High-strength coating formed by virtue of photo-thermal dual-curing and preparation method thereof

A dual-curing, high-strength technology, applied in the preparation of the above-mentioned coatings, in the field of high-strength coatings, can solve the problems of insufficient research on coating properties, cracking, and industrial application limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

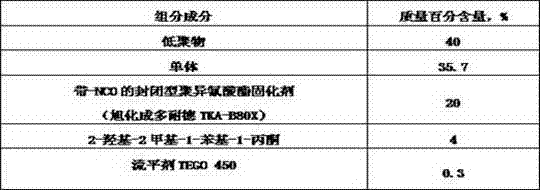

[0043] , coating formula (weight percent)

[0044]

[0045] 2. Coating preparation and coating and curing

[0046] According to the above formula, first weigh a certain amount of bisphenol A epoxy acrylate, disperse evenly with a high-speed mixer, and then add trihydroxymethylpropane triacrylate, tripropylene glycol diacrylate, ethyl methacrylate, Asahi Kasei-Donade TKA-B80X, 2-hydroxy-2-methyl-1-phenyl-1-acetone and leveling agent TEGO 450, etc., stir evenly for 15 minutes to obtain the coating; A good paint is coated on a clean glass plate, firstly under a light intensity of 400-500mJ / ㎝ 2 The cured film was cured on the UV curing machine of s, and the cured film was surface-dried, characterized by the finger-to-touch method, and then thermally cured in a blast drying oven, the temperature was controlled at 150°C, and the time was 60 min.

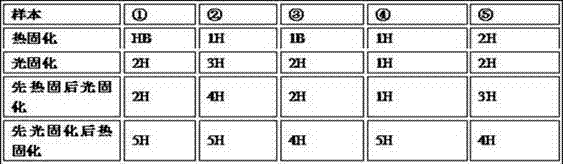

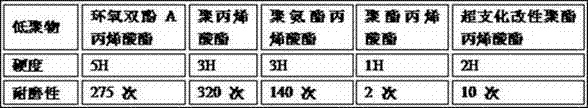

[0047] , Coating performance test results

[0048] serial number Coating properties Embodiment one Embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com