Patents

Literature

896 results about "Trimethylolpropane triacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylolpropane triacrylate (TMPTA) is a trifunctional monomer used in the manufacture of plastics, adhesives, acrylic glue, anaerobic sealants, and ink. It is useful for its low volatility and fast cure response. It has the property of resistance against weather, chemical, water and abrasion.

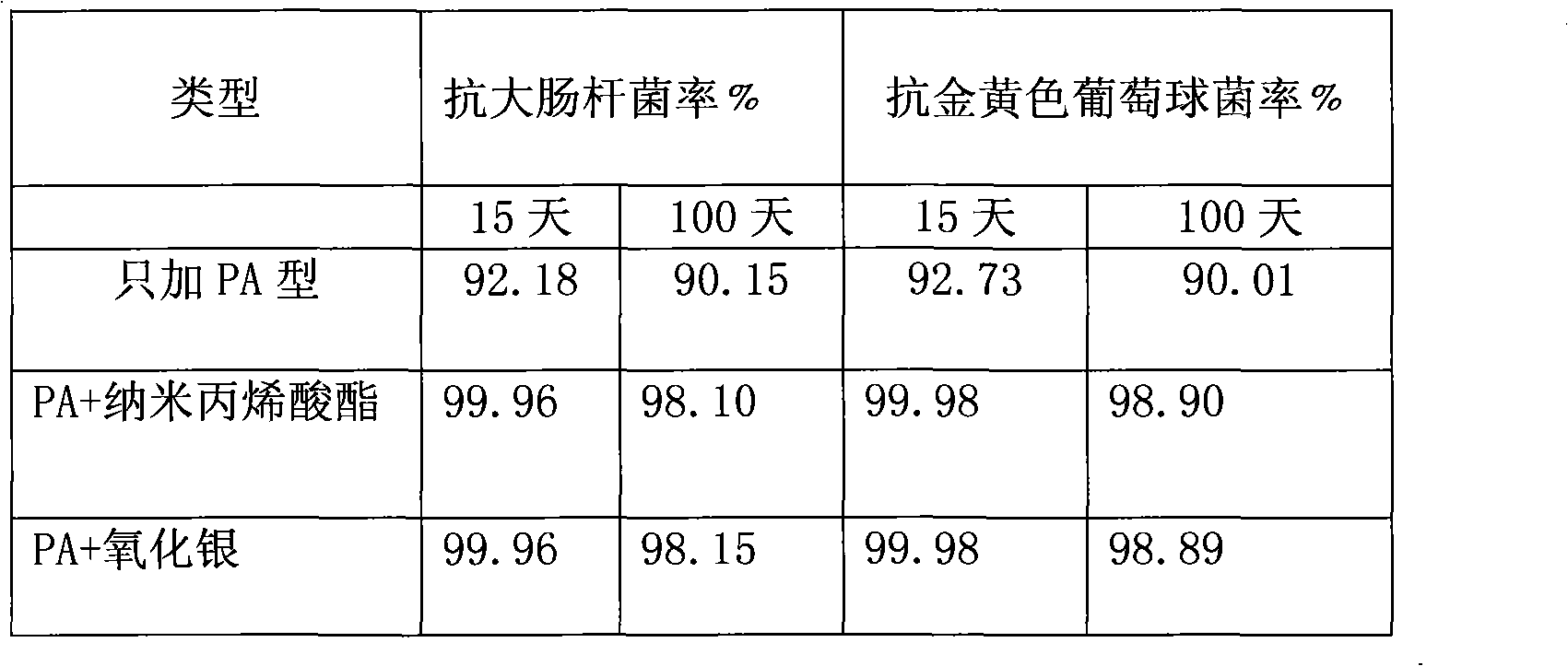

UV curing antibiotic coating and preparation thereof

InactiveCN101353545AImprove antibacterial propertiesSimple preparation processAntifouling/underwater paintsPaints with biocidesUV curingTMPTA

The invention discloses a UV-curable antimicrobial coating, the components of which are as follows: bisphenol A type epoxy acrylate EA; aliphatic PUA; special functional group acrylate PA; TPGDA; TMPTA; photoinitiators; nano acrylate; oxidized silver; and auxiliaries. The preparation method comprises the following steps of: step one, synthesizing special functional group heterocyclic compound PA and later adding phosphorus pentoxide to acrylic acid hydroxy esters so as to react with hydroxyl piperidine and then prepare special functional group heterocyclic compound PA; and step two, taking each component according to the formula, stirring and mixing each component so as to carry out dispersion at the speed of 900 to 1200r per min, then adding silver oxide and photoinitiators after being dispersed evenly, and finally obtaining UV-curable antimicrobial coating through dispersion. The UV-curable antimicrobial coating prepared by the invention has good anti-bacterial effect. As the self-prepared special functional group acrylate PA, the nano acrylate and the silver oxide are added, after UV-curable film-forming, the anti-coli rate can achieve over 99 percent and the anti-staphylococcal rate thereof achieves over 99 percent, and the effectiveness is long.

Owner:苏州市明大高分子科技材料有限公司

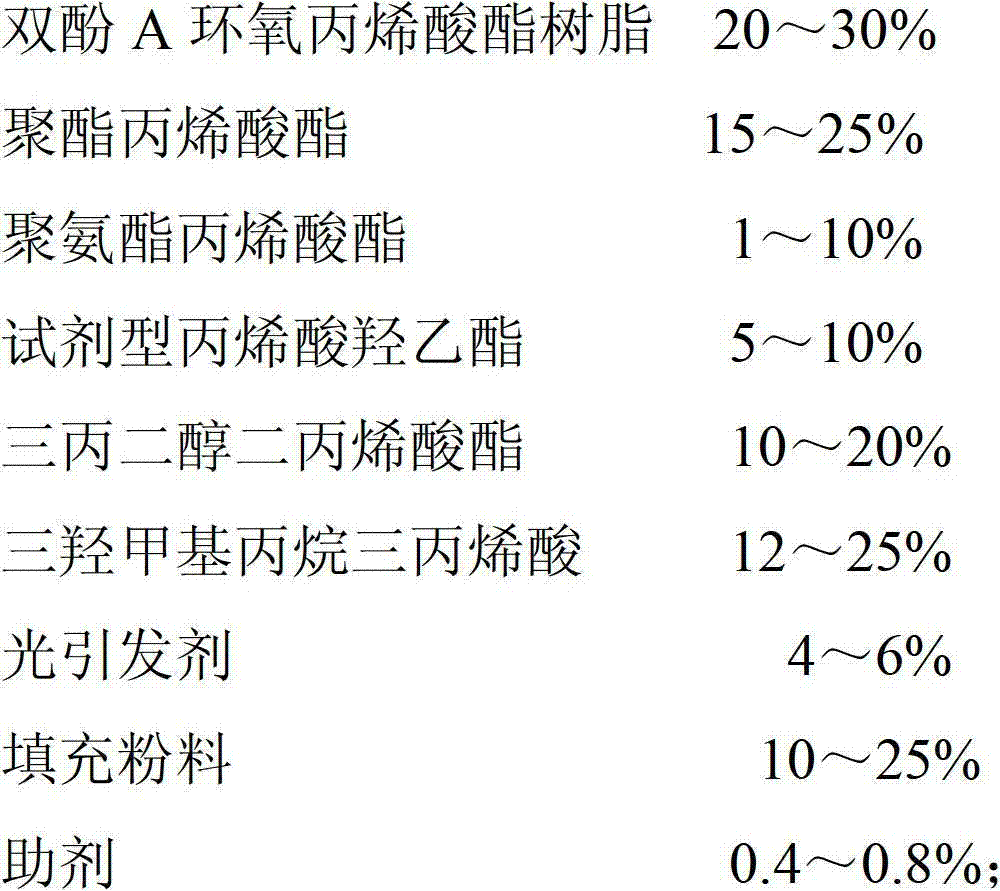

Ultraviolet light curing transparent priming paint and preparation method and use method thereof

ActiveCN102952455AReduce lossImprove product qualityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolyester

The invention discloses an ultraviolet light curing transparent priming paint and a preparation method and a use method thereof. The ultraviolet light curing transparent priming paint comprises the following components in percentage by weight: 20-30% of bisphenol A epoxy acrylate resin, 15-25% of polyester acrylate, 1-10% of urethane acrylate, 5-10% of reagent type hydroxyethyl acrylate, 10-20% of tripropylene glycol diacrylate, 12-25% of trimethylolpropane triacrylate, 4-6% of photoinitiator, 10-25% of filling powder and 0.4-0.8% of promotor. The ultraviolet light curing transparent priming paint is suitable for laser roller construction, has good grittiness and transparency, has the characteristics that sanding is not needed for semi-curing recoating between film layers and the like, and has thick coating performance and the performance that the surface is similar to a mirror surface, and compared with conventional roller coating, the coating weight is greatly increased, roller coating processes are saved, the priming paint is sanded by a sanding machine without large pressure and with a small number of sanded films, a workpiece has no bright spots, the fullness of a product is guaranteed, the product quality is improved, the loss of the machine is smallreduced, and the use amount of sanding belts is greatly reduced.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

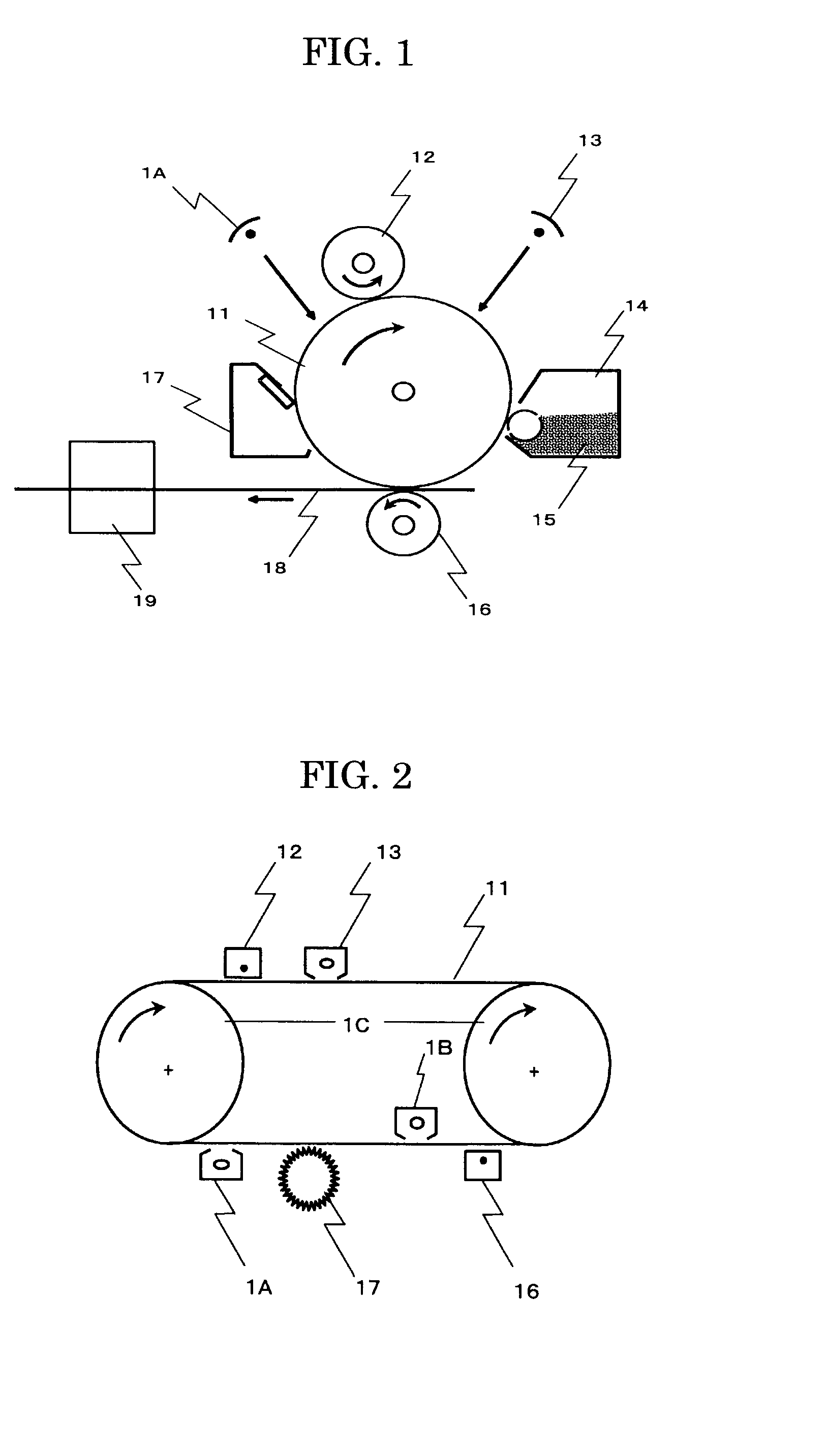

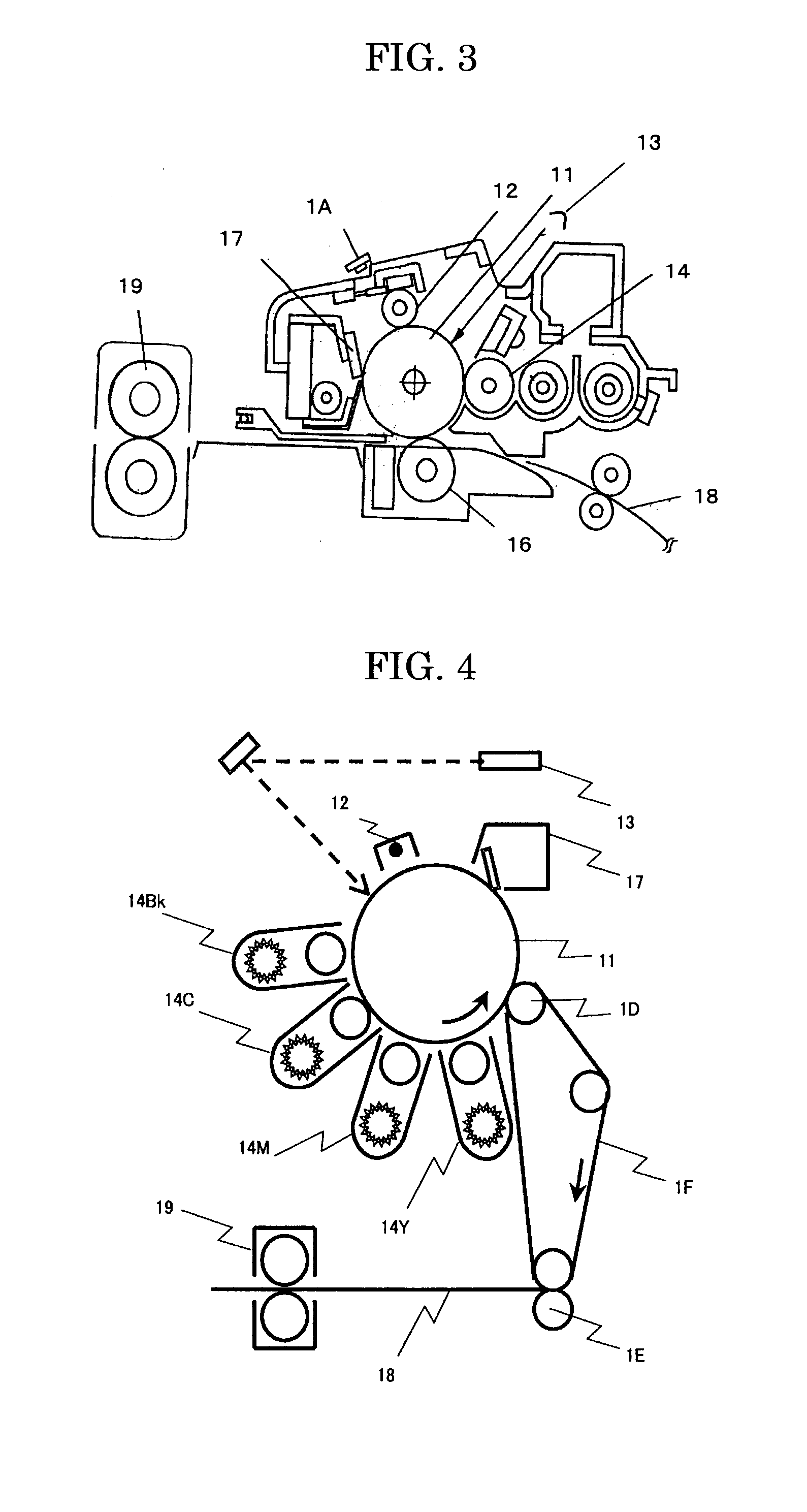

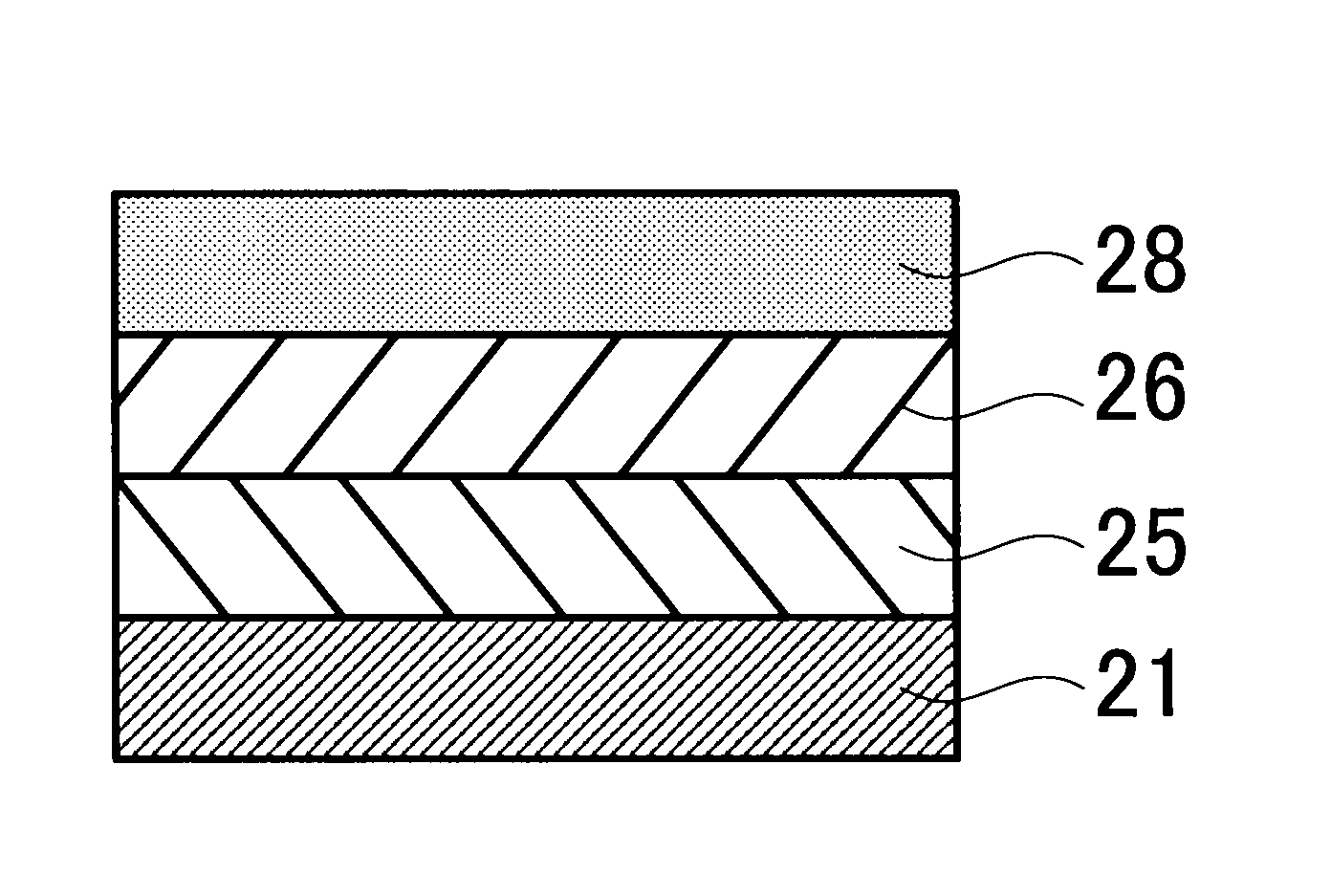

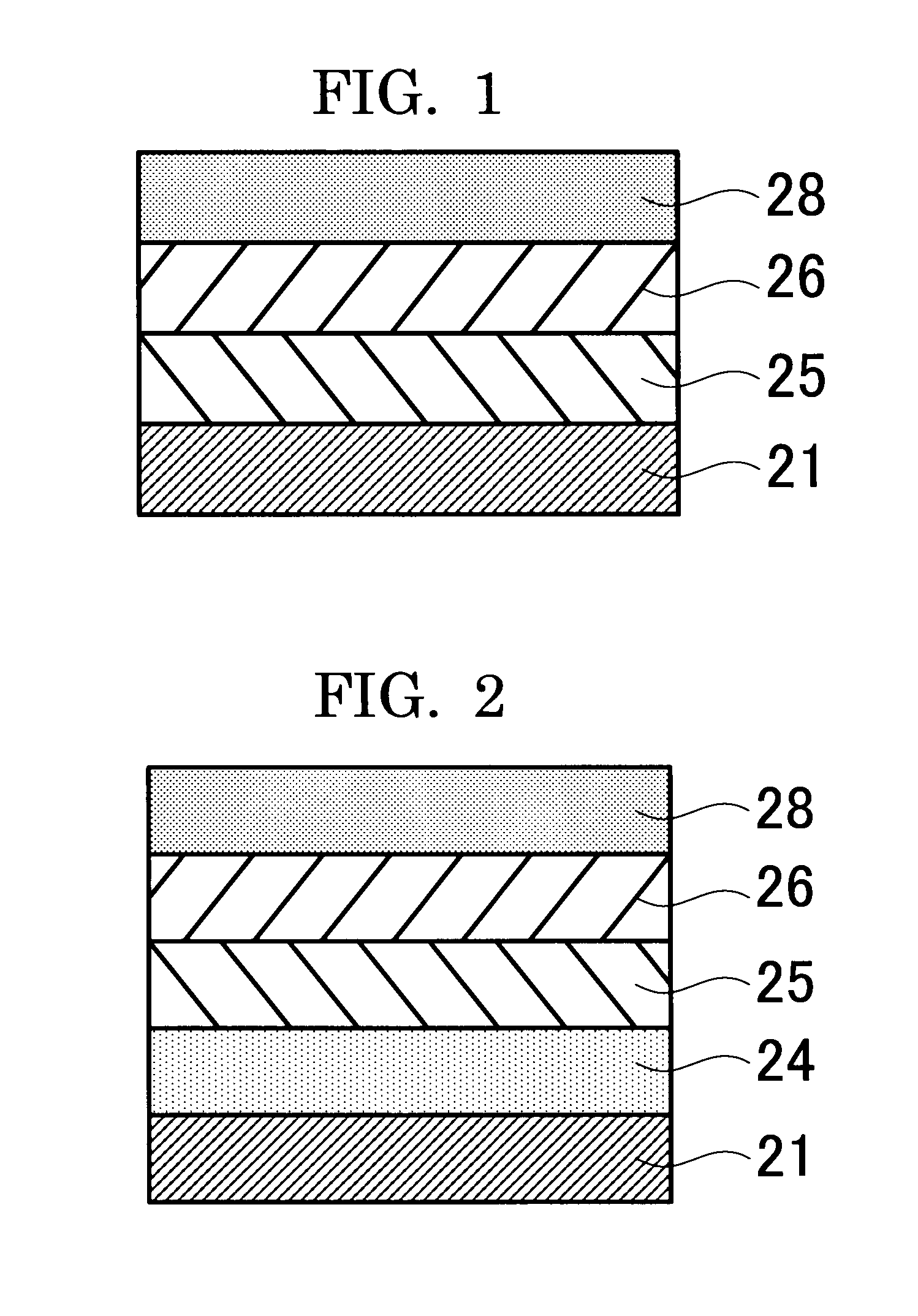

Electrophotographic photoconductor, and electrophotographic apparatus

InactiveUS20080085459A1Improve surface smoothnessImprove wear resistanceElectrographic process apparatusCross-linkElectrical conductor

There is provided an electrophotographic photoconductor which contains at least a conductive substrate, a photoconductive layer comprising a charge generating material and charge transport material, and a surface layer disposed on the photoconductive layer, disposed in this order, wherein the surface layer is a cross-linked resin which contains at least trimethylolpropane triacrylate, a charge transport material having a heat-curable or radical-polymerizable functional group, a silicone compound having a radical-polymerizable functional group, a fluorinated surfactant having a radical-polymerizable functional group, and a silicone compound removing material having a radical-polymerizable functional group having a wettability of 55 mN / m or more to less than 65 mN / m with the silicone compound.

Owner:RICOH KK

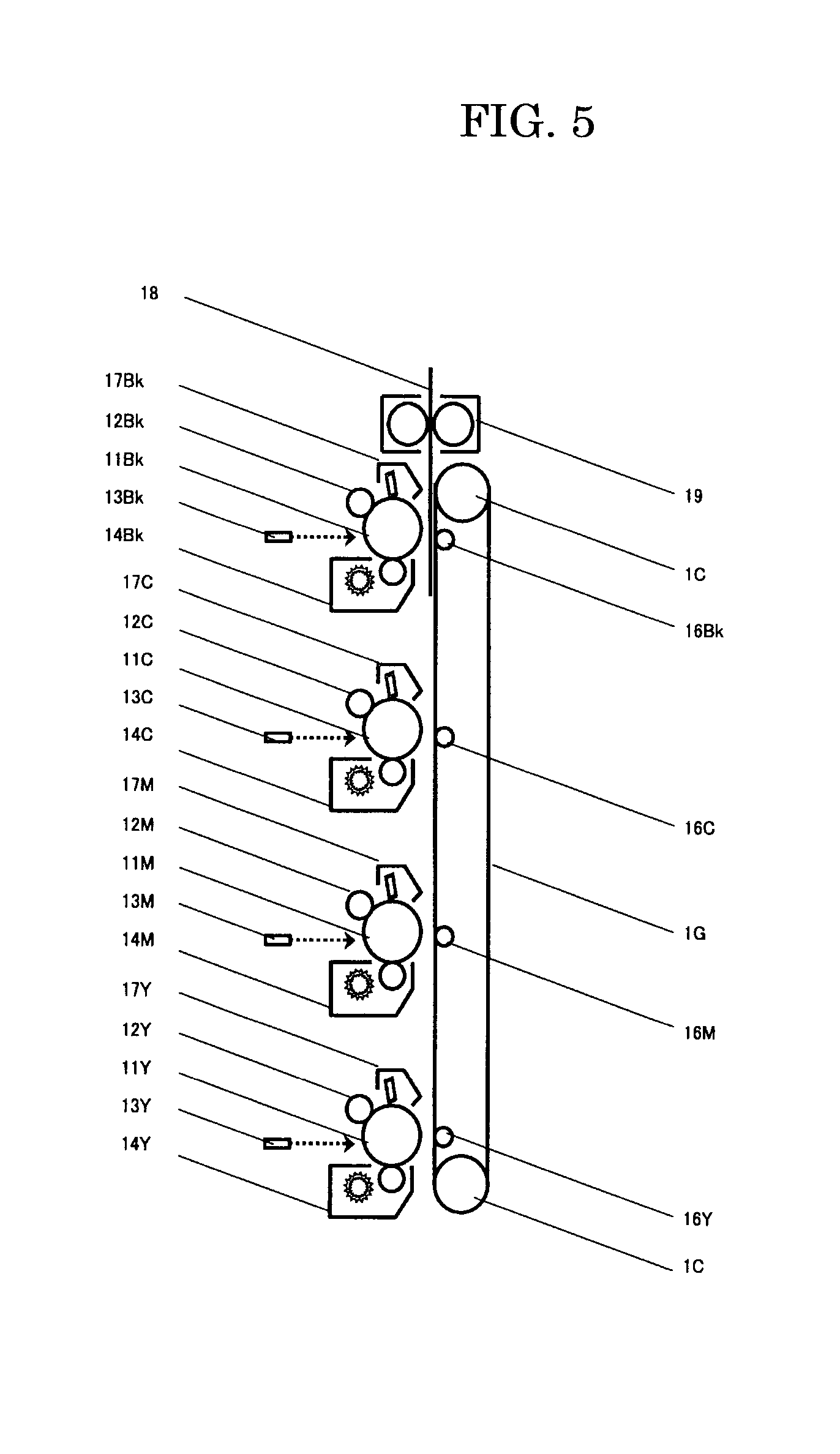

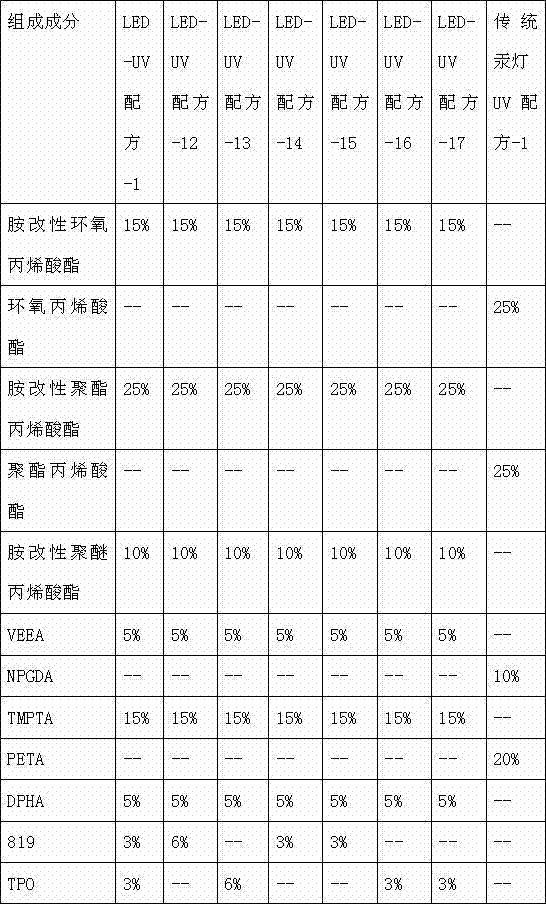

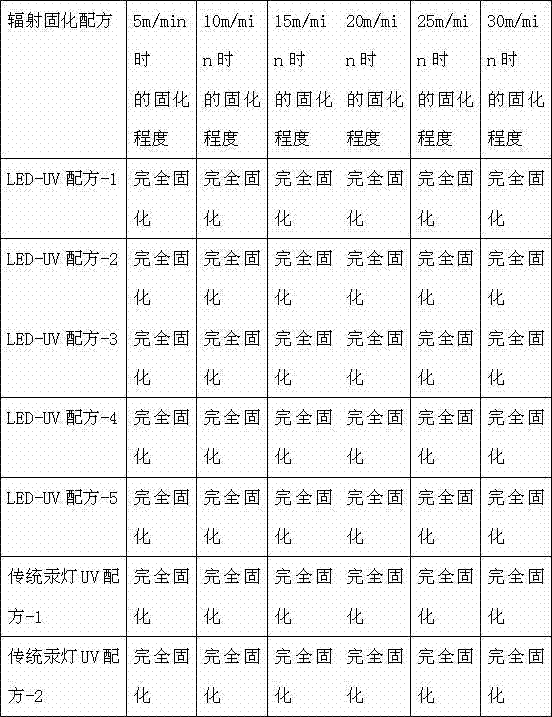

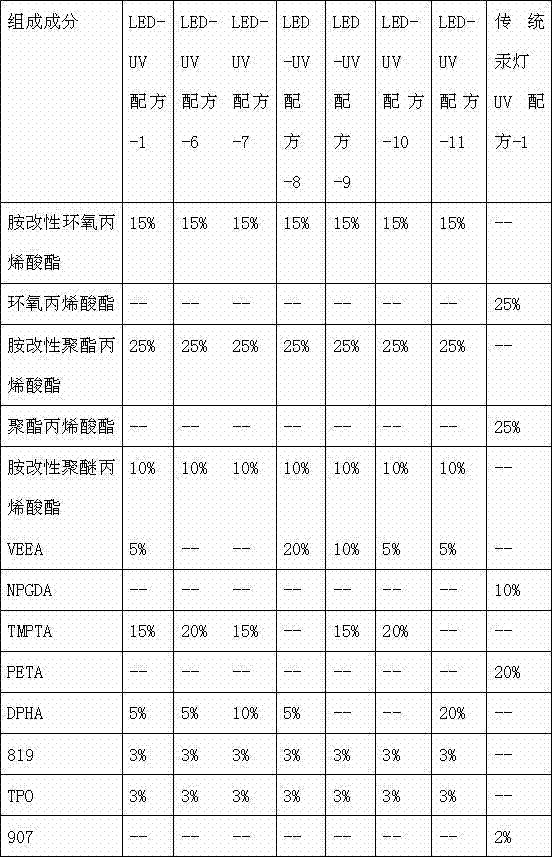

LED-UV surface light source light-curing silk-screen printing ink composition and preparation method thereof

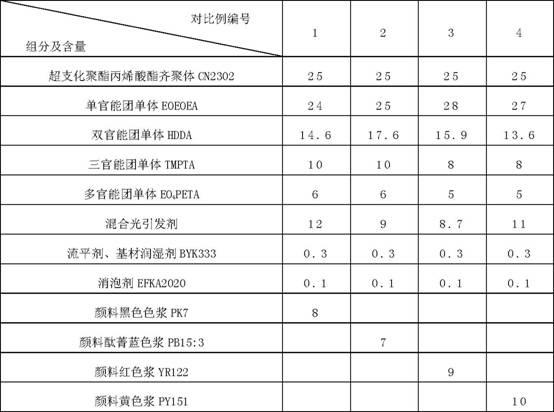

The present invention relates to the field of ink and a preparation process thereof, and particularly to a LED-UV surface light source light-curing silk-screen printing ink composition and a preparation method thereof. The composition is characterized by comprising 25-55% by weight of an LED-UV resin and 10-25% by weight of an LED-UV monomer, wherein the LED-UV resin is a mixture comprising one or a plurality of materials selected from an amine-modified epoxy acrylate resin, an amine-modified polyester acrylate resin, and an amine-modified polyether acrylate resin, and the LED-UV monomer is a mixture comprising one or a plurality of materials selected from a 2-(vinylethoxy)ethyl diacrylate monomer, a trimethylolpropane triacrylate monomer, and a dipentaerythritol hexaacrylate monomer. The LED-UV surface light source light-curing silk-screen printing ink composition of the present invention has advantages of rapid curing speed, good film coating property, high glossiness, environment protection, energy saving, and the like.manufacturing process

Owner:东营华科新材料科技有限公司

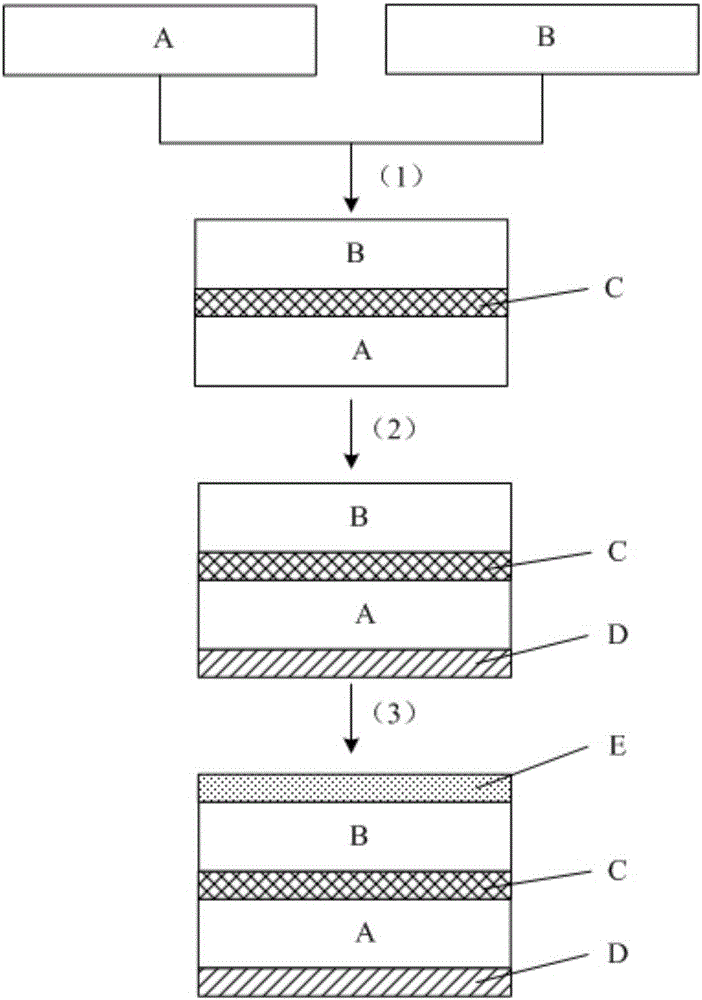

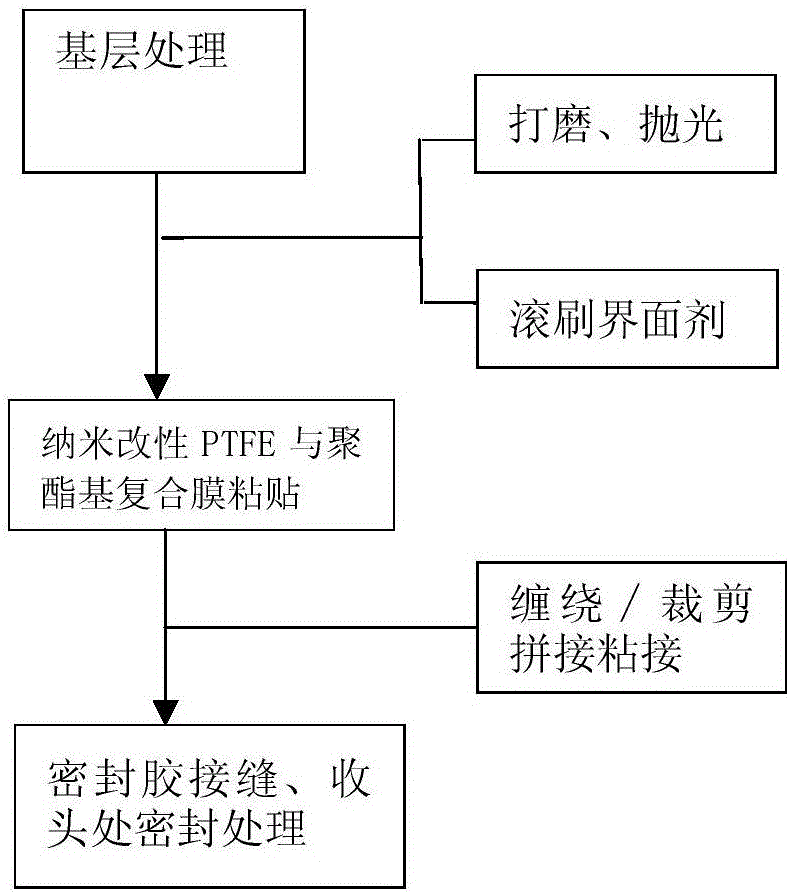

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

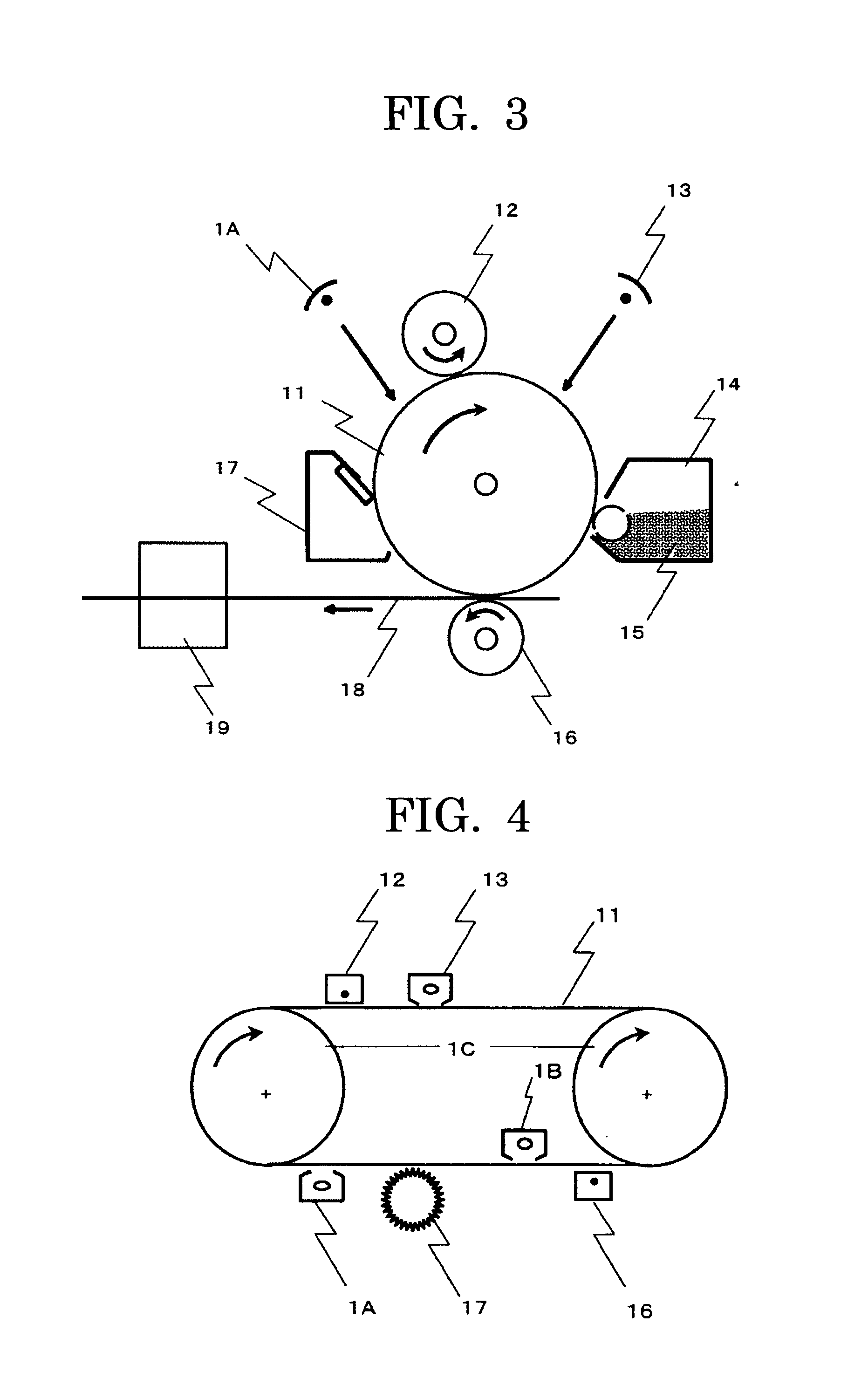

Electrophotographic photoconductor, electrophotographic process cartridge containing the same and electrophotographic apparatus containing the same

InactiveUS20080227008A1Low increase in friction coefficient and wearEasy to cleanElectrographic process apparatusCorona dischargeElectrical conductorSurface layer

An object of the present invention is to provide an electrophotographic photoconductor having an extremely low increase in friction coefficient and wear, while also having superior cleanability even after long-term or large-volume printing, and to provide an electrophotographic apparatus for forming an image using a polymerization toner without providing a unit for externally supplying a lubricant to a photoconductor. Namely, the present invention provides an electrophotographic photoconductor having a photosensitive layer and a crosslinked resin surface layer over a conductive substrate, wherein the crosslinked resin surface layer at least contains trimethylolpropane triacrylate, a dimethylpolysiloxane having a radically polymerizable functional group, and lubricating fine particles.

Owner:RICOH KK

UV-LED (ultraviolet-light emitting diode) photocureable coating and preparation method thereof

ActiveCN103980812AOxidizingImprove curing effectPolyurea/polyurethane coatings(Hydroxyethyl)methacrylateFunctional monomer

The invention discloses a UV-LED (ultraviolet-light emitting diode) photocureable coating and a preparation method thereof. The photocureable coating is characterized by consisting of the following components in percentage by mass: 20-30% of high-functionality fatty acid polyurethane acrylate oligomer 6197, 10-20% of two-functionality polyurethane acrylate 6071, 10-20% of TMPTA (trimethylolpropane triacrylate) serving as a three-functionality functional monomer and an active diluent, 0.1-0.3% of foam inhibitor TEGO920, 10-20% of NPGDA (neopentyl glycol diacrylate) serving as a two-functionality functional monomer and an active diluent, 10-20% of HEMA (hydroxyethyl methacrylate) serving as a single-functionality functional monomer and an active diluent, 0.2-0.5% of flatting agent BYK358N, and 5-10% of HABI-L (hexaarylbiimidazole-L) serving as a photo-initiator. The photocureable coating has the advantages of quick curing, energy conservation, environmental friendliness and the like, and the production efficiency of UV-LED photocuring is promoted.

Owner:SHANGHAI ZHENGOU IND

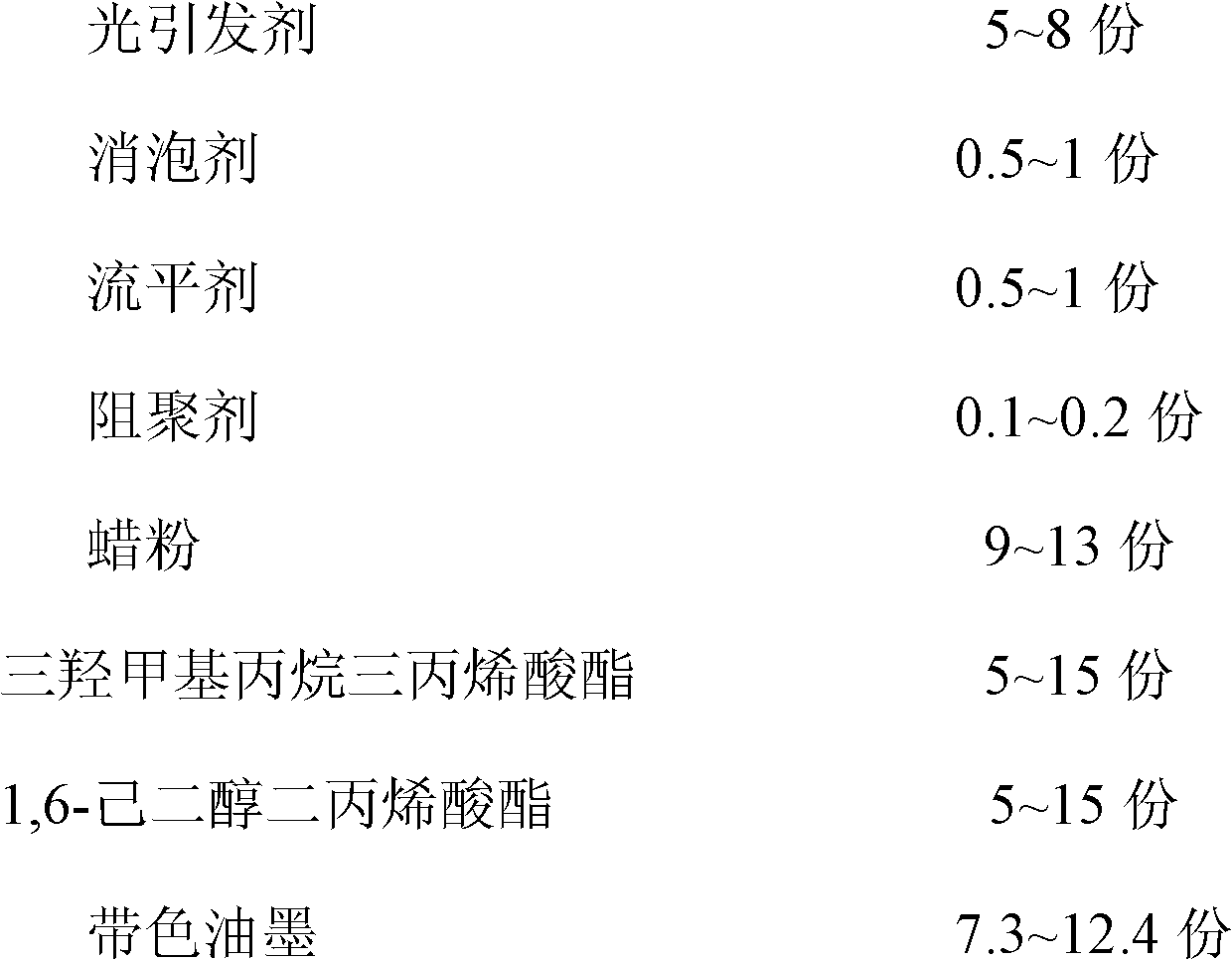

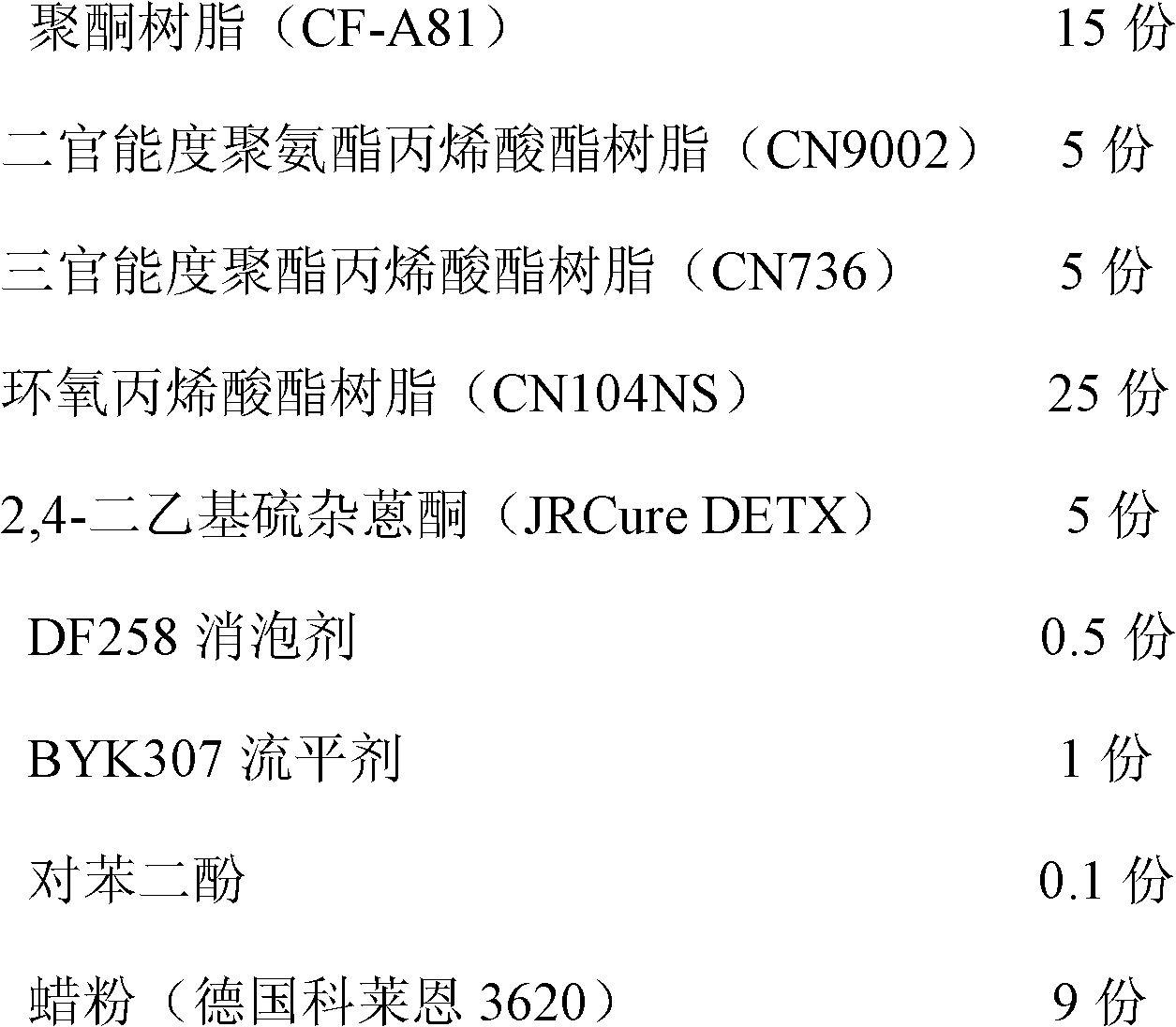

Ultraviolet light cured silk screen snowflake printing ink and preparation method thereof

The invention provides an ultraviolet light cured silk screen snowflake printing ink and a preparation method thereof. The ultraviolet light cured silk screen snowflake printing ink which has a viscosity of 1500-3000cps at the temperature of 25 DEG C is prepared by materials of 50-60 parts of ultraviolet light curable resins, 5-8 parts of photoinitiators, 0.5-1 part of defoamers, 0.5-1 part of flatting agents, 0.1-0.2 part of polymerization inhibitors, 9-13 parts of wax powders, 5-15 parts of trimethylolpropane triacrylate, 5-15 parts of 1, 6-hexanediol diacrylate and 7.3-12.4 parts of colored printing ink which are firstly subjected to a predispersion at a medium speed of 200rpm to 500rpm for 30 minutes in a disc mixer, and then subjected to a dispersion at a high speed of 3000rpm to 3500rpm for one hour. The ultraviolet light cured silk screen snowflake printing ink has the advantages that the appearance is unique, the decorative pattern is delicate, the weather resistance is good, the smell is mild, the printing ink is environment-friendly, printed products touch smooth, and the like.

Owner:WUHAN HONGZHICAI PACKAGING PRINTING

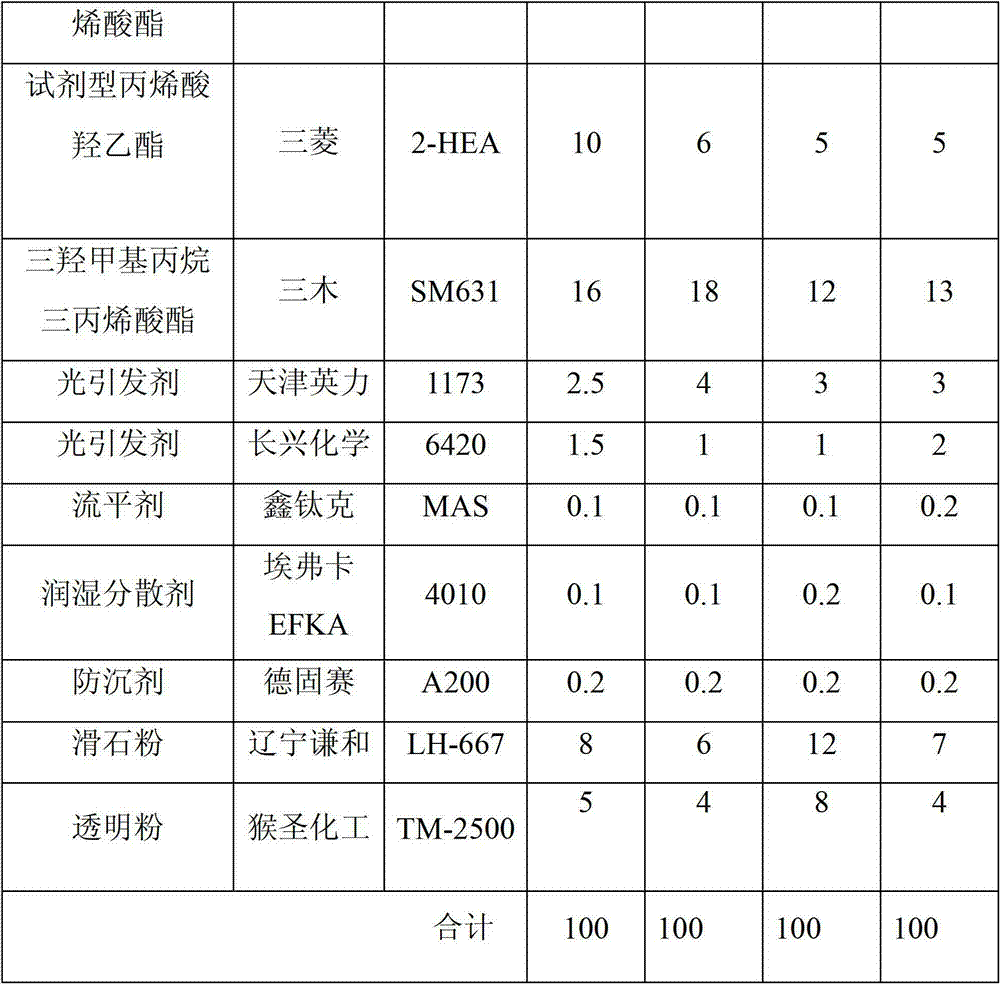

UV (Ultraviolet) curing white primer for laser roller painting of woodware and preparation and application methods thereof

InactiveCN103694862AReduce lossReduce usagePretreated surfacesPolyurea/polyurethane coatingsPolyesterUltraviolet

The invention discloses a UV (ultraviolet) curing white primer for laser roller painting of woodware, which has high coating quantity and flat and bright coated surface. The UV curing white primer comprises 15-25 percent of bisphenol A epoxy acrylate, 15-25 percent of polyester acrylate, 1-10 percent of polyurethane acrylate, 8-15 percent of tripropylene glycol diacrylate, 3-8 percent of reagent type hydroxyethyl acrylate, 10-25 percent of trimethylolpropane triacrylate, 5-8 percent of photoinitiator, 0.2-0.4 percent of wetting dispersant, 0.2-0.4 percent of anti-settling agent, 8-15 percent of talcum powder and 10-20 percent of titanium dioxide. The UV curing white primer has the characteristics that after laser roller painting construction is ended, the coating amount is capable of reaching 35-45g / m<2>, the coated surface is flat and bright, the covering power is stronger than that of a common roller painting UV white primer, and the semi-curing repainting between paint films is not required to be ground, and the like. When being used for performing coating, the UV curing white primer has the advantages of time and labor saving, high fullness of products, and less loss of a machine.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

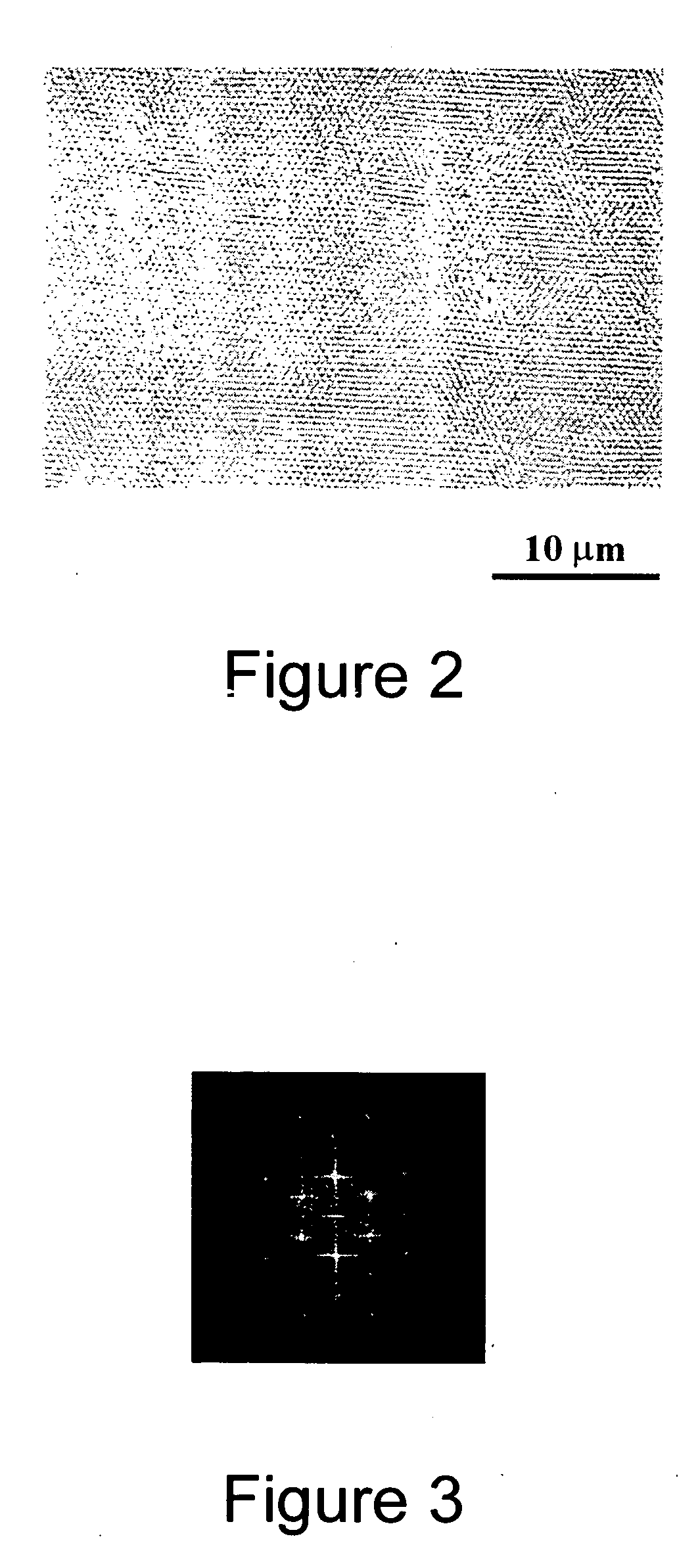

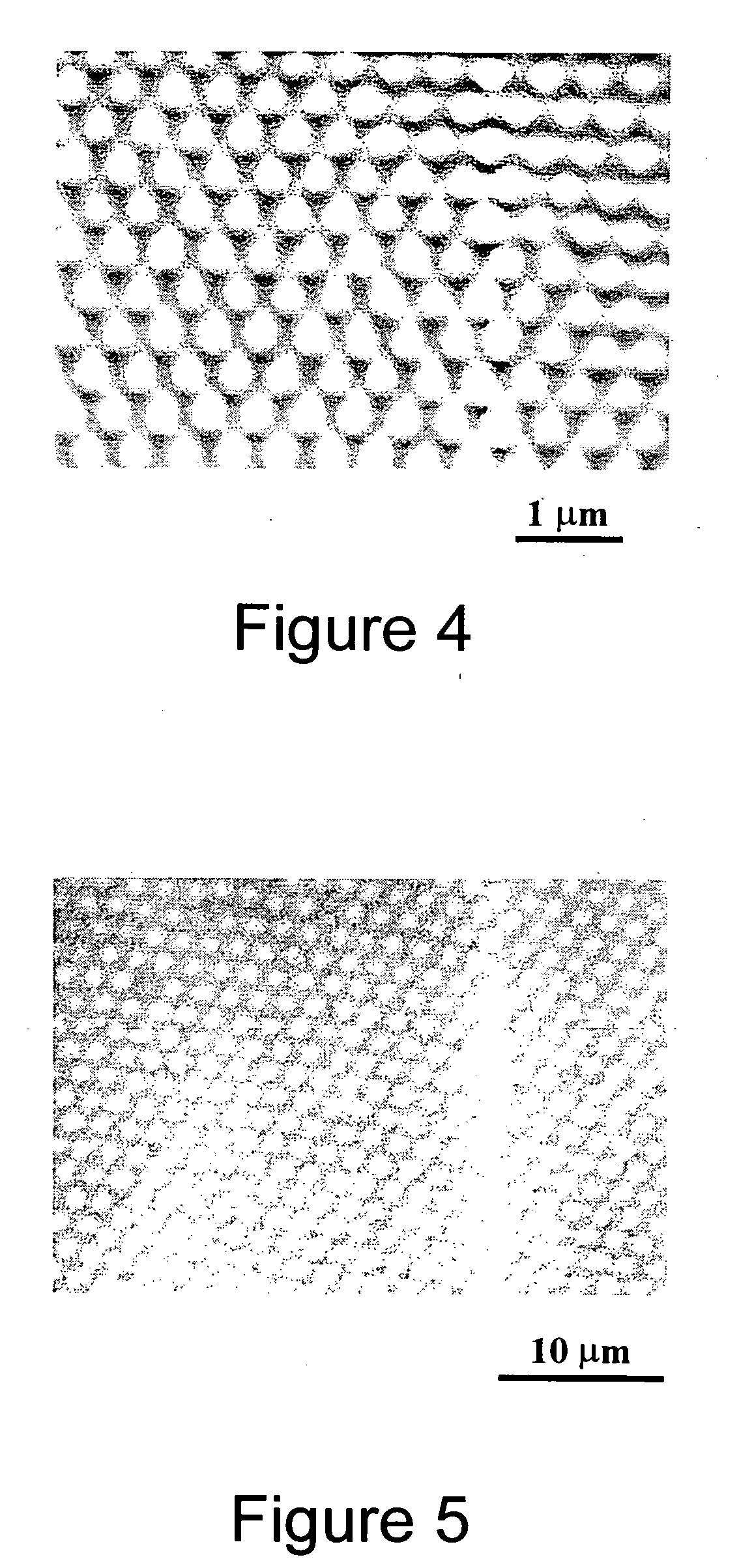

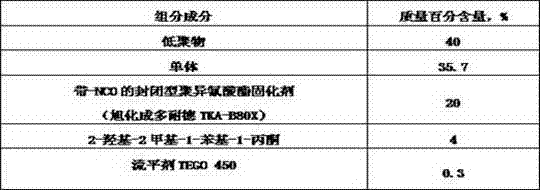

Large-scale colloidal crystals and macroporous polymers and method for producing

Single domain wafer-scale colloidal crystals and macroporous polymers are formed by dispersing concentrated solutions of colloids, desirably mondisperse silica colloids, in a viscous monomer, desirably ethoxylated trimethylolpropane triacrylate, and spin-coating them onto a substrate. Subsequent photopolymerization produces three-dimensionally ordered colloidal crystals trapped inside a polymer matrix. Selective removal of the polymer matrix, such as by oxygen plasma treatment, or removal of the silica spheres, such as by wet etching, produces large-area colloidal crystals and macroporous polymers, respectively.

Owner:CORNING INC

Method for radiation curing of pure organic silicone coated fabric by using electron beams

InactiveCN102965908AImprove thermal stabilityGood chemical stabilityPhysical treatmentSurface-active agentsSolvent

The invention relates to a method for radiation curing of a pure organic silicone coated fabric by using electron beams. The method comprises the following steps of: dispersing vinyl silicone oil, dimethyl silicone oil, hydrogen-containing silicone oil, a silane coupling agent, trimethylolpropane triacrylate, nanoscale silica, a flatting agent and a surface active agent in a vacuum kneading machine, mixing evenly to obtain a coating, finishing a fabric with certain humidity by a rubber blanket preshrinking machine, hot pressing the fabric through a hot pressing roller of a mirror glazing calendar to obtain base cloth, evenly coating the coating on the base cloth, and placing the base cloth on a transmission beam rack of a low-energy electron accelerator through a transmission roller for radiation curing to obtain the fabric. The fabric produced by the method is silky and soft in hand feel, waterproof, anti-seepage, and good in breathability and moisture permeability, and can be widely used in clothing, outdoor, fashionable fabrics and the like; the clothing does not have wrinkles, is easy to iron, and has stretching and recovering properties, and outdoor textiles can withstand the invasion of sun, wind and water; and the coating provided by the invention does not contain any solvent, and is environment-friendly, safe, non-toxic, pollution-free, simple in preparation technology, convenient in operation and construction, and low in energy consumption.

Owner:JIHUA 3509 TEXTILE

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

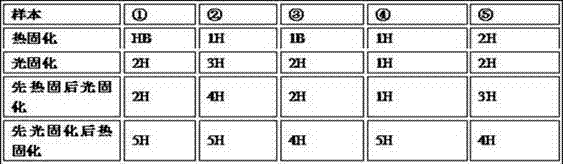

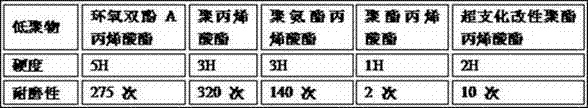

High-strength coating formed by virtue of photo-thermal dual-curing and preparation method thereof

InactiveCN104745055AUniform and dense spatially cross-linked network structureDense unimolecular space structurePolyurea/polyurethane coatingsPolymer scienceMeth-

The invention provides a coating which is formed under the condition of photo-thermal dual-curing and is good in hardness and high in wear resistance. The coating is obtained by performing UV (ultraviolet) curing at first and then performing thermal curing on the following materials in percentage by weight: 30-60% of a low polymer with -OH, 15-36% of a monomer with -OH, 19-30% of a closed type polyisocyanate curing agent with -NCO, 2-5% of a photoinitiator and 0.2-0.8% of an auxiliary agent, wherein the low polymer with -OH is bisphenol A epoxy acrylate, polyacrylate or polyurethane acrylate, and the monomer is one, two or three types of ethyl metrhacrylate, tri(propylene glycol) diacrylate or trimethylolpropane triacrylate. The polyurethane polymer and the polyacrylate polymer in the coating provided by the invention are crosslinked by virtue of chemical bonds, and a formed single-molecule space structure is more compact in structure, and is obviously improved on hardness and wear resistance. The invention also provides a preparation method of the coating.

Owner:汕头市大千高新科技研究中心有限公司

Ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying

ActiveCN105670463ALow priceHigh viscosityPolyurea/polyurethane coatingsPowdery paintsUltravioletUrethane acrylate

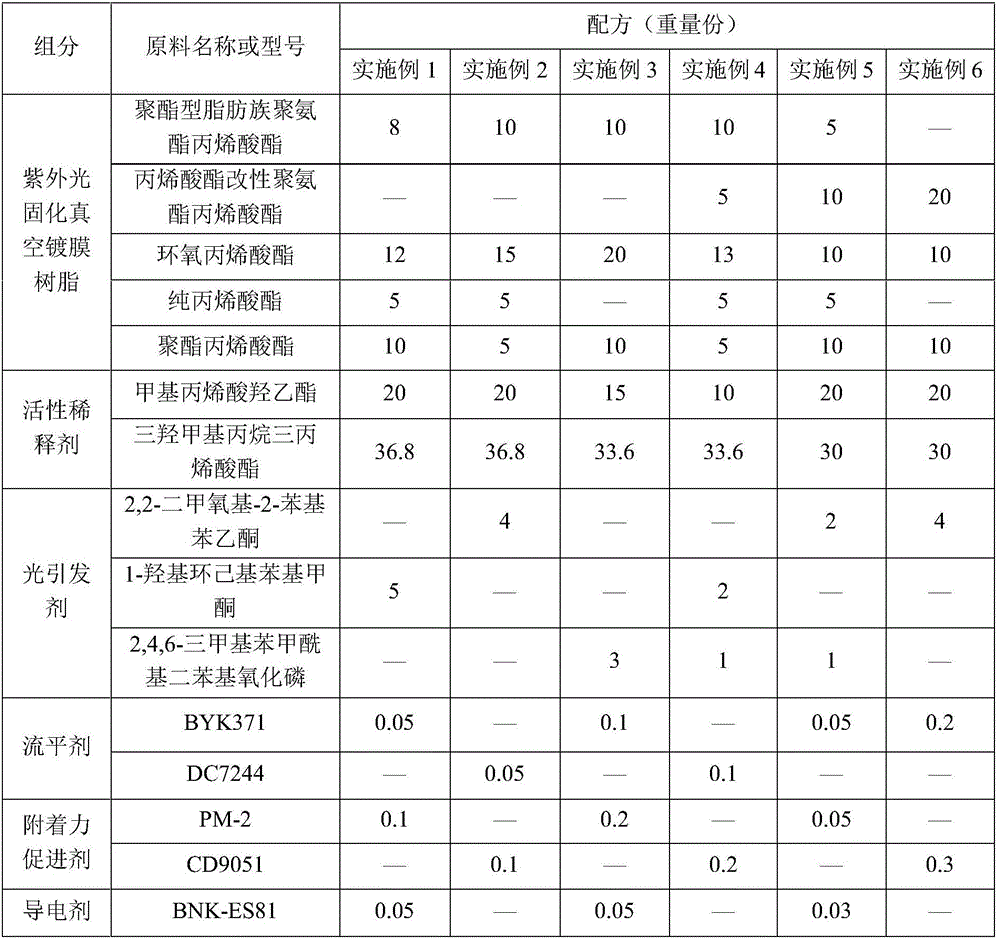

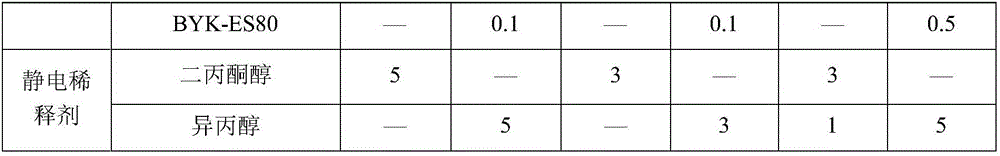

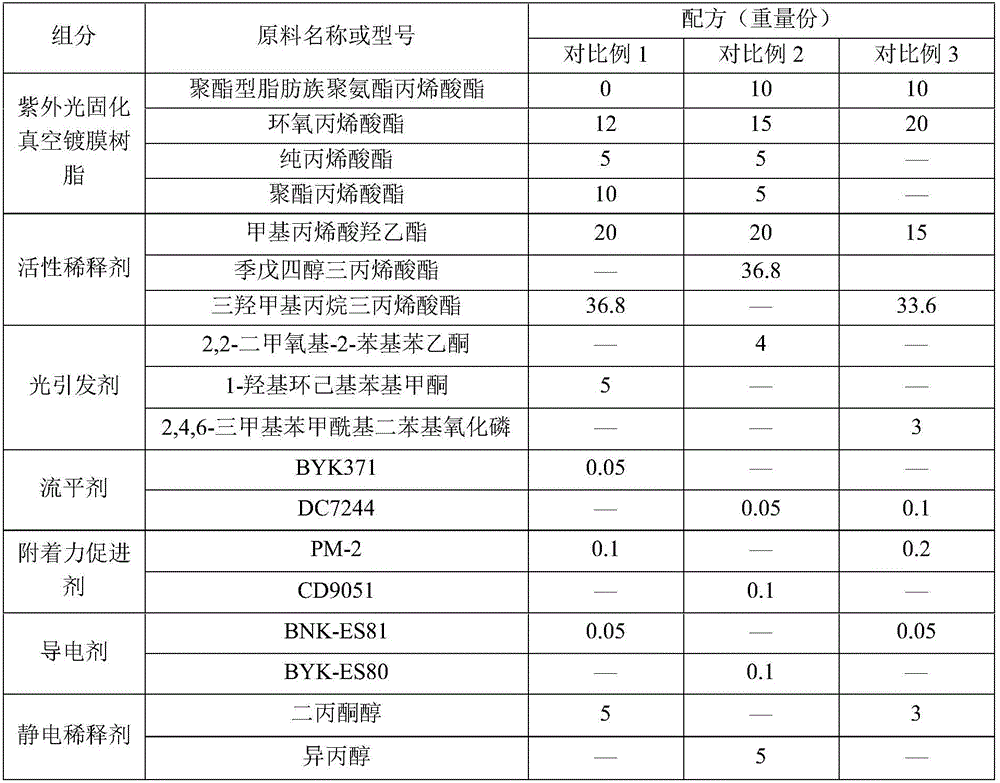

The invention discloses ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying and a preparation method thereof.The ultraviolet curing vacuum coating metal primer capable of achieving electrostatic spraying is prepared from, by weight, 5-20 parts of urethane acrylate, 10-20 parts of epoxy acrylate, 0-5 parts of pure acrylate, 5-10 parts of polyesteracrylate, 30-40 parts of trimethylolpropane triacrylate, 10-20 parts of low-functionality active diluted monomers, 2-5 parts of photoinitiator, 0.05-0.1 part of a flatting agent, 0.05-0.5 part of adhesion promoter, 0.01-0.5 part of a conductive agent and 3-5 parts of electrostatic thinner.The ultraviolet curing vacuum coating metal primer prepared through the method can be used for electrostatic spraying, has the advantages of being good in coating performance, good in adhesion, high in salt fog resistance, high in production efficiency, high in paint utilization rate and the like, and has wide market prospects.

Owner:GUANGDONG SHEN ZHAN IND CO LTD

Flame-retardant UV curing coating and preparation method thereof

InactiveCN103525272AGood chemical resistanceImprove low temperature resistanceFireproof paintsPolyester coatingsPolyesterSodium thiocyanate

A flame-retardant UV curing coating is prepared from the following raw materials in part by weight: 10-12 parts of trimethylol propane triacrylate, 50-55 parts of polyester acrylate, 3-5 parts of isopropanol, 5-8 parts of ethoxylated trimethylolpropane triacrylate, 1-2 parts of tetrabutylphosphonium chloride, 2-3 parts of sodium thiocyanate, 2-6 parts of hexabromocyclododecane, 3-4 parts of diethylene glycol butyl ether, -5 parts of benzil dimethyl ketal, 2-3 parts of 2-hydroxy-2-methyl-1-phenyl-1-acetone, 3-4 parts of dispersing auxiliary agent and 4-5 parts of dispersing auxiliary agent. The flame-retardant UV curing coating has excellent chemical resistance and low temperature resistance, and has strong adhesion to difficultly-adhered substrates, such as plastic; after addition of the dispersing auxiliary agents, the flame-retardant UV curing coating is good in leveling property, can form a uniform and thin coating layer, and is high in curing speed; and by adding tetrabutylphosphonium chloride and the hexabromocyclododecane, the flame-retardant UV curing coating has excellent flame retardance.

Owner:安徽蓝柯复合材料有限公司

Hydrolyzable UV (ultraviolet) protection ink

The invention provides a hydrolyzable UV (ultraviolet) protection ink, which is prepared by mixing the following components in parts by weight: 30-48 parts of modified organosilicon acrylic resin, 6-15 parts of modified epoxy acrylic resin, 5-12 parts of isobornyl acrylate, 10-15 parts of trimethylolpropane triacrylate, 5-12 parts of chlorinated rubber, 7-15 parts of grass green pigment, 2-5 parts of silane coupling agent, 0.1-0.5 part of defoaming agent, 0.5-1.0 part of leveling agent, 0.02-0.04 part of polymerization inhibitor, 5-15 parts of calcium carbonate and 2-8 parts of 369 photoinitiator. The UV protection ink provided by the invention is a hydrolyzable UV curing protection ink of which the curing time can be obviously shortened. In addition, after finishing processing touch screen cover plate glass or ITO glass, the protective film can be removed by soaking in alkaline water. The UV protection ink has the advantage of no residue, can be peeled easily, and thus, has wide application prospects.

Owner:XIAMEN HOWER MATERIAL

Coating for UV cured plastic and use

The invention relates to a UV cured coating used for plastics, and purposes thereof. The composition of the coating by the weight percent is as follows: 25 to 50 of hexa-functional polyurethane acrylic acid resin, 10 to 20 of trifunctional polyurethane acrylic acid resin, 10 to 20 of acrylic acid resin, 10 to 20 of trimethylolpropane 3-acrylic ester, 2 to 5 of N-methyl diethano lamine, 2 to 5 of UV absorbent, 0.4 to 13 of assistant, and 10 to 30 of mixed solvent. When the coating is used, the components are evenly mixed by the proportion and spray coated on plastic work pieces, and then cured by a UV curing machine. The coating of the invention can be used for coating of ABS and PC plastics. The coating is characterized by high hardness, good wear resistance, hard object scratching resistance, high lustrousness, no pollution to the environment, etc.

Owner:深圳市美丽华科技股份有限公司

UV curing luminous plate and its preparing process

ActiveCN101397495ANo emissionsNo pollutionSynthetic resin layered productsLuminescent compositionsNon toxicityAcrylic resin

An UV curing luminescent panel consists of a luminescent layer and a reflective layer. The luminescent layer with the thickness of 0.02-5.0mm consists of light-cured resin (10-40 percent of resins such as epoxy acrylic resin, polyurethane acrylic resin, polyester acrylic resin and the like), photosensitive diluent (photosensitive diluent is 10-20 percent of resins of ethoxylated acrylic ester, propoxylated neopentyl glycol diacrylate, TMPTA and the like), photoinitiator (2-10 percent of beans development kit BDK and the like), luminescent materials (10-65 percent) and additive (0-5 percent). The UV curing luminescent panel has the advantages of no solvent emission, saving energy due to instant drying of UV curing, high production efficiency due to on-line processing, and being applicable to base materials sensitive to heat; furthermore, the prepared luminescent panel is characterized by high brightness, long luminescent time, excellent acid and alkali resistance and weatherability, good printing performance, non-toxicity, no radiation and stable physicochemical performance.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

Ceramic pulp for photo-curable 3D printing and preparation method and application of ceramic pulp

ActiveCN110627501AHigh viscosityAdditive manufacturing apparatusCeramic shaping apparatusTripropylene glycolMeth-

The invention discloses ceramic pulp for photo-curable 3D printing and a preparation method and application of the ceramic pulp. The ceramic pulp includes ceramic powder, photo-curable resin, a photoinitiator and a dispersant, wherein the photo-curable resin comprises the components: in percent by mass, 10-60% of bisphenol A epoxy acrylate, 10-60% of trimethylolpropane triacrylate, 10-60% of tripropylene glycol diacrylate and 10-60% of isobornyl methacrylate. The rheological performance of the slurry can be adjusted through selection of reactive diluents with different functionalities and adjustment of the ratio of the diluents, needs of light curing molding can be met by the slurry, and degreasing and sintering are performed on a molded sample so as to obtain a high-density zirconia ceramic product with a relative density of up to 98.8%.

Owner:SHENZHEN RES INST CENT SOUTH UNIV +1

Ink composition for ink-jet printing

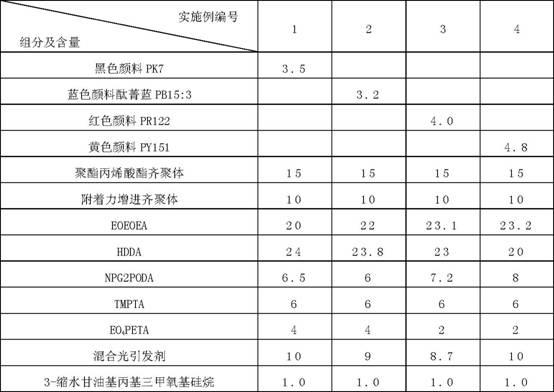

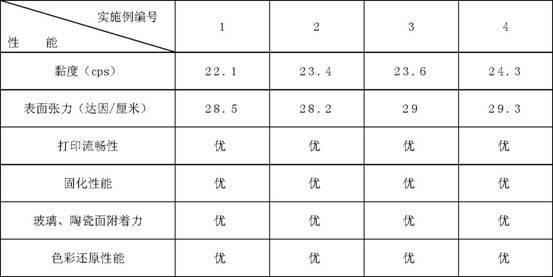

ActiveCN101921511ASimplify the UV-curable printing processReduce inkjet production costsInksPolyesterUltraviolet

The invention relates to an ink composition for ink-jet printing, which contains 10-35% by weight of at least one selected from polyurethane (methyl) acrylate oligomer and polyester acrylate oligomer, 5-20% by weight of adhesion promoting oligomer, 40-70% by weight of at least one selected form EOEOEA, THFA, IBOA, PHEA, HDDA, DPGDA, TPGDA, HEMA, TMPTA, EO3TMPTA, PO3TMPTA, EO4PETA and DPHA, 0.1-3% by weight of at least one selected from N-(beta-aminoethyl)-alpha-aminopropyltrimethoxysilane, methacrylate propyltrimethoxysilane, styrene chloro diamino silane and 3-glycidyl propyltrimethoxysilane and 2-6% by weight of paint. The ink composition is applicable to applying direct printing on an inorganic matter without being precoated, thereby simplifying the ultraviolet curing and spray printing process carried out on the surface of the inorganic matter, reducing the production cost and improving the production efficiency of inkjet printing.

Owner:ZHUHAI FREE TRADE ZONE NEOJET APOLLOJET IMAGING MATERIALS

High-water-resistance quick-photocuring pearlescent water-based UV paint, and preparation method and application method thereof

ActiveCN105969161AHigh hardnessImprove wear resistancePretreated surfacesPolyurea/polyurethane coatingsEpoxyWater based

The invention relates to a water-based UV paint, particularly a high-water-resistance quick-photocuring pearlescent water-based UV paint, and a preparation method and application method thereof. The paint is prepared from a water-based polyurethane acrylate resin, a water-based epoxy acrylic resin, a functional monomer, a photoinitiator, a leveling agent, an anti-settling agent, pearl powder and a solvent, wherein the functional monomer comprises at least one of dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate. The number of the functional groups of the dipentaerythritol hexaacrylate, pentaerythritol triacrylate and trimethylolpropane triacrylate is 3 or above. The photocured paint film has the advantages of high crosslinking density, excellent hardness, excellent tensile strength and excellent mechanical properties. The water-based epoxy acrylic resin is introduced on the basis of the water-based polyurethane acrylic resin, thereby enhancing the water resistance of the paint film. By introducing the pearl powder and anti-settling agent, the paint film has gorgeous pearl effects.

Owner:深圳市嘉卓成科技发展有限公司 +1

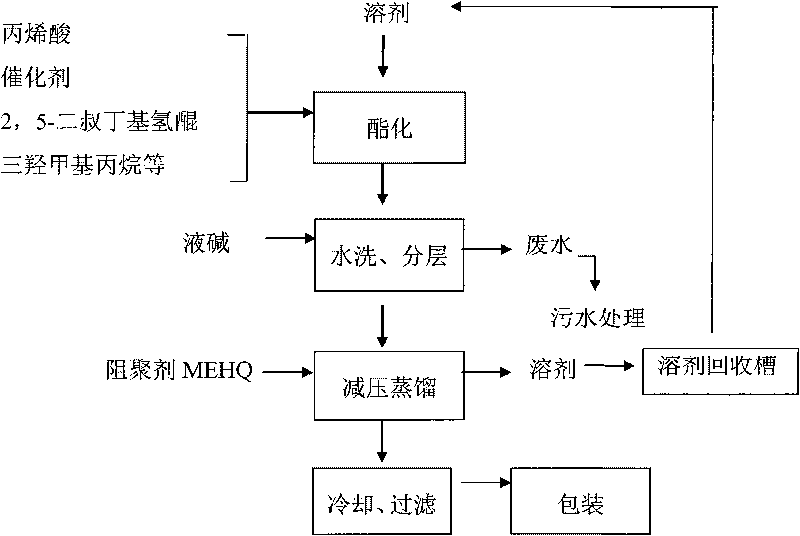

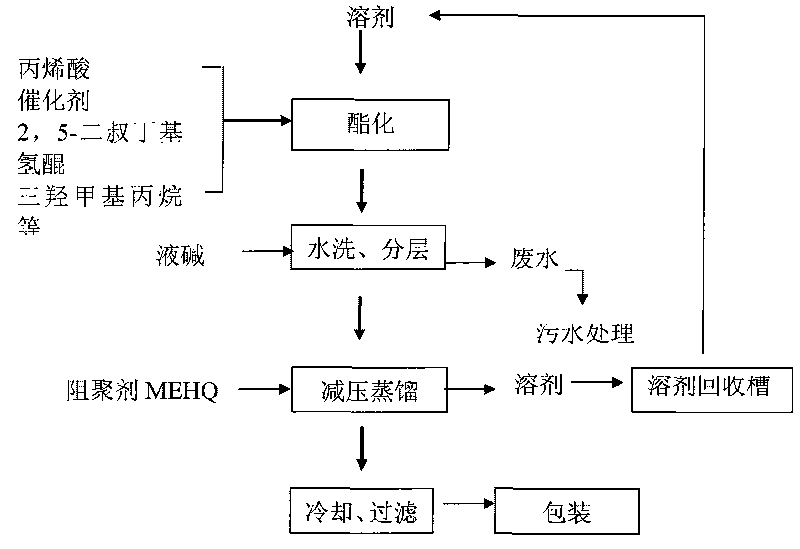

Trimethylolpropane triacrylate and preparation method thereof

ActiveCN101704745AShort reaction timeEasy to washOrganic compound preparationCarboxylic acid esters preparationReaction temperatureWaste treatment

The invention relates to trimethylolpropane triacrylate and a preparation method thereof. The formula of the trimethylolpropane triacrylate comprises the following raw materials in part by weight: solvent 20-50, trimethylolpropane 18-25, catalyst 4-8, 2,5-di-tert-butylhydroquinone 0.06 to 0.1 and acrylic acid 15-20. The preparation method comprises: placing the raw materials into a reaction kettle according to requirements of the formula and stirring the raw materials to perform reaction for 2 to 9 hours; starting a vacuum pump and raising the temperature in the reaction kettle till refluxingis generated and keeping refluxing for 1 to 3 hours; stopping raising the temperature when detecting the mass percentage of hydroxyl in reaction solution is 2 to 4 percent; adding caustic soda liquidinto the reaction kettle, controlling the pH value of the solution to be 7 to 8; standing the solution for delamination; leading waste water in the lower layer to a waste water treatment system; preferably adding polymerization inhibitor into the solution from which the waste water is removed; and distilling the solution at reduced pressure to remove methylbenzene and obtaining the product. Compared with the prior art, the method has the advantages of short reaction time, few by products, low reaction temperature and low production cost.

Owner:CAC NANTONG CHEM

UV paint with resistance to yellowing, and its preparation method and construction process

InactiveCN102229784AGood yellowing resistanceEasy to preparePretreated surfacesPolyurea/polyurethane coatingsPolymer scienceAcrylic resin

The invention provides a UV paint with resistance to yellowing, and its preparation method and construction process. The UV paint comprises, by weight, 5.0 to 15.0% of polyurethane acrylic acid oligomer, l0.0 to 20.0% of aliphatic polyurethane acrylate, 12.0 to 18.0% of trifunctional aliphatic polyurethane acrylate, 3.0 to 6.0% of thermoplastic acrylic resin, 3.0 to 6.0% of trimethylolpropane triacrylate, 2.0 to 4.0% of dipentaerythritol pentaacrylate, 2.0 to 3.0% of 1-hydroxycyclohexyl phenyl methanone, 0.1 to 0.3% of a photoinitiator, 15.0 to 22.0% of acetic ester, 2.5 to 3.0% of a leveling agent, 0.1 to 0.2% of an antifoaming agent, 5.0 to 10.0% of butyl acetate and 10.0 to 15.0% of toluene. The UV paint provided in the invention has excellent resistance to yellowing; the preparation method for the UV paint is simple and convenient; during construction, the paint can form into a film in 20 to 23 seconds under curing by UV radiation, being rapid and highly efficient in film forming; a substrate with the formed film has the characteristics of high strength, high hardness, high wear resistance, high gloss, high weatherability, high solvent resistance, etc., and is beautiful and durable in use, not easy to turn yellow.

Owner:周荣华 +1

Photo-curing thermoplastic fiber-reinforced epoxy composite material and preparation method thereof

ActiveCN103660310AImprove processing and manufacturing speedRealize mass productionFiberLiquid state

The invention discloses a photo-curing thermoplastic fiber-reinforced epoxy composite material and a preparation method thereof. During preparing, trimethylolpropane triacrylate is taken as a diluent monomer to prepare an epoxy acrylate diluent; the epoxy acrylate diluent and a photoinitiator are mixed and heated into a liquid glue state to obtain liquid photosensitive resin; a piece of thermoplastic fiber-reinforced cloth is coated with the liquid photosensitive resin in a brushing manner, and a piece of prepreg cloth is prepared; and the prepreg cloth is paved on a forming mold and placed on UV(ultraviolet) curing forming equipment for curing forming, so that the thermoplastic fiber-reinforced epoxy composite material is obtained. The thermoplastic fiber-reinforced epoxy composite material can be used for manufacturing a novel electromobile body support frame. The novel photo-curing electromobile body support frame manufactured with the method is good in performance and environment-friendly, and has no harmful influence on a human body and surrounding environment, and simultaneously, the curing effect meets the national standard.

Owner:SHANGHAI COMPOSITES SCI & TECH CO LTD

High temperature resistant release coating material for artificial synthetic leather release paper, and preparation method and application thereof

ActiveCN103740262AClear textureRealistic texturePolyurea/polyurethane coatingsTextiles and paperTripropylene glycolMethacrylate

The invention relates to a high temperature resistant release coating material for artificial synthetic leather release paper, and a preparation method and an application thereof. The release coating material is composed of modified urethane acrylate, modified epoxy acrylate, tripropylene glycol diacrylate, trimethylolpropane triacrylate ethoxylate, perfluoromethacrylate and gamma-methylacryloxypropyltrimethylsilane. A method for preparing the high temperature resistant release coating material for the artificial synthetic leather release paper comprises the steps of orderly putting all the components in a container, mixing and stirring so that the solid components are dissolved, and thus obtaining an even and approximately transparent coating. The release paper is clear and vivid in lines; due to the optimization of the formula, the release paper can be caused to be moderate in hardness, good and stable in release property, numerous in repeated use times, and excellent in solvent resistance and high-temperature resistance.

Owner:ZHEJIANG KAREN SPECIALTY MATERIALS

High-fire-retardant ultraviolet curing coating

InactiveCN105038569AImprove wear resistanceStrong adhesionFireproof paintsPolyurea/polyurethane coatingsPolyethylene glycolDefoaming Agents

The invention discloses a high-fire-retardant ultraviolet curing coating. The high-fire-retardant ultraviolet curing coating comprises the following raw materials: urethane acrylate, epoxy acrylate, epoxidized soybean oil acrylate, phosphorus-containing acrylate, N-vinyl pyrrolidone, polyethylene glycol acrylate, tri(propylene glycol) diacrylate, pentaerythritol triacrylate, trimethylolpropane triacrylate, benzophenone, 2-methyl-2-hydroxyl-1-phenylacetone, coumarone, nano-silica, nano aluminum hydroxide, ammonium polyphosphate, silica powder, expanded graphite, a flattening agent, a defoaming agent, a wetting agent, a dispersant and a coupling agent. The high-fire-retardant ultraviolet curing coating disclosed by the invention is good in flame retardance property, high in adhesion force, excellent in comprehensive performance and long in service life.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Ultraviolet curing coating formula for eliminating formaldehyde in air and preparation technology thereof

ActiveCN103305115AWork quicklyStrong adhesionPolyurea/polyurethane coatingsUltravioletHexanediol diacrylate

The invention relates to the technical field of ultraviolet curing coatings, and particularly relates to an ultraviolet curing coating formula for eliminating formaldehyde in air and a preparation technology thereof. The coating consists of the following components in percentage by weight: 20-40% of urethane acrylate, 10-30% of 1,6 hexanediol diacrylate, 1-10% of trimethylolpropane triacrylate, 1-5% of 2-phenoxy ethyl acrylate, 1-5% of dispersing agent, 2-6% of superfine silicon dioxide, 1-4% of superfine aluminum oxide powder, 1-12% of matte powder, 1-4% of wax powder, 4-6% of 2-hydroxyl-2-methyl-1-phenyl-1-acetone, 0.1-2% of surface aid and 1-15% of formaldehyde removal aid. The preparation technology of the coating comprises the steps of sequentially feeding the raw materials and stirring for uniformly mixing. Through the formula and the technology provided by the invention, the prepared coating is applicable to the fast operation of a factory production line, and also has the protection functions such as good adhesion, scratch resistance and the like.

Owner:韶关市和荣化工有限公司

LED UV curing glass ink

The invention provides LED UV curing glass ink and mainly solves the technical problems that thermo-curing ink is universally in the existing glass ink industry, the energy consumption is high, the efficiency is low and the like. The main point of the technical scheme is that the glass ink is prepared from the raw materials, by weight, of 30%-60% of resin, 3%-20% of UV monomer, 1%-10% of photoinitiator, 0.1%-5% of auxiliary, 0.1%-10% of pigment and 5%-30% of filler, and the resin comprises organic silicone modified epoxy acrylic resin, polyester acrylic resin, acrylic modified alkyd resin and acrylic modified silicone resin; the UV monomer comprises IBXA, acryloyl morpholine, spiro orthocarbonate, DPHA, (EO)n-TMPTA, tetrahydrofuran acrylate, lauryl acrylate and 9,9'-bis[4-(2'-hydroxy-3'-methacryloyloxypropoxy)phenyl]fluorene. The glass ink is manufactured with an LED UV curing method, has the advantages that energy is saved and the environmental protection efficiency is high and is mainly applied to the glass ink industry.

Owner:湖南永红环保科技有限公司

Polyether polyurethane-acrylate and preparation method thereof

InactiveCN101608010AGood chemical resistanceImprove high temperature resistancePolyurea/polyurethane coatingsHydroxybenzoate EthersPolymer science

The invention provides polyether polyurethane-acrylate and a preparation method thereof. The polyether polyurethane-acrylate comprises the following compositions in portion by weight: 40 to 60 portions of polyether glycol, 10 to 30 portions of polyisocyanates, 10 to 30 portions of hydroxypropyl acrylate or hydroxy-ethyl acrylate, 0.1 to 0.5 portion of triethylamine or dibutyltin dilaurate, 5 to 10 portions of absolute ethanol, 0.1 to 0.8 portion of p-hydroxyanisole or 2.6- di-tert-butyl-4-methylphenol, 5 to 20 portions of tripropylene glycol diacrylate, 5 to 20 portions of TMPTA, and 0.01 to 0.02 portion of nitrobenzene. The invention has excellent mechanical abrasion resistance and toughness, high elongation at break, excellent chemical resistance and high temperature resistance when coating a film, has low temperature performance and good adhesive force. The polyether polyurethane-acrylate has better using effect when assembling epoxy acrylate, and is the polyurethane acrylate with lowest cost.

Owner:上海展辰涂料有限公司 +2

UV film-pressed yellowing-resistant topcoat gloss paint

ActiveCN103289456ADry fastImprove the decorative effectPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolymer science

The invention provides an UV (Ultra Violet) film-pressed yellowing-resistant topcoat gloss paint, comprising the following components by weight percent: 35%-45% of functional monomer, 17%-23% of polyurethane acrylate, 26%-40% of epoxy acrylic resin, 0.2-0.3% of defoamer, 0.4%-0.6% of flatting agent and 5%-7% of photoinitiator. The functional monomer is a mixture of hydroxyethyl methacrylate, dipropylene glycol diacrylate, tripropylene glycol diacrylate and trimethylolpropane triacrylate. The UV film-pressed yellowing-resistant topcoat gloss paint provided by the invention is good in adhesive force, excellent in resistance to yellowing, low cost, simple and flexible to operate, high in drying speed, free of waste and high in production efficiency.

Owner:上海展辰涂料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com