Transparent non-yellowing UV gloss oil and preparation method and application method thereof

A transparent and varnish technology, applied in inks, applications, household utensils, etc., can solve the problems of UV varnish yellowing and yellowing, achieve bright gloss, improve fluidity, surface smoothness and gloss improvement Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

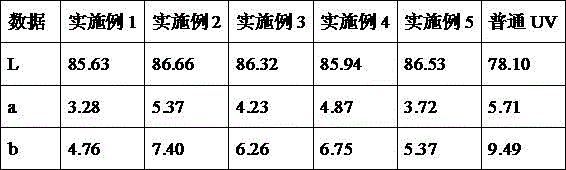

Examples

Embodiment 1

[0041] Acyl phosphorus oxide: tripropylene glycol diacrylate: trimethylolpropane triacrylate: polyether modified polydimethylsiloxane: ultramarine blue ink: titanium dioxide: aliphatic polyurethane acrylic resin The mass-number ratio is 2.5 :18.35:19.5:1.5:0.15:6:51.

[0042] In the temperature range of 25 degrees Celsius, under the condition of avoiding light and ventilation,

[0043] 1) Fully pre-disperse ultramarine ink, titanium dioxide and oligomers at a ratio of 0.15:6:51 in parts by mass for 30 minutes;

[0044] 2) Add photoinitiator, reactive diluent, surfactant and remaining oligomers to the pre-dispersed ultramarine blue ink and titanium dioxide, and stir for 60 minutes;

[0045] 3) Stir the mixture in step 2) until there are no blue or white fine free matter in the mixture, then complete the stirring.

[0046] The transparent non-yellowing UV varnish prepared above was printed on a substrate with a mesh of 500 mesh / inch.

Embodiment 2

[0048] Acyl phosphorus oxide: tripropylene glycol diacrylate: trimethylolpropane triacrylate: polyether modified polydimethylsiloxane: ultramarine blue ink: titanium dioxide: aliphatic polyurethane acrylic resin The mass-number ratio is 2.2 :19.8:19.1:1.2:0.14:5:51.56.

[0049] In the temperature range of 25 degrees Celsius, under the condition of avoiding light and ventilation,

[0050] 1) Fully pre-disperse ultramarine ink, titanium dioxide and oligomer for 30 minutes according to the mass-number ratio of 0.14:5:51.56;

[0051] 2) Add photoinitiator, reactive diluent, surfactant and remaining oligomers to the pre-dispersed ultramarine blue ink and titanium dioxide, and stir for 60 minutes;

[0052] 3) Stir the mixture in step 2) until there are no blue or white fine free matter in the mixture, then complete the stirring.

[0053] The transparent non-yellowing UV varnish prepared above was printed on a substrate with a mesh of 600 mesh / inch.

Embodiment 3

[0055] Acyl phosphorus oxide: tripropylene glycol diacrylate: trimethylolpropane triacrylate: polyether modified polydimethylsiloxane: ultramarine blue ink: titanium dioxide: aliphatic polyurethane acrylic resin The mass-number ratio is 2.6 :17.85:18.5:1.4:0.11:6.5:48.3.

[0056] In the temperature range of 25 degrees Celsius, under the condition of avoiding light and ventilation,

[0057] 1) Fully pre-disperse ultramarine ink, titanium dioxide and oligomer for 30 minutes according to the ratio of mass and number of parts: 0.11:6.5:48.3;

[0058] 2) Add photoinitiator, reactive diluent, surfactant and remaining oligomers to the pre-dispersed ultramarine blue ink and titanium dioxide, and stir for 60 minutes;

[0059] 3) Stir the mixture in step 2) until there are no blue or white fine free matter in the mixture, then complete the stirring.

[0060] The transparent non-yellowing UV varnish prepared above was printed on a substrate with a mesh of 600 mesh / inch.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com