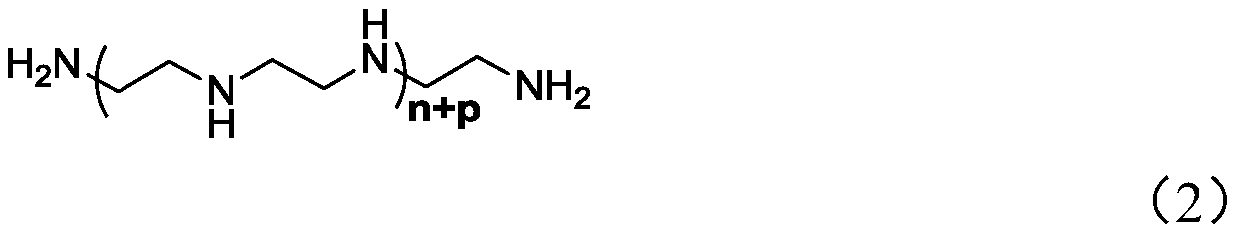

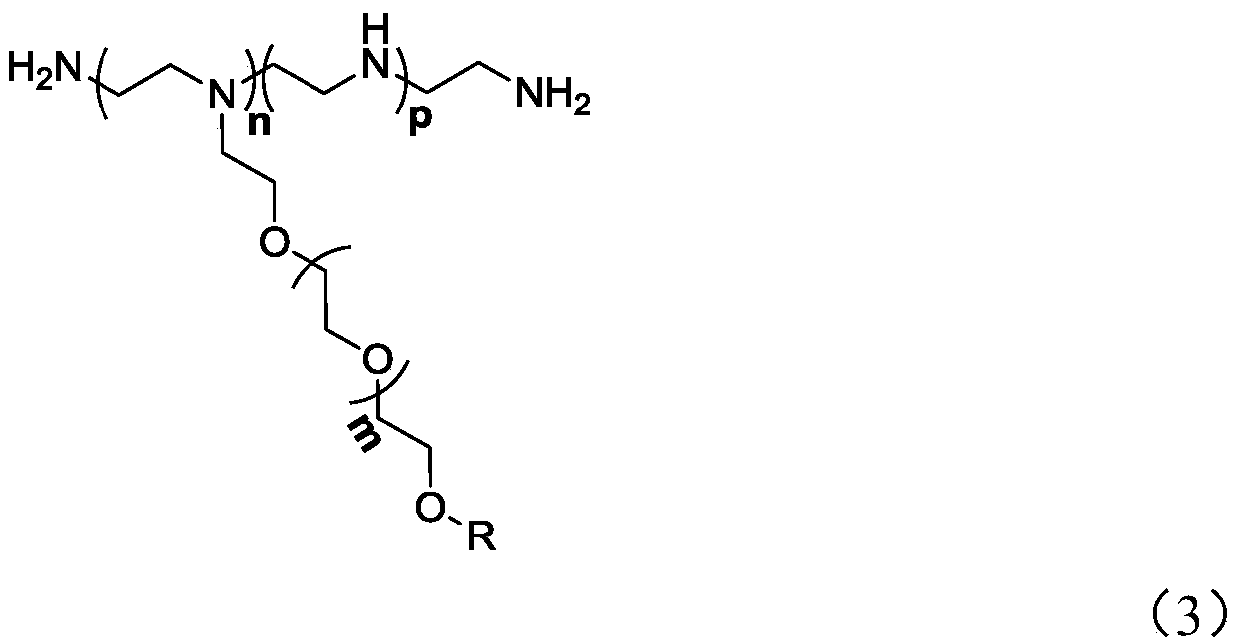

[0049] In a glass reactor equipped with a thermometer and a stirrer, add 105 g of deionized water, and simultaneously add 60 g of MPEG-Cl-1000 (molecular weight 1000, 0.06 mol, m=24) and 10 g of PEI (molecular weight 1000, 0.01 mol, n+p= 24), the molar ratio of chlorinated polyether to imino H is 1:4, the temperature is raised to 30°C while stirring to dissolve, and the temperature is continued to rise to 100°C for 8 hours to obtain a 40% PEI-EO aqueous solution. Then 16 mL of HCl (mass concentration: 37%, 0.19 mol, 18.74 g) was added and stirred evenly. Then add H 3 PO 3 (0.19mol, 15.58g) and aqueous formaldehyde (mass concentration is 37%, 0.19mol, 15.42g) (polyethyleneimine, H 3 PO 3 , HCHO, HCl molar ratio is 1:19:19:19). Stir well. And react at 100° C. for 12 hours. A red transparent solution with a mass concentration of 43.7% was obtained, the polymer molecular weight was 8900, and the acid-ether ratio was 19:6.

Embodiment 2

[0051] In the glass reactor equipped with thermometer and stirrer, add 350g deionized water, add 150g MPEG-Cl-5000 (molecular weight 5000, 0.03mol, m=114) and 10gPEI (molecular weight 1000, 0.01mol, n+p= 24), the molar ratio of chlorinated polyether to imino H is 1:8, the temperature is raised to 60°C while stirring to dissolve, and the temperature is continued to rise to 140°C for 7 hours to obtain a 31.3% PEI-EO aqueous solution. Then 17.5 mL of HCl (mass concentration: 37%, 0.21 mol, 20.71 g) was added and stirred evenly. Then add H 3 PO 3 (0.21mol, 17.22g) and formaldehyde aqueous solution (mass concentration is 37%, 0.21mol, 17.04g) (polyethyleneimine, H 3 PO 3 , HCHO, HCl molar ratio is 1:21:21:21). Stir well. And react at 120° C. for 24 hours. A red transparent solution with a mass concentration of 33.83% was obtained, the molecular weight of the polymer was 19000, and the acid-ether ratio was 21:3.

Embodiment 3

[0053] In the glass reactor equipped with thermometer and stirrer, add 140g deionized water, add 192g MPEG-Cl-2400 (molecular weight 2400, 0.08mol, m=55) and 10gPEI (molecular weight 1000, 0.01mol, n+p= 24), the molar ratio of chlorinated polyether to imino H is 1:3, the temperature is raised to 40°C while stirring to dissolve, and the temperature is continued to rise to 130°C for 6 hours to obtain a 59.1% PEI-EO aqueous solution. Then 15 mL of HCl (mass concentration: 37%, 0.18 mol, 17.75 g) was added and stirred evenly. Then add H 3 PO 3 (0.18mol, 14.76g) and formaldehyde aqueous solution (mass concentration is 37%, 0.18mol, 14.6g) (polyethyleneimine, H 3 PO 3 , HCHO, HCl molar ratio is 1:18:18:18). Stir well. And react at 110° C. for 14 hours. A reddish-brown transparent solution with a mass concentration of 58.78% was obtained, the molecular weight of the polymer was 22000, and the acid-ether ratio was 9:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com