Patents

Literature

45results about How to "Affect transparency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Barrier material comprising a thermoplastic and a compatible cyclodextrin derivative

InactiveUS6218013B1Easy to derivatizeImprove surface propertiesSemi-permeable membranesFlexible coversThermoplasticMoisture

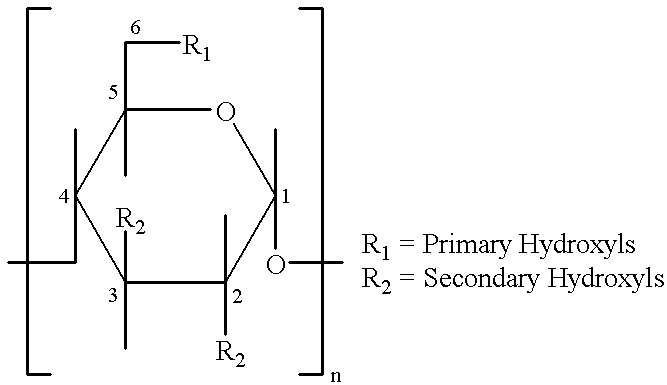

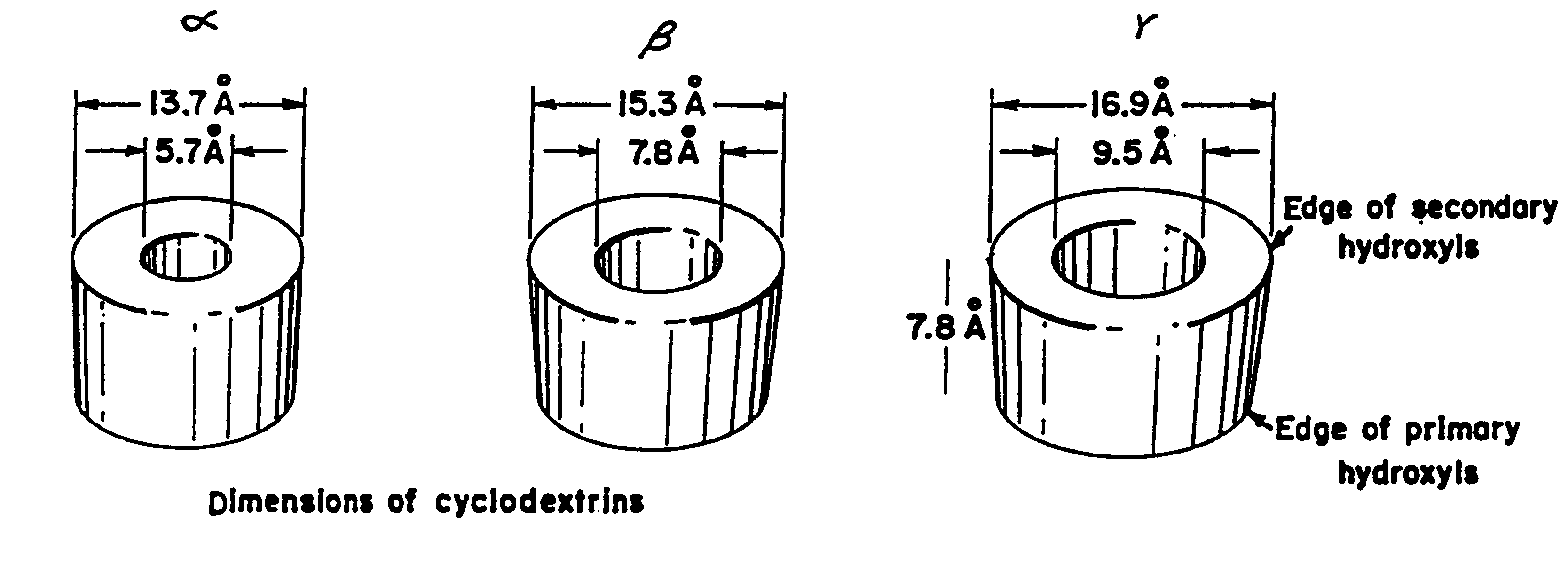

A barrier film composition can comprise a thermoplastic web comprising a thermoplastic polymer and a dispersed cyclodextrin composition having substituents that compatibilize the cyclodextrin in the film. The thermoplastic / cyclodextrin film obtains substantial barrier properties from the interaction between the substituted cyclodextrin in the film material with a permeant. The substituents on the cyclodextrin molecule causes the cyclodextrin to be dispersible and stable in the film material resulting in an extrudable thermoplastic. Such materials can be used as a single layer film material, a multilayer film material which can be coated or uncoated and can be used in structural materials wherein the thermoplastic is of substantial thickness resulting in structural stiffness. The cooperation between the cyclodextrin and the thermoplastic polymer provides barrier properties to a web wherein a permeant can be complexed or entrapped by the cyclodextrin compound and held within the film preventing the permeant from passing through the film into the interior of a film, an enclosure or container. The permeant can comprise a variety of well known materials such as moisture, aliphatic or aromatic hydrocarbons, monomer materials, off flavors, toxic compounds etc.

Owner:CELLRESIN TECH

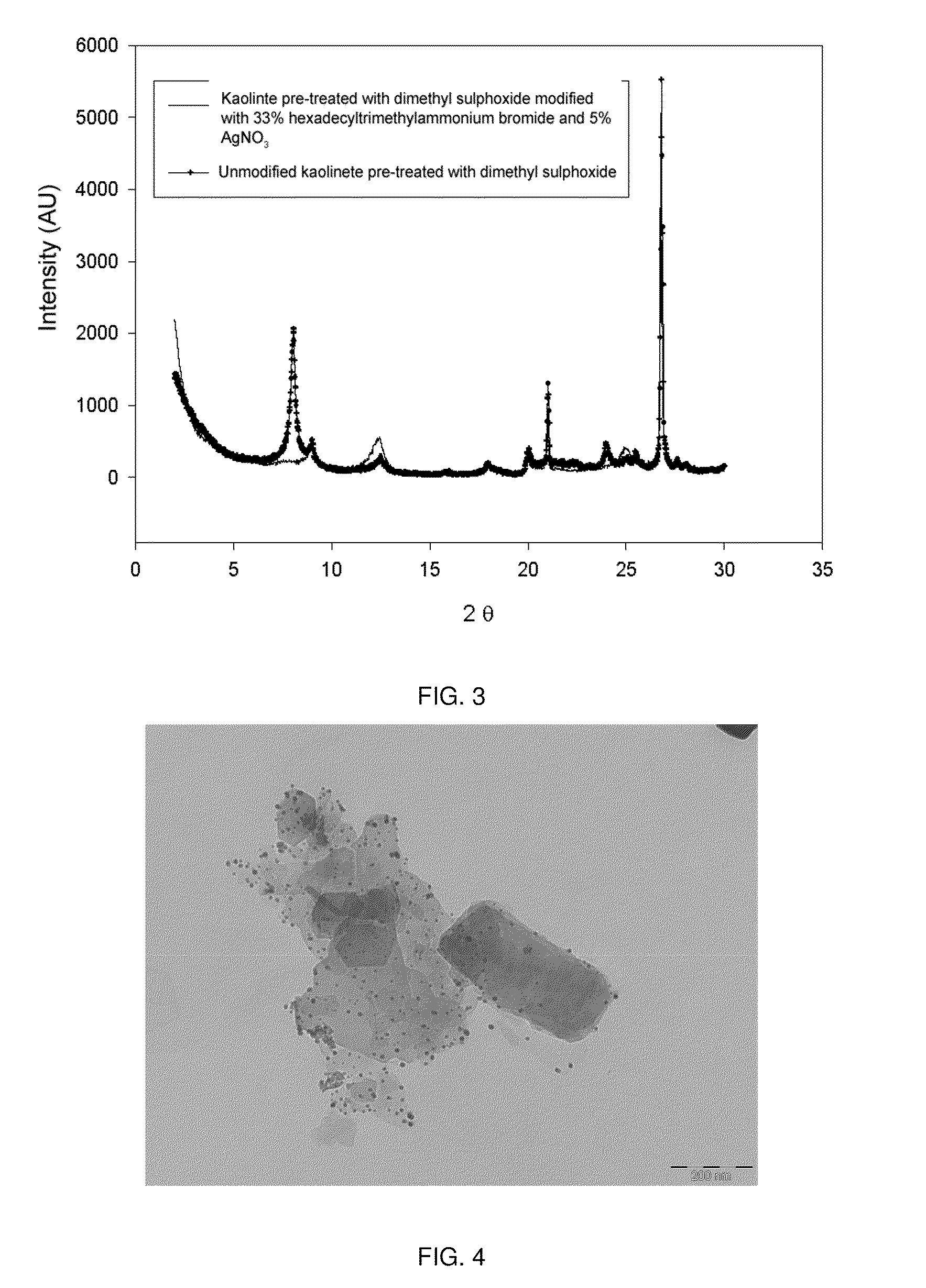

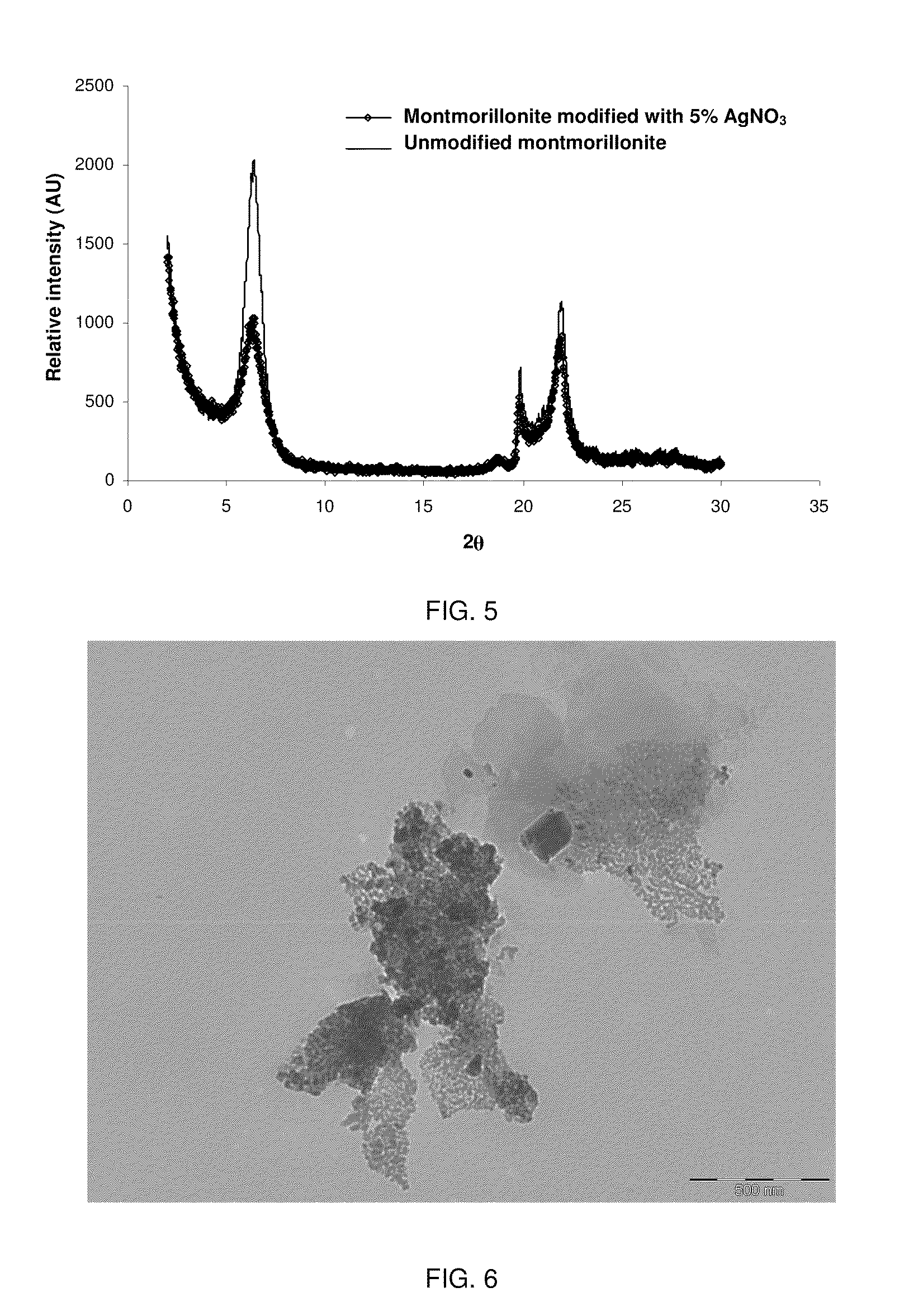

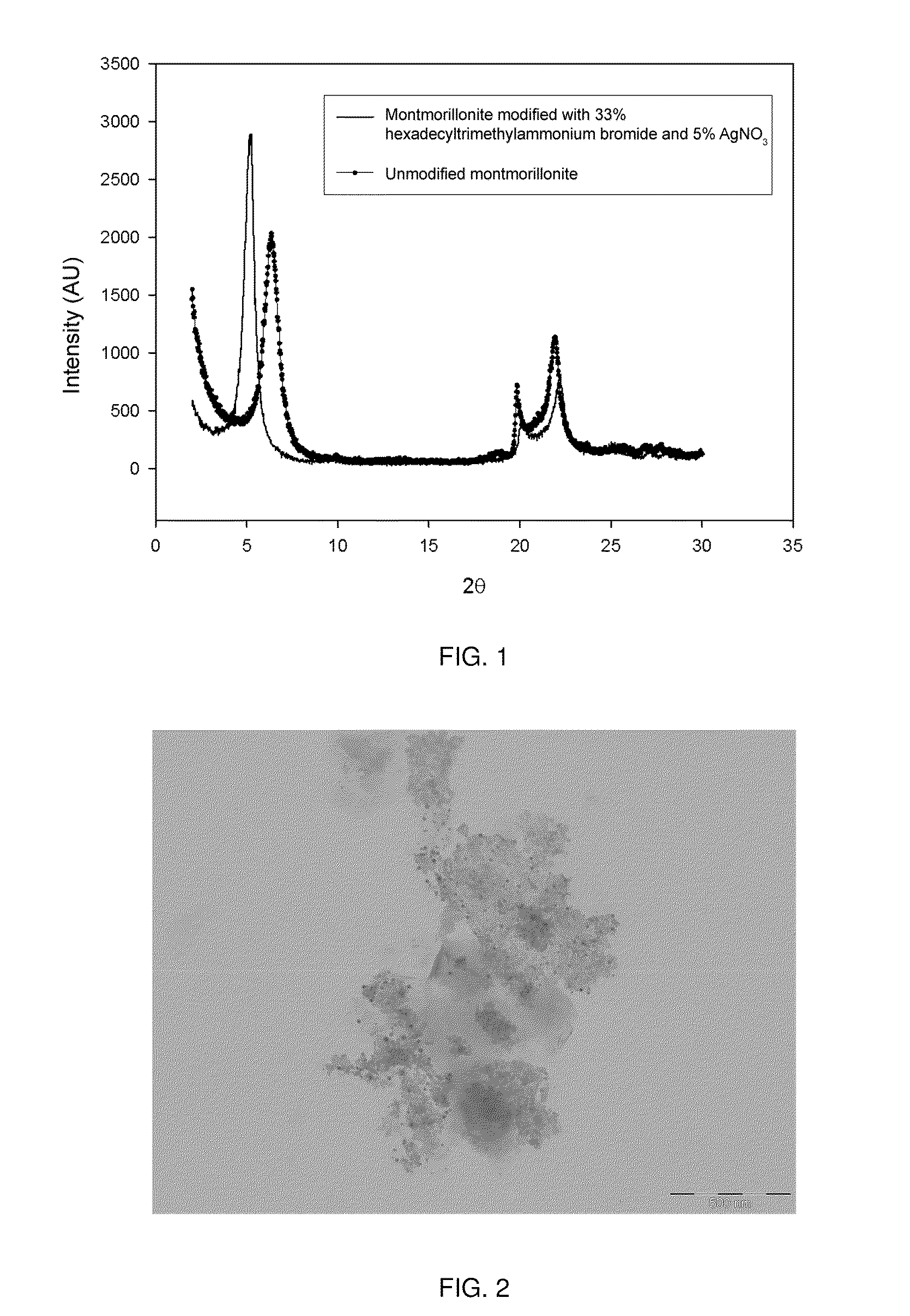

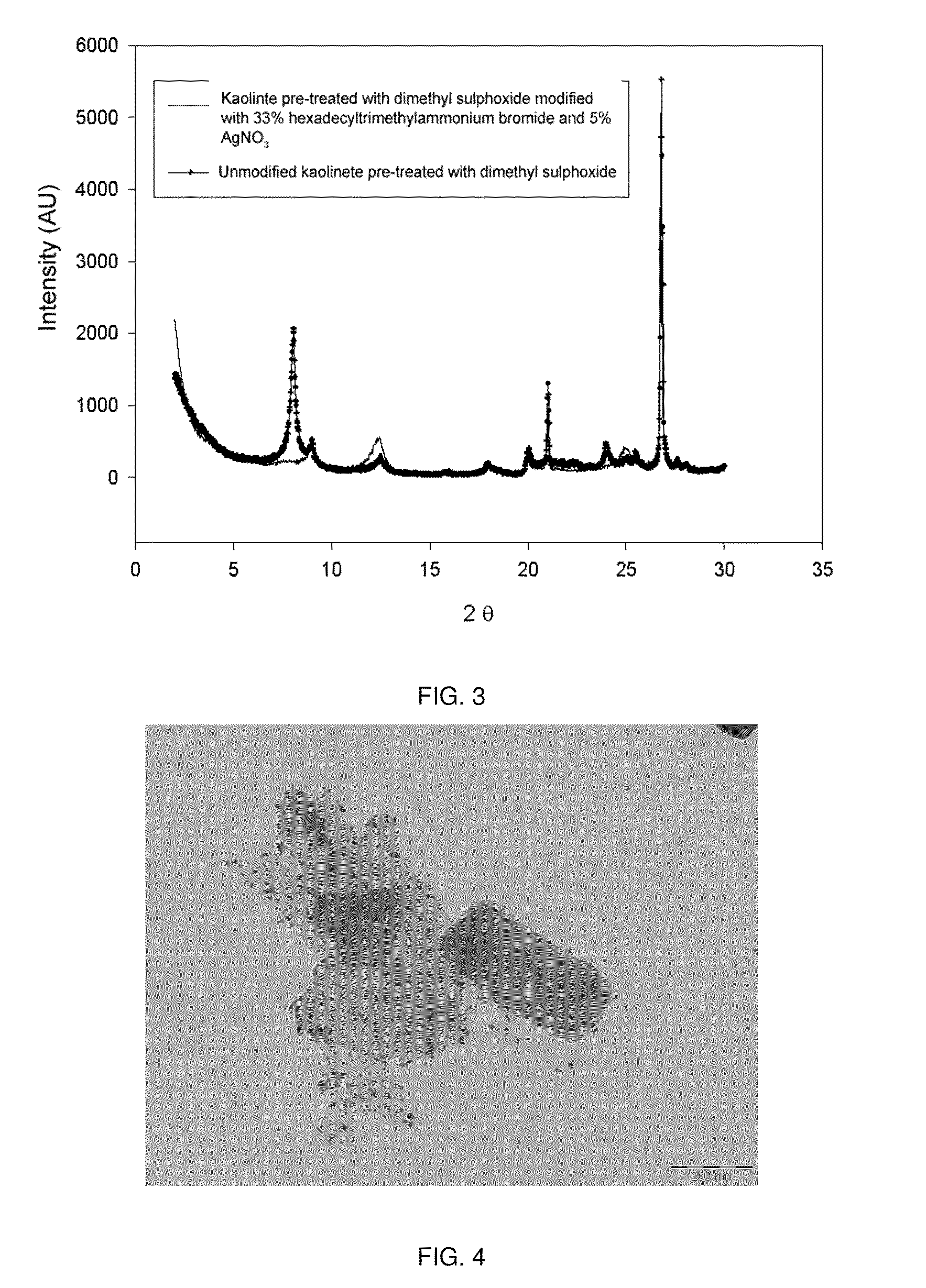

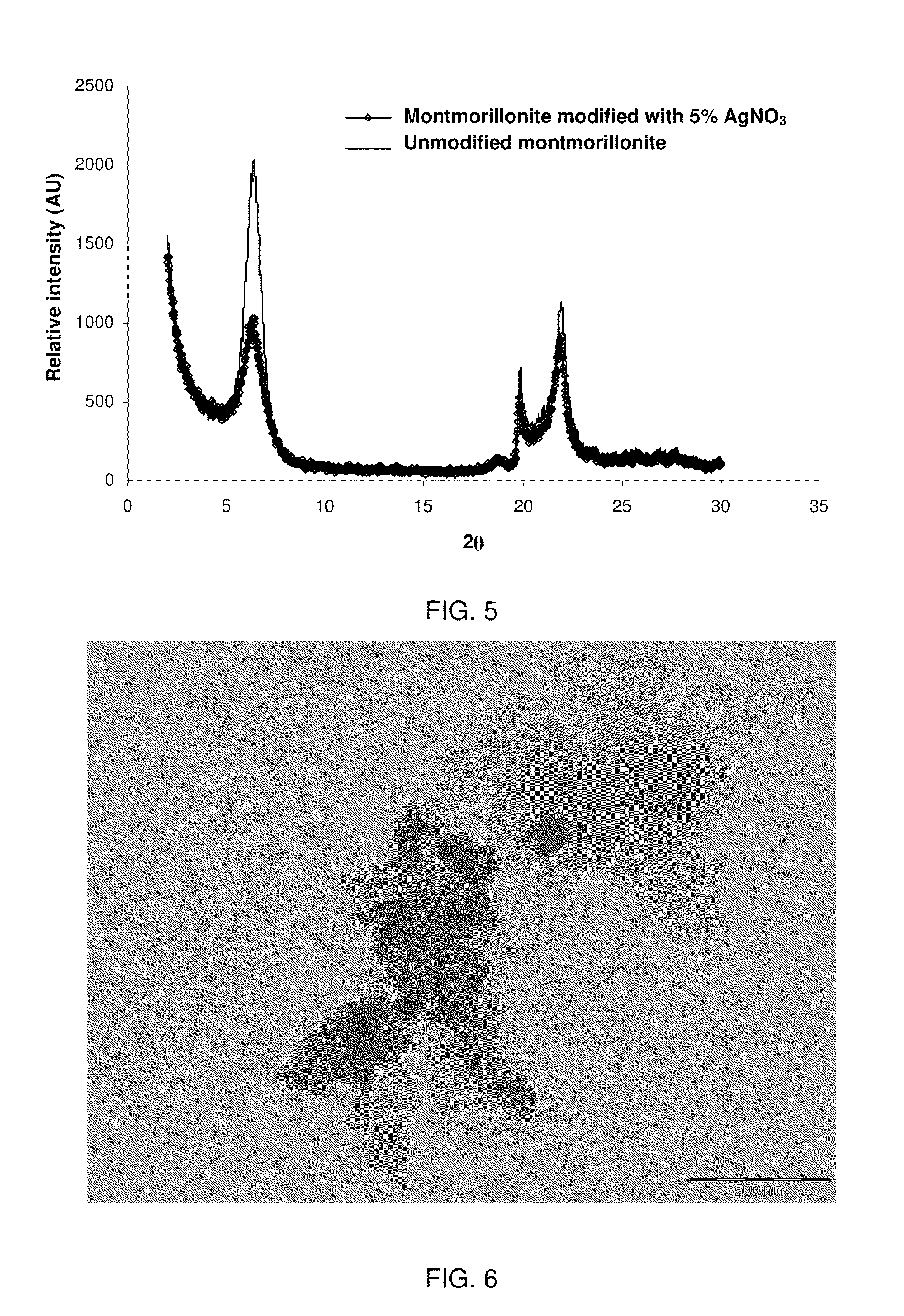

Active nanocomposite materials and production method thereof

ActiveUS20110142899A1Easy to oxidizeImprove efficiencyPigmenting treatmentMaterial nanotechnologyMaterials scienceIndustry sector

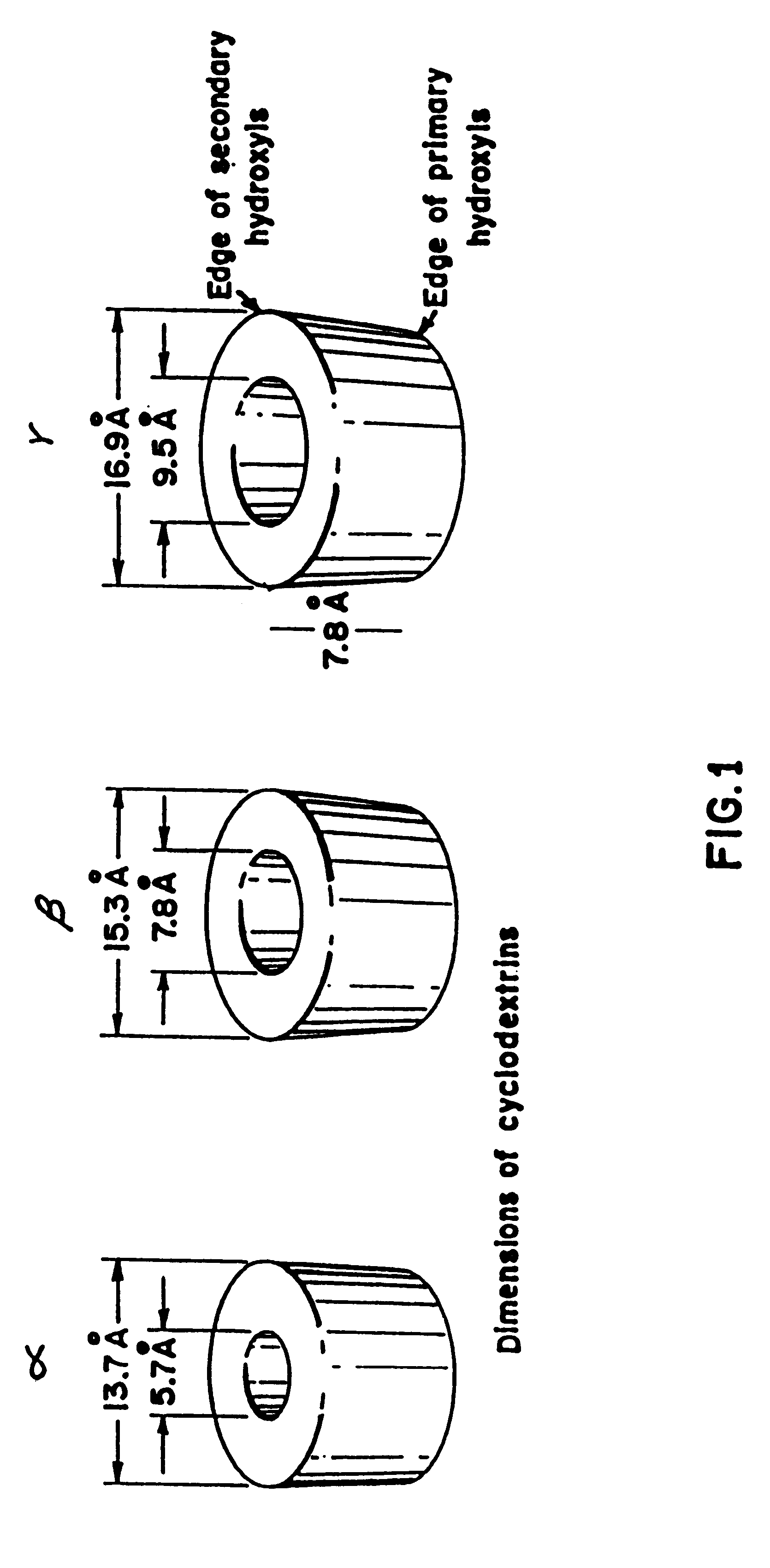

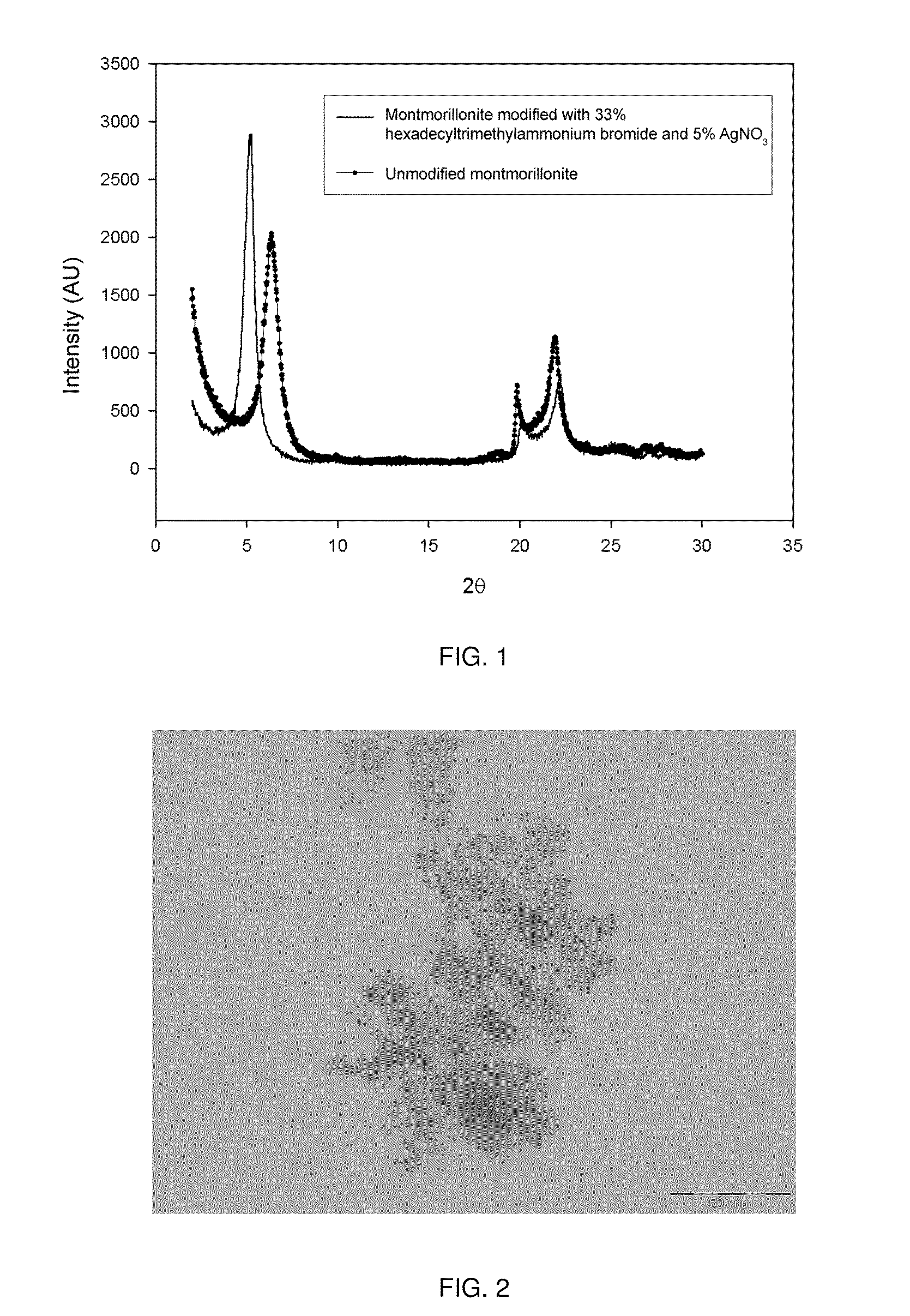

SUMMARY The present invention refers to new active nanocomposite materials, comprising a matrix and additives. The present invention also describes a process for obtaining these nanocomposite materials and their use in various industry sectors.

Owner:LAB ARGENOL

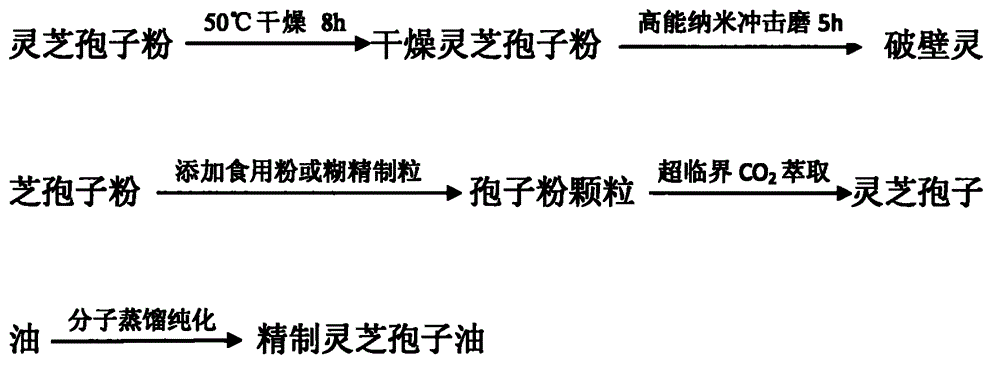

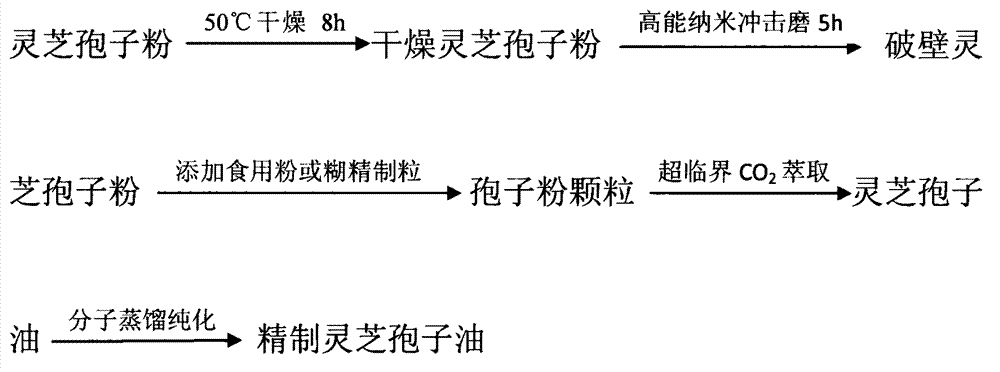

High-bioactivity ganoderma spore oil and supercritical preparation method thereof

ActiveCN102973616AReduce lossesOptimize the breaking processMetabolism disorderImmunological disordersSporeDistillation

The invention aims to disclose high-bioactivity ganoderma spore oil and a preparation method thereof, and belongs to the field of Chinese medicament. The method comprises the following steps: breaking walls of ganoderma spore powder by adopting a high-energy nano impact mill, performing dry granulation, supercritical CO2 extraction, molecular distillation and purification, and thus obtaining the ganoderma spore oil. The operation process of the method is carried out in an anhydrous environment, so that oxidation of the spore oil in the processing process is reduced, and the obtained product is stable in property; the freezing transparent test time of the ganoderma spore oil prepared by the method exceeds 5.5 hours; and the measured unsaturated fatty acid content is between 60 and 80 percent, the total triterpenoid content is 2 to 3 percent, the total ergosterol content is 2 to 5 mg / g, the ganoderic acid A content is more than 1 mg / g, the peroxide value is less than 5mmol / kg, and the acid value is less than 10 mg KOH / g.

Owner:厦门爱逸零食研究所有限公司

High heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate and preparation method thereof

InactiveCN102558791AEasy to manufactureSimple processPolytetramethylene terephthalatePolyethylene terephthalate

The invention relates to a high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic and a preparation method thereof, which solves the problem that no high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic exists at present. The high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic and the preparation method thereof are characterized in that the engineering plastic includes, by weight, 100 parts of the polybutylene terephthalate, 0.1-1.5 parts of main antioxygen, 0.1-1.5 parts of auxiliary antioxygen, 0.3-1.5 parts of a lubricant, 1-9 parts of flexibilizer, 0.2-1.5 parts of a nucleating agent, 0.2-1.5 parts of a crystallization accelerating agent and 0.5-3 parts of padding. The high heat resistance, high gloss, low volatility and rapid prototyping polybutylene terephthalate engineering plastic and the preparation method thereof have the advantages of simple formula, easiness in preparation and performances of high heat resistance, high gloss, low volatility and rapid prototyping.

Owner:新宏隆特种材料科技(苏州)有限公司

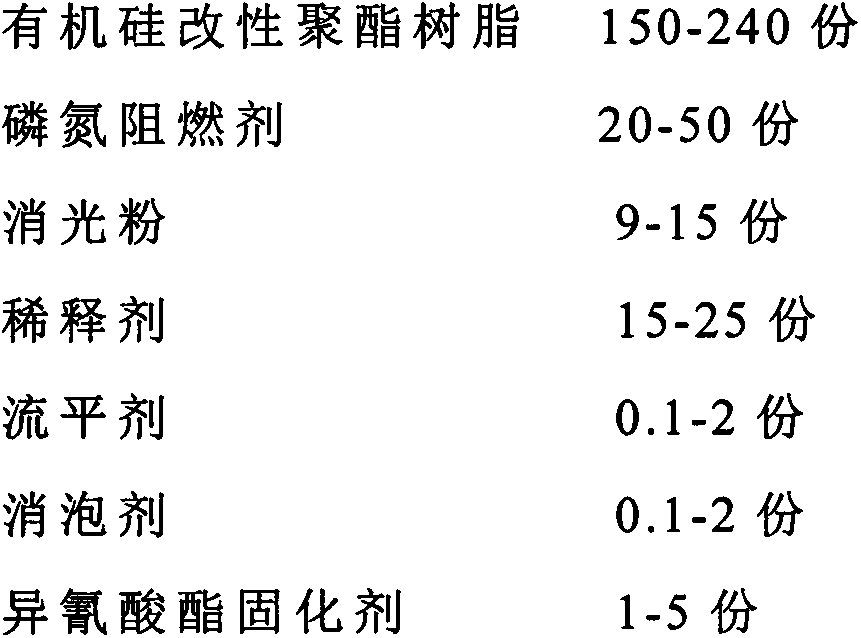

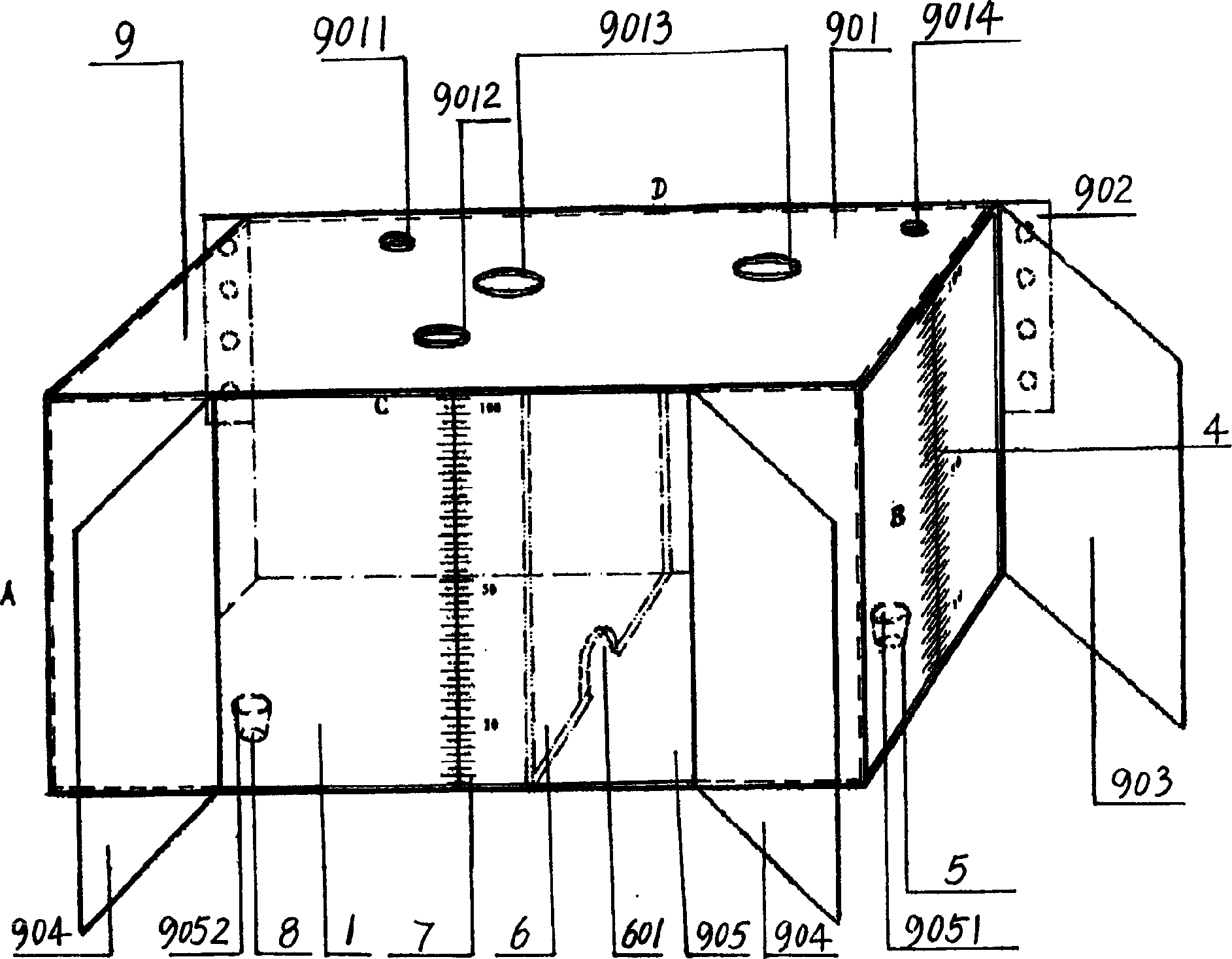

Thermoset high-flame-retardant lusterless ink used for PET substrate

The invention discloses a thermoset high-flame-retardant lusterless ink used for a PET substrate. The ink is prepared by mixing a phosphorus-nitrogen containing flame retardant, a silicone-modified polyester resin, and delustering powder with a part of diluent, performing high-speed dispersion for 20-50 min; adding a leveling agent and an antifoaming agent, and performing low-speed dispersion for 5-15 min to obtain a main agent; adding an isocyanate curing agent and the left diluent into the main agent; and performing uniform stirring to obtain the thermoset high-flame-retardant lusterless ink. The ink is good in mechanical properties, flame retardance, heat resistance and solvent resistance, is good in adhesion to the substrate and small in environmental pollution and doesn't affect the appearance of the PET substrate. The ink is reasonable in composition, good in component coordination and excellent in overall performance.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

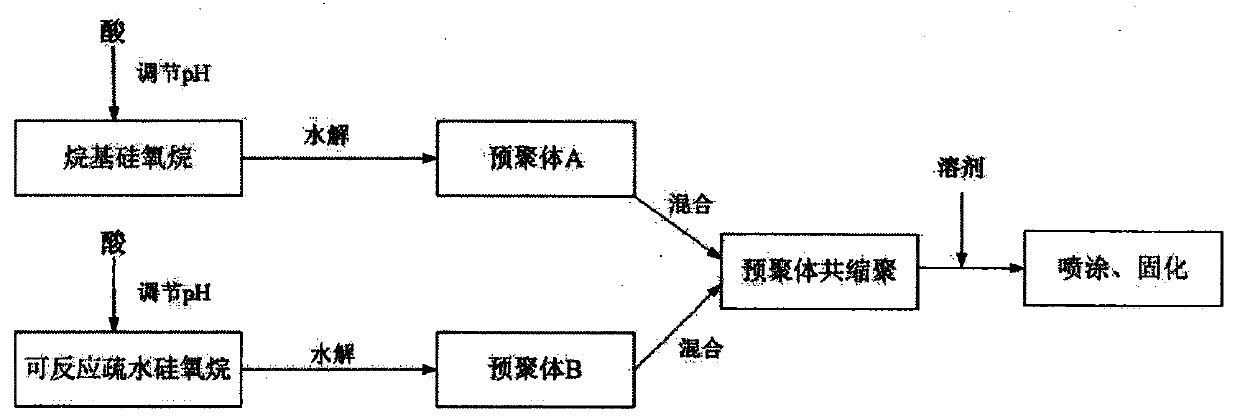

Far infrared emission high-temperature-resistant kitchen and bath paint and preparation method thereof

InactiveCN104212341AAccelerate the copolymerization processEffective dispersionCoatingsSilicic acidSolvent

The invention provides far infrared emission high-temperature-resistant kitchen and bath paint. The far infrared emission high-temperature-resistant kitchen and bath paint is characterized in that the raw materials comprise the following components: 15-30wt% of a component A, 20-30wt% of a component B, 0.5-1wt% of a flatting agent and the balance of a solvent, wherein the flatting agent and the solvent constitute a component C; the component A comprises methyl trialkoxy silane, tetraethyl orthosilicate and water; a molar ratio of the methyl trialkoxy silane to the tetraethyl orthosilicate is (1:1.5)-(1:0.25); the component B comprises reactive hydrophobic siloxane, silicon carbide nanoparticle and water, wherein the average particle size of the silicon carbide nanoparticle is 20-50nm. The coating has a heat-resistance temperature over 350 DEG C, can be used at a high temperature of 250 DEG C for a long time, has a static contact angle with the water of over 105 degrees, far infrared emissivity over 88% and good hydrophobic durability, is capable of satisfying common surface hydrophobic treatment requirements and capable of being applied to the fields such as kitchen and bath, buildings and industry.

Owner:DONGHUA UNIV

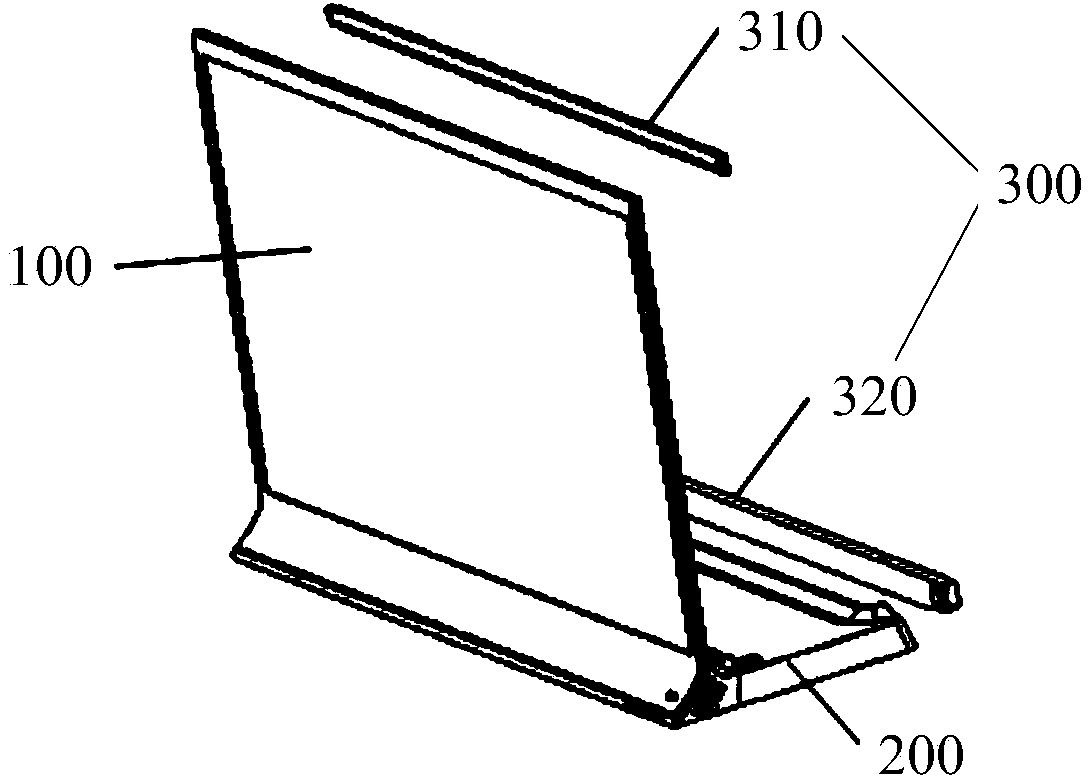

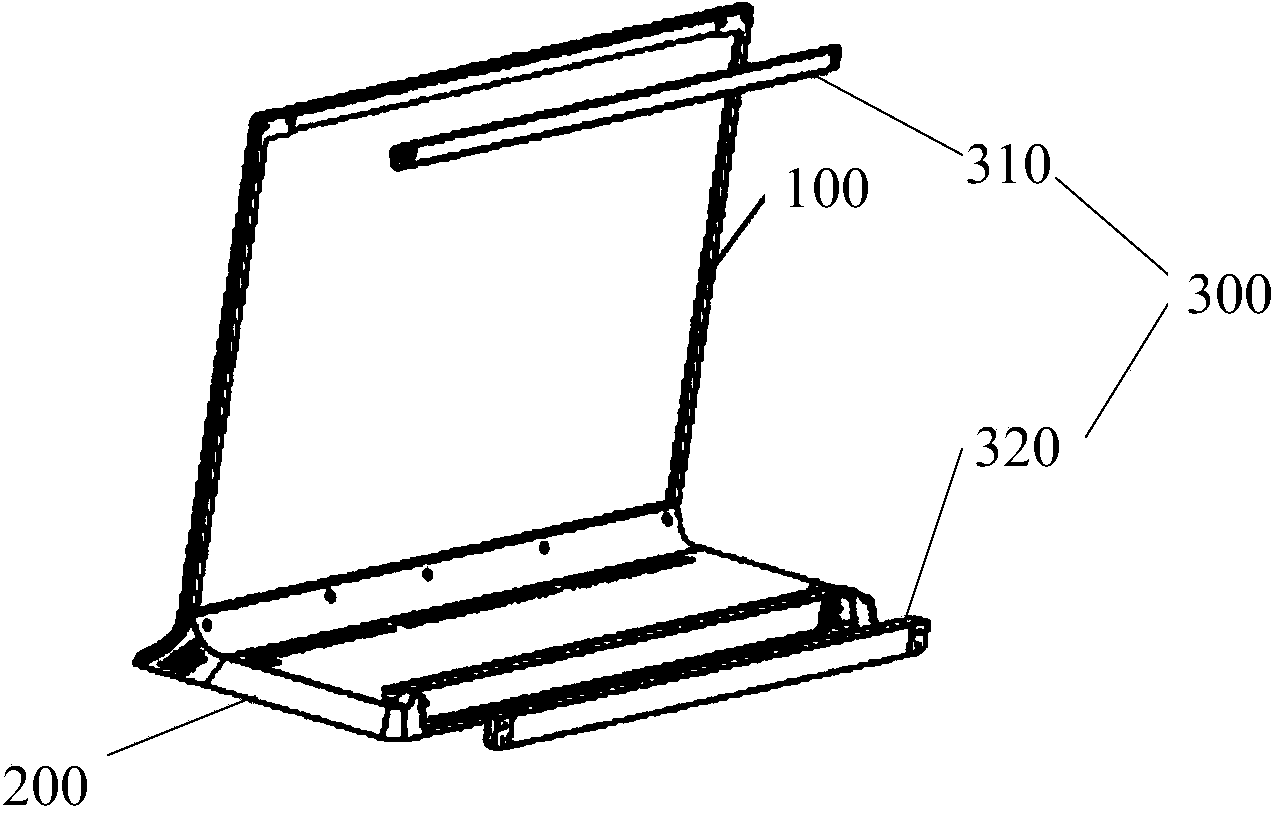

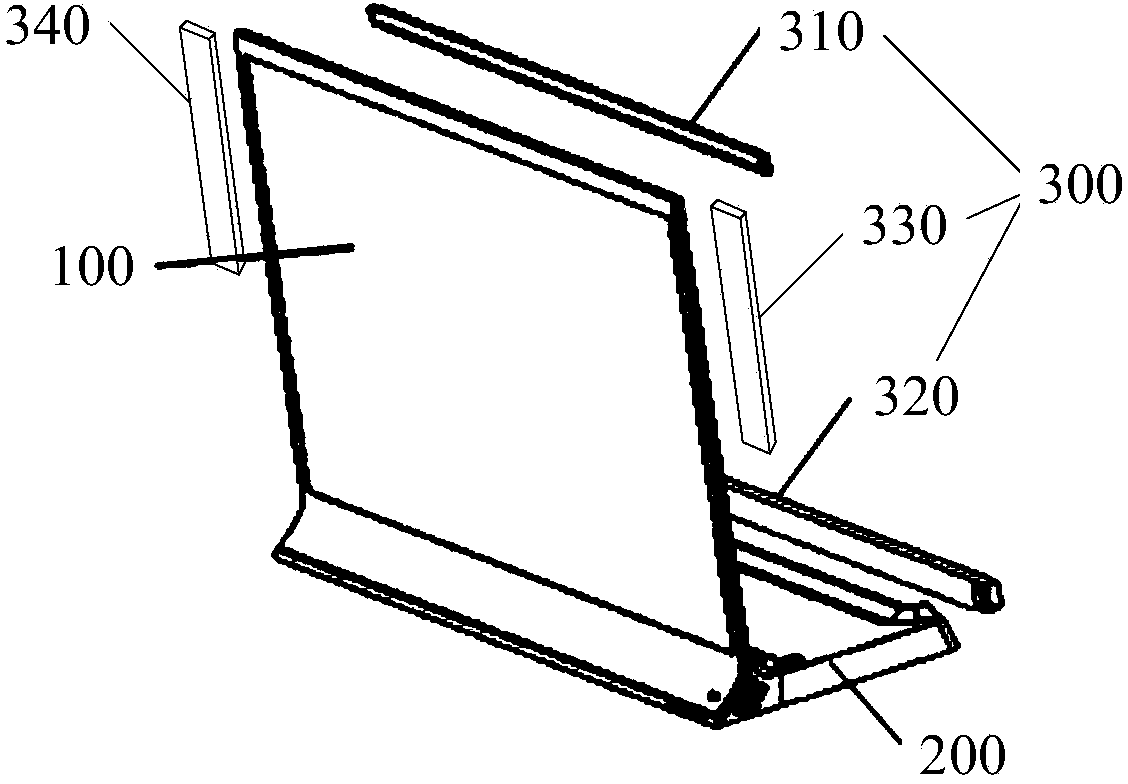

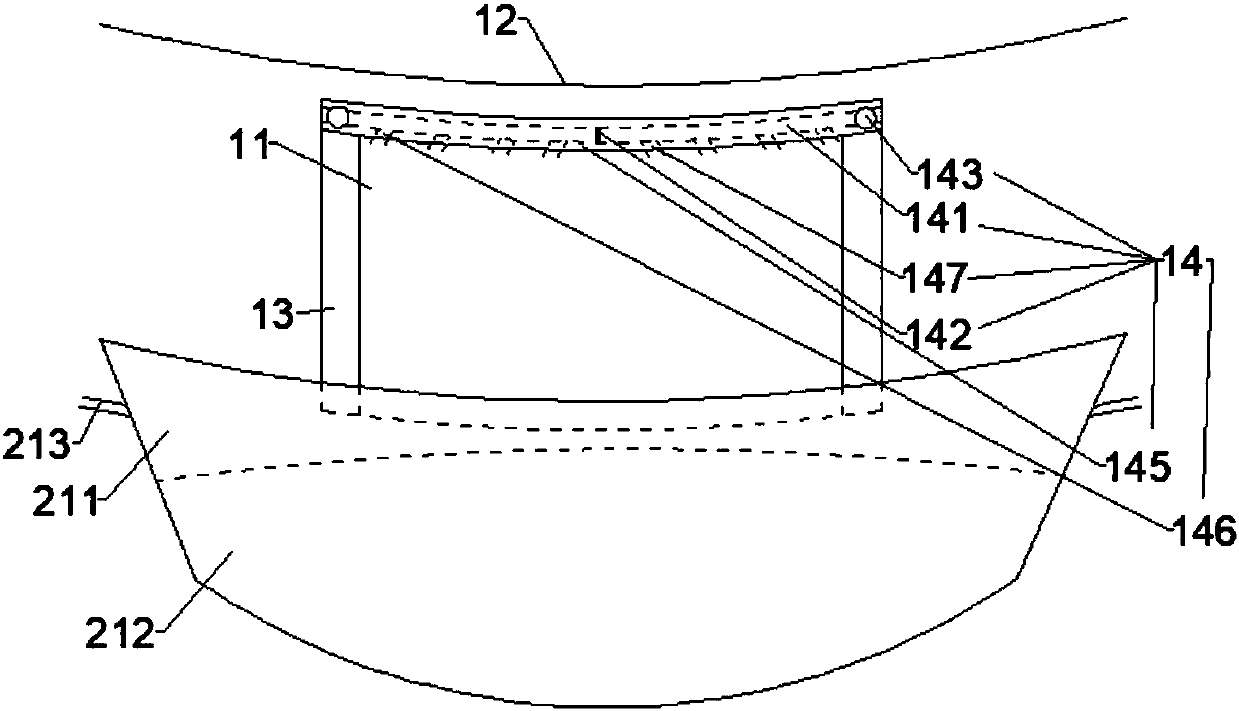

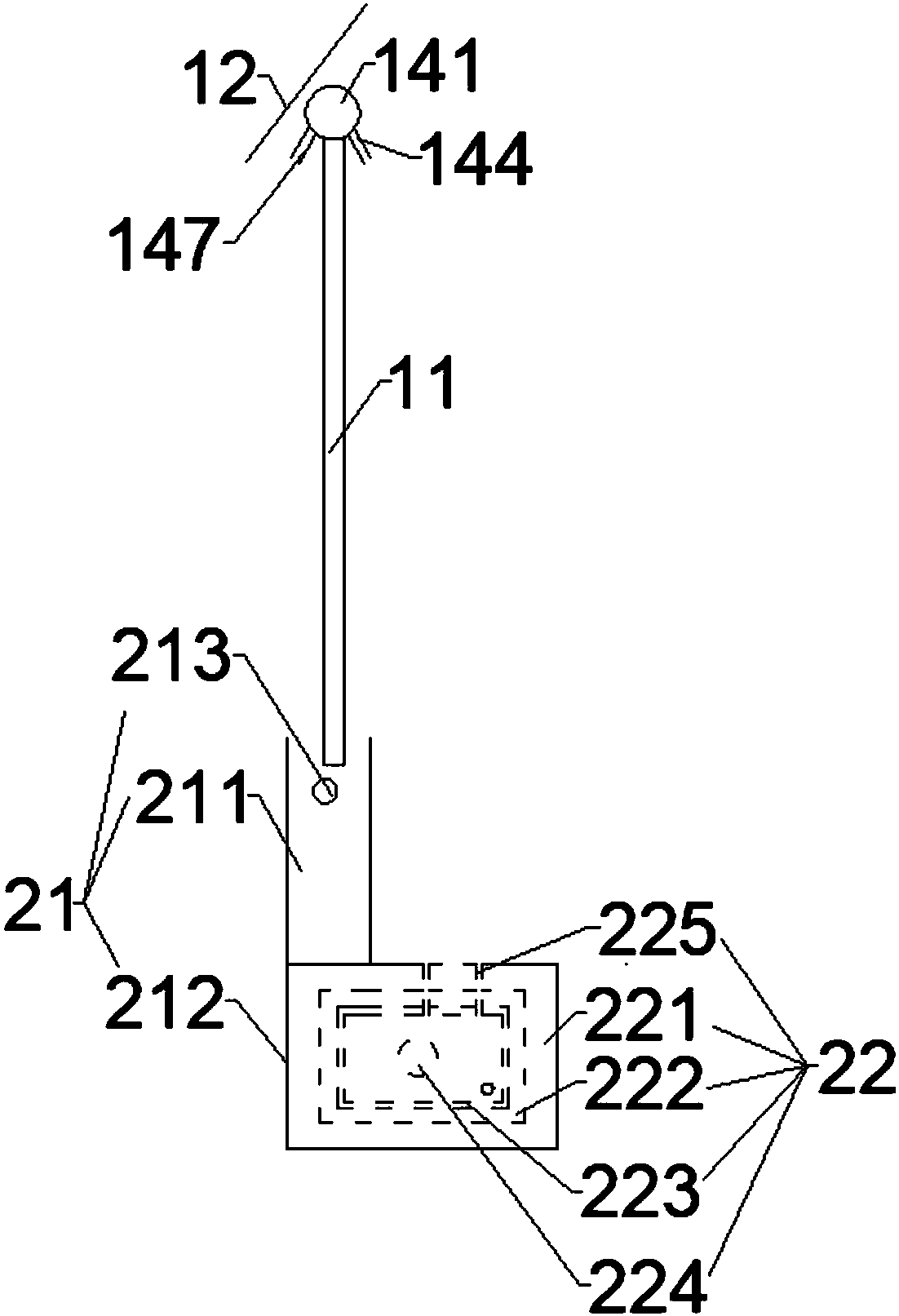

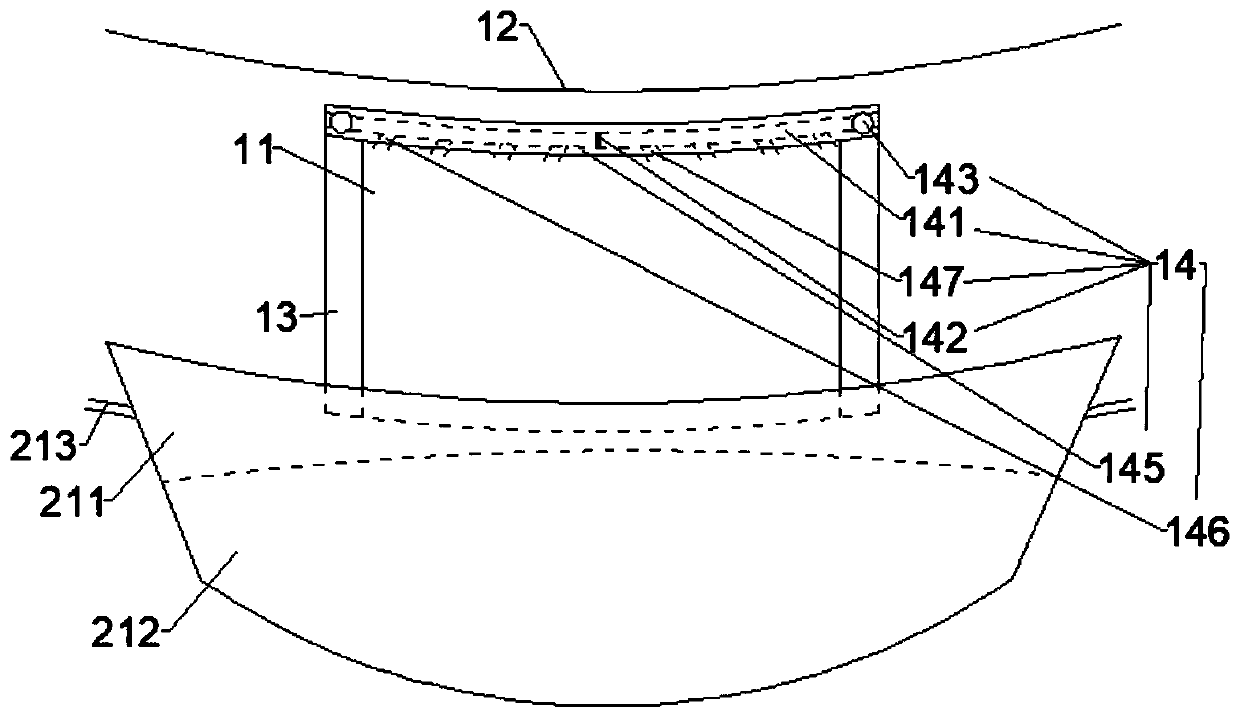

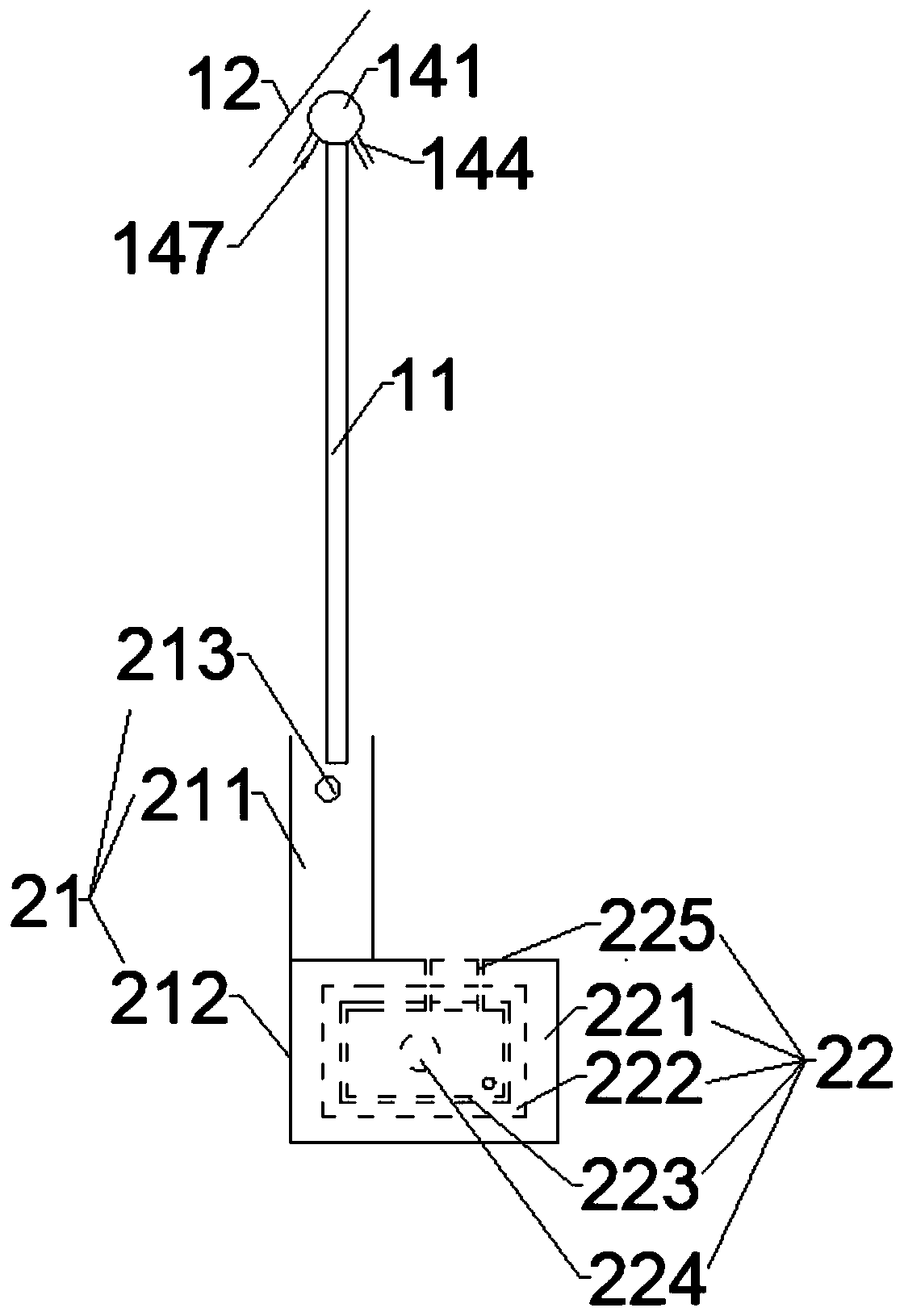

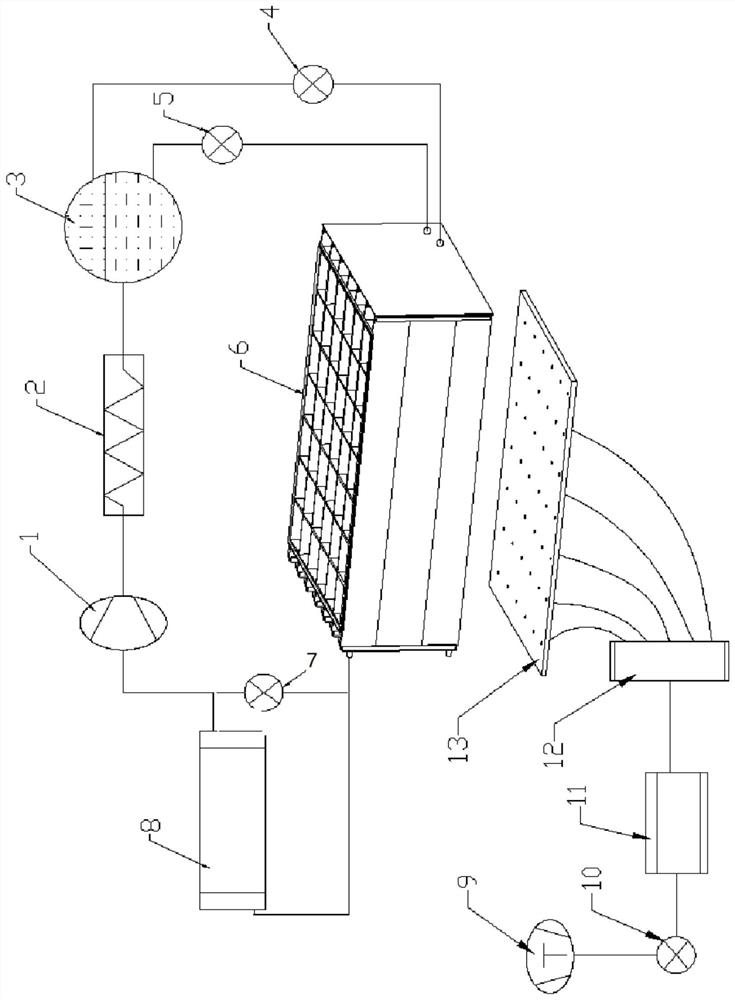

Transparent display device

ActiveCN103676314AAffect transparencyDoes not increase thicknessShow cabinetsPoint-like light sourceLight guideTransparent display

The invention discloses a transparent display device. A second light source arranged on a base and / or a first light source arranged on one side, deviating from the base, of a display panel are / is used as system light sources / a system light source, and light irradiating toward the lower back portion of the display panel from the first light source and light irradiating toward the upper back portion of the display panel from the second light source irradiate objects placed behind the display panel, and then can form space light right behind the display panel after being reflected (generally in a diffusing mode) by the objects. The space light is equal to the function of background light in effect and irradiates the display panel to realize transparent display. Compared with an existing transparent display device, a light guide plate arranged behind the display panel can be omitted, the guide plate is prevented from influencing the transparency of the transparent display device, a lamp box used for placing objects can be omitted, and the transparent display device can be made to be lighter and thinner.

Owner:BOE TECH GRP CO LTD

Less water drop residual glass for hydrophobic vehicle and preparation method thereof

The invention discloses a piece of less water drop residual glass for a hydrophobic vehicle and a preparation method thereof, belonging to the field of vehicle glass. The method comprises the following steps of firstly plating silicate ester hydrolysate on the surface of a clean glass surface and drying, then plating silane mixture hydrolysate of different hydrophobic degrees, finally carrying out heat treatment on the glass, wherein the silane mixture hydrolysate of different hydrophobic degrees comprises silane I with relatively high hydrophobic degree and silane II with relatively low hydrophobic degree, and the weight ratio of the silane I and the silane II is (1-5):(0.1-2). According to the method, the less water drop residual glass for the hydrophobic vehicle is prepared by forming films of different hydrophobic degrees on the surface of the glass, so that when a car drives on rainy days, small water drops converge by taking an area with low hydrophobic degree on the surface of the hydrophobic glass as a center so as to form large water drops, and the large water drops slip off from the surface of the hydrophobic glass by self, therefore, the small water drops avoid being left on the surface of the glass so as not to affect the transparence of the vehicle glass, and the traffic safety is improved.

Owner:CHERY AUTOMOBILE CO LTD

Phosphate/polyurethane modified waterborne alkyd anticorrosive coating

ActiveCN108276864AAffect water resistanceAffect transparencyAnti-corrosive paintsVegetable oilPhosphate

The invention relates to a phosphate / polyurethane modified waterborne alkyd anticorrosive coating. The coating is composed of phosphate / polyurethane modified waterborne alkyd resin, a cosolvent, a filler, an antirust pigment, an auxiliary agent and deionized water, wherein the phosphate / polyurethane modified waterborne alkyd resin is prepared by performing a reaction on vegetable oil fatty acid, isophthalic acid, an organic acid anhydride, a diol, a branched-chain polyol, dimethylolpropionic acid, alkyl acrylate phosphate, polyisocyanate and a neutralizer. The phosphate / polyurethane modified waterborne alkyd anticorrosive coating provided by the invention has a phosphate group and a metal substrate, forms a compact phosphating film, thereby improving water resistance and rust resistance ofa coating film; and the coating is combined with the characteristics of polyurethane chemical resistance, aging resistance, flexibility and wear resistance, and the prepared phosphate / polyurethane modified waterborne alkyd anticorrosive coating has excellent adhesion, water resistance, flash rust resistance, chemical resistance, aging resistance, corrosion resistance and salt spray resistance.

Owner:ZHUHAI JELEE CHEM ENTERPRISE CO LTD

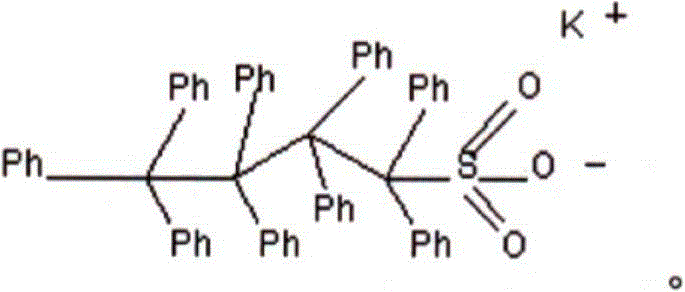

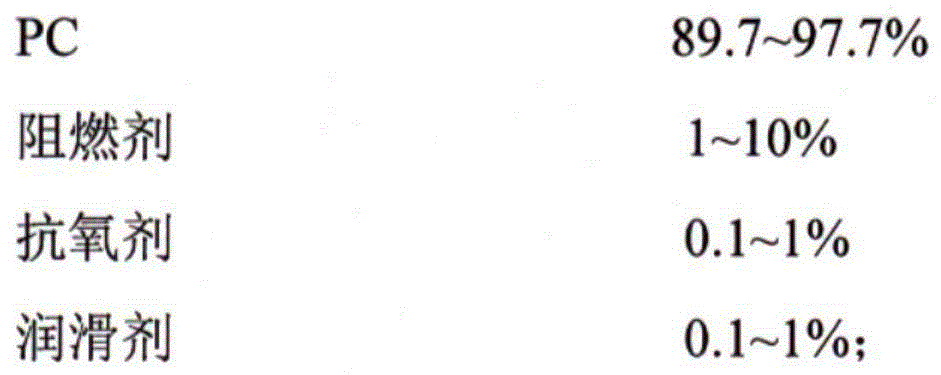

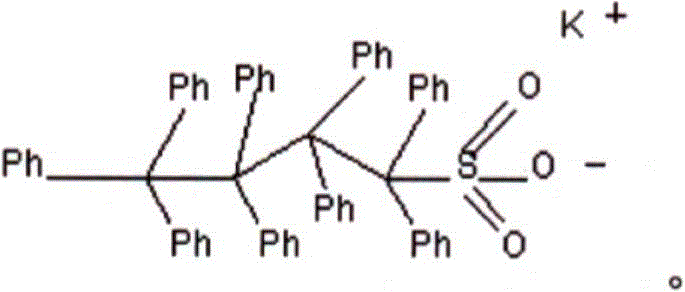

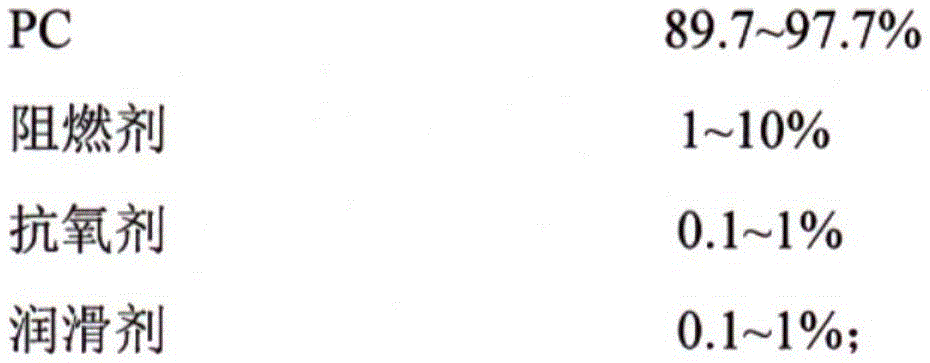

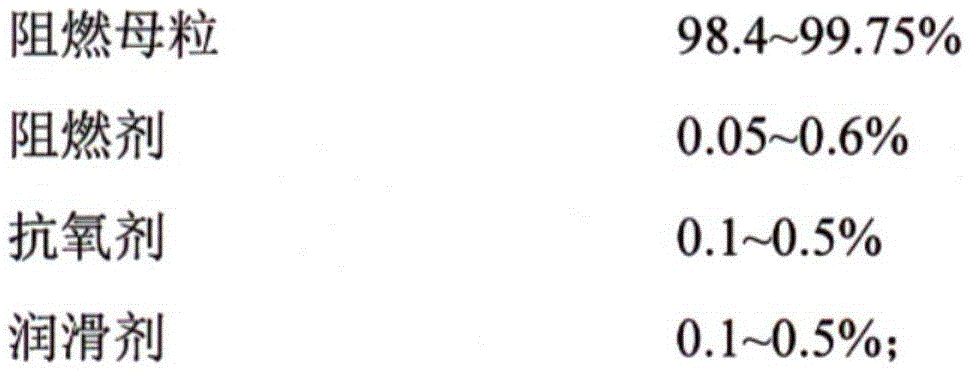

Transparent halogen-free flame-retardant polycarbonate resin and preparation method thereof

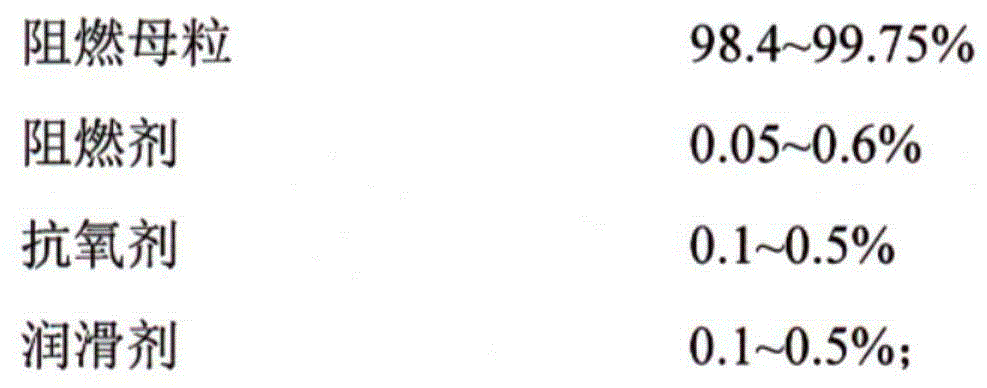

The invention relates to a transparent halogen-free flame-retardant polycarbonate resin. The resin comprises the following components in percentage by weight: 98.4-99.75% of flame-retardant master batches, 0.05-0.6% of a fire retardant, 0.1-0.5% of an antioxidant and 0.1-0.5% of a lubricant. The preparation method comprises the following steps: preparing materials according to the components, adding PC, the fire retardant, the antioxidant and the lubricant in percentage by weight into a high-speed mixing machine, sufficiently mixing the PC, the fire retardant, the antioxidant and the lubricant, and placing the PC, the fire retardant, the antioxidant and the lubricant, which are mixed, into a screw rod machine for extruding and pelleting so as to obtain flame-retardant master batches; adding the flame-retardant master batches and the rest of the components into the high-speed mixing machine together, sufficiently mixing the flame-retardant master batches and the rest of the components, and then placing the flame-retardant master batches and the rest of the components, which are sufficiently mixed, into the screw rod machine for extruding and pelleting so as to obtain products. Compared with the prior art, the method disclosed by the invention fully uses phenyl butyl sulfonic acid potassium as the fire retardant, after the fire retardant, the antioxidant, the lubricant and the flame-retardant master batches are mixed, extruded and pelleted, the whole preparation technology is simple, a complex ladder temperature control step is not needed, the obtained products have the characteristics of transparence, thin walls, high impact strength, excellent flame retardant property, zero toxicity and zero harm, and the application range is wide.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

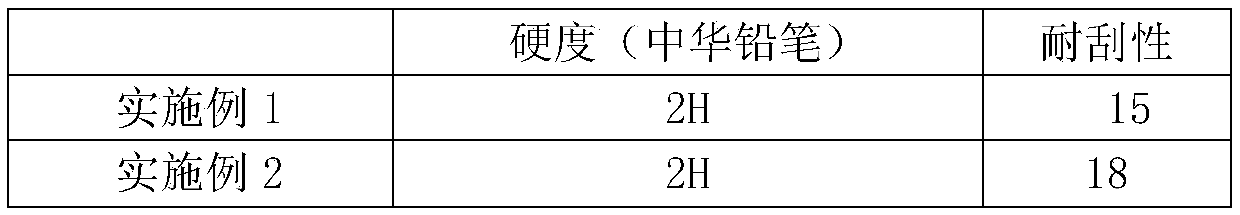

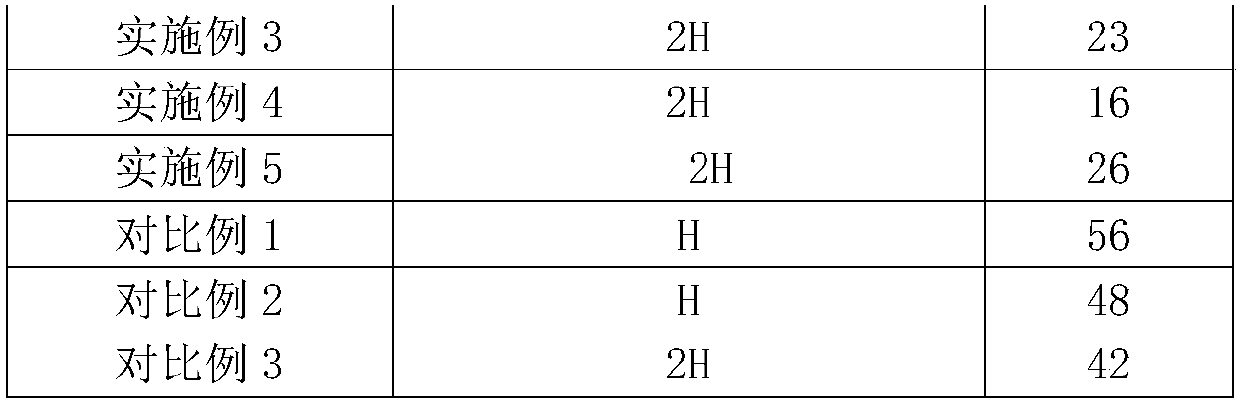

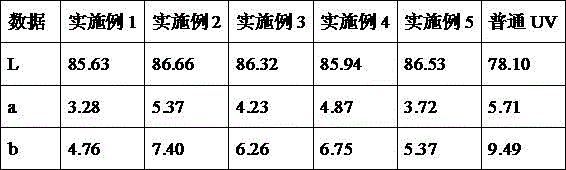

Water-based high-clarity high-scratch-resistance five-splitting main finish paint as well as preparation method thereof and double-component clear surface paint

ActiveCN109575776AHigh hardnessImprove permeabilityAntifouling/underwater paintsPaints with biocidesNano siliconWater based

The invention belongs to the field of special paint, and discloses water-based high-clarity high-scratch-resistance five-splitting main finish paint. The water-based high-clarity high-scratch-resistance five-splitting main finish paint comprises the following components in parts by weight: 70 to 80 parts of hydroxyl acrylic emulsion, 5 to 10 parts of nano silicon sol, 4 to 8 parts of glass powder / aluminum oxide and an appropriate amount of pH regulator, thickening agent and water for adjusting the system to the appropriate viscosity and pH value; and the hydroxyl value of the hydroxyl acrylicemulsion is 3. The water-based high-clarity high-scratch-resistance five-splitting main finish paint has the advantages of rapidness in curing, good water resistance and scratch resistance.

Owner:YINGDE YAJIA PAINT

Transparent non-yellowing UV gloss oil and preparation method and application method thereof

ActiveCN106833108ASolve yellowingIncrease brightnessInksPrinting after-treatmentOligomerReactive diluent

The invention discloses transparent non-yellowing UV gloss oil and a preparation method and an application method thereof. The transparent non-yellowing UV gloss oil is prepared from the following components: a photoinitiator, a reactive diluent, a surfactant, ultramarine printing ink, titanium dioxide and an oligomer according to the ratios in parts by weight of (2-3):(35-40):(1-2):(0.1-0.2):(5-8):(47-55). From the structure of the transparent non-yellowing UV gloss oil of the present invention, the problem of yellowing of the UV gloss oil is solved from a physical standpoint through the actions of the ultramarine printing ink and the titanium dioxide in the UV gloss oil.

Owner:JIANGSU JIN JIA NEW PACKAGING MATERIALS CO LTD

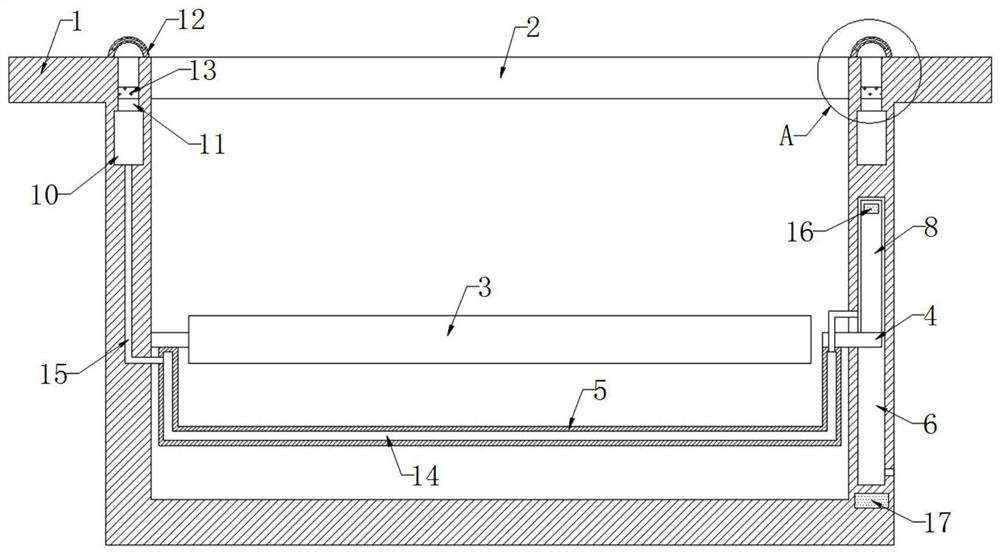

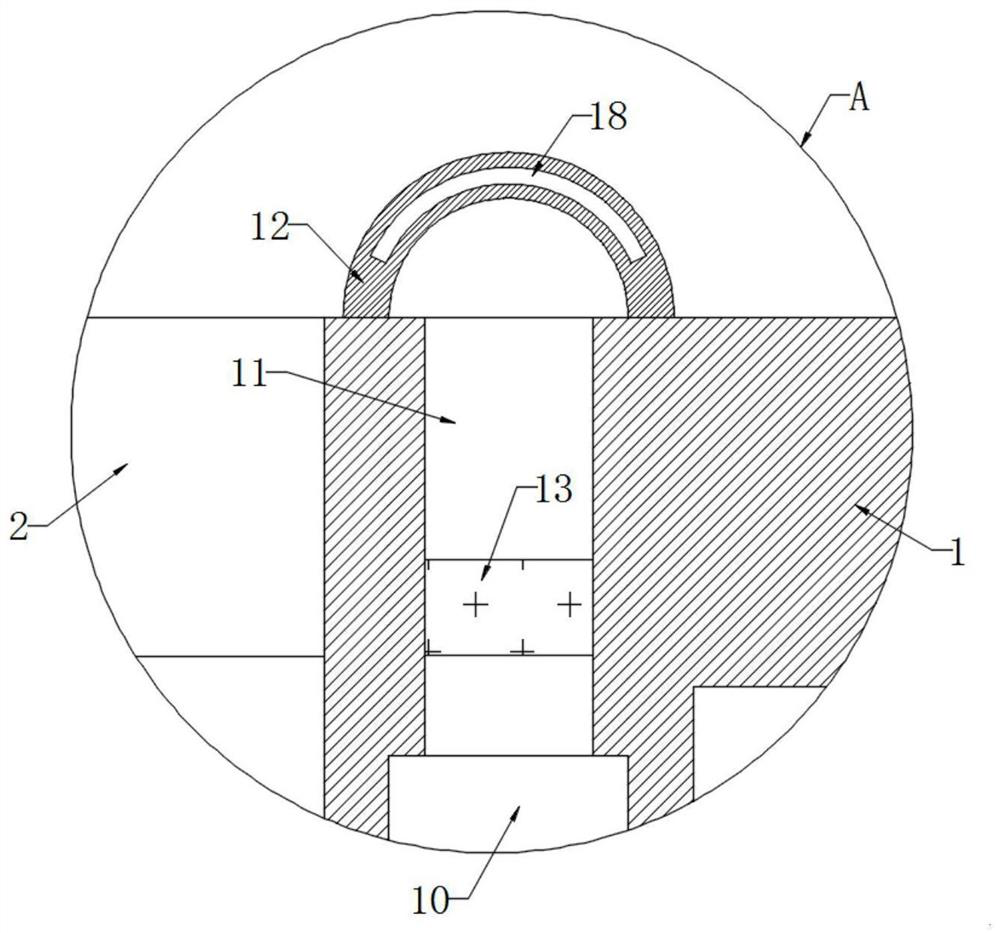

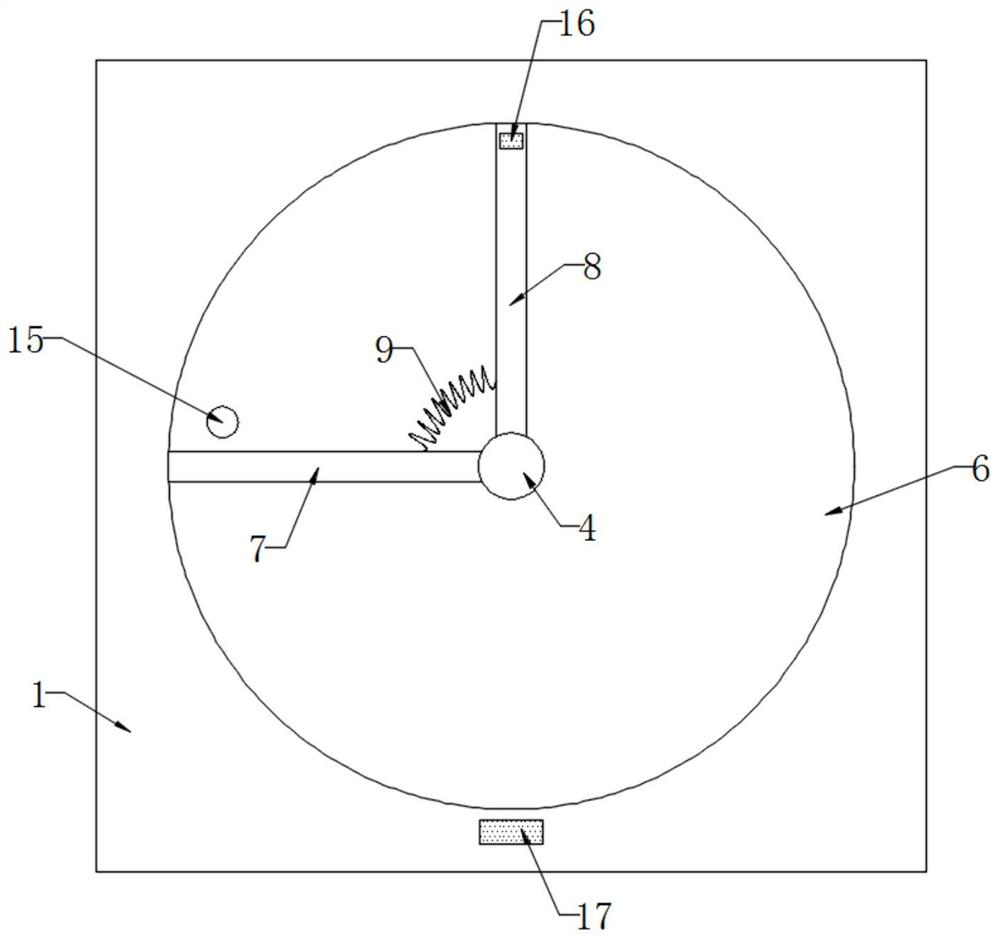

Anti-dazzle high-heat-dissipation type LED underground lamp

PendingCN111928163ACause irritationBig spaceLighting heating/cooling arrangementsGas-tight/water-tight arrangementsEngineeringCircular cavity

The invention discloses an anti-dazzle high heat dissipation type LED underground lamp. The lamp comprises a shell, the inner wall of the shell is fixedly connected with a transparent plate, a lamp body is fixedly connected to the inner wall of the shell through a fixing rod, a rotating shaft is connected to the inner wall, away from the fixing rod, of the shell in a rotating mode, a light shieldis fixedly connected to the side wall of the rotating shaft, a circular cavity is formed in the shell, a fixing plate is fixedly connected to the inner wall of the circular cavity, and the side wall of the rotating shaft penetrates through the side wall of the shell and is fixedly connected with a sliding plate. According to the invention, the elastic plate is extruded to deform downwards, the plurality of magnetic blocks slide downwards, the cooling liquid in the liquid storage cavity is extruded into the circular cavity, the sliding plate is pushed to rotate forwards by half a circle, so that the light shield is driven to rotate forwards by half a circle, the light shield is just rotated to the position over the lamp body, light emitted by the lamp body is partially shielded, the situation that the light stimulates the human eyes, the human eyes are transiently blinded, and accidents are likely to be caused is avoided.

Owner:刘刚

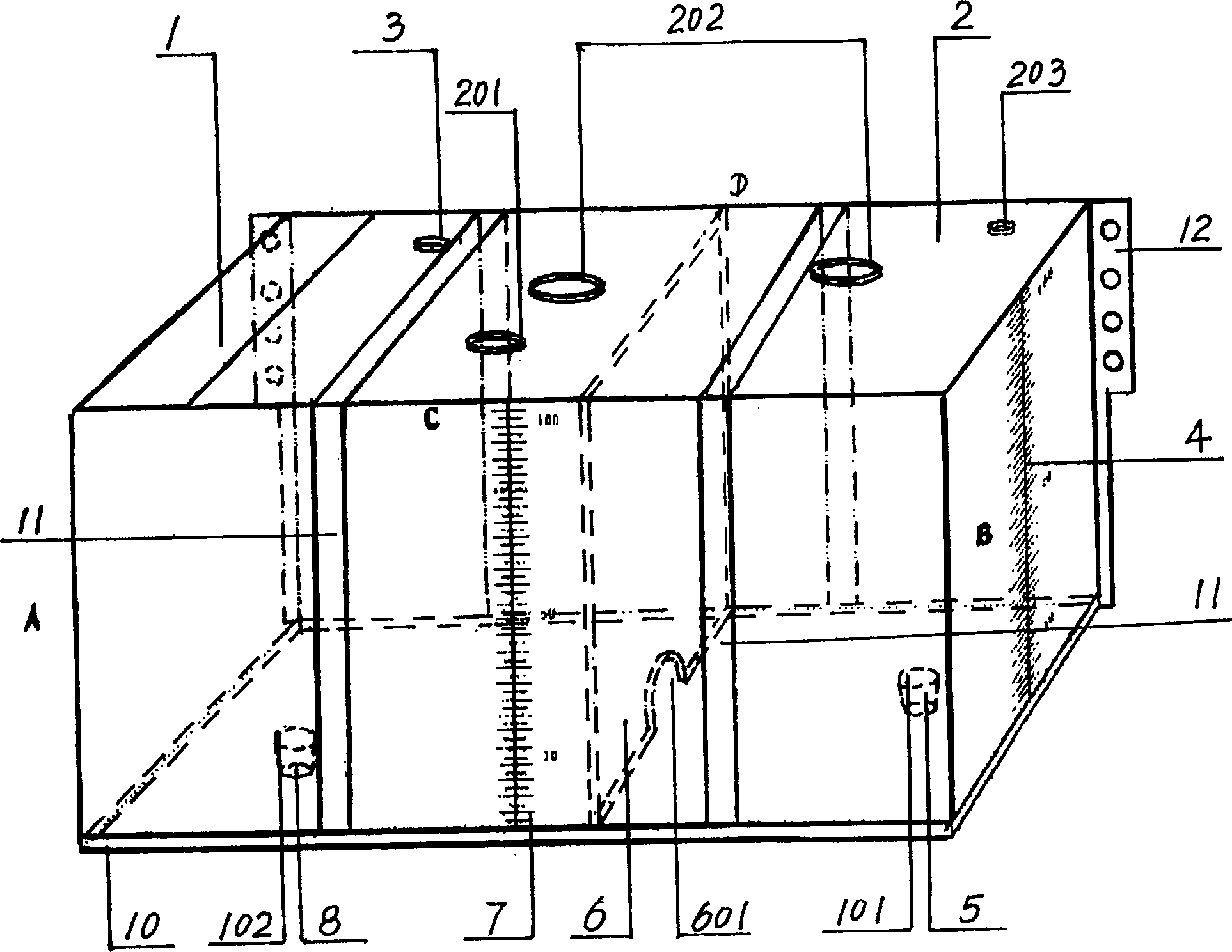

Ecological interception ditch for controlling agricultural non-point source pollution

InactiveCN107059796AImprove the landscape effectHigh removal rateWater contaminantsMultistage water/sewage treatmentDitchCombined treatment

The invention relates to an ecological interception ditch for controlling agricultural non-point source pollution. The ecological interception ditch comprises a sedimentation tank for depositing sediment, a primary treatment area for planting reeds and a combined treatment area in order along a water flow direction. Adsorption fillings and functional plants are arranged in the combined treatment area, and the functional plants comprise nitrogen fixing plants and phosphorus fixing plants. Compared with the prior art, on the base of ensuring the basic attributes of water collection and drainage of the ditch, the ecological interception ditch can effectively intercept organic pollutants and extra nutrients such as, N, P, etc. not to be directly discharged into water areas such as rivers, lakes, etc., and can utilize the extra nutrients such as, N, P, etc., thereby turning waste to wealth.

Owner:无锡金利达生态科技股份有限公司

Warm helmet

ActiveCN108030186APrevent liquefactionPrevent liquefaction into fogHelmetsHelmet coversWater vaporEngineering

The invention discloses a warm helmet, which includes the body of helmet, on which a wind shield cover is installed. A rain flange is installed on the body of helmet and is located right on the wind shield cover. A groove and components for blowing rain are provided on the wind shield cover. The warm helmet also includes a warming mechanism, including a tank, which is a hollow structure approximately in the shape of L. The tank includes a tank for collecting rain, which is used to store the lower edge of the wind shield cover and a warming tank fixed on the lower end surface of the wind shieldcover. The upper end surface of the tank for collecting rain is unrestricted. Water holding tanks are installed on both the left side and the right side of the tank for collecting rain. A wind outlettube is installed on the left side of the water holding tank. In addition, the warm helmet includes warming components, including an insulating layer, a heating layer and a water proofing layer in sequence, which are all installed on the warming tank. Besides, the warm helmet includes an air-extractor, which is stored in the space formed in the water proofing layer, and several wind inlet tubes.The warm helmet has the beneficial effects of blowing the gases with high content of water vapor exhaled by people from the surface of the wind shield cover to avoid the water vapor liquefying into fog on the wind shield cover and guiding the gases into the warming mechanism to provide warmth for the neck of a person.

Owner:卢志文

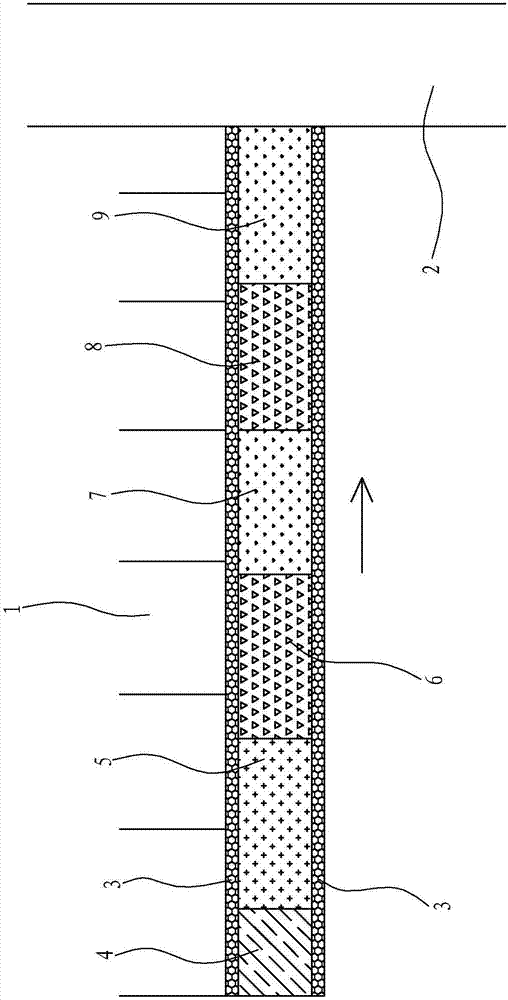

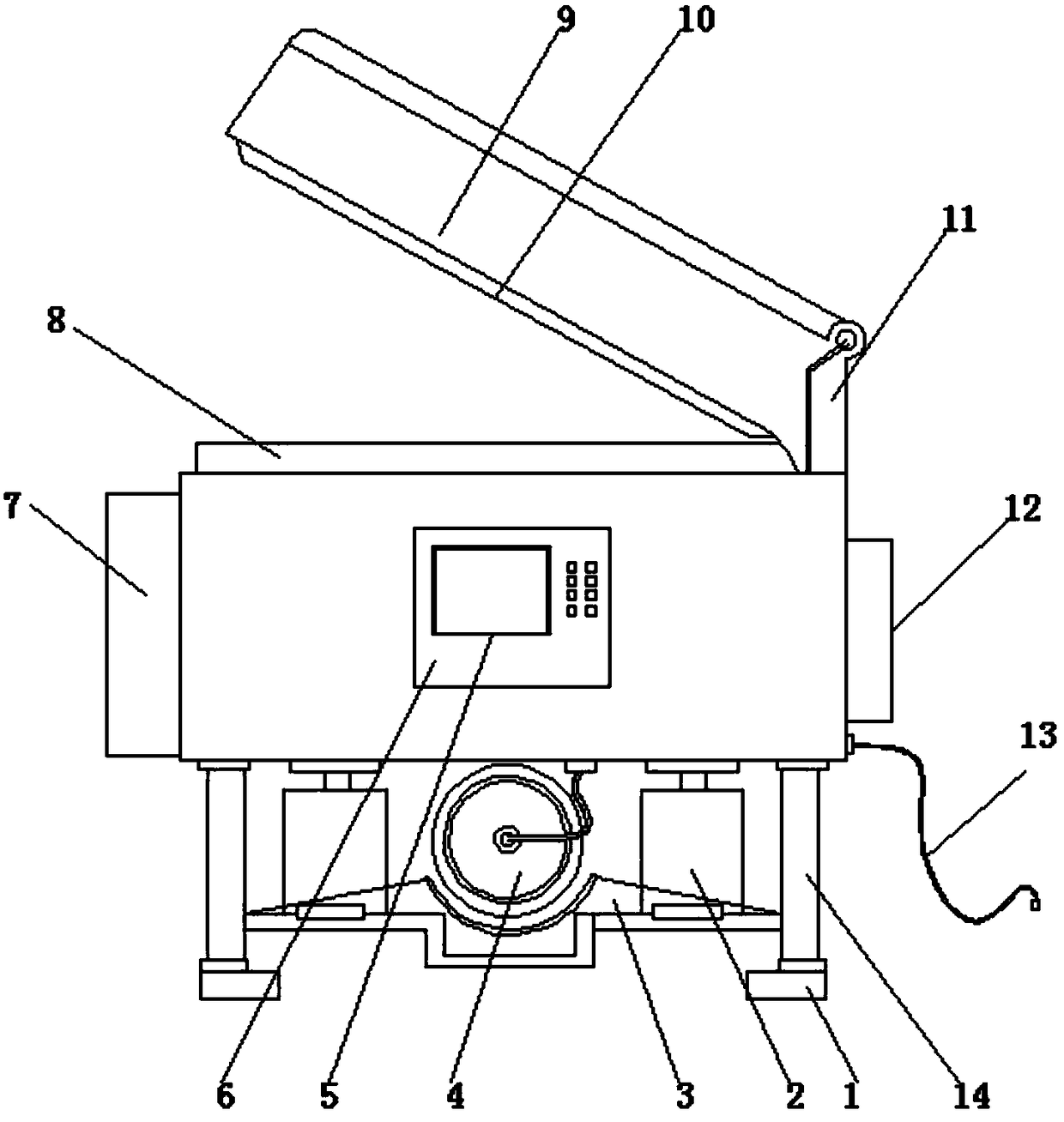

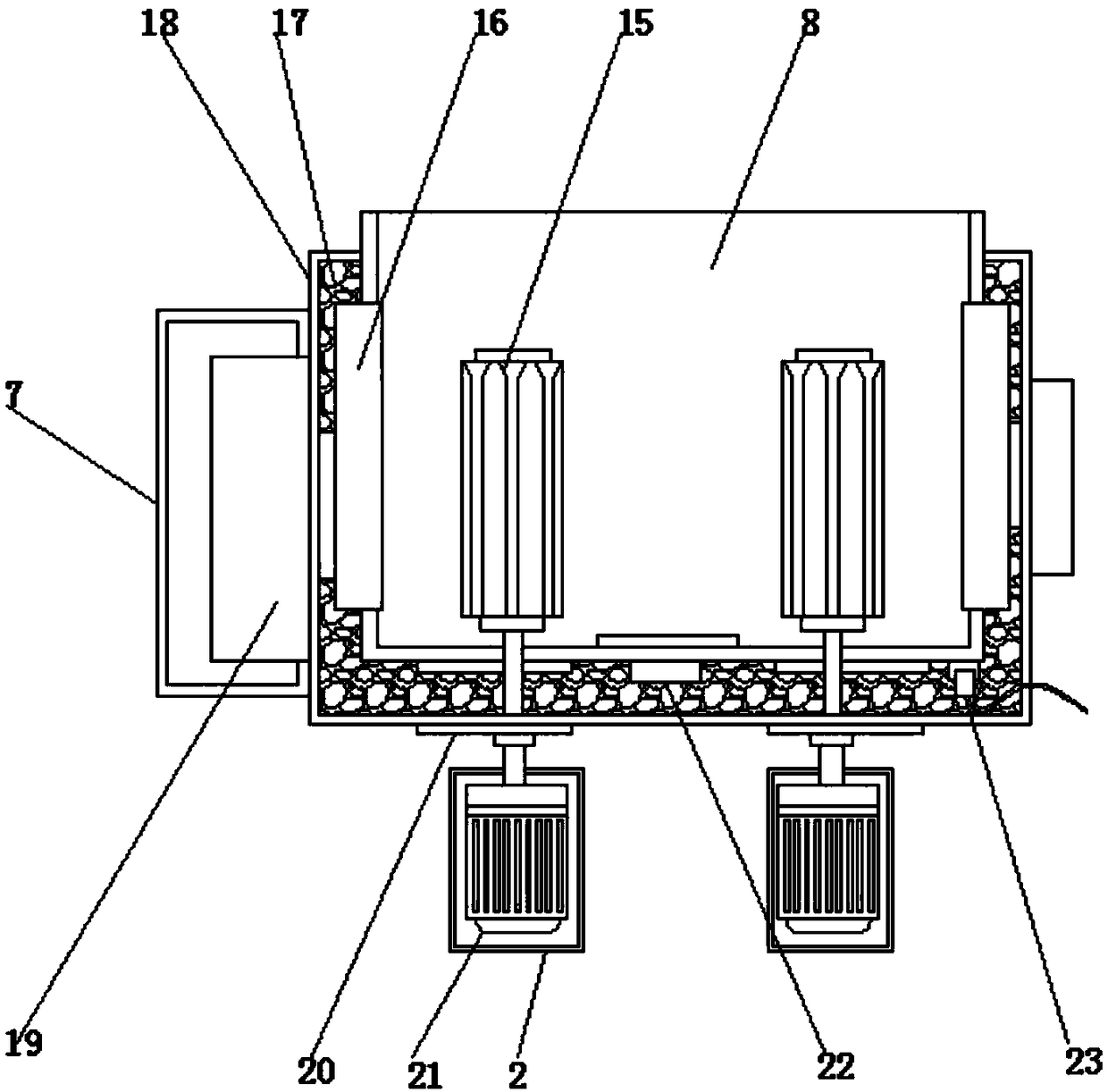

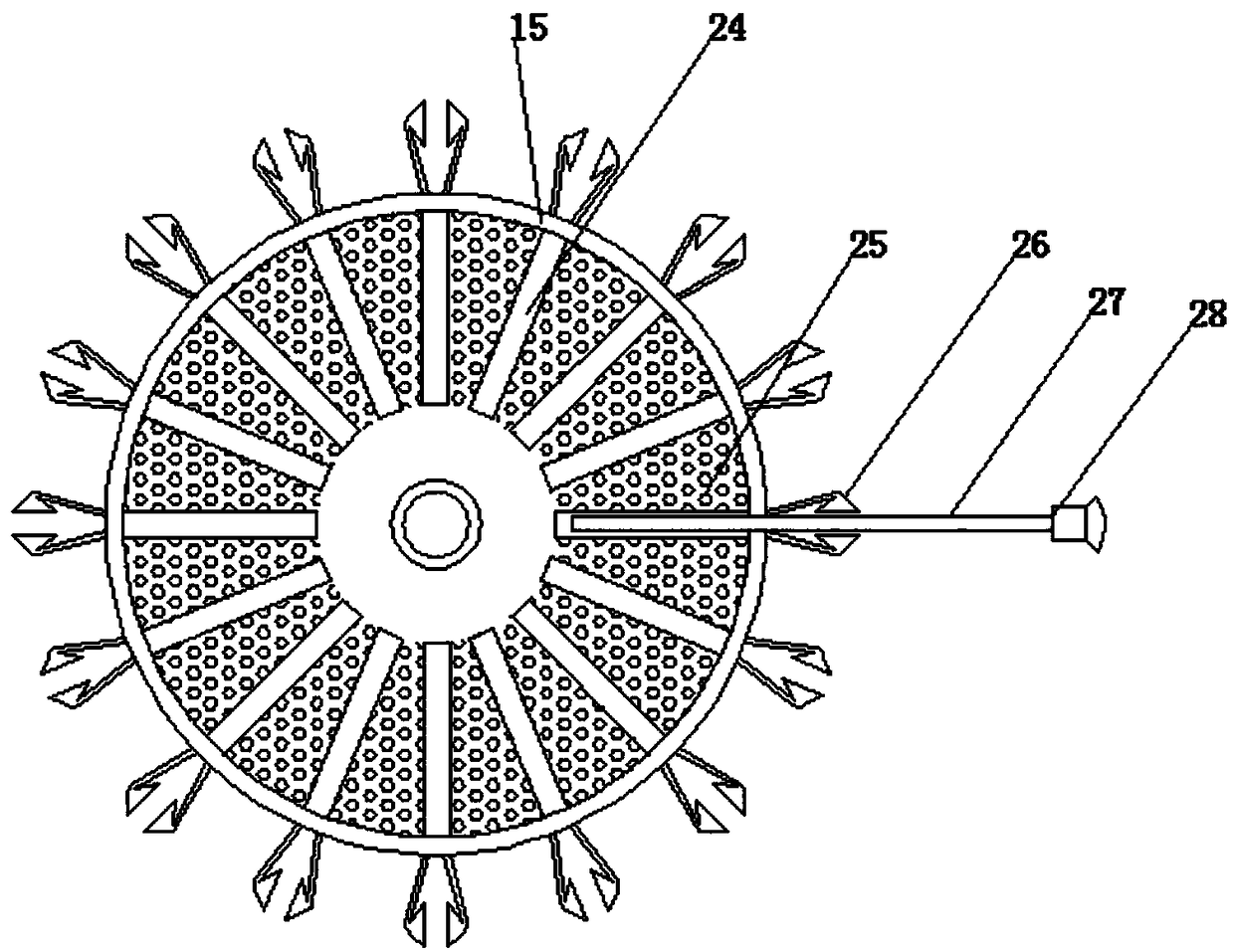

Tempered glass ultrasonic cleaning equipment

InactiveCN108421774AEasy to rinseLarger cleaning contact surfaceDrying gas arrangementsCleaning using liquidsBiochemical engineeringMegasonic cleaning

The invention belongs to the technical field of cleaning equipment, in particular to tempered glass ultrasonic cleaning equipment. Aiming at the problem that the cleaning contact surface of the ultrasonic cleaning equipment is small, the cleaning liquid residue cannot be cleaned completely, and the state of the cleaning liquid and the glass is insufficiently detected, the invention provides the following solution, the tempered glass ultrasonic cleaning equipment comprises a base, wherein the top outer wall of the base is welded with a strut, and the top outer wall of the strut is welded with an outer box; the outer wall of one side of the outer box is welded with a detection box, and the outer wall of the other side of the outer box is welded with a distribution box. According to the tempered glass ultrasonic cleaning equipment provided by the invention, instead of the traditional grid-type placement, an insertion-connection cylinder cooperates with a motor and an ultrasonic transducerto perform rotary impact and ultrasonic impact, so that the cleaning is more sufficient; a drying cover removes the excess residual cleaning liquid by wind and heat without stains; a solution concentration sensor can detect the concentration of a cleaning solution; a temperature sensor can detect the drying and heating process of a glass plate to avoid crack of the glass caused by an excessive temperature difference.

Owner:顾可琴

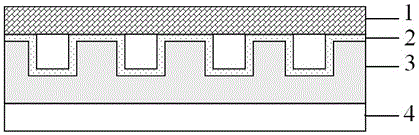

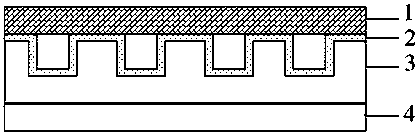

Heat-resistant holographic anti-counterfeiting film

The invention discloses a heat-resistant holographic anti-counterfeiting film. The film adopts a layered structure and sequentially comprises a carrier layer, an anti-counterfeiting information layer, a film release layer and a bonding layer from outside to inside, wherein the carrier layer is a PET (polyethylene terephthalate) film, the anti-counterfeiting information layer is a cured heat-resistant acrylic resin layer, nanoscale fumed silica is added to the cured heat-resistant acrylic resin layer, the anti-counterfeiting information layer contains concave and convex holographic patterns, the film release layer is a fluorine-containing coating, and the bonding layer is a hot melt adhesive layer or a pressure-sensitive adhesive layer. The anti-counterfeiting information of the heat-resistant holographic anti-counterfeiting film adopts the heat-resistant acrylic resin layer with the nanoscale fumed silica added, can bear mold pressing temperatures of 260 DEG C or above and is good in transparency, the anti-counterfeiting information layer can be stripped from a mold pressing plate easily after mold pressing by the aid of the film release layer, the integrity and higher definition of anti-counterfeiting information are guaranteed, the anti-counterfeiting information layer is cured after mold pressing, and the stability of holographic patterns is further improved.

Owner:中山市利丰胶粘制品有限公司

Active nanocomposite materials and production method thereof

ActiveUS8834907B2Easy to oxidizeImprove efficiencyPigmenting treatmentMaterial nanotechnologyMaterials scienceIndustry sector

The present invention refers to new active nanocomposite materials, comprising a matrix and additives. The present invention also describes a process for obtaining these nanocomposite materials and their use in various industry sectors.

Owner:LAB ARGENOL

Preparation technology of ultra-white glass substrate

PendingCN110981208AImprove overall performanceGood practical value and promotion valueSurface treatment compositionsSi substrateThiourea dioxide

The invention relates to the technical field of new energy utilization glass, and concretely relates to a preparation technology of an ultra-white glass substrate. Raw materials used in the inventioncomprise, by mass, 700 parts of fluoride, 30-60 parts of sulfate, 120-150 parts of titanium dioxide, 60-80 parts of chlorate, 50-70 parts of an acidic material, 15-30 parts of thiourea dioxide, 60-80parts of kaolin, 60-100 parts of a stabilizer and 50-80 parts of bentonite. A frosting liquid is prepared from raw materials; and a glass substrate is soaked in the frosting liquid, then the frosted rough surface is coated with an antireflection film, then the surface of the antireflection film is coated with a refection reducing film, and the surface of the refection reducing film is coated witha transparent super-hydrophobic coating. The antireflection effect, the refection reducing effect and the anti-pollution effect on the surface of the glass are good, and the glass substrate has good practical values and promotional values.

Owner:DENGFENG CITY YUKE GLASS TECH

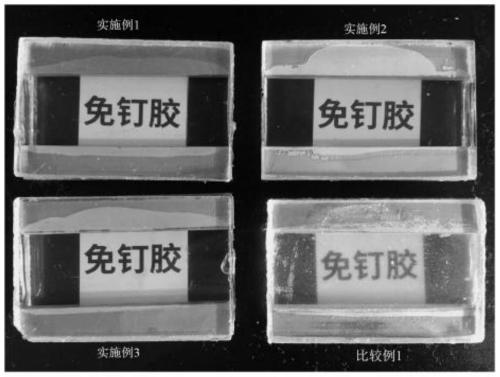

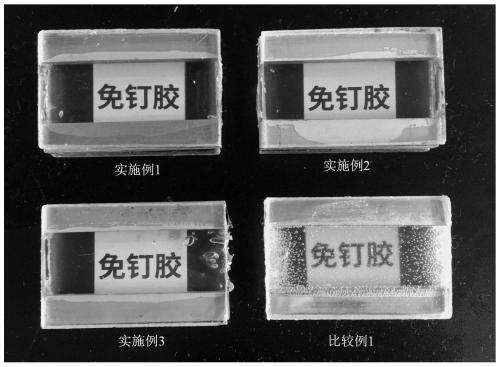

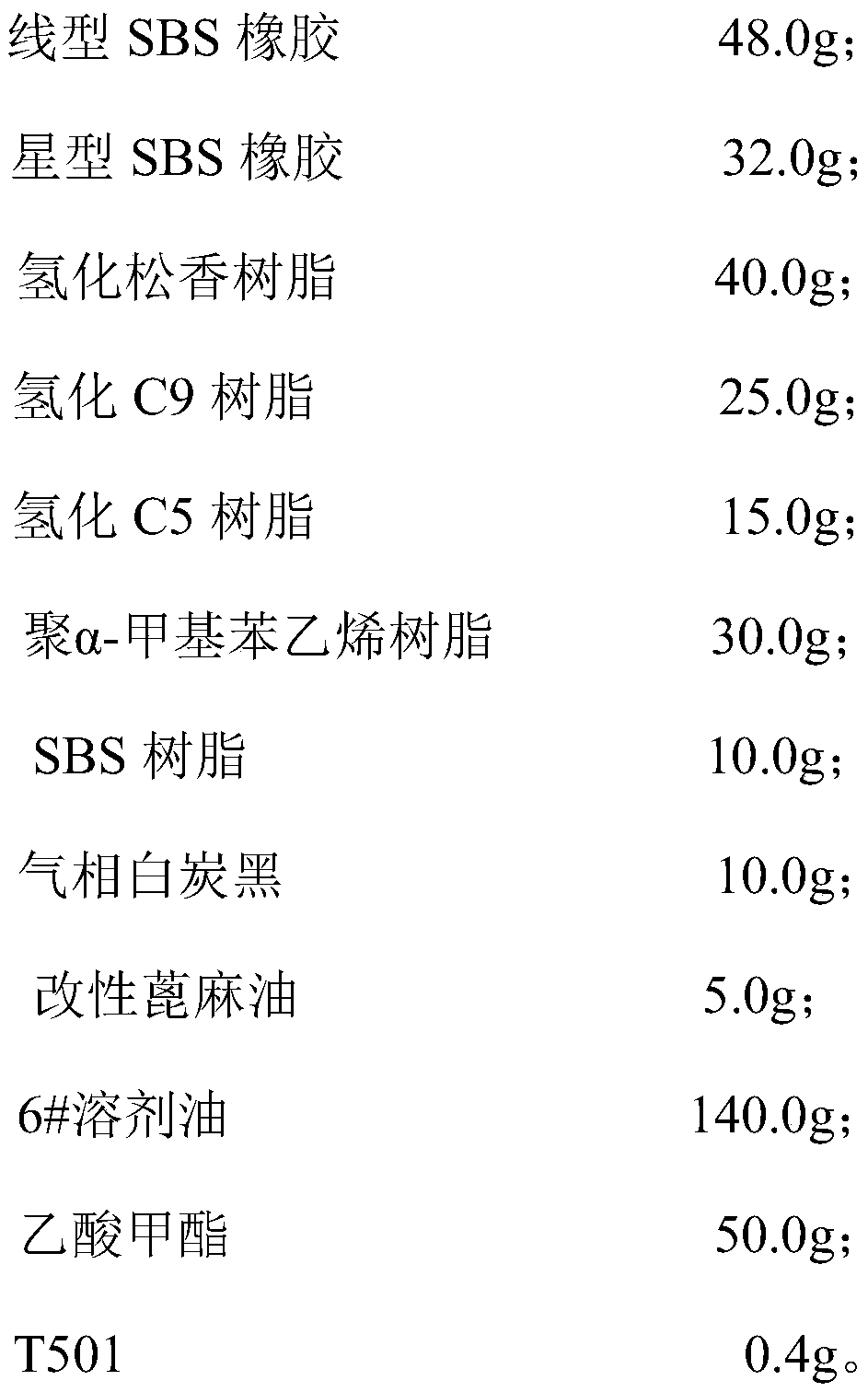

Environment-friendly nail-free glue special for advertising words and preparation method thereof

PendingCN111320954AExcellent initial transparencyIncrease viscosityMineral oil hydrocarbon copolymer adhesivesMacromolecular adhesive additivesElastomerAdhesive cement

The invention provides environment-friendly nail-free glue special for advertising words and a preparation method thereof. The special environment-friendly nail-free adhesive for the advertising wordscomprises the following main components: a rubber elastomer, tackifying resin, a thixotropic agent, an environment-friendly solvent system and an antioxidant, the preparation method comprises the following steps: putting the environment-friendly solvent system into a high-speed dispersion power mixer, starting stirring, sequentially adding the rubber elastomer and the tackifying resin, and stirring for 2-3 hours until the materials are uniformly dispersed; and adding the thixotropic agent and the antioxidant, and stirring for 10-30 minutes at the rotating speed of 1000+ / -50r / min until the materials are uniformly dispersed, thereby obtaining the special environment-friendly nail-free adhesive for the advertising words. An environment-friendly solvent system is used as a dispersion medium,so that a base material is not corroded; the hydrogenated resin, the poly-alpha-methylstyrene resin and the high-transmittance reinforced SBS resin are used, so that the transparency of a glue solution is guaranteed, and the weather resistance and the bonding strength of the adhesive are improved. The nail-free adhesive disclosed by the invention has the characteristics of transparent colloid, traceless adhesion, high curing speed, multiple types of adhesive materials and wide application range.

Owner:GLEIHOW NEW MATERIALS CO LTD

Preparation process for suction head through silicification

The invention discloses a preparation process for a suction head through silicification. The preparation process comprises the following steps: 1) weighing polypropylene resin and silicone masterbatch with a ratio of 98.5: 1.5; 2) respectively preparing the polypropylene resin and the silicone masterbatch into powder with a particle size of 100 to 300 meshes, then carrying out drying treatment, carrying out mixing under stirring, and allowing powder components to be uniformly mixed; 3) placing prepared raw materials into an injection molding machine, opening a water tower, a power switch and a machine power switch at the same time, and controlling a heating temperature of a material pipe in a range of 240 to 260 DEG C; 4) opening the main engine of the injection molding machine, and opening an air pump, wherein pressure is 6 MPa; 5) carrying out treatment for 1 minute under an electrostatic ion removal blower gun; and 6) carrying out boxing and encasing. According to the process provided by the invention, the silicone masterbatch is a solid form of organic silicone oil, and is directly added into plastic particles in the process of production of the suction head, so operation is simple, convenient and reliable; high proportion of the silicone masterbatch affects transparency of a product; meanwhile, low proportion of the silicone masterbatch may not achieve a silicification treatment effect and affects the quality of the product.

Owner:浙江立博生物技术有限公司

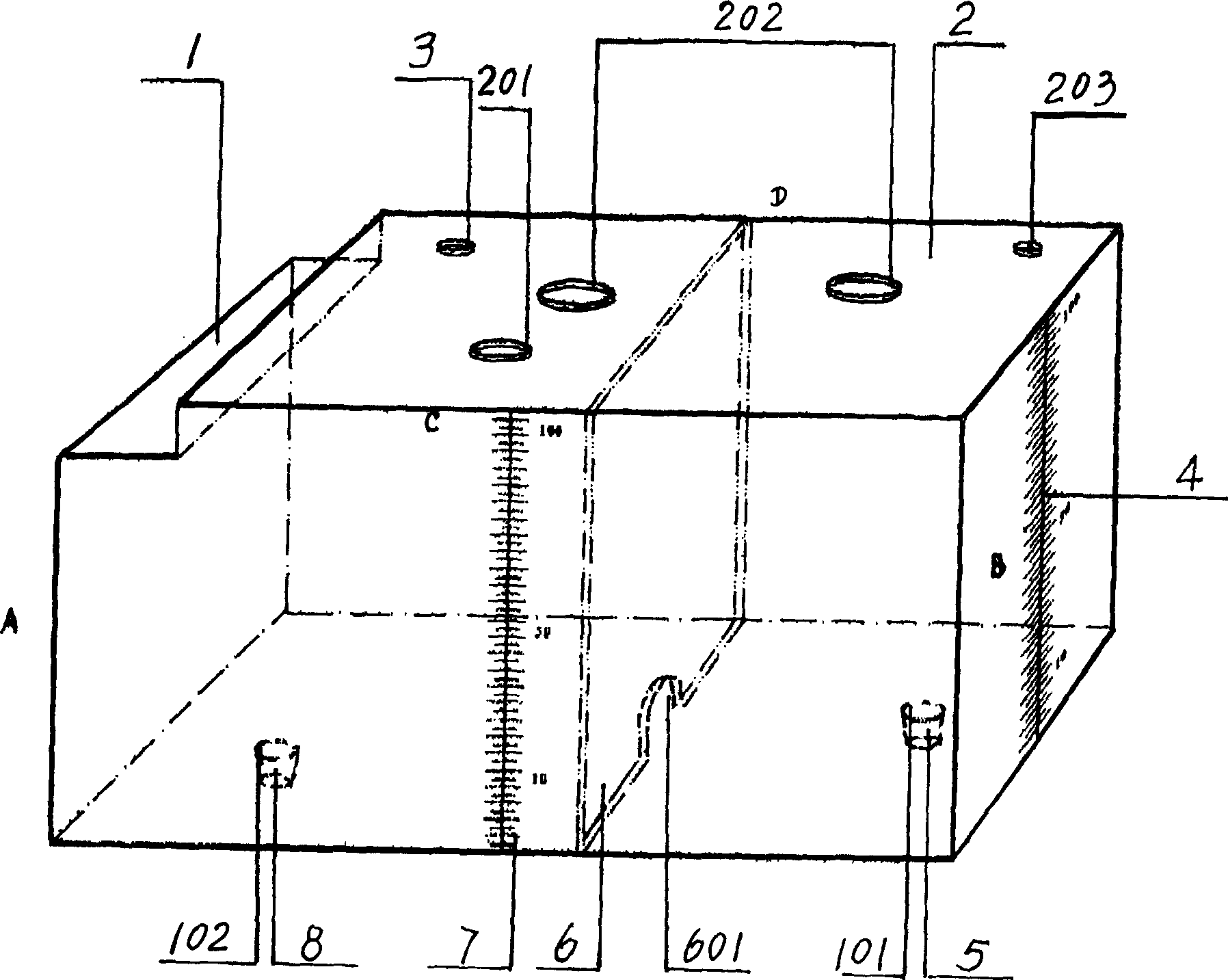

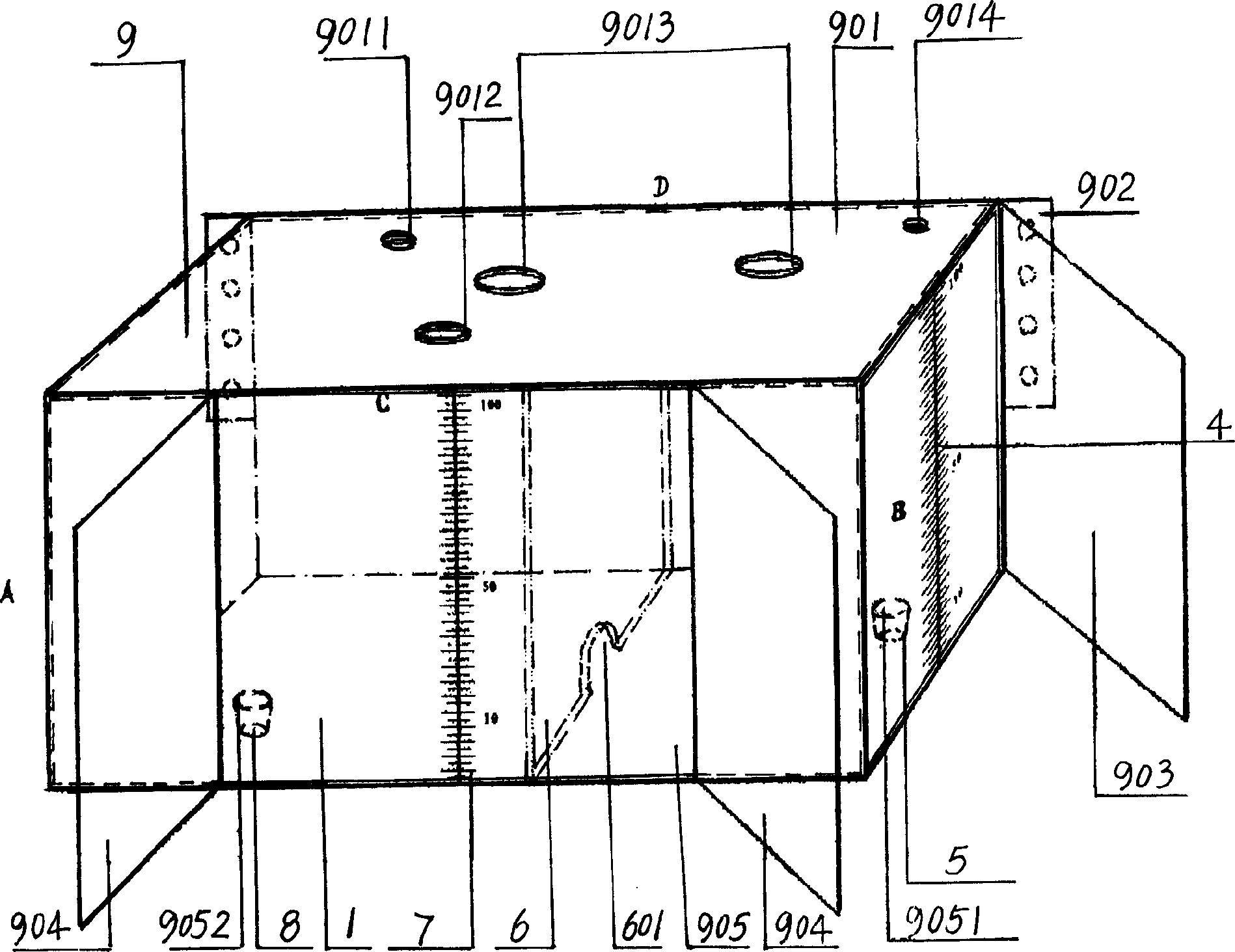

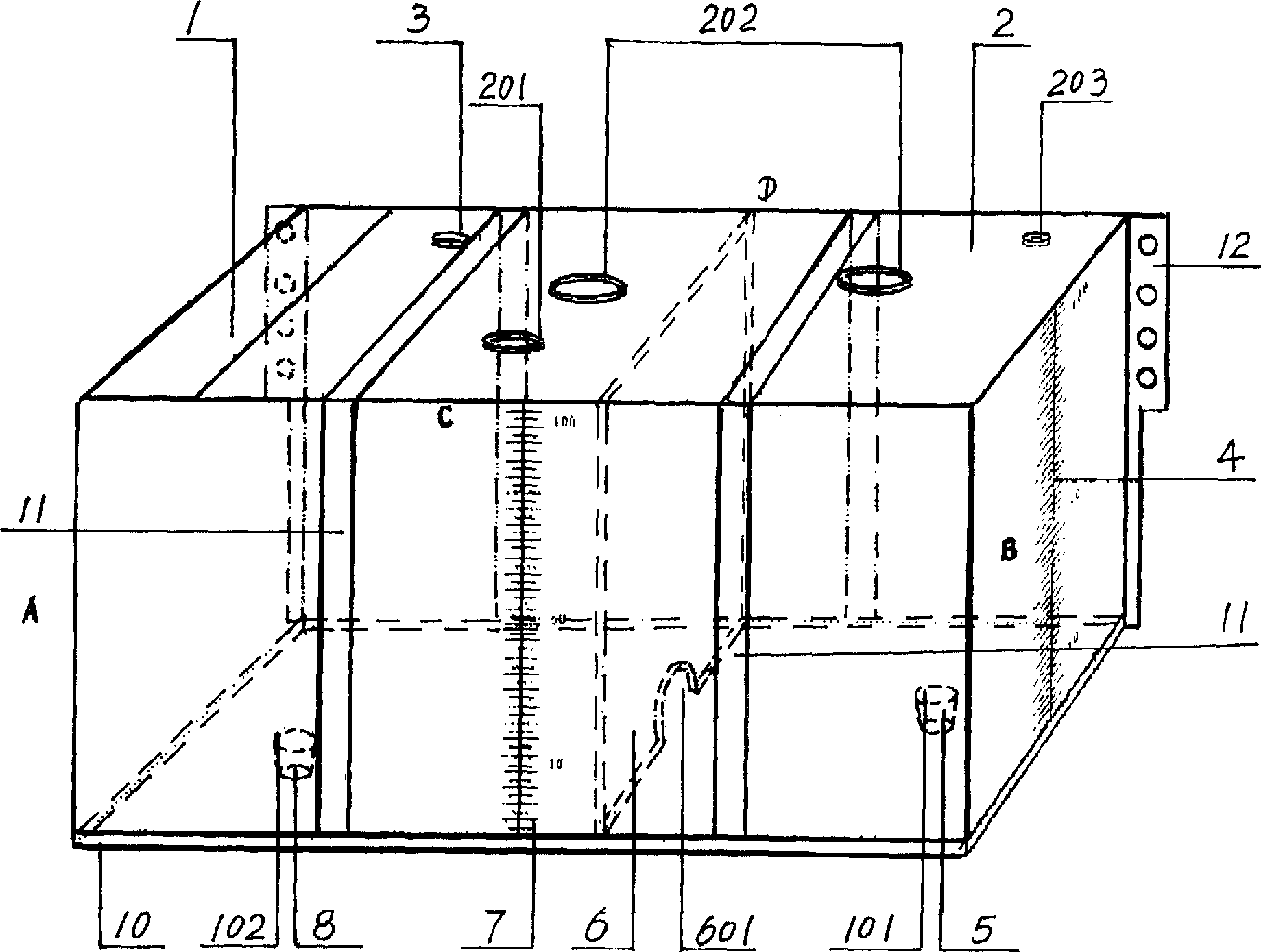

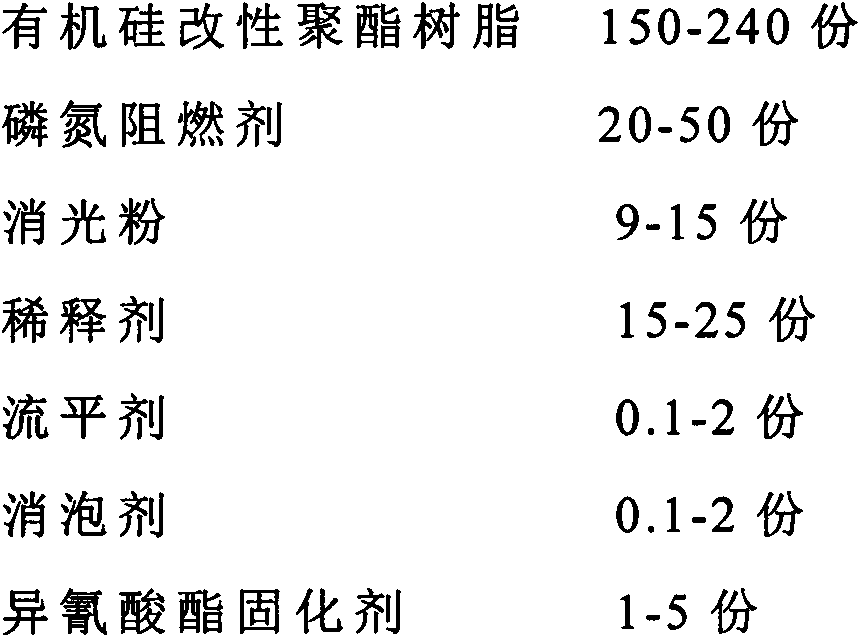

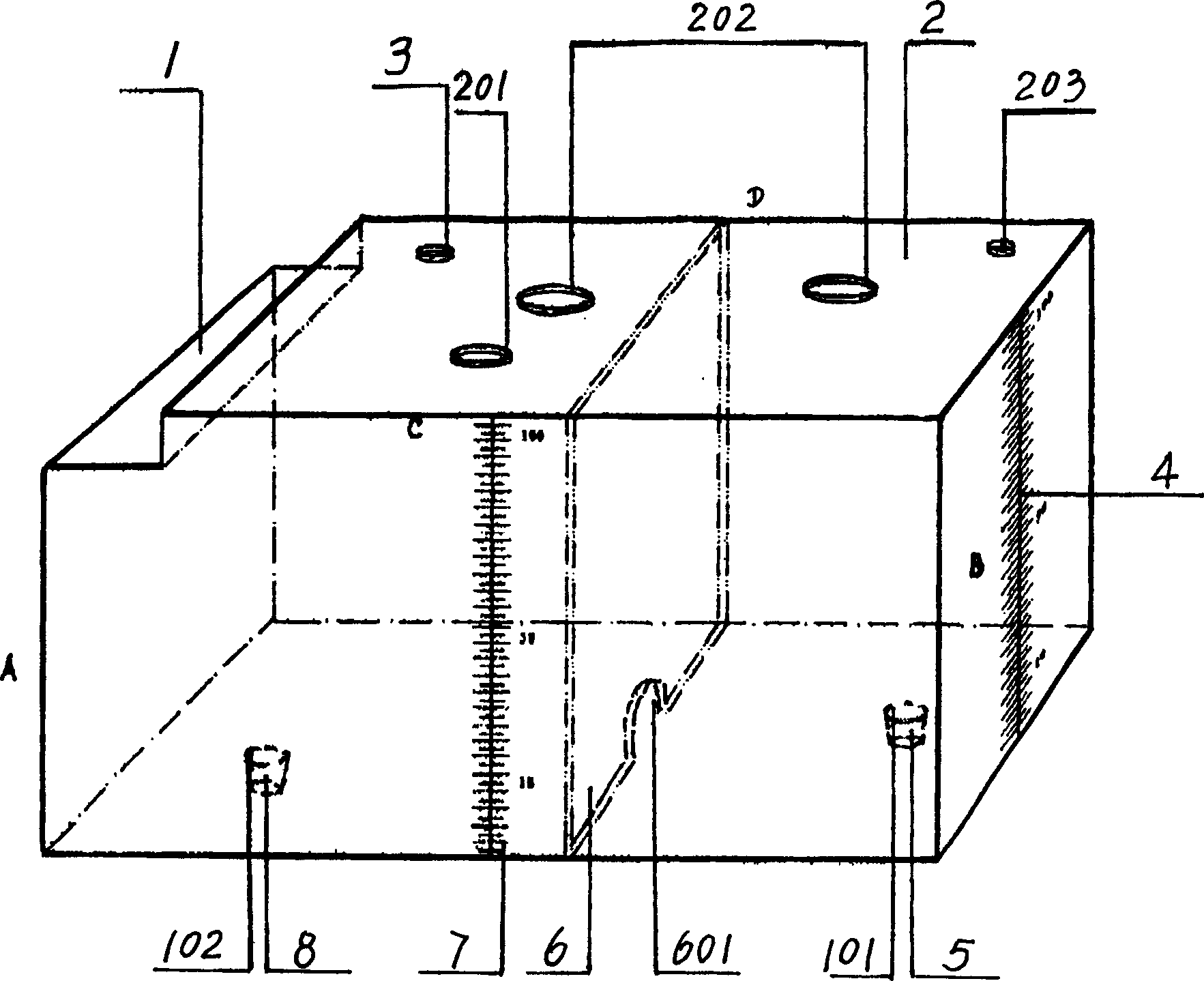

Transparent metering oil tank

The transparent measuring oil tank for motor vehicle, engineering machine and ship to detect oil amount and quality consists of transparent tank with drain outlet and plug; cover with oil feeding port, cleaning port and oil discharging port connected to the oil pipe of engine; and measuring rules in the front and side of the tank. The present invention may be used to replace available iron made oil tank and makes it possible to observe the quantity and quality of oil intuitively. The transparent measuring oil tank is light resistant, shock resistant, light and firm.

Owner:郁文明

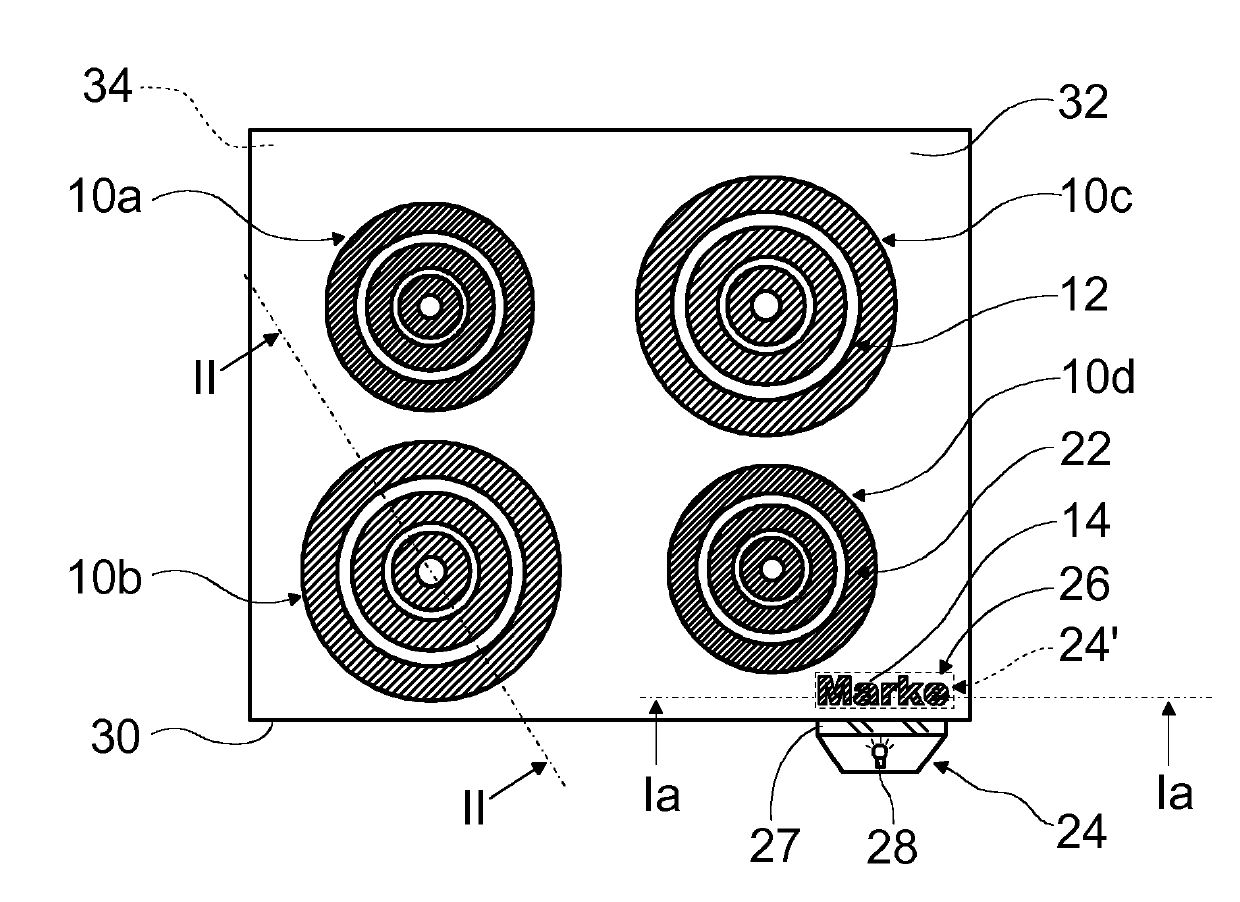

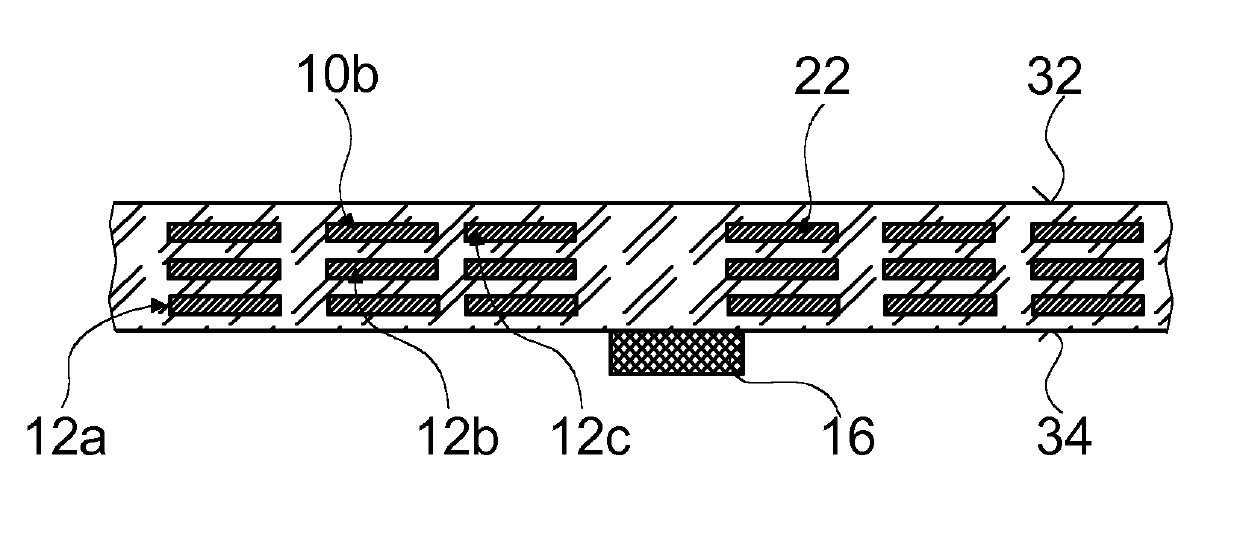

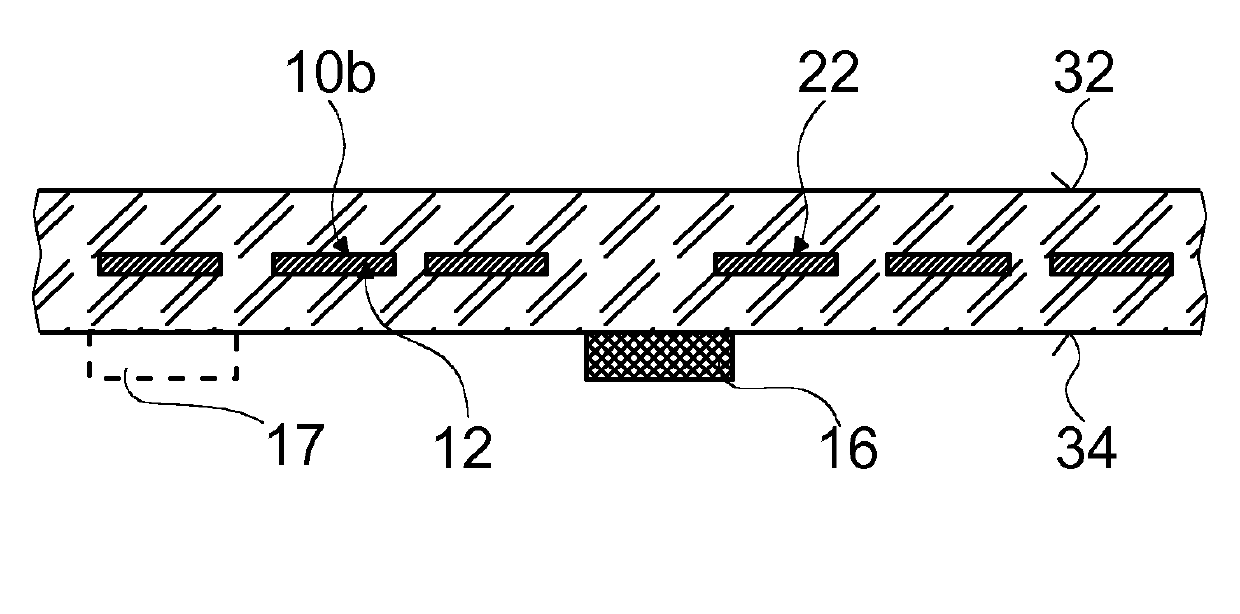

Household appliance cover plate comprising an internal laser engraving

The invention relates to a household appliance cover plate made of a glass or glass ceramic material having an internal laser engraving (12). In order to reduce the variety of components, the invention proposes that the glass or glass ceramic material is black.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

High-bioactivity ganoderma spore oil and supercritical preparation method thereof

ActiveCN102973616BReduce lossesOptimize the breaking processMetabolism disorderFatty-oils/fats refiningSporeHigh energy

Owner:厦门爱逸零食研究所有限公司

thermal helmet

ActiveCN108030186BPrevent liquefactionPrevent liquefaction into fogHelmetsHelmet coversWater vaporEngineering

The invention discloses a warm helmet, which includes the body of helmet, on which a wind shield cover is installed. A rain flange is installed on the body of helmet and is located right on the wind shield cover. A groove and components for blowing rain are provided on the wind shield cover. The warm helmet also includes a warming mechanism, including a tank, which is a hollow structure approximately in the shape of L. The tank includes a tank for collecting rain, which is used to store the lower edge of the wind shield cover and a warming tank fixed on the lower end surface of the wind shieldcover. The upper end surface of the tank for collecting rain is unrestricted. Water holding tanks are installed on both the left side and the right side of the tank for collecting rain. A wind outlettube is installed on the left side of the water holding tank. In addition, the warm helmet includes warming components, including an insulating layer, a heating layer and a water proofing layer in sequence, which are all installed on the warming tank. Besides, the warm helmet includes an air-extractor, which is stored in the space formed in the water proofing layer, and several wind inlet tubes.The warm helmet has the beneficial effects of blowing the gases with high content of water vapor exhaled by people from the surface of the wind shield cover to avoid the water vapor liquefying into fog on the wind shield cover and guiding the gases into the warming mechanism to provide warmth for the neck of a person.

Owner:卢志文

Thermosetting high flame retardant matte ink for pet substrates

ActiveCN106280696BGuaranteed bonding effectGuaranteed ease of processingInksPolymer sciencePet substrate

The invention discloses a thermoset high-flame-retardant lusterless ink used for a PET substrate. The ink is prepared by mixing a phosphorus-nitrogen containing flame retardant, a silicone-modified polyester resin, and delustering powder with a part of diluent, performing high-speed dispersion for 20-50 min; adding a leveling agent and an antifoaming agent, and performing low-speed dispersion for 5-15 min to obtain a main agent; adding an isocyanate curing agent and the left diluent into the main agent; and performing uniform stirring to obtain the thermoset high-flame-retardant lusterless ink. The ink is good in mechanical properties, flame retardance, heat resistance and solvent resistance, is good in adhesion to the substrate and small in environmental pollution and doesn't affect the appearance of the PET substrate. The ink is reasonable in composition, good in component coordination and excellent in overall performance.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD

Transparent metering oil tank

InactiveCN1275792CProtection of rights and interestsAccurately display litersFuel supplyMobile vehicleFuel tank

The transparent measuring oil tank for motor vehicle, engineering machine and ship to detect oil amount and quality consists of transparent tank with drain outlet and plug; cover with oil feeding port, cleaning port and oil discharging port connected to the oil pipe of engine; and measuring rules in the front and side of the tank. The present invention may be used to replace available iron made oil tank and makes it possible to observe the quantity and quality of oil intuitively. The transparent measuring oil tank is light resistant, shock resistant, light and firm.

Owner:郁文明

A heat-resistant holographic anti-counterfeiting film

ActiveCN106297548BAffect transparencyEnsure transparencyStampsAdhesivesInformation layerPolyethylene terephthalate

The invention discloses a heat-resistant holographic anti-counterfeiting film, which is a layered structure, which sequentially includes a carrier layer, an anti-counterfeiting information layer, a release layer and an adhesive layer from outside to inside, and the carrier layer is polyethylene terephthalate film, the anti-counterfeiting information layer is a curable heat-resistant acrylic resin layer, nano-scale fumed silicon dioxide is added to the curable heat-resistant acrylic resin, the anti-counterfeiting information layer has a concave-convex holographic pattern, and the release film The first layer is a fluorine-containing coating, and the adhesive layer is a hot-melt adhesive layer or a pressure-sensitive adhesive layer. The anti-counterfeiting information layer of the heat-resistant holographic anti-counterfeiting film of the present invention adopts a heat-resistant acrylic resin layer added with nano-scale fumed silica, which can withstand a molding temperature above 260°C and has good transparency. The existence of the release layer makes the anti-counterfeiting information The layer can be easily peeled off from the molded plate after molding to ensure the integrity and high clarity of the anti-counterfeit information, and the anti-counterfeit information layer is cured after the film is pressed, which further improves the stability of the holographic pattern.

Owner:ZHONGSHAN LIFENG ADHESIVE PROD CO LTD

A kind of transparent halogen-free flame-retardant polycarbonate resin and preparation method thereof

Owner:SHANGHAI KUMHO SUNNY PLASTICS

An automatic direct freezing transparent ice cube ice maker

ActiveCN109737657BAvoid Vulnerable DefectsPrevent extubationIce productionCompression machines with non-reversible cycleAir pumpEngineering

Owner:广州峻威换热科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com