Amine shale stabilizer for drilling fluid

A technology of shale stabilizer and drilling fluid, which can be used in drilling compositions, chemical instruments and methods, etc., and can solve problems such as lack of systematic and in-depth research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

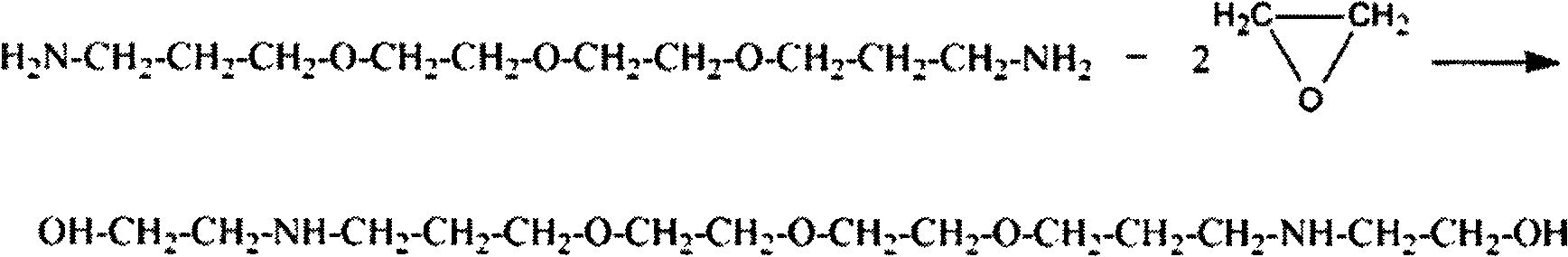

example 1

[0009] Add 330 g of diethylene glycol bis(3-aminopropyl) ether and 0.33 g of potassium hydroxide into a high-temperature and high-pressure reactor with a volume of 1 L, vacuumize the reactor and start heating, and start stirring at the same time, and the stirring speed is 300 r / min . When the temperature rose to 90°C, 26.4 g of ethylene oxide was introduced. Continue to raise the temperature, and when the temperature rises to 115° C., 105.6 g of ethylene oxide is introduced. After the reaction starts, maintain the reaction temperature at 120°C. After the pressure in the reactor drops and remains constant, continue to maintain the temperature for 30 minutes, then cool to room temperature, and discharge the material from the kettle to obtain a colorless or slightly yellow liquid, which can be directly added to the drilling fluid. as a shale inhibitor. The preparation reaction formula is as follows:

[0010]

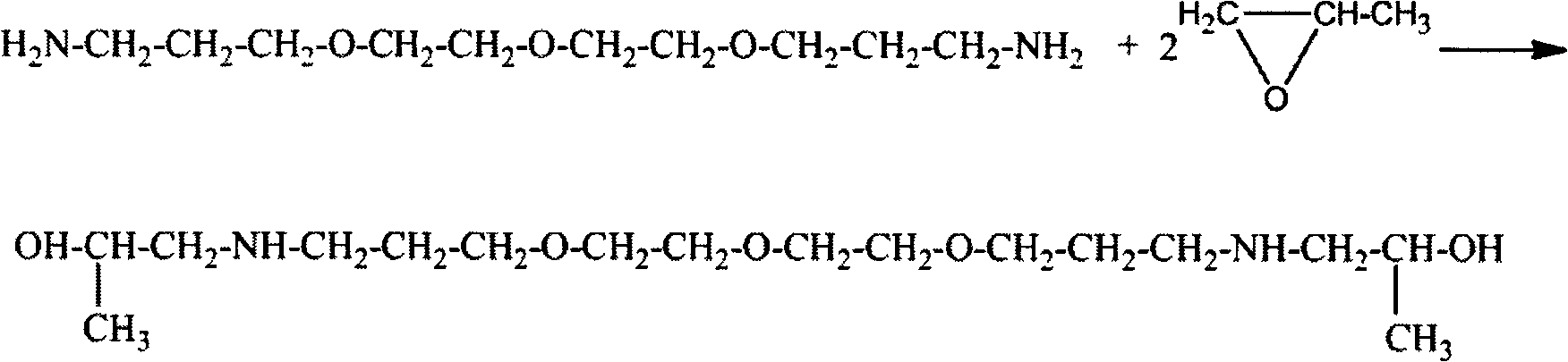

example 2

[0012] Add 330 g of diethylene glycol bis(3-aminopropyl) ether and 0.33 g of potassium hydroxide into a high-temperature and high-pressure reactor with a volume of 1 L, vacuumize the reactor and start heating, and start stirring at the same time, and the stirring speed is 300 r / min . When the temperature rose to 90°C, 26.4 g of ethylene oxide was introduced. Continue to raise the temperature, and when the temperature rises to 115° C., 105.6 g of ethylene oxide is introduced. After the reaction starts, keep the reaction temperature at 120°C. After the pressure in the reactor drops and remains unchanged, continue to maintain the temperature for 30 minutes, then cool to room temperature, and discharge the material from the kettle to obtain a colorless or slightly yellow viscous liquid, which can be directly added Used as shale inhibitor in drilling fluid. The preparation reaction formula is as follows:

[0013]

example 3

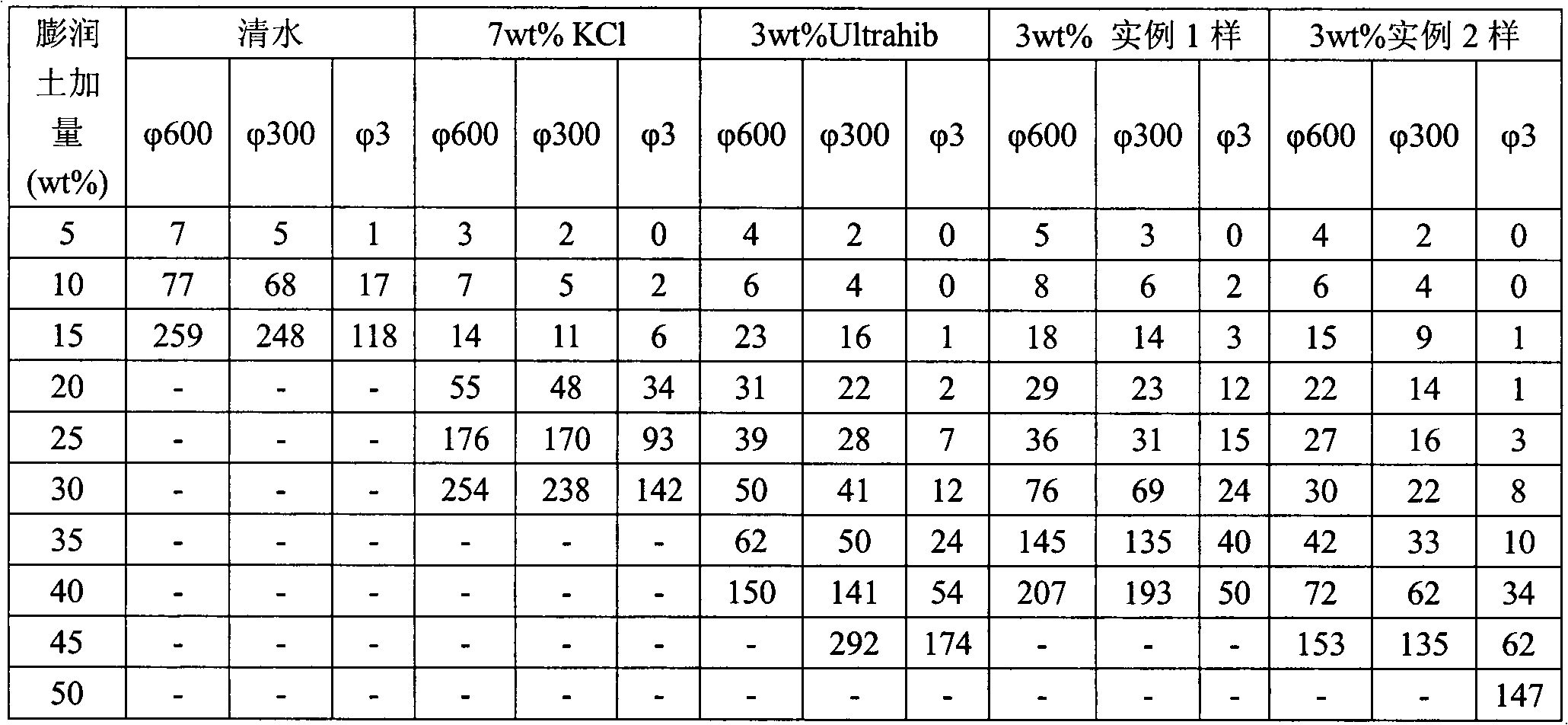

[0014] Example 3: Inhibitory Evaluation

[0015] In order to evaluate the inhibitory performance of the synthesized amine compound as a shale inhibitor, the performance of the synthesized amine shale stabilizer was compared with the traditional inorganic salt inhibitor KCl and the foreign shale inhibitor Ultrahib. Experimental evaluation was carried out by inhibiting bentonite slurrying test, buckling hardness test and shale rolling dispersion test respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com